#wireless remote control for cranes

Explore tagged Tumblr posts

Text

How Do You Inspect a Gantry Crane?

A vital piece of machinery in many industrial environments are gantry cranes. Their safety is vital since they are employed to lift and carry large weights. A gantry crane inspection is imperative to ensure they are in excellent operating condition and to spot any possible dangers.

Let’s have a look at the process of gantry crane inspection.

A Gantry Crane: What Is It?

An overhead crane, known as a gantry crane, is made of a bridge beam travelling on two parallel tracks. A hoist that is used to lift and transport weights is carried by the bridge beam. Gantry cranes are commonly employed in industrial environments to lift and move bulky items, including machinery and steel beams.

Why is a gantry crane inspection important?

Strong machinery like gantry cranes provide a significant danger of injury if improper maintenance is not given to them. Routine inspections are required to find any possible problems, including worn-out cables, broken wheels, or cracks in the bridge beam. These risks can cause the crane to malfunction, resulting in the cargo falling and hurting someone.

How frequently should a gantry crane be inspected?

The crane's usage frequency and the harshness of the environment in which it operates determine how frequently the crane has to be inspected. Gantry cranes should generally be examined regularly once a year or more if they are utilised extensively or in challenging conditions.

During gantry cranes inspection, a crane inspector will look for the following items:

The bridge: The inspector will look for any dents, cracks, or other damage. They will also inspect it to ensure that the bridge is correctly aligned with the legs.

The Trolley: The inspector will examine the trolley to look for any dents, cracks or other damage. Additionally, they will verify that the tram is correctly positioned concerning the bridge.

The Hoist: The inspector will examine the hoist for dents, cracks, or other damage. In addition, they will inspect the hoist to guarantee that it is correctly greased and functioning.

The Legs: The legs will be examined by the inspector to ensure no dents, cracks, or other issues. They will also inspect them to ensure that the legs are correctly aligned with the bridge.

Gantry cranes should undergo routine inspections to ensure they are safe to use. You can contribute to keeping your gantry crane safe and in excellent operating order by heeding the advice above.

#Gantry Crane Inspection#Gantry Cranes Inspection#Crane Remote Control Systems#Auto Crane Remote#Wireless Crane Controller#Auto Crane Wireless Remote

0 notes

Text

This day in history

I'm on tour with my new, nationally bestselling novel The Bezzle! Catch me in TORONTO on Mar 22, then with LAURA POITRAS in NYC on Mar 24, then Anaheim, and more!

#20yrsago Secret knocking codes for firewalls https://web.archive.org/web/20050212160334/http://www.linuxjournal.com/article/6811

#20yrsago The Talking Heads decision: the judicial system’s David Byrne infatuation https://web.archive.org/web/20040630151030/http://www.legalunderground.com/2004/02/i_was_ready_to_.html

#20yrsago Bush and Kerry’s RSS, side by side https://web.archive.org/web/20040401181052/http://coollame.org/bushkerry.php

#15yrsago Derivatives exposures is worth $190K/human being on Earth https://www.siliconvalleywatcher.com/the-size-of-derivatives-bubble--190k-per-person-on-planet/

#10yrsago British spies lied about getting super-censorship powers over Youtube https://www.techdirt.com/2014/03/14/turns-out-uk-government-only-wishes-it-had-special-powers-to-censor-youtube/

#10yrsago Florida set to delete Hampton, a town with a questing, rent-seeking, corrupt wang https://www.loweringthebar.net/2014/03/hampton-fl.html

#10yrsago Peak Facebook https://medium.com/a-programmers-tale/the-facebook-experiment-has-failed-lets-go-back-f7b8c66109ea

#5yrsago Beto O’Rourke was in the Cult of the Dead Cow and his t-files are still online https://www.reuters.com/investigates/special-report/usa-politics-beto-orourke/

#5yrsago Security researchers reveal defects that allow wireless hijacking of giant construction cranes, scrapers and excavators https://www.trendmicro.com/vinfo/us/security/news/vulnerabilities-and-exploits/attacks-against-industrial-machines-via-vulnerable-radio-remote-controllers-security-analysis-and-recommendations

#5yrsago Letterlocking: the long-lost art of using paper-folding to foil snoops https://www.atlasobscura.com/articles/what-did-people-do-before-envelopes-letterlocking

#5yrsago Self-insurer Walmart flies its sick employees to out-of-state specialists to avoid local price-gougers https://www.cnbc.com/2019/03/14/walmart-sends-employees-to-top-hospitals-out-of-state-for-treatment.html

#5yrsago Big Chemical says higher pollution levels are safe in West Virginia because residents don’t drink water, and are so fat that poisons are diluted in their bodies https://washingtonmonthly.com/2019/03/14/the-real-elitists-looking-down-on-trump-voters/

#1yrago Learning from Silicon Valley Bank's apologists https://pluralistic.net/2023/03/15/mon-dieu-les-guillotines/#ceci-nes-pas-une-bailout

Name your price for 18 of my DRM-free ebooks and support the Electronic Frontier Foundation with the Humble Cory Doctorow Bundle.

5 notes

·

View notes

Text

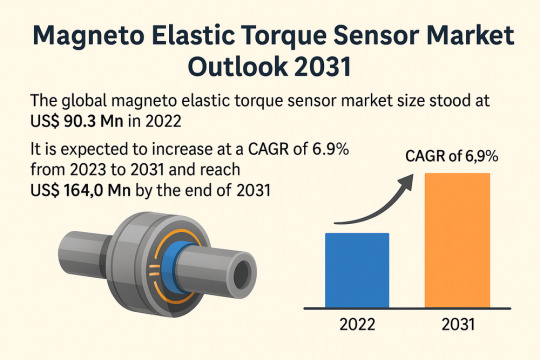

Global Magneto Elastic Torque Sensor Market Set for 6.9% CAGR Surge Through 2031

The global Magneto Elastic Torque Sensor Market is poised for substantial expansion, projected to grow from USD 90.3 Mn in 2022 to USD 164.0 Mn by the end of 2031, advancing at a compound annual growth rate (CAGR) of 6.9% during the forecast period from 2023 to 2031. Increasing demand for accurate torque measurement in electric mobility, robotics, and smart industrial applications is expected to drive this growth trajectory.

Market Overview: Magneto elastic torque sensors are critical in measuring the torque or twisting force on rotating components like shafts, motors, and gearboxes. Their non-contact operation, high accuracy, and compact design make them ideal for applications across automotive, aerospace, industrial automation, healthcare, and research sectors.

These sensors work on the principle of measuring strain-induced changes in magnetic permeability. Their versatility, long-term reliability, and digital compatibility have rendered them indispensable in environments requiring precise motion control and performance optimization.

Market Drivers & Trends

The rapid shift toward electric and hybrid vehicles and the expansion of automated industrial systems are among the primary factors accelerating magneto elastic torque sensor market growth. Torque sensors play a crucial role in managing and improving the performance of EV drivetrains, offering precise torque feedback for real-time adjustments and efficiency gains.

Moreover, stringent emission regulations are driving the adoption of torque sensors in combustion and hybrid engines to improve fuel efficiency and reduce CO₂ output. The trend toward smart factories, powered by Industry 4.0 technologies, has further amplified demand for compact and wireless torque sensors that support predictive maintenance and remote diagnostics.

Latest Market Trends

Recent trends shaping the market include:

Miniaturization of sensors to fit confined spaces, particularly in aerospace and automotive applications.

Wireless and non-contact torque sensors gaining traction for their ease of integration and lower maintenance needs.

Integration with IoT platforms, enabling real-time data acquisition and torque analysis for smart manufacturing systems.

Growing use of torque sensors in wind energy systems and medical devices for enhanced operational safety and efficiency.

Key Players and Industry Leaders

The global magneto elastic torque sensor market is consolidated, with a few prominent players commanding a significant share. These companies are continuously investing in R&D, product innovation, and strategic collaborations to expand their global footprint. Key players include:

ABB Ltd.

Applied Measurements Ltd.

Crane Electronics Ltd.

Honeywell Sensing and Control

HITEC Sensor Developments, Inc.

Kistler Instrumente Ltd.

MagCanica

Methode Electronics

Texas Instruments, Inc.

Recent Developments

Several noteworthy developments have taken place in the industry:

April 2021: Datum Electronics Ltd. partnered with Nautils Labs to provide predictive decision support and vessel digitalization for the maritime industry.

November 2020: HBM launched the T40CB torque transducer, optimized for confined automotive testing environments, featuring digital and analog interfaces.

May 2020: Kistler Holding collaborated with Vehico for advanced vehicle testing systems.

April 2020: Infineon Technologies AG completed the acquisition of Cypress Semiconductor Corporation to strengthen its capabilities in connectivity and embedded systems.

These strategic moves highlight a growing focus on digital transformation, expanded sensor functionalities, and diversified application scopes.

Examine key highlights and takeaways from our Report in this sample - https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=24872

Market Opportunities

Opportunities abound in this market, especially in sectors embracing digitalization and green technologies:

E-mobility boom: The global push for electric vehicles opens new avenues for torque sensor integration in EV drivetrains and battery monitoring systems.

Industrial automation: With Industry 4.0 adoption on the rise, torque sensors are critical in machine learning environments for real-time diagnostics.

Healthcare sector: Miniaturized sensors are increasingly being deployed in prosthetics, surgical robotics, and precision instruments.

Renewable energy: Torque measurement is vital in optimizing wind turbines and hydroelectric systems for efficient energy conversion.

The emergence of smart torque sensing solutions integrated with AI and machine learning is expected to unlock new potential in process optimization and equipment lifecycle management.

Future Outlook

The magneto elastic torque sensor market is on a stable growth trajectory, bolstered by macroeconomic trends in clean energy, smart manufacturing, and digital healthcare. As industries demand higher levels of precision, real-time monitoring, and system intelligence, the role of advanced torque sensing will become even more critical.

Future innovation is likely to focus on:

Multi-sensor integration for simultaneous measurement of torque, temperature, and pressure.

AI-powered predictive analytics for preventive maintenance.

Cloud-based torque monitoring systems for remote asset management.

By 2031, the market is expected to be characterized by smarter, more compact, and interoperable torque sensing solutions with applications across emerging and established economies.

Market Segmentation

The magneto elastic torque sensor market is segmented as follows:

By Application:

Automotive: Dominant application, particularly in EVs and hybrid powertrains.

Aerospace & Defense: For load monitoring and structural testing.

Research and Development: Academic and industrial torque testing.

Industrial: Robotics, automation, machine tools.

Others: Healthcare devices, renewable energy systems.

By Region:

Asia Pacific: Leading the market with significant contributions from China, Japan, South Korea, and India. The region benefits from a strong automotive base and growing EV adoption.

North America: High technology integration in manufacturing and defense sectors.

Europe: Home to key automotive and industrial automation players.

Rest of World: Emerging opportunities in South America and the Middle East driven by industrial digitization.

Regional Insights

Asia Pacific dominated the global market in 2022 and is projected to maintain its lead throughout the forecast period. The region’s growth is propelled by:

High production and export volume of electric and hybrid vehicles.

Strong governmental support for industrial automation and emission control.

Advancements in manufacturing technologies in countries such as China, Japan, and India.

Other regions such as North America and Europe are also witnessing steady growth due to their robust R&D infrastructure, early adoption of IoT technologies, and stringent safety standards in automotive and industrial systems.

Why Buy This Report?

This report provides:

A comprehensive overview of market dynamics including drivers, restraints, and opportunities.

In-depth segmentation by application and region, with detailed analysis.

Competitive landscape featuring major players, their strategies, and recent developments.

Historical and forecasted market size from 2017 to 2031.

Insights into current and emerging trends shaping the industry.

Strategic recommendations for stakeholders, investors, and new entrants.

Customizable data formats (PDF & Excel) for quick access and business planning.

0 notes

Text

The Advantages of Wireless Hydraulic Remote Controls for Industry

In today’s fast-paced industrial landscape, precision, safety, and efficiency are non-negotiables. Whether you're operating heavy-duty construction equipment, managing forestry machinery, or working in high-risk zones like mining or petrochemical plants—remote control technology is transforming the way hydraulic systems are operated.

At Gerrard Hydraulics, we proudly supply advanced hydraulic remote control systems from industry leaders Lodar and Gross Funk. These systems are engineered for tough Australian conditions, giving operators maximum control while staying safely out of harm’s way.

Explore All Remote Controls Lodar Remotes | Gross Funk Remotes

Why Upgrade to Wireless Hydraulic Remote Control?

Whether you call it a remote control hydraulic kit, a wireless hydraulic remote control, or simply a hydraulic wireless remote control system, the benefits are clear:

Enhanced Safety

Operators can maintain full control from a safe distance, especially useful in hazardous areas such as construction zones, industrial plants, or remote forestry locations.

Increased Productivity

Wireless operation allows faster setup, improved response times, and less downtime. No more climbing in and out of machinery just to activate a function.

Reduced Wear and Tear

By eliminating long cable runs and mechanical linkages, wireless remote hydraulic controls reduce wear and extend the life of your hydraulic system.

Top Applications for Wireless Remote Control in Hydraulics

These systems are used across various sectors, including:

Agriculture – Control sprayers, seeders, or attachments without leaving the cab.

Construction – Ideal for cranes, winches, and concrete pumps.

Forestry – Safe and precise control of winches, blades, and cutters.

Industrial Plants – Used for presses, lifts, and conveyor systems.

Transport & Towing – Great for tilt trays, tailgates, and hydraulic ramps.

Mining & Petrochemical – Intrinsically safe options available for hazardous zones.

Lodar Wireless Remotes – Built for the Harshest Environments

Lodar is a leading name in hydraulic wireless remote control systems, trusted across Australia for their rugged reliability, intuitive operation, and customisation options.

Lodar Mini

Compact, waterproof (IP67)

2 or 4 function options

Ideal for small equipment and limited space installs

Lodar Standard

Up to 6 functions

Tactile dome buttons with protective overlay

Perfect for towing, tilt trays, and everyday use

Lodar Industrial Pro

2 to 40 functions available

Built for large-scale automation, cranes, and complex control needs

IP-rated, custom labelling available

Looking for a Lodar remote in Australia? We’ve got you covered with:

Lodar remotes for sale

Lodar radio remote systems

Lodar receivers, covers, aerials, solenoids and more

Full range of Lodar accessories and remote control cases

Gross Funk – Industrial-Grade Radio Control Systems

When it comes to mission-critical remote control hydraulic systems, Gross Funk delivers German-engineered excellence.

Key Models:

GF-T13 / T13+

Smallest push-button remotes

Available in 2 or 6 button versions

Ideal for compact equipment and forestry gear

GF-T14 / T20 / T53

Larger units with two-level push buttons and optional LCD displays

Excellent for cranes, sawmills, and construction machinery

Touchscreen control available on select models

GF2000 CAB Control

Permanent transmitter options for fixed stations

Ideal for multi-transmitter operations in factories or heavy machinery operations

Gross Funk radio remote control systems are used in:

Construction and industrial cranes

Forestry machines

Rescue vehicles

Steel and mining industries

Stage automation and more

👉 Explore Gross Funk Remotes

Why Gerrard Hydraulics?

As a trusted hydraulic systems and components distributor and control systems expert in Perth, Gerrard Hydraulics brings:

✔ In-house technical support and installation advice ✔ Industry-grade products for heavy-duty use ✔ Customisable systems to suit your equipment ✔ Full stock of accessories, receivers, and spares ✔ Expertise across hydraulic wireless remote control systems and manual solutions

Ready to Upgrade Your Control System?

Whether you're after a lodar wireless remote, gross funk radio remote control, or a full remote control hydraulic kit, Gerrard Hydraulics has the solution for your specific needs. Browse our full range or speak to our team to find the right fit.

Need help? Call us or visit our Perth store for expert advice.

#hydraulic remote control#remote control hydraulic kit#wireless remote hydraulic controls#wireless remote control for hydraulic#wireless hydraulic remote control#lodar remote#lodar remote control#lodar remote australia#lodar wireless remote#lodar remote for sale#gross funk radio remote control#gross funk

0 notes

Text

Mini Cranes - Crane Latest Price, Manufacturers & Suppliers | Nilkanth Machine Tools

Construction and industrial development, mini cranes have become an essential piece of machinery for efficient material handling and safe lifting. Compact in size but powerful in performance, these cranes are designed to optimize space, save time, and reduce labor intensity—making them an indispensable tool across various job sites. As a leading Mini Crane Manufacturer, Nilkanth Machine Tools has set a benchmark in delivering reliable and high-performance mini cranes to clients across India and beyond.

What is a Mini Crane?

A Mini Crane is a compact lifting device engineered to perform material handling tasks in areas with space constraints or limited accessibility. Unlike conventional cranes, mini cranes are smaller in size, making them ideal for urban construction, high-rise building projects, and interior works where large cranes cannot be deployed.

Despite their compact size, mini cranes can handle impressive loads and offer robust lifting capabilities, making them suitable for a range of lifting operations in both indoor and outdoor environments.

Why Choose Mini Cranes?

Whether you're operating a small-scale construction project or handling materials in a warehouse, a Construction Mini Crane or Material Handling Mini Crane brings a host of advantages:

Compact Size: Ideal for narrow spaces or congested areas.

Versatility: Can be used for lifting, shifting, and placing materials.

Enhanced Safety: Minimizes the risk of manual handling injuries.

Improved Efficiency: Speeds up construction timelines.

Cost-effective: Reduces labor costs and increases productivity.

Types of Mini Cranes Offered by Nilkanth Machine Tools

As a trusted Mini Crane Supplier in Ahmedabad, Nilkanth Machine Tools manufactures a wide range of mini cranes tailored to different construction and industrial needs:

Construction Mini Crane: Perfect for construction sites, this crane is designed to lift bricks, cement, sand, and other heavy materials to higher floors. It features a strong steel body, robust motor, and enhanced safety controls for efficient vertical lifting.

Material Handling Mini Crane: Used in factories and warehouses, this crane helps in transporting raw materials, tools, and finished goods across the premises. Its compact design and ease of maneuverability make it ideal for indoor operations.

Electric Mini Crane for Construction: This eco-friendly crane runs on electricity and is a preferred choice for operations where noise and emissions must be minimized. Equipped with user-friendly controls and powerful lifting capabilities, it's ideal for urban projects and indoor environments.

Mini Lifting Crane: A versatile solution designed for quick and easy lifting tasks, this crane is suitable for both construction and industrial applications. It offers a high load-bearing capacity, adjustable boom, and 360-degree rotation options.

Key Features of Nilkanth’s Mini Cranes

As a reputed Mini Lifting Crane Manufacturer, we ensure our products meet the highest industry standards. Our mini cranes come with:

Heavy-duty Frame: Built with durable materials to withstand rigorous usage.

High Load Capacity: Can lift up to 500 kg or more, depending on the model.

Easy Installation & Operation: Plug-and-play systems reduce downtime.

360° Rotation: Enables efficient material placement without repositioning the crane.

Remote Control Functionality: Some models come with wireless controls for ease of use.

Safety Systems: Includes emergency stop, overload protection, and anti-tilt features.

Applications of Mini Cranes

Mini cranes serve a wide array of industries, thanks to their adaptable and multifunctional nature:

Construction Sites: Lifting materials to upper floors in high-rise buildings.

Warehouses: Shifting goods and tools between storage racks or workstations.

Factories: Handling parts and equipment in production lines.

Maintenance Work: Used for installation and repair jobs in difficult-to-reach places.

Interior Renovations: Ideal for working in confined indoor spaces.

Why Nilkanth Machine Tools?

When you're looking for a reliable Mini Crane Manufacturer or Mini Crane Supplier in Ahmedabad, Nilkanth Machine Tools is the name you can trust. Here’s why:

Years of Experience: With decades of expertise in the construction machinery industry, we understand what makes a crane efficient, durable, and safe.

Custom Solutions: We manufacture cranes based on your specific lifting needs, site conditions, and usage frequency.

Quality Assurance: All our mini cranes undergo stringent quality checks and performance tests before dispatch.

After-Sales Support: We offer prompt maintenance, servicing, and spare parts supply to ensure long-term performance.

Affordable Pricing: We provide the latest mini crane prices without compromising on quality—ensuring maximum ROI for your business.

How to Choose the Right Mini Crane?

When investing in a mini crane, consider the following:

Load Capacity: Choose a crane that can comfortably handle your heaviest load.

Power Source: Electric cranes are ideal for indoors; diesel/petrol options are better for outdoor use.

Lift Height: Determine how high materials need to be lifted.

Portability: Check if the crane needs to be stationary or mobile.

Safety Features: Opt for models with adequate safety mechanisms.

Many construction companies, contractors, and industrial clients have benefited from our top-grade Material Handling Mini Cranes and Electric Mini Cranes for Construction. One of our clients, a leading high-rise builder in Gujarat, reported a 30% increase in construction speed after switching to Nilkanth’s mini cranes for floor-to-floor material transportation.

Another client from a warehouse in Gujarat praised the compact design and easy operation of our mini lifting crane, which helped them optimize storage logistics and reduce manpower.

Industries We Serve

Civil Construction

Real Estate Development

Warehousing & Logistics

Mechanical Workshops

Infrastructure Development

Renovation & Interior Works

Mini Crane – Latest Price and Availability

Looking for the Best Mini Crane price? At Nilkanth Machine Tools, we offer competitive pricing based on your specific model and customization needs. Our sales team is always ready to provide you with an updated quote, delivery schedule, and detailed product specifications.

We ensure timely deliveries across India, including major cities like Mumbai, Delhi, Bangalore, Chennai, and especially across Gujarat with Ahmedabad being our core operational hub.

Ready to invest in a high-quality Mini Crane? Trust the experts at Nilkanth Machine Tools – your reliable Mini Crane Manufacturer and Mini Crane Supplier in Ahmedabad.

Our team is here to assist you with product demos, pricing queries, and tailored solutions for your lifting needs. Let’s build smarter, safer, and faster with Nilkanth’s cutting-edge mini crane solutions.

Visit: https://nilmac.com/ Contact: 9724452725 Email id:[email protected] Location: Near, 5503/1,GIDC, Cross Road, Trikampura Patiya, Vatva Vatva, Ahmedabad, Gujarat 382445

#Mini Crane#Mini Crane Manufacturer#Mini Crane Supplier in Ahmedabad#Construction Mini Crane#Material Handling Mini Crane#Electric Mini Crane for Construction#Mini Lifting Crane Manufacturer

0 notes

Text

What Is a Crane Scale? A Simple Guide for First-Time Buyers in India

In India, industries like manufacturing, logistics, shipping, and construction deal with heavy materials every day. Weighing these materials safely and accurately is very important for both safety and efficiency. That’s where a crane scale comes in. It’s a smart and modern solution for weighing heavy loads directly while lifting them.If you're a first-time buyer or just curious about how crane scales work, this blog is your easy and complete guide. We'll explain everything in simple Indian English so that you can make a smart choice.

What Is a Crane Scale?

A crane scale is a type of weighing scale that is attached to a crane or a hook-lift system. It helps to measure the weight of an object while it's being lifted. Instead of placing the item on a platform (like traditional scales), the item is hung using chains or hooks. The scale shows the weight directly on a digital or analog display.

This type of scale is mainly used in heavy-duty industries where lifting and weighing happen at the same time — like in steel plants, godowns, ports, transport yards, and construction sites.

How Does a Crane Scale Work?

Crane scales work using load cells. These are special sensors that feel the pressure or tension created when a heavy object is lifted. The pressure is then converted into weight and shown on a screen. Most modern crane scales come with a digital display, remote control, and even wireless connectivity for easy use. Some even support Bluetooth or apps for smartphones.

Here’s a basic step-by-step:

Attach the crane scale to the lifting hook of your crane or hoist.

Secure the load using shackles, chains, or hooks.

Start the lifting process. The scale will sense the tension/load.

The display shows the exact weight of the lifted item.

Record or transfer the weight data (if it’s a digital system).

Why Do Indian Industries Use Crane Scales?

Crane scales are growing in popularity across Indian industries because they solve many practical problems. Here are some strong reasons:

1. Save Time

No need to shift heavy items to a platform scale. Weigh them directly while lifting.

2. Save Space

You don’t need extra floor space for a large weighing platform.

3. Improve Safety

Avoid accidents from overloading. Know the exact weight in real-time.

4. Digital Accuracy

Get correct and reliable weight readings, which reduce calculation errors.

5. Mobile and Flexible

Use it anywhere your crane can go. Great for field sites and remote locations.

Where Are Crane Scales Commonly Used in India?

Crane scales are used in many sectors, such as:

Steel & Metal Industry: For weighing steel coils, pipes, rods, and scrap.

Shipping & Logistics: For containers, packages, and bulk materials.

Warehousing: To handle large inventories safely.

Construction Sites: For lifting heavy materials like cement bags, steel bars, and machines.

Factories: For day-to-day weighing of raw materials or finished goods.

Types of Crane Scales

There are different types of crane scales based on usage:

Digital Crane Scale

The most common one today. It has a digital display, remote control, and sometimes even a printer.

Heavy-Duty Crane Scale

Designed for very heavy loads (up to 100 tons or more). Used in ports and steel plants.

Wireless Crane Scale

Allows users to read weight data from a distance using a remote or app.

Mini Crane Scale

For smaller loads, perfect for warehouses and light industries.

Key Features to Check Before Buying a Crane Scale

If you’re planning to buy a crane scale in India, make sure to check the following:

1. Weight Capacity

Choose a scale that can handle your maximum load safely. Available options are 1 ton, 5 ton, 10 ton, and more.

2. Accuracy

Look for scales that give precise readings with minimum error margin.

3. Build Quality

A strong metal body, waterproof design, and good paint finish are signs of a quality scale.

4. Display

Bright and easy-to-read digital display, even in low-light environments.

5. Safety Features

Auto overload alerts, power cut protection, and strong shackles.

6. Battery Backup

Long-lasting battery for working in remote areas or power-cut zones.

Top Benefits of Using a Crane Scale

Let’s sum up why crane scales are a great investment for Indian industries:

Reduces labor cost and effort

Saves time and improves productivity

Prevents accidents and overloading

Helps in accurate billing and logistics

Space-saving solution for small workspaces

Why Crane Scales Are the Future

As India’s industries move toward automation, smart machinery, and data-driven decisions, crane scales offer the perfect balance of technology and practicality. They are now essential tools in modern industrial operations.

With features like wireless data transfer, remote displays, and digital accuracy, crane scales are no longer a luxury — they are a necessity for efficiency, accuracy, and safety.

Conclusion

If you work in an industry where heavy items are lifted, moved, or transported, investing in a crane scale is a smart move. It saves time, space, and effort while ensuring accurate weight measurements.As a first-time buyer in India, keep in mind your load requirements, safety needs, and environment. Choose a trusted brand that offers quality, warranty, and good customer support. By understanding how crane scales work and how they can help your business, you can make a smart, cost-effective choice that benefits your operations in the long run.

#pitless weighbridge#largest manufacturers of electronic weighbridge#electronic scales#mobile weighbridge#electronic weighbridge#pit type weighbridge#heavy duty platform scale#crane scale#weighbridge manufacturers in india#electronic scales in india

0 notes

Text

Best Electric Hoists Manufacturer in Ahmedabad

Electric hoists are powerful lifting devices designed to handle heavy loads with precision, speed, and minimal human effort. Operated by electric motors, these machines are commonly used in industries such as construction, manufacturing, warehousing, and logistics. The core function of an electric hoist is to lift and lower materials vertically, making it an essential component for material handling in environments where safety and efficiency are paramount. Electric hoists come in various capacities, ranging from a few hundred kilograms to several tons, and are built with features such as overload protection, emergency stop functions, and high-torque motors to ensure safe operation. One of the key advantages of using electric hoists is their ability to streamline workflow and improve productivity. Unlike manual or chain hoists, electric hoists provide a smooth, consistent lift without requiring physical labor, reducing the risk of injury and fatigue. They are typically mounted on cranes, beams, or trolleys, allowing operators to maneuver loads effortlessly across short distances. Their compact design, combined with rugged construction, makes them suitable for indoor and outdoor applications. Moreover, the availability of both single-phase and three-phase models ensures compatibility with a wide range of industrial power systems. Electric hoists are evolving with advancements in automation and smart control systems. Many modern hoists now feature wireless remote controls, programmable lifting limits, and energy-efficient motors to support sustainable operations. Maintenance has also become simpler, with accessible parts and diagnostic features that alert users to any potential issues before they become major problems. Whether for small workshops or large industrial facilities, electric hoists offer a reliable and efficient solution for lifting needs, contributing to safer and more productive work environments.

For More Details Click Here: https://www.indiantradebird.com/product/electric-hoists

0 notes

Text

Carry Deck Crane Market Expanding Applications and Advancements in Safety and Operational Efficiency

The carry deck crane market has witnessed steady growth in recent years, driven by its versatility and ability to perform in confined spaces where traditional cranes cannot operate. A carry deck crane is a type of mobile crane equipped with a small, compact design that features a rotating deck and can carry heavy loads, making it an essential tool for industries that require efficient and effective lifting solutions. This article explores the current trends, growth factors, challenges, and future outlook of the carry deck crane market.

What is a Carry Deck Crane?

A carry deck crane is a mobile, compact crane designed for handling loads in tight, limited spaces such as warehouses, construction sites, and industrial plants. Unlike larger cranes, carry deck cranes are equipped with a low-profile, four-wheeled design that allows them to maneuver easily in areas with limited space and low ceiling heights. The crane’s deck, which can rotate, is typically mounted above the wheels, and it is capable of lifting and transporting materials to different areas of the job site.

Market Overview

The global carry deck crane market has grown at a steady pace due to the increasing demand for efficient lifting and material handling equipment in industries such as construction, manufacturing, and logistics. With their ability to operate in small spaces and their versatile lifting capabilities, carry deck cranes have gained popularity in sectors where space is limited, and large cranes cannot access or maneuver effectively.

The market is also experiencing a rise in adoption driven by advancements in technology, including remote operation systems, improved safety features, and enhanced lifting capacities. These innovations have contributed to the widespread use of carry deck cranes in diverse sectors, further expanding their market potential.

Growth Drivers

Several factors are contributing to the growth of the carry deck crane market:

Compact Design and Maneuverability: One of the primary advantages of carry deck cranes is their compact design, which allows them to navigate through tight spaces. This feature makes them ideal for indoor and confined site operations where other cranes cannot fit. Their ability to rotate 360 degrees also adds to their versatility.

Rising Demand in the Construction Industry: The construction industry, particularly in urbanized areas, has witnessed increased demand for smaller, more maneuverable lifting equipment. Carry deck cranes are increasingly being used for lifting materials in small spaces, such as in building renovations, factory maintenance, and infrastructure development.

Technological Advancements: The integration of advanced technologies, such as GPS tracking, wireless controls, and telematics, is enhancing the operational efficiency and safety of carry deck cranes. These technological innovations make it easier for operators to control the crane from a distance and monitor performance in real-time, thereby improving productivity and minimizing downtime.

Safety Regulations and Standards: Stringent safety regulations and lifting standards in various regions have prompted industries to adopt more advanced and efficient lifting equipment, like carry deck cranes. These cranes are designed to meet global safety requirements, providing higher levels of safety for operators and reducing the risk of accidents at the workplace.

Cost Efficiency: Compared to larger cranes, carry deck cranes are cost-effective in terms of both initial investment and operational costs. Their compact size and efficient design reduce the need for larger cranes and specialized operators, making them a more affordable choice for small to medium-scale projects.

Challenges Facing the Market

Despite their numerous advantages, the carry deck crane market faces several challenges:

Limited Load Capacity: Carry deck cranes are generally designed for smaller loads compared to full-sized cranes. While this is not an issue for many applications, it may limit their use in industries or projects requiring the lifting of heavier materials or equipment.

High Operational Costs in Some Regions: While carry deck cranes are cost-effective, their operation may be more expensive in certain regions due to high fuel and maintenance costs. Additionally, the availability of skilled operators may also affect operational costs in some regions.

Market Competition: The presence of numerous players in the global market, including both large crane manufacturers and smaller companies, increases competition in the carry deck crane segment. This may lead to pricing pressures, affecting the profitability of manufacturers.

Limited Awareness in Developing Regions: While carry deck cranes are gaining popularity in developed markets, their adoption in developing regions may be slower due to limited awareness and a preference for larger, more established crane types.

Market Segmentation

The carry deck crane market can be segmented based on the following factors:

Capacity: The cranes are available in different load capacities ranging from small (up to 5 tons) to larger models (over 10 tons). The demand for different capacities varies depending on the industry and specific application requirements.

End-User Industry: The key industries using carry deck cranes include construction, manufacturing, oil & gas, utilities, and logistics. The construction sector, in particular, remains the largest consumer of these cranes due to the ongoing urbanization and infrastructure development globally.

Region: North America and Europe are significant markets for carry deck cranes, driven by advanced infrastructure and increasing construction activities. However, the Asia Pacific region is expected to experience the highest growth in the coming years, owing to rapid industrialization and urbanization in countries like China and India.

Future Outlook

The carry deck crane market is expected to continue expanding as demand for space-efficient lifting solutions rises across various industries. Technological advancements, coupled with growing awareness about the benefits of these cranes, will further boost market growth. The increasing need for automation and safety in material handling will drive innovation and contribute to the adoption of carry deck cranes in both developed and emerging markets.

#CarryDeckCrane#CraneMarket#ConstructionEquipment#LiftingSolutions#IndustrialMachinery#CompactCranes

0 notes

Text

Remote display and data transmission heavy duty crane scales

Electronic 300kg digital crane scales for commercial Our crane scales are electronic, designed with high efficiency and intelligence in mind. It is modular and composed of a terminal and scale body, which is made of steel and resists wear and tear and shock. These scales are easy to install, easy to clean, and requires minimal maintenance.

The attractive and Standard crane Scale meets most weighing needs for the cost-conscious retailer. The precision load cell gives superior reliability and complete accuracy with every use. Battery power makes this scale highly versatile and portable.

Application areas include mobile business, fruits and vegetables, meats and cheese, delicatessens, confectionary, coffee and tea, portion control, and many more!

digital hanging scale - crane weighing scales Kampala Accurate Weighing Scales has supplied crane weighing scales with reliability and safety in mind. Whether you need a small 50kg legal for trade scale for your luggage or a 5 tons crane scale in your scrap metal business, Accurate Weighing Scales has a crane scale capable of checking the weight of incoming and outgoing materials across a range of industries.

These weighing scales are built to last with their sturdy aluminium die casting. The OCS Series Crane Scale offers a compact portable design and will give you years of trouble-free operation. Use in recycling, material handling applications, shipping/receiving.

digital industrial crane scales OCS series Kampala suppliers The Accurate Weighing Scales’ Series Crane Scale is a full featured, rugged industrial crane scale with a backlit LCD display suitable for viewing even in direct sunlight! These Series is available in capacities ranging from 1000 kg to 10000 kg. ZigBee Wireless Capabilities.

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us Office +256 (0) 705 577 823, +256 (0) 775 259 917 Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036 Email: [email protected]

#fish scales#health ( height and weight ) scales#kitchen scales#mini palm scales#waterproof scales#counter scales#bathroom scales#baby scales#whole sale scales

0 notes

Text

Why Should You Use Wireless Crane Controls in Your Business?

Are you looking forward to enhancing the operations of your business? The best way to do so is by aligning all your operations with modern technology. Radio-controlled devices are playing significant roles in every industry nowadays. In fact, most cranes are equipped with these features, which is why controlling them has now become easier. If you have the same requirement, you should quickly grab an auto crane wireless remote and make your operations smooth. But why should you consider them your ideal companions in running your business? Below are some reasons that you should explore now:

Rigging and Guiding Can Both be Done by the Same Person

You don’t need two workers for rigging and guiding. You can appoint one for both jobs and still keep them easy and smooth. This way, you can cut down on hiring people, especially for controlling cranes.

Enjoying Visibility

Both before and during an operation, wireless crane controls offer great visibility on site. They allow you to move around the area in order to get an unobstructed view of the crane being operated. You also don’t need a spotter to do so.

Fewer Workers are Needed for Operations Related to Cranes

When running a business, you mainly think about cutting costs in order to enjoy greater profitability. This is exactly what a wireless crane controller allows you to do. Having it on site ensures that fewer workers are appointed to control cranes. This is because there is no extra effort for rigging or spotting in the area.

If you want your business to be extremely smooth and profitable with fewer workers on site, you should start using wireless crane controls now. They are the key to success in today’s world. Get in touch with the best company offering the same, acquire the remote controllers, and get started with your operations.

#Crane Remote Control#Auto Crane Wireless Remote#Wireless Crane Controller#Auto Crane Remote#Crane Remote Control Systems#Gantry Crane Radio Control

0 notes

Text

Why Interior Fit-Out Design is the Key to a Productive and Stylish Workspace

Let’s talk about your workspace. It’s more than just four walls and a desk — it’s where ideas come to life, where your team spends most of their day, and where clients form their first impression of your brand. But how do you turn a bland, generic space into one that fuels productivity, sparks creativity, and feels uniquely yours? The answer lies in interior fit-out design.

What Exactly is Interior Fit-Out Design?

Imagine moving into a new building. You’ve got an empty shell — concrete floors, bare walls, and zero personality. Fit-out design is the process of transforming that shell into a functional, beautiful space tailored to your needs. It’s not just picking paint colors or furniture (though that’s part of it!). It’s about planning every detail to align with how your team works and what your brand stands for. Think:

Smart layouts that keep people from tripping over printers or shouting across noisy desks.

Lighting that doesn’t leave everyone squinting at screens.

Tech setups that make meetings feel seamless, not like a battle with tangled cords.

Design touches that make clients think, “Wow, this company gets it.”

It’s like tailoring a suit. Off-the-rack might work, but custom-fit? That’s where the magic happens.

How a Thoughtful Design Gets Your Team in the Zone

Let’s be honest — no one does their best work in a cramped, dimly lit cubicle. Here’s how a well-designed workspace can boost productivity:

1. Layouts That Actually Make Sense Ever worked in an office where the sales team is wedged between the breakroom and the bathroom? Not ideal. A good fit-out designer maps out workflows to create zones that work. For example:

Open areas for brainstorming sessions where sticky notes and whiteboards rule.

Quiet corners for deep focus (no “Hey, can I borrow your charger?” interruptions).

Strategic placement of printers, supplies, and meeting rooms to cut down on wasted time.

2. Furniture That Doesn’t Kill Your Back Uncomfortable chairs, wobbly desks, and screens positioned at neck-craning angles aren’t just annoying — they’re productivity killers. Fit-out designers prioritize ergonomics with:

Adjustable desks so you can stand or sit.

Chairs that support posture (no more slouching by 3 p.m.).

Monitor arms and keyboard trays that keep everything at eye level.

3. Tech That Works For You, Not Against You There’s nothing worse than a video call that freezes mid-presentation. A modern fit-out integrates tech smoothly:

Hidden charging stations so no one’s crawling under desks to plug in.

Smart boards and wireless screens that make collaboration feel effortless.

Climate controls you can adjust from your phone (goodbye, thermostat wars).

Style Matters More Than You Think

A stylish workspace isn’t about being Instagram-ready (though that’s a bonus!). It’s about creating an environment that reflects your brand’s personality and makes people want to show up. Here’s how design elevates your space:

1. Branding That Speaks Without Words Your office should scream “this is who we are” the second someone walks in. A creative agency might use bold colors, funky art, and open spaces to shout “innovation!” A law firm? Maybe rich wood tones and sleek, minimalist lines to whisper “trustworthy and precise.” Fit-outs weave your brand into:

Wall graphics or murals that tell your story.

Color schemes that match your logo or industry vibes.

Décor details — like plants for eco-conscious brands or vintage maps for travel companies.

2. Spaces That Spark Joy (Seriously!) Colors and textures affect mood more than we realize. Soft blues and greens can calm a high-stress environment. Natural wood and sunlight make spaces feel warm and welcoming. Even small touches — like a cozy coffee nook or a wall of plants — can turn a sterile office into a place people enjoy being.

3. Flexibility for the Unpredictable Today’s office needs to adapt — fast. Maybe you need a quiet room for remote interviews, or a lounge that doubles as a client meeting spot. Fit-outs use tools like:

Modular furniture that can be rearranged in minutes.

Movable partitions to create privacy on the fly.

Multi-use spaces (a café that moonlights as a workshop area).

Happy Employees = Better Business

A workspace that cares for well-being isn’t just a perk — it’s a game-changer. Here’s how fit-out design supports your team:

1. Let There Be (Natural) Light! Harsh fluorescent lighting drains energy. Studies show natural light boosts mood and focus. Fit-outs maximize windows and add mirrors to bounce light around. Some even add “biophilic” elements — think living walls, indoor water features, or wood accents — to bring the outdoors in.

2. Silence the Noise Open offices are great for collaboration… until you’re trying to write a report while Karen two desks over debates lunch options. Sound-absorbing panels, carpeting, or even white-noise systems can keep distractions at bay.

3. Room to Recharge A burned-out team isn’t a productive one. More companies are adding:

Meditation rooms for quick mental resets.

Small gyms or yoga spaces (because a stretch break beats a coffee crash).

Nap pods (yes, really!) for shift workers or late-night project sprints.

Why This is Worth the Investment

Sure, fit-outs cost money upfront. But think of it as planting seeds for long-term growth:

Attract (and Keep) Top Talent: Want the best hires? A modern, comfortable workspace is a huge selling point. People want to work somewhere that values their well-being.

Impress Clients Instantly: A polished office or showroom signals professionalism. Clients remember the vibe as much as the pitch.

Adapt Without Overhauling: A flexible design grows with your business. Need to add 10 new hires? Rearrange the modular desks instead of knocking down walls.

Real-Life Example: From Drab to Dynamic

Take a Riyadh marketing firm that felt “stuck.” Their office was a maze of beige cubicles, fluorescent lights, and zero personality. After a fit-out redesign, they added:

Collaborative zones with writable walls for brainstorming.

Soundproof booths for private calls.

A lounge area with games and comfy seating.

Branded murals showcasing their creative edge.

Result? Employees stayed longer, clients lingered during visits, and creativity skyrocketed.

Finding the Right Fit-Out Partner

Not all designers are created equal. Look for:

Experience in your industry (an office designer might not nail a retail space).

Sustainability focus (eco-friendly materials save costs and the planet).

Post-build support (because even the best designs need tweaks).

Final Thoughts

Your workspace isn’t just a place to work — it’s a tool that can drive success. A well-designed fit-out bridges the gap between “functional” and “inspiring,” making every day a little easier and a lot more enjoyable. Whether you’re a startup or a decades-old company, investing in your space is investing in your people, your brand, and your future.

Ready to turn your workspace into a productivity powerhouse? Start the conversation with a fit-out designer today — you might be surprised at what’s possible.

0 notes

Text

High Quality Radio Remote for EOT Cranes - Available at industries Syndicate

Industries Syndicate, an ISO 9001:2015 certified company, offers high-performance Radio Remote Controls for EOT cranes and industrial applications. Designed for precision, durability, and safety, our remote systems enable wireless crane operation, enhancing efficiency and reducing manual effort.

Our Radio Remote Controls feature:

Long-range signal transmission for seamless crane operation

Ergonomic, user-friendly design for effortless control

High-frequency, interference-free communication

Rugged, weatherproof build for industrial environments

Reliable emergency stop and fail-safe mechanisms

With over six decades of expertise, we provide customized remote control solutions that meet industry safety standards, ensuring smooth and secure material handling operations.

Address: 7 Chittaranjan Avenue, Laha Paint House, 6th Floor, Kolkata - 700 072, West Bengal,

India

Phone: +91-33-2237-5540/ +91-33-2237-6295

Email: [email protected] / [email protected]

Website: https://indusynd.com/

0 notes

Text

In today’s fast-paced business environment, accuracy, efficiency, and reliability are crucial for success. Whether you’re running a retail store, a manufacturing unit, a logistics company, or a fitness center, having the right weighing scale can make all the difference. At UP Scales, we offer a wide range of high-quality weighing solutions designed to meet the diverse needs of modern businesses. In this blog, we’ll explore our top products and help you choose the perfect weighing scale for your business.

Why Choosing the Right Weighing Scale Matters

A weighing scale is more than just a tool to measure weight—it’s an essential part of your business operations. From inventory management and shipping to quality control and customer satisfaction, the right scale can streamline your processes, reduce errors, and improve efficiency. Here’s why choosing the right scale is critical:

Accuracy: Precise measurements ensure you’re not losing money due to over or under-weighing.

Efficiency: A reliable scale speeds up operations, saving time and labor costs.

Compliance: Legal metrology standards require accurate and certified scales for certain industries.

Customer Trust: Accurate weighing builds trust with your customers, whether you’re selling products or services.

At UP Scales, we understand these challenges and offer a wide range of scales tailored to your specific needs.

Top Weighing Scales by UP Scales

Here’s a closer look at some of our most popular products:

1. Platform Weighing Scale

Ideal for: Industrial weighing, logistics, warehouses, and manufacturing.

Key Features: High capacity (up to 2000 kg), durable construction, and customizable accessories like second displays and printers.

Why Choose It: Perfect for heavy-duty applications, this scale is built to withstand harsh environments while delivering accurate results.

2. Stainless Steel (SS 304) Platform Weighing Scale

Ideal for: Food processing, pharmaceuticals, and chemical industries.

Key Features: Fully SS 304 construction, waterproof and dustproof design, and high precision load cells.

Why Choose It: Its hygienic and corrosion-resistant design makes it perfect for industries where cleanliness and durability are critical.

3. Portable Counter Scale

Ideal for: Retail stores, small-scale manufacturing, and mobile vendors.

Key Features: Lightweight, compact design, LED display, and multiple power options (AC adapter or dry cell batteries).

Why Choose It: Highly portable and easy to use, this scale is perfect for businesses that need a mobile weighing solution.

4. Heat Shield Crane Scale

Ideal for: Steel manufacturing, foundries, and high-temperature environments.

Key Features: Heat-resistant design, high capacity (up to 20 Ton), and wireless remote control.

Why Choose It: Designed to withstand extreme temperatures, this scale ensures accurate weighing even in the toughest conditions.

5. Electronic Weighing Scale (Premium Table Top Series)

Ideal for: Retail, pharmaceuticals, laboratories, and food processing.

Key Features: High precision (up to 0.1 g), sleek design, and multiple weighing units (grams, kilograms, pounds, ounces).

Why Choose It: Its premium design and high accuracy make it perfect for businesses that require precise measurements.

6. Gym Weighing Scale

Ideal for: Gyms, fitness centers, and health clubs.

Key Features: High capacity (up to 200 kg), non-slip surface, and large LCD display.

Why Choose It: Designed for fitness enthusiasts, this scale helps track weight and monitor progress with ease.

How to Choose the Right Weighing Scale for Your Business

With so many options available, selecting the right scale can be overwhelming. Here are some factors to consider:

Capacity and Accuracy: Determine the maximum weight you need to measure and the level of precision required.

Environment: Consider the conditions where the scale will be used (e.g., high temperatures, wet environments, or heavy-duty use).

Portability: If you need a mobile solution, opt for lightweight and portable scales like the Portable Counter Scale.

Compliance: Ensure the scale meets legal metrology standards and comes with a Government Calibration Verification Certificate.

Features: Look for additional features like tare functionality, label printing, and wireless connectivity.

Why Choose UP Scales?

At UP Scales, we’re committed to delivering high-quality, reliable, and accurate weighing solutions. Here’s why businesses trust us:

Wide Range of Products: From industrial platforms to portable counter scales, we offer scales for every need.

Government Certification: Our scales come with a Government Calibration Verification Certificate, ensuring compliance with legal standards.

1-Year On-Site Warranty: We provide a 1-year on-site warranty for all our products, ensuring peace of mind.

Same-Day Delivery & Installation: Enjoy same-day free delivery and installation services in Delhi NCR.

Expert Support: Our team is always ready to assist you. Call us at 9899008683 for immediate support.

Choosing the right weighing scale is essential for the success of your business. At UP Scales, we offer a wide range of high-quality, reliable, and accurate scales designed to meet your specific needs. Whether you’re in retail, manufacturing, logistics, or fitness, we have the perfect solution for you.

Ready to upgrade your weighing solutions? Visit our website to explore our products: https://upscales.buyweighingmachine.com

For inquiries or assistance, call us at 9899008683. Let UP Scales help you achieve precision, efficiency, and success in your business!

0 notes

Text

Purchase remote control crane scale with LCD display

digital industrial crane scales OCS series Kampala suppliers The Accurate Weighing Scales’ Series Crane Scale is a full featured, rugged industrial crane scale with a backlit LCD display suitable for viewing even in direct sunlight! These Series is available in capacities ranging from 1000 kg to 10000 kg. ZigBee Wireless Capabilities.

Thank you for allowing Accurate Weighing Scales (U) Ltd the privilege to serve you in advance. For inquiries on deliveries contact us Office +256 (0) 705 577 823, +256 (0) 775 259 917 Address: Wandegeya KCCA Market South Wing, 2nd Floor Room SSF 036 Email: [email protected]

0 notes

Text

Electric Hoists: Revolutionizing Material Handling with Efficiency and Safety

In industries ranging from manufacturing and construction to warehousing and logistics, the ability to lift heavy loads quickly and safely is crucial for maintaining productivity. Traditional manual lifting methods, such as using ropes or chains, have been largely replaced by more efficient and safer technology. One such innovation that has revolutionized material handling is the electric hoist. This powerful machine makes lifting tasks easier, faster, and more precise, improving both safety and efficiency across various industries.

In this blog, we’ll take an in-depth look at what an electric hoist is, its advantages, applications, and why it’s become a go-to tool in modern material handling.

What is an Electric Hoist?

An electric hoist is a lifting device powered by an electric motor, designed to raise, lower, or move heavy loads vertically with precision and ease. Unlike manual hoists, which rely on human effort to operate, electric hoists automatically lift and lower loads using electric power, reducing the amount of labor needed and increasing the speed at which heavy objects are moved.

Electric hoists typically consist of:

Motor: The motor powers the lifting mechanism and is the heart of the hoist. It's usually a single-phase or three-phase motor depending on the load capacity and application.

Hoist Drum or Chain: The load is attached to a chain or rope wound around a drum, which allows it to be lifted or lowered with ease.

Controls: The hoist is operated via a wired or wireless remote control, allowing the operator to control the speed and direction of the load’s movement.

Brake Mechanism: A crucial safety feature, the brake ensures the load is securely held in place when it’s not being moved.

Electric hoists come in a variety of designs, including overhead electric hoists, suspended electric hoists, and monorail hoists, each designed for specific types of lifting tasks.

Advantages of Electric Hoists

Electric hoists offer several distinct advantages over manual lifting systems, making them a preferred choice for many industries:

Increased Efficiency and Speed: Electric hoists can lift and lower heavy loads much faster than manual methods, increasing productivity and reducing the time spent on each lift. This is especially important in high-demand environments such as factories and warehouses.

Reduced Labor Intensity: The motorized operation of electric hoists eliminates the physical strain of manually lifting heavy objects, allowing workers to focus on other tasks while the hoist does the heavy lifting.

Improved Safety: Electric hoists are designed with multiple safety features such as overload protection, emergency stop buttons, and fail-safe braking systems. These features help prevent accidents and ensure the safe handling of heavy loads, protecting both workers and equipment.

Precision Control: Electric hoists offer finer control over the lifting process compared to manual systems. Operators can adjust lifting speeds and directions with greater precision, which is especially useful when dealing with delicate or oversized loads.

Cost-Effective in the Long Run: While the initial investment in an electric hoist may be higher than manual lifting equipment, the long-term benefits in terms of efficiency, safety, and labor savings make them a cost-effective solution for businesses that need to move heavy loads regularly.

Adaptability: Electric hoists come in different models, with varying capacities and lifting heights, making them adaptable to a wide range of applications. Some models are portable, while others can be fixed to overhead rails, cranes, or gantries, depending on the space and operation requirements.

Applications of Electric Hoists

Electric hoists are versatile tools used across a wide range of industries. Some of the most common applications include:

Construction Sites: Electric hoists are used to lift building materials, tools, and machinery to higher levels on construction sites. They save time and reduce manual labor, helping construction projects progress more efficiently.

Factories and Manufacturing Plants: In manufacturing plants, electric hoists are employed to move raw materials, components, and finished goods throughout the production line. Their precision and ability to handle heavy loads make them essential for industries such as automotive, steel production, and heavy machinery assembly.

Warehouses and Distribution Centers: In warehouses, electric hoists are used to lift and move heavy pallets, boxes, or storage containers. Their speed and ease of use significantly improve efficiency in logistics operations.

Shipyards and Ports: Electric hoists are vital in shipbuilding and port operations, where heavy parts and containers need to be moved. They’re also used for lifting and lowering heavy cargo onto ships and vessels.

Maintenance and Repair: Electric hoists are often used in maintenance and repair applications, where lifting and moving equipment or machinery components is necessary. They help in tasks like hoisting engines, motors, and other large components.

Automotive Industry: In automotive workshops and factories, electric hoists are used for lifting and moving car parts, engines, and vehicles during assembly or repairs.

Choosing the Right Electric Hoist

When choosing an electric hoist, it’s important to consider several factors to ensure you select the right model for your needs:

Load Capacity: Electric hoists come in a range of load capacities, typically from 500 kg to several tons. It’s essential to choose a hoist that can handle the maximum weight of the loads you intend to lift.

Lifting Height: Consider the height at which you need to lift objects. Ensure that the hoist's lifting height meets your operational requirements.

Power Supply: Electric hoists are available in both single-phase and three-phase configurations. Single-phase hoists are often used in residential or light industrial applications, while three-phase hoists are better suited for heavy-duty industrial use.

Speed Control: Depending on the nature of your work, you may need variable speed control for smoother and more precise lifting.

Durability and Environment: Consider the operating environment—whether indoors or outdoors, and the environmental conditions (such as moisture, dust, or corrosive elements). You may need a hoist with additional protective coatings or enclosures for added durability.

Safety Features: Look for hoists that come equipped with features such as overload protection, limit switches, and emergency stops, to ensure the safety of workers and equipment.

Maintenance of Electric Hoists

Regular maintenance is key to ensuring the longevity and smooth operation of electric hoists. Here are some tips for maintaining your electric hoist:

Inspect the Chain or Rope: Regularly check the chain or rope for wear, corrosion, or damage. Replace it immediately if any issues are found to prevent accidents.

Lubrication: Periodically lubricate the hoist’s moving parts, including the gears, drum, and motor, to keep them functioning properly.

Check the Brakes: Ensure that the brake mechanism is working correctly and that the hoist can safely hold the load in place when needed.

Electrical System Check: Have a qualified technician inspect the hoist's electrical components, such as wiring, switches, and control panels, to ensure everything is functioning as it should.

Conclusion

Electric hoists are essential equipment for industries that require the lifting and moving of heavy loads. Offering greater efficiency, improved safety, and reduced labor, they are a versatile solution for a wide range of applications, from construction sites to warehouses. With the right model and regular maintenance, an electric hoist can significantly enhance productivity and ensure the safe handling of materials in your operations. When selecting an electric hoist, be sure to consider factors such as load capacity, speed control, safety features, and the working environment to find the best match for your needs.

0 notes

Text

3 Ton Electric Wire Rope Hoist with trolley (SGRH-3T) BD

3 Ton Electric Wire Rope Hoist with trolley (SGRH-3T) is a type of material handling equipment, installed on a single beam crane, linear curve stander beams or it can be used at the hoisting mechanism of double beam crane, gantry crane, linear crane for material handling by industrial and mining enterprises, railways, and warehouses, etc. The lifting capacity of single speed electric wire rope hoist is 3 ton and the working class is M3.

This is single speed, electric hoist. Electric Wire rope hoist is the most common lifting equipment, which can be installed on single girder overhead crane or single beam gantry crane. With different design principles and using environments, small electric hoist remote control have two kinds of type, which is traveling hoist and stationary hoist. Generally speaking, electric hoisthas pendent control and wireless control.

FEATURES OF 3 TON ELECTRIC WIRE ROPE HOIST WITH TROLLEY (SGRH-3T)

Lifting Capacity (T) 3 TON.

Lifting Height (m) 8 Meter.

Lifting Speed (m/min) 8.

Running Speed (m/min) 20/30.

Wire Rope Type 6×37+1.

I-Beam Track Model 16-28b.

Working Duty M3.

Lifting Height Power(kw) 4.5.

Lifting Height R.P.M(r/min) 1380.

Lifting Height Power supply 220-440v 50/60hz 3phase.

Running Motor Power (kw) 0.4.

Running Motor R.P.M(r/min) 1380.

Running Motor Power supply 220-440v 50/60hz 3phase.

Weight 353 kg.

Certification CE, ISO.

1 note

·

View note