#spaceframe structures

Explore tagged Tumblr posts

Text

Spaceframe Structure - McCoy

To know more about Spaceframe click the below link -

space frame model

0 notes

Photo

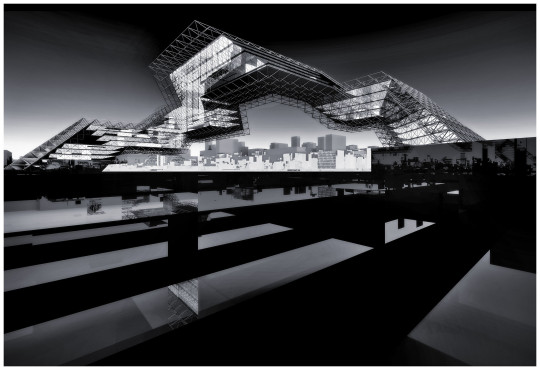

The space frame roof of the Kyoto Station is a striking and modern architectural feature that helps to make the building an iconic and easily recognizable landmark in the city of Kyoto.

#kyotojapan#kyotogram#stationtrain#travel#kyoto#trainstation#traveling#travelblogger#wanderlust#urbanshot#structure#roofing#infrastructure#steelstructure#spaceframe#structuredesign#diostructure#architecture#city#engineering#building#manmade

4 notes

·

View notes

Photo

The space frame roof of the Kyoto Station is a striking and modern architectural feature that helps to make the building an iconic and easily recognizable landmark in the city of Kyoto.

#kyotojapan#kyotogram#stationtrain#travel#kyoto#trainstation#traveling#travelblogger#wanderlust#urbanshot#structure#roofing#infrastructure#steelstructure#spaceframe#structuredesign#diostructure#architecture#city#engineering#building#manmade

2 notes

·

View notes

Text

With a superior build and unmatched quality, our coal shed ensures durability and reliability. Trust in the best for your storage needs.

1 note

·

View note

Text

Coal storage shed roof construction

✨ Wear-resistant and long life. 😜 Reasonable internal structure, convenient coal in and out. Fire and collapse prevention, ensuring safety. 👏 For coal storage, it is the best choice. 💕

Steel structure coal storage bunker

1 note

·

View note

Text

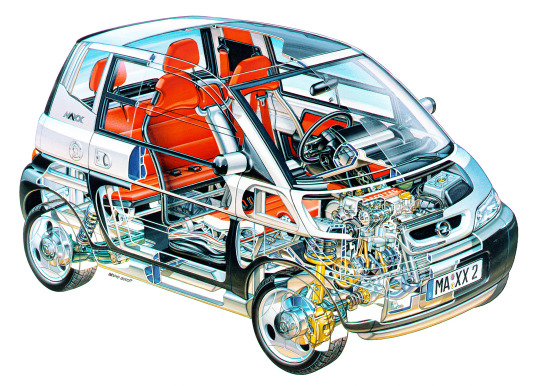

Opel Maxx Concept, 1995, by Bertone. A mini car prototype using an aluminium spaceframe structure that panels and windows hung off making them easily removable so that the car could be opened up

#Opel#Opel Maxx#Bertone#1995#mini car#small car#concept#prototype#design study#1990s#aluminium spaceframe#General Motors#General Motors Europe

124 notes

·

View notes

Text

Spaceframe structure [2014]

11 notes

·

View notes

Text

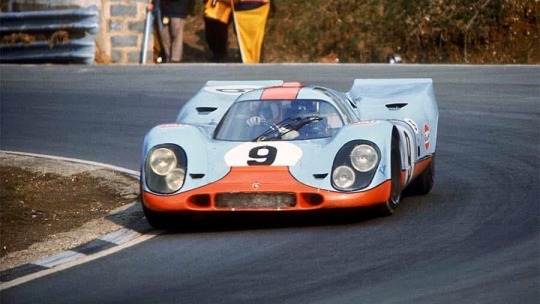

The death gage inside the Porsche 917

Nitrogen pressure gauge inside the Porsche 917. The aluminum spaceframe was made so thin that 3/4 failed on testing. 1/4 were put into use for the race cars. To calm the nerves of their drivers, they filled the chassis’ tube structure with nitrogen. If the chassis started to crack, which they did, the nitrogen would leak and pressure would drop, telling the driver chassis failure is imminent. It still wore on the nerves of their drivers.

Porsche discarded every chassis after every race.

14 notes

·

View notes

Note

What's your favorite subsystem on the Cerritos?

Other than propulsion, obviously

"other than propulsion" you're being cruel to me.

the tractor beams are pretty cool. People don't realize how much goes into maintaining them, from subspace field dynamics to structural engineering to, yes, coordination with the propulsion systems.

The Cerritos is designed for excellent towing characteristics. There are other towing-dedicated crafts, but none in regular service as large as the California class. And that means that the tractor emitters are under a LOT of physical stress, and over time that has worked some play into their supports. During refits we try to replace the structural members wherever we can, but eventually the entire spaceframe has begun to bend slightly. There's no getting around it when the Cerritos has to tow massive alien artifacts, adrift Galaxy class ships, and asteroid moons around on the regular.

So the tractor beam emitters have a LOT of complicated processing and calibration that needs to be maintained, and it's a job I liked to do. (Not as much as working on the impulse and reaction control systems)

5 notes

·

View notes

Text

1991 BMW Z11 E1 Concept

In an era when electric vehicles (EVs) were largely considered a futuristic fantasy, BMW took a bold step forward with the 1991 BMW Z11 E1 Concept. Unveiled at the 1991 Frankfurt Motor Show, the E1—internally code named Z11—was a pioneering effort by BMW Technik GmbH to merge sustainability with the brand’s hallmark driving dynamics.

Though it never reached production, the E1 was a radical departure from BMW’s gasoline-powered lineup of the early 1990s. At just 11.4 feet (3.46 meters) long, it was a compact hatchback designed for urban environments. Its lightweight construction was a standout feature: an extruded aluminum spaceframe provided structural rigidity, while plastic body panels kept the curb weight down to approximately 1,984 lbs (900 kg ). This focus on efficiency foreshadowed the lightweight philosophies later seen in BMW’s i-series electric cars. The design was both functional and forward-thinking. Aerodynamic lines and a minimalist aesthetic gave it a sleek, modern look, while the iconic kidney grille—hiding a charging port—nodded to BMW’s heritage. Inside, the E1 offered a spartan yet practical cabin, prioritizing space efficiency for its four occupants over luxury flourishes.

At the heart of the Z11 E1 was a 50 hp (37 kW) electric motor mounted at the rear, driving the rear wheels in true BMW fashion. This setup delivered a top speed of 75 mph (120 km/h)—respectable for a city-focused EV—and a range of around 124 miles (200 km), thanks to its innovative sodium-sulfur battery pack. While sodium-sulfur technology promised high energy density, it also required high operating temperatures, presenting practical challenges that BMW sought to address. For 1991, these specs were groundbreaking. The E1 proved that an electric car could offer usable range and performance without sacrificing the engaging drive that BMW was known for. Acceleration was modest, but the instant torque of the electric motor made it nimble in urban settings.

Despite its promise, the Z11 E1 Concept faced an abrupt end. The sole prototype was tragically destroyed in a fire during a charging session—an incident attributed to the experimental sodium-sulfur battery. This setback, combined with the high costs of production and a market not yet ready for mass EV adoption, led BMW to shelve the project. However, the E1’s legacy endured, influencing future electric concepts and eventually culminating in the 2013 BMW i3.

The 1991 Z11 E1 Concept was more than a one-off experiment; it was a proof of concept that electric mobility could align with BMW’s core values. Its lightweight construction, rear-wheel-drive layout, and focus on efficiency laid the groundwork for the company’s later electrification efforts. Today, as EVs dominate automotive innovation, the E1 stands as a reminder of BMW’s early willingness to push boundaries.Though it never hit the streets, the E1’s story resonates with enthusiasts and historians alike. It was a glimpse into a future that, at the time, seemed distant—but one that BMW helped bring closer with every subsequent electric endeavor.

0 notes

Link

Have you been thinking of using the best material in the construction of the new store? Perhaps, you can avail space frames to create a solid foundation for your new store. Here, we will share with you what is a space frame, and what are the advantages of having it installed.

#Space Frame Company#Space Frame Design#Frame Manufacturers USA#Spaceframe Buildings#Space Frame Structure#Architecture#Design#Engineers#USA

1 note

·

View note

Text

Spaceframe Structure - McCoy

To know more about Spaceframe click the below link -

space frames design

0 notes

Photo

The Kyoto Station's space frame roof is a marvel of engineering, held up by a series of slender steel columns that are rooted in foundation beams. A network of steel beams and girders forms the roof's top, combining to create a striking triangular pattern. These shapes are cleverly interconnected to create a lattice-like structure that lets light and air into the building's interior.

#kyotojapan#kyotogram#stationtrain#travel#kyoto#trainstation#traveling#travelblogger#wanderlust#urbanshot#structure#roofing#infrastructure#steelstructure#spaceframe#structuredesign#diostructure#architecture#city#engineering#building#manmade

0 notes

Link

#Airport Steel Structure manufacturer#Airport terminal buildings manufacturer#Airport space frame structure#long span structures#spaceframe#airport terminal building

0 notes

Text

Choose a steel structure ceiling to add more space to your warehouse.

1 note

·

View note

Photo

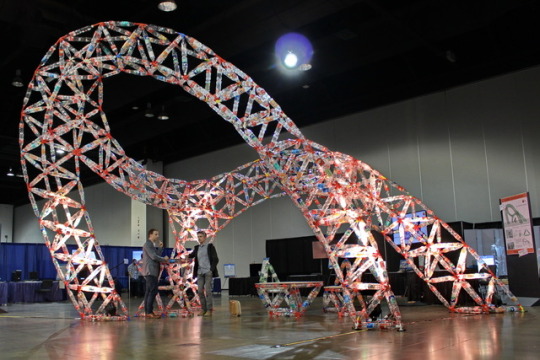

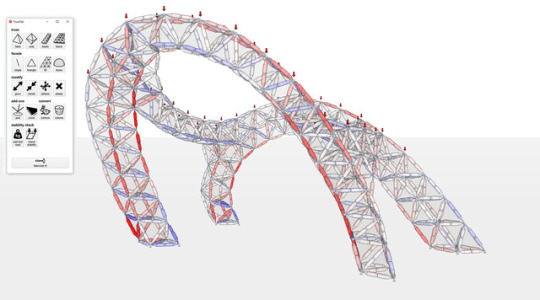

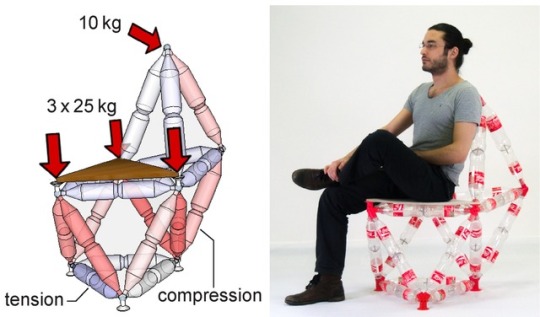

With only Trussfab’s Sketchup editor, a desktop 3D printer, and the necessary materials, anyone can now design and fabricate a large-scale structure capable of supporting human weight. Once the main truss structure has been created, users can also add decorative facades and other details. For non-structural parts of a design, if desired the Trussfab system will also design flat facades with hubs that can be laser-cut instead of 3D printed, the files for which are also automatically generated. Today: This Sketchup Plugin Designs Structures Made From Plastic Bottles and 3D-Printed Joints

The capabilities of personal 3D printing and fabrication are only beginning to be tested, but a new system is pushing the boundaries for feasible, structurally-sound large scale structures. Unlike other structures created by 3D printing systems, Trussfab doesn’t require access to specialized equipment, nor specific engineering knowledge, to print and build large-scale structures capable of supporting human weight. Phd researcher Robert Kovacs with his team from the Human Computer Interaction Lab at the Hasso Plattner Institute in Potsdam, Germany created Trussfab as an end-to-end system allowing users to fabricate sturdy, large-scale structures using plastic bottles and 3D-printed connections, making them easy and relatively quick to construct.

Trussfab treats plastic bottles like beams, forming structurally-sound closed triangles which join together to form trusses. These trusses are the basic building blocks of any Trussfab structure. The Trussfab editor is available as a plugin to Sketchup, in which the embodied engineering knowledge within the program allows users to validate their designs using the integrated structural analysis. The Sketchup plugin has the option to automatically convert an existing 3D model into a Trussfab structure, in addition to the capability to build and manipulate a structure from scratch.

#3D printing#recycling#Trussfab#Sketchup#truss structure#plastic bottles#3D-Printed Joints#design#spaceframe#construction

1 note

·

View note