#terminals of electronic connectors

Explore tagged Tumblr posts

Text

How often should headlight bulbs be replaced?

The replacement frequency for headlight bulbs depends primarily on the bulb type, with significant differences in lifespan. Here’s a breakdown:

💡 By Bulb Type: Halogen Bulbs:

Lifespan: 450–1,000 hours (typically 1–3 years with normal use).

Why: Filaments degrade over time due to heat/vibration.

Replacement Trigger: Gradual dimming, yellowing output, or sudden failure. HID/Xenon Bulbs:

Lifespan: 2,000–10,000 hours (typically 5–10 years).

Replacement Trigger: Flickering, color shift (blue → purple), or failure to ignite.

Note: Bulbs and ballasts may need replacement. LED Bulbs/Modules:

Lifespan: 15,000–50,000+ hours (often 10–20+ years).

Replacement Trigger: Rarely replaced individually; entire assemblies fail due to:

Fan/cooling system failure.

Driver/electronics malfunction (e.g., flickering, partial dimming).

Physical damage (moisture ingress, impact). Sealed Beam Halogens:

Lifespan: Similar to halogen bulbs (replace every 2–5 years).

⚠️ Key Factors Affecting Lifespan: Vibration/Road Conditions: Potholes and rough roads kill halogen filaments faster.

Electrical Issues: Voltage spikes (failing alternator) or poor grounds shorten bulb life.

Moisture/Corrosion: Water in housings corrodes connectors (especially HID/LED).

Usage Patterns: Daily highway driving vs. short city trips (frequent on/off cycles stress bulbs).

Quality: Cheap halogens fail sooner; premium brands (Philips, OSRAM) last longer.

🛠️ When to Replace (Regardless of Type): Visibly Dimmed Output (e.g., <50% of original brightness).

Uneven Lighting (one light dimmer than the other).

Flickering/Intermittent Operation.

Physical Damage (blackened bulb, moisture inside).

Failed State Inspection (most states require functional headlights).

✅ Best Practices: Replace in Pairs: If one bulb fails, replace both to maintain even light output and color.

Clean Connectors/Housings: Prevent corrosion (use dielectric grease on terminals).

Avoid Touching Halogen Bulbs: Skin oils create hot spots, shortening lifespan (use gloves/clean cloth).

Check Voltage/Alternator: Ensure stable 13.5–14.5V charging (prevents voltage spikes).

💎 Key Takeaway: Halogens: Replace every 2–4 years or at first sign of dimming.

HID: Replace every 5–8 years.

LEDs: Rarely need replacement; expect 10+ years unless damaged.

Always prioritize safety—replace if illumination is compromised! Regular inspections (every 6 months) ensure optimal visibility. 🌟

#led lights#car lights#led car light#youtube#led auto light#led headlights#led light#led headlight bulbs#ledlighting#young artist#The replacement frequency#Halogen Bulbs#halogen headlights#halogen bulb#halogen#lifespan#headlight replacement#replace#replacement#HID#led light bulbs#car rental#classic cars#electric cars#car#cars#carlos sainz#truck#suv#lamborghini

2 notes

·

View notes

Text

Copper Alloys Market Disruption: How New Tech Is Changing Everything

Rising Demand and Transformative Growth in the Global Copper Alloys Market

The global copper alloys market is experiencing an era of substantial expansion, projected to grow at a CAGR of 11.2% between 2024 and 2031. As the demand for high-performance, corrosion-resistant, and electrically conductive materials surges across sectors—particularly in electronics, construction, automotive, marine, aerospace, and renewable energy—copper alloys have emerged as indispensable components of modern industrial ecosystems.

Request Sample Report PDF (including TOC, Graphs & Tables): https://www.statsandresearch.com/request-sample/40473-global-copper-alloys-market

Copper Alloys Market Dynamics Driving Growth:

Surging Electrical and Electronics Applications

The electronics and electrical segment remains the largest end-user of copper alloys, leveraging their exceptional conductivity, durability, and thermal management properties. Copper alloy wires, connectors, and terminals are vital in:

Smart grids and renewable energy systems

High-performance computing devices

Consumer electronics and telecom infrastructure

As the global transition to electric vehicles (EVs) and green power accelerates, the demand for copper alloys in EV batteries, charging systems, and powertrain architectures is poised for exponential growth.

Get up to 30%-40% Discount: https://www.statsandresearch.com/check-discount/40473-global-copper-alloys-market

Infrastructure Modernization and Construction Boom

Modern construction projects emphasize aesthetic appeal, longevity, and sustainability. Copper alloys—used in roofing, cladding, plumbing, and ornamental components—are at the core of smart infrastructure development across North America, Europe, and Asia-Pacific. Their low maintenance costs and resistance to weathering make them ideal for both residential and commercial applications.

Automotive and Marine Sector Momentum

In automotive manufacturing, copper alloys serve in radiators, bushings, connectors, and sensor housings, enhancing both performance and safety. Meanwhile, marine applications increasingly depend on copper-nickel and aluminum bronze for their superior seawater corrosion resistance, significantly reducing maintenance in ships, offshore structures, and desalination plants.

Strategic Copper Alloys Market Segmentation

By Alloy Type

Brass (Copper + Zinc)

Preferred for its machinability, strength, and aesthetic finish, brass finds extensive use in:

Plumbing fixtures

Musical instruments

Decorative hardware

Bronze (Copper + Tin)

A legacy alloy with exceptional wear resistance and strength, bronze is key to:

Sculptures

Bearings

Marine components

Copper-Nickel Alloys (Cu-Ni)

Known for superior corrosion resistance, especially in saltwater, Cu-Ni alloys are indispensable in:

Shipbuilding

Coinage

Heat exchangers

Nickel-Silver

This silver-like alloy offers high strength and visual appeal in:

Cutlery

Jewelry

Optical frames

Phosphor Bronze

Valued for elasticity and fatigue resistance, it's used in:

Electrical contacts

Fasteners

Precision springs

Aluminum Bronze

With superior tensile strength and oxidation resistance, it serves in:

Oil & gas valves

Aerospace fasteners

High-load bushings

Beryllium Copper (BeCu)

A high-performance alloy offering spark resistance and thermal stability for:

Explosive environments

Instrumentation tools

Aerospace connectors

By Product Form

Sheets & Plates: Construction and machinery

Bars & Rods: Automotive and electrical applications

Wires: Critical in power transmission and electronics

Tubes & Pipes: Plumbing, HVAC, industrial systems

Strips & Foils: Electrical connectors, precision electronics

Fittings: Used extensively in HVAC, plumbing, and electrical systems

Regional Copper Alloys Market Analysis

Asia-Pacific

China, India, Japan, and South Korea lead in both consumption and production.

Infrastructure growth, EV proliferation, and industrialization are major growth catalysts.

Dominant manufacturing hub for electronics and heavy machinery.

North America

The United States remains a technological innovator, particularly in aerospace, defense, and healthcare.

Emphasis on sustainable infrastructure and electric mobility is boosting demand.

Europe

Nations like Germany, France, and the UK drive demand through green energy adoption and precision engineering.

Strong focus on recyclability and eco-friendly materials.

Middle East and Africa

Rising construction activity and energy sector investments, especially in UAE and Saudi Arabia.

Marine and oilfield applications fueling growth in copper-nickel alloys.

South America

Brazil is a dominant player with strong construction and mining sectors.

Expanding urbanization fosters copper alloy usage in utilities and infrastructure.

Competitive Landscape

The copper alloys market is moderately consolidated with a blend of global giants and regional specialists. Key players are driving innovation through advanced metallurgy, sustainability initiatives, and expansion into high-growth regions.

Major Companies Include:

KME Germany GmbH

Wieland

Aurubis AG

Mueller Industries

Poongsan Corporation

NGK Insulators, Ltd.

Mitsubishi Materials Corporation

Hitachi High-Tech Analytical Science

Cadi Company, Inc.

Hussey Copper

Chase Brass and Copper Company, LLC

Metalminotti

Shri Manak Copper

Aviva Metals

Diehl Stiftung & Co. KG

Their strategies revolve around:

Geographic Expansion

Sustainable Recycling Techniques

Strategic Mergers and Acquisitions

R&D in High-Performance Alloys

Future Copper Alloys Market Outlook (2024–2031)

The trajectory of the copper alloy market is unequivocally upward. With clean energy adoption, urbanization, and industrial automation on the rise, demand for durable, conductive, and recyclable materials will only intensify. Copper alloys are perfectly positioned to meet these multi-industry needs, underscoring their role in the future of sustainable industrial materials.

Key Copper Alloys Market Growth Forecasts:

Widening use in EVs and renewable energy infrastructure

Surge in demand from healthcare and defense sectors

Expanded R&D investments in next-generation alloys

Purchase Exclusive Report: https://www.statsandresearch.com/enquire-before/40473-global-copper-alloys-market

Conclusion

The global copper alloys market is undergoing transformative growth, anchored in its unmatched versatility and performance across critical sectors. As industrial demands evolve toward sustainability, precision, and efficiency, copper alloys will remain central to powering tomorrow's innovations.

Our Services:

On-Demand Reports: https://www.statsandresearch.com/on-demand-reports

Subscription Plans: https://www.statsandresearch.com/subscription-plans

Consulting Services: https://www.statsandresearch.com/consulting-services

ESG Solutions: https://www.statsandresearch.com/esg-solutions

Contact Us:

Stats and Research

Email: [email protected]

Phone: +91 8530698844

Website: https://www.statsandresearch.com

1 note

·

View note

Text

Cable termination refers to the process of securely connecting the end of a cable to a device or another cable using specialized connectors or terminals. It's a crucial step in various industries like telecommunications, electrical engineering, networking, and electronics manufacturing. Proper termination ensures reliable connections, minimizing signal loss, electrical interference, and mechanical damage. Techniques can vary from simple methods like soldering or crimping to more complex approaches such as insulation displacement or compression. Efficient cable termination is essential for maintaining the integrity and performance of electrical and data transmission systems.

2 notes

·

View notes

Text

USB terminals are one of the most used terminals to power the electronic devices from battery chargers like wall charger and battery banks as they are robust and have been in use for many years now and are mainly used in medical equipment, phone chargers, powering development boards and small battery powered devices like dc motors etc. It is hard to read voltage and current flowing through it if something is not working so this USB Current and Voltage Tester which works as Ammeter and Voltmeter both to determine and debug the USB connector. This dongle plugs between the USB connector and output devices. You can use this device from the 3.5-7VDC input voltage (although most USB devices tend to hover around 4.75 to 5.25) and up to 3A of current. It flips between voltage and current readouts every 3 seconds or so.

5 notes

·

View notes

Text

Exploring the World of Leading Wire Harness Innovators

Wire harness manufacturers play a crucial role in various industries, providing essential components that ensure seamless connectivity and electrical integration in a wide array of applications. These manufacturers design and produce intricate wire harness systems tailored to specific requirements, adhering to strict quality standards and industry regulations.

For More Information Please visit, top wire harness manufacturers

key aspects of wire harness manufacturing

Industry Overview : Wire harness manufacturers operate in a highly competitive and evolving industry. They serve sectors such as automotive, aerospace, electronics, telecommunications, and healthcare, among others. The demand for custom wire harness solutions continues to grow as industries advance technologically.

Customization and Design : One of the significant aspects of wire harness manufacturing is customization. Manufacturers work closely with their clients to understand their unique needs. This involves designing wire harnesses that meet specific requirements, including size, shape, number of wires, insulation materials, and connector types.

Quality Assurance: Quality is paramount in wire harness manufacturing. Manufacturers invest in state-of-the-art testing equipment and employ skilled technicians to ensure that each harness meets the required standards. Rigorous testing procedures are in place to check for electrical continuity, insulation resistance, and overall durability.

Materials and Components: Wire harnesses consist of various materials and components, including wires, connectors, terminals, tubing, and insulation materials. Manufacturers carefully select these components based on the application's requirements, taking into account factors such as temperature, voltage, and environmental conditions.

Compliance and Certification: Wire harness manufacturers adhere to industry standards and regulations to guarantee the safety and performance of their products. Compliance with standards such as IPC/WHMA-A-620 ensures that the manufactured harnesses meet the necessary criteria for reliability and functionality.

Advanced Manufacturing Techniques : Modern wire harness manufacturing involves advanced techniques such as automated assembly, which enhances efficiency and precision. Computer Numerical Control (CNC) machines are employed for accurate cutting, stripping, and crimping of wires and connectors.

Supply Chain Management : Efficient supply chain management is crucial for timely production and delivery of wire harnesses. Manufacturers work closely with suppliers to source high-quality materials and components, ensuring a seamless flow of production.

Research and Development : Continuous research and development efforts drive innovation in the wire harness industry. Manufacturers invest in developing new materials, manufacturing processes, and technologies to improve the performance and longevity of wire harnesses.

Environmental Sustainability : Many wire harness manufacturers focus on sustainable practices, including the use of eco-friendly materials and recycling initiatives. Sustainability efforts contribute to reducing the environmental impact of manufacturing processes.

Conclusion

Wire harness manufacturers operate at the intersection of technology and precision engineering. Their commitment to quality, innovation, and customer satisfaction drives the industry forward, enabling seamless integration of electrical systems in various applications across the globe.

2 notes

·

View notes

Text

Wire Harness Components: Exploring the Building Blocks of Electrical Systems

In the realm of electrical engineering and connectivity, wire harnesses serve as unsung heroes, enabling the smooth transmission of power and signals across an array of industries. These vital components have become indispensable in modern applications, ensuring efficiency, reliability, and safety.

In this comprehensive guide, we delve into the world of wire harnesses, exploring their functionality, applications, and significance in various sectors.

For More Information Please visit, wiring harness manufacturers near me

What are Wire Harnesses?

A wire harness, also known as a cable harness or wiring assembly, is a bundled arrangement of multiple electrical wires or cables. These wires are bound together using various methods, such as tape, zip ties, or sleeves, to form a unified and organized unit. The purpose of a wire harness is to facilitate the efficient and tidy transmission of electrical signals, power, and data within complex systems.

Structure and Components:

Wire harnesses are designed to suit specific applications, and their structure can vary accordingly. Typically, a wire harness consists of the following components:

Wires/Cables: The core elements of a wire harness are the electrical wires or cables, which come in various gauges and types, depending on the application's requirements.

Connectors: Connectors are the crucial interface points that link the wire harness to other electrical components, devices, or systems.

Terminals: Terminals serve as the end points of individual wires, making electrical connections with connectors or other terminals.

Sleeves and Sheaths: To protect the wires from external elements and prevent damage, sleeves and sheaths are used as protective coverings.

Tapes and Labels: Tapes are utilized to bundle the wires together, while labels aid in identification and organization.

Applications in Different Industries:

Wire harnesses find extensive applications in numerous industries due to their efficiency and reliability. Some of the key sectors that heavily rely on wire harnesses include:

Automotive: In vehicles, wire harnesses are essential for transmitting electrical signals, power, and data to various components, such as engines, lights, sensors, and infotainment systems.

Aerospace: The aerospace industry uses wire harnesses to ensure secure and organized connectivity within aircraft, satellites, and spacecraft.

Electronics: From consumer electronics to industrial machinery, wire harnesses are crucial for connecting and powering electronic components.

Telecommunications: In the world of telecommunications, wire harnesses facilitate the smooth flow of data and power in network infrastructure.

Healthcare: Medical devices and equipment rely on wire harnesses to ensure precision and safety in their electrical connections.

Advantages of Using Wire Harnesses:

The adoption of wire harnesses brings forth several advantages:

Simplified Installation: Wire harnesses streamline the installation process by eliminating the need to deal with individual wires, reducing assembly time and errors.

Improved Reliability: Organized and secure connections enhance the overall reliability and performance of electrical systems.

Space-Efficient: Wire harnesses help conserve space, especially in compact devices and machinery.

Enhanced Safety: Properly insulated and protected wires reduce the risk of electrical hazards and ensure operator safety.

Conclusion:

Wire harnesses are the unsung heroes that play a vital role in ensuring seamless electrical connectivity across a myriad of industries. From automotive to aerospace, electronics to healthcare, these organized bundles of wires provide efficiency, reliability, and safety in diverse applications. As technology continues to advance, wire harnesses will remain a cornerstone of modern electrical engineering, contributing to innovation and progress across the globe.

2 notes

·

View notes

Text

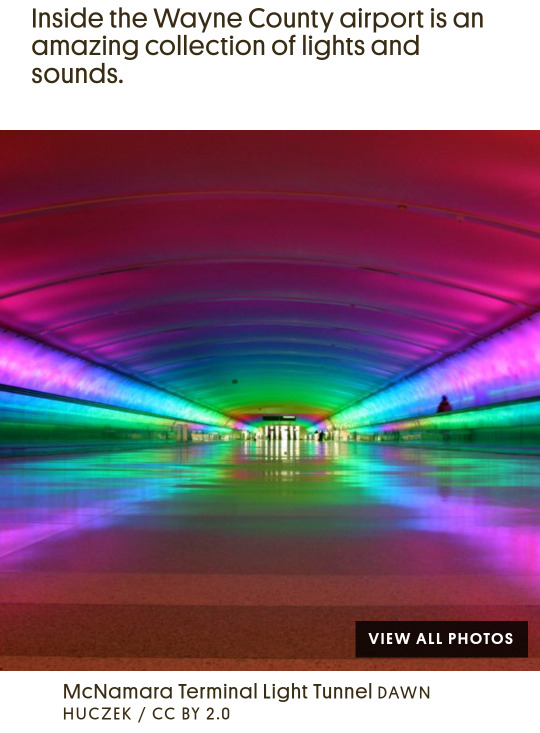

For those in the comments who are confused, that is indeed Detroit (image from an Atlas Obscura article about it) & not Chicago

THIS is what the O'Hare airport in Chicago's rainbow tunnel looks like

Both are connector tunnels between terminals & the lights in both of these move & are accompanied by music.

Detroit's was installed in 2001 & originally had a Motown soundtrack (but has since mostly switched to soft atmospheric stuff) while O'Hare's was completed in 1987 (& is technically an art piece called Sky's the Limit by Michael Hayden) with custom music by composer William Kraft called Electronic Music

why does the airport i go to have the fucking willy wonka tunnel in it i’m going insane

83K notes

·

View notes

Text

RF Cable Assemblies and Jumpers Market: Revenue Forecast by Frequency Range and Application 2025-2032

MARKET INSIGHTS

The global RF Cable Assemblies and Jumpers Market size was valued at US$ 2,170 million in 2024 and is projected to reach US$ 3,420 million by 2032, at a CAGR of 6.7% during the forecast period 2025-2032.

RF cable assemblies and jumpers are critical components used for transmitting high-frequency signals in various applications. These assemblies consist of coaxial cables terminated with connectors, ensuring minimal signal loss and interference. They play a vital role in telecommunications, defense systems, medical equipment, and automotive electronics, supporting seamless connectivity in complex RF environments.

The market growth is driven by increasing demand for high-speed data transmission, expansion of 5G networks, and rising investments in defense communication systems. Furthermore, the automotive sector's shift toward connected vehicles and advanced driver-assistance systems (ADAS) is creating new opportunities. Key players such as TE Connectivity Ltd, Amphenol RF, and Molex LLC are expanding their product portfolios to cater to evolving industry needs, further fueling market expansion.

MARKET DYNAMICS

MARKET DRIVERS

Proliferation of 5G Networks to Accelerate RF Cable Assemblies Demand

The global rollout of 5G infrastructure represents the most significant driver for RF cable assemblies and jumpers. With telecom operators worldwide investing over $300 billion annually in 5G deployments, the need for high-frequency, low-loss coaxial connections has surged dramatically. These specialized cables must maintain signal integrity at millimeter wave frequencies while withstanding environmental stressors. The transition to 5G Standalone networks particularly benefits semi-rigid cable assemblies which demonstrate superior performance in base station RRUs and massive MIMO antenna configurations. Furthermore, small cell densification projects increasingly utilize ultra-flexible jumper cables to accommodate tight installation spaces in urban environments.

Defense Modernization Programs Driving Military-grade RF Connectivity Solutions

Global defense expenditures exceeding $2 trillion annually continue to fuel demand for ruggedized RF interconnect solutions. Modern electronic warfare systems, satellite communications equipment, and radar installations require cable assemblies that maintain strict impedance matching while enduring extreme temperatures, vibrations, and electromagnetic interference. Recent contracts illustrate this trend, including multi-year procurement programs for military aircraft upgrades and naval communication systems upgrades. Phase array radars particularly benefit from emerging lightweight coaxial designs that reduce payload while maintaining GHz-range performance. The shift towards software-defined radios across NATO allied forces further multiplies the need for broadband RF interconnection capabilities.

MARKET RESTRAINTS

Commoditization Pressures in Low-Frequency Applications Constrain Margins

While high-performance RF interconnects command premium pricing, substantial portions of the market face intensifying price competition. The sub-6GHz commercial telecom segment has seen average selling prices decline approximately 8% annually as manufacturers standardize components and automate production. This commoditization particularly impacts legacy connector types and basic coaxial cables where technical differentiation proves challenging. Original equipment manufacturers increasingly consolidate suppliers, leveraging volume purchasing to extract cost concessions. Additionally, the rise of generic connector compatibility specifications allows lower-cost alternatives to penetrate traditionally brand-loyal market segments.

Material Cost Volatility Disrupts Supply Chain Predictability

RF cable assemblies incorporate precious metals and specialized materials that exhibit significant price fluctuation. Silver-plated conductors and PTFE dielectrics have experienced 30-45% cost variations over recent procurement cycles, complicating long-term pricing strategies. The industry's reliance on specific rare earth elements for high-performance shielding compounds further exacerbates supply vulnerabilities. These material challenges intersect with labor shortages in precision assembly operations, where experienced technicians command premium wages to maintain stringent impedance tolerances. Together, these factors compress profitability for standard product lines while increasing working capital requirements for inventory buffers.

MARKET OPPORTUNITIES

Emerging mmWave and THz Applications Open New Frontiers

The evolution toward higher frequency bands creates substantial opportunities for innovative interconnect solutions. Automotive radar systems operating at 77GHz require specialized cable assemblies maintaining low insertion loss despite constant vibration exposure. Similarly, emerging terahertz imaging applications in security screening and medical diagnostics drive demand for novel waveguide transition technologies. The satellite industry's transition to low-earth orbit constellations presents another high-growth segment, where radiation-hardened RF jumpers must withstand extreme thermal cycling while minimizing passive intermodulation effects. These applications command substantial price premiums, with mmWave assemblies frequently achieving 3-5x the unit pricing of conventional microwave components.

Automotive RF Integration Creates Parallel Growth Channels

Modern vehicles incorporate over 40 separate RF subsystems, from infotainment to collision avoidance radars, creating compound annual growth exceeding 12% for automotive-grade interconnects. The transition to autonomous driving architectures particularly benefits shielded cable assemblies that minimize electromagnetic interference between sensors. Emerging vehicle-to-everything (V2X) communication standards further expand the addressable market, requiring robust RF connectivity solutions that endure harsh underhood environments. Tier 1 suppliers increasingly partner with interconnect specialists to co-develop application-specific solutions, creating lucrative design-win opportunities with extended product lifecycles.

MARKET CHALLENGES

Precision Manufacturing Requirements Limit Production Scalability

High-performance RF interconnects demand exacting manufacturing tolerances often measured in microns, creating substantial production challenges. Achieving consistent impedance matching across production lots requires sophisticated process controls and 100% electrical testing, which limits throughput efficiencies. The industry faces particular difficulties in scaling production of phase-stable cables for phased array systems, where even minor variations in dielectric concentricity degrade system performance. These constraints become more pronounced as operating frequencies ascend beyond 40GHz, where traditional connector interfaces approach practical physical limitations.

Design Complexity Increases Time-to-Market Pressures

Developing application-specific RF interconnect solutions requires extensive electromagnetic simulation and prototyping cycles. The validation process for aerospace-grade components frequently exceeds 18 months due to rigorous qualification testing for vibration, temperature extremes, and outgassing performance. This extended development timeline conflicts with commercial sector demands for rapid product iterations, particularly in consumer electronics and IoT applications. Manufacturers must balance customization capabilities against standardization benefits, navigating intricate tradeoffs between performance, reliability, and cost targets across diverse market verticals.

RF CABLE ASSEMBLIES AND JUMPERS MARKET TRENDS

5G Network Expansion Driving Demand for High-Performance RF Cable Assemblies

The global rollout of 5G infrastructure is significantly boosting the RF Cable Assemblies and Jumpers market, with demand expected to grow at a CAGR of 7-9% through 2032. These components are critical for maintaining signal integrity in high-frequency applications, particularly in base stations and small cell deployments. The shift toward millimeter-wave (mmWave) frequencies in 5G networks has particularly increased demand for low-loss coaxial cables with frequencies exceeding 40 GHz. Leading manufacturers are responding with innovations in dielectric materials and shielding technologies to minimize insertion loss, which can exceed 3 dB/meter in conventional cables at these frequencies.

Other Trends

Automotive Radar and ADAS Applications

Advanced Driver Assistance Systems (ADAS) and autonomous vehicle technologies are creating substantial demand for ruggedized RF cable assemblies capable of withstanding harsh automotive environments. The typical automotive radar system now utilizes 12-24 GHz or 77 GHz frequencies requiring specialized cable solutions. Market growth in this segment is projected at 11-13% annually, outpacing the broader market due to increasing vehicle electrification and regulatory mandates for safety systems.

Miniaturization Trend in Connectivity Solutions

The electronics industry's push toward smaller form factors is driving innovation in micro-miniature RF connectors and ultra-thin coaxial cables. Products like 1.0 mm and 0.8 mm coaxial connectors now comprise nearly 30% of new designs in consumer electronics and IoT devices. However, this miniaturization presents technical challenges - insertion loss increases by approximately 15% for every 0.2 mm reduction in connector size, requiring advanced materials engineering to mitigate performance degradation.

Defense Modernization Programs Spurring Growth

Military applications continue to account for 25-30% of the high-end RF cable assemblies market, driven by global defense spending exceeding $2 trillion annually. Modern radar systems, electronic warfare platforms, and satellite communications require specialized cable solutions with extended temperature ranges (-55°C to +200°C) and enhanced EMI/RFI shielding. The growing adoption of phased array antennas is particularly demanding flexible yet durable jumper solutions capable of handling complex signal routing in confined spaces.

COMPETITIVE LANDSCAPE

Key Industry Players

Market Leaders Focus on Technological Innovation to Maintain Competitive Edge

The global RF Cable Assemblies and Jumpers market demonstrates a moderately consolidated structure, with established players accounting for significant market share while smaller competitors carve out specialized niches. TE Connectivity Ltd emerges as a dominant force, leveraging its extensive product portfolio and manufacturing footprint across North America, Europe, and Asia-Pacific. The company's market leadership stems from continuous R&D investments and strategic acquisitions in high-frequency connectivity solutions.

Radiall GmbH and Aptiv Plc maintain strong positions in the aerospace and automotive sectors respectively, with their specialized RF assembly solutions for mission-critical applications. These companies benefit from long-standing relationships with defense contractors and automotive OEMs, enabling stable revenue streams even during market fluctuations.

Meanwhile, WL Gore & Associates differentiates itself through proprietary ePTFE cable technology, particularly in high-reliability medical and military applications. The company's focus on premium, high-performance solutions allows it to command price premiums in niche segments.

Recent industry developments show accelerating competition in 5G infrastructure components, with Molex LLC and Amphenol RF making significant strides in low-loss millimeter wave assemblies. Both companies have launched new product lines specifically targeting telecom base stations and small cell deployments, capitalizing on the global 5G rollout.

List of Key RF Cable Assemblies and Jumpers Manufacturers

TE Connectivity Ltd (Switzerland)

Radiall GmbH (France)

Aptiv Plc (Ireland)

Rosenberg GmbH (Germany)

WL Gore & Associates (U.S.)

Lighthorse Technologies, Inc. (U.S.)

Molex LLC (U.S.)

Amphenol RF (U.S.)

Pasternack Enterprises Inc. (U.S.)

Samtec Inc. (U.S.)

Segment Analysis:

By Type

Connectors Segment Leads the Market Due to High Demand in Telecom and Defense Applications

The market is segmented based on type into:

Connector

Plug

Switch

Other

By Application

IT & Telecommunication Dominates Market Share Owing to 5G Network Expansion

The market is segmented based on application into:

IT and Telecommunication

Defense

Automobile

Healthcare

Others

By Frequency Range

High Frequency Segment Gains Traction with Increasing Demand for High-Speed Data Transmission

The market is segmented based on frequency range into:

Low Frequency

Medium Frequency

High Frequency

Very High Frequency

Regional Analysis: RF Cable Assemblies and Jumpers Market

North America The North American market for RF cable assemblies and jumpers is predominantly driven by advancements in 5G infrastructure, defense modernization programs, and growing demand for high-speed connectivity in IT & telecommunications. The U.S. holds the largest share, supported by government investments in aerospace and defense, estimated at $842 billion for FY2024. Major players like TE Connectivity Ltd and Amphenol RF dominate the market due to their robust supply chains and R&D capabilities. However, stringent regulatory standards for RF components and supply chain disruptions pose challenges for manufacturers. The shift toward miniaturized, high-frequency connectors for IoT and autonomous vehicles further fuels regional demand.

Europe Europe’s market is characterized by strong adoption of RF cable assemblies in automotive and healthcare sectors, particularly in Germany and France. The EU’s focus on 5G deployment under the Digital Decade Policy Programme accelerates demand for low-loss, high-performance RF solutions. Regulations like RoHS and REACH mandate eco-friendly materials for cables, pushing manufacturers to innovate. Companies like Radiall GmbH and Rosenberg GmbH lead with specialized solutions for industrial IoT and medical devices. However, high production costs and competition from Asia-based suppliers restrain growth. The region’s emphasis on renewable energy integration also opens new opportunities for RF jumpers in smart grid applications.

Asia-Pacific Asia-Pacific is the fastest-growing market, with China accounting for over 40% of global RF cable assembly demand due to telecom expansions and defense investments. India and Japan follow, spurred by local manufacturing initiatives (e.g., India’s PLI scheme) and increasing 5G adoption. Low-cost production hubs in Southeast Asia attract global players like Molex LLC and Samtec Inc., though price sensitivity limits premium product penetration. The rise of smart cities and EV infrastructure further augments market potential. However, intellectual property concerns and fluctuating raw material costs remain key challenges.

South America This region shows moderate growth, driven by Brazil’s telecom sector and Argentina’s aerospace projects. The lack of domestic manufacturing forces reliance on imports, creating opportunities for U.S. and European suppliers. Economic instability and currency volatility hinder large-scale investments, but rising demand for broadband connectivity in urban areas sustains market progress. Local governments are gradually improving infrastructure, yet regulatory bottlenecks slow adoption of advanced RF technologies.

Middle East & Africa The MEA market is emerging, with growth concentrated in GCC countries due to oil & gas sector digitization and defense spending. The UAE and Saudi Arabia lead in smart city projects, boosting demand for RF assemblies in surveillance and IoT networks. Africa’s expansion is slower but shows promise with submarine cable projects enhancing connectivity. Challenges include limited technical expertise and reliance on foreign suppliers. Long-term potential hinges on infrastructure development and economic diversification.

Report Scope

This market research report provides a comprehensive analysis of the global and regional RF Cable Assemblies and Jumpers markets, covering the forecast period 2024–2032. It offers detailed insights into market dynamics, technological advancements, competitive landscape, and key trends shaping the industry.

Key focus areas of the report include:

Market Size & Forecast: Historical data and future projections for revenue, unit shipments (in KM), and market value across major regions and segments. The global market was valued at USD million in 2024 and is projected to reach USD million by 2032.

Segmentation Analysis: Detailed breakdown by product type (Connector, Plug, Switch, Others), application (IT & Telecommunication, Defense, Automobile, Healthcare), and end-user industry to identify high-growth segments.

Regional Outlook: Insights into market performance across North America (U.S., Canada, Mexico), Europe (Germany, France, U.K.), Asia-Pacific (China, Japan, India), and other regions with country-level analysis.

Competitive Landscape: Profiles of leading market participants including TE Connectivity Ltd, Radiall GmbH, Aptiv Plc, and their product offerings, R&D focus, manufacturing capacity, and recent developments.

Technology Trends & Innovation: Assessment of emerging technologies in RF connectivity, miniaturization trends, and evolving industry standards for high-frequency applications.

Market Drivers & Restraints: Evaluation of 5G deployment, defense modernization programs, automotive electronics growth, along with supply chain constraints and material cost fluctuations.

Stakeholder Analysis: Strategic insights for component suppliers, OEMs, system integrators, and investors regarding emerging opportunities in the RF connectivity ecosystem.

Primary and secondary research methods are employed, including manufacturer surveys, expert interviews, and analysis of verified market data to ensure accuracy and reliability of insights.

FREQUENTLY ASKED QUESTIONS:

What is the current market size of Global RF Cable Assemblies and Jumpers Market?

-> RF Cable Assemblies and Jumpers Market size was valued at US$ 2,170 million in 2024 and is projected to reach US$ 3,420 million by 2032, at a CAGR of 6.7% during the forecast period 2025-2032.

Which key companies operate in Global RF Cable Assemblies and Jumpers Market?

-> Key players include TE Connectivity Ltd, Radiall GmbH, Aptiv Plc, Rosenberg GmbH, WL Gore & Associates, Molex LLC, and Amphenol RF, with the top five players holding approximately % market share in 2024.

What are the key growth drivers?

-> Key growth drivers include 5G network deployment, increasing defense electronics expenditure, automotive connectivity solutions, and healthcare equipment modernization.

Which region dominates the market?

-> North America currently leads in market share, while Asia-Pacific is projected to grow at the highest CAGR during the forecast period.

What are the emerging trends?

-> Emerging trends include high-frequency RF solutions for 5G/6G, miniaturized connectors for IoT devices, and radiation-resistant cables for aerospace applications.

Related Reports:https://semiconductorblogs21.blogspot.com/2025/06/automotive-magnetic-sensor-ics-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/ellipsometry-market-supply-chain.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/online-moisture-sensor-market-end-user.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/computer-screen-market-forecasting.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/high-power-gate-drive-interface.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/strobe-overdrive-digital-controller.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/picmg-half-size-single-board-computer.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/automotive-isolated-amplifier-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/satellite-messenger-market-regional.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/sic-epi-wafer-market-innovations.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/heavy-duty-resistor-market-key-players.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/robotic-collision-sensor-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/gas-purity-analyzer-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/x-ray-high-voltage-power-supply-market.htmlhttps://semiconductorblogs21.blogspot.com/2025/06/reflection-probe-market-industry-trends.html

0 notes

Text

Why Custom Metal Components Are Key to Industrial Efficiency

In today's fast-paced industrial landscape, the demand for precision, reliability, and durability is at an all-time high. Off-the-shelf parts often fail to meet the exact specifications needed in specialized machinery or advanced systems. This is where custom metal components come into play, driving operational efficiency across industries ranging from automotive to aerospace.

Custom metal components are engineered to match specific design, material, and performance criteria. Unlike standard parts, they fit seamlessly into unique systems, reducing the risk of malfunction and improving system longevity. Whether it's for compact electronic assemblies or heavy-duty industrial machinery, these tailor-made components ensure optimal alignment and smooth functionality.

For instance, industries often rely on brass precision components to meet tight tolerances while resisting corrosion and wear. Brass is not only easy to machine but also offers excellent electrical and thermal conductivity, making it a preferred choice for both mechanical and electrical applications.

Benefits of Custom Metal Components:

Tailored Fit: Built to match exact equipment needs

Greater Efficiency: Enhances performance and minimizes energy waste

Improved Reliability: Reduces breakdowns and maintenance intervals

Material Optimization: Specific alloys chosen for intended use

Cost Savings: Long-term operational efficiency reduces total ownership costs

One prime example is the use of brass turned part in hydraulic systems, electrical terminals, and sensor housings. These parts are manufactured using CNC turning processes, ensuring high repeatability and precise finishes every time.

Key Industries Benefiting from Custom Components:

Automotive: Custom fittings, nozzles, and connectors

Telecommunications: Signal connectors and grounding components

Aerospace: High-precision parts for complex assemblies

Medical Devices: Safe and sterile-grade components for surgical tools

Energy: Efficient power transmission elements and control systems

Efficiency in industrial processes is no longer a luxury but a necessity. With custom metal components, businesses gain a competitive edge through reduced downtime, better product quality, and longer system life. Investing in the right components is not just about parts—it’s about performance, precision, and profitability.

0 notes

Text

Why Should You Rely on Connector Wrenches for Precision and Safety?

Introduction to Connector Wrenches

Connector wrenches are essential tools engineered to simplify the tightening and loosening of connectors in a wide variety of electrical, electronic, and mechanical assemblies. Unlike generic wrenches, connector wrenches are specially designed to provide optimal torque control, ensuring secure connections without damaging delicate components. Their role is increasingly important in precision-driven industries, from telecommunications and aerospace to electronics manufacturing and data centers. The compact design and compatibility with hard-to-reach spaces make these tools a must-have for technicians and engineers working with connectors, sensors, cables, microcontrollers, and other sensitive components.

Why Are Connector Wrenches So Important?

Connector wrenches serve as the interface between quality installation and long-lasting performance. Whether assembling fiber optic cables or tightening RF connectors in communication equipment, these wrenches ensure a perfect fit and torque consistency, reducing the risk of signal loss or component failure.

Their significance extends across multiple fields:

In electronics, they provide careful application of pressure, preserving internal components.

In safety-critical environments, they prevent under-tightening or over-tightening, which can compromise functionality.

In thermal and high-frequency environments, they help maintain signal integrity and reduce potential system malfunctions.

With the rise in automated systems, robotics, and microelectronic devices, connector wrenches have become more refined, precise, and essential.

What Are the Key Features of a Connector Wrench?

Connector wrenches are built with attention to detail, functionality, and durability. The best models are manufactured using high-grade materials like stainless steel or anodized aluminum, and are compatible with various connector types and industry standards.

Key features include:

Ergonomic handles that provide a comfortable, anti-slip grip during repetitive tasks

Torque-limiting designs to prevent damage to sensitive terminals or threaded connectors

Slim or angled profiles to access connectors in tight or obstructed areas

Interchangeable heads to work with different connector sizes or standards

Non-magnetic materials to ensure safety in environments with magnetic-sensitive components like capacitors, sensors, and microprocessors

These design features make connector wrenches versatile for professionals working with thermal pads, controllers, contactors, and other high-performance equipment.

How Are Connector Wrenches Used in Industry?

Connector wrenches are utilized across several technical sectors where precise connectivity is essential. In telecommunications, for example, connector wrenches are commonly used to install coaxial or fiber connectors. In the aviation and aerospace industry, they’re instrumental in ensuring vibration-resistant terminations. In electronics, especially during PCB assembly or repair, connector wrenches help technicians maintain uniform pressure on connector housings, cable grips, and solderless terminals.

They are also integral in:

Automotive electronics installation and diagnostics

Sensor placement in industrial automation systems

Power connector setup in energy distribution equipment

Secure mounting of thermal systems involving heatsinks or fans

Connector wrenches not only streamline workflows but also improve the longevity and safety of complex systems.

What Types of Connector Wrenches Are Available?

There is a wide range of connector wrenches, each tailored for specific applications or connector types. Selecting the right wrench ensures compatibility and precision.

Common types include:

Fixed-head connector wrenches for specific connector sizes and types

Adjustable connector wrenches for handling multiple dimensions with one tool

Torque-limiting connector wrenches with calibrated mechanisms for consistent tightness

T-handle and L-handle styles that enhance torque application in confined spaces

Ratcheting connector wrenches for high-efficiency repetitive tasks

Insulated connector wrenches designed for working with electrical connectors in live circuits

Selecting the correct type ensures compatibility with connectors in tools, switches, safety modules, microcontrollers, and more.

Where Are Connector Wrenches Most Commonly Applied?

Connector wrenches are ubiquitous in various high-tech and industrial environments. Their ability to handle components without risking deformation makes them especially useful in sensitive electrical and data systems.

Typical applications include:

Networking installations involving coaxial, SMA, or fiber connectors

Aerospace electronic equipment where vibration-resistant assembly is vital

Medical devices requiring delicate yet firm connection fittings

Industrial automation systems incorporating sensors, thermal components, and fuses

Consumer electronics involving microprocessors, LEDs, and compact controllers

Renewable energy systems for secure connection of high-power terminals and capacitors

These tools are ideal for use during both installation and maintenance phases.

What Are the Benefits of Using the Right Connector Wrench?

Using the right connector wrench can enhance performance, increase safety, and reduce rework. As systems become increasingly compact and complex, the precision offered by connector wrenches becomes even more valuable.

Key benefits include:

Enhanced reliability of electrical and mechanical connections

Minimization of torque-related connector damage

Efficient installation and maintenance of components such as switches, thermal pads, and cables

Reduction in installation time and human error

Compliance with technical standards in regulated industries

The result is a cleaner, more stable connection with increased system performance and reduced maintenance costs.

How to Choose the Ideal Connector Wrench?

Choosing the right connector wrench depends on various factors such as the type of connector, environment, access space, and required torque.

Consider the following criteria:

Material durability and resistance to wear

Ergonomic design suited for extended use

Compatibility with specific connector types (e.g., SMA, N-Type, DIN)

Availability of torque control if precision is critical

Magnetic safety when working near microelectronics

Size and weight for ease of transport in fieldwork

Investing in a quality wrench tailored to your workflow can make all the difference in precision and efficiency.

Final Thoughts

Connector wrenches play a vital role in ensuring reliable, secure, and professional-grade connectivity across electronics, automation, communications, and industrial applications. As the demand for high-performance systems increases, the importance of using precise tools like connector wrenches becomes evident. These tools enhance system performance, improve safety, and prolong the lifespan of critical components.

Whether you're an electronics technician working with sensors and microcontrollers or an engineer installing power connectors and thermal solutions, connector wrenches are your trusted companion for clean, secure, and efficient assembly. Explore quality options from trusted brands and elevate your toolkit for modern-day applications.

0 notes

Text

Is it possible to change turn signal lights to LEDs?

Yes, it is technically possible to replace your turn signal lights with LED lights, but it requires careful retrofitting to avoid electrical problems and violations. Here’s what you need to know:

✅ Benefits of LED Turn Signal Lights Lifespan: LED lights have a lifespan of 25,000-50,000 hours, while halogen lights have a lifespan of 500-1,000 hours.

Brightness: 200-300% more light output (up to 1,500 lumens).

Faster Response: Instant on/off for improved visibility.

Power Saving: Each bulb consumes about 0.5-1A, while halogen lights consume 2.0A per bulb.

⚠️ Main Challenges & Solutions Overclocked Flashing (Fast Flashing)

Cause: Halogen lights consume more power → the factory flasher relay expects this load. LEDs consume less power → the relay “thinks” the bulb is burned out.

Solution:

Load resistance: Add parallel resistors to simulate the power consumption of halogen lamps (e.g. 6Ω per bulb, 50W).

Disadvantage: Generates a lot of heat (needs heat sink/metal bracket).

LED flasher relay: Replace the factory relay with an electronic flasher (e.g. EP36 for GM, CF18 for Japanese cars).

CAN bus decoder: Must-have for modern cars (e.g. iJDMtoY/LASFIT kits). CAN bus system error

Problem: Modern cars monitor circuit resistance. Low LED current triggers "bulb off" warning/dashboard error.

Solution: Use CAN bus compatible LED bulbs with built-in resistors (e.g. SNGL, Philips Ultinon). Legal compliance

Colors: Amber (front/side) and red (rear) are legally mandatory in most areas. Pure white LED turn signals are illegal.

Beam Pattern: LED lamps must not cause glare (reflector housing bulb designs only - LEDs may not be used in projector housings unless DOT certified).

Photometric Standards: Must meet SAE/DOT or ECE R6 regulations (look for "SAE/DOT compliant" packaging).

Housing Compatibility

Avoid using halogen housing LED lamps that are not equipped with a beam cutoff. Glare can blind other drivers.

Solution: Replace the entire housing with an OEM/LED-specific component.

🔧 Step-by-Step Installation Guide Check Compatibility:

See your vehicle manual for bulb type/size (e.g., PY21W, 7440).

Use a compatibility tool (e.g., Google Lookup). Get Parts:

LED Bulbs: Front: Amber (e.g., SNGL 7443), Rear: Red (e.g., SNGL 7506).

Resistors/Relays: Use a kit such as the Lumen LM200 Resistor Kit. Installation:

Disconnect negative battery terminal.

Replace bulb: Unscrew socket → remove old bulb → install LED (align pins).

Place resistors across positive/negative wires of each bulb (use solder/heat shrink tubing).

Mount resistors on metal surface (not plastic/trim). Testing and debugging:

Turn on hazard and signal lights. Verify there is no overclocked flashing.

Scanner dial error (use OBD2 scanner).

📜 Legality Checklist Requirements: US EU/UK Color (frontlight): Amber or white¹ Amber only Color (rearlight): Red Red Intensity: ≤100–300 cd² ≤170 cd (sidelights) Beam diffusion: DOT/SAE compliant ECE R6 compliant

¹ Only factory-equipped turn signals are white (check individual state laws).

² Photometric testing of aftermarket bulbs is rare, but must be done on factory designs.

💡 Smart Alternatives Plug-and-play kits: Brands like OPT7/LASFIT include resistors and connectors.

Full LED taillight assemblies: Replace the entire assembly (e.g., modern factory LED upgrades).

Hybrid bulbs: Halogen/LED combos to avoid overclocked flicker (e.g., Philips X-tremeUltinon).

🛠️ Cost breakdown Component price range LED bulb (pair) 20–60 Load resistor (pair) 10–15 LED flasher relay 15–40 Professional installation 100–200

⚠️ Key risks to avoid Fire hazard: Never mount resistors on plastic. Use wire sleeves and thermal tape instead.

Warranty void: Modifying factory wiring may void dealer warranty.

Insurance issues: Non-compliant LEDs may complicate accident claims.

Recommendations: For classic cars: Resistors + standard amber LEDs.

For modern cars (2010 and later): CAN bus compatible bulbs + flasher relays.

When in doubt: Use the Philips Ultinon Pro6000 kit with built-in decoder.

Always test the beam pattern against a wall at night and verify compliance with local DOT/ECE standards. If DIY isn’t an option, specialty shops like CARiD can provide vehicle-specific kits.

#led lights#car lights#led car light#youtube#led auto light#led light#led headlights#led headlight bulbs#ledlighting#young artist#car rental#electric cars#classic cars#car#cars#porsche#truck#automobile#lamborghini#bmw#carlos sainz#autonomous vehicle headlights#overtake another vehicle#vehicle#older vehicles#auto mode#automobiles#auto#automotive#autos

6 notes

·

View notes

Text

How PCB Connectors Power Compact and Reliable Electronic Assemblies

Devices are shrinking, but expectations are rising. Whether it’s in smart lighting, factory control units, or automation systems, size is getting smaller, and reliability? Non-negotiable.

As electronics move toward denser, multi-functional designs, dependable interconnections become the unsung heroes holding these systems together. One of the most trusted realities stems from not properly seeing and often underappreciating PCB Connectors.

What Are PCB Connectors? Types and Where They Are Used

PCB connectors are mechanical interfaces that join a printed circuit board with another PCB, wire, or an external device. They are found almost everywhere in today's applications-from smart thermostats to LED drivers, programmable logic controllers, and small industrial sensors.

Types vary, and their structure depends heavily on form and function. Here's a snapshot:

The wire-to-board connectors: It is used to connect external wiring to the board.

Board-to-board connectors: Very much given for modular arrangements or compact layering.

Wire-to-wire connectors: Less frequent but may be required in some routing cases.

Pluggable connectors: These allow for installing some components without the mundane toil of doing it by hand and also can be quickly taken off and replaced.

Now here’s where it gets interesting: the ideal connector doesn’t just transfer signals or power. It prevents vibration failure, allows easy wiring, and maintains integrity across thermal cycles, all while helping devices get smaller and smarter.

Why WAGO’s PCB Connectors Are a Game-Changer for Compact and Tough Assemblies

WAGO's engineering approach cuts through the clutter. They’re not just making smaller components; they’re optimizing how those components function under stress, over time, and in the tightest spaces.

Now, PCB connectors, particularly the tool-free lever models WAGO offers, bring tangible advantages. Right in the middle of your control unit or LED module, these connectors make installation so much easier and faster, and still ensure that over 30+ terminations maintain solid contact under vibration or movement. They’re especially appreciated in tight builds where space constraints don’t leave room for error, or for a screwdriver.

Key Features That Matter:

Tool-free connection: You don’t need to reach for any special gear. Just lift, insert, press, done.

Vibration-proof reliability: Spring-pressure technology holds tight, even in mobile or high-motion applications.

Compact footprint: Helps reduce overall product size, vital for miniaturization goals.

Multiple conductor types: Whether it's stranded, solid, or fine-stranded, compatibility isn’t an issue.

It’s not hype; it’s practical design thinking that shows up in real-world use. Engineers know that rework, time, and failure risk are all minimized when connectors just work, and WAGO’s models do.

Where Are These PCB Connectors Actually Used?

In a nutshell, anywhere you need strong connections in confined areas. However, the following top-use cases illustrate their adaptability:

1. Systems of Lighting

With their secure yet small form factors, PCB connectors help ensure reliable power delivery without the need for large wiring terminals, making installation easier in tight spaces or suspended fixtures, whether you're wiring LED drivers or building modular lighting tracks.

2. Industrial Automation

You’ve got multiple sensors, signal pathways, and real-time controls packed into a DIN-rail-mounted controller, these connectors simplify wire management, reduce error margins, and allow rapid replacement during maintenance cycles, directly impacting uptime and system resilience.

3. Machine and Motion Control Panels

In dynamic systems exposed to continuous vibrations or movement, PCB connectors, when properly rated and tested for such environments, ensure that your control board doesn’t just survive, it performs optimally even after thousands of hours in operation.

Conclusion: The Right Connector Isn’t Just a Part, It’s a Strategic Choice

Here’s what it comes down to, your choice of connector can either amplify your product’s reliability or quietly sabotage it. The push toward smaller, smarter, more interconnected electronics means that interconnect quality can't be an afterthought.

When PCB connectors are engineered for tool-free use, vibration resistance, and compact layout, like WAGO’s solutions, they don’t just fit into your assembly. They elevate it. And in a space where every millimeter and every second counts, that makes all the difference.

According to a 2024 report by MarketsandMarkets, the global PCB connector market is projected to reach $17.3 billion by 2028, driven by automation, smart devices, and the rapid miniaturization of electronics.

Need help integrating high-performance connectors into your product design? Now’s the time to evaluate your current setup—and upgrade where it truly counts.

0 notes

Text

What Are the Advantages of Brass vs. Copper Machined Parts?

Explore the benefits of brass versus copper machined parts. Understand their unique properties to make informed decisions for your manufacturing needs.

Copper and brass machined parts are two excellent options when choosing materials for precise components. Although each material has special advantages, knowing how they differ can assist engineers, procurement teams, and manufacturers choose the best option for the project sinnar-ureplas.

In order to assist you in making your decision, we will compare the qualities, functionality, and cost-effectiveness of copper and brass in order to examine their advantages in machining. Whether you work in industrial manufacturing, plumbing, automotive, or electrical, the quality and performance of your products can be greatly impacted by the material you choose.

Brass Machined Parts: Key Advantages

1. Excellent Machinability Brass is widely known for its exceptional machinability. It allows for faster cutting speeds and produces less wear on tools, which reduces operational downtime and tooling costs. This makes brass machined parts ideal for high-volume production where precision and repeatability are crucial.

2. Corrosion Resistance Brass offers strong corrosion resistance, especially in environments with water, oil, and mild chemicals. This makes it a popular choice in marine, plumbing, and HVAC applications.

3. Aesthetic Appeal The gold-like finish of brass makes it an attractive choice for decorative fittings, hardware, and precision components that require both functionality and a polished appearance.

4. Dimensional Stability Brass parts maintain tight tolerances due to their rigid structure, which enhances performance in assemblies where fit and accuracy are critical.

5. Cost-Effective Compared to copper, brass is generally more affordable due to its alloy composition (typically a combination of copper and zinc). This makes it a cost-effective choice for industries that require bulk production without compromising quality.

Copper Machined Parts: Key Advantages

1. Superior Electrical Conductivity Copper is unmatched in its ability to conduct electricity. Copper machined parts are widely used in the electrical and electronics industries for components like connectors, terminals, and busbars.

2. Excellent Thermal Conductivity In addition to electrical conductivity, copper is also a superior conductor of heat. This makes it suitable for heat sinks, thermal connectors, and applications in power systems and electronics.

3. Antimicrobial Properties Copper naturally kills bacteria and microbes, making it ideal for medical devices, food processing components, and sanitary environments.

4. High Ductility and Malleability Copper is softer and more malleable than brass, allowing for complex shaping and intricate designs, especially in custom or low-volume runs.

5. Non-Magnetic and Spark-Resistant Copper’s non-magnetic properties make it valuable in sensitive electronic or magnetic field applications. Additionally, it is spark-resistant, which is essential for environments with flammable gases or dust.

The particular requirements of your application will determine whether to use copper or brass machined parts. Copper is better for electrical performance. Brass is frequently a preferable option for mechanical applications requiring cost-effectiveness, corrosion resistance, and durability.

Trusted Source for Brass and Copper Machined Parts

If you’re looking for high-quality, precision-engineered brass and copper machined parts, Sinnar Ureplas offers customized machining solutions tailored to your industry. With a focus on CNC precision, material excellence, and global supply capability, they are a trusted partner for industries across the globe.

Copper Brass Machined parts each have advantages of their own. Cost, machinability, durability, and conductivity must all be balanced when selecting a material. You may make decisions that enhance product performance and manufacturing efficiency by being aware of the unique benefits of copper and brass machined parts.

Always think about collaborating with a reputable manufacturer who can consistently supply quality and is aware of the demands of your business if you want long-term success.

Visit: https://sinnar-ureplas.com/copper-brass-machined-parts.phpContact: +91 8975322242

0 notes

Text

Best Brass Coils Manufacturers in India – Premium Quality from KWM India

Brass Coils Manufacturers in India – Precision, Durability & Trust with KWM India

Brass coils have become essential components across various industries due to their excellent formability, corrosion resistance, and appealing finish. Whether it’s for electrical, plumbing, or decorative applications, the demand for high-quality brass coils continues to grow. Among the leading brass coil manufacturers in India, KWM India is recognized for its top-tier production standards and customer-centric solutions.

Why Brass Coils?

Brass coils are versatile and widely used in:

Electrical terminals and connectors

Decorative metalwork

Heat exchangers

Automotive and mechanical parts

Sanitary and plumbing fittings

They offer an ideal balance of strength, flexibility, and resistance to corrosion, making them suitable for both structural and aesthetic uses.

KWM India – One of India’s Leading Brass Coil Manufacturers

KWM India has built a strong reputation in the non-ferrous metal industry by offering superior quality brass coils that meet the highest performance and safety standards. Here’s why KWM is a preferred name in the industry:

1. High-Grade Raw Materials

KWM India uses carefully selected copper and zinc blends to produce brass with uniform composition, ensuring strength, conductivity, and workability.

2. Precision Rolling Technology

With modern machinery and skilled technicians, KWM India manufactures brass coils with perfect thickness tolerance, smooth edges, and excellent surface finish.

3. Wide Range of Specifications

Whether it's for mass production or specialized applications, KWM offers coils in various thicknesses, widths, and tempers, customized to your exact needs.

4. Strict Quality Control

Each batch undergoes rigorous testing for tensile strength, composition, dimensional accuracy, and surface finish—ensuring dependable and durable products.

5. Pan-India and Global Reach

KWM India serves clients across India and exports to international markets, offering reliable supply chains and timely deliveries.

Applications of KWM Brass Coils

Electronic connectors and contacts

Decorative trims and furniture accents

Marine hardware

Heat transfer equipment

Precision components in manufacturing

Conclusion

If you are searching for dependable and high-performance brass coils manufacturers in India, look no further than KWM India. With a focus on quality, precision, and customer satisfaction, KWM continues to be the go-to choice for businesses across multiple sectors.

Visit:- https://www.kmwindia.com/brass-coils.html

0 notes

Text

Why Choose a Crimp Terminal Kit? A Complete Guide for DIYers and Professionals

Understanding Crimp Terminal Kits

A crimp terminal kit is an essential toolkit for professionals and hobbyists working with electrical systems, electronic assemblies, and hardware projects. These kits contain a variety of crimp connectors designed to ensure strong, reliable, and safe wire connections. Whether you're repairing cables in a laptop or wiring microcontrollers in a new build, a crimp terminal kit simplifies your work by providing all necessary terminals and tools in one convenient package.

What Makes a Crimp Terminal Kit So Valuable?

Crimp terminal kits are ideal for managing diverse wiring needs, offering everything from ring terminals to spade and butt connectors. These kits are especially useful in environments where durable and vibration-resistant connections are required, such as in controllers, microprocessors, and even industrial contactors. With everything organized in one kit, you reduce downtime, boost productivity, and improve safety on the job.

Key Components in a Typical Crimp Terminal Kit

A high-quality crimp terminal kit usually includes:

A range of terminals including ring, fork, spade, butt, and bullet types

Color-coded insulation for easy wire size identification

Heat-shrink or vinyl insulation for added protection

A crimping tool with interchangeable jaws or multi-functional features

Features That Make These Kits Essential

When it comes to selecting a crimp terminal kit, several standout features enhance its usability:

Pre-insulated terminals compatible with various wire gauges

Durable crimping tool designed for long-term use

Organised compartments that simplify selection and storage

Easy compatibility with standard cables, thermal wires, and LED leads

Ready-to-use design, suitable for on-site repairs and installations

Advantages of Using a Crimp Terminal Kit

Switching from soldering to crimping offers multiple benefits. Here’s why crimp terminal kits are a smart investment:

Speeds up wiring tasks by eliminating the need for heat or solder

Reduces the risk of overheating delicate sensors or capacitors

Provides a consistent connection quality for repeat jobs

Ensures safer terminations by reducing loose wire hazards

Enhances professionalism in electronics and automotive projects

Where Can You Use Crimp Terminal Kits?

Crimp terminal kits have versatile applications across various domains. Here are some key areas where they prove invaluable:

Electronics: Ideal for connecting LEDs, capacitors, microcontrollers, and sensors in circuit boards

Automotive repairs: Reliable connections for lights, switches, and fuses

Home improvement: Installing lighting fixtures, sockets, and safety alarms

Industrial equipment: Wiring machines, contactors, and control systems

Laptop repair: Rewiring broken cables, fan connections, and power jacks

DIY projects: Creating custom electronics, robotics, or smart home setups

Tips for Using Crimp Terminals Properly

To ensure optimal performance and long-term reliability of your crimped connections:

Strip the correct amount of insulation from the wire

Match the wire gauge to the correct terminal size

Use the appropriate crimping tool for the terminal type

Test the strength of the connection before installation

Add thermal pads or protective sleeves when working in high-heat zones

Crimping vs. Soldering: Which Is Better?

Although soldering has its place in electronics, crimping offers faster, cleaner, and more vibration-resistant connections. Crimp terminals are easier to handle, especially when you're working in tight spaces like electrical panels, under dashboards, or inside laptop housings. Moreover, crimped joints are widely accepted in professional industries because of their consistent quality and reduced need for post-installation inspection.

Choosing the Right Kit for Your Needs

When selecting a crimp terminal kit, it's essential to consider the following:

Connector variety: Does the kit include connectors for your specific projects involving controllers or sensors?

Wire range compatibility: Can it handle standard sizes used in electronics and thermal setups?

Tool durability: Is the crimping tool ergonomic and suited for repeated use with cables and grips?

Kit size: Does it include enough pieces for large projects without constant repurchasing?

Final Thoughts: Why Every Workshop Needs a Crimp Terminal Kit

In summary, a crimp terminal kit is a smart, convenient, and safety-driven investment for anyone working with electronics, wiring, or repairs. It enhances workflow, provides secure and long-lasting connections, and supports a broad range of applications, whether you're fixing microcontrollers, setting up switches, or managing sensors in an industrial setting. With benefits that span across tools, cables, oils, connectors, and more, there's no reason to delay adding one to your workspace.

0 notes

Text

Precision and Automation Redefined: Robotic Soldering Station in India – Powered by Ascomp Inc

As the demand for high-speed, precision-based electronics manufacturing continues to grow, manual soldering is no longer sufficient for maintaining consistency, safety, and throughput. Enter the robotic soldering station in India, a powerful innovation that brings automation to one of the most critical steps in PCB assembly. At Ascomp Inc, we supply cutting-edge robotic soldering solutions built for modern Indian factories—designed to enhance productivity, reduce human error, and ensure flawless results.

What is a Robotic Soldering Station?

A robotic soldering station is an automated machine equipped with programmable arms, temperature-controlled soldering tips, and precise motion control systems. It is used to automate repetitive soldering tasks on circuit boards, connectors, and terminal blocks.

Unlike traditional hand soldering, robotic soldering offers:

Consistent solder joints

Reduced operator fatigue

Greater speed and throughput

Lower rework and rejection rates

Better control over temperature and solder feed

Whether you're running a high-volume SMT line or a mid-scale EMS setup, a robotic soldering station in India delivers unmatched accuracy and repeatability.

Key Features of Ascomp Inc’s Robotic Soldering Systems

🤖 Multi-axis robotic arm for precise solder point control

🔥 Temperature-controlled iron tip with programmable profiles

🎯 Vision system and sensors for auto-alignment and inspection

💡 Custom jig fixtures to suit different PCB layouts

🛠️ Automated solder feeding system for consistent wire delivery

⚙️ User-friendly programming interface for custom routines

We also offer fume extraction integration and ESD-safe construction to meet electronics industry safety standards.

Ideal Applications

Our robotic soldering stations are suited for:

SMT and through-hole component soldering

Wire-to-board connections

Connector pin soldering

LED assemblies

Fine-pitch PCB assemblies

Automotive and EV electronics

Telecom and defense equipment manufacturing

Whether you're automating a high-speed production line or improving quality in low-volume, high-precision builds, Ascomp Inc has a model that fits your needs.

Why Invest in Robotic Soldering?

✅ Higher throughput with minimal manual intervention

✅ Lower training and labor costs

✅ Repeatable quality across thousands of units

✅ Fewer operator-related defects

✅ Improved traceability and data logging

It’s not just a tool—it’s a productivity multiplier for forward-thinking electronics manufacturers.

Why Choose Ascomp Inc?

📦 Ready stock of robotic soldering machines in India

🔧 Pre-sales guidance and post-installation support

💼 Integration with existing conveyor or workbench setups

🖥️ Training and programming assistance

🔄 Availability of spare parts and maintenance contracts

🛠️ Proven track record with EMS companies and R&D units

Our solutions are scalable, reliable, and fully customizable based on your board layout and workflow.

#RoboticSolderingIndia#AscompInc#PCBAssemblyTools#ElectronicsAutomationIndia#SMTProductionIndia#AutomatedSolderingStation#IndustrialSolderingRobot#SolderingAutomation#ESDCompliantSoldering#PrecisionElectronicsIndia

0 notes