#overhead conveyor chains

Explore tagged Tumblr posts

Text

Overhead Conveyors Manufacturer

Laxmi Conveyor System is a renowned manufacturer of high-quality Overhead Conveyor, designed to streamline material handling processes across various industries. We design and develop overhead conveyors that are efficient, economical and very user-friendly. The conveyor system comes with different wheel configurations, and can be useful for different industries as their efficient load handling application. These overhead conveyors are designed to move on the ceiling tracks and can process a variety of loads.

Since 2007, Laxmi Conveyors has been a leader in boosting productivity and efficiency in manufacturing operations and distribution centers around the world. As a provider of overhead conveyor, we offer durable, high-quality solutions designed to meet specific operational needs.

An overhead conveyor is an elevated system, but it is not belt driven. Instead, thin chains are used to move suspended trolleys holding items. The conveyor chain transports the materials from one place to another in a loop. Overhead conveyors are particularly useful in industries such as automotive, food processing, textiles, and electronics, where precision and speed are essential.

Website_ https://www.laxmiconveyor.in/overhead-conveyor-manufacturer/

1 note

·

View note

Text

“Blood and revenge are hammering in my head” goes the line from Titus Andronicus the RSC have shoved to the top of the publicity for this new revival. It promises something visceral, busy, berserk even. And the drains at the side of the thrust stage at the Swan in Stratford, with screens protecting the front row from the blood and bodies set to be deposited there, suggests artfully horrible things ahoy.

All this and Simon Russell Beale in the title role too. His faded Roman warrior will see two sons killed and a daughter raped and mutilated. He will hack off his own hand too before finally feeding his enemy’s sons to her in a pie. Shakespeare’s first and bloodiest tragedy is brutal, and bananas.

And yet Max Webster’s production ends up stylish but polite. While Beale is as supremely watchable and outstandingly lucid as ever, he is a statesmanlike rather than martial figure. His anger is considered, his parenting as ruminative as his revenge. Even when he finally puts on a white pinny to serve up the fateful dinner to the goth queen Tamora (Wendy Kweh) — who, nice touch, keeps eating in defiance once she knows what’s in the pie — he is wry rather than ravaged. A stage production scene showing an actor being showered with sparks as another actor holds a chainsaw.

There is a sharp enough look from Joanna Scotcher’s monochrome design, though, to make you keep hoping it will find its blackly comical focus. Bursts of blood disrupt the postwar mod elegance of the charcoal clothing. An overhead mechanical conveyor system bears chains to hang people and other nasty things from. Four of the cast winch a heavy square of stage floor to turn it into a grave, and it’s a strong moment.

People stab each other from a distance, and blood spurts out of them anyway. It’s a neat touch. When blood gets poured on from cans or hosepipes at the end, it’s overthought. When a few fluid ounces of blood from strung-up victims falls on to plastic sheeting, whose contents are then carefully poured into the drain, it’s downright anal retentive.

Webster (The Life of Pi, the David Tennant Macbeth) is an inventive user of stage space, yet in his RSC debut he lacks an obvious moral angle on the material. Without more dramatic heat you notice how Titus gets almost everything wrong, how everyone protects themselves poorly. Events just seem unenlighteningly awful.

Do I oversell the limitations? Natey Jones, as the evil Aaron, tears into the language and dominates the stage with alpha-male relish. Tristan Arthur (one of three young actors alternating the role) impresses as Titus’s grandson, singing a requiem between scenes too. Emma Fielding is an elegantly irked presence as Titus’s sister Marcia (brother Marcus in the text). There is some imagination and skill in all departments. It’s just all a bit too neat to make these vicious Shakespearean shenanigans quite catch fire. ★★★☆☆ 164min Swan Theatre, Stratford, to Jun 7

4 notes

·

View notes

Text

The Unsung Heroes of Modern Warehousing

Efficiency is crucial in the hectic fields of logistics and production. Whether it's handling goods across countries or completing online purchases, companies depend on backend systems that silently handle the laborious tasks. Conveyor systems stand out among them; they are crucial but frequently disregarded.

What Exactly Are Conveyor Systems?

Conveyor systems are essentially mechanical devices that move goods from one location to another. Sounds easy? Not exactly. In factories, warehouses, and distribution centres, these systems are made to maximise speed, minimise manual handling, and establish smooth operation. They can be roller conveyors, belt-driven lines, or overhead conveyors, among other types.

The Significance of Roller Conveyors

One of the most widely used kinds, roller conveyors provide a useful and affordable means of moving things, particularly in settings involving manufacturing or packing. Consider them to be highways for pallets, crates, or boxes. Because the rollers lessen friction, moving big objects requires less effort and personnel. Additionally, because they are modular, companies can add, delete, or reroute pieces in response to changing needs.

While gravity roller conveyors rely on incline and basic physics, powered roller conveyors use motors to transport objects automatically. Both kinds provide safety, speed, and consistency, things that physical labour can't always provide.

Smart Conveyor Systems' Ascent

Conveyor systems change with the industry. Smarter than ever, today's setups frequently incorporate robotics, automation software, and sensors. These intelligent technologies notify operators of maintenance requirements prior to a breakdown, track goods in real-time, and modify speeds based on load.

Conveyor systems are now the foundation of dependable, scalable operations in the cold chain, pharmaceutical, and e-commerce industries. They guarantee that goods travel from point A to point B without interruption, harm, or misunderstanding.

Choosing Trustworthy Conveyor Belt Suppliers

If you plan to set up or change your system, working with experienced conveyor belt suppliers is crucial. When choosing a conveyor, the type of material, needed speed, load weight, and available space are all crucial factors to take into account. Whether it's belt conveyors for fragile goods or roller systems for bulk movement, effective design and component selection can have a big impact on long-term performance.

0 notes

Text

Top Automotive Conveyor System Manufacturers in the UK: Driving Innovation in Industrial Automation

The automotive industry thrives on speed, efficiency, and precision. At the heart of these capabilities lies a robust material handling system – and nothing plays a more crucial role than automotive conveyor systems. In the UK, several manufacturers are leading the charge, offering state-of-the-art conveyor solutions tailored to the demands of automotive assembly lines.

Whether it's for transporting engines, chassis, or assembled components, automotive conveyor systems help streamline production, reduce human error, and improve overall safety. This blog highlights some of the top automotive conveyor system manufacturers in the UK and what sets them apart in the market.

1. L.B. Foster Automation

L.B. Foster stands out for its advanced material handling systems and turnkey solutions for automotive manufacturing. They offer everything from belt conveyors to robotic integration systems, ensuring smooth production flow.

Key Features:

Custom-built systems for specific automotive applications

Integration with robotics and IoT sensors

In-house engineering and support

2. Conveyor Units Ltd

As one of the UK’s leading conveyor manufacturers, Conveyor Units Ltd supplies a wide variety of roller conveyors and chain conveyors ideal for automotive plants. Their robust systems are designed to handle high-load components with precision.

Why Choose Them:

Proven track record in automotive installations

Modular and scalable designs

UK-wide service and support

3. Amber Industries

Amber Industries specialises in overhead and floor conveyor systems, perfect for complex automotive assembly environments. Their Autotrack™ systems are widely used in paint shops and final assembly lines.

Highlights:

Overhead chain conveyors for body shops

Floor-mounted solutions for heavy loads

Custom control systems

4. Automotion Components

Known for their high-precision solutions, Automotion Components delivers modular conveyor systems designed to be easily integrated into any automotive production line. They also provide extensive spare parts and upgrade options.

Notable Offerings:

Modular belt and slat conveyors

Compact, space-saving designs

Comprehensive parts catalogue

5. Monk Conveyors

With decades of experience in the UK automation sector, Monk Conveyors provides tailored solutions for the automotive industry. Their systems improve production efficiency while maintaining strict safety standards.

Features Include:

Pallet conveyor systems

Transfer units and robot interfacing

Advanced control systems

Why Automotive Conveyor Systems Matter

Automotive conveyor systems are more than just a means of transport — they are central to lean manufacturing strategies. From just-in-time delivery to synchronized workflows, these systems reduce downtime, improve productivity, and support the complex logistical needs of modern automotive plants.

Conclusion

When choosing an automotive conveyor system manufacturer in the UK, it’s crucial to consider experience, scalability, and the ability to customize solutions to your production line. The companies listed above are leading the way in innovation and reliability, helping UK-based automotive manufacturers stay competitive in a fast-paced global market.

0 notes

Text

North America Conveyor System Market Trends, Size, Segment and Growth by Forecast to 2030

Market Overview and Dynamics

The conveyor system market in North America is expected to grow from US$ 1963.15 million in 2019 to US$ 2,747.41 million by 2027; it is estimated to grow at a CAGR of 4.5% from 2020 to 2027. Various manufacturing industries are heavily investing on the adoption of automated solutions. Additionally, the adoption of data-driven solutions has gained significant popularity among various leading manufacturers and business owners to mitigate unforeseen errors, faults, and damages. Increasing demand for conveyor systems with integrated technologies across various industrial applications is expected to propel the market growth in the coming years. The mounting implementation of Industry 4.0 has led to an extensive digital overhaul across the manufacturing industry. Digital technologies such as artificial intelligence (AI) and predictive maintenance are used by the conveyor system providers for maintaining visibility across the supply chain with improved operations, transparency, and productivity. Additionally, technologies such as automation, the Internet of Things (IoT), and robotics are also gaining more prominence. Industry 4.0 based applications make it less challenging to coordinate operations across multiple industries than ever. 📚Download Full PDF Sample Copy of Market Report @ https://www.businessmarketinsights.com/sample/TIPRE00017311

Key Market Segments

In terms of system type, the belt segment accounted for the largest share of the North America conveyor system market in 2019. In terms of belt type, the medium segment held a larger market share of the North America conveyor system market in 2019. Further, the Others segment held a substantial share of the North America conveyor system market based on end user industry in 2019.

Major Sources and Companies Listed

A few major primary and secondary sources referred to for preparing this report on the conveyor system market in North America are company websites, annual reports, financial reports, national government documents, and statistical database, among others. Major companies listed in the report are Daifuku Co., Ltd., DEMATIC, Emerson Electric Co., Honeywell Intelligrated, Interroll Holding, GmbH, Siemens AG, SSI Schäfer, Swisslog, TGW Logistics Group, Vanderlande Industries B.V.

Reasons to buy report

To understand the North America conveyor system market landscape and identify market segments that are most likely to guarantee a strong return

Stay ahead of the race by comprehending the ever-changing competitive landscape for North America conveyor system market

Efficiently plan M&A and partnership deals in North America conveyor system market by identifying market segments with the most promising probable sales

Helps to take knowledgeable business decisions from perceptive and comprehensive analysis of market performance of various segment form North America conveyor system market

Obtain market revenue forecast for market by various segments from 2020-2027 in North America region.

A conveyor system is mechanical equipment or assemblies that carry material from one location to another with less effort. There are various types of conveyor systems, such as overhead, floor, roller, and belt, upon which the materials move. These systems come in different varieties to suit the different materials or products required to be transported. While deploying conveyor systems in any industry, several key factors, such as abrasiveness, corrosiveness, flowability, size, and moisture content should be taken into consideration to fulfill the industry needs. The system is usually complex in their design and construction due to their huge scales and integration into different factory processes. However, the modular nature of this system makes it readily attainable. The increasing demand for automation in verticals is one of the significant drivers for the growth of the North America conveyor systems market. The rising adoption of assembly line systems and mass production, coupled with increase in vehicle manufacturing, contributes to market growth.

The soaring foreign direct investment (FDI) investments in the automotive industry, material safety concerns, rising industrialization, requirement of automation to mitigate manufacturing costs, and expansion of the e-commerce sector with the adoption of conveyor systems are the key factors propelling the growth of the North America conveyor system market. The leading market players are focusing on broadening their addressable market by diversifying client bases, expanding current product portfolios by developing new products. Moreover, the pandemic has positively impacted the market growth, particularly in the e-commerce and food & beverage industries. Thus, blooming E-commerce industry to bolster the demand for conveyor systems is expected to create a significant demand for conveyor system in the coming years, which is further anticipated to drive the North America conveyor system market.

Furthermore, North America is severely affected by the COVID-19 pandemic. North America is one of the significant regions for the adoption and growth of advanced technologies due to favorable government policies to accelerate innovation, a huge industrial base, and high purchasing power, especially in developed countries, such as the US and Canada. Hence, any impact on the growth of industries is expected to affect the economic growth of the region negatively. The US is a prominent market for the conveyor systems, especially in the logistics sector. The huge increase in number of confirmed cases and rise in reported deaths has affected this industry. The factory and business shutdowns across the US, Canada, and Mexico are impacting the adoption of the conveyor system market. COVID-19 has had a severe impact on logistics operations, transportation, and trade activity. Owing to this pandemic, the manufacturing sector is facing dormancy because of the business shutdown. The companies resuming their manufacturing facilities face scaled-down production for conveyor belt systems due to a massively affected supply chain. This would hinder the adoption of conveyor systems in the region. The impact of the coronavirus outbreak is anticipated to be quite severe in the year 2020 and likely in 2021. However, online retailing and food businesses have boosted sales in the region. Consumers are spending on products that would help them manage the COVID-19 crisis. The impact of COVID-19 is short-term; it is likely to decrease in the coming years.

North America Conveyor System Strategic Insights

Strategic insights for the North America Conveyor System provides data-driven analysis of the industry landscape, including current trends, key players, and regional nuances. These insights offer actionable recommendations, enabling readers to differentiate themselves from competitors by identifying untapped segments or developing unique value propositions. Leveraging data analytics, these insights help industry players anticipate the market shifts, whether investors, manufacturers, or other stakeholders. A future-oriented perspective is essential, helping stakeholders anticipate market shifts and position themselves for long-term success in this dynamic region. Ultimately, effective strategic insights empower readers to make informed decisions that drive profitability and achieve their business objectives within the market. key company profiles Daifuku Co., Ltd.

DEMATIC

Emerson Electric Co.

Honeywell Intelligrated

Interroll Holding GmbH

Siemens AG

SSI Schäfer

Swisslog

TGW Logistics Group

Vanderlande Industries B.V. North America Conveyor System Regional Insights

The geographic scope of the North America Conveyor System refers to the specific areas in which a business operates and competes. Understanding local distinctions, such as diverse consumer preferences (e.g., demand for specific plug types or battery backup durations), varying economic conditions, and regulatory environments, is crucial for tailoring strategies to specific markets. Businesses can expand their reach by identifying underserved areas or adapting their offerings to meet local demands. A clear market focus allows for more effective resource allocation, targeted marketing campaigns, and better positioning against local competitors, ultimately driving growth in those targeted areas. About Us: Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Défense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications Author’s Bio Akshay Senior Market Research Expert at Business Market Insights

0 notes

Text

Stay Safe on the Job: Material Handling Safety Essentials

Whether you’re running a warehouse, factory, or logistics center, safety isn’t just a priority—it’s a necessity. Material handling tasks, especially those involving heavy loads and machinery, carry a high risk of accidents if proper precautions are not in place. Fortunately, many of these risks can be significantly reduced with the right safety essentials.

In this article, we’ll walk you through the core safety equipment, best practices, and tools that every workplace involved in material handling should implement. These essentials not only keep your workforce safe but also improve productivity, reduce downtime, and ensure compliance with safety regulations.

Why Safety in Material Handling Is Non-Negotiable

Material handling involves the movement, storage, control, and protection of goods and materials throughout the supply chain. It includes the use of equipment such as forklifts, pallet jacks, trolleys, hoists, and conveyors.

Here’s why safety matters:

Worker Protection: Prevent injuries from falls, collisions, lifting strains, and falling loads.

Equipment Longevity: Reduce wear and tear or avoid damage from misuse.

Regulatory Compliance: Avoid fines and legal trouble from failing safety audits.

Operational Continuity: Minimize downtime and maintain smooth workflows.

Top Material Handling Safety Essentials

Let’s explore the safety essentials that should be standard in any facility that deals with material handling.

1. Personal Protective Equipment (PPE)

No material handling task should begin without proper PPE. These items protect workers from direct physical harm and are legally required in most industrial settings.

Must-Have PPE Includes:

Hard Hats – To guard against head injuries from falling objects.

High-Visibility Vests – Ensures workers are seen by operators and moving equipment.

Steel-Toed Boots – Protects feet from heavy falling objects and sharp debris.

Gloves – Provides grip and protects hands from cuts, abrasions, or heat.

Goggles or Face Shields – Keeps eyes safe from dust, sparks, or splashes.

Back Support Belts – Useful in tasks requiring frequent lifting.

Tip: Ensure PPE meets national or international safety standards such as OSHA, ISI, or ANSI.

2. Forklift Safety Equipment

Forklifts are essential for lifting and moving heavy materials���but they’re also a common source of workplace injuries. Forklift safety accessories are vital for both operator and pedestrian protection.

Recommended Forklift Safety Add-Ons:

Blue or Red Spotlights – Project warning zones on the floor to alert nearby workers.

Back-Up Alarms – Notify others when forklifts are reversing.

Overhead Guards – Protect drivers from falling materials.

Load Backrests – Prevent loads from toppling backward onto the operator.

Speed Limiters – Control speed to reduce chances of accidents.

3. Floor Markings and Signage

Clear visual communication is essential in any material handling environment.

Key Visual Aids Include:

Floor Tape and Markings – Separate pedestrian zones, loading areas, and equipment lanes.

Caution and Instruction Signs – Warn of hazardous zones or operating procedures.

Traffic Flow Arrows – Direct both foot and vehicle traffic safely.

These small but impactful tools help reduce confusion and enhance site organization.

4. Material Handling Equipment Accessories

Accessories that improve the safety of hand trucks, pallet jacks, and platform trolleys can prevent load spills and operator strain.

Popular Add-Ons:

Anti-Slip Platform Mats – Reduce the risk of slipping or shifting loads.

Wheel Locks or Chocks – Prevent equipment from rolling while stationary.

Handle Guards – Protect hands from impact when maneuvering through tight spaces.

Regular maintenance checks of these tools are just as important as having them.

5. Fall Protection Systems

When working with raised platforms, mezzanines, or loading docks, fall protection is a must.

Common Fall Safety Equipment Includes:

Guardrails and Handrails – Install on elevated workstations or along ramps.

Safety Harnesses – Required when working at height.

Ladder Safety Cages and Anti-Slip Steps – Provide secure climbing and descent.

Falls are among the leading causes of workplace injuries and fatalities—so prevention must be proactive.

6. Loading Dock Safety Tools

Loading docks are busy, high-risk zones. Ensuring they’re equipped with proper safety tools prevents injury and keeps operations smooth.

Important Dock Safety Items:

Dock Bumpers – Absorb trailer impact and protect dock structures.

Vehicle Restraints and Wheel Chocks – Prevent trucks from moving during loading/unloading.

Dock Lights and Traffic Control Systems – Ensure visibility and coordination with drivers.

These measures also protect valuable goods during transit operations.

7. Emergency Preparedness Gear

Even with the best safety plans, emergencies can occur. Having the right gear on hand—and knowing how to use it—can make all the difference.

Essential Emergency Gear:

First Aid Kits – Stocked with wound care, burn treatments, and emergency meds.

Fire Extinguishers – ABC-rated extinguishers suitable for various fire types.

Eye Wash Stations – Especially important in areas where chemicals are handled.

Spill Kits – Contain hazardous material leaks or oil spills promptly.

Routine drills and training should accompany emergency preparedness equipment.

Best Practices for Material Handling Safety

Besides equipment, safety is also a matter of habits, culture, and training. Consider these best practices:

Conduct Regular Safety Training – Educate workers on how to handle materials safely.

Follow Load Capacity Guidelines – Don’t exceed the equipment’s or racks’ rated limits.

Keep Aisles Clear – Cluttered workspaces lead to accidents.

Encourage Reporting of Hazards – Make it easy and judgment-free for workers to report unsafe conditions.

Schedule Routine Maintenance – Prevent equipment failure by checking wear and tear regularly.

Benefits of Prioritizing Safety

When you commit to workplace safety, you’re investing in:

Lower accident rates and compensation claims

Higher employee morale and retention

Fewer delays and disruptions

Compliance with safety regulations

A reputation for professionalism and care

A safer workplace is also a more productive one.

Conclusion

Material handling is the backbone of industrial and warehouse operations. But without the right safety essentials, it can quickly become dangerous. By incorporating PPE, safety accessories, visual aids, fall protection, and emergency gear, businesses can significantly reduce risks and enhance their overall efficiency.

Stay safe, stay productive, and equip your workplace with the right tools—because safety isn’t a cost, it’s an investment.

0 notes

Text

The Future of Logistics in Malaysia: Smart Supply Chain and Inventory Innovations

Malaysia’s logistics and manufacturing sectors are growing fast—but so are the challenges. Rising costs, supply disruptions, and shifting customer expectations demand smarter, more integrated solutions. The secret? Partnering with a reliable Supply Chain Consultant Company, deploying efficient Material Handling Services, and using Optimal Inventory Management to streamline operations and reduce waste.

This trio is helping Malaysian businesses across industries build more resilient, data-driven supply chains that are ready for the future.

Summary

This article highlights how Malaysian companies can improve logistics and operational performance by working with a professional Supply Chain Consultant Company, investing in reliable Material Handling Services, and implementing Optimal Inventory Management. It outlines practical applications and benefits, including real-world strategies and expert insights.

Why Supply Chain Consultants Matter More Than Ever

Planning and Performance from an Expert’s Perspective

Many businesses in Malaysia are now realizing the benefits of hiring a Supply Chain Consultant Company to help streamline operations. These professionals assess your current systems and develop customized strategies to cut costs, increase delivery speed, and reduce supply chain risks.

They help with:

Network and route design

Vendor optimization

Sustainability planning

Cost-to-serve modeling

Digital transformation planning

Their external perspective provides valuable insights that internal teams may overlook—especially when scaling or entering new markets.

Malaysian Market-Specific Knowledge

A local or regionally experienced Supply Chain Consultant Company understands Malaysia’s unique logistics environment, including port congestion, regional customs regulations, and infrastructure challenges. This makes their advice more relevant and actionable compared to generic global models.

How Material Handling Services Improve Productivity

What Modern Handling Looks Like

Efficient Material Handling Services ensure that goods move smoothly throughout your facility—from receiving to shipping. This includes the use of equipment like forklifts, stackers, conveyors, trolleys, cranes, and storage systems.

Professional providers offer:

Custom handling system setup

Warehouse floor layout planning

Automated systems integration

Safety training and compliance

In Malaysia’s competitive environment, automation and handling efficiency can give businesses a clear edge.

Supporting Faster Fulfillment

Speed is everything in today’s logistics world. With effective Material Handling Services, warehouses reduce picking times, lower human error, and improve overall order accuracy.

Whether it's in a warehouse in Penang or a factory in Selangor, smart handling solutions shorten delivery lead times and improve throughput—leading to better customer experiences and reduced overhead.

Why Optimal Inventory Management Is the Key to Agility

Balancing Demand, Stock, and Storage Costs

Maintaining the right inventory levels is one of the biggest challenges for Malaysian businesses. Optimal Inventory Management focuses on stocking what you need—no more, no less. It involves real-time visibility, forecasting, order planning, and stock analysis.

This helps:

Avoid stockouts

Reduce expired or obsolete products

Improve working capital

Increase order fill rates

With the right tools and analytics, companies can anticipate demand shifts and adjust stock levels before problems arise.

Inventory as a Strategic Asset

Optimal Inventory Management isn't just about saving space—it’s about enabling responsiveness. When stock is accurate and accessible, your business can pivot faster to demand changes, new product launches, or disruptions.

Malaysian companies operating in high-velocity industries (like food, electronics, or apparel) benefit significantly from real-time inventory dashboards and automated reorder systems, often integrated with ERP or WMS platforms.

How These Three Elements Work Together

Integrated Logistics for Real Business Results

Imagine you're running a mid-sized retail chain in Malaysia. Your supply chain is struggling—your inventory turns are low, handling delays are frequent, and fulfillment costs are climbing. By engaging a Supply Chain Consultant Company, you first identify where inefficiencies lie.

Next, you upgrade your physical operations with advanced Material Handling Services—automated pickers, optimized flow paths, and new racking systems. Finally, you implement a cloud-based Optimal Inventory Management system that syncs with your POS and warehouse.

The outcome?

Faster delivery times

Lower carrying costs

Greater transparency across the supply chain

This holistic approach is what sets industry leaders apart.

Customization for Business Size and Industry

These solutions aren’t just for large corporations. Malaysian SMEs can also benefit—whether you're a local furniture maker in Johor or a cosmetics brand in Kuala Lumpur. Solutions are scalable and adaptable to your business size, product type, and customer base.

Success Snapshot: Malaysian Logistics Firm Adopts a New Strategy

A logistics firm in Klang recently restructured its operations to handle higher freight volumes. With the help of a Supply Chain Consultant Company, they redesigned their hub-and-spoke model to reduce last-mile delays.

They also partnered with a Material Handling Services provider to install a new conveyor and sorting system. Finally, they upgraded their WMS to incorporate Optimal Inventory Management, gaining real-time insights into stock levels.

The result?

22% faster order dispatch

30% improvement in storage efficiency

19% reduction in logistics costs within six months

These numbers show the real-world impact of aligning strategy, execution, and technology.

Tips for Getting Started

Thinking of integrating these solutions in your business? Here are some tips:

Start with an audit: Engage a supply chain consultant to assess current performance and identify improvement areas.

Prioritize automation: Manual handling processes are time-consuming and error-prone—automate where you can.

Invest in inventory tools: Even a simple dashboard can improve stock visibility and purchasing accuracy.

Train your teams: Tools and systems are only as effective as the people who use them.

By starting small and scaling strategically, you can see results quickly and build momentum across departments.

Conclusion

Malaysia’s supply chain ecosystem is evolving rapidly—and businesses must evolve with it. Working with a trusted Supply Chain Consultant Company, using advanced Material Handling Services, and embracing Optimal Inventory Management can unlock new levels of efficiency, scalability, and customer satisfaction.

These aren't optional upgrades—they’re essential for businesses that want to thrive in today’s competitive landscape. With the right strategy and tools, Malaysian businesses can create supply chains that are agile, intelligent, and built to last.

0 notes

Text

Efficient Warehousing Starts with the Right Pallet Dispenser

In modern warehousing and logistics, efficiency is no longer optional—it’s essential. A key component in streamlining material handling operations is the pallet dispenser. Often working in tandem with a pallet stacker, this equipment automates one of the most overlooked steps in warehouse workflows: dispensing and stacking pallets.

What Is a Pallet Dispenser?

A pallet dispenser is a mechanical device designed to automatically release or stack pallets without the need for manual handling. Commonly used in distribution centers, manufacturing plants, and packaging lines, these machines reduce downtime and improve worker safety by minimizing manual lifting.

Pallet dispensers can handle wooden, plastic, and sometimes even metal pallets, and they come in various configurations—floor-mounted, overhead, or integrated into conveyor systems.

Why Warehouses Are Turning to Pallet Dispensers

As labor shortages and operational costs continue to impact supply chain dynamics, automation is becoming an integral part of warehouse optimization. Pallet dispensers, when combined with pallet stackers, can lead to significant improvements in:

Productivity: Continuous feed of pallets eliminates manual placement delays.

Safety: Reduces the risk of injuries related to lifting and moving heavy pallets.

Consistency: Ensures uniform pallet handling, reducing operational errors.

“Since we implemented a pallet dispenser and stacker combo, our warehouse throughput has improved by nearly 30%. It’s reduced both idle time and workplace injuries.” — Carlos M., Logistics Manager, Northern Freight Solutions

Pallet Dispenser vs. Pallet Stacker: Understanding the Difference

While both are used in handling pallets, their functions differ:

Integrating both systems creates a closed-loop pallet management solution, minimizing idle time and maximizing operational flow.

Use Cases Across Industries

Pallet dispensers are not industry-specific. They are used in:

Food & Beverage: For maintaining hygiene and preventing contamination through minimal contact.

Pharmaceuticals: Ensuring consistent pallet availability during automated packaging.

Retail Distribution: Speeding up order fulfillment operations.

Automotive: Managing heavy-duty pallets for parts and components.

How to Choose the Right Pallet Dispenser

Selecting the ideal pallet dispenser depends on several operational factors:

Pallet Type and Size: Compatibility with standard or custom pallet dimensions.

Capacity: Number of pallets handled per cycle or per hour.

Integration Requirements: Whether it needs to work alongside conveyors, robots, or pallet stackers.

Space Constraints: Floor-mounted vs. overhead models depending on available warehouse space.

“Choosing a dispenser that integrates easily with our conveyor line made a significant difference. It wasn’t just about the machine—it was about how well it fit into our existing layout.” — Stephanie T., Plant Supervisor, Midstate Manufacturing Co.

Maintenance and Lifecycle Cost

Though typically low-maintenance, routine checks on mechanical parts, sensors, and hydraulic components are essential for longevity. Many dispensers offer diagnostics features to alert users of wear and tear, further reducing downtime.

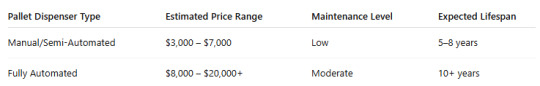

Here’s a general overview of cost expectations: Pallet Dispenser

Final Thoughts

For operations seeking to reduce manual labor, enhance safety, and improve throughput, a pallet dispenser paired with a pallet stacker offers a robust, scalable solution. With proven applications across diverse industries, it's clear that these machines are more than just convenience—they're a strategic investment in productivity.

0 notes

Text

Overhead Conveyor Manufacturer

An overhead conveyor is a highly efficient material handling system used to transport products or components above the work area, optimizing floor space and improving workflow in industrial environments. These conveyors are ideal for assembly lines, painting booths, packaging units, and warehouse operations where continuous movement and clear floor space are essential. Overhead conveyors operate using trolleys suspended from an overhead track and are typically powered by chains or motors for automated, consistent movement.

One of the leading manufacturers in this field is Laxmi Conveyor System, a trusted name known for delivering high-quality, durable, and customizable conveyor solutions. Based in India, Laxmi Conveyor System offers a wide range of overhead conveyor models suitable for light-duty to heavy-duty industrial applications. Their systems are built using robust materials to withstand tough operational conditions and are designed with flexibility to accommodate curves, inclines, and complex layouts.

Laxmi Conveyor System also integrates modern automation features such as sensors, control panels, and variable speed drives to meet diverse industry requirements. Their commitment to quality, timely delivery, and customer support makes them a preferred choice across sectors like automotive, food processing, and general manufacturing. With tailored designs and advanced engineering, they help industries streamline operations and boost productivity.

0 notes

Text

Material Handling Equipment

Material Handling Equipment: Streamlining Operations and Improving Efficiency

Material handling is an essential aspect of any business that deals with physical goods. Whether in a warehouse, manufacturing plant, or distribution center, the efficient movement, storage, and control of materials can make or break the productivity of an operation. One of the most significant factors in ensuring smooth and effective material handling is the use of material handling equipment (MHE).

Material handling equipment refers to the range of tools, machines, and systems used to facilitate the movement, storage, and control of materials throughout a manufacturing or distribution environment. It plays a vital role in improving efficiency, reducing human error, and ensuring that goods are handled safely and effectively. In this article, we will explore what material handling equipment is, why it's needed, its various types, and its applications and advantages.

What is Material Handling Equipment?

Material handling equipment refers to a wide variety of mechanical devices and systems designed to move, store, protect, and control materials throughout the manufacturing, warehousing, and distribution processes. These equipment types can vary from manual tools such as hand trucks and forklifts to automated systems like conveyors and cranes. In essence, material handling equipment is any device that aids in moving or managing goods, products, or raw materials during their journey through the supply chain.

The purpose of material handling equipment is to ensure that materials are moved in a safe, efficient, and cost-effective manner. The proper equipment helps businesses minimize labor costs, reduce product damage, and increase productivity by streamlining operations.

Why You Need Material Handling Equipment

Having the right material handling equipment is critical for any business that deals with physical products. Below are some of the key reasons why material handling equipment is necessary:

1. Increased Efficiency and Productivity

One of the primary reasons businesses invest in material handling equipment is to increase efficiency. Manual handling of materials is time-consuming and labor-intensive, whereas using the appropriate machinery or equipment significantly reduces the time it takes to move and store materials. This increase in speed translates to improved productivity in both manufacturing and distribution processes. Automated material handling systems, such as conveyor belts or robotic arms, can move goods continuously, without the need for constant human intervention, maximizing throughput.

2. Reduced Labor Costs

Material handling equipment can reduce the need for a large workforce to perform tasks that could be automated. By investing in machinery like forklifts, cranes, or automated guided vehicles (AGVs), businesses can minimize manual labor and cut down on the associated costs. This reduction in labor costs allows businesses to allocate resources to other areas, ultimately increasing profitability.

3. Enhanced Safety

Material handling can be physically demanding and potentially dangerous, particularly in environments where heavy, bulky, or hazardous materials are handled. Material handling equipment, such as forklifts, pallet jacks, or overhead cranes, can help prevent injuries by minimizing the need for manual lifting and reducing the risk of accidents. Additionally, many pieces of equipment come with safety features, such as load sensors, safety cages, and automatic braking systems, to further improve worker safety.

4. Better Space Utilization

Effective material handling systems help businesses maximize their storage capacity by using space more efficiently. This is particularly important in warehouses or distribution centers where space is at a premium. By utilizing automated storage and retrieval systems (ASRS), conveyors, or pallet racking systems, companies can optimize storage layouts, increase vertical space utilization, and reduce aisle space needed for manual handling.

5. Improved Inventory Control

Material handling equipment can significantly improve inventory management by making it easier to track goods and materials. Automated systems like RFID scanners or barcode systems, integrated with material handling equipment, allow businesses to monitor inventory levels in real-time and improve accuracy in stock counts. This reduces the chances of inventory discrepancies, ensuring that businesses maintain the right levels of stock and avoid costly stockouts or overstocking.

Types of Material Handling Equipment

Material handling equipment comes in various forms, each designed to serve a specific function in the handling and movement of goods. The key types of material handling equipment include:

1. Manual Equipment

Manual material handling equipment includes tools that require human effort to operate. These are typically used for smaller, lighter loads and are ideal for environments where automation isn’t practical or cost-effective. Common examples of manual equipment include:

Hand Trucks: Used for moving small loads such as boxes or containers over short distances.

Pallet Jacks: Designed to move palletized loads from one location to another within a warehouse or factory.

Carts and Trolleys: Used to carry goods that can be easily moved by hand, typically in offices or retail environments.

While manual material handling tools are low-cost and simple to operate, they require more labor and can be less efficient for larger-scale operations.

2. Industrial Trucks

Industrial trucks are motorized material handling equipment designed to carry heavy loads over longer distances. These include:

Forklifts: One of the most common industrial trucks, forklifts are used to lift and move heavy loads, such as pallets, from one place to another. They come in various configurations, including sit-down, stand-up, and narrow aisle models.

Tow Tractors: Used to pull or tow material-laden carts or trailers, these vehicles are typically found in factories or large warehouses.

Stackers: Compact, motorized devices that can lift and stack goods, similar to a forklift but smaller in size and often used in tight spaces.

3. Conveyors

Conveyors are mechanical systems used to transport materials across various parts of a production or distribution line. They are widely used in industries such as manufacturing, packaging, and logistics. Types of conveyors include:

Belt Conveyors: Consists of a belt that continuously moves materials along the production line.

Roller Conveyors: Made up of rollers that allow items to move with gravity or motors.

Chain Conveyors: Used for heavy-duty loads or materials that require more power to move, such as in mining or heavy manufacturing.

Conveyors are invaluable for transporting large quantities of materials quickly and efficiently over long distances within a facility.

4. Cranes and Hoists

Cranes and hoists are used to lift and move extremely heavy materials that cannot be handled by manual equipment. They are typically used in manufacturing environments, shipping yards, and construction sites. There are different types of cranes and hoists, including:

Overhead Cranes: These cranes are mounted on tracks above the work area, allowing them to move heavy loads across the entire workspace.

Jib Cranes: Fixed cranes with a rotating arm, often used in smaller spaces for moving heavy objects.

Hoists: Devices used to lift and lower materials vertically, often in conjunction with cranes.

Cranes and hoists provide a safe and efficient way to move heavy or bulky items that would otherwise require multiple workers to handle.

5. Automated Material Handling Systems

Automated material handling systems (AMHS) use robotics and advanced technology to move materials without human intervention. These systems are widely used in warehouses, factories, and distribution centers to improve efficiency and reduce labor costs. Common examples include:

Automated Guided Vehicles (AGVs): Robots that move materials through a facility based on pre-programmed paths or sensors.

Automated Storage and Retrieval Systems (ASRS): Systems that automatically store and retrieve materials from high-density storage racks.

Robotic Arms: Used for picking, placing, and assembling materials or products with high precision and speed.

These systems are ideal for high-volume environments, offering continuous operation and high levels of accuracy.

Applications of Material Handling Equipment

Material handling equipment is used in a wide range of industries to streamline operations, improve safety, and enhance efficiency. Some of the most common applications of material handling equipment include:

1. Manufacturing

In manufacturing plants, material handling equipment plays a crucial role in moving raw materials to the production line and finished goods to storage. Automated systems like conveyors and robotic arms are commonly used to transport parts and products through assembly lines.

2. Warehousing and Distribution

Warehouses and distribution centers rely heavily on material handling equipment to store, sort, and ship products. Forklifts, pallet jacks, and conveyors help move inventory around the facility, while automated systems like ASRS assist with inventory control and order fulfillment.

3. Retail

In retail environments, material handling equipment is used to move products from storage areas to shelves or display areas. Equipment like trolleys, hand trucks, and automated conveyors ensure that products are delivered to the sales floor quickly and efficiently.

4. Shipping and Receiving

Shipping and receiving departments in warehouses and distribution centers use material handling equipment to load and unload trucks, containers, and ships. Cranes, forklifts, and conveyors help streamline the transfer of goods from one mode of transportation to another.

5. Construction

Construction sites rely on cranes, hoists, and forklifts to move building materials, equipment, and supplies across the site. These machines allow workers to safely and efficiently move heavy loads that would be too dangerous or difficult to handle manually.

Advantages of Material Handling Equipment

Using material handling equipment offers numerous advantages that can benefit a variety of industries:

1. Improved Efficiency

By automating and streamlining material movement, businesses can increase productivity, reduce cycle times, and lower labor costs.

2. Enhanced Safety

Using the appropriate equipment reduces the risk of workplace injuries by minimizing manual lifting and physical strain.

3. Cost Savings

Investing in material handling equipment can result in significant cost savings by reducing labor needs, improving space utilization, and minimizing product damage.

4. Better Inventory Management

With integrated systems, material handling equipment can help track inventory in real-time, ensuring businesses have the right products at the right time.

5. Scalability

Material handling systems can be easily scaled to accommodate increasing demands, making them a long-term solution for growing businesses.

Conclusion

Material handling equipment is an essential part of modern industrial and commercial operations. From manual tools to sophisticated automated systems, the right equipment can drastically improve the efficiency, safety, and profitability of any business that deals with physical goods. Whether you are looking to move materials in a warehouse, streamline a manufacturing process, or improve safety on a construction site, the appropriate material handling equipment will help you achieve these goals. By investing in the right equipment, businesses can ensure smoother operations, reduce labor costs, and improve overall performance.

1 note

·

View note

Text

Leveraging Technology to Enhance Efficiency in Logistics Management

In today’s fast-paced global economy, logistics management plays a crucial role in ensuring the seamless movement of goods and services across supply chains. With rising customer expectations and the need for cost efficiency, leveraging technology has become imperative for businesses to stay competitive and improve operational efficiency. From automation to real-time data analytics, technology is reshaping the logistics landscape, enabling businesses to optimize processes, reduce costs, and enhance customer satisfaction logistic institute in kochi

The Role of Technology in Logistics Management

The adoption of advanced technologies in logistics management has revolutionized traditional practices, making operations more efficient and transparent. Key technological innovations that have a transformative impact include automation, Internet of Things (IoT), artificial intelligence (AI), blockchain, and cloud computing. These technologies help organizations address challenges such as complex supply chain networks, high operational costs, and unpredictable demand patterns.

1. Automation and Robotics

Automation in logistics has streamlined repetitive tasks, reduced human error, and increased productivity. Automated systems, such as robotic process automation (RPA) and conveyor belt sorting systems, have transformed warehousing and distribution operations. Advanced robotics, including autonomous mobile robots (AMRs) and collaborative robots (cobots), assist in picking, packing, and inventory management, reducing turnaround times and minimizing labor costs.

For instance, companies like Amazon have adopted robotic systems to enhance warehouse efficiency, enabling faster order processing and delivery. Automated guided vehicles (AGVs) are also widely used for transporting goods within warehouses and factories, ensuring accuracy and reducing the risk of damage.

2. IoT and Real-Time Tracking

The Internet of Things (IoT) has brought unprecedented visibility into logistics operations. IoT-enabled sensors and devices provide real-time data on the location, condition, and status of goods, allowing businesses to monitor shipments and assets across the supply chain.

IoT technology ensures better fleet management by providing insights into vehicle performance, fuel consumption, and route optimization. Real-time tracking enables businesses to proactively address delays, manage risks, and provide accurate delivery timelines to customers. For example, cold chain logistics benefit greatly from IoT by ensuring temperature-sensitive goods are transported under optimal conditions.

3. Artificial Intelligence and Machine Learning

AI and machine learning are transforming logistics by enabling predictive analytics, demand forecasting, and route optimization. AI algorithms analyze historical data and market trends to predict demand fluctuations, helping businesses manage inventory efficiently and reduce overstocking or stockouts.

Route optimization tools powered by AI identify the most efficient delivery routes, saving time and fuel costs while improving delivery accuracy. Additionally, AI-powered chatbots enhance customer service by providing instant responses to inquiries, tracking updates, and issue resolutions.

4. Blockchain for Transparency and Security

Blockchain technology enhances transparency and trust in logistics by creating a decentralized, immutable ledger for tracking transactions and shipments. It ensures secure data sharing among stakeholders and reduces fraud by providing a tamper-proof record of all supply chain activities.

Smart contracts, a feature of blockchain, automate payment processing and compliance checks, reducing administrative overhead. Companies in industries such as pharmaceuticals and food are leveraging blockchain to track product origins, ensuring compliance with safety and quality standards.

5. Cloud Computing for Collaboration and Scalability

Cloud computing has revolutionized logistics management by enabling seamless collaboration among supply chain partners. Cloud-based platforms provide real-time access to data, improving decision-making and fostering transparency.

Scalable cloud solutions allow businesses to adapt quickly to changing demands and integrate with other technologies like IoT and AI. For instance, transportation management systems (TMS) and warehouse management systems (WMS) hosted on the cloud provide centralized control and real-time updates, enabling businesses to operate more efficiently.

Benefits of Technology in Logistics Management

The integration of technology into logistics management offers numerous advantages:

Enhanced Efficiency: Automation and data-driven insights streamline processes, reducing manual effort and improving operational speed.

Cost Reduction: Technologies like route optimization and predictive analytics minimize fuel consumption, labor costs, and waste.

Improved Customer Satisfaction: Real-time tracking and proactive communication ensure timely deliveries, enhancing customer trust.

Greater Transparency: Blockchain and IoT provide visibility across the supply chain, fostering trust among stakeholders.

Scalability: Cloud-based solutions enable businesses to scale operations efficiently to meet growing demands.

Challenges and Considerations

While technology offers immense benefits, its adoption comes with challenges that businesses must address:

High Initial Costs: Implementing advanced technologies like robotics and IoT requires significant investment.

Data Security: The increased use of digital platforms raises concerns about data breaches and cybersecurity threats.

Integration Issues: Integrating new technologies with legacy systems can be complex and time-consuming.

Skill Gaps: Businesses need to invest in training employees to operate and manage advanced systems effectively.

Future Trends in Technology-Driven Logistics

The future of logistics management will see the convergence of emerging technologies to create fully automated, data-driven supply chains. Trends to watch include:

Autonomous Vehicles: Self-driving trucks and drones will revolutionize last-mile delivery, reducing dependency on human drivers.

5G Connectivity: Faster data transmission will enhance IoT applications and real-time communication across supply chains.

Digital Twins: Virtual replicas of physical systems will enable businesses to simulate and optimize operations before implementation.Sustainability Initiatives: Green technologies like electric vehicles and energy-efficient systems will become integral to logistics logistics courses in kochi

0 notes

Text

Boosting Efficiency with Powered Roller Conveyors: The Smart Solution for Modern Material Handling

Introduction

In today’s fast-paced industrial landscape, efficiency, safety, and productivity are more important than ever. Whether you're running a warehouse, distribution center, or production facility, smooth material flow can make or break your operations. That’s where Powered Roller Conveyors come in — a game-changing solution for handling materials with speed, precision, and minimal human intervention.

What is a Powered Roller Conveyor?

A powered roller conveyor is a type of conveyor system where the rollers are driven by motors or belts to move loads automatically. Unlike gravity conveyors, which rely on slope and manual force, powered systems provide controlled, consistent movement of goods, making them ideal for a variety of industrial applications.

Key Benefits of Powered Roller Conveyors

Increased Efficiency Powered conveyors can handle large volumes of products quickly and consistently, significantly reducing manual labor and downtime.

Improved Safety Automated material transport reduces the need for forklifts and manual handling, decreasing the risk of workplace injuries.

Customizable for Diverse Needs From light-duty packaging lines to heavy-duty pallet transport, powered roller conveyors can be tailored to suit different load types, sizes, and weights.

Energy Efficiency Many modern systems feature energy-saving motors and zone control, where only the necessary sections operate when needed, reducing power consumption.

Smooth Integration with Automation These conveyors can easily integrate with sensors, sorters, scanners, and robotic arms — essential for smart factories and Industry 4.0 environments.

Common Applications

Warehousing and Distribution Centers: For fast sorting and shipping of products.

Manufacturing Plants: To move raw materials, work-in-progress goods, or finished items.

Food and Beverage Industry: For clean, efficient transport of packaged goods.

E-commerce Fulfillment: Speeding up order picking and packing processes.

Automotive Industry: Handling components and assemblies on production lines.

Types of Powered Roller Conveyors

Line Shaft Conveyors: Suitable for light to medium loads; powered by a single motor and shaft system.

Chain-Driven Live Roller (CDLR) Conveyors: Ideal for heavy-duty applications like pallet transport.

Belt-Driven Roller Conveyors: A good choice for fragile or irregularly shaped items that need steady movement.

Motorized Roller Conveyors: Equipped with individual motors in each roller, offering precise control and energy savings.

Why Invest in Powered Roller Conveyors?

By automating your material handling with powered roller conveyors, you streamline operations, reduce overhead costs, and increase throughput. The return on investment is clear — faster movement of goods, fewer delays, and a safer work environment.

Conclusion

Powered roller conveyors are more than just a tool — they’re a strategic investment for companies looking to stay competitive in a rapidly evolving industrial world. Whether you're upgrading an existing system or building a new one from the ground up, choosing the right powered conveyor solution can revolutionize your workflow.

Looking to install powered roller conveyors at your facility? Contact us today for expert guidance, custom solutions, and industry-leading technology.

0 notes

Text

North America Conveyor System Market Trends, Size, Segment and Growth by Forecast to 2030

Market Overview and Dynamics

The conveyor system market in North America is expected to grow from US$ 1963.15 million in 2019 to US$ 2,747.41 million by 2027; it is estimated to grow at a CAGR of 4.5% from 2020 to 2027. Various manufacturing industries are heavily investing on the adoption of automated solutions. Additionally, the adoption of data-driven solutions has gained significant popularity among various leading manufacturers and business owners to mitigate unforeseen errors, faults, and damages. Increasing demand for conveyor systems with integrated technologies across various industrial applications is expected to propel the market growth in the coming years. The mounting implementation of Industry 4.0 has led to an extensive digital overhaul across the manufacturing industry. Digital technologies such as artificial intelligence (AI) and predictive maintenance are used by the conveyor system providers for maintaining visibility across the supply chain with improved operations, transparency, and productivity. Additionally, technologies such as automation, the Internet of Things (IoT), and robotics are also gaining more prominence. Industry 4.0 based applications make it less challenging to coordinate operations across multiple industries than ever. 📚Download Full PDF Sample Copy of Market Report @ https://www.businessmarketinsights.com/sample/TIPRE00017311

A conveyor system is mechanical equipment or assemblies that carry material from one location to another with less effort. There are various types of conveyor systems, such as overhead, floor, roller, and belt, upon which the materials move. These systems come in different varieties to suit the different materials or products required to be transported. While deploying conveyor systems in any industry, several key factors, such as abrasiveness, corrosiveness, flowability, size, and moisture content should be taken into consideration to fulfill the industry needs. The system is usually complex in their design and construction due to their huge scales and integration into different factory processes. However, the modular nature of this system makes it readily attainable. The increasing demand for automation in verticals is one of the significant drivers for the growth of the North America conveyor systems market. The rising adoption of assembly line systems and mass production, coupled with increase in vehicle manufacturing, contributes to market growth. The soaring foreign direct investment (FDI) investments in the automotive industry, material safety concerns, rising industrialization, requirement of automation to mitigate manufacturing costs, and expansion of the e-commerce sector with the adoption of conveyor systems are the key factors propelling the growth of the North America conveyor system market. The leading market players are focusing on broadening their addressable market by diversifying client bases, expanding current product portfolios by developing new products. Moreover, the pandemic has positively impacted the market growth, particularly in the e-commerce and food & beverage industries. Thus, blooming E-commerce industry to bolster the demand for conveyor systems is expected to create a significant demand for conveyor system in the coming years, which is further anticipated to drive the North America conveyor system market. Furthermore, North America is severely affected by the COVID-19 pandemic. North America is one of the significant regions for the adoption and growth of advanced technologies due to favorable government policies to accelerate innovation, a huge industrial base, and high purchasing power, especially in developed countries, such as the US and Canada. Hence, any impact on the growth of industries is expected to affect the economic growth of the region negatively. The US is a prominent market for the conveyor systems, especially in the logistics sector. The huge increase in number of confirmed cases and rise in reported deaths has affected this industry. The factory and business shutdowns across the US, Canada, and Mexico are impacting the adoption of the conveyor system market. COVID-19 has had a severe impact on logistics operations, transportation, and trade activity. Owing to this pandemic, the manufacturing sector is facing dormancy because of the business shutdown. The companies resuming their manufacturing facilities face scaled-down production for conveyor belt systems due to a massively affected supply chain. This would hinder the adoption of conveyor systems in the region. The impact of the coronavirus outbreak is anticipated to be quite severe in the year 2020 and likely in 2021. However, online retailing and food businesses have boosted sales in the region. Consumers are spending on products that would help them manage the COVID-19 crisis. The impact of COVID-19 is short-term; it is likely to decrease in the coming years. North America Conveyor System Strategic Insights

Strategic insights for the North America Conveyor System provides data-driven analysis of the industry landscape, including current trends, key players, and regional nuances. These insights offer actionable recommendations, enabling readers to differentiate themselves from competitors by identifying untapped segments or developing unique value propositions. Leveraging data analytics, these insights help industry players anticipate the market shifts, whether investors, manufacturers, or other stakeholders. A future-oriented perspective is essential, helping stakeholders anticipate market shifts and position themselves for long-term success in this dynamic region. Ultimately, effective strategic insights empower readers to make informed decisions that drive profitability and achieve their business objectives within the market.

Market leaders and key company profiles Daifuku Co., Ltd.

DEMATIC

Emerson Electric Co.

Honeywell Intelligrated

Interroll Holding GmbH

Siemens AG

SSI Schäfer

Swisslog

TGW Logistics Group

Vanderlande Industries B.V. North America Conveyor System Regional Insights

The geographic scope of the North America Conveyor System refers to the specific areas in which a business operates and competes. Understanding local distinctions, such as diverse consumer preferences (e.g., demand for specific plug types or battery backup durations), varying economic conditions, and regulatory environments, is crucial for tailoring strategies to specific markets. Businesses can expand their reach by identifying underserved areas or adapting their offerings to meet local demands. A clear market focus allows for more effective resource allocation, targeted marketing campaigns, and better positioning against local competitors, ultimately driving growth in those targeted areas.

Key Market Segments

In terms of system type, the belt segment accounted for the largest share of the North America conveyor system market in 2019. In terms of belt type, the medium segment held a larger market share of the North America conveyor system market in 2019. Further, the Others segment held a substantial share of the North America conveyor system market based on end user industry in 2019.

Major Sources and Companies Listed

A few major primary and secondary sources referred to for preparing this report on the conveyor system market in North America are company websites, annual reports, financial reports, national government documents, and statistical database, among others. Major companies listed in the report are Daifuku Co., Ltd., DEMATIC, Emerson Electric Co., Honeywell Intelligrated, Interroll Holding, GmbH, Siemens AG, SSI Schäfer, Swisslog, TGW Logistics Group, Vanderlande Industries B.V.

Reasons to buy report

To understand the North America conveyor system market landscape and identify market segments that are most likely to guarantee a strong return

Stay ahead of the race by comprehending the ever-changing competitive landscape for North America conveyor system market

Efficiently plan M&A and partnership deals in North America conveyor system market by identifying market segments with the most promising probable sales

Helps to take knowledgeable business decisions from perceptive and comprehensive analysis of market performance of various segment form North America conveyor system market

Obtain market revenue forecast for market by various segments from 2020-2027 in North America region.

Can you see this our reports

Europe Learning Management System Market – https://postyourarticle.com/europe-learning-management-system-market-trends-size-segment-and-growth-by-forecast-to-2030-4/

Europe Dental Market – https://github.com/businessmarketinsights985/business-market-insights/issues/18

North America Medical Laser Systems Market – https://findit.com/uwttwdjttmkjdpa/RightNow/northamerica-medical-laser-systemss/ea672c78-2f49-4851-986c-6f17f7e783af

Europe Railway Cyber Security Market – https://businessmarketins02.blogspot.com/2025/05/europe-railway-cyber-security-market.html

Europe Antibiotics Market – https://sites.google.com/view/businessmarketinsights126/home About Us: Business Market Insights is a market research platform that provides subscription service for industry and company reports. Our research team has extensive professional expertise in domains such as Electronics & Semiconductor; Aerospace & Défense; Automotive & Transportation; Energy & Power; Healthcare; Manufacturing & Construction; Food & Beverages; Chemicals & Materials; and Technology, Media, & Telecommunications Author’s Bio Akshay Senior Market Research Expert at Business Market Insights

0 notes

Text

Choosing the Right Conveyor Loading System for Your Warehouse

Selecting the ideal conveyor loading system can transform your warehouse operations, enhancing productivity, safety, and efficiency. However, with so many types and configurations available, choosing the right system can be challenging. In this guide, we’ll explore the key considerations to keep in mind when selecting a conveyor loading system, from types and functionality to maintenance needs and adaptability. By understanding these factors, you can make an informed choice that aligns with your warehouse’s unique needs.

Why Invest in a Conveyor Loading System?

A conveyor loading system is more than just a mechanism for moving goods—it’s a strategic investment that can improve warehouse productivity and streamline operations. A well-chosen system can reduce labor costs, minimize handling times, and improve overall workflow efficiency. If your warehouse handles high volumes of products, investing in an efficient conveyor loading system can offer substantial returns over time.

Key Considerations When Choosing a Conveyor Loading System

To select the best conveyor loading system for your warehouse, you’ll need to evaluate several factors. Here are the primary considerations to guide your decision.

1. Type of Products and Material Handling Needs

The first step in choosing a conveyor loading system is to consider the type of products your warehouse handles. Different systems are optimized for specific types of materials and handling needs:

Heavy items: Roller conveyors or chain conveyors are best for heavy items, as they can handle significant weight without compromising speed.

Light or fragile items: Belt conveyors with soft surfaces or padded options can safely transport fragile goods.

Irregularly shaped items: Flexible or modular conveyors adapt well to items of varying shapes and sizes.

Understanding your product’s size, weight, and fragility will help determine which conveyor loading system will deliver the best results.

2. Warehouse Space and Layout

Warehouse space plays a crucial role in conveyor selection. A compact warehouse may benefit from an overhead or vertical conveyor loading system to save floor space, while larger warehouses can accommodate extensive horizontal conveyors for optimal efficiency.

Compact spaces: Consider vertical or ceiling-mounted conveyors to maximize floor space.

Larger layouts: Belt and roller conveyors can cover long distances, connecting multiple areas for efficient material flow.

Modular setups: For warehouses that frequently change layouts, a modular conveyor loading system offers flexibility and easy reconfiguration.

Tip: Assess your warehouse layout and plan conveyor paths in advance to optimize both space and efficiency.

3. Speed and Throughput Requirements

How quickly does your warehouse need to move goods from one area to another? Your conveyor loading system should match your throughput requirements to avoid bottlenecks.

High-speed conveyors: Ideal for facilities that require rapid movement of goods.

Variable-speed conveyors: Allow you to adjust speed based on specific needs, such as handling fragile items carefully or increasing speed during peak times.

Automated sorting options: Some conveyors include sorting mechanisms to further improve accuracy and speed.

Matching conveyor speed to your warehouse’s demand can help avoid delays and keep operations running smoothly.

4. Automation and Integration Capabilities

Automation is a growing trend in warehouses as companies strive to streamline operations and reduce reliance on manual labor. An automated conveyor loading system can further improve efficiency, especially when integrated with warehouse management software (WMS).

Automated loading and unloading: Reduces the need for manual intervention, accelerating processes.

Integrated scanning and sorting: Systems with built-in scanners and sorters can ensure items reach the correct destinations.

Compatibility with WMS: Integration with warehouse software allows real-time tracking, improving inventory accuracy.

Tip: Look for a conveyor loading system that supports future automation upgrades to keep pace with technological advances.

5. Maintenance Requirements

A conveyor loading system is an investment that requires regular maintenance to ensure it operates efficiently. When selecting a system, consider its maintenance needs and whether you have the resources for upkeep.

Durability: Opt for a conveyor made from high-quality materials to reduce wear and tear.

Ease of maintenance: Choose a system with easy-access components for quick repairs.

Maintenance schedule: Conveyor systems with long service intervals can reduce downtime and maintenance costs.

Tip: Create a maintenance plan that includes regular inspections, cleaning, and part replacements to extend the life of your conveyor loading system.

6. Budget and ROI

While initial costs may be a factor, the long-term benefits of a conveyor loading system can offer significant ROI. Calculate potential cost savings by estimating reductions in labor costs, time saved, and the potential for increased throughput.

Initial costs: Conveyor systems vary in price based on type, size, and features. Determine a budget that aligns with your warehouse needs.

Operational savings: A well-maintained conveyor loading system can reduce manual labor, leading to substantial savings over time.

Improved efficiency: With faster loading, unloading, and transportation of goods, conveyors enable your warehouse to process more orders, boosting profitability.

Types of Conveyor Loading Systems

To meet specific material handling needs, consider the types of conveyor loading systems available:

Belt Conveyors: Suitable for transporting a wide range of products, including light and fragile items.

Roller Conveyors: Designed for heavy or bulky items, roller conveyors are durable and require minimal maintenance.

Chain Conveyors: These conveyors handle heavy loads and are ideal for transporting pallets.

Modular Conveyors: Flexible and easy to reconfigure, making them suitable for warehouses with changing layouts.

Vertical and Overhead Conveyors: Ideal for compact warehouses needing to maximize floor space.

Each conveyor type offers unique advantages, so it’s essential to align the system’s features with your warehouse’s specific requirements.

Best Practices for Implementing a Conveyor Loading System

After selecting the right conveyor loading system for your warehouse, effective implementation is crucial to maximizing its potential. Here are some best practices:

Plan the layout: Design a layout that optimizes material flow from loading docks to storage areas and shipping zones.

Train staff: Ensure employees are trained on system operation and safety protocols to maintain efficiency and minimize accidents.

Perform regular maintenance: Schedule inspections and repairs to prevent downtime and extend system longevity.