#roller for conveyor

Explore tagged Tumblr posts

Text

figure status update - real world task | source

#talos gifs#stim gifs#stim#robot stim#robotics#robotcore#robotkin#metallic#metal#mechanical#technology#silver#white#black#grey#gray#blue#plastic#crates#roller conveyor#im pertty sure thats what thats called#gif ids#id in alt

60 notes

·

View notes

Text

Top Applications of Gravity Roller Conveyors in Industrial Settings

In today’s fast-moving industrial environments, efficient and reliable material handling systems are essential. Among the many options available, gravity roller conveyors stand out as a simple, cost-effective, and highly versatile solution. These conveyors use the natural force of gravity to move goods along a roller track, requiring no motor or power source. Their minimal maintenance needs, low energy costs, and adaptability make them ideal for a variety of industrial applications.

Below are the top uses of gravity roller conveyors across different industrial settings and how they contribute to smoother workflows and improved productivity.

Assembly Lines

Gravity roller conveyors are commonly used in assembly line operations, where products must move from one workstation to another. Workers can assemble components while items move along the conveyor, reducing the need for manual handling and increasing process efficiency.

For example, in the automotive or electronics industry, sub-assemblies are often built in stages. Gravity conveyors help maintain a steady flow of parts without requiring powered systems, particularly in low-speed or semi-manual operations.

Packaging and Shipping Areas

In warehouses and distribution centers, gravity conveyors are a popular choice for packaging and shipping zones. Cartons or packages can be placed on the conveyor after picking and flow down to packing or shipping stations. This hands-free movement reduces manual labor and speeds up order processing.

They are particularly helpful in order fulfillment centers, where high volumes of small-to-medium-sized boxes need to be quickly sorted, labeled, and dispatched.

Loading and Unloading Docks

At loading docks, gravity roller conveyors are frequently used to move goods between trucks and warehouse storage areas. Whether it’s unloading incoming shipments or loading outbound packages, gravity conveyors help workers move items quickly with less physical effort.

Expandable or telescoping gravity conveyors are especially useful here they can be extended into the back of a trailer and then retracted when not in use, saving space and increasing safety.

Sorting and Inspection Stations

Gravity conveyors are ideal for product inspection and sorting applications. Items can be directed onto different conveyor paths based on size, weight, or quality without relying on powered systems. Workers can visually inspect products as they roll by and pull off items that require attention.

This application is common in the food and beverage industry, where visual inspection is essential for quality control before packaging or palletizing.

Work-In-Progress (WIP) Movement

In manufacturing plants, managing work-in-progress materials is a crucial part of production. Gravity roller conveyors make it easy to stage, buffer, and move WIP parts between departments or machines.

For example, in a metal fabrication shop, parts can move from cutting to welding to finishing areas via gravity conveyors, helping to keep the workflow organized and continuous.

Storage and Staging Areas

Gravity conveyors are also used in temporary storage and staging zones, especially in first-in, first-out (FIFO) systems. Items can be loaded on one end and retrieved at the other, maintaining order and minimizing handling.

This setup is ideal in cold storage facilities or high-turnover inventory areas, where fast movement and easy access are necessary.

Conclusion

From assembly lines and packaging areas to docks and inspection stations, gravity roller conveyors play a vital role in keeping industrial processes efficient and organized. Their low cost, minimal maintenance, and flexibility make them an excellent investment for businesses looking to optimize their material handling operations. No matter the size or scope of your facility, gravity conveyors can be tailored to fit your needs supporting smoother workflows, reducing labor demands, and contributing to a safer, more productive workplace.

0 notes

Text

Rubber Roller - Industrial Rubber Roller Manufacturer | Jekmin Industries

Jekmin Industries is a leading Industrial Rubber Roller Manufacturer known for precision-engineered rubber rollers used across various industries. We manufacture and supply printing rubber rollers, conveyor rollers, PU coated rollers, EPDM rollers, and silicone rollers tailored to client specifications. Our industrial rollers are made from high-grade materials ensuring superior performance, durability, and resistance to wear and chemicals. Ideal for applications in printing, packaging, textile, paper, plastic, and lamination industries, our rollers meet global quality standards. With years of expertise and commitment to innovation, Jekmin Industries is your trusted partner for reliable rubber roller solutions.

Visit: https://www.jekminindustries.com/rubber-rollers.html

#Rubber Roller#Industrial Rubber Roller Manufacturer#Printing Rubber Roller#PU Roller#EPDM Roller#Conveyor Roller#Rubber Roller Manufacturer India#Rubber Rollers Supplier

0 notes

Text

The Unsung Heroes of Modern Warehousing

Efficiency is crucial in the hectic fields of logistics and production. Whether it's handling goods across countries or completing online purchases, companies depend on backend systems that silently handle the laborious tasks. Conveyor systems stand out among them; they are crucial but frequently disregarded.

What Exactly Are Conveyor Systems?

Conveyor systems are essentially mechanical devices that move goods from one location to another. Sounds easy? Not exactly. In factories, warehouses, and distribution centres, these systems are made to maximise speed, minimise manual handling, and establish smooth operation. They can be roller conveyors, belt-driven lines, or overhead conveyors, among other types.

The Significance of Roller Conveyors

One of the most widely used kinds, roller conveyors provide a useful and affordable means of moving things, particularly in settings involving manufacturing or packing. Consider them to be highways for pallets, crates, or boxes. Because the rollers lessen friction, moving big objects requires less effort and personnel. Additionally, because they are modular, companies can add, delete, or reroute pieces in response to changing needs.

While gravity roller conveyors rely on incline and basic physics, powered roller conveyors use motors to transport objects automatically. Both kinds provide safety, speed, and consistency, things that physical labour can't always provide.

Smart Conveyor Systems' Ascent

Conveyor systems change with the industry. Smarter than ever, today's setups frequently incorporate robotics, automation software, and sensors. These intelligent technologies notify operators of maintenance requirements prior to a breakdown, track goods in real-time, and modify speeds based on load.

Conveyor systems are now the foundation of dependable, scalable operations in the cold chain, pharmaceutical, and e-commerce industries. They guarantee that goods travel from point A to point B without interruption, harm, or misunderstanding.

Choosing Trustworthy Conveyor Belt Suppliers

If you plan to set up or change your system, working with experienced conveyor belt suppliers is crucial. When choosing a conveyor, the type of material, needed speed, load weight, and available space are all crucial factors to take into account. Whether it's belt conveyors for fragile goods or roller systems for bulk movement, effective design and component selection can have a big impact on long-term performance.

0 notes

Text

1 note

·

View note

Text

Conveyor Roller Manufacturer & Supplier – Jekmin Industries

At Jekmin Industries, we take pride in being a trusted Conveyor Roller Manufacturer delivering high-performance solutions tailored to the needs of modern industries. Our Conveyor Rollers are designed with precision to enhance the efficiency, reliability, and durability of your conveyor systems, making them ideal for applications across manufacturing, logistics, warehousing, mining, and more. As an experienced Conveyor Roller Supplier, we offer a wide range of rollers including gravity rollers, idler rollers, powered rollers, and custom-built variants to meet diverse operational requirements. Each roller is manufactured using high-grade materials such as mild steel, stainless steel, and polymer coatings to ensure long-term performance under demanding conditions. As a customer-focused Conveyor Roller Manufacturer, Jekmin Industries combines innovation with excellence. Our in-house team ensures every product undergoes stringent quality checks to meet international standards. We serve clients across India and overseas with timely deliveries and responsive support. Choosing Jekmin Industries as your Conveyor Roller Supplier means you gain a reliable partner committed to enhancing your material handling capabilities.

For More Details Clicks Here - https://www.jekminindustries.com/conveyor-rollers.html

0 notes

Text

Grooved Conveyor Roller Manufacturer, Exporter - Conveline Rollers

Conveline Rollers, established in 2014, is a leading Grooved Conveyor Roller Manufacturer, exporter based in Gujarat, India. Export countries such as China, South Africa, the UAE, and several European nations, Specializing in the production of high-quality grooved conveyor rollers, Conveline Rollers assures optimal performance, durability, and efficiency for material handling systems. Our products are designed to meet the diverse needs of various industries, offering reliable solutions for smooth and efficient conveyor operations. As a trusted Grooved Conveyor Roller Manufacturer in India, Conveline Rollers is committed to providing innovative, cost-effective solutions that enhance productivity and reduce operational costs, making them the preferred choice for businesses in need of quality conveyor systems. Visit: https://www.convelinerollers.com/grooved-rollers

#Grooved Conveyor Roller#Grooved Conveyor Roller Manufacturer#Grooved Conveyor Roller Exporter#Grooved Conveyor Roller in India#Grooved Conveyor Roller Manufacturer in India#Grooved Conveyor Roller Exporter worldwide#China#South Africa#UAE#Europe

0 notes

Text

Roller Conveyor in Faridabad | Vashnavi Conveyor Industry

Vashnavi Conveyor Industry offers high-quality roller conveyors in Faridabad for smooth and efficient material handling across various industrial sectors. Whether you need gravity or powered roller conveyors, our systems are engineered for durability, easy installation, and seamless movement of goods in warehouses, production lines, and distribution centers.

#Roller conveyor Faridabad#conveyor system manufacturer#Vashnavi Conveyor#gravity roller conveyor#powered roller conveyor#material handling equipment#industrial conveyors

0 notes

Text

Efficient Warehousing Starts with the Right Pallet Dispenser

In modern warehousing and logistics, efficiency is no longer optional—it’s essential. A key component in streamlining material handling operations is the pallet dispenser. Often working in tandem with a pallet stacker, this equipment automates one of the most overlooked steps in warehouse workflows: dispensing and stacking pallets.

What Is a Pallet Dispenser?

A pallet dispenser is a mechanical device designed to automatically release or stack pallets without the need for manual handling. Commonly used in distribution centers, manufacturing plants, and packaging lines, these machines reduce downtime and improve worker safety by minimizing manual lifting.

Pallet dispensers can handle wooden, plastic, and sometimes even metal pallets, and they come in various configurations—floor-mounted, overhead, or integrated into conveyor systems.

Why Warehouses Are Turning to Pallet Dispensers

As labor shortages and operational costs continue to impact supply chain dynamics, automation is becoming an integral part of warehouse optimization. Pallet dispensers, when combined with pallet stackers, can lead to significant improvements in:

Productivity: Continuous feed of pallets eliminates manual placement delays.

Safety: Reduces the risk of injuries related to lifting and moving heavy pallets.

Consistency: Ensures uniform pallet handling, reducing operational errors.

“Since we implemented a pallet dispenser and stacker combo, our warehouse throughput has improved by nearly 30%. It’s reduced both idle time and workplace injuries.” — Carlos M., Logistics Manager, Northern Freight Solutions

Pallet Dispenser vs. Pallet Stacker: Understanding the Difference

While both are used in handling pallets, their functions differ:

Integrating both systems creates a closed-loop pallet management solution, minimizing idle time and maximizing operational flow.

Use Cases Across Industries

Pallet dispensers are not industry-specific. They are used in:

Food & Beverage: For maintaining hygiene and preventing contamination through minimal contact.

Pharmaceuticals: Ensuring consistent pallet availability during automated packaging.

Retail Distribution: Speeding up order fulfillment operations.

Automotive: Managing heavy-duty pallets for parts and components.

How to Choose the Right Pallet Dispenser

Selecting the ideal pallet dispenser depends on several operational factors:

Pallet Type and Size: Compatibility with standard or custom pallet dimensions.

Capacity: Number of pallets handled per cycle or per hour.

Integration Requirements: Whether it needs to work alongside conveyors, robots, or pallet stackers.

Space Constraints: Floor-mounted vs. overhead models depending on available warehouse space.

“Choosing a dispenser that integrates easily with our conveyor line made a significant difference. It wasn���t just about the machine—it was about how well it fit into our existing layout.” — Stephanie T., Plant Supervisor, Midstate Manufacturing Co.

Maintenance and Lifecycle Cost

Though typically low-maintenance, routine checks on mechanical parts, sensors, and hydraulic components are essential for longevity. Many dispensers offer diagnostics features to alert users of wear and tear, further reducing downtime.

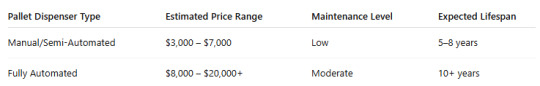

Here’s a general overview of cost expectations: Pallet Dispenser

Final Thoughts

For operations seeking to reduce manual labor, enhance safety, and improve throughput, a pallet dispenser paired with a pallet stacker offers a robust, scalable solution. With proven applications across diverse industries, it's clear that these machines are more than just convenience—they're a strategic investment in productivity.

0 notes

Text

𝐂𝐍𝐂 𝐦𝐚𝐜𝐡𝐢𝐧𝐞 𝐟𝐨𝐫 𝐜𝐮𝐭𝐭𝐢𝐧𝐠 𝐠𝐫𝐨𝐨𝐯𝐞𝐬 𝐚𝐧𝐝 𝐜𝐡𝐚𝐦𝐟𝐞𝐫𝐢𝐧𝐠 𝐭𝐡𝐞 𝐞𝐧𝐝𝐬 𝐨𝐟 𝐢𝐝𝐥𝐞𝐫 𝐫𝐨𝐥𝐥𝐞𝐫 𝐬𝐡𝐚𝐟𝐭𝐬

we have successfully automated the CNC machining process for roller shafts precisely shaping flat ends, chamfers, and grooves with unmatched efficiency and accuracy. Visit now https://en.guderoller.com

0 notes

Text

0 notes

Text

Roller Chain Repair Kit

Looking for a reliable Roller Chain Repair Kit? USA Roller Chain & Sprockets offers premium repair kits designed for quick and easy chain maintenance. Whether you need to fix industrial roller chains, conveyor systems, or agricultural equipment, our high-quality kits come with everything you need for a seamless repair. Built for durability and precision, our repair solutions ensure extended chain life and optimal performance. Shop now at USA Roller Chain & Sprockets for top-tier roller chain repair kits at competitive prices!

#conveyor systems#or agricultural equipment#aluminum coupling cover#piv chains#plastic roller chain sprockets#hollow pin chain breaker

0 notes

Text

How Conveyor Systems Keep the World Moving

In the fast-paced warehouse, industrial, and fulfilment industries, one unsung hero keeps everything going smoothly: the conveyor system. You probably don't know it, but without conveyor systems, everything from e-commerce transactions to processed meals would move slowly. These machines are productivity machines, moving objects with precision while rolling, lifting, and transferring, and they don't even pause for coffee.

So, what is a conveyor system, and how does it work? Let's go into the intriguing realm of rollers, belts, and vertical lifts to see how this little-known technology enhances global production.

What Is A Conveyor System?

A conveyor system is a method for transporting objects from one point to another. Conveyors systems exist in a range of forms and sizes to meet specific requirements, whether carrying small bolts or large boxes. They are an essential part of warehouse automation and industrial efficiency, executing repetitive movement tasks with speed and precision.

Consider a conveyor system as the building's vascular system. It moves products from reception to storage, packing to shipping, and everything in between. Conveyor systems boost productivity while minimizing fatigue and human error by removing the need for manual labour.

Roller Conveyors: The Smooth Operators

Roller conveyors are among the most popular and dependable types of conveyor systems. They transport goods along a flat track using a chain of cylindrical rollers, which can be driven or gravity-propelled. If you've ever seen packages move smoothly down a line at a distribution centre, you were undoubtedly seeing a roller conveyor in action.

These systems are suited for transferring boxes, trays, and containers of any form or size. They are adaptable, affordable, and may be built to sustain a wide range of weight capacities. They can be arranged in straight lines, curves, or even as pop-up sorting sections. This is the sort of seamless operation that keeps manufacturing moving.

Vertical Conveyors: Taking Productivity Up A Notch

Vertical conveyors are useful for transporting goods that cannot be carried horizontally. Vertical conveyors move products up and down between levels, maximising the vertical space available in a warehouse or factory. If your company has many floors or mezzanines, vertical conveyors may move products up without the use of forklifts or physical labour.

Vertical conveyors are commonly employed in comprehensive systems to connect floors, link storage and picking locations, and carry products directly to packing stations. They alleviate ground-floor congestion and accelerate operations, particularly in high-volume circumstances. In summary, they do more than just lift boxes; they also boost productivity.

How Conveyor Systems Improve Operations

The advantages of conveyor systems are numerous. To begin, they move things more quickly. Products flow more swiftly through the complex, allowing firms to complete orders faster and fulfil tight deadlines. They also bring uniformity to the process. Conveyors, unlike humans, do not tire, grow distracted, or become unreliable. They simply continue to run at the same speed, hour after hour, shift after shift.

Conveyors also lower the danger of industrial accidents. The conveyor handles the heavy lifting and long-distance walking for the workers. This enhances worker safety while reducing time wasted due to fatigue or strain.

Don't forget how conveyor systems help to maximize space. A roller conveyor may be customised to go along specific paths within constrained locations, whereas vertical conveyors enable firms to expand upwards rather than outwards. This allows you to transport more objects in fewer square feet, which is very useful in constrained or expensive facilities.

Smart Integration Of Modern Technology

Modern conveyor systems are now integrated into a broader smart warehouse framework. They can interface with sensors, scanners, and automation software to offer real-time information and updates. For example, a roller conveyor system may be equipped with barcode scanners that scan packages as they pass through and update inventory in real-time.

Vertical conveyors can also be combined with automated guided vehicles and robotic arms to provide uninterrupted vertical and horizontal motion. This enables organisations to expand operations, enhance accuracy, and minimise their reliance on manual handling, all while enhancing overall production.

Choosing The Right Conveyor System

With so many alternatives, selecting the best conveyor system is a matter of knowing what your company requires. Roller conveyors are great for simple transportation over large distances, particularly when the commodities are uniform in shape and size. Vertical conveyors are the ideal answer for multi-level applications requiring upward or downward movement.

In most circumstances, integrating multiple technologies produces the greatest results. It's about creating a system that fits your procedures, space, and long-term goals.

Keep Everything Going

Conveyor systems, from the smooth glide of a roller conveyor to the upward surge of a vertical conveyor, are essential components of contemporary logistics and industry. They transport products swiftly, correctly, and reliably, helping businesses to meet demand while remaining competitive in an increasingly fast-paced world.

So, the next time you receive a package in 24 hours or select a nicely wrapped food item off the store shelf, take a moment to appreciate the conveyor system that runs it. The unsung hero is responsible for moving everything.

0 notes

Text

While the terms “efficiency,” “cost-effectiveness,” and “safety” may be the keywords for retaining one’s competitive edge in modern manufacturing, the most plausible means to attain these would be with advanced technology. One such example of an advanced technological aid in improving workflow, reducing labor costs, and enhancing safety in manufacture is the Roller Conveyor System. Below are some of the amazing benefits of the roller conveyors, including companies like Yontro Mechatronic Systech that can help you realize the full benefits of this technology.

#Industrial Workstation#Roller Conveyor#Roller Conveyor System#Flat Belt Conveyor#Assembly Conveyor#Inclined Conveyor Belt

0 notes