#plc interface modules

Explore tagged Tumblr posts

Text

Unlock Customizability: SEEZOL Crane Load Moment Indicator

SEEZOL customizable crane load moment indicator(LMI)focuses on the differentiated needs of customers and working conditions, and can be deeply customized from four dimensions: hardware, software, function, and interaction. The following is a detailed description:

I. Hardware adaptation customization

1. Sensor selection and installation

Select sensors according to the operating scenario: strain gauge load cells for high-precision lifting; high-temperature resistant and waterproof pressure sensors for harsh environment operations. Flexible installation, tower cranes use axle pin sensors at the root of the boom to measure tension, and gantry cranes are equipped with sensors at the end of the wire rope or the outrigger to monitor weight.

2. Control and display adaptation

The control unit can adjust the size, interface and protection level as needed. Small cranes use integrated units, and the protection of harsh environment equipment reaches IP67. The display terminal provides a variety of options such as color touch screens and high-brightness LED screens, and supports customization of night vision functions.

II. Software system customization

1. Algorithms and alarm logic

Customize algorithms according to crane characteristics, optimize the torque calculation of jib cranes, and develop special amplitude compensation algorithms. Users can customize three-level alarm thresholds (85% warning, 95% second-level warning, 105% overload alarm) and corresponding actions, such as sound and light alarm, speed limit or forced shutdown.

2. Communication protocol customization

Supports multiple protocols such as Modbus and Profibus, which is convenient for integration with crane control systems and monitoring platforms. For example, smart ports transmit data through 5G, and industrial production lines and PLCs work in depth.

III. Function expansion customization

1. Industry-specific modules

Customize wind speed compensation function for wind power installation, increase radiation protection for nuclear power construction, and develop fast parameter switching function for rental cranes.

2. Standard specification adaptation

Meet domestic standards such as GB/T 28264-2020, adapt to international standards such as EU CE and US OSHA, and support internal safety process customization of enterprises.

IV. Human-computer interaction customization

1. Interface and operation optimization

Provide a multi-language interface, simplify parameter settings, support shortcut key customization and graphical operations, and lower the threshold for use.

2. Data report customization

Record basic operation data and equipment status information as needed, generate daily and weekly reports in various formats, support Excel and PDF export, and help safety management and data analysis.

Through all-round customization, the customizable crane load moment indicator has become a safety solution that meets customer needs, taking into account both operation safety and management efficiency.

1 note

·

View note

Text

Can an automatic paper bag machine be customized for different bag sizes and shapes?

In today’s packaging industry, flexibility is power. Whether you're supplying grocery stores, fashion retailers, food delivery services, or pharmacies, each client may require paper bags of different sizes, styles, and shapes. To stay competitive and meet diverse customer needs, manufacturers need a machine that does more than just produce paper bags—it must adapt, scale, and deliver variety.

This leads to a common question we hear at Prakash Machineries Pvt. Ltd: Can an automatic paper bag machine be customized for different bag sizes and shapes? The short answer is—absolutely yes.

Modern paper bag machines are built with flexibility in mind. In this article, we’ll explore how our advanced automatic paper bag machines can be customized to produce a wide range of bag dimensions and formats, and how this capability benefits your business.

Why Customization Matters in Paper Bag Production

As the demand for eco-friendly alternatives to plastic continues to rise, different industries are looking for tailored paper bag solutions. For example:

A restaurant may need medium-sized square bottom bags with handles for food deliveries.

A retail outlet might want printed shopping bags in multiple sizes.

A pharmacy may prefer flat, compact bags for lightweight items.

A grocery store might need heavy-duty flat bottom bags in bulk.

Without customization, you’d need separate machines or manual setups for each size—which reduces efficiency and increases cost. This is where a customizable automatic paper bag machine offers a major competitive edge.

How Automatic Paper Bag Machines Offer Customization

Modern automatic paper bag machines, especially those from Prakash Machineries Pvt. Ltd, are engineered for flexibility. Here’s how they enable quick and easy customization:

1. Adjustable Forming Plates and Tubes

The forming unit is the heart of the bag-making process. By changing or adjusting the forming plate and tube, you can produce bags of different widths and gusset sizes. This allows you to create small, medium, and large paper bags using the same machine.

Adjustable Parameters Include:

Bag width

Bag length

Bottom width (flat or square)

Side gusset width (for volume capacity)

With tool-less adjustments or quick-change mechanisms, switching between bag sizes becomes a matter of minutes—not hours.

2. PLC-Controlled Settings for Size Variability

Our machines are equipped with PLC-based touchscreen interfaces that allow operators to input desired bag dimensions with ease. You can set the length, bottom width, and cutting parameters electronically, ensuring precise output every time.

This not only enhances accuracy but also reduces the chances of human error during changeovers.

3. Multi-Format Bag Production

Advanced machines are capable of producing various types of paper bags from a single setup. These include:

Flat bottom bags for groceries and medicine

Square bottom bags for retail and takeaway

V-bottom/satchel bags for bakery and pharmacy use

Handle bags (twisted rope or flat handle)

Printed bags with custom branding

The ability to switch between formats on the same machine gives your business a huge advantage in catering to different market segments.

4. Compatible with Various Paper Grades and Roll Widths

To accommodate different bag shapes and weights, our machines can process multiple paper types such as:

Kraft paper

White or brown recycled paper

Coated/laminated paper for moisture resistance

With adjustable roll holders and web aligners, you can easily switch between different paper rolls and thicknesses, ensuring compatibility with diverse applications.

5. Optional Add-Ons for Advanced Features

At Prakash Machineries Pvt. Ltd, we offer machines with optional modules that can be integrated based on your product line:

Handle pasting units for retail carry bags

Inline flexographic printing units for branded bags

Window patching units for bakery or gift bags

Lamination compatibility for water-resistant bags

These upgrades can be added at the time of purchase or later as your business grows.

Benefits of Customization for Your Business

Having a customizable paper bag machine opens up numerous advantages:

✅ Serve Multiple Industries

Adapt your product offering to cater to retail, food service, healthcare, and more.

✅ Improve Profit Margins

Produce premium, value-added bags like printed or handled bags that command higher prices.

✅ Stay Competitive

Offer a wide variety of bag sizes to meet changing customer demands and stand out from competitors with limited options.

✅ Scale Seamlessly

Start with basic production and expand your capabilities without replacing your machine.

✅ Faster Order Fulfillment

Switch between sizes and designs quickly to fulfill small or bulk orders efficiently.

Why Choose Prakash Machineries Pvt. Ltd?

At Prakash Machineries Pvt. Ltd, we specialize in delivering machines that are not only durable and high-speed, but also highly customizable. Our paper bag machines are designed to adapt to your production requirements, offering:

Precision-engineered forming systems

Easy-to-use control panels

Servo-driven mechanisms for accuracy

Modular designs for future upgrades

We also provide complete training, technical support, and after-sales service to ensure your team can operate the machine to its full potential.

Conclusion: One Machine, Endless Possibilities

In a dynamic and growing market, versatility is key. A customizable automatic paper bag machine allows you to stay ahead of trends, expand your customer base, and increase your profits—all without investing in multiple machines.

Whether you're launching a new production line or upgrading your current setup, the ability to produce different bag sizes and shapes on one machine is a smart, future-proof investment.

Ready to make your paper bag production more flexible and profitable? Contact Prakash Machineries Pvt. Ltd today to explore our range of customizable automatic paper bag machines—engineered for performance, precision, and scalability.

#manufacturer#paper bag manufacturer#square bottom#machines#paper bag#flexo#v bottom#bags#paper#dan and phil#cake#chris sturniolo#cooking#critical role#baking#alien stage#chocolate#delicious#breakfast

1 note

·

View note

Text

Allen Bradley Analog Input Modules 1734-IE2C & 1734-IE2V

youtube

Allen Bradley Analog Input Module is an electronic device used in industrial automation, data acquisition, and control systems to interface analog signals from the physical world to digital systems for processing, monitoring, and analysis. These modules play a crucial role in converting continuous analog signals, such as voltage or current levels, into discrete digital values that can be easily processed by microcontrollers, programmable logic controllers (PLCs), computers, or other digital devices.

Show on more :- https://youtu.be/it9_cN-eEs8?si=HSdS2r2TDsJaFG9g

🌐Website :- https://asteamtechno.com

👉Contact us :- +919537840404

📧Email :- [email protected]

#tumblr trends#automation#viralpost#viral#trendingnow#bestdeals#allen bradley#trending#plc#rockwell automation#Youtube

2 notes

·

View notes

Text

Torque Sensors by Star EMBSYS: Smart Force Measurement for Modern Industry

Torque sensors are vital components in today’s precision-driven industrial and research environments. These devices measure the twisting force—known as torque—applied to an object, typically a rotating shaft or axle. As automation, robotics, and electric mobility gain momentum, torque measurement becomes increasingly essential for monitoring efficiency, ensuring safety, and enhancing performance. At the forefront of this technology is Star EMBSYS, a pioneer in embedded and sensor systems, offering high-performance torque sensors built for accuracy, durability, and intelligent integration.

What is a Torque Sensor?

A torque sensor, also called a torque transducer, is a device that converts mechanical torque into an electrical signal. It is commonly used to monitor how much rotational force is being applied, either in a static (non-rotating) or dynamic (rotating) system.

There are two primary types of torque sensors:

Static (Reaction) Torque Sensors – Measure torque without rotating, often used in assembly systems or testing labs.

Rotary Torque Sensors – Measure torque in rotating systems such as motors, engines, or gearboxes.

These sensors use various technologies such as strain gauges, magnetoelastic sensing, or optical methods to detect mechanical stress and translate it into measurable electrical output.

Star EMBSYS Torque Sensor Solutions

Star EMBSYS offers a range of torque sensors designed for precision, robustness, and easy integration with modern electronics and control systems. Whether for industrial machinery, electric vehicles, robotics, or test benches, Star EMBSYS torque sensors provide:

High Accuracy and Sensitivity: Engineered with high-quality strain gauges and optimized signal conditioning electronics.

Durability in Harsh Environments: Withstands shock, vibration, and wide temperature ranges, suitable for both lab and field use.

Digital and Analog Outputs: Compatible with embedded systems, data acquisition modules, and PLCs.

Customizable Design: Torque range, output type, and mechanical interface can be tailored to specific applications.

Embedded System Integration: Optimized for real-time monitoring and control in smart systems.

Applications of Torque Sensors

Torque sensors from Star EMBSYS are deployed across various industries, including:

Automotive – In engine testing, drivetrain analysis, and electric vehicle performance evaluation.

Industrial Automation – For monitoring torque in production equipment, robotic arms, and conveyors.

Energy Sector – In wind turbines and power generation systems to ensure load balancing and fault detection.

Aerospace – For structural testing and control system diagnostics.

Medical Devices – In surgical robots and rehabilitation equipment for force feedback and control.

Why Choose Star EMBSYS?

Star EMBSYS blends mechanical engineering with embedded electronics expertise to provide innovative and reliable torque measurement solutions. Their focus on custom development, precision manufacturing, and real-time data handling ensures their torque sensors meet the exact needs of modern industry. Backed by dedicated engineering support and a track record of successful deployments, Star EMBSYS stands as a reliable partner in force and motion sensing.

Conclusion

Torque sensors are critical in today’s technology-driven industries where precision, efficiency, and safety are top priorities. With advanced features and smart integration capabilities, Star EMBSYS torque sensors empower businesses and researchers to achieve greater control and insight into their systems. Choose Star EMBSYS for high-performance torque measurement you can trust.

Visit:- https://www.starembsys.com/torque-sensor.html

0 notes

Text

Why SINAMICS G120 is the Preferred Choice for Industrial Drives

In this day's competitive industrial scenario, everything has to run faster, smarter, and energy-efficiently. The kind of drive system you choose will determine if operations succeed in manufacturing, processing, or materials handling. That has somewhat forced many industries worldwide to consider the SINAMICS G120 Drive of Siemens: a drive system that needs to possess a high degree of versatility and performance to answer current automation needs.

Learn more, How SINAMICS G120 Supports Energy-Saving in Industrial Applications

What is SINAMICS G120?

The Drive SINAMICS G120 is a frequency inverter that is modular and is meant for securing the speed and torque of three-phase motors. With such freeway capabilities, it found applications in a vast array of industrial processes: pumps, fans, conveyors, compressors, mixers, and others.

What distinguishes Drive G120 from its competitors is the smart idea behind it: basically, this means it consists of two main components, the Control Unit (CU) and the Power Module (PM), which can be combined and replaced separately. This makes it an extremely flexible choice, easily integrated into existing systems.

Why Choose the SINAMICS G120 Drive?

Some reasons why various industries choose this drive system include:

Energy Efficiency: Regenerative feedback and ECO mode assist in keeping electricity expenses low.

Integrated Safety Functions: Safe Torque Off (STO) and other safety features protect the operator and ensure compliance with international standards.

Seamless Communication: Through communications such as PROFINET, PROFIBUS, and Modbus RTU, it can be interfaced into most automation networks.

Reliable Performance: Superior motor control is provided for constant and variable torque applications.

Drive G120 in Real-Life Application

User industries report increased system efficiency, with reductions in maintenance and performance, occurring with the installation of the Drive SINAMICS G120. Thus, in water treatment plants or automated warehouses, the drive keeps operations running smoothly and reliably.

For example, applications that require conveyors with constant speed change between different loads will benefit greatly from the Drive G120 torque controlling capability to minimize mechanical wear and maximize output.

Simple Setup and Maintenance

The simple web server and powerful diagnostics make for a very user-friendly interface for the SINAMICS G120. Parameterization, monitoring, and fault diagnostics can also easily be carried out by your maintenance crew within a very short time, with or without specialized training.

Another aspect of the modular design is that the components can be individually replaced, thereby reducing downtime in the maintenance process or when upgrading.

Final Thoughts

If the automation system demands enhanced drive solutions, then the SINAMICS G120 by Naksh Technology Solutions LLP can be regarded as the choice facing modern times. It has been crafted to meet contemporary industrial requirements-powerfully, modularly, and safely. Siemens engineered it to over-deliver: from Drive G120 flexible configuration to seamless integration with your existing PLC or HMI setup.

Want to upgrade or optimize your system? Then the SINAMICS G120 Drive is just what your operation needs.

0 notes

Text

How Do Contact Output Modules Improve Flexibility in Turbine Control Systems?

In modern industrial automation and turbine control environments, scalability and signal expansion are essential. As systems grow in complexity, they often require additional I/O capabilities—especially for sending command signals to auxiliary devices, alarms, and field relays. This is where Contact Output Expansion Modules, like the IS200DTBDG1A, come into play. These modules allow you to extend the number of dry contact outputs available within GE Mark VI or VIe control systems, providing greater control flexibility without the need for complete system overhauls. Let’s explore what contact output modules do, where they are used, and why they are essential for scalable and reliable turbine control architectures. What Is a Contact Output Expansion Terminal Module? A contact output module is a terminal board that provides additional relay outputs or dry contact points used to control field devices. The IS200DTBDG1A is a GE-designed board that interfaces with the main control processor to output discrete signals when triggered by automation logic. Each contact acts like an electrical switch, opening or closing based on the controller’s command—ideal for controlling: Relays Circuit breakers Solenoids Warning indicators Shutdown signals Key Functions of the IS200DTBDG1A Board 1. Signal Expansion for Complex Systems As control systems grow—whether through added sensors, alarms, or safety functions—the need for more outputs increases. This board adds dedicated dry contact outputs without needing to replace or upgrade the main controller. 2. Discrete Command Signal Control Each contact output can represent a binary state (on/off) to trigger critical field equipment. This makes it ideal for alarm systems, motor starters, and interlock systems. 3. Integration with GE Mark VI Systems The module is fully compatible with GE’s Mark VI/VIe platforms, ensuring seamless integration without signal mismatch or configuration issues. 4. Rugged, Industrial Design Designed for harsh conditions found in turbine enclosures and control panels, the IS200DTBDG1A can operate reliably in environments with high vibration, temperature fluctuations, and electrical noise. Where Is It Used? The IS200DTBDG1A contact output module is commonly used in: Gas and steam turbine control panels Power plant automation systems Industrial DCS/PLC cabinets Oil & gas skids and compressor control units Its key role is to transmit safe, isolated command signals to field devices from the central control logic. Operational Benefits ✔ Scalability Instead of replacing a controller when output points are maxed out, you can simply add modules like the IS200DTBDG1A for quick expansion. ✔ Isolation and Protection Contact outputs are electrically isolated, which protects the main controller from voltage spikes or grounding issues in field wiring. ✔ Simplified Maintenance With clearly labeled terminals and test points, these boards make it easy for technicians to troubleshoot and verify control signals during shutdowns or commissioning. Installation and Maintenance Considerations To ensure long-term reliability: Use shielded cables to avoid interference Regularly check terminals for secure connections Verify logic mapping in the controller to confirm that outputs are assigned correctly Also, replacing these modules with OEM-certified hardware—such as the IS200DTBDG1A—ensures continued compatibility and system reliability. Conclusion In critical control systems like those found in gas and steam turbines, every signal matters. The IS200DTBDG1A Contact Output Expansion Terminal Module ensures that your control system has the flexibility, reliability, and capacity to scale with operational needs. Whether you're automating alarms, controlling breakers, or sending trip signals, this module provides a trusted, field-proven interface for executing your most essential commands. For operators and engineers alike, it's an indispensable component for robust and responsive turbine automation.

0 notes

Text

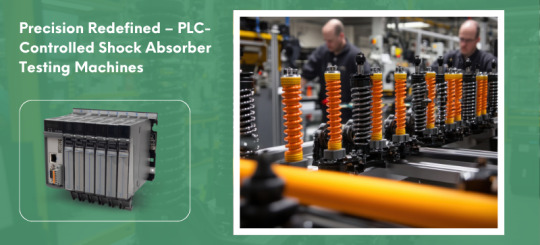

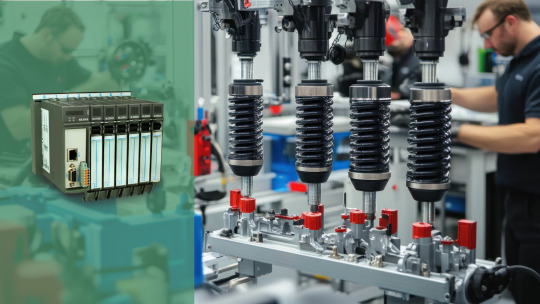

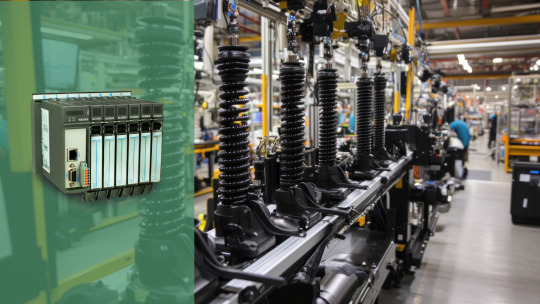

Precision Redefined – PLC-Controlled Shock Absorber Testing Machines

Precision – a word that keeps on getting thrown around often in the world of engineering. However, when it comes to shock absorber testing, precision isn’t a luxury—it’s survival. Every curve, every jolt, every rebound of a shock absorber must be captured, tested, and analysed to microscopic exactness. Gone are the days when manual testing could keep up.

The role of shock absorbers in today’s high-speed automotive innovation and precision engineering is to provide safety, comfort, and performance protection. But how can we make sure that these absorbers meet the high standards required by modern vehicles? This is where PLC automation becomes a useful tool.

The old-fashioned testing methods, which were cumbersome, unreliable, and laborious, have been replaced by PLC-based automation systems. Imagine a testing line with the capacity to think, adapt and respond in real time. The precision of Programmable Logic Controllers (PLCs) is not solely a promise, but rather adherence to standardised protocols.

How PLCs Enhance Shock Absorber Testing

There has been an evolution in the science of testing shock absorbers. Let’s understand how smart and compact PLCs can automate and optimise critical testing stages by providing consistency, control, and clarity.

Centralised Control with High Reliability

A robust industrial PLC is the foundation of our testing machines. The real-time control systems embedded in our automation design enable seamless functioning of all sensor, actuator, and motorised components.

Multiple sensors? Check.

Complex test sequences? Seamlessly handled.

From servo motion controllers managing high-speed vertical displacements to compact PLCs managing individual test stations, the formation is digital, deliberate, and dependable.

Real-Time Data Acquisition & Analysis

Here's where things get exciting. Tests on shock absorbers are more than just passing or failing. It's about quantifiable performance with our automation controllers:

Damping force curves

Displacement maps

Velocity and resistance profiles.

The data is gathered by high-resolution sensors and then processed through HMI with PLC controllers. The integration of this with databases is achieved through integrated PLC-based software, resulting in predictive maintenance and long-term performance insights

Feedback Loops for Adaptive Control

Ever wondered what would happen if the test differs? What would be the outcome? Well, with the use of real-time PLC communication protocols (like MODBUS and Ethernet/IP) and closed-loop control enable our systems to identify anomalies mid-test while enabling automatic correction.

Additionally, dynamic adjustment of actuator velocity in a system is possible when the response rate of the unit is slower than the tolerance. Or if temperatures spike? After a system shutdown, it sends an alert via the web server PLC and logs the fault. This requires more than just testing -- intelligent testing.

NX-ERA JET PLC System Architecture

Now let’s explore the engine room that fuels our innovation. The NX-ERA JET PLC, the foundation of our automated testing platform, undergoes a thorough architecture and connectivity analysis.

Core Hardware Components

With its compact size, modular design, and future scalability, the NX-ERA JET PLC is a formidable beast. It houses:

Simple servo systems designed for precise motion control

Energy-efficient motors can be powered by Variable Frequency Drives (VFDs)

HMI interfaces that enable the creation of visual dashboards and manual overrides

I/O modules for interfacing with third-party equipment.

Its modular design makes it suitable for both high-volume testing environments and small-batch production lines that use Micro PLCs or Mini PLCs

Communication & Connectivity

Connectivity should be a fundamental aspect of the entire setup, not an extra one.

Modbus PLC Interface is responsible for ensuring device-to-device communication

High-speed data relays are made possible with Ethernet-based controller systems

PLC with TCP/IP can be used for remote data logging and system control, as well as firmware updates

IoT-ready PLCs enable the integration of the testing machine with ERP, MES, and SCADA

Key Benefits of PLC-Controlled Testing Machines

Indeed, inefficient processes are not easily exploited in the fast-paced manufacturing industry. Your requirements include testing devices that don't blink even when pressured, systems that guarantee high quality, and technology that evolves as your business grows. Our PLC-based automation solutions are precisely in tune with that.

They offer:

Repeatability and Precision - One unit can be tested with ease and accuracy. But what about testing thousands with zero deviation? Our automation solutions that utilize PLCs accomplish this objective. You get:

Identical test cycles

Calibrated control parameters

Automated calibration routines

It implies improved quality control and enhanced audit accessibility.

High Throughput with Reliability - Traditional systems often require individuals to choose between speed and accuracy. Not here. The configurations of our NX-ERA JET PLC enable:

Sub-second test cycles

Parallel station control

Integrated logic and safety layers

All without compromising test integrity.

Reduced Manual Intervention - By utilizing HMI integration, and adaptive PLC programming, operators can not only monitor and but control:

Reduced human error

Faster changeovers

Safer work environment

Safety and Compliance – Safety is crucial for any industrial setup. With our smart PLCs, you can easily:

Emergency stop circuits

Real-time fault diagnostics

Layered safety logic

PLCs are designed to provide timely and effective alerts and shutdowns, complying with international standards such as ISO and CE.

Adaptable and Future-Ready - Different testing may be required for tomorrow's shock absorber. Good news: you won’t need a new machine.

Reprogram testing logic

Add new motion profiles

Update firmware via PLC with IoT

That’s the power of modular PLCs.

Whether you're chasing precision, throughput, or transformation, our PLC-controlled shock absorber testing machines deliver across the board. These benefits aren’t just technical specs—they’re business advantages, engineered to give you control, confidence, and a competitive edge.

Why Choose Messung’s Programmable Logic Controllers for Automation Solutions

Your choice of controller can determine your plant's success in a world propelled by data-driven decision-making, agility, and accuracy. We offer complete PLC-based automation solutions meant to grow with your demands rather than just supply PLCs. Our PLCs are not only intelligent but also necessary for the following reasons:

Smart and Connected PLCs - Our smart PLCs dynamically optimise by adjusting to handle changes. Embedded intelligence enables them to learn from repeated tests, predict component failures, and optimize actuator profiles automatically. Moreover, our edge-computing enabled PLCs help for quicker decisions by lowering cloud dependence.

HMI Integration for Better User Control - No more enigmatic command-line interfaces. With our smart PLCs, you get touchscreen HMIs, customised dashboards and real-time analytics displays.

Compact and Versatile PLC (Programmable Logic Controller) Options - Squeezed on space? You can get the complete power of a typical controller, without worrying about the size, with our compact PLC, micro PLC, and mini PLC range.

From intelligence that anticipates, to interfaces that simplify, to form factors that adapt—Messung’s PLC Programming range is designed not just to meet your automation goals, but to exceed them. Because when you choose Messung, you don’t just adopt automation; you embrace transformation.

Applications Beyond Shock Absorbers

Although shock absorber testing is where our PLC automation solutions show their power, that's just one section in our automation playbook. Beyond the same technology, fine-tuned for real-time control, precision, and adaptability, extends far. Messung's intelligent PLC solutions provide flexibility and value across a range of sectors, whether you are forming metal or transporting materials.

Let's explore how our PLC Control Systems have a range much outside the damping zone:

Motion Control Systems - Conveyor automation and actuator-driven systems all fall under our motion control solutions. Through synced servo motion controllers, we guarantee millisecond-level accuracy.

Machine Tool Controllers - Integrated with smart CNC tools, our machine tool controllers use feedback to adjust cutting speeds, minimise tool wear and even optimise material usage.

Advanced Automation – Through this end-to-end automation, sending raw material to finished parts, fully automated quality checks and centralized command via connected PLCs can easily become possible.

One shouldn't limit automation to just one purpose. Whether it is in high-speed assembly lines or precise machining at Messung, our PLC automation systems are flexible enough to meet the demands of many industries. Beyond shock absorbers, our solutions usher in intelligent manufacturing possibilities one motion at a time.

Conclusion

Accuracy is a standard, not only a specification. If you are still using obsolete testing configurations, it's time to change course. Designed to bring not just performance but also purpose to your production floor, Messung's PLC-controlled shock absorber testing equipment helps you to achieve this.

Testing has to be quick, adaptable, and flawless, whether you are creating luxury cars or robust trucks. That is precisely what Messung's PLC control systems promise—and deliver.

We do not just automate; we elevate, from servo-tight control to smart data acquisition, from seamless integration to Industry 4.0-based controllers.

At Messung, accuracy is not just redefined. It has changed everything. Hence, go for it. Redefine accuracy. One test at a time!

FAQs

What makes Messung’s PLC Control Systems ideal for shock absorber testing?

Messung’s PLCs (Programmable Logic Controller) offer centralised control, real-time data capture, adaptive feedback loops, and ensure peak accuracy and speed.

Can Messung’s PLC Programming integrate with existing equipment?

Yes. With protocols like MODBUS, TCP/IP, and Ethernet-based controllers, our PLCs are designed for easy retrofitting and compatibility.

How do PLC Control Systems improve the testing process?

PLCs provide real-time emergency stop functionality, error detection, and ensure the equipment runs within safe operational parameters.

Do you offer remote access features?

Absolutely. With web server PLC (Programmable Logic Controller) capabilities and HMI with PLC controllers, you can monitor and manage testing remotely.

Is your PLC solution scalable?

Yes. With modular PLCs and IoT-ready systems, you can scale your setup to match your growth.

#PLC control systems#Programmable Logic Controllers (PLC).#Messung Industrial Automation#PLC automation systems#Smart PLC control#PLC-based AHU control system#modular PLC#Energy management systems#IEC 61131 based PLCs#compact PLC#IEC 61131-3 standard PLC Control Systems#MODBUS RTU#Modbus TCP#NX-ERA JET#PLC for energy systems#IEC 61131-3 compliant PLCs#modular PLCs#HMI with PLC controller#smart automation systems#programmable logic controller#smart PLCs#Modular PLCs

0 notes

Text

High-Speed Candy Wrapping Machine by Dhiman Industries

Dhiman Industries presents a revolutionary solution for the confectionery sector with its high-speed candy wrapping machine, designed to streamline and elevate the packaging process of candies in commercial production lines. Engineered with advanced automation and built for long-term performance, this high-speed candy wrapping machine reflects the brand’s legacy of precision, innovation, and reliability in sweet manufacturing equipment. The machine ensures maximum operational efficiency while reducing manual intervention, making it ideal for manufacturers seeking high-output candy production with consistent wrapping quality.

This high-speed candy wrapping machine from Dhiman Industries is meticulously crafted to handle various candy shapes and sizes with ease, from square and rectangular to round and oval forms. It boasts a dynamic feeding system that aligns candies with exactitude, preparing them for the synchronized wrapping mechanism that operates seamlessly even at high speeds. Every mechanical motion within the machine is optimized for durability and minimal downtime, allowing production teams to meet large-scale orders without compromising on wrapping aesthetics or sealing integrity.

One of the defining advantages of this high-speed candy wrapping machine is its adaptability across wrapping materials such as wax paper, aluminum foil, cellophane, and laminated films. This multi-material compatibility opens possibilities for customized packaging based on branding, preservation needs, and target markets. The machine's quick-change tooling system further allows operators to switch formats rapidly, reducing idle time during product transitions. Whether wrapping butter candies, fruit toffees, or center-filled treats, the machine delivers consistent results at impressive speeds.

At the heart of the Dhiman high-speed candy wrapping machine is its electronic control panel, powered by programmable logic controllers (PLC). This intelligent interface allows real-time monitoring of machine status, speed regulation, wrapping cycle synchronization, and fault detection alerts for smooth operation. Additionally, sensor-based feeding and cutting systems ensure that each candy piece is wrapped with precision, reducing material wastage and enhancing the final presentation of the product. These integrated smart systems make the machine not only efficient but also user-friendly and safe to operate.

The robust stainless-steel construction of the machine guarantees hygiene, resistance to corrosion, and easy maintenance. It complies with international food-grade safety standards, ensuring candies remain uncontaminated throughout the wrapping process. Cleaning and servicing are simplified with modular components and accessible design, reducing long-term maintenance efforts and operational interruptions. Moreover, the compact footprint of the machine makes it suitable even for factories with limited floor space, while still delivering industrial-scale output.

With speeds exceeding several hundred wraps per minute, this high-speed candy wrapping machine empowers manufacturers to scale their business without additional manpower or complex logistics. The machine also incorporates automatic feeding conveyors and waste collection systems, creating a closed-loop process that enhances productivity while maintaining cleanliness in the workspace. Noise reduction technology further ensures a quieter operation, contributing to a more pleasant working environment for factory staff.

Dhiman Industries has always prioritized precision engineering and customer-centric design in its machinery, and this candy wrapping machine is a true embodiment of that vision. The machine can be tailored with optional attachments such as embossing rollers for branding, date coding modules, and customized cutting knives for specific edge finishes. These value-added features help brands stand out in competitive markets by enhancing the packaging’s visual appeal and information accuracy. The machine's scalability also allows integration with downstream packaging systems like carton box fillers and shrink-wrapping units, completing the full production cycle.

Training and support provided by Dhiman Industries further add to the overall value of the machine. Clients receive installation assistance, operator training, maintenance guides, and access to a responsive technical support team that ensures continuous performance and peace of mind. The company’s commitment to after-sales service makes it a trusted partner for businesses looking to invest in reliable high-speed wrapping technology for long-term growth.

In conclusion, the high-speed candy wrapping machine by Dhiman Industries is a game-changing solution for the confectionery industry. It brings together speed, accuracy, hygiene, and smart automation in one compact, efficient, and adaptable system. For manufacturers aiming to improve their production capacity, reduce labor dependency, and deliver attractively wrapped products to the market, this machine stands as the perfect investment. Dhiman Industries continues to set benchmarks in confectionery machinery, and this innovative high-speed candy wrapping machine reinforces its leadership in delivering performance-driven solutions for modern candy production lines.

0 notes

Text

Why Should You Choose FSTN Positive Character LCD for Your Next Electronics Project?

Introduction to FSTN Positive Character LCDs

FSTN (Film-compensated Super Twisted Nematic) Positive Character LCDs are a preferred choice in today’s electronics industry due to their superior visibility, low power requirements, and excellent readability in various lighting conditions. These character-based displays are optimized for embedded systems, controllers, microcontrollers, and other critical tools used across different sectors.

FSTN Positive Character LCDs enhance the performance of interfaces used in thermal equipment, microprocessors, diagnostic tools, and safety systems, delivering crystal-clear character displays in both indoor and outdoor applications.

Key Features of FSTN Positive Character LCDs

Enhanced Visual Performance

High contrast ratios for improved character readability

Wide viewing angles with minimal distortion

Reflective and transflective display modes for flexible lighting environments

Low Power Consumption

Ideal for battery-powered tools, sensors, and portable equipment

Efficient voltage operation suitable for microcontroller circuits and control systems

Seamless Integration

Compatible with popular microcontrollers and microprocessors

Supports connectivity through standard cables and connectors

Easily embedded in thermal equipment, controllers, and digital tools

Applications of FSTN Positive Character LCDs in Electronics

Industrial and Automation Systems

FSTN LCDs are widely used in control panels, PLCs, and monitoring systems where real-time data needs to be displayed reliably. These displays are often integrated with:

Sensors for temperature and environmental monitoring

Contactors, fuses, and switches for power control

Thermal pads for heat dissipation and insulation

Medical and Laboratory Devices

Used in diagnostic kits and digital thermometers

Clear output for measuring devices like insulation testers and voltage detectors

Compatible with safety-critical tools and measurement accessories

Consumer Electronics and Embedded Projects

Display modules for laptops, portable tools, and smart controllers

Microcontroller-based educational and hobby projects

Interfaces for smart tools using grips, switches, and controllers

Comparison with Conventional LCD Technologies

Why FSTN Outperforms TN and STN

Film compensation reduces ghosting and enhances sharpness

Better performance in direct sunlight compared to standard STN displays

Longer operational life and enhanced stability over time

FSTN Positive Character LCDs also show superior performance when combined with components such as:

Capacitors for voltage regulation

Thermal sensors for adaptive brightness control

LEDs for backlighting in low-light applications

Integration with Common Electronics Components

Compatibility and Design Flexibility

FSTN character LCDs are highly adaptable and work well with:

Microprocessors and development boards such as Arduino, STM32, and Raspberry Pi

External connectors for data input and programming interfaces

Voltage regulators and switches used in embedded designs

Supporting Components for Stable Performance

Thermal pads and oils for thermal regulation

Cables and cable grips for secured wiring

Fuses for circuit protection and electrical safety

Advantages in Harsh Environments

Durability and Reliability

Strong build quality with robust enclosures

Resistant to shock, vibration, and moisture

Suitable for outdoor tools and industrial-grade equipment

These characteristics make them ideal for use in:

Field equipment for electrical testing

Factory monitoring tools

Thermal detection instruments and portable voltage meters

Eco-Friendly and Energy-Efficient Displays

FSTN Positive LCDs consume less power and last longer, supporting sustainable technology development. They are perfect for:

Solar-powered monitoring stations

Low-energy data loggers

Portable testing kits and handheld analyzers

Conclusion

FSTN Positive Character LCDs are a versatile and essential display solution in the world of electronics. Their clarity, low power usage, and robust design make them ideal for use in tools, sensors, safety systems, controllers, laptops, and embedded projects. With seamless integration capabilities alongside microcontrollers, capacitors, thermal components, and LED lighting systems, these LCDs empower engineers and hobbyists to build efficient and reliable devices.

Choose FSTN Positive Character LCDs for your next project and ensure a balance of performance, readability, and energy efficiency—whether you're working with switches, thermal pads, fuses, or smart microcontroller-based tools.

0 notes

Text

Why Siemens SIMATIC S7-1200 PLC is Ideal for Modern Industries

In today’s rapid-paced manufacturing environment, the roles of automation are the improvement in productivity, quality, and efficiency. At the core of many intelligent automation systems, there is the versatile and powerful PLC SIMATIC S7-1200 developed by Siemens.

Learn more about, Top 10 Features of the SIMATIC S7 1200 That Makes It a Game Changer

What is SIMATIC S7-1200?

The SIMATIC S7-1200 is a compact and modular PLC designed for small to medium automation tasks. It is scalable in nature and comes with integrated communication and user-friendly programming using the TIA Portal (Totally Integrated Automation). Be it a simple machine or a highly complex process; the Siemens SIMATIC S7-1200 strikes a perfect balance between performance and affordability.

Key Features of Siemens SIMATIC S7-1200 PLC

Packed with features, the Siemens SIMATIC S7-1200 PLC can adapt perfectly to a variety of industrial applications.

Modular Design: Easily expand your system by attaching different signal modules, communication modules, or signal boards.

Integrated Communication: Provides a built-in PROFINET interface.

High-Speed Processing: Operation with precise control and response.

Web Server: Access to the system diagnostics remotely through a web-based interface.

Security Functions: Protect with a password and access control security functions.

Energy Monitoring: Optimizes power usage in the production processes.

This makes the SIMATIC S7-1200 a perfect fit to be a controller for packaging, HVAC, conveyor systems, and other applications.

Why Choose Siemens SIMATIC S7-1200 for Automation?

Scalability:

Automation needs grow with Siemens SIMATIC S7-1200; start small and work your way up along with your processes.

Programming Flexibility:

This system supports ladder diagrams, function block diagrams, and structured text, allowing both newbie and seasoned programmers to use them.

Robust Performance:

Operating under harsh industrial conditions, the Siemens SIMATIC S7-1200 PLC looks after consistent performance even when challenged by environmental conditions.

Integrated System Diagnostics:

Diagnose and fix problems immediately without the aid of external tools to minimize system downtime and maximize operational efficiency.

Learn more, Why Siemens PLC S7-1200 is the best choice for Compact Automation System

Applications of SIMATIC S7 1200

The SIMATIC S7-1200 finds applications in several industrial fields, including:

Automotive: Automated assembly lines and robotics are controlled.

Food & Beverage: Packaging and processing lines are handled with precision.

Textile: Improves control of dyeing and printing machines.

Water treatment: Monitoring and control of pumps and filters are performed.

Material Handling: Smart conveyors and warehouse automation present a challenging application.

Because of its versatility, the Siemens SIMATIC S7-1200 PLC continues to be a very reliable solution in the industrial automation world.

Conclusion

Whether updating an existing automation system or embarking on a brand-new project, the S7-1200 affords the performance, flexibility, and reliability you need. Its intelligence and easy integration make it a wise choice in any industrial setting.

If you are considering procurement or implantation of Siemens SIMATIC S7-1200 PLC, Naksh Technology Solutions LLP is your trusted partner. With years of experience in the field of industrial automation coupled with a sturdy portfolio of Siemens products, Naksh Technology ensures the development of seamless solutions that fit your business needs.

0 notes

Text

ARM Embedded Industrial Controller BL370 Applied to Smart Warehousing Solutions

Case Details

The ARMxy BL370 series embedded industrial controller can fully leverage its high performance, flexible scalability, and industrial-grade stability in smart warehousing solutions. Below is an analysis of its typical applications in smart warehousing scenarios, based on the features of the BL370 series.

Application Scenarios of BL370 in Smart Warehousing

Smart warehousing involves automated equipment (such as AGVs, robotic arms, and conveyor belts), sensor networks, data acquisition and processing, and connectivity with cloud platforms. The following features of the BL370 series make it highly suitable for such scenarios:

High-Performance Computing and AI Support: Equipped with the Rockchip RK3562/RK3562J processor (quad-core Cortex-A53, up to 2.0GHz) and a built-in 1TOPS NPU, it supports deep learning frameworks like TensorFlow and PyTorch, enabling image recognition (e.g., barcode scanning, shelf item detection) or path optimization in warehousing.

Rich I/O Interfaces: Supports 1-3 10/100M Ethernet ports, RS485, CAN, DI/DO, AI/AO, and other interfaces, allowing connection to sensors, PLCs, RFID readers, etc., for cargo tracking, environmental monitoring (e.g., temperature and humidity), and device control.

Flexible Scalability: Through X-series and Y-series I/O boards, users can configure RS232/485, CAN, GPIO, analog inputs/outputs, and more to adapt to various warehousing equipment (e.g., stackers, conveyors).

Communication Capabilities: Supports WiFi, 4G/5G modules, and Bluetooth, suitable for real-time data transmission to Warehouse Management Systems (WMS) or cloud platforms for inventory management and remote monitoring.

Industrial-Grade Stability: Operates in a wide temperature range of -40 to 85°C, with IP30 protection, and has passed electromagnetic compatibility and environmental adaptability tests, suitable for warehousing environments with potential vibration, dust, and temperature fluctuations.

Software Support: Pre-installed with BLloTLink protocol conversion software, supporting protocols like Modbus, MQTT, and OPC UA, it seamlessly integrates with WMS, ERP, or mainstream IoT cloud platforms (e.g., AWS IoT, Alibaba Cloud). Node-RED and Docker enable rapid development of warehousing automation workflows.

Specific Application Cases

Here are several typical applications of the BL370 in smart warehousing:

1. AGV Navigation and Control

Function: The BL370 serves as the core controller for AGVs (Automated Guided Vehicles), handling navigation algorithms, sensor data fusion (e.g., LiDAR, ultrasonic sensors), and path planning.

Implementation:

(1)Uses the NPU for real-time image processing (e.g., landmark or obstacle recognition).

(2)Communicates with motor drivers via CAN or RS485 to control AGV movement.

(3)Y-series I/O boards (e.g., Y95/Y96) support PWM output and pulse counting for precise control and positioning.

(4)4G/5G modules enable real-time communication with the central scheduling system.

Advantages: High-performance processor and flexible I/O configurations support complex navigation algorithms, while wide-temperature design ensures stable operation in cold storage environments.

2. Cargo Tracking and Inventory Management

Function: Real-time cargo tracking via RFID or barcode scanning, with data uploaded to WMS for inventory management.

Implementation:

(1)X-series I/O boards (e.g., X20) provide multiple RS232/485 interfaces to connect RFID readers or barcode scanners.

(2)BLloTLink software converts collected data into MQTT protocol for upload to cloud platforms (e.g., Thingsboard).

(3)Node-RED enables rapid development of data processing workflows, such as inventory anomaly alerts.

Advantages: Multiple interfaces support various device integrations, and protocol conversion software simplifies integration with existing systems.

3. Environmental Monitoring and Energy Management

Function: Monitors warehouse environmental conditions (temperature, humidity) and energy consumption data to optimize energy use and ensure proper storage conditions.

Implementation:

(1)Y-series I/O boards (e.g., Y51/Y52) support PT100/PT1000 RTD measurements for high-precision temperature and humidity monitoring.

(2)Data is transmitted to an Energy Management System (EMS) via Ethernet or 4G.

(3)BLRAT tool enables remote access for maintenance personnel to monitor environmental status in real time.

Advantages: Wide voltage input (9-36VDC) and overcurrent protection ensure stability in complex power environments.

4. Automated Equipment Control

Function: Controls conveyor belts, stackers, robotic arms, etc., for automated sorting and storage.

Implementation:

(1)X-series I/O boards (e.g., X23/X24) provide DI/DO interfaces for switching control and status detection.

(2)Supports Qt-5.15.10 for developing Human-Machine Interfaces (HMI), output via HDMI to touchscreens for operator monitoring.

(3)Docker containers deploy control programs, improving system maintainability.

Advantages: Modular I/O design enables quick adaptation to different devices, and the Linux system supports complex control logic.

Advantages of Smart Warehousing Solutions

Using the BL370 series for smart warehousing solutions offers the following benefits:

Modular Design: SOM boards and I/O board combinations meet the needs of different warehouse scales and equipment, reducing customization costs.

High Reliability: Passes EMC tests (ESD, EFT, Surge, etc.) and environmental tests (-40 to 85°C, vibration, drop), ensuring long-term stable operation.

Rapid Deployment: Pre-installed BLloTLink and BLRAT software support mainstream protocols and cloud platforms, shortening system integration time.

Development Support: Rich development examples (Node-RED, Qt, Docker, NPU, etc.) reduce secondary development complexity, ideal for rapid prototyping and customization.

Implementation Recommendations

Hardware Selection:

(1)For scenarios requiring high-performance computing (e.g., vision processing), choose SOM372 (32GB eMMC, 4GB LPDDR4X, RK3562J).

(2)For multi-device connectivity, select BL372B (3 Ethernet ports, 2 Y-board slots).

(3)For cold storage applications, choose SOM370/371/372, supporting -40 to 85°C.

Software Configuration:

(1)Use Ubuntu 20.04 and Qt-5.15.10 to develop HMI interfaces for enhanced user interaction.

(2)Leverage BLloTLink for protocol conversion with WMS/ERP, recommending MQTT for efficient communication in low-bandwidth environments.

(3)Deploy Node-RED to design automation workflows, such as triggers for cargo inbound/outbound processes.

Network and Security:

(1)Use 4G/5G modules to ensure real-time data transmission, with BLRAT for remote maintenance.

(2)Regularly update the Linux kernel (5.10.198) to address potential security vulnerabilities.

Testing and Validation:

(1)Conduct electromagnetic compatibility and environmental tests before implementation to ensure stability in actual warehousing environments.

(2)Simulate high-load scenarios (e.g., multiple AGVs working collaboratively) to test system performance.

Conclusion

The ARMxy BL370 series embedded industrial controller, with its high-performance processor, flexible I/O expansion, robust software ecosystem, and industrial-grade reliability, is highly suitable for smart warehousing solutions. Whether for AGV control, cargo tracking, environmental monitoring, or automated equipment management, the BL370 provides efficient and stable support. Through its modular design and rich development resources, users can quickly build customized smart warehousing systems, improving efficiency and reducing operational costs.

0 notes

Text

Top Benefits of Implementing ABB Freelance Solutions in Bangalore’s Manufacturing Plants

Modern manufacturing plants in Bangalore are continually seeking ways to boost productivity, increase reliability, and maintain compliance with evolving industry standards. One technology that has gained widespread adoption is ABB Freelance Solutions in Bangalore, a compact Distributed Control System (DCS) designed to offer DCS-level reliability with PLC-like flexibility. As automation advances further, integrating Robotic vision solutions in Bangalore alongside ABB Freelance can deliver even greater benefits. This article explores the key advantages of adopting ABB Freelance in manufacturing facilities and highlights how pairing it with robotic vision enhances operational excellence.

1. Cost-Effective Scalability

Traditional DCS platforms often come with high upfront costs and complex licensing models. ABB Freelance, however, provides a modular architecture that allows manufacturers to add control loops and I/O modules gradually, matching budget constraints and production growth. This pay-as-you-grow model ensures that plants only invest in the capacity they need initially, with the option to expand seamlessly. Over time, this translates to significant savings compared to monolithic DCS installations.

2. Rapid Deployment and Reduced Engineering Effort

One of the standout features of ABB Freelance is its intuitive engineering environment, which leverages the System 800xA interface. Preconfigured function blocks, drag-and-drop graphics, and standardized libraries simplify control logic development. As a result, commissioning times shrink dramatically, enabling plants to achieve faster return on investment. Engineers spend less time on tedious coding and more on optimizing processes, making it ideal for Bangalore’s dynamic manufacturing landscape.

3. High Availability and Robust Reliability

Minimizing unplanned downtime is critical in high-value production environments. ABB Freelance offers redundant controllers, hot-swappable I/O modules, and fault-tolerant communication networks. In the event of a hardware failure, the system automatically switches to backup modules without interrupting control processes. This level of reliability is crucial for sectors like pharmaceuticals, water treatment, and food processing, where any interruption can lead to costly production losses or compliance breaches.

4. Seamless Integration with Existing Infrastructure

Most manufacturing plants in Bangalore already have legacy PLCs, SCADA systems, or fieldbus networks in place. ABB Freelance excels at integrating with these existing components through backplane communication and standardized protocols such as Profibus, Modbus, and Ethernet/IP. This interoperability allows plants to modernize their control strategy without ripping out perfectly functional equipment. Furthermore, combining Freelance with Robotic vision solutions in Bangalore—which rely on real-time process data—enhances quality control and reduces manual inspection tasks.

5. Unified Operations and Situational Awareness

ABB Freelance utilizes the System 800xA HMI to deliver a unified control platform where operators can monitor process variables, alarms, and trends from a single interface. This centralized view improves situational awareness and reduces operator training time. When integrated with robotic vision systems, operators gain real-time visual feedback on product quality, enabling quick adjustments and reducing scrap rates. The synergy between control data and vision analytics empowers teams to make data-driven decisions.

6. Simplified Maintenance and Diagnostics

Built‑in diagnostics and asset management tools are hallmarks of ABB Freelance. The system continually monitors hardware health—tracking I/O status, network performance, and controller integrity—and generates proactive alerts. Maintenance teams receive advance warning of potential issues such as sensor drift or network degradation, allowing them to intervene before failures occur. When combined with robotic vision systems that also self-diagnose camera alignment or lighting anomalies, plants achieve a comprehensive predictive maintenance strategy that drastically limits unscheduled shutdowns.

7. Enhanced Safety and Regulatory Compliance

Safety is paramount in manufacturing, and ABB Freelance includes safety controller options that integrate seamlessly into the DCS framework. Plants can implement safety interlocks, emergency shutdown sequences, and fail-safe architectures without deploying separate safety PLCs. This integrated safety approach simplifies compliance with international standards such as IEC 61511. Moreover, pairing automated vision inspection—through Robotic vision solutions in Bangalore—ensures critical safety checks (e.g., weld seam verification or seal integrity) occur consistently, meeting strict regulatory mandates.

8. Future-Proof Architecture

Industry 4.0 demands connected, data-centric ecosystems. ABB Freelance supports Industrial Internet of Things (IIoT) protocols and cloud connectivity, making it straightforward to integrate with higher-level analytics platforms, MES, or ERP systems. As production scales or new technologies emerge, Freelance’s open architecture adapts rapidly. Likewise, robotic vision systems can leverage the same networked infrastructure to feed image and quality data into enterprise analytics, enabling continuous improvement and innovation.

Conclusion

Implementing ABB Freelance Solutions in Bangalore’s manufacturing plants offers clear advantages: cost-effective scalability, fast deployment, high availability, and seamless integration with legacy systems. When paired with Robotic vision solutions in Bangalore, plants gain an additional layer of quality assurance and data-driven process control. As a leading engineering service provider in the region, Madox Technologies excels at delivering turnkey ABB Freelance installations and integrating advanced vision technologies to create smarter, safer, and more efficient production environments. By embracing these combined solutions, Bangalore’s manufacturers can maintain a competitive edge in an increasingly automated world.

visit for more info https://madox.in/product/cobot-welder/

0 notes

Text

ERP Software Market Size, Share, Analysis, Forecast, and Growth 2032: Increasing Investments in Digital Infrastructure

The Enterprise Resource Planning Software Market was valued at USD 62.49 billion in 2023 and is expected to reach USD 175.63 billion by 2032, growing at a CAGR of 12.23% from 2024-2032.

Enterprise Resource Planning Software Market is witnessing a significant transformation as companies prioritize operational efficiency and data-driven decision-making. Organizations across industries are turning to ERP solutions to unify processes, streamline workflows, and gain a competitive edge. This trend is particularly strong in the USA and Europe, where digital maturity and cloud adoption drive ERP upgrades and integration efforts.

ERP Software Market Trends and Regional Demand Forecast in the United States

Enterprise Resource Planning Software Market is evolving rapidly with the rise of cloud-native platforms, real-time analytics, and AI-powered automation. Businesses are embracing ERP to move beyond legacy systems and build agile, scalable, and responsive operations. From manufacturing to retail, ERP is no longer just a backend tool—it's becoming central to business strategy.

Get Sample Copy of This Report: https://www.snsinsider.com/sample-request/2964

Market Keyplayers:

Epicor Software Corporation (Epicor ERP, Prophet 21)

Hewlett-Packard Development Company, L.P (HP Adaptive Management, HP Project Portfolio Management)

Infor Inc. (Infor CloudSuite, Infor M3)

IBM Corporation (IBM Cognos Analytics, IBM Maximo)

Microsoft Corporation (Microsoft Dynamics 365, Microsoft Power BI)

NetSuite Inc. (NetSuite ERP, NetSuite CRM+)

Oracle Corporation (Oracle NetSuite, Oracle Fusion Cloud ERP)

Sage Group plc (Sage Intacct, Sage 300cloud)

SAP SE (SAP S/4HANA, SAP Business ByDesign)

Unit4 (Unit4 ERP, Unit4 Financial Planning & Analysis)

Workday Inc. (Workday Financial Management, Workday Human Capital Management)

Deltek (Deltek Costpoint, Deltek Vantagepoint)

QAD Inc. (QAD Adaptive ERP, QAD Cloud ERP)

IFS AB (IFS Cloud, IFS Applications)

Acumatica (Acumatica Cloud ERP, Acumatica Construction Edition)

Syspro (SYSPRO ERP, SYSPRO Avanti)

Tally Solutions Pvt Ltd (TallyPrime, Tally ERP 9)

Odoo SA (Odoo ERP, Odoo CRM)

Priority Software (Priority ERP, Priority Zoom)

Ramco Systems (Ramco ERP Suite, Ramco Global Payroll)

abas Software GmbH (abas ERP, abas Distribution)

Plex Systems Inc. (Plex Smart Manufacturing Platform, Plex ERP)

Market Analysis

The ERP Software Market is expanding due to a growing need for centralized platforms that can handle complex business functions including finance, supply chain, HR, and customer relationship management. Modern ERP systems offer integration across departments, improving visibility, compliance, and decision-making. The USA leads the market with high enterprise adoption and cloud investments, while Europe’s regulatory standards and focus on data security influence ERP customization and deployment strategies.

Market Trends

Shift from on-premise to cloud-based ERP platforms

AI and machine learning for real-time analytics and forecasting

Integration with IoT and edge computing for manufacturing and logistics

Mobile-first ERP interfaces for on-the-go access

Industry-specific ERP modules gaining traction

Enhanced cybersecurity features to protect sensitive data

Growing demand for subscription-based ERP models (SaaS)

Market Scope

The ERP Software Market offers broad potential as organizations scale and diversify operations. Cloud deployment, automation, and flexibility are key drivers shaping its growth trajectory.

All-in-one business process integration

Customizable modules tailored to industry needs

Scalable architecture for SMEs and large enterprises

Streamlined compliance and audit trails

AI-assisted planning and inventory management

Unified customer and supplier management systems

Real-time KPIs and performance dashboards

Forecast Outlook

The future of the ERP Software Market lies in intelligent, agile platforms that drive efficiency and innovation. As more businesses transition to cloud infrastructure, ERP will serve as a digital backbone—enabling faster adaptation, seamless collaboration, and data transparency. The emphasis will shift toward user-friendly, mobile-accessible, and AI-enhanced ERP solutions. Both the USA and Europe will continue to lead in innovation, driven by strong enterprise demand and regulatory environments that push for smarter, more secure systems.

Access Complete Report: https://www.snsinsider.com/reports/erp-software-market-2964

Conclusion

The evolution of ERP is no longer about replacing legacy systems—it's about redefining how businesses operate in a connected, data-centric world. From Berlin to Boston, companies are leveraging ERP not just as software but as a strategic enabler of agility and growth.

Related Reports:

Analyze the growth of Trade Management Software within the US industry landscape

Discover leading collaboration tools for teams across America

About Us:

SNS Insider is one of the leading market research and consulting agencies that dominates the market research industry globally. Our company's aim is to give clients the knowledge they require in order to function in changing circumstances. In order to give you current, accurate market data, consumer insights, and opinions so that you can make decisions with confidence, we employ a variety of techniques, including surveys, video talks, and focus groups around the world.

Contact Us:

Jagney Dave - Vice President of Client Engagement

Phone: +1-315 636 4242 (US) | +44- 20 3290 5010 (UK)

#ERP Software Market#ERP Software Market Scope#ERP Software Market Share#ERP Software Market Growth#ERP Software Market Trends

0 notes

Text

Top Features to Look for in a Hospital Sewage Treatment Plant

Healthcare facilities generate complex wastewater streams containing pathogens, chemicals, pharmaceuticals, and high organic loads. Installing the right Sewage Treatment Plant (STP) is critical to safeguard public health, meet regulatory standards, and protect the environment. Here are the top features to look for when selecting a hospital sewage treatment plant.

1. Multi-Stage Treatment Process

Hospitals require robust multi-barrier treatment to eliminate diverse contaminants. Look for plants that combine:

Primary Treatment (screening, grit removal)

Secondary Biological Treatment (activated sludge, MBBR, or SBR)

Tertiary Treatment (filtration, disinfection via UV or chlorination)

This layering ensures effective removal of solids, organics, and pathogens.

2. Advanced Disinfection System

Disinfection is non-negotiable in hospital STPs. UV reactors and ozone systems are preferred over chlorine due to:

No harmful byproducts

Instant pathogen inactivation

Low chemical handling risks

Ensure the system offers consistent dose control and easy maintenance.

3. Compact & Modular Design

Space is often at a premium in urban hospitals. Opt for compact, skid-mounted, or modular STP units that can be:

Easily retrofitted into existing basements or rooftop areas

Scaled up by adding modules when wastewater volumes grow

4. Automated Monitoring & Control

Real-time Remote monitoring of key parameters (pH, turbidity, dissolved oxygen, chlorine residual) ensures:

Instant alerts for deviations

Data logging for compliance reporting

Remote shutdown or adjustment to prevent discharge violations

A PLC or SCADA interface with mobile app access is ideal.

5. Corrosion-Resistant Materials

Hospital wastewater can be aggressive. Tanks and piping crafted from HDPE, FRP, or stainless steel will resist chemical attack and extend system life.

6. Energy-Efficient Operation

Look for energy-saving features such as high-efficiency blowers, variable-frequency drives (VFDs), and optimized aeration controls to reduce operating costs.

Conclusion

A hospital’s STP must combine rigorous multi-stage treatment, advanced disinfection, compact design, automated controls, durable construction, and energy efficiency. By prioritizing these features, healthcare facilities in Pune can ensure safe wastewater management, regulatory compliance, and minimal environmental impact.

0 notes

Text

How SPLKPM Saves Malaysian Teachers Time

Hey, Malaysian teachers! Ever feel like there’s not enough coffee in the world to juggle lesson plans, grading, and professional development? Meet SPLKPM, the Malaysia teacher training system that’s like a personal assistant for your digital professional development. This professional development platform for educators helps you earn your 42 annual credits without losing your sanity. Let’s peek into a teacher’s day to see how this secure teacher training platform saves time and boosts teamwork.

A Day with Lina, the Multitasking Teacher

Picture Lina, a KL-based secondary teacher. Her mornings are chaos: teach science, grade quizzes, prep for a parent meeting. Professional training? Felt like a distant dream until she found SPLKPM. Logging into the official teacher training portal with her MyKad (super secure with two-factor authentication), Lina squeezes in a 4-hour webinar on AI tools during her free period. Boom—6 credits toward her 5-day KPM requirement, done from her laptop while sipping teh tarik.

Why SPLKPM Rocks

SPLKPM’s a game-changer for busy teachers like Lina:

Quick Credits: A 6-hour webinar or book summary counts as a full training day. Lina knocked out 10 credits in a week!

Collaboration Vibes: Professional Learning Communities (PLCs) let you swap teaching hacks with colleagues, earning up to 20 credits. Rima Akter’s right—collaboration is everything. PLCs are like staff room chats, but with lesson-planning superpowers.

Work-Life Balance: No more weekend workshops. Lina logs training at night, syncing with Google Workspace for smooth sharing.

Making It Work

Lina’s trick? She uses Modul Individu to pick courses (think STEM or financial literacy) and tracks them in “Pembelajaran Kendiri.” Forgot your password? The “Lupa Kata Laluan” feature’s a lifesaver, or ping your SULDP coordinator. Some teachers find the interface a bit clunky, but recent updates make it smoother. Lina’s now planning a PLC to share her AI webinar tips, logging more credits while chilling

1 note

·

View note

Text

Remote Monitoring with PLC Panels: Managing Your Plant from Anywhere

Introduction

In today’s fast-moving industrial world, being physically present on the shop floor every hour of the day is neither practical nor necessary. Thanks to modern PLC Panels, plant managers and engineers can now monitor and control their operations from virtually anywhere.

This is where remote monitoring comes in—a game-changing feature that turns your PLC Panel into a smart control center for your entire plant.

What is Remote Monitoring in PLC Panels?

Remote monitoring allows real-time access to your PLC Panel’s data through cloud-based platforms or networked software systems. It enables you to:

View machine status live

Monitor performance metrics

Receive alerts and diagnostics

Control start/stop operations remotely

Whether you’re at another site, at home, or travelling, you can manage your plant operations with just a laptop or smartphone.

Benefits of Remote Monitoring with PLC Panels

Real-Time Oversight Instantly check the status of equipment and production without being on-site.

Faster Problem Resolution Receive immediate alerts for faults, so downtime can be minimized.

Cost Savings Reduce the need for constant physical supervision and travel between sites.

Improved Decision-Making Access to live data helps you make informed decisions quickly.

Enhanced Safety Monitor high-risk processes remotely, minimizing exposure for workers.

Ready to take control from anywhere? Partner with a reliable PLC Panel Manufacturer to implement secure, remote-ready automation systems.

Key Features to Look For in Remote-Ready PLC Panels

Ethernet and Wi-Fi Connectivity Enables seamless data transfer between your PLC and remote devices.

Cloud Integration Support Compatible with platforms like MQTT, OPC UA, or custom dashboards.

Secure Access Protocols SSL encryption, VPN access, and password protection keep your system safe.

User-Friendly Interfaces Easy-to-use mobile or web apps that show real-time visualizations.

SCADA or HMI Compatibility Gives a centralized view with alarms, trends, and historical data logs.

Industries That Benefit the Most

Water Treatment Plants – Monitor pumps, levels, and chemical dosing remotely

Renewable Energy Farms – Supervise solar or wind operations from central control

Cold Storage Units – Keep track of temperature and humidity offsite

Manufacturing Units – Detect faults or delays without halting production

Agricultural Automation – Manage irrigation or feeding schedules remotely

How to Get Started

Collaborate with an experienced Programmable Logic Controller Panel Manufacturer who can:

Customize the panel with remote access modules

Integrate your system with cloud services

Train your team to monitor and control remotely

Ensure top-level cybersecurity protocols are in place

Conclusion

Remote monitoring with PLC Panels is no longer a luxury—it’s a necessity in a digital-first industrial world. It saves time, boosts productivity, and enhances control like never before. To enable this, choose a PLC Panel Manufacturer that delivers smart, secure, and remote-ready solutions tailored to your industry.

Control your plant from anywhere—talk to a trusted PLC Panel Manufacturer and upgrade your operations today.

Also read:

PLC Panels vs. SCADA Systems: Understanding Their Roles and Differences

Why PLC Panels Are a Must-Have for Small and Medium Enterprises (SMEs)

Retrofitting Old Machinery with Modern PLC Panels

Using PLC Panels in HVAC Automation for Commercial Buildings

#plc electrical panel#plc#electrical panel#plc panel#Programmable Logic Controller Panel Manufacturer#PLC Panel Manufacturer

0 notes