Don't wanna be here? Send us removal request.

Text

Aluprof Adds CAB’s Closed Loop Recycling to Their Holistic Approach to Sustainability

By Wojciech Brożyna - MD Aluprof UK

Aluminium is a strategic raw material with distinctive characteristics that enable repeated recycling without compromising its original properties. Recycling aluminium is a highly effective method for reducing carbon emissions throughout our value chain, requiring only 5% of the energy necessary for primary production. Additionally, it significantly enhances the UK’s resource efficiency and strategic autonomy. Nevertheless, the UK and Europe continue to export valuable aluminium scrap at record rates, with 1.2 million tonnes exported in 2023 alone.

Scrap exports primarily consist of energy and secondary raw materials. Given the UK’s high energy costs and resource scarcity, retaining this strategic material within the UK presents a mutually beneficial opportunity for its competitiveness, sustainability, and decarbonisation efforts.

The CAB Closed Loop Recycling Scheme offers significant sustainability benefits by promoting the recycling of aluminium within its specific alloy grades. By ensuring that aluminium scrap remains within closed, well-defined material streams, the scheme minimises the mixing of alloy grades that can reduce the overall value and performance of recycled material. This quality-controlled approach not only helps maintain the inherent properties of the metal through multiple recycling cycles but also saves energy and reduces greenhouse gas emissions. The environmental benefits are substantial, as the initiative supports a circular economy, diverts waste from landfills, and contributes to the reduction of embodied carbon in construction projects.

In addition to environmental advantages, closed loop aluminium recycling also drives economic benefits. By lowering energy and raw material costs, manufacturers can achieve greater efficiency and cost-effectiveness, enhancing their competitiveness in global markets. This recycling approach also spurs local job creation in recycling and manufacturing sectors and fosters innovation in material processing and waste management. Overall, adopting closed loop recycling not only contributes to a greener economy but also supports long-term economic stability and growth in the UK.

Beyond its environmental advantages, the scheme delivers practical operational and economic benefits for participating organisations. By requiring Members of the CAB Closed Loop Recycling Scheme to collect and sort aluminium scrap accurately using modern technology such as handheld XRF analysers, the scheme enhances the traceability and quality of scrap material, ensuring it is reprocessed into the same high-quality alloy grade. This systematic approach not only increases the resale value of the scrap but also strengthens the sustainability credentials of suppliers and contractors in a market where proof of low embodied carbon is becoming increasingly important. As more companies and main contractors adopt such practices, participation in the CAB Closed Loop Recycling Scheme can serve as a differentiator, demonstrating commitment to best practices in sustainability while optimising resource recovery.

Aluprof UK are proud to announce that they have recently joined the CAB Closed Loop Recycling Scheme and can offer its benefits on any upcoming projects where main contractors wish to reduce their carbon impact on new construction. The work is ongoing to reduce carbon embodiment in all aluminium production.

Grupa Kety, Aluprof UK’s parent company, have already done a great deal of work in primary aluminium production, where carbon embodiment has been significantly reduced. According to a 2020 White Paper, ‘Low-carbon Aluminium, Solution for Sustainable Construction & Renovation’, primary aluminium from China, which has been as high as 20 CO2e/t (carbon dioxide emissions equivalent per tonne of aluminium), drops now to an average global production output of primary aluminium of 16.7 CO2e/t. ‘Low-carbon’ primary aluminium in 2020 on average was reported as releasing 6.67 CO2e/ per tonne of aluminium.

Today, whilst ‘low carbon’ primary aluminium is not formally defined, a carbon footprint of less than 4 CO2e/t is a common reference, representing the very lowest achievable with currently available technologies. This carbon footprint is often referred to as ‘Cradle to Gate’. The global aluminium industry has achieved this figure through the use of renewable energy sources such as hydro power and other renewable technologies. Further reductions will soon be possible as the industry begins to adopt emerging green hydrogen technology during the production cycle.

The amount of recycled aluminium utilised worldwide, often termed secondary production, has shown little variation, maintaining a range of 31-33% since 2000, with a notable peak of 34% in 2019. Given aluminium's high market value, collection rates tend to be robust; in 2019, collection rates for new scrap (pre-consumer) surpassed 95%, whilst those for old scrap (post-consumer) were just over 70%. It is vital to continue to improve the collection of post-consumer scrap, as recycling this material is significantly more energy-efficient and this is where the CAB Closed Loop Recycling Scheme is so important.

According to a statement made by the Aluminium Stewardship Initiative (ASI) in February 2022, “Under a 1.5 degree scenario, the aluminium sector must reduce its GHG (Green House Gas) emissions from over a billion tonnes of CO2e to around fifty million tonnes by 2050. This is less than one-twentieth of current emissions.” LowCarbonKety, a subsidiary of Grupa Kety, Aluprof’s parent company, offers aluminium billet with an impressively low carbon footprint of 2.9 kg of CO2 for every kilogram of aluminium produced. These low-carbon products are composed of up to 75% post-consumer scrap, around 10% pre-consumer scrap, and a minimal amount of primary aluminium, all manufactured using renewable energy sources.

It is important to consider that extended lead times may affect project timelines, potentially resulting in additional carbon costs. Conversely, selecting low-carbon products, including aluminium, may yield certain BREEAM credits for the project. These factors underscore the uniqueness of each project, necessitating a tailored approach. Engaging product suppliers during the early design phase is essential to explore viable options. Aluprof's experienced design team is available to assist in identifying the most suitable aluminium sources and systems for any project during your specification process.

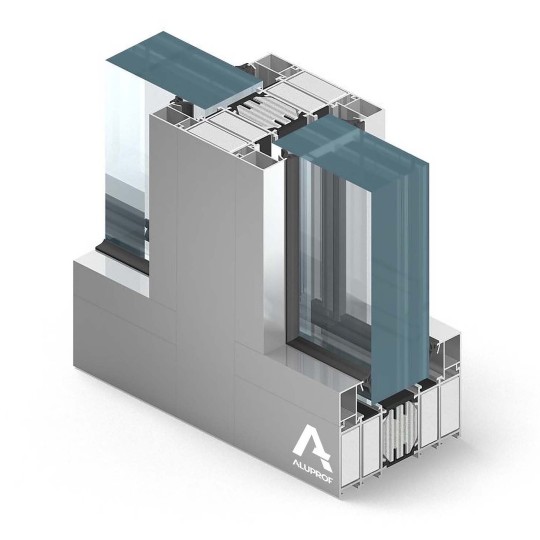

Whilst it is crucial to reduce ‘Embedded Carbon’ in profile supply, here at Aluprof we take a holistic approach to carbon reduction by also reducing ‘Operational Carbon’. Aluprof aluminium windows and doors play a crucial role in decreasing operational carbon emissions by improving the energy efficiency of buildings. The exceptional thermal insulation properties of our systems reduce the need for heating and cooling, thereby lowering energy consumption and the related carbon emissions. Additionally, the durability and minimal maintenance needs of aluminium contribute to the longevity of these systems, further reducing their environmental footprint. By opting for aluminium windows and doors, buildings can attain a more sustainable and reduced carbon footprint.

Aluprof UK have been supporting specifiers in the UK and Ireland for over fifteen years with advanced systems that include, high performance windows doors and facade systems. Many UK and Ireland based fabricators and installers supply these systems and are on hand to offer surveys and cost analysis as to what improvements can be made with likely paybacks. Further information about systems and specification support is available through the company website at aluprof.co.uk or direct from their UK head office in Altrincham by phoning +44 (0) 161 941 4005.

0 notes

Text

Aluprof Support on Gateway 2 Compliance

By Wojciech Brożyna - MD Aluprof UK

Gateway 2 is a crucial regulatory checkpoint introduced under the Building Safety Act 2022, applying to higher-risk buildings, typically those over eighteen metres tall or with seven or more storeys and containing at least two residential units. Compliance is required before construction begins, meaning no work can legally start until the Building Safety Regulator (BSR) has reviewed and approved a detailed building control application. This application must demonstrate that the building’s design meets all relevant Building Regulations and properly considers fire safety and structural safety risks.

The building control application submitted at the Gateway 2 stage is much more thorough than traditional applications. It requires developers to submit full design documentation, including plans, calculations, and specifications, along with a fire and emergency file and evidence that competent professionals are overseeing the project. Developers must also show how they will maintain the ‘Golden Thread’ which is a clear, up-to-date record of safety information applicable throughout the building’s life cycle. The application must also set out how any design changes during construction will be managed and reported to the regulator.

The introduction of Gateway 2 is part of a wider push to improve building safety following the Grenfell Tower tragedy, ensuring safety is prioritised from the very start of construction. By requiring a ‘stop/go’ decision point before work can begin, Gateway 2 aims to prevent unsafe designs from progressing into construction, increasing accountability and ensuring higher standards across the industry. This stricter process is designed to reduce safety risks during both construction and the eventual occupation of the building.

Gateway 2 is part of a staged process, the three gateways in the new system are: Gateway 1 – Pre-Planning: Considering safety risks at the planning application stage. Gateway 2 – Pre-Construction: Ensuring the design is safe before building starts. (this is where Gateway 2 compliance applies). Gateway 3 – Post-Construction: A final check before the building is occupied.

Aluprof UK has demonstrated a strong commitment to aligning with the Building Safety Act’s requirements, particularly concerning Gateway 2 approvals. Its broad range of high performance façade solutions, all 3rd party tested to the relevant standards makes Aluprof the ideal partner. In addition their major projects team collaborates closely with specialist façade contractors to ensure that all necessary supporting documentation and compliance measures are meticulously prepared for submission to the Building Safety Regulator (BSR). This proactive approach is essential, especially in light of recent challenges faced by the BSR, such as delays in processing Gateway 2 applications due to an outsourced delivery model and a shortage of in-house technical expertise.

Aluprof’s vertical integration benefits specifiers by ensuring consistent product quality, streamlined supply chains, and enhanced technical support. With in-house system design, manufacturing, and testing, Aluprof delivers high-performance aluminium systems that meet stringent UK and EU building regulations, including Gateway 2 requirements under the Building Safety Act. This integrated approach allows for greater customisation, faster lead times, and improved cost efficiency, giving specifiers confidence in project timelines and compliance. Additionally, direct collaboration with Aluprof’s experts ensures tailored solutions that align with architectural intent while enhancing sustainability and energy efficiency.

UK-based facade specialists, Century Facades, in conjunction with the team at Aluprof UK, have recently progressed with the Gateway 2 application for the Devonshire Place project in London. The submission is currently under review, and final decision will be made within the statutory timelines unless an extension is agreed upon. Marcin Bara, Design Director at Century Facades takes up the story:

“In the context of UK construction industry, Gateway 2 focuses on ensuring compliance with the functional requirements of the Building Regulations and forms a “hold point” between the design and construction phases. It is crucial for a facade specialist contractor to work closely with the facade system supplier and vice versa to align on design intricacies, material specifications, and safety requirements. This collaboration must be based on trust and true partnership as only this ensures that the facade would not only meet aesthetic criteria but also adheres to performance and safety standards mandated by current Building Regulations via Gateway processes.

“Effective communication and coordination between the contractor and supplier help in identifying potential issues early, optimising resource use, and ensuring the facade system contributes to the building’s overall compliance, sustainability, and safety objectives. This is where key partners such as Aluprof can work as an extension arm to our competent and fully qualified in-house Design and Engineering Teams to ensure the application produced for Gateway 2 is of the highest possible standards.

“It is crucial for the system supplier to offer tailored approach to this new approval regime, so that their offer and service provided is project specific and matches our requirements as a specialist facade contractor fully. This is where our close partners such as Aluprof can play a key role in producing quality submissions, meeting expectations of our Clients entirely.”

Between October 1, 2023, and September 16, 2024, the Building Safety Regulator (BSR) reported that they had received 1,018 Gateway 2 applications. Of these, only 146 were approved, equating to an approval rate of approximately 14%. The BSR rejected 25 applications, while the status of the remaining 847 applications was not specified. These delays have been attributed to several factors, including an unexpected surge in applications, a high number of incomplete or unclear submissions, and resource constraints within the BSR. Developers have expressed concerns that these bottlenecks are hindering essential housing projects, including student accommodations and build-to-rent homes.

The BSR has acknowledged these challenges and is working to stabilise and improve the building control approval process for higher-risk buildings. They emphasise the importance of submitting clear and comprehensive applications to facilitate quicker decision-making and reduce delays. It seems there is still some confusion over the process with contractors and developers.

In short, Gateway 2 compliance is about proving to the Building Safety Regulator that the design of a higher-risk building meets all safety requirements before work starts on site. It is part of a much stricter regulatory process introduced after the Grenfell Tower disaster, aiming to raise standards and accountability across the construction sector.

Aluprof UK has been supporting specifiers in the UK and Ireland for over fifteen years with advanced systems that include high-performance windows, doors, and facade systems. Many UK and Ireland-based fabricators and installers supply these systems and are on hand to offer surveys and cost analysis as to what improvements can be made with likely paybacks. Further information about systems and specification support is available through the company website at aluprof.co.uk or direct from their UK head office in Altrincham by phoning +44 (0) 161 941 4005.

#aluprof#aluminium#architecture#facade#aluminium systems#fenestration#aluminium facade#aluminium windows#curtain wall#windows

1 note

·

View note

Text

Aluprof Partner’s Day

A major event in Aluprof’s 2025 calendar, the 29th ofJanuary saw over one hundred delegates from sixty-seven companies attend the inaugural Aluprof Partner’s Day, held at the company’s prestigious 550 sq.m. conference showroom in Altrincham. Senior-level delegates included architects, fabricators, installers, and association guests. The full-day conference offered delegates valuable insights into the current state of the fenestration market, emerging trends, and an opportunity for delegates to review and ask questions about the company’s latest high-performance systems.

The idea behind the Aluprof Partner Day was to bring people together and create a platform for exploring opportunities arising from megatrends and key industry topics. It aimed to connect these insights with our partners, fostering business growth and introducing innovative solutions to the wider industry. Throughout the day, delegates had the opportunity to attend a series of insightful conference presentations, each addressing key topics relevant to the fenestration industry. These sessions were delivered by industry experts and Aluprof representatives, offering valuable knowledge on sustainability, regulatory challenges, and cutting-edge solutions in aluminium systems.

One of the key presentations, "A Holistic Approach to Sustainability," was delivered by Aleksandra Baksik, Brand & Sustainable Development Manager at Aluprof SA. Aleksandra emphasised the importance of integrating sustainability into every aspect of the construction industry, from material sourcing to energy-efficient building solutions. Her session provided a comprehensive overview of Aluprof’s sustainability initiatives and how the company is committed to reducing environmental impact by its holistic approach and offering low and ultra-low carbon aluminium to the construction industry.

Alan Budden, Architect and Passivhaus Designer, and Director at ECO Design Consultants, presented "Operational Carbon." This session explored the concept of operational carbon in building design and how architects and developers can reduce energy consumption throughout a building’s lifespan. By incorporating Passivhaus principles and energy-efficient design strategies, Alan demonstrated how the industry can make a significant contribution to achieving net-zero targets.

The importance of recycling and circular economy practices was addressed in "The CAB Closed Loop Recycling Initiative," presented by Nigel Headford, CEO of the Council for Aluminium in Building (CAB). Nigel introduced delegates to CAB’s innovative recycling programme, of which Aluprof UK is a partner, promotes the reuse of aluminium materials within the construction sector. This initiative aims to minimise waste and enhance the environmental credentials of aluminium-based systems, aligning with the industry’s growing focus on sustainability.

Regulatory challenges were another crucial topic, with Marcin Bara, Design Director at Century Facades, leading a session titled "The Challenges of Gateway 2." Marcin provided a detailed analysis of the implications of Gateway 2, a key stage in the new Building Safety Act, highlighting the stricter compliance requirements for façade design and installation. Marcin’s presentation helped delegates understand the evolving regulatory landscape and how companies must adapt to meet these new safety standards.

Finally, Kevin Mellor, Product Development & Technical Manager at Aluprof UK, led an engaging session titled "Finding Solutions with Aluprof Systems and Support." Kevin showcased Aluprof’s latest high-performance aluminium systems and discussed how they can address the challenges faced by architects and fabricators. Delegates were given an in-depth look at Aluprof’s technical support services and how the company partners with industry professionals to deliver innovative, compliant, and efficient façade solutions.

These presentations formed a key part of the conference, equipping attendees with valuable insights and practical solutions to navigate the evolving fenestration market. The event reinforced Aluprof’s position as a leader in sustainable and high-performance aluminium systems while fostering meaningful discussions among industry professionals. Highlight of the day’s proceedings was the Safari Presentations where delegates broke out into four groups and were introduced to showroom products by Aluprof’s Project Consultants and Sales Managers. These break-out groups allowed in-depth Q&A sessions explaining systems capabilities as well as receiving valuable future product development feedback from delegates.

Sean Butler, Aluprof UK’s Sales Director, reviews the feedback on the day’s presentations, “It was really important when we were actually presenting our new innovations and our new products that we tried to align them with the most interesting and important topics of the industry. So today we focused on sustainability and talked about our low carbon offer from a both embedded carbon point of view, but also operational carbon point of view. I think that this was well received by the audience. The other megatrend that we talked about was the Building Safety Act and how we wanted to align that with regards to compliance and also helping our partners to show their competence. Finally, given the background, we then presented all of our new systems in our beautiful new showroom here in Altrincham.”

Aluprof UK has been supporting specifiers in the UK and Ireland for nearly twenty years with advanced systems that include high-performance windows, doors, and facade systems. Many UK and Ireland-based fabricators and installers supply these systems and are on hand to offer surveys and cost analysis as to what improvements can be made with likely paybacks. Further information about systems and specification support is available through the company website at aluprof.co.uk or direct from their UK head office in Altrincham by phoning +44 (0) 161 941 4005.

0 notes

Text

Aluprof Showcases Cutting-Edge Aluminium Solutions at BAU 2025

BAU (Building, Architecture, and Urban Planning), the world’s leading trade fair for architecture, materials, and systems, is held every two years. It brings together everyone involved in the international community for planning, building, and architectural design. Visitors include architects, planners, investors, representatives from the industrial and commercial sectors, the building trades, and certainly manufacturers of building systems and products. BAU aggregates expertise from all sectors of industry and trades at a high international level. It facilitates a direct exchange of ideas and information, acts as an intermediary, and generates synergies. BAU has consistently been the ideal venue for investment decisions. It enables exhibitors to enter new international markets and provides all visitors with genuine, practice-oriented future prospects and lasting added value.

Aluprof attended BAU 2025 held in Munich from January 13th to 17th, 2025, to showcase their innovative window, door, façade, and sun-protection systems. Their 120-square-metre exhibit, located at booth 528 in Hall B1, featured a range of eco-friendly building solutions, aligning with the event’s focus on sustainable construction. Highlights included the new MB-79N thermally efficient window and door system, the MB-GFT100 ground floor treatment system, the MB-Opensky 120 Pergola, and the MB-82HS Lift and Slide Door System.

Participating in BAU 2025 provided Aluprof with an opportunity to present their latest sustainable solutions to a broad audience of industry professionals. Members of the Aluprof UK team attended and helped visitors at the exhibition whilst also bringing a contingent of fourteen specifier guests from the UK, these included colleagues from, Century Facades, Britplas, Elite Aluminium, AlufoldDirect, OWS, St James / Berkeley Group, Walsh Windows and Innovated Aluminium Technology.

Aluprof’s exhibition stand reinforced the fact that the business is actively engaged in reducing carbon emissions through several ongoing key business objectives:

Investing in Low-Carbon Aluminium Production. Aluprof has achieved a carbon footprint of 2.79 tCO₂e per tonne of products by utilising advanced manufacturing processes and incorporating an average of 65% recycled aluminium scrap into new extrusion.

Ongoing development of Energy-Efficient Products. Aluprof’s aluminium windows and doors enhance building energy efficiency, especially when specifying their class leading Passivhaus certified products, thereby decreasing operational carbon emissions.

By continuing to research and adopt Sustainable Practices. Aluprof emphasises energy-efficient processes and sustainable actions across all areas, including electricity consumption, heating, and recycling. Through these efforts, Aluprof contributes to a more sustainable Construction Industry and a reduction in global carbon emissions. This management of resources is under consistent review helping Aluprof to maintain its position as one of the world’s most efficient, vertically integrated, aluminium systems companies.

Aluprof UK have been supporting specifiers in the UK and Ireland for over fifteen years with advanced systems. Many UK and Ireland based fabricators and installers supply these systems and are on hand to offer surveys and cost analysis as to what improvements can be made with likely paybacks.

Further information about systems and specification support is available through the company website at aluprof.co.uk or direct from their UK head office in Altrincham by phoning +44 (0) 161 941 4005.

1 note

·

View note

Text

Aluprof Excel in Passivhaus Projects

Passivhaus design is a set of standards and design principles to achieve exceptional energy efficiency, significantly reducing heating and cooling demands in buildings. By employing rigorous insulation standards, airtight construction and high-performance windows, Passivhaus buildings minimise energy loss and maintain stable indoor temperatures. The use of heat recovery ventilation systems ensures that fresh air is continuously supplied, whilst retaining warmth in winter and coolness in summer. This leads to dramatically lower energy bills and a reduced carbon footprint. Additionally, the controlled indoor environment enhances occupant comfort, eliminating drafts, temperature fluctuations, and cold bridging.

Specifying Passivhaus windows, doors and facades from Aluprof contributes to sustainability by reducing reliance on fossil fuels and supporting the transition to net-zero carbon emissions. The methodology prioritises efficient use of materials, often incorporating sustainable and recycled options. Beyond environmental benefits, Passivhaus buildings promote superior indoor air quality through continuous ventilation and effective pollutant filtration. This is particularly beneficial for occupants with respiratory issues or allergies. The focus on thermal comfort and noise reduction further enhances the well-being of occupants, making Passivhaus a holistic approach to healthy and sustainable living spaces.

Aluprof was the first systems company in the UK to design and supply Passivhaus certified aluminium framed glazing systems and currently has the widest range of Passivhaus Trust certified aluminium windows, doors and curtain wall systems. Utilising low-carbon aluminium helps reduce embodied carbon emissions during the production phase, while the thermally efficient products further lower operational carbon emissions throughout the building's life by reducing energy demand. Sustainability is further enhanced as quality methods of construction with high quality finishes, well specified and designed products supplied by Aluprof, can offer many decades of extended service life.

Some of the projects supplied by Aluprof in recent years include the following high profile buildings:

The RAD Building (GERA Building) is a 2,500 sqm Passivhaus certified research facility for the University of Nottingham, providing laboratory, office and support accommodation for the UK Government Energy Research Acceleration Initiative, known as the ‘RAD’ Building (Research Acceleration & Demonstration) on the Jubilee campus. The building achieves a BREEAM Excellent rating and includes extensive Passivhaus measures to reduce energy requirements. Aluprof’s high performance TT50 curtain wall & MB104 window and door systems have been used throughout the building offering very high levels of insulation. On completion the building has been extensively tested and has gained the coveted Passivhaus certification.

Purdown View at University of Western England (UWE) Bristol, is a remarkable milestone in sustainable living, featuring more than 900 bedrooms distributed across three striking six-story buildings. With a total floor area of 21,000 sqm, Purdown View is distinguished as the largest certified Passivhaus development in the United Kingdom to date. It was designed by Stride Treglown and uses Aluprof’s high performance TT50 curtain wall & MB104 window and door systems, the project was fabricated and installed by DenvalCo.

The Greenhaus project stands as the largest Passivhaus affordable housing initiative in the North West. The development was completed for the English Cities Fund (ECF), a collaborative effort involving Muse, Legal & General, and Homes England, in partnership with Salix Homes, a Housing Association in Salford, and with the support of Salford City Council. Greenhaus features 96 highly sustainable and affordable residences within a nine-storey structure located on Chapel Street in Salford. The project, designed by Buttress architects and constructed by Eric Wright Construction, has received official certification from the Passivhaus-Institut, the organisation dedicated to promoting and certifying this internationally recognised building standard.

Voreda House in Penrith has undergone a significant transformation from its previous role as an NHS office to become the council's energy-efficient northern anchor building. This facility is notable for being the first retrofit office in the UK to achieve the Passivhaus EnerPHit standard, with projected energy savings of 85%. This initiative aligns with the council's dedication to minimising its carbon footprint and taking a leading role in the pursuit of carbon neutrality.

The British Antarctic Survey (BAS) undertakes groundbreaking research and maintains a Research Station located 67º south on Adelaide Island which was established in 1975. Known as Rothera, the busy station is used as a hub for other countries working in the area, offering a landing strip and wharf. The site has continued to develop over the years and in 2018 work began on the new Discovery Building, named to commemorate the discovery of Antarctica 200 years ago by the British naval officer Edward Bransfield in 1820. High thermal performance windows specified on the project have been provided by Aluprof. The MB-86 ST window and door system has been designed to offer outstanding insulation properties. Offered in three varieties, ST, SI and AERO the MB-86 was the first ever aluminium system to employ silica aerogel, a nano-porous material that has a very high proportion of free void volume compared to conventional solid materials. Aerogel’s high pore volume, low solid content, and its ‘torturous path amorphous structure’ offer very low values of thermal conductivity.

Aluprof UK have been supporting specifiers in the UK and Ireland for over fifteen years with advanced systems that include, high performance windows doors and facade systems. Many UK and Ireland based fabricators and installers supply these systems and are on hand to offer surveys and cost analysis as to what improvements can be made with likely paybacks. Further information about systems and specification support is available through the company website at aluprof.co.uk or direct from their UK head office in Altrincham by phoning +44 (0) 161 941 4005.

1 note

·

View note

Text

The Aluprof Awards

Leading Aluminium Systems Company, Aluprof, recently held their fifth bi-annual Future Builders International Conference in Poland to great acclaim. Members of the Aluprof UK & Ireland team and their guests attended the event which took place on 16th October at the DoubleTree by Hilton Hotel in Warsaw.

The diverse panel assembled for the event featured not only distinguished architects but also prominent experts from the construction sector, including engineers, urban planners, specialists in sustainable building, and sociologists focused on spatial dynamics. Their discussions centred on the future trajectory of the Global Construction Industry and the necessary directions for its development. The event was designed to be inclusive, allowing a wide array of participants from the construction field to engage actively by posing questions or sharing their insights. To reach the widest audience, the event was streamed online, ensuring that those unable to attend in person could still partake in the proceedings.

The panel debated the future of architecture in the context of sustainable building. The discussions also embraced the challenges facing the sector and an analysis of trends in architecture, encompassing the direction of travel in the development of our cities and towns. Acclaimed figures among the panellists this year included José Pareja Gómez of the renowned Zaha Hadid Architects and Ian Bogle, the founder of the multiple award-winning architecture and design studio Bogle Architects, along with leading Polish Architects.

This year's Future Builders international conference featured three panel discussions that showcased prominent architects and various experts as panellists. The event also included a presentation of the winner of the 2022 Building of the Year Created with ALUPROF Systems competition, as well as a discussion on an innovative development utilising architectural aluminium systems by ALUPROF. The first panel, entitled "Sustainability in Architecture: A Genuine Necessity or Just a Trend?", was moderated by Paweł Gregorczyk, the brands communication manager at ALUPROF, alongside Wojciech S. Wocław, a trainer in business etiquette and public speaking. During this session, the panellists engaged in a comprehensive discussion on various subjects, focusing on how modern technologies can assist architects and designers in addressing climate change and striving for a sustainable future. They also exchanged insights from their respective countries, highlighting the systemic solutions being adopted within those contexts.

The second panel at the Future Builders conference, entitled New or ReNEWed: Revitalising Buildings as the Future of Architecture, focused on the increasingly relevant topic of building renovation, a trend that has gained traction in recent years, largely due to the European Union decarbonisation initiatives. Agnieszka Kalinowska-Sołtys, in her presentation, highlighted that whether engaging in the renovation of existing buildings or the construction of new ones, an endeavour that remains essential is our efforts being rooted in sustainable development. The panellists collectively emphasised the critical importance of achieving a harmonious balance between new projects and renovated buildings, whilst also aiming to reduce the environmental footprint of the Construction Industry.

The third session of the conference showcased the esteemed architect Professor Ewa Kuryłowicz, affiliated with the prestigious Kuryłowicz & Associates studio. She delivered a presentation on the Faculty of Modern Languages and Institute of Applied Linguistics building at Warsaw University, which was awarded the Grand Prix in the fourth edition of the Building of the Year Created with Aluprof Systems competition in 2022. In her case study, she explored the innovative solutions implemented in this notable construction project, one of the most remarkable in Poland in recent years, whilst also discussing the various challenges her studio faced during the conceptual development of the building.

Following the third session a panel discussion entitled "Is a Decade in Architecture Long Enough?" took place offering the audience an opportunity to engage in the conversation. This debate was organised to commemorate the fifth anniversary of the Building of the Year Created with ALUPROF Systems competition and featured a panel of previous winners. The panellists unanimously expressed that the designs they had developed for their award-winning projects would remain unchanged today. Nonetheless, they acknowledged that the significant advancements in building technology over the last decade would enable them to incorporate even more sustainable solutions.

In what has now become a tradition, the Future Builders conference culminated in a gala where the winners of the international Building of the Year Created with Aluprof Systems competition were announced. This year marks the tenth anniversary of the initiative, which was conceived for architectural practices and independent architects and designed to single out the most interesting buildings featuring aluminium solutions by Aluprof. The winners award went to Maćków Pracownia Projektowa for Bernardyńska 4, a residential and retail complex in Wrocław, Poland. In the global category, third place winner went to the Sheppard Robson Architects project, 68-86 Farringdon Road, London which was featuring Aluprof’s MB-70HI , MB-77HS window door systems and MB-SR50N curtain walls that are fabricated by Alu-Fix Facades.

Aluprof UK have been supporting specifiers in the UK and Ireland for over fifteen years with advanced systems that include, high performance windows doors and facade systems. Many UK and Ireland based fabricators and installers supply these systems and are on hand to offer surveys and cost analysis as to what improvements can be made with likely paybacks. Further information about systems and specification support is available through the company website at aluprof.co.uk or direct from their UK head office in Altrincham by phoning +44 (0) 161 941 4005.

#aluprof#aluminium#architecture#aluminium systems#aluminium facade#aluminium windows#fenestration#facade#curtain wall#windows

0 notes

Text

Fire Safety Enhanced by Aluprof

October 2024 By Wojciech Brożyna - MD Aluprof UK

Leading aluminium systems company, Aluprof, well known for providing high performance fire resistant glazed screens, doors, windows and curtain walls, now supply fire resistant glass to complete their systems offer. The new company ‘Glassprof’, whose headquarters are located in Ogrodzona in Poland, specialises in the production of fire-resistant glass and the processing of glazed units that work in harmony with Aluprof’s fire rated aluminium systems. This is a first for the aluminium systems industry and allows Aluprof UK to offer a single, tested source of supply for fire rated fenestration installation across the UK & Ireland.

Fire resistant fenestration systems are used both internally and externally to reduce the risk of the spread of fire whilst offering occupants safe routes of escape. Whilst specified on construction of various building types, who is responsible for maintaining these systems so that they perform correctly on the outbreak of a fire? According to the Regulatory Reform (Fire Safety) Order 2005 (RRFSO), the landlord or building manager is designated as the 'responsible person' for fire safety. This individual is legally obligated to implement adequate and suitable fire safety measures. Consequently, one of their primary responsibilities is to conduct a fire risk assessment.

The fire risk assessment serves to identify potential fire hazards, provide recommendations for risk reduction, and document the implementation of these recommendations. It is a systematic approach to recognising fire risks and taking proactive measures to lessen their likelihood and potential consequences. This assessment encompasses not only potential ignition sources but also evaluates the adequacy and accessibility of escape routes, fire doors, fire safety equipment, and the effectiveness of compartmentation, which involves constructing parts of a building to inhibit the spread of fire to other areas or adjacent properties.

In the wake of the Grenfell Tower tragedy in 2017, fire safety regulations for multi-occupancy residential buildings have undergone significant review, leading to the enactment of the Fire Safety Act 2021. This legislation clarifies the responsibilities and procedures related to fire safety in such properties. Additionally, following the Grenfell incident, the PAS 79:2020 was introduced, offering more detailed guidance on fire risk assessments specifically for landlords and building managers.

The new Building Safety Act (BSA) building control framework was fully implemented in April 2024, and the industry is beginning to grasp the practical implications of the new Gateway approval process for high-risk buildings (HRBs).

Launched on October 1, 2023, ‘Gateway 2’ serves as a critical checkpoint in the new building control framework for High-Rise Buildings (HRBs) during the transition from design to construction. It mandates the submission of a comprehensive application to the Building Safety Regulator (BSR), which is designated as part of the Health and Safety Executive (HSE) under the Building Safety Act 2022. This application must detail how the project will adhere to the functional requirements of building regulations, including supplementary information on competence, fire safety, control measures, and mandatory reporting. A multi-disciplinary team, comprising a registered Building Inspector and various specialists, review the application under the BSR. The Gateway application forms as a definitive halt, prohibiting any onsite work until the necessary approval is obtained.

The HSE outlines that the objective of the Gateway 2 process is threefold. Firstly, it aims to ensure that potential design issues are identified and resolved at an early stage rather than being inherently integrated into the design. Secondly, it seeks to confirm that the design is adequately advanced to instil confidence in moving forward with all aspects of the construction. Lastly, it verifies that the duty holders possess the requisite capability to implement the design effectively.

As a prominent systems company in Europe, Aluprof have firmly established themselves as a leader in the field of aluminium framed fire-rated windows, doors, screens and curtain walls. As a building project supplier, this places Aluprof in the enviable position not only of being able to develop and test both framing and glazing together, but to be able to supply complete and fully tested products direct to site.

Thanks to the use of the latest and fully automated production technology, Glassprof offers glazed units that combine various glazing options to include fire protection, thermal insulation, solar control and sound insulation. Aluprof firmly believes that the collaboration with Glassprof will offer comprehensive and hassle-free glazing solutions that will prove advantageous to a wide range of buildings, including libraries, schools, hotels, and student accommodations. Given the paramount importance of fire safety as a critical design consideration, this partnership strives to provide architects and specifiers with a profound sense of assurance and peace of mind.

Together with the new Glassprof products, Aluprof offer a comprehensive range of aluminium fire resistant systems to cater for all building requirements. The MB-118 EI is designed to offer internal or external fire rated partitions that can offer resistance up to EI120. The system suites with Aluprof's MB-78EI and carries many of the same fire restart components. With a structural depth of just 118mm the system carries a generous 34mm wide thermal break for thermal insulation.

The MB-78EI door with its own 78mm wide framing system can be made up into screens that offer various fire resistance classes up to EI90 when tested to the standard, PN-EN 13501-2+A1:2010. The MP-78EI system offers an excellent thermal insulation coefficient Uf due to the adoption of 34 mm wide thermal break. Depending on the required fire resistance class, GKF (fire protection plasterboard) or CI (polymer–ceramic composite) strips are inserted inside the chambers of profiles and within the thermal insulation space between the aluminium profiles. Fire rated glasses of up to 49mm in width can be accommodated within the system.

Complimenting the windows, doors and screen systems is the MB-SR50N EI, a stick curtain wall system which can offer various fire resistances up to EI60 when tested to the standards PN-EN 1364-3 and PN-EN 1364-1. The curtain wall can also be used in glazed roof coverings and offer a fire resistance class of RE30 as per the standard PN-EN 1365-2. Along with this 50mm wide capped curtain wall system, a further version of the curtain wall system, the MB-SR50N EI EFEKT offers fire resistance of up to EI60 in a cap-less curtain wall system as used at high level on the The Core, a refurbishment project in Manchester which uses the cap-less curtain wall which is unique to Aluprof. These curtain wall systems are enhanced within the profile to cater for an EI60 fire resistance. Specifiers can use the non-enhanced system for the complete building and only use the fire resistant construction in areas where fire resistance is required, this enables consistency in visible sight lines across the build.

Aluprof UK, part of Aluprof based in Poland have been supporting specifiers in the UK and Ireland for over fifteen years with advanced systems that include, high performance windows doors and facade systems. Many UK and Ireland based fabricators and installers supply these systems and are on hand to offer surveys and cost analysis as to what improvements can be made with likely paybacks.

Further information about systems and specification support is available through the company’s website at aluprof.co.uk or direct from their UK head office in Altrincham by phoning +44 (0) 161 941 4005.

0 notes

Text

Choosing the Low-carbon Aluminium Option from Aluprof

September 2024 By Wojciech Brożyna - MD Aluprof UK

Climate change, exacerbated by greenhouse gas emissions, presents a profound threat to ecosystems and communities globally. The aluminium production process is particularly intensive in emissions, contributing about 2% to the total global greenhouse gas emissions. Direct emissions are mainly produced from the energy required for alumina refining and aluminium smelting, whilst indirect emissions are generated along the value chain, including the extraction of raw materials, their transportation and the manufacturing processes involved.

Aluminium is a fundamental component of modern life, used in various applications ranging from infrastructure to transportation and packaging. It is therefore essential to ensure that its production is managed responsibly. Unchecked emissions from aluminium production will significantly contribute to climate change, resulting in increased temperatures, altered weather patterns and a rise in extreme weather events. These changes threaten biodiversity, strain natural resources like water, diminish agricultural yields, and elevate risks to infrastructure, human health, and livelihoods. It is crucial for the aluminium industry to engage in urgent climate action to reduce emissions in accordance with the Paris Agreement goal of limiting global warming to 1.5°C, thereby averting the most severe impacts of climate change.

A great deal of work has already been done in primary aluminium production, where carbon embodiment has been significantly reduced. According to a 2020 White Paper, ‘Low-carbon Aluminium, Solution for Sustainable Construction & Renovation’, primary aluminium from China, which has been as high as 20 CO2e/t (carbon dioxide emissions equivalent per tonne of aluminium), drops to an average global production output of primary aluminium of 16.7 CO2e/t. ‘Low-carbon’ primary aluminium in 2020 on average was reported as releasing 6.67 CO2e/ per tonne of aluminium.

Today, while ‘low carbon’ primary aluminium is not formally defined, a carbon footprint of less than 4 CO2e/t is a common reference, representing the very lowest achievable with currently available technologies. This carbon footprint is often referred to as ‘Cradle to Gate’. The global aluminium industry has achieved this figure through the use of renewable energy sources such as hydro power and other renewable technologies. Further reductions will soon be possible as the industry begins to adopt emerging green hydrogen technology during the production cycle.

The amount of recycled aluminium utilised worldwide, often termed secondary production, has shown little variation, maintaining a range of 31-33% since 2000, with a notable peak of 34% in 2019. Given aluminium's high market value, collection rates tend to be robust; in 2019, collection rates for new scrap (pre-consumer) surpassed 95%, whilst those for old scrap (post-consumer) were just over 70%. It is vital to continue to improve the collection of post-consumer scrap, as recycling this material is significantly more energy-efficient, requiring only 5% of the energy needed for primary aluminium production. It is also important to note that aluminium can be recycled many times over without loss of quality.

According to a statement made by the Aluminium Stewardship Initiative (ASI) in February 2022, “Under a 1.5 degree scenario, the aluminium sector must reduce its GHG (Green House Gas) emissions from over a billion tonnes of CO2e to around fifty million tonnes by 2050. This is less than one-twentieth of current emissions.”

LowCarbonKety, a subsidiary of Grupa Kety, Aluprof’s parent company, offers aluminium billet with an impressively low carbon footprint of 2.9 kg of CO2 for every kilogram of aluminium produced. These low-carbon products are composed of up to 75% post-consumer scrap, around 10% pre-consumer scrap, and a minimal amount of primary aluminium, all manufactured using renewable energy sources.

It is important to consider that extended lead times may affect project timelines, potentially resulting in additional carbon costs. Conversely, selecting low-carbon products, including aluminium, may yield certain BREEAM credits for the project. These factors underscore the uniqueness of each project, necessitating a tailored approach. Engaging product suppliers during the early design phase is essential to explore viable options. Aluprof's experienced design team is available to assist in identifying the most suitable aluminium sources and systems for any project during your specification process.

Whilst it is crucial to reduce ‘Embedded Carbon’ in profile supply, here at Aluprof we take a holistic approach to carbon reduction by also reducing ‘Operational Carbon’. Aluprof aluminium windows and doors play a crucial role in decreasing operational carbon emissions by improving the energy efficiency of buildings. The exceptional thermal insulation properties of our systems reduce the need for heating and cooling, thereby lowering energy consumption and the related carbon emissions. Additionally, the durability and minimal maintenance needs of aluminium contribute to the longevity of these systems, further reducing their environmental footprint. By opting for aluminium windows and doors, buildings can attain a more sustainable and reduced carbon footprint.

The Future Homes Standard is currently influencing construction practices in the UK by emphasising enhanced energy efficiency and reduced carbon emissions. With the implementation of updated building regulations, we are prepared to adapt to these more rigorous standards in collaboration with the industry. Furthermore, as a Patron Member of the Passivhaus Trust UK, we engage closely with specifiers and various organisations to minimise operational carbon in buildings. Our thermally efficient glazing systems and Passivhaus-certified products are specifically engineered to comply with these standards, providing exceptional insulation and airtightness to facilitate lower carbon emissions.

Our flagship MB-79N Window and Door System redefines industry standards. It delivers remarkable thermal insulation, integrating energy efficiency with a modern aesthetic. Additionally, it offers the flexibility to design larger openings with reduced sightlines. The system boasts a thermal performance rating of Uw from just 0.64 W/(mK) at 1700mm x 2700mm / Part L compliant system CEN size and Passive House level Uw values of 0.79W/m²K at CEN size.

Aluprof are proud to be one of Europe's largest aluminium systems companies. Specification support is available through the company’s website at aluprof.co.uk, directly from their UK head office in Altrincham or from their London office at the Building Design Centre by phoning +44 (0) 161 941 4005.

0 notes

Text

Aluprof Sets a New Standard in Aluminium Windows and Doors

Window design has seen many incremental changes over the last decade providing ever higher performance systems. It is not often that we see a product that offers a real step change in performance but, Aluprof can lay claim to such an innovative step change with the launch of the MB-79N system.

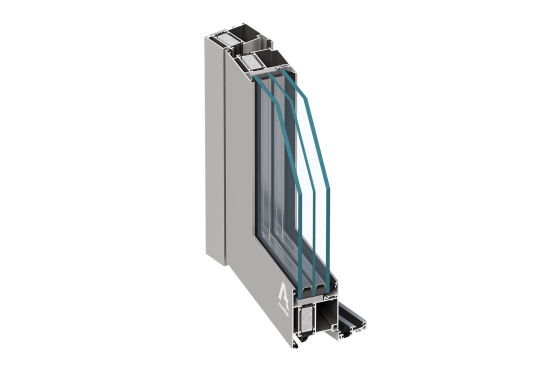

Successor to the company’s popular MB-70 system, the new system provides class leading thermal insulation properties within a slim 70mm depth of frame. With a Uw starting at just 0.79 W/m2K at CEN size and just 0.64W/m²K at 1700mm x 2700mm for a Part L compliant system. The slim depth of frame reduces material content without compromising on thermal performance, which translates into increased economy. Available as an open-in, open out window complete with door options, the system is set to become a favourite with many specifiers offering exceptional performance, slim sight lines, durability, and aesthetics for both residential and commercial projects.

Thermal efficiency of the new system is achieved through the use of advanced thermal break technology, multi-chamber profiles and high-quality insulation materials which help to create a highly effective reduction of thermal conductivity for heat transfer. These features help create a comfortable and energy-efficient indoor environment all year round.

It is the first time that such a slim frame, just 70mm depth, can offer class leading thermal insulation down to 1.18W/m²K with DGU & 0.79W/m²K Passive House level U values available in such a slim system. Slim sightlines are available alongside large operational sizes allowing for greater application across more projects.

Similar to other Aluprof systems, the MB-79N profiles are available in three thermally efficient variants. The efficiency version, MB-79N E, features a one component central seal. The MB-79N ST version is offered with a two component central seal and the MB-79N SI variant is provided with a two component central seal along with inserts of thermal insulation cores for the highest performance levels. For external doors, Aluprof also offers the MB-79N SI+ variant that comes with an internal perimeter gasket and insulation cores inside the profiles.

Together with thermally efficient framing profiles the new system can accommodate double or triple glazed units up to 62 mm thickness in windows and up to 53mm thickness in doors. These options make it possible to specify common thickness of glazed units, including acoustic glazing. The new system is PAS24/Q-marked for windows and doors and furthermore, the MB-79N System is designed to offer security glazed doors, rated RC1 to RC3 including the option of providing panel doors in an extensive range of designs.

The MB-79N aluminium system joins a wide range of architectural aluminium systems provided by the leading European systems company. UK Product Development & Technical Manager, Kevin Mellor explains the design concept behind the new system, “The Aluprof product portfolio includes many popular systems favoured in the UK. However, our customers are asking us to reduce frame sizes and optimise the design to provide a competitive system. We believe the MB-79N system accomplishes that, and showing our commitment to the UK architectural market we have suited into the new system an open-out window arrangement as well. We believe it will be a game-changer for architects, designers, and developers who prioritise sustainability, performance, and aesthetics in their projects.”

MB-79N is also compatible with two existing Aluprof systems, the MB-86 and the MB-104 Passive, both of which are well known to the company’s customers. These systems share the same accessories and gaskets with popular multi-point locking systems by renowned companies such as Roto, FUHR and GEZE.

Aluprof is a renowned brand in the UK construction industry, with a reputation for delivering high-quality aluminium systems that meet the evolving needs of the market. The MB-79N system is backed by extensive research, development, and testing, ensuring compliance with the latest industry standards and regulations. Aluprof UK also provides comprehensive technical support, including specification and design assistance, installation guidance, and after-sales service, to ensure a smooth and successful implementation of the MB-79N system in any project.

Further information about systems and specification support is available through the company’s website at aluprof.co.uk or direct from their UK head office in Altrincham by phoning +44 (0) 161 941 4005.

0 notes

Text

The Rise of the Pergola

By Shaun Cartwright - National Sales Manager Domestic & Residential Systems

Outdoor living areas have experienced significant growth following the pandemic, as the trend of staying at home, unwinding and hosting gatherings in the convenience of our own outdoor space has become increasingly popular.

As the typical average UK garden spans 188 square metres, which is in fact the same size as a regulation tennis court, our outdoor spaces are proving to be one of our most prized possessions. Given the abundance of additional living area this offers, it is hardly surprising that our gardens are evolving into more inviting spaces, mirroring the comfort of indoor living. Advancements in materials have opened up a world of possibilities when it comes to sustainable outdoor textiles, rugs, lounge sets, and lighting that can be just as stylish outdoors as they are indoors. However, it is important to be prepared for the unpredictable Great British weather. Awnings not only provide shade on sunny days but also create a new outdoor room ambiance. Integrated lighting and heating options allow you to enjoy your outdoor space even in the evening.

A more substantial outdoor canopy is another great option. With the choice of a louvered, retractable or flat solid roof, a canopy can be freestanding or fixed against existing walls and will remain relatively weathertight when closed. Fixed roofs offer simplicity, with the bonus of being able to offer shelter in all but the most inclement weather, whereas louvered and retractable designs allow control over how much light and openness you want on sunnier days. These options also work well when attached to your house, allowing you to open the roof at the press of a button to draw more light back into your interior space and offer a seamless transition between inside and outside.

These freestanding structures are known as ‘pergolas’ and have a long history. Originating in Ancient Egypt as ornamental features providing shade from the sun, nowadays, they serve similar functions while also providing opportunities to expand living areas. Garden pergolas can be placed in various locations in the garden to capture the best aspect or midday sun.

Aluminium is an excellent material of choice for a freestanding pergola, or lean-to canopies. With its high resistance to corrosion and availability in a wide range of finishes and colours, a structure can be designed to blend in perfectly with any garden. Aluminium also provides excellent structural capabilities negating the need for any further supporting structural materials. Today’s pergola is an incredibly versatile solution for covering small or expansive areas. It serves as a stylish addition that seamlessly aligns with many contemporary or traditional construction trends.

The pergola is not only beneficial for single-family homes as part of terrace or garden enhancements, but also for commercial structures. It serves as a modern and functional roofing element for outdoor spaces in such places as cafes, restaurants and office complexes. With the option of additional side screens and sliding glass panels, the pergola can be adapted to be used all year round, regardless of the weather conditions.

Aluprof provide two pergola systems, the premium MB-OpenSky 140 and the MB-OpenSky 120.

The concept design of both ‘MB-OpenSky Pergola’ system allows for the installation of Aluprof’s ‘SkyRoll’ side screens or ‘MB-OpenSlide’ sliding glass panels, offering the opportunity to create a unique outdoor space. Additionally, the pergola can be customised with LED lighting that won't interfere with the roof slats and optional infrared heating units. The lighting design includes an LED strip on the roof slats, a spotlight, and extra lighting around the upper edge of the structure.

The roof structure consists of rotating adjustable slats and a mechanism to change their angle from 0º to 135º. The slats have custom seals to protect against rain and the posts contain a concealed drainage system to efficiently direct water to a rainwater drain or soak away. Tests confirm that for structures measuring 6 metres in length, 4 metres in width and 3 metres in height, the maximum permissible snow load is 200 kg/m², equivalent to approximately 1m height of snow and a simultaneous wind load of around 59 mph.

There are two system versions to select from, a free-standing arrangement and a wall-mounted design. The wall-mounted version is supplied with custom-designed brackets for wall installation depending on the substrate being fixed to. Both freestanding and wall mounted systems allow for maximum dimensions of 7 metres in length, 5 metres in width, and 3 metres in height per section to be achieved. Several sections can be combined to cover large areas of outdoor space in commercial situations.

The concept of outdoor living is rapidly gaining recognition in the UK as the climate changes and offers significant opportunities from home improvement companies to widen their product portfolio for homeowners wishing to explore options for their outdoor living spaces.

Further information about the wide range of systems on offer and specification support is available through the company’s website at aluprof.co.uk or contact Aluprof’s UK & Ireland’s head office in Altrincham by phoning +44 (0) 161 941 4005.

0 notes

Text

Aluprof UK supports the Irish Construction Industry

By Wojciech Brożyna - MD of Aluprof UK

For the third consecutive year, Aluprof participated in the ICE Awards hosted in Dublin which is considered a significant construction event for Ireland. Aluprof, as the Gold Sponsor for the Gala Event, presented awards for the top 'Healthcare Project’, the ‘Education Project up to €10m value’ and the 'Education Project over €10m value' categories.

The Irish Construction Excellence Awards, established by the Irish Building Magazine in 1993, are commonly referred to as the ICE Awards and serve as the foremost acknowledgement of exceptional performance in the Construction Industry in Ireland. Ireland's top construction experts regularly attend the Gala Night, providing a platform for construction leaders, design & supply chain partners and clients to come together to honour outstanding achievements in construction.

Ever since Aluprof made its mark on the UK and Ireland market eighteen years ago, it has been offering a robust European portfolio of architectural aluminium systems that consistently exceed the needs of specifiers. Aluprof has established itself as a major systems supplier in Ireland, ensuring weekly deliveries from their extensive stock in Poland. Their comprehensive facilities for powder coating and thermal breaks enable them to meet any specification. Furthermore, Aluprof provides a fabrication service to meet program expectations and supports a network of fabricator installers across the region. With a dedicated team of support technicians on the ground, Aluprof has solidified its position as a leading systems supplier in the region.

Together with the Aluprof team at the awards ceremony were senior management guests from GLF Facades, BDA Facade Consultants and Alucraft. Sean Butler, Aluprof’s Sales Director presented awards to the winners who were:

Boyle Construction for ‘Healthcare Project’ for the project at the South Donegal Community Nursing Unit. The design team being, Rhatigan Architects, Structural Civil Engineer, Roughan O’Donovan and Service Engineers, Varming Consulting Engineers. Boyle Construction were pleased to have been selected for this significant project in Ballyshannon, which is a highly anticipated and necessary community development for Donegal. The project presented various challenges, including the modular construction of wards and the refurbishment of the Rock Hospital, as well as the complete strip-out and fit-out of the Sheil Hospital. Additionally, the project involved the construction of a new 80-bed Cognitive Neurology Uni and extensive external works along the river Erne.

Eamon Costello (kerry) LTD for ‘Education Project up to €10m value’ for the project at St Brogans College Bandon. The design team being, Kelly. Barry. O’Brien. Whelan Architects, Structural & Civil Engineers, Downes Associates Engineers and Mechanical & Electrical Engineers, Semple McKillop Consulting Engineers. St. Brogans is a recently completed comprehensive construction which included the addition of a three-story standalone extension utilising precast concrete and rain screen cladding. This expansion was designed to accommodate a variety of facilities such as classrooms, laboratories, offices, storage areas, restrooms, and additional spaces. The complex site work involved the removal of tarmac courts, excavation, retaining walls, the establishment of a new bus drop-off zone, the construction of boundary walls, service management, the installation of drainage systems and landscaping.

ABM Contractors Ltd for ‘Education Project over €10m value’ for the Sports Science, Health and Recreation Building Development at the Technological University Dublin Tallaght Campus. The design team being Coady Architects and Engineering, AECOM. The project offers educational areas that accommodate formal learning, modern science labs equipped with cutting-edge technologies that will facilitate research and teaching in Sports Science. The facilities comprise lecture seating for classroom use and the construction of a state-of-the-art multi-purpose Sports Hall, designed with the strategic vision of hosting National and Regional sporting events and competitions.

60 Dawson Street

Glencar House

Among the many projects completed using Aluprof UK systems in the Republic of Ireland, the headquarters of Microsoft, Twitter, and Google stand out as large-scale office buildings that demand high-quality specifications in building components. Aluprof UK also proudly provided the aluminium windows and doors for six projects in the Dublin Landings development area, as well as the recently completed 60 Dawson Street and Glencar House in Dublin.Aluprof UK also takes pride in being the supplier of aluminium windows and doors for six newly constructed commercial buildings in the Dublin Landings area. These buildings, together the headquarters of Microsoft, Twitter, and Google offer significant office spaces in the Republic of Ireland and have been specified with Aluprof’s high quality building facade systems.

Further information about systems and specification support is available through the company’s website at aluprof.co.uk or direct from their UK head office in Altrincham by phoning +44 (0) 161 941 4005.

0 notes

Text

Aluprof - A Vertically Integrated Systems Supplier

Elzbieta Kantor - Aluprof Operations Director

What is ‘vertical integration?’ and why is it important to the specifier when choosing suppliers? Vertical integration for any business is gaining control of upstream processes, normally by bringing them in-house to gain more control and consolidate costs. It is important from a specification process viewpoint as it offers many advantages in ease of supply, quality and costs.

An architectural aluminium systems company designs windows, doors, curtain wall systems and other products for use in building construction. These products are supplied in system form to fabricators and installers who manufacture and install under contract. Each system is extensively tested and carries the appropriate standards and performance levels for various applications.

When single systems are shared among several fabricators, the cost of development, testing, and updating is divided among them, with the systems company handling these tasks.

Many systems companies supply warehouse stock to their customers for ‘off-the-shelf’ windows, doors and curtain walls. As projects become more complex and expect higher performance levels, a systems company that looks to become more vertically integrated offers many advantages to the specifier. Vertical integration can include the ability to smelt aluminium, the design of dies to extrude profiles, inserting thermal breaks in profiles and offering finished profiles, either powder coating or anodised.

Only a few of the leading systems companies operating across the UK and Europe are vertically integrated. Having control of each process that completes a window door or curtain wall system helps limit risk. Between separate suppliers, such as between an extruder and a systems company, conflict can arise when the extrusion supplied does not meet expectations from the systems company, for various reasons, this poses risk, both on supply time and costs.

Following extrusion, main profiles often require thermal breaks to be inserted by first knurling the profile, inserting the thermal break, often made of polyamide along with additional insulation materials and then rolling the profile to create a single section. Being able to integrate a thermal break also allows the systems company to develop special designs of polyamide profiles that can enhance the performance both in thermal and weathering characteristics. In-house finishing of profiles further enhances system allowing for single or bespoke dual colour profiles to be created. All systems companies now offer QUALICOAT powder coated profiles as a standard which is recognised globally. Powder coating all profiles in-house reduces both time and transport requirements.

Vertical process integration can improve safety in the workplace by removing many of the operations where transport is required between businesses. Fewer loadings and unloading of profiles not only reduce potential health and safety issues, but also reduces the risk of profile damage in transit. A further consideration is the reduction in packaging need when profiles require protection when shipped between companies for processing.

Reduced handling of profiles allows for optimisation of processes and improvement in logistics. For example, batches of profiles of various sizes can more easily be processed economically rather than having to opt for the advantages of scale to save costs. With the reduction of minimum process quantities comes the benefit of speed of production thereby reducing order lead times for customers.

With the advantages of vertical integration mentioned above, a further benefit to the specifier is a reduction in carbon emissions. Reduced handling requirements and carbon miles automatically save energy, but linking the processes can also allow for further reductions to be accommodated when processing in a single location. With less handling and closer communication up and down the supply chain can lead to a more consistent profile quality. A single company that controls the entire process from start to finish has a vested interest in reducing wastage, minimising energy use and providing an optimised system, often bespoke on a project per project basis.

Aluprof, as a vertically integrated systems supplier encompass the development and production of various systems for applications in a wide range of building projects. In the UK & Ireland Aluprof UK offers local support to specifiers and contractors. Aluprof UK place more emphasis on flexibility with their ‘Tailored Solutions’ approach. For example, by having an experienced and extensive design team in Poland, Aluprof UK can quickly create bespoke profiles to suit any project. With an experienced design team in the UK Aluprof will collectively work with architects and fabricators to agree a solution which carries Aluprof’s warranty into the project which is passed onto the client.

All customers in the UK & Ireland enjoy weekly deliveries direct from Aluprof’s distribution centre based in Poland. Delivering directly to the customer reduces lead times, reduces handling damage and saves carbon, compared to double-handle project-specific material, such as delivering to a UK warehouse and then onto a further delivery vehicle for final delivery. Aluprof also ship orders complete, which enables the fabricator to schedule fabrication from delivery, rather than having to check and wait for all the materials to arrive. Both these approaches to supply, significantly reduce lead times allowing the fabricator to get products installed on site quicker and hopefully help improve cash flow throughout a contract.

Aluprof also recognised that not all fabricators can put on extra shifts to meet busy times as production facilities often utilise a lean working ethic to maintain competitiveness. To assist fabricators, Aluprof introduced a fabrication facility in Poland that can support fabricators in manufacturing some of the supplies at their request. This has proven to be a real benefit to customers who contract and often use this facility to manufacture the more difficult constructions required on a project.

Value Management, which encompasses Value Engineering, looks at every process from order through to completion. To begin with, an overview of the complete project programme is needed, with each of the processes and deadlines for completion itemised. It is at this stage that options are discussed. One of the obvious choices is that of the systems to be used for the windows, doors or facade. As a high end systems company, Aluprof offer their systems in various designs to meet the exact needs of the building. An example of this can be seen in Aluprof's popular MB-SR50N Curtain Wall system, far from being a single system there are many options to choose from, these include various insulation levels, capping options or structural arrangements, each choice represents a cost or a cost saving. It's a little like specifying options on a new car taking the base model of choice as a starting point.

A further consideration is the optimisation of aluminium profile cutting. To reduce wastage on fabrication, profiles can be extruded to special lengths which offer high levels of cutting optimisation which in turn reduces material waste, which then reduces costs. These are just some of the important issues that are reviewed in the Value Management process which ensures that the completed project performs exactly as specified and perfectly meets with the clients' expectations.

So, from specification through to installation, the Aluprof team in the UK ‘partners’ with specifiers and customers to ensure that system supply is value managed, minimising cost and carbon footprint. Aluprof UK believe this ���Value Management’ strengthens the relationship with customers who then often request Aluprof to partner them on projects that they have secured.

Aluprof are proud to be one of Europe's largest aluminium systems companies. Specification support is available through the company’s website at aluprof.co.uk, directly from their UK head office in Altrincham or from their London office at the Building Design Centre by phoning +44 (0) 161 941 4005.

0 notes

Text

How Aluprof Systems Help Specifiers Meet the Climate Emergency Design Guide

By Wojciech Brożyna - MD Aluprof UK

Formed in 2017, the London Energy Transformation Initiative (LETI) was established to review what our capital’s future construction should look like to meet our low-carbon future. Released back in 2020, the Climate Emergency Design Guide has gained extensive support from architects, developers, and professionals in the built environment throughout the UK. It has been downloaded more than 60,000 times in over 100 countries, and its requirements are acknowledged and adhered to by building professionals across the UK. With LETI’s growing influence across the UK, the team behind LETI renamed their network as the ‘Low Energy Transformation Initiative’.

In the UK 49% of annual carbon emissions are attributable to buildings and, with increased cost of energy, there continues to be a great deal of concern as to how people and businesses can continue to heat and power their homes and offices in the future. Whilst the cost of energy has recently stabilised, it will inevitably remain a large part of a future household budget. As the government softens its move away from fossil fuels and legislation in the form of a weakened Document L proposal for 2025, it seems that specifiers in the UK are taking the lead in our transition to a zero carbon future.

In the past our building professionals have been trying to educate property owners why investing in thermally efficient construction is cost effective, but, with relatively low energy costs, the increase in construction costs has often lead to schemes being cut back in preference to profit. With the understanding of commercial building rating schemes such as BREEAM and LEED it has been proven to businesses that the investment does indeed save costs and demonstrates a business’s commitment to helping save the environment. The same can be said for residential development where homeowners are beginning to realise that a low-carbon, or Passivhaus constructed home offers some form of future proofing and is a good investment. A huge amount has been learned by building professionals over the past twenty or more years on how to design, build and successfully operate these zero carbon buildings.