#spm automation solutions

Explore tagged Tumblr posts

Text

Why Every Process Automation Consultant Relies on Smart Conveyor Solutions

n today’s fast-paced manufacturing world, efficiency isn't just about speed, it's about building systems that work together seamlessly. Among all components in a factory’s automation setup, the conveyor system plays a central role. For any experienced process automation consultant, a smart, responsive conveyor isn’t just equipment it’s the backbone of a well-integrated operation.

Whether it's streamlining movement, reducing labor fatigue, or enabling predictive workflows, conveyors are essential to how automated plants function today.

Conveyors: The Hidden Engine Behind Automation

At first glance, a conveyor might seem like a simple mechanical setup but in reality, it's one of the most critical tools in industrial automation. Modern conveyors are capable of:

Adjusting speeds based on load

Integrating with sensors and control systems

Communicating data for performance tracking

Reducing downtime through built-in diagnostics

In this sense, they don’t just move materials, they support the logic, efficiency, and rhythm of the entire production line.

The Consultant’s First Check: Material Flow

When a process automation consultant begins work on an automation strategy, the first step is understanding how materials move. Poor material handling is often the root cause of slowdowns, inconsistencies, or safety issues on the floor.

That’s where conveyor systems come in and why working with a reliable conveyor system manufacturer in India is so important. These systems need to be designed not just for the present, but for future expansions, layout changes, and new automation tools. This level of foresight and flexibility is what defines a truly scalable solution.

High-Impact Sectors for Smart Conveyor Systems

Today’s conveyor systems aren’t one-size-fits-all. They’re highly engineered solutions tailored to the demands of specific industries, including:

Automotive: Synchronized conveyors for just-in-time assembly

Pharmaceuticals: GMP-compliant systems with hygiene-friendly materials

Electronics: Anti-static conveyors with vision system integration

Logistics & E-commerce: Automated sorters and belt systems for fast order fulfillment

These examples show how integral conveyors are to mo

dern automation supporting not just speed, but precision, data, and decision-making.

What Consultants Look for in a Conveyor Partner

For consultants working on full automation projects, the right conveyor partner makes all the difference. Important considerations include:

Custom engineering capabilities

System integration with robots, sensors, and PLCs

Post-installation support and service

Safety features and operator-friendly controls

That’s why many consultants prefer working with manufacturers who offer not just products, but problem-solving manufacturers who understand real-world factory environments.

Why Pure Machine Design Is a Trusted Choice

At Pure Machine Design, we specialize in building conveyor systems that fit seamlessly into automation plans. As a practical, engineering-driven team, we don’t just deliver hardware we deliver performance. We collaborate with process automation consultants, system integrators, and plant engineers to build conveyors that are smart, compact, scalable, and tailored to your goals.

Being a forward-thinking conveyor system manufacturer in India, we focus on real-world implementation, not just CAD models. From concept to commissioning, Pure Machine Design stays hands-on to ensure your automation system delivers exactly what your operations need.Final Thoughts

Conveyors may seem like a small part of your automation setup, but they do the heavy lifting literally and strategically. With a well-planned conveyor system, designed by a manufacturer who understands automation end-to-end, you create a smoother, smarter, and more reliable production environment.

At Pure Machine Design, our conveyor systems are built not just to move but to move your business forward. Read more : Top Conveyor Companies in India and Their Role in Process Automation

0 notes

Text

Leading Automation Solutions and Robotic Welding Fixture Manufacturers in Pune and India

In this blog, we’ll explore how these technologies work and which companies are leading the way in Pune and across India.

Automation Solutions Companies in Pune

Pune is home to some of India’s best automation solutions companies. These companies help factories reduce human error, increase speed, and improve safety.

From assembly lines to material handling, automation plays a crucial role in modern manufacturing. PLC programming, SCADA systems, robotics integration, and sensor-based automation are now widely adopted.

Why choose automation solutions in Pune?

Skilled engineering talent

Strong IT and mechanical ecosystem

Cost-effective and scalable solutions

Some automation companies in Pune also offer complete turnkey projects. These include electrical control panels, robot cells, and HMI-based systems.

Whether you are in automotive, packaging, or FMCG, automation helps save time and reduce costs. Many companies in Pune now focus on Industry 4.0 technologies and smart factory integration too.

BIW Projects Design & Manufacturing Solutions Provider

BIW (Body-in-White) is a key phase in vehicle manufacturing. It involves the design and welding of the car body structure before painting. Companies that offer BIW project design and manufacturing solutions focus on both accuracy and speed.

What is BIW design?

BIW design involves:

Weld spot planning

Fixture design

Simulation for strength and rigidity

Robotic path planning

Leading providers ensure the entire BIW assembly line is optimized. From conveyors to clamps, every part is designed with precision.

Services provided by BIW solutions providers:

3D modeling and simulations

Robotic cell integration

Process validation

Fixture and gripper manufacturing

Turnkey BIW lines

The demand for BIW solutions is high in Pune due to the presence of top automotive OEMs and Tier-1 suppliers. Companies in this domain work with global quality standards and provide support from concept to commissioning.

Welding SPMs Design & Manufacturing in Pune

SPM (Special Purpose Machines) are custom machines designed for specific tasks. In welding, Welding SPMs are widely used for high-volume, repetitive jobs. Pune has many experienced players in designing and manufacturing welding SPMs.

These machines are tailored for:

Spot welding

MIG welding

TIG welding

Seam welding

Welding SPMs increase production efficiency and ensure consistent weld quality. Most machines are semi-automatic or fully automatic and can be integrated with robotic arms.

Benefits of Welding SPMs:

Reduced cycle time

Improved safety

High repeatability

Custom tooling options

Pune-based SPM manufacturers use CAD/CAM software and simulate the entire process before production. From fixture design to final assembly, everything is handled in-house.

They also offer after-sales service, control panel integration, and remote troubleshooting. That’s why industries in Pune trust local SPM makers for high-performance and durable welding machines.

Robotic Welding Fixtures Manufacturers in India

For robotic welding to work effectively, the fixtures holding the parts must be perfectly designed. This is where robotic welding fixtures manufacturers in India come into play.

What is a robotic welding fixture?

It is a tool used to:

Secure the components to be welded

Maintain alignment and accuracy

Allow easy loading and unloading

Minimize operator involvement

These fixtures are made with high-strength steel and use pneumatic or hydraulic clamping systems. Some also have sensors to detect part placement and alignment.

Leading Indian manufacturers offer:

Design and simulation of fixtures

Integration with robotic arms

Support for different weld processes

Customization based on component geometry

Robotic welding fixtures made in India are exported globally. These are used in industries like automotive, aerospace, defense, and construction machinery.

Why Pune and India Are Ideal for Automation and Welding Solutions

Pune and other Indian cities are now global players in the field of industrial automation and welding technologies. Here's why:

Skilled workforce: Engineers with mechanical, electrical, and automation expertise.

Cost-effective manufacturing: High quality at lower cost.

Technology integration: Use of advanced CAD tools, simulation software, and robotics.

Global supply chain: Export-ready capabilities with strong logistics support.

Whether you're setting up a new plant or upgrading an old one, Pune-based companies offer end-to-end solutions. From automation and SPMs to BIW systems and robotic fixtures, everything is locally available and globally reliable.

FAQs

Q. What are automation solutions in manufacturing? Automation solutions involve using machines, sensors, and software to run industrial processes with minimal human input.

Q. What is BIW in the automotive sector? BIW stands for Body-in-White, the stage in car manufacturing where the vehicle frame is assembled before painting.

Q. How do SPMs improve productivity? Welding SPMs are designed for speed, accuracy, and repetitive tasks. They cut down manual work and increase efficiency.

Q. Are robotic welding fixtures expensive? Not necessarily. Indian manufacturers offer cost-effective fixtures that meet international standards.

Q. Can I get custom automation solutions in Pune? Yes, many Pune-based companies offer customized automation systems based on your industry needs.

Final Thoughts

If you are searching for:

Automation solutions companies in Pune

BIW projects design & manufacturing solutions provider

Welding SPM’s design & manufacturers in Pune

Robotic welding fixtures manufacturers in India

— then Pune is the place to explore top-tier engineering and manufacturing partners.

These companies not only offer cutting-edge products but also partner with you through the entire journey—from design to delivery.

#automation solutions pune#BIW projects india#welding SPMs pune#robotic welding fixtures india#industrial automation#smart manufacturing#automotive manufacturing india#special purpose machines#robotics integration#pune engineering companies#robotics welding

0 notes

Text

Royal Cyber: Market Leader in Latest Technologies, Solutions, and SaaS Products

Services | Platforms | Industries | Innovations | Resources | Company | Careers | Contact Us

ServiceNow Brilliance Unleashed: Chosen by Peers, Recognized by Gartner

Transform Your ServiceNow Experience

As your dedicated ServiceNow partner, Royal Cyber offers top-tier ServiceNow services. Our skilled professionals specialize in various modules, ensuring your organization excels on this robust platform. Trust us to elevate your ServiceNow experience with unmatched expertise and commitment.

Get Started with ServiceNow Today!

Gartner-Endorsed ServiceNow Partner

Our ServiceNow Partnership

Royal Cyber, founded on trust, expertise, and shared success, empowers your organization with:

Cutting-Edge Solutions

Certified Experts

Priority Support

Proven Success

ServiceNow Expertise

ServiceNow ITOM: Optimize your IT infrastructure with our deep understanding of IT Operations Management.

ServiceNow ITAM: Gain control over your IT assets, reduce costs, and enhance compliance with our expertise in IT Asset Management.

ServiceNow ITSM: Streamline IT service processes and improve customer satisfaction with IT Service Management.

ServiceNow SPM: Drive business success through efficient resource allocation with Strategic Portfolio Management.

ServiceNow GRC: Manage risks, vendor compliance, and ensure long-term resilience with Governance, Risk, and Compliance.

ServiceNow HRSD: Enhance employee experiences and efficiency with Human Resources Service Delivery.

ServiceNow SecOps: Stay secure with proactive threat detection and incident response through Security Operations.

ServiceNow CSM: Enhance customer satisfaction and loyalty with Customer Service Management.

ServiceNow Now Assist: Elevating Business Workflows with Advanced AI Solutions

ServiceNow CMDB: Unlock the power of your IT infrastructure with our comprehensive CMDB Assessment.

Source-To-Pay: Transform Source-To-Pay operations with ServiceNow.

Cherwell Alternative: Seamlessly migrate from Cherwell to ServiceNow.

Washington DC Release: Streamline operations with new features.

ServiceNow Services

Royal Cyber offers tailored services to meet your business needs:

Implementation: Start or enhance your ServiceNow setup.

Customization: Tailor ServiceNow to your unique requirements.

Integration: Seamlessly integrate ServiceNow with existing IT systems.

Support: Ensure smooth platform operation with dedicated support.

Training: Empower your team with essential skills.

Customized ServiceNow Solutions from RC Labs

GoTestPro: AI-driven test automation for ServiceNow.

Employee Rating Card: Intuitive employee performance management.

ServiceNow ADO: IT management with Azure DevOps integration.

Integration Wizard: Unlock seamless ServiceNow integration.

AI Assist: Reduce incident resolution turnaround time.

AI KnowledgeGen: Empower IT support with dynamic knowledge management.

VDI Intake: Provide a unified, consumer-like experience.

IT Helpdesk Automation: Automate IT operations tasks.

MS Teams + ServiceNow: Notifications for new or updated incidents.

SCCM Integration: ServiceNow Graph Connector for SCCM.

Copilot: Future of enterprise operations with ServiceNow and Copilot.

ServiceNow for Industry Verticals

Healthcare: Improve patient care and streamline operations.

Financial Services: Enhance compliance and efficiency.

Retail: Optimize customer service and operations.

Manufacturing: Streamline production and supply chain management.

Telecommunications: Improve network management and customer service.

Education: Modernize and enhance service delivery.

Government: Drive transparency and citizen service excellence.

Energy and Utilities: Optimize resource allocation and reliability.

Hire a ServiceNow Developer

Unlock the full potential of ServiceNow for your business. Hire a Royal Cyber developer to tailor solutions to your needs.

Request a Quote!

Real Results with ServiceNow

Explore Our Case Studies

Request a Quote!

Financial Services: Increased HR operational efficiency by 60% with HRSD.

Hospitality Operations: Success story in streamlining operations.

Manufacturing: Efficiency with workflow automation.

Contact Sales Team: 1.630.355.6292 | [email protected]

#ServiceNow#CustomerEngagement#CustomerService#OrderManagement#EngagementMessenger#NextExperience#CustomerSupport#BusinessEfficiency#ServiceNowConsultingServices#ServiceNowDevelopment#ServiceNowIntegration

1 note

·

View note

Text

CNC Job Work in India – Precision Machining by Vihir Engineering

In today's rapidly evolving manufacturing landscape, precision, consistency, and speed are critical. That's where Vihir Engineering steps in—as a leading provider of CNC job work in India, delivering world-class machining solutions for a variety of industries including automotive, hydraulics, pharmaceuticals, packaging, and diamond tooling.

About Vihir Engineering

Located in Ahmedabad, Gujarat, Vihir Engineering is an ISO 9001:2015 certified company specializing in:

CNC Machining Job Work

VMC & 4-Axis Job Work

Custom Precision Component Manufacturing

SPM Machining & Investment Casting Support

With a strong commitment to quality and accuracy, Vihir Engineering serves clients across India with tailor-made machining services built on modern infrastructure and skilled manpower.

CNC Job Work Services We Offer

CNC Milling & Turning

High-precision operations on metals and alloys using CNC-controlled machinery. We ensure exact dimensions and smooth surface finishes.

VMC & 4th-Axis Machining

Complex, multi-dimensional parts machined with speed and accuracy using advanced Vertical Machining Centers.

Prototype & Custom Part Manufacturing

From one-off prototypes to small-batch and bulk production, we provide scalable solutions.

Component Categories

Hydraulic Parts

Pump & Valve Bodies

Automotive Components

Mould & Die Elements

Pharma & Packaging Machinery Parts

Diamond Tool Housings

Industries We Serve

Automotive

Pharmaceutical

Industrial Machinery

Diamond Tooling

Hydraulics & Pumps

Packaging Equipment

Whether you're a startup building prototypes or an OEM looking for reliable bulk machining, Vihir Engineering has the tools, technology, and talent to meet your requirements.

CNC Job Work Trends in India

India’s CNC machining industry is booming, with a growing need for high-precision, cost-effective parts. Companies like Vihir Engineering are bridging the gap between design and manufacturing by:

Supporting just-in-time manufacturing

Enabling small-batch production runs

Reducing production time through automation

Minimizing material waste through CNC accuracy

Contact Us for CNC Job Work

Vihir Engineering, Ahmedabad, Gujarat Email: [email protected] Website: https://vihir.in Phone: Mentioned on the website’s contact page

Let’s Work Together

Need custom CNC machined parts, die & mould job work, or precision metal components? Partner with Vihir Engineering for efficient, cost-effective, and quality-driven CNC job work in India.

Request a Quote Today → https://vihir.in/contact

0 notes

Text

Industrial Handling Solutions

At 3D CAD Global, we deliver customized Industrial Handling Solutions that streamline operations, improve efficiency, and reduce manual effort in manufacturing environments. Our systems are designed to handle materials, parts, and products with precision, speed, and safety — across diverse industries such as automotive, electronics, FMCG, and engineering.

🔧 What Are Industrial Handling Solutions?

Industrial Handling Solutions refer to automated or semi-automated systems used to move, position, load, or transfer components during production. These solutions play a vital role in improving workflow, minimizing downtime, and enhancing the safety of workers on the factory floor.

⚙️ Our Handling Capabilities

At 3D CAD Global, we offer end-to-end support for material and part handling with:

Robotic Pick-and-Place Systems

Gantry and Linear Handling Units

Custom Grippers and End Effectors

Servo and Pneumatic Handling Solutions

Conveyor Integration and Synchronization

Load/Unload Stations for SPM and CNC Machines

All systems are integrated with PLCs, sensors, and HMI panels for intelligent control and real-time monitoring.

✅ Why Choose 3D CAD Global?

Custom-Engineered Designs based on your specific application

High-Speed, Accurate Handling for small or large components

Integration with Automation Systems to boost production flow

Enhanced Safety & Ergonomics for operator interaction

Tested for Performance, Durability, and Reliability

📈 Applications of Our Industrial Handling Solutions

Assembly lines and SPMs

Material feeding in packaging systems

Product transfer in robotic cells

Component handling in inspection systems

Palletizing and de-palletizing systems

🔍 Boost Your Manufacturing Efficiency

Let 3D CAD Global help you optimize your factory floor with advanced Industrial Handling Solutions that are reliable, scalable, and built for performance. Whether it’s a new project or an upgrade, we deliver precision handling that matches your production goals.

📩 Get in touch today to discuss your handling automation needs. 🌐 Visit: www.3dcad-global.com

0 notes

Text

Precision and Power in One Setup with Vertical Turning Lathes, 5-Axis Turnmills, and Special Purpose Machines

In the world of advanced manufacturing, the demand for precision, efficiency, and reliability is constantly growing. Industries ranging from aerospace and automotive to energy and heavy machinery are looking for machines that can keep up with complex requirements while optimizing time and resources. That’s where the synergy of a Vertical Turning Lathe, a 5-axis turnmill, and Special Purpose Machines comes into play.

Together, they form a trifecta that empowers manufacturers to produce intricate components with minimal error and maximum productivity. And when these technologies are delivered by an industry leader like WIDMA, the results speak for themselves.

Why a Vertical Turning Lathe is the Backbone of Heavy Machining

A Vertical Turning Lathe (VTL) is not just a machine—it’s a powerhouse for handling large, heavy, and awkwardly shaped workpieces. Unlike horizontal lathes, a VTL holds the workpiece vertically, allowing gravity to assist in positioning. This is particularly useful for parts such as brake discs, engine casings, and turbine housings.

The vertical orientation provides several advantages. For one, it offers excellent rigidity, which helps in achieving accurate cuts even under heavy load. It also simplifies the clamping of large components, minimizing setup time and reducing the chances of misalignment. With these benefits, manufacturers can maintain tight tolerances while improving throughput.

The VTL’s ability to perform turning, facing, boring, and grooving operations in a single setup makes it a go-to choice for applications where size, weight, and complexity matter.

The Versatility of a 5-Axis Turnmill Machine

If flexibility had a name in machining, it would be the 5-axis turnmill. This hybrid machine brings together the capabilities of both turning and milling, and then takes it several steps further with multi-directional control. What sets it apart is its ability to work on five axes simultaneously, enabling intricate operations on complex geometries without needing to reposition the workpiece.

Imagine producing a component with angled holes, contoured surfaces, and multiple features—all in one go. That’s the magic of a 5-axis turnmill. By reducing the number of setups, it not only saves time but also drastically cuts down the chances of human error. And because everything is done in a single clamping, the consistency in part quality is significantly improved.

From aerospace parts to medical implants and precision tooling, the 5-axis turnmill is designed for tasks that demand both complexity and accuracy. It also supports simultaneous turning and milling operations, which further enhances productivity in high-volume environments.

Special Purpose Machines: Built for Precision, Designed for Speed

Sometimes, standard machines just don’t cut it—literally and figuratively. That’s when Special Purpose Machines (SPMs) become essential. These machines are engineered to perform dedicated operations tailored to specific production needs. Whether it's drilling hundreds of identical holes, machining a specialized engine block, or automating a niche assembly process, SPMs are built to deliver repeatability at speed.

The key advantage of SPMs lies in their customizability. Since they are purpose-built, every feature—from tooling configuration to automation integration—is designed with the end-use in mind. This results in significantly reduced cycle times, higher accuracy, and lower operational costs in the long run.

Industries that rely on mass production or need to maintain ultra-consistent quality across batches—such as automotive, defense, and electronics—often find SPMs to be the most cost-effective solution.

How WIDMA Integrates These Technologies Seamlessly

When it comes to high-precision machining solutions, WIDMA has carved out a reputation for excellence. A division of Kennametal India, WIDMA is known for designing and manufacturing machines that not only meet but exceed industry standards. Their product range covers everything from advanced Vertical Turning Lathes and dynamic 5-axis turnmill machines to custom-built Special Purpose Machines for a variety of industries.

What sets WIDMA apart is their commitment to innovation and integration. For instance, a WIDMA VTL can be equipped with intelligent sensors and CNC controls that adapt in real-time, ensuring consistent performance even during long production runs. Similarly, their 5-axis turnmills are engineered for seamless multitasking—turning, milling, drilling, and tapping all in one station.

And let’s not forget WIDMA’s prowess in designing Special Purpose Machines. Their engineering teams work closely with clients to understand the production goals, then develop machines that fit perfectly into existing lines or create entirely new workflows optimized for speed and reliability.

Real Benefits You Can Measure

Consider a manufacturer that needs to machine a turbine casing. Traditionally, it might take two or even three different machines to complete all the operations—turning, facing, milling, and drilling. With a WIDMA 5-axis turnmill, that entire process can be done in a single setup. This not only cuts production time in half but also ensures better part consistency and reduces labor costs.

Now picture an automotive company that needs to produce thousands of identical transmission housings every month. Instead of relying on standard machining centers and dealing with constant retooling, they could invest in a WIDMA Special Purpose Machine that automates the entire process—from raw part to finished product—while maintaining micron-level precision.

Conclusion: Why WIDMA is the Right Choice

In a market where every second and every micron counts, manufacturers need more than just machines—they need smart, reliable, and high-performance solutions. That’s exactly what WIDMA delivers.

By combining the rugged strength of a Vertical Turning Lathe, the versatility of a 5-axis turnmill, and the efficiency of Special Purpose Machines, WIDMA provides a unified approach to modern machining. Their machines are not only engineered for today’s challenges but also designed with tomorrow’s innovations in mind.

If you're looking to boost your manufacturing capabilities with machines that offer precision, reliability, and value, WIDMA is the partner you can trust. Let WIDMA power your next breakthrough in machining excellence.

0 notes

Text

Revolutionizing Industrial Automation with Moldtek Engineering

In the fast-evolving world of industrial automation, Moldtek Engineering has emerged as a dynamic player, offering cutting-edge solutions for custom machinery and design services. As industries increasingly demand tailored systems to enhance productivity, Moldtek steps in with unmatched expertise in SPM design full form, which refers to Special Purpose Machines — innovative tools built for dedicated tasks beyond the capacity of standard machinery.

Moldtek's core strength lies in its ability to deliver precision-driven special purpose machine design services that align perfectly with the unique requirements of various manufacturing sectors. Whether it's for the automotive industry, pharmaceuticals, or heavy engineering, their team of seasoned engineers crafts machines that streamline operations, improve output quality, and reduce downtime.

What sets Moldtek apart is their emphasis on performance-focused special machine design that integrates advanced automation, robotics, and ergonomic layouts. Their solutions go beyond mere equipment — they provide strategic value by boosting operational efficiency and ensuring long-term reliability.

Another key area of Moldtek's excellence is SPM mechanical design, where mechanical robustness and functional accuracy take center stage. From conceptual sketches to detailed engineering drawings and 3D models, their design process ensures every mechanical component is optimized for strength, durability, and operational precision.

As industry demand for specialized equipment continues to rise, companies seek partners who understand the nuances of engineering custom machines. Moldtek Engineering not only meets this demand but leads the way with innovation, technical skill, and a client-focused approach.

In conclusion, Moldtek Engineering is redefining the future of industrial machinery through its expertise in special machine design, offering dependable and performance-oriented solutions that drive modern manufacturing forward.

0 notes

Text

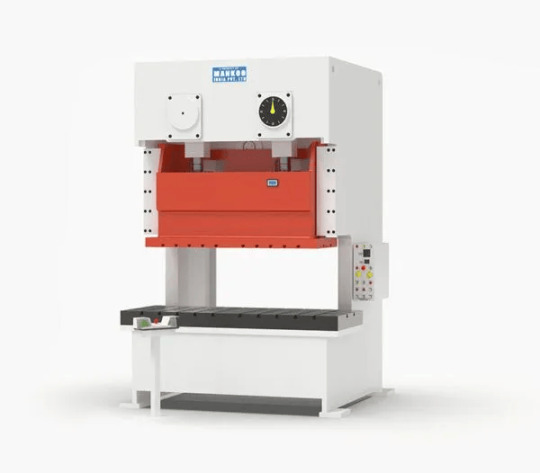

Crafting Heavy Forming with Ease – Mankoo Double Crank Power Press

In the industrial landscape, where precision and power drive productivity, Mankoo Presses stands out as a trusted name in heavy-duty metal forming machinery. Among its flagship innovations, the Double Crank Cross Shaft Press Machine is a high-performance solution designed for demanding applications across the manufacturing sector.

With its rugged build, precise synchronization, and consistent output, this machine symbolizes reliability and efficiency—ideal for operations that involve large dies, thick sheets, and high-tonnage production requirements.

Mankoo Presses – Engineering Excellence Since Inception

Based in Ludhiana, Punjab, Mankoo Presses has carved a niche in the metalworking industry with decades of experience and engineering innovation. Known for delivering heavy-duty presses that combine Indian manufacturing with global standards, Mankoo has become the preferred choice for manufacturers across automotive, appliance, electrical, and construction industries.

At the heart of its product lineup, the Double Crank Cross Shaft Power Press showcases Mankoo’s capability to deliver performance under pressure—literally.

Understanding the Double Crank Cross Shaft Power Press

This advanced machine is designed to handle large dies and high-impact forming operations. Unlike single crank presses, the double crank configuration ensures:

Greater slide stability

Uniform load distribution

A larger working bed

Precise parallelism for die sets

The cross shaft mechanism allows the power to be transmitted across a wide area, reducing deflection and increasing structural rigidity—key for mass production of heavy components.

Where It’s Used: Industrial Applications

Mankoo’s Double Crank Press is trusted by various industries due to its versatile performance:

Automobile Industry: Forming car body panels, engine parts, and chassis components

Appliances Manufacturing: Stamping parts for refrigerators, washing machines, and air conditioners

Electrical Industry: Manufacturing switchgear cabinets, electrical enclosures, and cable trays

Railway & Aerospace: Producing high-strength, structurally sound components

Agricultural Equipment: Forming parts for tractors, ploughs, and mechanical tools

If your production demands volume, accuracy, and durability—this is the machine to count on.

Why Choose Mankoo’s Double Crank Power Press?

1. Superior Build Quality

Mankoo uses high-grade alloy steel and precision machining in the construction of its press bodies, ensuring long-term reliability even in demanding production cycles.

2. High Efficiency

The double crank setup allows for faster operation, better force distribution, and lower vibrations. It handles large dies with less stress on the frame and tooling, enhancing efficiency without compromising safety.

3. Wide Bed & Slide Area

Its large working area supports bigger tooling, enabling the production of oversized components in fewer operations.

4. Safety & Automation Ready

Equipped with:

Pneumatic clutch & brake system

Hydraulic overload protector

Centralized automatic lubrication

Emergency stop controls It also supports automation through feeders, conveyors, and robotic integration—making it future-ready.

5. Custom-Built to Order

Mankoo offers customized models based on client-specific tonnage, stroke length, and die height—ensuring that every machine fits into your workflow perfectly.

Technical Specifications (Typical Range)

Each Mankoo Double Crank Cross Shaft Power Press can be tailored to your needs. Below are standard specification ranges:

Capacity: 250 to 1000 Tons

Stroke Length: 200 mm to 400 mm

Slide Adjustment: 100 mm to 150 mm

Die Height: 500 mm to 800 mm

Bed Area: 2000 x 1000 mm to 3500 x 1500 mm

Motor Power: 15 HP to 75 HP

Stroke per Minute (SPM): 20 to 50

These ranges reflect Mankoo’s ability to customize the press to suit diverse forming operations.

Low Maintenance, Long Life

Mankoo’s machines are engineered for longevity and ease of maintenance:

Centralized auto-lubrication reduces manual upkeep

Slide guides and bearings are built for long life

Quick-access doors make routine inspection hassle-free

Heavy-duty bearings ensure consistent alignment over years of operation

This not only lowers downtime but also reduces operating costs over the long term.

Global Standards, Local Support

Mankoo’s presses are proudly Made in India, with components that meet international quality benchmarks. Beyond domestic dominance, the brand exports to numerous countries, offering a global product with strong local support.

What makes Mankoo truly dependable is their dedicated after-sales service, including:

On-site commissioning & training

Scheduled maintenance programs

Rapid spare parts delivery

Remote or in-person technical assistance

Finally Boost Your Manufacturing Potential

The Mankoo Double Crank Cross Shaft Power Press is more than a machine—it’s a production powerhouse. Whether you're scaling your operations or seeking to improve output consistency, this press offers the force, form, and functionality your business needs to stay ahead.

By investing in Mankoo’s double crank system, you benefit from:

Higher uptime

Better accuracy

Long-term reliability

Support that grows with your operations

#Power Press machine#Double crank power press#press machine suppliers#power presses in India#Power presses in UAE#Power presses in Russia

0 notes

Text

Madox Technologies offers a comprehensive process control system designed to enhance accuracy, productivity, and real-time monitoring across industrial operations. As a trusted Control solutions company in Bangalore, we specialize in developing integrated automation frameworks that streamline complex processes. Our solutions are tailored for industries requiring high precision, including automotive, manufacturing, and assembly lines. With advanced integration of Nutrunner SPM in Bangalore, we ensure torque control and fastening accuracy for mission-critical tasks. Our systems support seamless connectivity with SCADA, PLC, and industrial IoT platforms, delivering efficiency and scalability. Choose Madox for intelligent control solutions that meet global standards.

0 notes

Text

How a Pipe Bending Machine for Pipeline Can Minimize the Risk of Damage

How Pipe Bending Machines Improve Pipeline Construction

SPM Equipment is a leading manufacturer and Exporter of Pipe Bending Machine. Pipeline infrastructure plays an important role in the Oil and Gas construction industry, requiring precision and durability to withstand extreme conditions. One of the most essential tools in this industry is the Pipe Bending Machine, which ensures accurate and damage-free bending of pipes. Improper bending can lead to pipeline failures, leaks, and costly repairs. In this, we will explore how a Pipe Bending Machine helps minimize the risk of damage, enhances efficiency, and contributes to the success of Oil and Gas construction projects.

The Importance of a Pipe Bending Machine in Oil and Gas Construction

1. Prevents Structural Weakness

Manually bending pipes or using outdated equipment can result in irregular bends, leading to weak points in the pipeline. A Pipe Bending Machine ensures precise and consistent bends, maintaining the structural integrity of the pipeline.

2. Reduces Material Waste

Without a high-quality bending machine, pipes may suffer from cracks, deformations, or incorrect angles. This leads to material wastage and increased project costs. Advanced Pipe Bending Machines eliminate these issues, reducing waste and optimizing resources.

3. Enhances Operational Efficiency

Manually bending pipes is time-consuming and labor-intensive. A Pipe Bending Machine automates the process, significantly increasing productivity while maintaining accuracy. In large-scale Oil and Gas construction projects, this efficiency is vital for meeting deadlines and reducing costs.

4. Improves Pipeline Safety

A poorly bent pipe can compromise the entire pipeline system, resulting in leaks or even catastrophic failures. A Pipe Bending Machine ensures smooth, even bends that reduce stress points and improve pipeline safety.

5. Facilitates On-Site Flexibility

Pipelines often need to be installed in challenging environments, such as remote areas or rugged terrains. Portable Pipe Bending Machines make it easier to handle on-site modifications, allowing adjustments without the need for extensive transportation and reworking.

Each of these machines is built to handle different pipe sizes and materials, making them ideal for various pipeline applications.

Benefits of Using a Pipe Bending Machine

1. Consistency and Precision

A Pipe Bending Machine guarantees uniform bends, eliminating inconsistencies that could lead to operational failures in Oil and Gas construction.

2. Cost-Effective Solutions

By minimizing material wastage and reducing labor costs, businesses can achieve greater cost savings in pipeline construction and maintenance.

3. Increased Durability of Pipelines

Well-bent pipes reduce stress concentration and enhance the longevity of pipelines, ensuring they withstand extreme pressures and temperatures.

4. Environmentally Friendly Operation

With minimal waste generation and efficient energy consumption, modern Pipe Bending Machines contribute to sustainable pipeline solutions.

Applications of Pipe Bending Machines in Oil and Gas Construction

Pipeline Construction & Maintenance – Essential for forming bends in long-distance oil and gas pipelines.

Offshore & Marine Industry – Used in building subsea pipelines and offshore rig structures.

Refinery & Petrochemical Plants – Helps create efficient piping systems for transporting raw materials and finished products.

Infrastructure Development – Supports the creation of underground and above-ground pipeline networks.

Choosing the Right Pipe Bending Machine

When selecting a Pipe Bending Machine, consider the following factors:

Pipe Material & Diameter Compatibility – Choose a machine that supports the type and size of pipes used in your projects.

Bending Angle & Radius Requirements – Look for models that provide flexibility in bending angles and radii.

Machine Portability – Opt for transportable models if on-site adjustments are necessary.

Durability & Performance – Select machines made from high-quality materials for long-lasting use in harsh environments.

Why Choose Spm Equipment?

At Spm Equipment, we are the leading manufacturer of Pipe Bending Machines for Oil and Gas construction. Our machines are designed with cutting-edge technology, high durability, and user-friendly controls to enhance productivity and precision. With our commitment to quality, we provide robust solutions that help pipeline projects run smoothly and efficiently. Whether you need a machine for large-diameter pipes or high-pressure pipeline applications, we have the perfect solution to meet your needs.

Conclusion

A Pipe Bending Machine is a vital asset in Oil and Gas construction, minimizing the risk of pipeline damage and enhancing operational efficiency. By investing in high-quality bending machines, companies can achieve safer, more cost-effective, and durable pipeline systems.

For more information about advanced Pipe Bending Machines and how they can improve your pipeline projects, call us at +91 9574770022 or email us at [email protected]. Our experts are here to provide tailored solutions for your specific project needs.

0 notes

Text

https://www.puremachinedesign.com/?utm_source=offpage&utm_medium=Ymay&utm_campaign=social&utm_id=19%2F57

"India’s Leading Provider of SPM Design and Automation Solutions

Pure Machine Design is a top-rated company offering SPM design services in India. They specialize in designing and delivering high-quality Special Purpose Machines (SPMs) customized for industrial needs. Recognized as the best SPM design provider in India, they help businesses automate, optimize, and innovate their manufacturing processes through smart engineering and tailored machine solutions."give tags

#SPM design services India#Special Purpose Machines#SPM design company#SPM automation solutions#Industrial automation India

0 notes

Text

Revolutionizing Manufacturing: How Automation Solutions Companies in Pune Are Reshaping India's Industrial Future

The bustling industrial hub of Pune has emerged as the epicenter of India's automation revolution, where cutting-edge technology meets traditional manufacturing excellence. As global markets demand faster production cycles and higher precision, automation solutions companies in Pune are stepping up to transform the way industries operate across the country.

From automotive giants to aerospace manufacturers, businesses are increasingly turning to robotic automation solutions providers to maintain their competitive edge in an evolving marketplace. This transformation isn't just about replacing manual labor—it's about reimagining entire production processes to achieve unprecedented levels of efficiency, quality, and safety.

The Thriving Ecosystem of Automation Solutions Companies in Pune

Pune's strategic location, robust infrastructure, and skilled workforce have created the perfect storm for automation excellence. The city now hosts numerous automation solutions companies in Pune that cater to diverse industrial needs, from simple material handling systems to complex robotic welding lines.

The Indian Automation Solutions Industry is experiencing explosive growth, with India Industrial Automation Market valued at USD 16.2 billion in 2024 and expected to reach USD 37.42 Billion by 2030, projecting robust growth with a CAGR of 14.8% through 2030. This remarkable expansion reflects the increasing adoption of automation technologies across various sectors.

Key Players Driving Innovation

The city's automation landscape features a diverse mix of established players and innovative startups. These companies specialize in:

Robotic welding and assembly systems: Advanced solutions for automotive and manufacturing industries

Special Purpose Machines (SPMs): Custom-designed equipment for specific industrial processes

Process automation: Integrated systems that optimize entire production workflows

Material handling solutions: Automated systems for warehouse and factory operations

Understanding the Robotic Automation Solutions Provider Landscape

A robotic automation solutions provider does more than just supply equipment—they serve as strategic partners in industrial transformation. These companies offer comprehensive services that include system design, integration, installation, and ongoing support.

Core Services Offered

System Integration: Modern automation providers excel at integrating multiple technologies into cohesive solutions. They combine robotics, artificial intelligence, sensors, and control systems to create seamless production environments.

Custom Engineering: Every manufacturing process has unique requirements. Leading providers offer bespoke solutions tailored to specific industry needs, whether it's automotive assembly lines or medical device manufacturing.

Technology Consultation: With the rapid pace of technological advancement, businesses need guidance on selecting the right automation solutions. Expert providers offer strategic consulting to help companies make informed decisions about their automation investments.

Training and Support: Successful automation implementation requires skilled operators. Top providers offer comprehensive training programs and ongoing technical support to ensure optimal system performance.

Industry Applications Transforming Manufacturing

The versatility of modern automation solutions has enabled their adoption across numerous industries:

Automotive Sector: From robotic painting systems to automated assembly lines, the automotive industry has been at the forefront of automation adoption. Pune's proximity to major automotive manufacturers has made it a natural hub for automotive automation solutions.

Aerospace and Defense: Precision manufacturing requirements in aerospace have driven demand for sophisticated automation systems. Companies specializing in this sector offer solutions for complex machining, assembly, and quality control processes.

Medical Device Manufacturing: The medical device industry's stringent quality requirements have created opportunities for specialized automation providers. These systems ensure consistent quality while maintaining the sterile conditions required for medical device production.

Electronics and Semiconductors: The miniaturization of electronic components has created demand for ultra-precise automation systems. Specialized providers offer solutions for PCB assembly, component placement, and testing processes.

The Indian Automation Solutions Industry: A Growth Story

The Indian Automation Solutions Industry is experiencing unprecedented growth, driven by several key factors that are reshaping the manufacturing landscape across the country.

Government Initiatives Fueling Growth

The Indian government's "Make in India" initiative has created a favorable environment for automation adoption. Manufacturing production in India increased by 5.7% year-over-year in May 2023, exceeding market estimates of 1.8%. The government's initiatives like "Make in India" and favorable FDI policies are fostering an environment conducive to automation implementation.

Industry 4.0 Adoption

The India Industry 4.0 market revenue is projected to reach from USD 5,373.3 million in 2024 to USD 21,862.0 million by 2032, growing at a CAGR of 19.2% during the forecast period. This remarkable growth demonstrates the increasing integration of smart technologies in manufacturing processes.

Competitive Advantages Driving Adoption

Labor Cost Optimization: While India has traditionally relied on its large workforce, rising labor costs and the need for greater precision are driving automation adoption. Companies are finding that automation provides long-term cost advantages while improving product quality.

Quality Consistency: Automated systems eliminate human error and ensure consistent quality across production runs. This is particularly important for industries with strict quality standards, such as automotive and medical device manufacturing.

Scalability: Automation solutions provide the flexibility to scale production up or down based on market demands. This adaptability is crucial in today's volatile market conditions.

Safety Enhancement: Automated systems can perform dangerous tasks, reducing workplace accidents and improving overall safety standards. This is especially important in industries involving heavy machinery or hazardous materials.

Technology Trends Shaping the Future

Artificial Intelligence Integration

Modern automation solutions increasingly incorporate AI capabilities, enabling predictive maintenance, quality control, and process optimization. Machine learning algorithms analyze production data to identify patterns and optimize performance continuously.

Collaborative Robotics

The rise of collaborative robots (cobots) has made automation more accessible to small and medium enterprises. These robots work alongside human operators, combining the precision of automation with human flexibility and decision-making capabilities.

IoT and Connectivity

Internet of Things (IoT) integration allows for real-time monitoring and control of automated systems. This connectivity enables remote diagnostics, predictive maintenance, and data-driven optimization of production processes.

Sustainability Focus

Environmental concerns are driving demand for energy-efficient automation solutions. Modern systems are designed to minimize energy consumption while maximizing productivity, contributing to sustainable manufacturing practices.

Challenges and Opportunities

Skills Gap and Training

The rapid adoption of automation technologies has created a skills gap in the workforce. However, this challenge presents opportunities for training providers and educational institutions to develop specialized programs for automation technicians and engineers.

Initial Investment Concerns

While automation provides long-term benefits, the initial investment can be substantial. This has led to the development of flexible financing options and phased implementation strategies that make automation more accessible to smaller companies.

Customization Requirements

Every manufacturing process is unique, requiring customized automation solutions. This presents opportunities for providers who can offer flexible, adaptable systems that can be tailored to specific requirements.

The Future of Automation in Pune

Emerging Technologies

The future of automation in Pune looks incredibly promising, with emerging technologies like quantum computing, advanced AI, and next-generation sensors poised to further revolutionize manufacturing processes.

Ecosystem Development

Pune's automation ecosystem continues to evolve, with new players entering the market and existing companies expanding their capabilities. This competitive environment drives innovation and benefits end-users through improved solutions and competitive pricing.

Global Competitiveness

As Pune-based automation companies gain experience and expertise, they are becoming increasingly competitive in global markets. This international exposure brings new technologies and best practices back to the local market, further strengthening the ecosystem.

Frequently Asked Questions

What types of automation solutions are most popular in Pune?

Pune's automation companies specialize in robotic welding systems, assembly line automation, material handling solutions, and custom Special Purpose Machines (SPMs). The automotive and aerospace sectors drive significant demand for these solutions.

How do I choose the right automation solutions provider?

Look for providers with proven experience in your industry, comprehensive service offerings (design, installation, training, support), and a track record of successful implementations. Consider their ability to provide customized solutions that meet your specific requirements.

What is the typical ROI timeframe for automation investments?

Most automation investments show positive returns within 2-3 years, depending on the complexity of the system and application. Factors like labor cost savings, quality improvements, and increased productivity contribute to the ROI calculation.

Are automation solutions suitable for small and medium enterprises?

Yes, modern automation solutions are increasingly accessible to SMEs. Collaborative robots, modular systems, and flexible financing options make automation viable for smaller companies. Many providers offer scalable solutions that can grow with your business.

What industries benefit most from automation in Pune?

Automotive, aerospace, medical devices, electronics, and general manufacturing are the primary beneficiaries. However, automation applications are expanding into new sectors like food processing, pharmaceuticals, and logistics.

How important is ongoing support after automation implementation?

Ongoing support is crucial for maximizing automation benefits. This includes regular maintenance, software updates, operator training, and system optimization. Choose providers who offer comprehensive support packages.

What are the latest trends in robotic automation?

Key trends include AI-powered quality control, collaborative robotics, IoT integration for predictive maintenance, and sustainable automation solutions focused on energy efficiency.

Can existing manufacturing processes be automated?

Yes, most existing processes can be automated to varying degrees. The key is conducting a thorough assessment to identify automation opportunities and develop a phased implementation strategy that minimizes disruption to current operations.

The transformation of India's manufacturing sector through automation is not just a technological shift—it's a fundamental reimagining of how products are made, quality is ensured, and competitiveness is maintained in a global market. As automation solutions companies in Pune continue to innovate and expand their capabilities, they are not just serving local markets but positioning India as a global leader in automated manufacturing solutions.

This revolution is creating new opportunities for businesses of all sizes to enhance their operations, improve quality, and compete more effectively in domestic and international markets. The future of manufacturing in India is being written today, and Pune is at the center of this exciting transformation.

#robotics engineering#robotics technology#robotics innovation#machinery#automation#automation solutions#welding technology#welding supplies#welding services#Indian welding machines

0 notes

Text

Introduction

IBM Cúram Online Training Top & Best Score of Banglore 2025 is a comprehensive Social Program Management (SPM) solution designed to help government agencies and social organizations deliver effective and efficient services to citizens. It provides case management, eligibility determination, benefits administration, and compliance tracking to improve service delivery in sectors like healthcare, social security, and workforce programs.

IBM Cúram Online Training is designed to equip professionals with the skills needed to configure, implement, and manage IBM Cúram solutions. This training is ideal for IT professionals, business analysts, social service workers, and consultants who want to specialize in SPM and enhance their careers in the public sector and social services industries.

Key Features of IBM Cúram Online Training

Comprehensive Course Content – Covers IBM Cúram functionalities, case management, eligibility rules, and workflow automation.

Hands-on Practical Training – Real-time scenarios, case studies, and hands-on exercises for practical exposure.

Expert-Led Sessions – Training is delivered by certified IBM Cúram consultants with real-world experience.

Flexible Learning Modes – Provides instructor-led, self-paced, and virtual training options.

Certification Assistance – Helps learners prepare for IBM Cúram certification exams to enhance their credentials.

Course Curriculum

The IBM Cúram Online Training typically includes:

Introduction to IBM Cúram – Overview of SPM, architecture, and key functionalities.

Case Management – Managing citizen cases, service plans, and benefits tracking.

Eligibility and Entitlement Rules – Configuring eligibility criteria, rules-based assessments, and automated decision-making.

Cúram Workflow and Business Processes – Automating social service workflows and approvals.

Cúram Data Model and Security – Understanding data structures, security roles, and access control.

System Configuration and Customization – Configuring Cúram applications to meet specific agency requirements.

Integration with External Systems – Connecting IBM Cúram with other enterprise applications for seamless operations.

Benefits of IBM Cúram Online Training

Specialized Career Opportunities – High demand for IBM Cúram consultants in government and social service sectors.

Increased Salary Potential – Certified professionals can earn competitive salaries due to specialized expertise.

Global Recognition – IBM Cúram certification is internationally recognized and valued.

Practical Hands-on Experience – Gain real-time exposure to Cúram implementations and case management solutions.

Enhanced Public Service Delivery Skills – Learn to optimize social program operations and improve citizen engagement.

Who Should Attend?

Business Analysts

IT Professionals

Social Service Administrators

SAP/ERP Consultants

Government Program Managers

Developers and Technical Consultants

Conclusion

IBM Cúram Online Training is an excellent opportunity for professionals seeking expertise in social program management solutions. With increasing adoption by government agencies and social organizations, IBM Cúram professionals are in high demand. This training provides the necessary knowledge, hands-on experience, and certification preparation to help individuals secure high-paying roles and contribute to improving public service delivery

0 notes

Text

Handling

At 3D CAD Global, we specialize in intelligent handling solutions that streamline material movement, improve workflow efficiency, and enhance safety across automated systems. Whether it's part handling, component transfer, or product packaging, our customized solutions ensure precision and reliability at every step of the process.

🔧 What is Industrial Handling?

Handling in manufacturing and automation refers to the controlled movement of parts, tools, or materials within a production environment. It involves equipment and systems designed to lift, place, align, or transport components—either manually, semi-automatically, or fully automatically.

⚙️ Our Handling Capabilities Include:

Robotic pick-and-place systems

Pneumatic and servo-based handling arms

Gantry and linear transfer systems

Conveyor integration for smooth part movement

Custom grippers and end-effectors

Safe load/unload stations for manual interaction

✅ Why Choose 3D CAD Global for Handling Systems?

🔄 Custom Engineering – Tailored to your product and process

⚙️ Integrated Automation – Seamless coordination with PLCs, sensors, and machines

🚀 Increased Throughput – Reduce cycle times and human error

🛡️ Improved Safety – Minimize operator intervention and ensure safe material transfer

📈 Applications of Handling in Automation

Assembly line automation

Inspection and testing stations

Packaging and palletizing systems

Precision loading in CNC and SPM machines

Electronics and medical device manufacturing

Let 3D CAD Global help you transform your operations with efficient and reliable handling solutions. From concept to commissioning, we ensure smooth integration into your production line.

📩 Get in touch today to discuss how we can optimize your material handling systems.

#3dcad#3dcad global#3dcad india#handling#handling solutions#handling autmation#handling solutions for global industries

0 notes

Text

Enhancing Logistics Operations with Software Project Management Integration

In today’s fast-evolving logistics sector, efficiency and precision are key to maintaining a seamless supply chain. The integration of Software Project Management (SPM) into Logistics Software is a game-changer, ensuring structured workflow automation, streamlined project execution, and enhanced collaboration between teams. By incorporating project management methodologies into logistics systems, businesses can optimize operations, reduce risks, and achieve higher efficiency.

Understanding Software Project Management in Logistics

Software Project Management (SPM) is a systematic approach to planning, executing, and monitoring software-driven projects. When embedded within logistics software, it enables companies to manage shipments, warehouse activities, fleet operations, and customer service processes with greater control and accountability.

Learn how QuickMove’s Transport Management System (TMS) enhances logistics workflow automation.

Benefits of Integrating Software Project Management into Logistics Software

1. Structured Planning & Workflow Automation

With SPM, logistics companies can automate workflows, set milestones, and track progress in real time. Project timelines, assigned responsibilities, and task dependencies ensure smooth execution of freight forwarding, inventory management, and last-mile delivery operations.

Discover QuickMove’s Freight Forwarding Software to automate logistics planning and execution.

2. Efficient Resource Allocation

SPM tools integrated into logistics software allow businesses to optimize resource utilization by analyzing workload distribution, tracking fleet availability, and monitoring warehouse capacity.

Optimize warehouse operations with QuickMove’s Warehouse Management System (WMS).

3. Real-Time Collaboration & Communication

Project management integration fosters seamless collaboration between logistics teams, drivers, warehouse managers, and customers. It provides shared dashboards, automated alerts, and real-time reporting, ensuring all stakeholders stay informed.

Enhance customer interactions with QuickMove’s Customer Service Portal.

4. Risk Mitigation & Compliance Management

A structured project management approach in logistics helps identify potential risks, track compliance with regulatory requirements, and prevent bottlenecks before they disrupt operations.

5. Data-Driven Decision Making

By integrating SPM, logistics companies gain access to predictive analytics, performance reports, and KPI tracking, enabling data-driven decisions that improve overall supply chain efficiency.

How QuickMove Technologies Integrates Software Project Management in Logistics

QuickMove Technologies provides state-of-the-art logistics solutions that incorporate project management functionalities. With AI-powered analytics, cloud-based automation, and smart workflow tools, businesses can:

Reduce operational inefficiencies and enhance team productivity

Automate task tracking and real-time reporting

Ensure seamless integration between fleet, warehouse, and supply chain units

Drive strategic business growth with optimized logistics workflows

Explore how QuickMove’s SaaS-based logistics solutions enhance project-driven logistics operations.

Final Thoughts

Integrating Software Project Management into Logistics Software is a transformative approach for logistics businesses aiming to achieve operational excellence. By leveraging automated workflows, data-driven analytics, and real-time collaboration, logistics providers can enhance efficiency, reduce costs, and improve service quality.

To future-proof your logistics operations, consider adopting SPM-integrated logistics solutions. Partner with QuickMove Technologies today to unlock smarter, faster, and more efficient supply chain management.

0 notes

Text

Exploring Swift Package Manager: Simplifying Dependency Management for iOS Apps

In the world of iPhone mobile application development, managing dependencies can often be a daunting and time-consuming task. Developers face challenges when trying to integrate third-party libraries or frameworks into their projects. Without a streamlined process, dependency management can easily lead to version conflicts, compatibility issues, or unnecessary complexity in the project’s build system. Fortunately, Apple introduced the Swift Package Manager (SPM) as an official tool to handle these complexities, making it easier for developers to manage external dependencies and focus on writing high-quality code for their apps.

Swift Package Manager is integrated into the Swift toolchain and simplifies dependency management for iOS apps by offering a robust solution for including and distributing Swift code. Whether you’re working on a small-scale app or a large, enterprise-level project, SPM is a powerful tool that ensures dependencies are handled seamlessly, allowing iOS developers to focus on what matters most: creating intuitive, innovative applications for users. In this blog post, we’ll dive into how Swift Package Manager works, its benefits, and why it should be a vital tool for every iPhone mobile application development project.

What is Swift Package Manager?

Swift Package Manager is a tool that automates the process of managing libraries or packages in Swift-based projects. It was designed to work with the Swift programming language and has quickly become the standard way to manage third-party dependencies. Swift Package Manager is integrated into Xcode, which means it’s available for any iOS app development project, and it requires minimal configuration to use effectively.

Before Swift Package Manager, iOS developers relied on third-party tools like CocoaPods or Carthage to manage dependencies. While these tools were effective, they often introduced additional overhead, especially in terms of setup, configuration, and compatibility with new versions of Xcode. With SPM, however, Apple provides a streamlined solution that is natively supported within Xcode, making the whole process much simpler.

Benefits of Using Swift Package Manager

1. Simplicity and Integration with Xcode

The most significant advantage of Swift Package Manager is how seamlessly it integrates into Xcode. With just a few clicks, you can add a package to your project, and SPM handles the rest. No need to configure additional tools or manage complex files—everything is managed within Xcode’s native interface. This makes it especially appealing to developers who want a smooth and straightforward dependency management experience without dealing with extraneous configuration steps.

2. Version Control and Dependency Resolution

Managing versions is a common problem when dealing with third-party libraries. Swift Package Manager resolves this issue by ensuring that all dependencies and their specific versions are correctly aligned across the project. If there are multiple dependencies with shared libraries, SPM ensures they are compatible, eliminating potential conflicts.

In addition, SPM provides the ability to specify version ranges for dependencies, so you can ensure that you are using the most up-to-date or stable versions of libraries without breaking the compatibility with your project.

3. Open-Source and Community-Driven

Swift Package Manager is open-source, which means the development of the tool is driven by the community. Developers contribute to the improvement of SPM, ensuring it remains up to date and responsive to the needs of modern iOS app development. This open-source nature provides developers with the ability to track issues, contribute fixes, and participate in the evolution of the tool.

4. Cross-Platform Support

Another excellent feature of Swift Package Manager is its cross-platform compatibility. While it is most commonly used for iOS apps, SPM also supports macOS, watchOS, and tvOS projects, making it a versatile solution for managing dependencies across the entire Apple ecosystem. This flexibility allows developers to work on a variety of Apple platforms while maintaining a consistent approach to managing external libraries.

How to Use Swift Package Manager

Using Swift Package Manager in your iPhone mobile application development project is straightforward. To get started, you’ll need to launch Xcode and open your project. From there, you can add a Swift package by navigating to the "Swift Packages" section in your project settings. By entering the URL of the package you want to include, Xcode will automatically fetch and resolve the appropriate version for your project.

You can also customize your dependencies by specifying a version range or branch, ensuring compatibility with your project’s specific requirements. After adding the package, you can import it into your code and begin using it immediately—no need for extra setup steps. If your project contains multiple dependencies, SPM will handle all of them, ensuring that everything is resolved and correctly linked.

Mobile App Cost Calculator: Managing Project Budgets

One of the key challenges in iPhone mobile application development is keeping track of the costs associated with integrating external libraries and tools. With the increasing number of dependencies needed for modern iOS apps, managing development budgets can become complex. This is where a mobile app cost calculator can help.

A mobile app cost calculator is a useful tool for estimating the cost of building an app, taking into account various factors such as the number of dependencies, the complexity of the app, and the time required to implement them. By using such a tool, developers can better forecast the resources needed for their project and avoid unexpected costs associated with third-party integrations.

Streamlining Your Workflow with Swift Package Manager

As we’ve discussed, Swift Package Manager provides a simple yet powerful solution for managing dependencies in iOS app development. It reduces the complexity of integrating external libraries and helps avoid common pitfalls like version conflicts and compatibility issues. By streamlining your workflow, you can save time and focus on what truly matters—building great apps. If you're looking to make your iOS app development process more efficient, integrating Swift Package Manager into your workflow is a step in the right direction.

If you're interested in exploring the benefits of ios development services for your business, we encourage you to book an appointment with our team of experts. Book an Appointment

Conclusion

Swift Package Manager is a game-changer for developers working on iOS apps. It simplifies dependency management, reduces setup complexity, and integrates seamlessly with Xcode. If you are currently developing an app or planning to start a new iOS app development project, adopting Swift Package Manager is a smart choice that will help you save time and avoid headaches down the road. With its cross-platform support, version control capabilities, and ease of use, SPM is undoubtedly an essential tool in every iOS developer's toolkit.

By embracing Swift Package Manager, developers can ensure that their dependencies are managed with minimal hassle and focus on creating the best possible user experience. So, the next time you're working on an iOS app, consider incorporating Swift Package Manager for a smoother and more efficient development process.

0 notes