#pushbuttons

Explore tagged Tumblr posts

Text

Pushbutton Spring 2019

#runway#runway fashion#fashion#fashion week#rtw#ready to wear#alternative#alternative style#alternative fashion#pushbutton#spring 2019

13 notes

·

View notes

Text

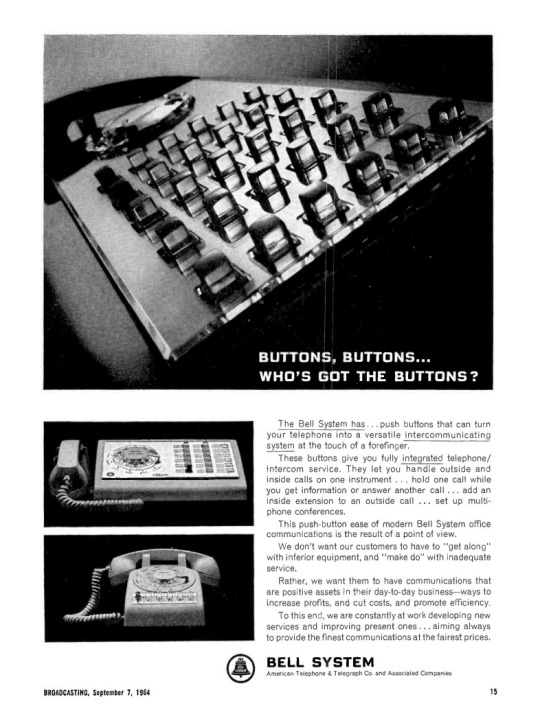

"The Bell System has push buttons that can turn your telephone into a versatile intercommunicating system at the touch of a forefinger." (1964)

#vintage#retro#advertising#vintage ad#black and white#old ad#1960s#bell system#telephone#vintage telephone#pushbutton#1960s ad

35 notes

·

View notes

Text

Pushbutton Spring 2025

#pushbutton#spring 2025#minimalism#minimal fashion#ready-to-wear#rtw 2025#fashion#style#rtw#ss25 rtw#spring rtw#rtw25#runway

9 notes

·

View notes

Text

Metal Push Button Switches: Metal shell, Dustproof and Waterproof, Tight and Durable, Exquisite Appearance, Long service life

2 notes

·

View notes

Text

Pushbutton Seoul Fall 2017

2 notes

·

View notes

Text

What Cutting-Edge Automation Goes Into One Electronic Switch?

en.dghongju.com

0 notes

Text

Call now: (770) 744-3623

locksmithssandyspringsga.com

Locksmiths are important to keeping cars and homes secure They help unlock cars make new keys if yours are lost and program key fobs To safeguard houses and businesses they fix or upgrade locks on doors Whether you need to get inside or improve your security locksmiths offer their services.

#locksmith#locksmithservices#locksmithtools#commerciallocksmith#residentiallocksmith#autolocksmith#SpareCarKeys#CarKeyReplacement#CarKeyServices#LostCarKeys#Convenience#Manila#LocksmithServices#carkeyservices#Allkeyslost#CarRemoteRepair#carkeyreplacement#transponderkey#lostcarkeys#carlockout#EmergencyAssistance#EmergencyLocksmith#AutoLocksmith#CallUsNow#keyduplication#keyfabrication#keycutting#pushbutton#pushbuttonstart

0 notes

Text

Car key duplication or car chip keys are required We are adept at unlocking car doors without any damage secondly We also provide a programming service for auto transponder keys for all makes and models Always fast and reliable services Safe with us.

Call now for mobile service : (404) 926-6081

Or visit our website : 24hour-locksmithatlanta.com

#SpareCarKeys#CarKeyReplacement#CarKeyServices#LostCarKeys#Convenience#Manila#LocksmithServices#carkeyservices#Allkeyslost#CarRemoteRepair#carkeyreplacement#locksmith#transponderkey#lostcarkeys#carlockout#EmergencyAssistance#EmergencyLocksmith#AutoLocksmith#CallUsNow#keyduplication#keyfabrication#keycutting#pushbutton#pushbuttonst

0 notes

Text

Looking to get a lock and door fixed Whether your locks are ageing damaged or simply not working right it's time to get them changed A professional will replace door lock quickly giving you a fully secure home.

Call us now: 281-789-8575

cheaplocksmithhoustontexas.com

#SpareCarKeys#CarKeyReplacement#CarKeyServices#LostCarKeys#Convenience#Manila#LocksmithServices#carkeyservices#Allkeyslost#CarRemoteRepair#carkeyreplacement#locksmith#transponderkey#lostcarkeys#carlockout#EmergencyAssistance#EmergencyLocksmith#AutoLocksmith#CallUsNow#keyduplication#keyfabrication#keycutting#pushbutton#pushbuttonstart#SmartKey#locksmiths#locksmithing#locksmithlife#locksmithnearme

0 notes

Text

I MISSED A DAY.

HOW SHALL I RECTIFY THIS MISTAKE!!!!!!!!!!!!!!!

1 note

·

View note

Photo

Random Old Comic: Make Buttons Great Again! https://www.toyboxcomix.com/2018/01/03/make-buttons-great-again/

0 notes

Text

Pushbutton Fall 2016

#runway#runway fashion#fashion#fashion week#rtw#ready to wear#alternative#alternative style#alternative fashion#pushbutton#fall 2016

10 notes

·

View notes

Text

Like this, and I'll send Jnx to bug your muse~

0 notes

Text

ootd: ITS GONNA BE A GREAT DAY BC I HAVE HAPPY99 AND PUSHBUTTON ANIME CUTIE BY MY SIDE 🙂↕️🤑⭐️🤸💖^_−☆

0 notes

Text

Pushbutton Seoul Fall 2017

4 notes

·

View notes

Text

Anti-Slip and Tactile Comfort Design for Metal Pushbutton Switches in Wet-Hand Operation Scenarios

1. Introduction: The Hidden Pitfalls of Wet-Hand Operations

With increasing levels of automation and intelligent design, metal pushbutton switches are widely used in public and commercial facilities such as automatic faucets in public restrooms, commercial kitchen appliances, and electric scooter control panels. In these scenarios, users often operate switches with wet hands or in humid, splash-prone environments. If the switch design does not address these conditions, common problems like slipping, failed triggering, uncomfortable force feedback, and even corrosion can arise, shortening product life and hurting user experience.

For B2B equipment manufacturers, designing metal pushbutton switches that remain slip-resistant, comfortable, responsive, and corrosion-resistant under wet-hand operation has become a crucial differentiator.

2. Typical Wet-Hand Scenarios & User Pain Points

Public Restroom Faucet Buttons

Automatic faucet or semi-auto water valve pushbuttons are common in airports, shopping malls, and office buildings.

Pain Points:

Users often have dripping wet hands after washing, making it easy to slip or fail to trigger the button.

Water residue, soap scum, or scale can build up if the surface is poorly designed.

Poor anti-slip surfaces can harbor bacteria, harming hygiene.

Commercial Kitchen Appliance Buttons

In professional kitchens, chefs use pushbuttons on steamers, fryers, ice makers, or induction cooktops with wet or greasy hands.

Pain Points:

The environment is hot, humid, and greasy, which makes bare metal surfaces slippery.

Frequent cleaning with harsh detergents can corrode poorly protected buttons.

Heavy push force requirements plus gloves can degrade tactile comfort.

Electric Scooter Control Buttons

For scooters and shared e-bikes, the on/off or gear switches are often used outdoors, exposed to rain or snow.

Pain Points:

Buttons get wet from rain or sweaty palms while riding.

Riders need clear tactile feedback at speed to confirm pressing.

Internal water ingress can damage the switch over time.

3. What B2B Customers Really Care About

Is the button surface slip-resistant with effective texture?

Why It Matters: A slip-resistant surface is the most direct, effective solution for wet-hand operations. Even dry fingers can slip on overly polished metal.

Practical Design Tactics:

CNC or Laser Etching: Add micro-scale raised dots, cross-hatch patterns, or concentric ripples on the button top to increase friction.

Rubberized Rings: Embed a high-friction rubber ring (e.g. silicone, TPU) around the button’s perimeter to blend anti-slip and aesthetics.

Embossed Logos: Integrate a brand logo as a raised feature, providing slip resistance and branding in one.

Case: An airport restroom faucet button uses CNC-etched anti-slip cross patterns so even soapy fingers won’t slide off during pressing.

Does wet-hand use require excessive force?

Why It Matters: Metal pushbutton switches rely on robust mechanical travel to ensure reliable contact. But excessive push force can make wet-hand operation fail.

Solutions:

Optimized Spring & Stroke: Tuning the spring stiffness and travel to lower initial force while preserving snap-back.

Two-Stage Action: Light pre-travel plus firm actuation prevents accidental presses while staying easy to trigger.

Adjustable Spring Module: For premium equipment, allow manufacturers to select different spring modules for different tactile options.

Case: A Nordic e-bike brand reduced push force from 2.5 N to 1.5 N for winter riders wearing gloves. The button still maintains clear feedback and works reliably in snow and rain.

Is the surface corrosion-resistant and stain-resistant?

Why It Matters: Public restrooms, kitchens, and outdoor vehicles all expose switches to harsh chemicals, salt spray, or acidic residues. If the metal or coating fails, the button will corrode, stain, or lose its finish.

Key Materials & Treatments:

Premium Metals: Use 304 stainless steel, 316L medical-grade stainless, or anodized aluminum for strong corrosion resistance.

Surface Finishes: Brushed, sandblasted, hard chrome plating, or PVD coatings enhance corrosion resistance and reduce fingerprints.

Self-Cleaning Features: Add hydrophobic or nano-coatings to resist soap and water buildup.

Case: A global restaurant chain’s kitchen cooktop pushbutton uses 316L stainless with a PVD titanium black coating that withstands over 500 hours of salt spray without discoloration.

4. Going Beyond Anti-Slip: Better User Experience

Backlight for Night Visibility

Wet-hand operation often happens in tricky lighting. An anti-slip button with a ring LED backlight improves visibility in kitchens, restrooms, or rainy streets.

Seamless Waterproofing

Slip-resistant designs must maintain IP67–IP68 protection:

Dual-seal ring structure

Tight-fit tolerances for the button-to-housing gap

High-transparency seals that don’t compromise looks

Resistant to High-Pressure Cleaning

Commercial kitchens and public restrooms often use high-pressure hoses or harsh disinfectants. The button must resist long-term washdowns without water ingress or loosening.

5. Engineering Challenges in Mass Production

Delivering slip-resistant, corrosion-resistant, waterproof buttons means:

Complex Surface Machining: CNC or laser textures must be consistent across batches.

Rubber Inserts: Must not compromise the seal or create new water entry points.

Multi-layer Coating: Must withstand daily use without flaking.

Full-Scale Tactile & Leak Testing: Each batch must pass consistent force and seal checks.

6. Conclusion: Wet-Hand Design Adds Real Product Value

In an era of hardware homogeneity, B2B buyers expect pushbutton switches to do more than just switch on/off. In wet-hand scenarios, slip resistance, tactile comfort, corrosion resistance, and cleanability mean fewer service calls, safer operation, and better user reviews. Partnering with a manufacturer who can design and mass-produce such robust metal pushbutton switches is an investment in product lifetime and brand trust.

en.dghongju.com

0 notes