#replacement mower engine

Explore tagged Tumblr posts

Text

A young cashier told an older woman that she should bring her grocery bags because plastic bags weren't good for the environment. The woman apologized, "We didn't have this green thing back in my day."

The young clerk said, "Your generation did not care enough to save our environment for future generations." She gave him a firm stare and a hard grin and said “Back then, we returned milk bottles, soda bottles, and beer bottles. The store sent them back to the plant to be washed sterilized and refilled, so it could use the same bottles over. They were recycled.

Grocery stores bagged our groceries in brown paper bags, which we reused for numerous things. We walked upstairs because we didn't have an escalator in every store and office building. We walked to the grocery and didn't climb into a 300-horsepower machine every time we had to go two blocks.

Back then, we washed the baby's diapers because we didn't have the throwaway kind. We dried clothes on a line, not in an energy-gobbling machine burning up 220 volts -- wind and solar power did dry our clothes back in our day. Kids got hand-me-down clothes from their brothers or sisters, not always brand-new clothing.

Back then, we had one TV, or radio, in the house -- not a TV in every room. The TV had a small screen the size of a handkerchief, not a screen the size of the state of Montana. In the kitchen, we blended and stirred by hand because we didn't have electric machines to do everything for us. When we packaged a fragile item to send in the mail, we used wadded-up old newspapers to cushion it, not Styrofoam or plastic bubble wrap.

Back then, we didn't fire up an engine and burn gasoline just to cut the lawn. We used a push mower that ran on human power. We exercised by working so we didn't need to go to a health club to run on treadmills that operate on electricity.

We drank from a fountain when we were thirsty instead of using a cup or a plastic bottle every time we had a drink of water. We refilled writing pens with ink instead of buying a new pen, and we replaced the razor blades with a razor instead of throwing away the whole razor just because the blade got dull.

Back then, people took a bus and kids rode their bikes instead of turning their moms into a 24-hour taxi service. We had one electrical outlet in a room, not an entire bank of sockets to power a dozen appliances. And we didn't need a computerized gadget to receive a signal beamed from satellites 23,000 miles in space to find the nearest burger joint. But the current generation laments how wasteful we old folks were just because we didn't have the green thing.”

The cashier stood there still and quiet as the old lady found her wallet to pay. Then lady turned to leave but stepped back and turned toward the cashier. She said “You have a world of knowledge in that little device in your hand. Pity you just use it to gossip, take pictures, and waste time. It would do you good to search a bit of history before you embarrass yourself like this again.

Forward this to another selfish old person who needs a lesson in conservation from a smart-ass young person.

12 notes

·

View notes

Text

Back in the day!

Anyone age approx 35 or over should read this - copied from a friend ... Checking out at the supermarket recently, the young cashier suggested I should bring my own bags because plastic bags weren't good for the environment. I apologised and explained, "We didn't have this green thing back in my earlier days". the cashier responded, "That's our problem today. Your generation did not care enough to save our environment for future generations".

She was right about one thing--our generation didn't have the green thing in “Our” day. So what did we have back then? After some reflection and soul-searching on "Our" day here's what I remembered we did have.... Back then, we returned milk bottles, pop bottles and beer bottles to the store. The store sent them back to the plant to be washed and sterilized and refilled, so it could use the same bottles repeatedly. So they really were recycled. But we didn't have the green thing back in our day.

We walked up stairs, because we didn't have an escalator in every store and office building. We walked to the grocery store and didn't climb into a 300-horsepower machine every time we had to go two blocks. But she was right. We didn't have the green thing in our day.

Back then, we washed the baby's nappies because we didn't have the throw-away kind. We dried clothes on a line, not in an energy gobbling machine burning up 240 volts -- wind and solar power really did dry our clothes back in our early days. Kids got hand-me-down clothes from their brothers or sisters, not always brand-new clothing. But that young lady is right. We didn't have the green thing back in our day.

Back then, we had one TV, or radio, in the house -- not a TV in every room. And the TV had a small screen the size of a handkerchief (remember them?), not a screen the size of the state of Wales. In the kitchen, we blended & stirred by hand because we didn't have electric machines to do everything for us. When we packaged a fragile item to send in the mail, we used wadded up old newspapers to cushion it, not Styrofoam or plastic bubble wrap. Back then, we didn't fire up an engine and burn petrol just to cut the lawn. We used a push mower that ran on human power. We exercised by working so we didn't need to go to a health club to run on treadmills that operate on electricity. But she's right. We didn't have the green thing back then.

We drank from a fountain when we were thirsty instead of using a cup or a plastic bottle every time we had a drink of water. We refilled writing pens with ink instead of buying a new pen, and we replaced the razor blades in a razor instead of throwing away the whole razor just because the blade got dull. But we didn't have the green thing back then.

Back then, people took the bus, and kids rode their bikes to school or walked instead of turning their mums into a 24-hour taxi service. We had one electrical outlet in a room, not an entire bank of sockets to power a dozen appliances. And we didn't need a computerized gadget to receive a signal beamed from satellites 2,000 miles out in space in order to find the nearest pizza joint. But isn't it sad the current generation laments how wasteful we older folks were just because we didn't have the green thing back then?

Please post this on your blog so another selfish old person who needs a lesson in conservation from a smarty-pants young person can read this!

44 notes

·

View notes

Text

Everything You Need to Know About Timing Belts: A Complete Guide

Whether you're an automotive enthusiast, a lawn mower owner, or a DIY mechanic, the timing belt is a small but critical component that deserves your attention. Its failure can lead to costly repairs or total engine failure, while timely maintenance can keep your equipment running smoothly for years.

This comprehensive guide will walk you through everything you need to know about belts, with a special focus on their use in lawn mowers. We’ll cover how they work, when to replace them, signs of wear, maintenance tips, and much more.

How a Timing Belt Works and Why It Matters? The timing belt is an essential component in many internal combustion engines, including vehicles and lawn mowers. Its primary function is to synchronize the crankshaft and camshafts, guaranteeing that the engine's valves close and open at the appropriate times throughout the exhaust and intake strokes of each cylinder. This synchronization is crucial for optimal engine performance. We'll examine the belt's purpose in this section, its importance, and how it contributes to the efficient operation of engine-powered equipment, particularly lawn mowers.

Understanding the Timing Belt Timing belts are an essential component in many engines, including those in lawn mowers and vehicles. It’s a continuous loop made from durable rubber, reinforced with strong synthetic fibers. These materials enhance its strength and resistance to stretching over time. Key features of a belt include

Located on the inner surface, these teeth precisely engage with the grooves of the crankshaft and camshaft pulleys to ensure synchronized rotation.

Designed to withstand tension, heat, and oil exposure common in engine environments.

Connects the crankshaft (at the bottom of the engine) to the camshaft (at the top), enabling precise valve timing.

An improperly functioning belt prevents the engine from coordinating the cycles of fuel intake and exhaust—leading to misfires, poor performance, or complete failure.

Timing Belt Function in Engine Operation A four-stroke internal combustion engine's ability to function depends on the exact timing of valve motions with respect to piston locations. The belt ensures this by maintaining synchronization between two fundamental rotating components: Crankshaft: It is attached to the pistons and transforms their linear action into rotating motion. Camshafts: Regulate how the intake and exhaust valves in the cylinder head open and close.

The camshafts rotate at exactly half the belt's speed, which is driven by the crankshaft. This precise relationship ensures that each intake valve opens as the piston moves down during the intake stroke and that each exhaust valve opens as the piston moves up during the exhaust stroke. This synchronization must be perfect. Even a minor discrepancy of a single tooth can disrupt combustion timing, reduce performance, and, in some engine types, cause severe mechanical damage.

Timing Belt Application in Lawn Mowers While belts are often associated with automotive engines, they also play an important role in lawn mowers, particularly in riding mowers and zero-turn models. In these machines, the belt's function is slightly different, but its importance remains critical for smooth operation. In many lawn mowers, the belt serves to:

To ensure consistent and effective cutting, synchronize the mower blades' rotation with the engine's speed.

To ensure constant blade performance across various grass kinds and circumstances, connect the crankshaft to the cutting deck.

Drive hydrostatic transmissions in more advanced models, facilitating smooth speed transitions and better maneuverability.

For the belt to perform effectively, it must maintain correct tension and alignment. If a worn, loose, or damaged belt is not fixed right away, it may cause uneven cutting, a loss of driving power, or even serious engine damage. To guarantee dependable operation and prolong the mower's lifespan, routine maintenance and prompt belt replacement are crucial.

Timing Belt vs. Timing Chain: Understanding the Difference Crankshafts and camshafts ensure the engine's valves close and open at the right times during the combustion cycle. However, despite serving the same purpose, belts and chains have distinct characteristics, advantages, and drawbacks that may affect how well they function, longevity, and maintenance requirements.

1. Material Composition and Construction One of the most significant differences between a timing belt and a timing chain lies in their material composition.

Timing Belt:Typically made of a reinforced rubber material, often featuring fiberglass or aramid (such as Kevlar) fibers embedded for added strength and flexibility. These fibers prevent the belt from stretching or breaking under the intense tension it faces while driving the camshaft. Because the timing belt's teeth are formed into the belt, they can precisely fit by engaging with the crankshaft and camshaft sprockets. Timing Chain:Chain is constructed from metal—usually steel—and functions similarly to a bicycle chain. To synchronize the engine's motions, the metal links and rollers are made to fit onto the crankshaft and camshaft sprockets. The chain’s metal construction makes it significantly more durable than a belt.

2. Durability and Longevity One of the key distinctions between a timing belt and a timing chain is their expected lifespan.

Timing Belt:These belts have a finite lifespan due to their rubber construction. Over time, they are subject to damage from the constant exposure to heat, friction, and engine oil. Belts should normally be changed every 60,000 to 100,000 miles. The engine may suffer catastrophic damage if a belt fails, potentially resulting in a significant repair bill. Timing Chain:These chains are built for longevity. Made of metal, they can withstand more damage, often lasting 150,000 miles or more without needing replacement. Since chains are less affected by heat and friction than rubber belts, they generally require less frequent maintenance. However, if a timing chain does fail (due to lack of lubrication or wear), it can also cause significant engine damage, although it is much less likely to snap compared to a belt.

3. Maintenance Requirements The level of maintenance required for a timing belt versus a timing chain also varies significantly.

Timing Belt: Needs regular maintenance to prevent potential failures. They should be inspected periodically for indications of damage, such as cracking, fraying, or discoloration. Additionally, belts often need to be replaced within a specific mileage or time frame, as mentioned earlier. If a worn-out belt is not replaced, it might break and cause pistons and valves to clash, seriously damaging the engine. Timing Chain: Requires less frequent maintenance compared to belts. Although they tend to be more robust, they may eventually wear down, especially if the engine is not properly maintained. A poorly lubricated chain can stretch, become noisy, or even cause misalignment. In some cases, the chain may need to be adjusted or replaced, but this is a rare occurrence compared to the need for belt replacement.

4. Noise and Performance The sound and overall performance of a timing belt versus a timing chain differ as well.

Timing Belt:Belts are relatively quiet and operate smoothly. The rubber material absorbs much of the noise created by the engine's internal components, which means they are less likely to cause engine noise. One of the reasons why many modern vehicles and lawn mowers utilize belts. Their quiet operation contributes to a smoother, quieter ride. Timing Chain:Chains, however, tend to be noisier than timing belts. Because they are made of metal, they create a distinct clinking or rattling sound, especially as they wear out. Over time, as the chain stretches, it can become noisier, and this is a sign that the chain may need to be adjusted or replaced. While this noise doesn’t directly affect the engine's performance, it can be an indicator that maintenance is required.

5. Cost and Replacement Cost is another significant factor when comparing belts and chains. The kind of engine, the intricacy of the system, and the model and brand of the equipment or vehicle can all have a significant impact on the cost of labor and replacement components.

Timing Belt:In general, replacing belts is less expensive than replacing timing chains. The parts themselves are less expensive, and since belts are typically located on the engine outside, the labor costs for replacement tend to be lower. The cost of replacing a belt can range from $300 to $1,000, depending on the vehicle or machine. Timing Chain:Costly to replace because of the system's complexity. To replace a chain, it is frequently necessary to remove components of the engine in addition to the chain itself, making the labor costs higher. The cost of replacing a timing chain can range from $1,000 to $2,500, based on the kind of engine and the degree of repair.

Despite its tiny size, the timing belt is important to the functionality and durability of your equipment. It’s responsible for ensuring everything runs smoothly, whether it's providing a clean lawn cut or preventing engine failure. For lawn mower owners, this often-overlooked component is essential in linking the engine to the cutting deck. Regular inspections, timely replacements, and a bit of maintenance know-how can prevent unexpected breakdowns and significantly increase the longevity of the equipment. By staying proactive with timing belt care, you’ll enjoy reliable performance and smooth operation season after season, keeping your mower in top shape.

Written by Allen Rode for WholeToolbox , your trusted source for a variety of top-quality lawn mowers and power tools, including timing belts.

#LawnMowerProblems#MowerMaintenance#powertoolsparts#lawnmowerparts#lawnequipmentparts#Engine Operation#Timing Belt

2 notes

·

View notes

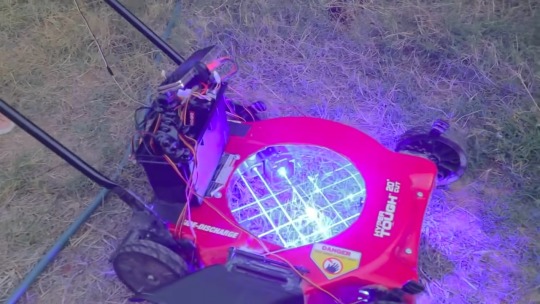

Photo

Engineer Replaces His Lawn Mower Blades With Lasers

6 notes

·

View notes

Text

Why Electric Lawn Mowers Are the Future of DIY Lawn Care

Introduction to Electric Lawn Mowers

Benefits of Using Electric Lawn Mowers

The environmental impact of switching to an electric lawn mower is one of the strongest arguments in favor of doing so. Electric mowers have no emissions, in contrast to gas mowers that release dangerous pollutants. This enhances the quality of the air surrounding your home in addition to helping the environment. Electric mowers also require less maintenance because they have fewer moving parts and don’t need air filters, spark plugs, or oil changes. Electric mowers are more user-friendly than gas ones because they are lighter and easier to handle, and they can be started with a single button.

Selecting the Right Electric Lawn Mower for Your Needs

Think about things like your lawn’s size, the terrain, and your preferred power source when selecting an electric lawnmower. Because they have an infinite runtime, corded models are perfect for smaller yards, but they do need to be near an electrical outlet. Larger lawns can benefit from cordless models, which offer greater mobility but have a shorter battery life. The mower’s cutting width, adjustable cutting heights, and capacity for side discharge, bagging, or mulching are important features to check for.

Ease of Use

Another benefit of electric lawn mowers is their user-friendliness. For homeowners of all ages and physical capabilities, they are the best option because they are typically lighter and more manageable than gas-powered mowers. Additionally, a lot of electric mowers have push-button start systems, which do away with the need to pull a cord in order to start the engine. For people who struggle to start traditional pull-start mowers or have mobility issues, this feature is especially helpful.

Electric mowers are quieter than their gas-powered counterparts and also easier to start. In addition to making mowing more enjoyable, the lower noise levels lessen the possibility of upsetting nearby residents. Those who live in neighborhoods with noise restrictions or in close proximity to other people should pay particular attention to this.

Safety Features

When using any lawn care equipment, safety is an important factor to take into account, and electric mowers have many benefits in this area. They do away with the possibility of fuel leaks and spills, which can be dangerous for the environment and the user. In addition, the dangerous fumes that gas-powered mowers release are not produced by electric mowers, lowering the possibility of breathing in hazardous substances.

Numerous electric lawn mowers come with safety features that prevent unintentional starts, like automatic shut-off upon handle release. In order to prevent potential hazards, the mower can modify its speed or stop completely. Certain models additionally come equipped with sensors that identify obstacles or changes in the terrain.

Reduced Maintenance

The fact that electric lawn mowers require less maintenance is one of their biggest benefits. To keep gas-powered lawn mowers operating smoothly, they need to have their oil changed, air filters changed, and spark plugs maintained on a regular basis. Depending on how long the mower lasts, these chores may be expensive and time-consuming.

In contrast, electric mowers require less maintenance because they have fewer moving parts. It is not necessary to deal with carburetor problems, change the oil, or replace the air filters. The only routine upkeep needed is to make sure the battery is charged and to keep the blades sharp. The mower lasts longer thanks to this less maintenance, which also saves time and money.

Maximizing the Lifespan of Your Electric Lawn Mower

2 notes

·

View notes

Text

A young cashier told an older woman that she should bring her grocery bags because plastic bags weren't good for the environment. The woman apologized, "We didn't have this green thing back in my day."

The young clerk said, "Your generation did not care enough to save our environment for future generations." She gave him a firm stare and a hard grin and said “Back then, we returned milk bottles, soda bottles, and beer bottles. The store sent them back to the plant to be washed sterilized and refilled, so it could use the same bottles over. They were recycled.

Grocery stores bagged our groceries in brown paper bags, which we reused for numerous things. We walked upstairs because we didn't have an escalator in every store and office building. We walked to the grocery and didn't climb into a 300-horsepower machine every time we had to go two blocks.

Back then, we washed the baby's diapers because we didn't have the throwaway kind. We dried clothes on a line, not in an energy-gobbling machine burning up 220 volts -- wind and solar power did dry our clothes back in our day. Kids got hand-me-down clothes from their brothers or sisters, not always brand-new clothing.

Back then, we had one TV, or radio, in the house -- not a TV in every room. The TV had a small screen the size of a handkerchief, not a screen the size of the state of Montana. In the kitchen, we blended and stirred by hand because we didn't have electric machines to do everything for us. When we packaged a fragile item to send in the mail, we used wadded-up old newspapers to cushion it, not Styrofoam or plastic bubble wrap.

Back then, we didn't fire up an engine and burn gasoline just to cut the lawn. We used a push mower that ran on human power. We exercised by working so we didn't need to go to a health club to run on treadmills that operate on electricity.

We drank from a fountain when we were thirsty instead of using a cup or a plastic bottle every time we had a drink of water. We refilled writing pens with ink instead of buying a new pen, and we replaced the razor blades with a razor instead of throwing away the whole razor just because the blade got dull.

Back then, people took a bus and kids rode their bikes instead of turning their moms into a 24-hour taxi service. We had one electrical outlet in a room, not an entire bank of sockets to power a dozen appliances. And we didn't need a computerized gadget to receive a signal beamed from satellites 23,000 miles in space to find the nearest burger joint. But the current generation laments how wasteful we old folks were just because we didn't have the green thing.”

The cashier stood there still and quiet as the old lady found her wallet to pay. Then lady turned to leave but stepped back and turned toward the cashier. She said “You have a world of knowledge in that little device in your hand. Pity you just use it to gossip, take pictures, and waste time. It would do you good to search a bit of history before you embarrass yourself like this again.

2 notes

·

View notes

Text

If you’ve got a fuel powered lawn mower that isn’t starting the engine needs three things to function:

Airflow

Fuel

A spark

If one of these things is not happening that engine isn’t going to start.

Check airflow = take a look at any intakes and air filters. If they’re dirty give them a clean or if the filters are filthy enough they can’t be savaged put a new filter in and if there’s debris clogging stuff pull it out.

Check fuel = take a look in the fuel tank. Is it empty or very low? Top it up. Take a look at the fuel lines. If there’s leaks anywhere they’ll need replacing. Dont forget to take a look at the carburettor these can get leaky or gummed up at times so you may need to open it up and give it a good clean and make sure the components aren’t too loose.

Check spark = take a look at the spark plug/s are they dirty? Give them a clean, pop them back in and if possible try to start up the engine while watching and see if the plugs are producing a spark. If they’re clean and not making a spark replace them.

If you’re getting it to start but it doesn’t STAY running fiddle around with the choke on the mower. Some decide to be a piece of shit and will refuse to run unless you’ve got that little lever set in just the right spot.

If all else fails scrap the piece of junk and buy an electric mower.

Basic trouble shooting for people who aren't mechanics and have no interest in becoming one:

1. Does it have a spiny part that's not spinning, or isn't spinning the way it's supposed to? Look at it- is there anything stringy wound around the spiny part? Remove it. Applies to: vacuums, aquarium filters, blenders, and rototillers, weed eaters, and lawn mowers.

1.b Is there debris from the spiny part that is building up on an nearby surface? Remove it. Applies to: vacuums, lawnmowers, probably other things.

2. Does it have a part that air, water, or other materials move through? Look at it- is there a clog, even a small or flimsy looking one? Remove it. Applies to: lawnmowers, vacuums, pumps, probably more.

3. If it has a gas engine, does it have gas? The right kind of gas? Does it have oil? If it's electric, is it plugged in? Or is it's battery charged?

4. Does it have a filter? Is the filter dirty/clogged? Clean it. Applies to vacuums, pumps, and some small engines.

5. Is it electric? Is there a safety feature where it won't work unless a certain peice is in place? Is there something keeping it from popping up or into place? Remove it. Did a small plastic peice break off? Can you super glue it back on in a safe manner?

6. Are there fluid tanks? Do they have fluid levels between the empty and full marks?

7. Are there tubes and/or wires? Are they all attached and going where they're supposed to? If it has spark plugs, are they all where they're supposed to be? If it has belts, are they taut?

8. Are there bolts and nuts? Screws? Are they all where they're supposed to be?

5K notes

·

View notes

Text

Top 5 John Deere X300 Problems: Transmission Failures and How to Fix Them

https://autorepairlebanontn.com/?p=3723 Top 5 John Deere X300 Problems: Transmission Failures and How to Fix Them The John Deere X300 lawn tractor has earned a reputation for reliability and performance, but even this beloved machine isn’t without its share of problems. We’ve researched common issues that X300 owners face to help you identify and troubleshoot potential headaches before they become major expenses. From transmission failures and electrical system glitches to mower deck issues and engine troubles, understanding these common X300 problems can save you time and money. Whether you’re considering purchasing this model or already own one, knowing what to watch for is essential for maintaining your investment and ensuring your lawn always looks its best. Table of Contents Toggle Overview of the John Deere X300 Lawn TractorCommon Engine Problems with the John Deere X300Oil Burning and ConsumptionRough Running and SurgingStarting Issues and Battery FailuresOverheating ConcernsTransmission and Drive System FailuresBelt Problems and ReplacementsHydrostatic Transmission IssuesMower Deck ChallengesCutting Quality ProblemsDeck Leveling DifficultiesElectrical System DefectsDashboard and Control Panel MalfunctionsWiring Harness IssuesCost of Repairs and Maintenance ConcernsTransmission Replacement ExpensesDIY Repair OptionsAdditional Maintenance CostsLong-Term Durability ConcernsComparing the X300 Problems to Other John Deere ModelsConclusionFrequently Asked QuestionsWhat are the most common issues with the John Deere X300 lawn tractor?How reliable is the John Deere X300’s transmission?What engine does the John Deere X300 use?How can I troubleshoot electrical problems on the X300?What causes the X300 mower deck to cut unevenly?How much do typical X300 repairs cost?How does the X300 compare to other John Deere models?What maintenance should I perform regularly on my X300? Overview of the John Deere X300 Lawn Tractor The John Deere X300 lawn tractor stands as a popular mid-range option in John Deere’s residential equipment lineup. Released in 2006, this model features a 42-inch mower deck and is powered by a Kawasaki FR651V engine delivering 18.5 horsepower. Its hydrostatic transmission offers infinite forward and reverse speeds without clutching, making it exceptionally user-friendly for homeowners managing properties up to 2.5 acres. Built with a full-length welded steel frame, the X300 provides durability that exceeds many competitors in its class. Four-wheel adjustable suspension contributes to a comfortable ride even on uneven terrain. The ergonomic design includes an adjustable seat with 15 positions and convenient dashboard controls that enhance operator comfort during extended mowing sessions. Many owners appreciate the X300’s versatility through compatible attachments such as baggers, snow blowers, and front blades. These accessories transform the mower from a simple grass-cutting machine into a year-round lawn maintenance solution. The machine’s edge-to-edge cutting technology ensures a clean, even cut across the entire width of the deck, resulting in a professional-looking lawn finish. Even though its robust construction, the X300 isn’t without its share of maintenance requirements and potential problems. Regular service intervals include oil changes every 50 hours, air filter replacements, and belt inspections. Understanding these maintenance needs helps owners maximize the lifespan of their investment while minimizing operational issues. Common Engine Problems with the John Deere X300 The John Deere X300 experiences several engine-related issues that can impact performance and longevity. These problems range from oil consumption to combustion irregularities that affect daily operation. Oil Burning and Consumption Oil burning is a frequent complaint among X300 owners, indicating potential internal engine issues or worn components. Many users report needing to add oil between scheduled changes, suggesting deterioration of engine seals or piston rings. This excessive consumption not only increases maintenance costs but can lead to engine damage if left unaddressed. Regular oil level checks are essential for catching this problem early before it causes more important damage. Rough Running and Surging Engine performance issues manifest as rough running, surging, or unexpected stalling during operation. These symptoms typically stem from: Worn or fouled spark plugs creating inconsistent combustion Faulty ignition system components interrupting proper firing sequences Fuel system problems including clogged filters or carburetor issues Dirty air filters restricting proper airflow Diagnosing these issues often requires systematic checking of each component, starting with the simplest answers like replacing spark plugs before moving to more complex fuel system troubleshooting. Starting Issues and Battery Failures Starting problems in the X300 frequently trace back to electrical system deficiencies. Bad cable connections and ground issues top the list of starting-related complications. Checking engine mounting bolts and starter connections reveals loose or corroded connections that prevent proper electrical flow. The starter solenoid also becomes a common failure point after extended use. Battery failures constitute another major starting obstacle. Even relatively new batteries can fail prematurely due to: Incorrect charging system operation Parasitic drains when the mower sits unused Extreme temperature exposure Loose terminal connections causing resistance Testing battery voltage both at rest and during cranking helps isolate whether the problem lies with the battery itself or with the starting system components. Overheating Concerns X300 engines can develop overheating issues that compromise performance and potentially cause permanent damage. Cooling system inefficiencies often result from debris buildup around cooling fins. Restricted airflow prevents proper heat dissipation, particularly during extended mowing sessions or hot weather operation. Air filter maintenance plays a crucial role in preventing overheating. Clogged filters restrict incoming air, creating improper air-fuel mixtures that run hotter than normal. This situation compounds when mowing in dusty conditions, making regular filter inspection essential for preventing temperature-related failures. Engine oil quality also affects operating temperature. Degraded oil loses its lubricating properties, increasing friction and heat generation within the engine. Maintaining the manufacturer’s recommended oil change intervals helps minimize this risk factor for overheating episodes. Transmission and Drive System Failures The John Deere X300 commonly experiences important transmission and drive system problems that frustrate many owners. These issues often emerge unexpectedly and can lead to costly repairs that impact the overall ownership experience of this otherwise capable lawn tractor. Belt Problems and Replacements Belt maintenance forms an essential part of routine X300 upkeep, though it’s not typically reported as a major failure point. Regular inspection of drive belts helps prevent unexpected breakdowns during crucial mowing seasons. Owners should check for signs of wear, cracking, or glazing during scheduled maintenance sessions. While the X300’s belt system is generally reliable, preventative replacement as part of normal service intervals extends the operational life of the machine and prevents cascading failures in connected systems. Hydrostatic Transmission Issues The hydrostatic transmission represents the most important and expensive failure point in the John Deere X300 lineup. Many users report complete transmission failures even after proper maintenance, with problems occurring after just several hundred hours of operation. The TuffTorq K46 transmission used in X300 models frequently requires replacement, costing owners between $1,000 and $1,700 for parts alone. Symptoms of impending transmission failure include: Difficulty starting the tractor Unexpected loss of power during operation The machine bogging down when traversing slopes Intermittent movement problems that complicate diagnosis Some owners have temporarily resolved transmission issues by changing the transmission fluid, but this solution rarely provides long-term relief. The intermittent nature of early transmission problems makes diagnosis particularly challenging, often leading to continued use until complete failure occurs. Unfortunately, even well-maintained X300 tractors aren’t immune to these transmission issues, as the fundamental design limitations of the TuffTorq K46 transmission make it a common point of failure across multiple units. Mower Deck Challenges The John Deere X300’s mower deck can present several operational challenges even though the tractor’s overall reliability. While transmission issues dominate reported problems, deck-related complications can significantly impact cutting performance and overall lawn maintenance quality. Cutting Quality Problems Cutting quality issues with the X300 often stem from basic maintenance oversights rather than design flaws. Dull blades create ragged grass tips that turn brown quickly, giving lawns an unhealthy appearance. Improper blade alignment causes uneven cutting patterns across the lawn, particularly noticeable on flat terrain. Incorrect mowing height settings contribute to scalping in some areas while leaving others too tall. Many owners experience these problems without realizing they’re related to regular maintenance requirements rather than equipment failure. Checking blade sharpness monthly during heavy use seasons ensures optimal cutting performance and reduces strain on the mower’s engine. Deck Leveling Difficulties Proper deck leveling remains essential for achieving an even cut with the X300’s 42-inch mower deck. Misadjusted deck leveling mechanisms commonly result from regular use over uneven terrain or after hitting obstacles. Worn-out components in the suspension system can create persistent leveling issues that require replacement parts rather than simple adjustments. The X300’s four-wheel adjustable suspension complicates the leveling process compared to simpler models, requiring more precise measurements. Troubleshooting guides rarely address the exact deck leveling procedures needed for optimal performance. Regular inspection of the deck’s mounting hardware helps identify loose connections before they create more important leveling problems. Consulting the owner’s manual for proper leveling specifications provides the most accurate guidance for this critical maintenance task. Electrical System Defects The John Deere X300’s electrical system has several documented issues that affect performance and safety. A important manufacturing defect impacts the interlock module, creating potential hazards for operators and requiring immediate attention. Dashboard and Control Panel Malfunctions Dashboard functionality on the X300 can be compromised when electrical system problems occur, particularly those related to the interlock module. These malfunctions aren’t widely reported as standalone issues but typically manifest as secondary problems stemming from primary electrical failures. Control panel responsiveness often deteriorates when electrical components begin to fail, leading to unpredictable operation of the tractor’s features. Users experiencing intermittent control problems should check connections between the dashboard components and the main electrical system as a first troubleshooting step. Wiring Harness Issues The X300’s wiring harness serves as the central nervous system for all electrical components, making any failures particularly problematic. A critical safety concern relates to the interlock module recall, where manufacturing defects can damage the electrical circuit within the module. This damage allows the mower blades to continue operating even without an operator in the seat, creating a serious safety hazard. Intermittent starting problems frequently indicate wiring harness deterioration, especially at connection points subjected to vibration and environmental exposure. Troubleshooting electrical issues often requires tracing the wiring harness for visible damage, loose connections, or corrosion at terminal points before determining whether replacement is necessary. Cost of Repairs and Maintenance Concerns Transmission Replacement Expenses Transmission failures represent the most important financial burden for John Deere X300 owners. The TuffTorq K46 transmission used in these models frequently develops problems that require complete replacement, costing between $1,000 and $1,700. This repair expense amounts to approximately one-third to one-half of the tractor’s original $3,100 purchase price. Many owners report transmission failures even after performing regular maintenance, with problems typically manifesting as grinding noises or complete loss of forward or reverse motion. DIY Repair Options Some maintenance tasks can be performed at home to potentially extend transmission life. Changing the transmission fluid occasionally resolves minor issues at a fraction of replacement costs. This DIY approach doesn’t guarantee a permanent fix but often provides temporary relief from transmission problems. Owners commonly share these maintenance tips in forums to help others avoid costly professional repairs when possible. Additional Maintenance Costs Transmission issues aren’t the only expenses X300 owners face. Drive pulleys and belts frequently require replacement, adding to the overall maintenance budget. Engine oil leaks develop in many units after extended use, requiring professional diagnosis and repair. Hood and hinge damage occurs with normal usage, while mower deck rusting becomes increasingly common as the machine ages, necessitating additional parts and labor costs. Long-Term Durability Concerns The X300’s long-term reliability raises serious questions even though John Deere’s reputation for quality. Many owners report transmission failures after just several hundred hours of operation, regardless of adherence to maintenance schedules. This premature failure pattern suggests inherent design limitations in the non-heavy-duty transmission that regular maintenance alone cannot overcome. The substantial repair costs relative to the machine’s initial price make these durability concerns particularly important for budget-conscious homeowners. Comparing the X300 Problems to Other John Deere Models The X300’s K46 transmission represents one of its most important weaknesses compared to other John Deere models. Unlike older models such as the LX178, which featured more robust transmissions, the X300’s lighter-duty K46 unit often fails when used on slopes or with heavy loads. Many X300 owners report transmission issues even after regular maintenance, while users of vintage John Deere tractors experience fewer transmission-related problems over longer periods. Engine oil consumption stands out as another area where the X300 lags behind its siblings in the John Deere lineup. The X300’s tendency to burn oil creates ongoing maintenance challenges not commonly reported in comparable models from the same manufacturer. This issue particularly affects long-term performance and increases operational costs compared to other John Deere tractors with more efficient engines. Deck durability differences become apparent when examining the X300 alongside alternative John Deere options. The X300’s deck rust problems and discontinued mulching deck components create frustration for owners who’ve had to fight for replacements. Other John Deere models typically feature more durable deck designs with better long-term performance and fewer rust-related concerns. Seat quality in the X300 falls dramatically short of standards set by other John Deere tractors. The seats frequently split or crack within a relatively short timeframe—an issue that’s been consistently reported yet poorly addressed by the manufacturer. Premium John Deere models generally feature more durable seating materials that withstand regular use without premature deterioration. Component longevity varies significantly across John Deere’s product range. The X300’s hood and hinges tend to deteriorate over time, with some owners reporting complete hood failure. Higher-end John Deere models generally incorporate more robust materials for these critical components, resulting in better durability and fewer replacement needs. Maintenance costs for the X300 often exceed those of similar John Deere tractors due to its exact component issues. While the X300 performs efficiently about fuel consumption, the expenses associated with transmission repairs, deck replacements, and other component failures typically surpass maintenance costs for comparable models in the John Deere lineup. Feature X300 Other John Deere Models Transmission K46 (prone to failure) More robust in older/premium models Engine Oil consumption issues Better efficiency in comparable models Deck Rust problems, discontinued parts More durable designs typically Seat Poor durability, splits/cracks Higher quality materials generally Hood Deteriorates, can fall apart More robust construction in premium models Maintenance Expensive dealer service Similar costs but fewer major issues Conclusion Even though its reliability the John Deere X300 has several common issues that owners should be aware of. From transmission failures and electrical glitches to mower deck problems and engine troubles regular maintenance is essential to maximize performance. We recommend keeping an eye on the K46 transmission which remains the most important weakness in this model. Budget-conscious owners should consider preventative maintenance like regular fluid changes to extend equipment life and avoid costly repairs. For those considering an X300 purchase weighing these potential problems against its durability and versatility is crucial. With proper care and attention to these known issues your X300 can still deliver years of dependable service for your lawn care needs. Frequently Asked Questions What are the most common issues with the John Deere X300 lawn tractor? The most common issues with the John Deere X300 include transmission failures (particularly with the TuffTorq K46), electrical system glitches, mower deck problems, and engine troubles such as oil consumption and starting difficulties. Many owners also report problems with deck rust and seat quality degradation over time. Regular maintenance can help prevent some but not all of these issues. How reliable is the John Deere X300’s transmission? The X300’s hydrostatic transmission (TuffTorq K46) is considered a weak point. Many owners experience transmission failures even with proper maintenance, particularly when used on slopes or under heavy loads. Warning signs include difficulty starting, unexpected power loss, and intermittent movement problems. Transmission replacements typically cost between $1,000 and $1,700. What engine does the John Deere X300 use? The John Deere X300 is equipped with an 18.5 horsepower Kawasaki FR651V engine. While generally reliable, these engines can develop issues with oil consumption, rough running, and starting problems. Regular maintenance including oil changes and air filter replacements is essential for maximizing engine performance and lifespan. How can I troubleshoot electrical problems on the X300? To troubleshoot X300 electrical issues, start by checking battery connections for corrosion, inspect the wiring harness for damage, and verify the interlock module is working properly. Pay special attention to the safety interlock system, as failures can create dangerous operating conditions. Dashboard malfunctions often indicate underlying electrical problems that require immediate attention. What causes the X300 mower deck to cut unevenly? Uneven cutting is typically caused by dull blades, improper deck leveling, incorrect height settings, or bent components. Regular blade sharpening and proper deck leveling are essential for quality cuts. Inspect the deck’s mounting hardware periodically and consult your owner’s manual for precise leveling specifications. Most cutting quality issues stem from maintenance oversights rather than design flaws. How much do typical X300 repairs cost? Transmission replacement is the most expensive repair at $1,000-$1,700. Other common repairs include engine rebuilds ($500-$800), electrical system repairs ($200-$400), mower deck refurbishment ($300-$500), and drive belt replacements ($50-$150). DIY maintenance like changing transmission fluid ($30-$50) can help reduce long-term costs. Budget for ongoing maintenance to prevent more costly repairs. How does the X300 compare to other John Deere models? The X300 is a mid-range residential tractor that offers good performance but has several comparative weaknesses. Its K46 transmission is less durable than those in higher-end models, particularly for heavy use or hilly terrain. The X300 also tends to have more oil consumption issues, deck rust problems, and inferior seat quality compared to premium John Deere tractors. What maintenance should I perform regularly on my X300? Regular maintenance should include changing engine oil every 50 hours, replacing air filters as needed, sharpening blades twice per season, checking/adjusting tire pressure, lubricating moving parts, inspecting belts for wear, and cleaning the mower deck after each use. Additionally, changing transmission fluid annually may help extend transmission life, though this isn’t guaranteed to prevent failures. https://autorepairlebanontn.com/?p=3723 Absolute Auto Repair

0 notes

Text

10 Non Traditional Fathers Day Gifts

So this Father’s Day I want to talk about 10 non traditional fathers day gifts. Fellas aren't we tired of fucking ties and gift cards to home improvement stores and and grills. Has anyone ever noticed that all of Father’s Day gifts are things that the dad needs to do to help the family but nothing to help himself. Think about it when you get him a home improvement gift card he’s improving the home for everyone. When you get him a grill so that everyone can eat. How about we get our dad some thing that fulfills him and not everybody else. 1. Hims Morning Glow Vitamin C Serum You’ve been told you need to eat your fruits and veggies, but what about using them in your skincare routine? Vitamin C is not only amazing at supporting your immune system, but also an important antioxidant when applied topically, helping you look as though you’ve slept 8 hours a night and have your shit together. 2. D Scents Candles Not all dads are created equally. For the man who enjoys a night of self care and a glass of whiskey. THIS IS FOR YOU! For the man experiencing first night jitters from his upcoming blind date. THIS IS FOR YOU! For the couple looking to ignite that flame from the kitchen to the bedroom. For those swiping right an keeping it tight. THIS IS FOR YOU! Whatever "D" you have in mind, let D. Scents help you find your way to a night of Vibez and ecstasy. THIS IS FOR THE BOYS... 3. Manscaped THE PERFORMANCE PACKAGE 4.0 Trimming in the shower is easy and can create less mess. Comfortably operate The Lawn Mower® 4.0 trimmer in wet or dry conditions.Premium 7,000 RPM motor with QuietStroke™ technology and a 600mA li-ion battery is rechargeable by a wireless charging system.The convenient dock wirelessly charges The Lawn Mower™ 4.0 by transferring energy from the dock to the trimmer via electromagnetic inductionLEDs light up individually when the trimmer is on to show charge level in increments of 33%.Up to 90 minutes of use with device firmware that features an over-charging and over-discharging protection circuit.Enjoy the travel lock safety feature to help reduce accidental powering of the device.We redesigned the ear and nose hair trimmer by focusing on maximum performance and comfort.Our replacement SkinSafe™ blade is engineered to safely and easily trim hair while promoting optimal hygiene.Designed specifically for a man’s most sensitive region, this deodorant helps to create an anti-chafing barrier and provide freshness below-the-waist. 4.Uncle Nearest Uncle Nearest Premium Whiskey is inspired by the best whiskey-maker the world never knew, the first African-American master distiller on record in the United States, Nearest Green. The Uncle Nearest brand, wholly owned by Uncle Nearest, Inc., encompasses a premium aged whiskey, an 11-year-old single barrel product, and a 7-year-old small batch offering, all distilled, aged, bottled and hand-labeled in Tennessee. The whiskey is currently available in all 50 states and 12 countries, in more than 25,000 stores, bars and restaurants. Uncle Nearest is the most awarded American Whiskey or Bourbon of 2019 and 2020. 5. Cigar Box ★ DIGITAL HYGROMETER ► We include the only built-in digital hygrometer on the market. This is the most accurate way to monitor and ensure your humidor is adequately seasoned. ★ SPANISH CEDAR ► Real Spanish cedar coaming and inlay makes this humidor a moisture holding machine. Keep those smokes just how you like them.★ ACCESSORY STORAGE ► Properly store your lighter, cigar cutters, and even a travel case in the large bottom slide out accessory storage drawer. The minimal design tastefully sits flush against the humidor when closed. (Accessories Not Included)★ GLASS DISPLAY TOP ► The top lid boasts a large stunning tempered glass display properly showing off your collection of fine smokes.★ PERFECT HUMIDIFICATION ► Built-in humidification system keeps your CE humidor perfectly seasoned between 65% to 70% RH. We recommend purchasing CE Humidor Solution for best taste and longevity.

★ If it’s not MAGNETICALLY SEALED ► it’s not a Case Elegance humidor. The magnetic enclosure creates an amazingly tight seal and easily passes the dollar bill test. We took no shortcuts and included our own HUMIDIFYING GEL and HYDRO STICKS that helps to keep your cigars perfectly seasoned. Simply, wet the Hydro Sticks with distilled water or propylene glycol and place in humidor. 6.Feets Refresh and moisturize your feet��with our hydrating foot mask designed specifically to comfortably fit most feet. Enriched and formulated with tea tree oil, peppermint oil, and other natural ingredients for the unique needs of the skin on your feet. Our mask leaves your feet feeling soothed and fresh. Deep hydration better than standard foot creamsReduces dry cracked skinSoftens callusesCools and relaxes active feetNatural energizing scentAll clean ingredientsDesigned for up to size 12.5 feet 7.Kent Bikes The 32" Kent Big League sports massive 32" wheels, an extra wide handlebar, large-diameter grips and a deluxe oversized comfort saddle. Extra Sturdy Steel Frame & Fork with Relaxed Ride GeometryExtra Large 32" Wheel Size Accommodates Bigger GuysOversized Alloy Handlebar for Wider GripOversized, Soft Foam Grips Accommodates Large HandsDeluxe Oversized Comfort SaddleQuick-Release Seat Post Clamp for Saddle Height Adjustments Front & Rear Fenders Heavy Duty KickstandSmooth Ride 2.125 Cruiser Tires with Red Sidewall 3pc Alloy Crankset with Extra Wide Cruiser PedalsAccommodates Riders 6'+ Tall and Weighing up to 325lbs 8. Amazon Basics Enameled Cast Iron Covered Dutch Oven, 6-Quart, White For the chef dads in your life. Cast iron covered dutch oven in white with side handles and fitted lid; oven safe to 400 degree FahrenheitCast iron for even heat distribution and retention; enamel doesn't have non-stick function; hand wash onlyAlways use hot-pads, oven mitts, or potholders while moving or removing cast iron cookware on or from the stove or ovenHolds 6 quartsThis medium dutch oven serves 4-6 people. Perfect for tossing pasta, frying chicken, or making soup. 9. Mixology Bartender Kit ★ MIX COCKTAILS LIKE A PRO » This bartending kit makes professional-level mixology shockingly easy. With all the essential bar accessories and leak-proof cocktail shaker, you won't have to worry about any mess, spillage, or getting your measurements wrong. Our martini shaker set also comes with unique recipe cards for a fun cocktail mixing experience.★ SLEEK STAND FOR DISPLAY AND STORAGE » Attracting your guest's attention has never been so easy. With this stylish wooden stand, you'll be able to proudly display your cocktail kit, upgrading your home decor. Not only that, this stand was carefully designed to keep your barware organized and accessible at all times -> No more clutter in your kitchen drawers and cabinets.★ BE THE BEST GIFT-GIVER » Wouldn't you be excited? an elegant bar tools set + a stylish wooden stand + cocktail recipes cards, all packed inside a classy gift box. Whether it's an anniversary, wedding, Christmas, Father's day or any other occasion, your recipient will be thrilled like a child in a candy store. The one present they'll remember.★ TOP QUALITY PERFORMANCE » Heavy-duty and high-grade, bar kit. This entire cocktail set is made of stainless steel alloy: SS304 & SS430. Worry not. it’s all dishwasher compatible, so forget about wear and tear with these bar supplies. 10. ALL-IN-ONE Podcast Production Studio with 3.5mm Microphone ALL IN ONE and EASY TO USE: Works as a USB sound card plus mixing station. Integrating audio mixing equipments into 1 comprehensive solution. It delivers superb sound quality and offers intuitive and full control to optimize vocal and sound effects. The S1 Bundle comes with a condenser microphone that let you start podcasting or live streaming easily in no time. Start recording when you plug into the smartphones or PC.SPECIAL EFFECTS: Four user recordable, eight Built-in special audio effects, and various adjustments available for your creation.

Fixed audio effects like APPLAUSE, LAUGHTER, CHEERING...Note please record your own audio effects you like to audio interface according to the instructions.BORN FOR LIVE STREAMING: MAONO DJ mixer controller supports up to 2 person, 4 devices and 4 platforms to stream simultaneously. Highlights of this set, you can change your voice to the male, female, girlish, robot. Two mic inputs, One Accompaniment input, and real-time monitoring, good noise reduction effect after pressing DENOISE button. It is compatible with IOS and Android systems. 10 Non Traditional Fathers Day Gifts. I wanted to give the Fathers in your life something to jump up and down about. Enjoy.

0 notes

Text

How Do Strimmers Enhance Garden Care? Exploring Their Role in Grounds Maintenance

Maintaining a beautiful garden requires more than just mowing the lawn. Strimmers play a crucial role in garden care, especially when it comes to trimming edges, tackling tough weeds, and reaching areas inaccessible to conventional lawn mowers. But what exactly are strimmers, and how do they fit into the broader range of grounds maintenance tools? This article dives deep into the benefits, types, and practical uses of strimmers, helping you understand their importance in everyday garden upkeep.

What Makes Strimmers Essential for Garden Maintenance?

Strimmers are versatile tools designed to cut grass, weeds, and light vegetation using a spinning nylon line or blade. Unlike hedge trimmers that focus on shaping hedges and shrubs, strimmers specialise in ground-level trimming and precision cutting around obstacles.

Ideal for maintaining neat lawn edges and pathways

Effective for clearing dense grass and stubborn weeds

Portable and easy to maneuver in tight spaces

Compatible with various power sources like electric, battery, and petrol

Complements hedge trimmers and other grounds maintenance tools

Because they can reach areas where lawn mowers cannot, strimmers are indispensable for detailed garden care.

Which Types of Strimmers Are Best for Different Garden Needs?

Choosing the right strimmer depends on factors like garden size, terrain, and user preference. Here are the primary categories:

Electric Strimmers

Perfect for small gardens and light trimming tasks

Require a power outlet, limiting range but providing consistent power

Lightweight and quiet operation

Battery-Powered Strimmers

Offer cordless convenience and greater mobility

Suitable for medium-sized gardens

Rechargeable batteries with varying runtime depending on model

Petrol Strimmers

Designed for heavy-duty jobs in large gardens or commercial grounds maintenance

Powerful engines can handle thick weeds and rough terrain

Heavier and require more maintenance but deliver maximum cutting performance

How Should You Use a Strimmer for Best Results?

To maximize efficiency and safety when using a strimmer, follow these guidelines:

Wear protective clothing including gloves, goggles, and sturdy shoes

Inspect the area for debris that could damage the line or cause injury

Hold the strimmer at a slight angle to the ground for smooth cutting

Use sweeping motions to evenly trim grass and weeds

Replace or adjust the cutting line regularly for optimal performance

Proper technique ensures cleaner cuts and prolongs the life of your strimmer.

How Do Strimmers Differ from Hedge Trimmers in Garden Care?

Although both are essential grounds maintenance tools, strimmers and hedge trimmers serve distinct purposes:

Strimmers are focused on cutting grass, weeds, and ground-level vegetation with a flexible line or blade

Hedge trimmers are equipped with blades to precisely shape and prune hedges and shrubs

Strimmers help maintain clean edges along paths, fences, and flower beds

Hedge trimmers provide sculpting and shaping for hedgerows and bushy plants

Together, they cover complementary tasks in a well-maintained garden.

What Are the Benefits of Using Strimmers Alongside Other Grounds Maintenance Tools?

Incorporating strimmers into your gardening arsenal offers several advantages:

Reach areas where lawn mowers cannot operate effectively

Maintain sharp, clean edges for a professional garden look

Save time compared to manual trimming with shears or scissors

Versatility in handling different vegetation types and garden terrains

Reduce physical strain thanks to lightweight and ergonomic designs

When combined with hedge trimmers and other tools, strimmers enhance the overall quality and efficiency of garden care.

What Features Should You Look for When Buying a Strimmer?

To find a strimmer that suits your garden needs, consider these important features:

Power source options to match garden size and user mobility

Cutting width for effective trimming over large or small areas

Adjustable handle height and shaft length for comfort and control

Weight and balance to reduce fatigue during extended use

Availability of replacement parts and accessories

Safety mechanisms like guards and automatic shut-offs

Selecting the right model ensures ease of use and long-lasting performance.

How Are Modern Strimmers Contributing to Eco-Friendly Gardening?

Many new strimmer models prioritize sustainability with battery-powered options that produce zero emissions and reduce noise pollution. These tools enable gardeners to maintain beautiful outdoor spaces without harming the environment, aligning with greener gardening practices. Additionally, efficient motors and recyclable materials contribute to minimizing environmental impact.

Final Thoughts: Why Should Gardeners Invest in Strimmers?

Strimmers are indispensable for anyone serious about garden care. Their ability to access hard-to-reach places, tackle tough weeds, and provide precise edging makes them a valuable addition to any grounds maintenance toolkit. By understanding the different types and features, gardeners can select the best strimmer to suit their needs.

Paired with hedge trimmers and other grounds maintenance tools, strimmers offer a comprehensive approach to keeping gardens pristine, healthy, and visually appealing. Investing in the right strimmer not only saves time and effort but also elevates the quality of your garden care routine, ensuring a beautifully maintained outdoor space year-round.

0 notes

Text

Efficient Solutions for Farm, Garden, and Car Care with Modern Tools

Managing a farm, maintaining a beautiful lawn, and keeping your vehicle clean might sound like unrelated tasks. But they all share a common requirement – the need for efficient and reliable tools. Whether you're a private homeowner, a landscape gardener, or someone involved in agriculture or construction, having the right equipment can save time, reduce effort, and deliver professional results. In this article, we explore the usefulness of three powerful tools: the Power Tiller, Electric Lawn Mower, and Car Vacuum Cleaner, and how they can make everyday maintenance simpler and more effective.

Improving Soil Health with a Power Tiller

For farmers and serious gardeners, soil preparation is the foundation of a productive harvest. This is where a Power Tiller becomes indispensable. Unlike traditional manual methods, a power tiller automates the process of turning the soil, making it easier to plant seeds and improve aeration.

What sets a power tiller apart is its ability to dig deep into the soil, breaking up compacted layers and mixing organic material evenly. This improves water retention and root penetration – crucial factors for healthy crop development. Modern power tillers come equipped with adjustable blades, user-friendly handles, and robust engines that can handle different soil types, including clay-heavy or sandy terrains.

From a cost-efficiency perspective, investing in a power tiller reduces the need for additional labor and significantly cuts down on the time required to prepare large fields. For small and medium-scale farmers, this tool becomes a smart investment that quickly pays for itself.

Keeping Lawns Pristine with an Electric Lawn Mower

Maintaining a lush green lawn requires more than just watering and fertilizing. Regular trimming ensures your lawn looks neat and grows evenly. The Electric Lawn Mower has become a favorite among homeowners and professional landscapers due to its eco-friendliness, low noise output, and ease of use.

Unlike petrol mowers, electric models start instantly with a push of a button. They operate quietly and don’t emit harmful fumes, making them suitable for residential areas and urban gardens. Moreover, they require less maintenance – no oil changes or spark plug replacements – which makes them user-friendly even for those new to garden maintenance.

Modern electric lawn mowers come with adjustable cutting heights, ergonomic handles, and foldable designs for easy storage. The clean, even cuts provided by these machines not only improve the visual appeal of your lawn but also promote healthier grass growth by preventing fungal infections and pest infestations.

Whether you have a small backyard or a large garden, an electric lawn mower offers consistent performance with a reduced carbon footprint – an essential step toward sustainable gardening.

Interior Car Care Simplified with a Car Vacuum Cleaner

Your car is more than just a means of transport – it's an extension of your lifestyle. Regular cleaning, especially inside the vehicle, not only improves hygiene but also preserves the value of your investment. A Car Vacuum Cleaner is the ideal solution for tackling dust, crumbs, pet hair, and other debris that collect in hard-to-reach areas.

Designed to be compact, powerful, and easy to maneuver, car vacuum cleaners offer precision cleaning with minimal effort. Most models come with interchangeable nozzles to clean under seats, in tight corners, and across upholstery. Cordless versions provide added convenience, allowing you to clean without worrying about power outlets or tangled wires.

The benefits extend beyond cleanliness. A clean interior contributes to better air quality inside the vehicle and can even improve your driving experience by eliminating allergens and odors. It’s a tool that every car owner should consider for maintaining a tidy and welcoming space.

The Right Tools for Every Task

Using specialized equipment not only delivers better results but also enhances safety and efficiency. The Power Tiller reduces physical strain during farming, the Electric Lawn Mower cuts grass effortlessly with precision, and the Car Vacuum Cleaner ensures spotless interiors with minimal effort. All three tools cater to different domains, yet they share a common goal – making life simpler and tasks more manageable.

Choosing the Right Brand Makes a Difference

While selecting these tools, quality and reliability should never be compromised. This is where STIHL stands out as a trusted name in outdoor and home equipment. With a reputation built on innovation, performance, and user satisfaction, STIHL offers a range of tools that are designed for real-world challenges – whether in agriculture, landscaping, or everyday cleaning.

STIHL’s Power Tillers are crafted for durability and performance across diverse soil conditions. Their Electric Lawn Mowers are designed to blend quiet efficiency with cutting-edge technology. And when it comes to Car Vacuum Cleaners, STIHL ensures powerful suction, ergonomic designs, and lasting reliability.

0 notes

Text

Lawn Mower Mufflers Replacement Parts | WholeToolBox

Lawn mower mufflers are essential components designed to reduce engine noise and control exhaust emissions, ensuring a quieter and more efficient mowing experience. These mufflers are commonly used in various equipment, including push mowers, riding lawn mowers, and other small engine-powered machines. A properly functioning lawn mower muffler replacement helps maintain engine performance by regulating airflow and preventing harmful emissions. Over time, mufflers can wear out due to rust, cracks, or excessive heat exposure, making timely replacement crucial for maintaining efficiency. Shop lawn mower muffler, including muffler shield, muffler assembly, and muffler kits at WholeToolBox. Enjoy with same-day shipping. Order now!

#LawnMowerParts#PowerToolsParts#wholetoolbox#HomeImprovement#LandscapingTools#GardenEquipmenParts#lawnmowermuffler#lawnmowermufflerParts

2 notes

·

View notes

Text

Spark Plug Market Growth Drivers Fueling Global Demand and Technological Advancements

The spark plug market is witnessing significant growth driven by multiple factors that are shaping the automotive and industrial sectors globally. Spark plugs, essential components in internal combustion engines, ignite the air-fuel mixture to power vehicles and machinery. Understanding the key drivers behind the market expansion provides valuable insight into current trends and future prospects.

1. Rising Automotive Production and Sales One of the primary drivers of the spark plug market is the rapid increase in automotive production, especially in emerging economies such as China, India, and Southeast Asia. The growing middle-class population, rising disposable incomes, and urbanization have led to heightened vehicle demand. As more vehicles hit the roads, the need for reliable and high-performance spark plugs naturally rises, fueling market growth.

2. Growing Demand for Fuel Efficiency and Emission Control With stringent government regulations aimed at reducing vehicular emissions, manufacturers are focusing on improving engine efficiency. Spark plugs play a critical role in enhancing combustion efficiency and minimizing fuel consumption. Advanced spark plug technologies, such as iridium and platinum-tipped plugs, offer better ignition and durability, supporting the demand for eco-friendly and fuel-efficient vehicles. This regulatory push for cleaner engines is a key driver behind increased adoption of advanced spark plugs.

3. Technological Innovations in Spark Plug Design Continuous innovation in spark plug technology is significantly driving the market. Manufacturers are investing in research and development to produce spark plugs that can operate at higher temperatures and pressures, increasing engine performance and longevity. Innovations such as fine-wire electrodes, multi-electrode designs, and improved insulator materials are enhancing spark plug efficiency. These technological advancements attract automakers to upgrade their engine components, contributing to market expansion.

4. Expansion of Aftermarket and Replacement Services The aftermarket segment for spark plugs is rapidly growing due to the frequent replacement cycles needed for optimal engine performance. Consumers and fleet operators prefer high-quality spark plugs to maintain vehicle efficiency and reduce maintenance costs. Moreover, the availability of a wide range of aftermarket options encourages users to replace spark plugs regularly, sustaining steady demand within the market.

5. Increasing Use of Gasoline-Powered Vehicles Despite the rise of electric vehicles, gasoline-powered internal combustion engines continue to dominate in many parts of the world. The ongoing preference for gasoline vehicles, particularly in developing nations, ensures continuous demand for spark plugs. Additionally, hybrid vehicles that combine internal combustion engines with electric motors also require spark plugs, further supporting market growth.

6. Growth in Industrial Applications Beyond automotive uses, spark plugs are critical in various industrial applications such as generators, lawn mowers, motorcycles, marine engines, and small engines used in construction and agriculture. The expansion of these sectors and rising mechanization in emerging economies stimulate demand for spark plugs, thus widening the market scope.

7. Increasing Focus on Engine Performance and Longevity Vehicle owners and manufacturers alike emphasize engine reliability and longer service intervals. High-performance spark plugs contribute significantly by ensuring consistent ignition, reducing engine misfires, and preventing power loss. This focus on enhancing engine performance drives demand for premium spark plugs, pushing market growth further.

8. Rising Urbanization and Infrastructure Development Urban expansion requires increased transportation and logistics activities, resulting in more commercial vehicles and motorcycles on the road. Infrastructure projects also boost construction equipment usage. Both trends increase the need for spark plugs, as internal combustion engines remain the backbone of these vehicles and machinery.

Conclusion The spark plug market is propelled by multiple interconnected drivers, including growing automotive production, stringent emission norms, technological advancements, and expanding industrial applications. As vehicle owners and manufacturers seek better fuel efficiency and engine reliability, the demand for high-quality and innovative spark plugs is set to rise. With ongoing urbanization and rising mechanization, the market outlook remains robust, offering significant growth opportunities for manufacturers and suppliers worldwide.

0 notes

Text

A Guide to Mower Parts: Keep Your Lawn Mower Running Like New

Whether you’re a weekend lawn warrior or a landscaping professional, a lawn mower is one of the most important tools in your shed. But like any machine, your mower is only as good as the parts that keep it running. Over time, components wear down, break, or simply need replacing. That’s why understanding the role of mower parts — and knowing when to replace them — is essential to maintaining a healthy lawn and a reliable machine.

In this guide, we’ll take a friendly look at the key mower parts, how to spot signs of wear, and where to find quality replacements to keep your equipment performing at its best.

Why Mower Maintenance Matters

Your lawn mower takes a beating every season. From dust and debris to thick grass and bumpy terrain, it’s working hard every time you fire it up. Regular maintenance and timely replacement of worn mower parts can:

Extend the life of your mower

Improve performance and fuel efficiency

Prevent costly repairs

Ensure a cleaner, more even cut

Keep you safe while operating your equipment

Skipping maintenance or using poor-quality parts can result in breakdowns or uneven lawn results — not to mention frustration.

Common Mower Parts That Need Replacing

Let’s break down the most common mower parts that require regular attention or replacement:

1. Blades

Blades are the most frequently replaced mower parts — and for good reason. They dull over time, especially if you mow over sticks, rocks, or thick weeds. Dull blades tear grass rather than cut it, which stresses your lawn and can lead to brown patches.

Tip: Sharpen blades every 20-25 hours of use or replace them if chipped, bent, or worn down.

2. Air Filters

A clean air filter keeps dirt and debris out of your engine. A clogged filter restricts airflow, reduces power, and increases fuel consumption. Replacing your mower’s air filter is an easy and affordable way to boost performance.

Tip: Check your air filter each month during the mowing season and replace it if it looks dirty or clogged.

3. Spark Plugs

A worn or fouled spark plug makes it harder to start your mower and can cause misfiring. This tiny component plays a big role in engine ignition and efficiency.

Tip: Replace spark plugs once a year or as recommended by your mower’s manual.

4. Oil Filters & Fuel Filters

If your mower has an oil filter or fuel filter, don’t overlook them. They help keep contaminants from entering the engine, ensuring smoother operation and reducing wear.

Tip: Replace filters each season or after every 25-50 hours of use, depending on the model.

5. Drive Belts

If you have a self-propelled or ride-on mower, drive belts are critical. They power the wheels or cutting deck. Over time, belts can stretch, crack, or snap.

Tip: Inspect belts regularly for wear and tension. Replace them if frayed or loose.

6. Wheels and Tyres

Worn wheels or tyres can affect maneuverability and cutting consistency. Flat spots or cracked rubber can make mowing a chore.

Tip: Replace damaged wheels to maintain smooth, level mowing.

7. Throttle and Pull Cords

The throttle cable and pull cord can wear out or break, especially with regular use. If your mower doesn’t start easily or the throttle doesn’t respond properly, these may be the culprits.

Tip: Lubricate cables occasionally and replace frayed cords or sticky throttles.

Choosing the Right Mower Parts

When replacing mower parts, it’s important to choose high-quality, compatible components. Here are a few tips:

Know your make and model: Always check your mower’s manual or identification label to match the right part.

Use OEM or trusted aftermarket parts: Original Equipment Manufacturer (OEM) parts guarantee compatibility. High-quality aftermarket parts are also reliable and often more affordable.

Buy from reputable suppliers: Avoid cheap, poorly made parts from unverified sellers. Stick with trusted local suppliers or specialized retailers like Small Engine Wreckers.

Why Buy Mower Parts from Small Engine Wreckers?

At Small Engine Wreckers, we specialise in a wide range of mower parts for both domestic and commercial machines. Whether you're fixing up a Honda, Victa, Briggs & Stratton, or a ride-on mower, we’ve got the parts and advice to help.

Why customers choose us:

✅ Expert support and advice ✅ Genuine and aftermarket parts ✅ Fast shipping across Australia ✅ Competitive prices ✅ Huge range in stock

We make it easy for you to find the right parts, whether you’re a DIY home user or managing an entire fleet of landscaping equipment.

Quick Maintenance Checklist

Want to keep your mower running like a dream? Here’s a simple seasonal maintenance checklist:

✅ Check and sharpen or replace blades

✅ Inspect air filter and clean or replace

✅ Change spark plug if dirty or worn

✅ Replace oil and oil filter (if applicable)