We are the best machine manufacturing company in Delhi having a reputed name in the field of all types of paper plate making machines. Call to ASV Engineering at 8800971968 or mail us @ [email protected] for purchasing machines at reasonable cost in India

Don't wanna be here? Send us removal request.

Text

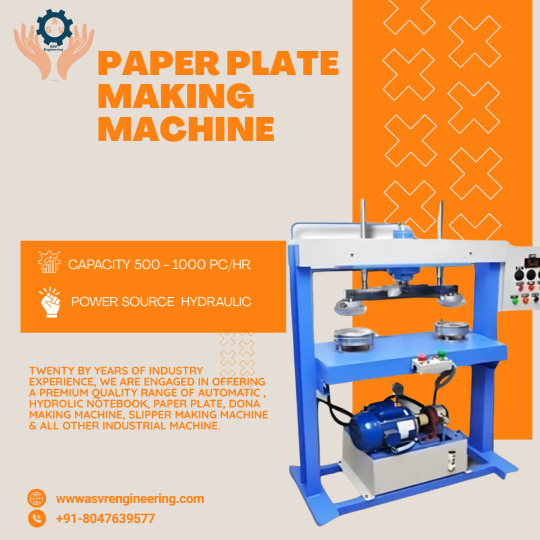

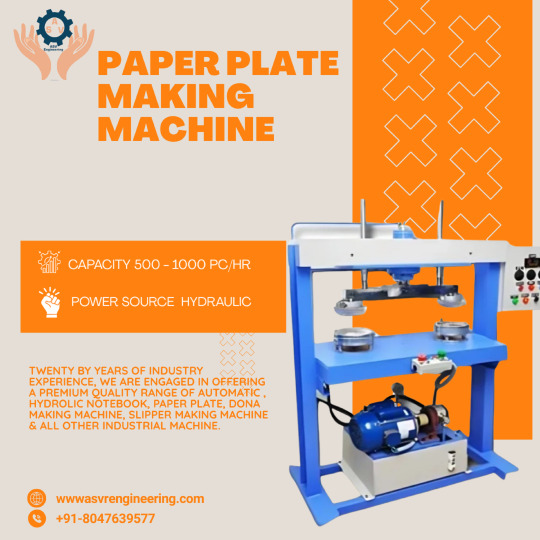

If you are searching for paper plate making machine in India. Then you are at the right place. We, ASVR Engineering Pvt. Ltd are the manufacturer and supplier in the field of best quality paper plate making machine in India. The machines generate the products using the supplied paper material because of their great performance and flawless working life. These machines are available at reasonable price for our clients.

0 notes

Text

If you are searching for paper plate making machine in India. Then you are at the right place. We, ASVR Engineering Pvt. Ltd are the manufacturer and supplier in the field of best quality paper plate making machine in India. The machines generate the products using the supplied paper material because of their great performance and flawless working life. These machines are available at reasonable price for our clients.visit us at:https://www.asvrengineering.com

0 notes

Text

"Make Delicious Khoya in No Time! 🧁⚡ Get the best Khoya Making Machine in Ranchi for smooth, efficient production. Perfect for sweets and dairy! 🐄🍬 #KhoyaMachineRanchi #SweetSolutions"

0 notes

Text

"Transform your incense production with our Agarbatti Making Machine! 🕉️🔥 Efficient, reliable, and perfect for creating aromatic wonders. #Agarbatti #IncenseMaking #QualityCraftsmanship"

0 notes

Text

"🛠️ Upgrade your notebook production in Delhi with cutting-edge notebook making machines. High efficiency, precision, and quality – powered by ASVR Engineering! 📚🚀"

0 notes

Text

"Take your snack game to the next level with ASVR ENGINEERING's Kurkure Making Machine! 🍟⚡ Reliable, fast, and built for unbeatable crunch. #ASVREngineering #KurkureMakingMachine #SnackSolutions #FoodTech #CrispySnacks #FoodIndustry #SnackInnovation #FoodEquipment #ProductionEfficiency"

0 notes

Text

"Start your atta chakki business today! Reliable machines, efficient grinding, and endless possibilities await. 💼🌾 #AttaChakkiMachine #BusinessOpportunity #Entrepreneurship"

0 notes

Text

✨ Celebrate Diwali with ASVR Engineering’s Noodles Making Machine at unbeatable festive prices! 🎉 Upgrade your business and enjoy high-efficiency production with our special Diwali offer. Limited time only—make this festive season even more profitable! 🎇🎁 #DiwaliDeals #NoodlesMakingMachine #ASVREngineering"

0 notes

Text

Double Die Paper Plate And Dona Plate Machine in Delhi

Are you looking to take your paper plate-making business to the next level? Then contact ASVR ENGINEERING for a Double Die Paper Plate Machine. This innovative machine has been designed to streamline the paper plate-making process, allowing you to produce more plates in less time and with greater efficiency. In this article, we will explore the features and benefits of the Double Die Paper Plate Machine, as well as compare it to other paper plate-making machines such as the single die paper plate machine and the all-in-one paper plate machine.

What is a Double Die Paper Plate Machine?

A Double Die Paper Plate Machine is a cutting-edge piece of equipment that is revolutionizing the paper plate-making industry. Unlike traditional paper plate-making machines that only have a single die, the Double Die Paper Plate Machine is equipped with two dies, allowing for the simultaneous production of two paper plates at once. This results in a significant increase in productivity and efficiency, making it the ideal choice for businesses looking to scale up their operations.

Features of the Double Die Paper Plate Machine

Dual Die Design: The most notable feature of the Double Die Paper Plate Machine is its dual die design, which allows for the production of two paper plates at the same time.

High Output: With the ability to produce double the number of paper plates in the same amount of time, the Double Die Paper Plate Machine boasts a high output capacity.

Easy to Operate: Despite its advanced technology, the Double Die Paper Plate Machine is surprisingly easy to operate, making it suitable for operators of all skill levels.

Durable Construction: Built to last, the Double Die Paper Plate Machine is made from high-quality materials that ensure longevity and durability.

Comparison with Single Die Paper Plate Machine

When comparing the double-die paper Plate Machine to a single-die paper plate machine, the advantages are clear. While a single-die machine can only produce one paper plate at a time, the double-die machine can produce two, effectively doubling the output. This means that with the Double Die Paper Plate Machine, you can meet demand quicker and more efficiently, leading to increased profits and customer satisfaction.

Comparison with All in One Paper Plate Machine

The all-in-one paper plate machine is another popular option for paper plate-making businesses. However, when compared to the Double Die Paper Plate Machine, it needs to improve in terms of output capacity. The Double Die Paper Plate Machine's ability to produce two paper plates simultaneously gives it a clear edge in terms of productivity and efficiency, making it the preferred choice for businesses looking to maximise their output.

Conclusion

the Double Die Paper Plate Machine is a game-changer for the paper plate-making industry. With its dual die design, high output capacity, and ease of operation, it offers unmatched productivity and efficiency. If you want to take your paper plate-making business to the next level, investing in a Double Die Paper Plate Machine is the way to go. Upgrade your equipment today and start reaping the benefits of increased profitability and customer satisfaction.

0 notes

Text

Wire Nail Making Machines

Are you in the market for a wire nail-making machine to boost your production of wire nails? Look no further! In this comprehensive guide, we will explore everything you need to know about wire nail-making machines, including how they work, their benefits, and factors to consider when choosing the right machine for your needs.

What is a Wire Nail Making Machine?

A wire nail-making machine is a piece of equipment designed to automate the process of manufacturing wire nails from coils of wire. These machines are widely used in the construction industry, furniture industry, and other manufacturing sectors where the demand for wire nails is high. By using a wire nail-making machine, manufacturers can increase their production efficiency and reduce labour costs.

How Does a Wire Nail Making Machine Work?

A wire nail-making machine operates by feeding a coil of wire into the machine, where it is cut to the desired length and shaped into a nail. The machine then processes the wire nail through various stages, including heading, pointing, and polishing, to produce a high-quality finished product. Most wire nail-making machines are fully automated, requiring minimal human intervention, which helps to streamline the production process.

Benefits of Using a Wire Nail Making Machine

There are numerous benefits to using a wire nail-making machine for manufacturing wire nails. Some of the key advantages include:

Increased Production Efficiency: Wire nail-making machines can produce large quantities of wire nails in a short amount of time, allowing manufacturers to meet high demand.

Consistent Quality: By automating the production process, wire nail-making machines ensure that every nail produced meets the same high standards of quality.

Cost-Effective: Investing in a wire nail-making machine can lead to cost savings in the long run, as it reduces the need for manual labour and increases production output.

Versatility: Wire nail-making machines can be used to manufacture a variety of nail sizes and types, making them a versatile tool for manufacturers.

Factors to Consider When Choosing a Wire Nail Making Machine

When selecting a wire nail-making machine for your business, there are several factors to consider to ensure you choose the right machine for your needs. Some important considerations include:

Production Capacity: Determine the volume of wire nails you need to produce to select a machine with the appropriate production capacity.

Nail Size Range: Consider the range of nail sizes and types the machine can produce to ensure it meets your specific requirements.

Automation Level: Evaluate the level of automation of the machine to determine if it aligns with your production goals and capabilities.

Maintenance and Support: Choose a machine from a reputable manufacturer that offers reliable maintenance and technical support services.

Wire Nails Polishing Machine

Once you have produced a batch of wire nails using a wire nail-making machine, you may want to enhance their appearance and durability by using a wire nail polishing machine. This machine is designed to polish the surface of wire nails, removing any rough edges or imperfections and giving the nails a smooth finish. By using a wire nail polishing machine, you can improve the quality of your wire nails and enhance their market appeal.

Conclusion

investing in a wire nail-making machine can greatly benefit your manufacturing operation by increasing production efficiency, ensuring consistent quality, and reducing costs. By following the tips outlined in this guide, you can choose the right wire nail-making machine for your business and take your wire nail production to the next level. So why wait? Upgrade your manufacturing process today with a high-quality wire nail-making machine!

0 notes

Text

Chappal making and slipper Making Machine in Delhi

Are you tired of manually crafting slippers and sandals, wasting time and effort on repetitive tasks? Look no further - the chappal-making machine is here to streamline your production process and revolutionize the footwear industry! In this article, we will explore the benefits and features of this innovative machine, including automatic chappal-making machine prices, manual chappal-making machine options, and more. Let's dive in!

The Evolution of Slipper Making Machines

From traditional handcrafting methods to modern machinery, the footwear industry has come a long way in terms of efficiency and productivity. The introduction of chappal-making machines has significantly reduced production time and labour costs, allowing manufacturers to meet the increasing demands of consumers worldwide. With the advancements in technology, slipper-making machines now come in various forms - from automatic chappal-making machines to manual options for small-scale production. These machines are equipped with advanced features such as cutting, shaping, and assembling, making the production process faster and more precise.

Automatic Chappal Making Machine Price

When considering investing in a chappal-making machine, the cost is a crucial factor to take into account. Automatic chappal-making machines typically come with a higher price tag due to their advanced technology and efficiency. However, the long-term benefits of reduced labour costs and increased production output make them a worthwhile investment for manufacturers looking to scale up their operations. On the other hand, manual chappal-making machines are more budget-friendly options for small businesses or beginners in the footwear industry. While they may require more manual effort and time, these machines are still capable of producing high-quality slippers and sandals at a lower cost.

Manual Chappal Making Machine

Manual chappal-making machines are ideal for those looking to start small or test the waters in the footwear manufacturing business. These machines are user-friendly and easy to operate, making them a popular choice among entrepreneurs and craftsmen. With a manual chappal-making machine, users have more control over the production process, allowing for customisation and flexibility in design. While they may not offer the same level of automation as their automatic counterparts, manual machines are cost-effective solutions for those looking to kickstart their footwear production journey. In conclusion, the chappal-making machine has revolutionised the footwear industry by streamlining production processes and reducing labour costs. Whether you choose an automatic or manual machine, investing in this innovative technology will bring efficiency and precision to your manufacturing operations. Say goodbye to manual labour and hello to the future of slipper-making with the chappal-making machine!

Conclusion

the chappal-making machine is a game-changer for the footwear industry, offering efficiency, precision, and cost-effective solutions for manufacturers. Whether you opt for an automatic or manual machine, investing in this innovative technology will take your slipper production to the next level. Are you ready to revolutionise your footwear manufacturing process?

0 notes

Text

All in one paper plate and dona paper plate machine

Are you looking to streamline your paper plate production process with a single machine that can do it all? the all-in-one paper plate machine. This innovative piece of equipment is designed to handle all aspects of paper plate production, from cutting to shaping to pressing, making it the perfect solution for businesses looking to increase efficiency and reduce costs.

The Single Die Paper Plate Machine: Efficiency at Its Finest

One of the key components of the all-in-one paper plate machine is the single-die paper plate machine. This machine is designed to cut paper plates into the desired shape and size with precision and accuracy. By using a single die, businesses can streamline the production process and eliminate the need for multiple machines or tools. This not only saves time but also reduces the risk of errors and inconsistencies in the final product.

The Hydraulic Paper Plate Machine: Power and Performance Combined

In addition to the single-die paper plate machine, the all-in-one paper plate machine also features a hydraulic paper plate machine. This powerful piece of equipment uses hydraulic pressure to shape and press the paper plates, ensuring a consistent and high-quality end product every time. The hydraulic system provides the necessary force to create durable and sturdy paper plates that are perfect for a wide range of uses.

The Double Die Paper Plate Machine: Versatility and Flexibility

Another key component of the all-in-one paper plate machine is the double-die paper plate machine. This machine allows businesses to produce two different sizes or shapes of paper plates simultaneously, increasing versatility and flexibility in production. Whether you need small dessert plates or large dinner plates, the double-die paper plate machine has you covered. This feature is especially useful for businesses that need to cater to a variety of customer needs and preferences. With the all-in-one paper plate machine, businesses can revolutionize their paper plate production process and take their operations to the next level. By combining the efficiency of the single-die paper plate machine, the power of the hydraulic paper plate machine, and the versatility of the double-die paper plate machine, businesses can increase productivity, reduce waste, and improve overall quality. Don't miss out on the opportunity to streamline your production process and stay ahead of the competition with this innovative piece of equipment.

Conclusion

The all-in-one paper plate machine is a game-changer for businesses in the paper plate industry. With its combination of efficiency, power, and versatility, this machine is revolutionizing the way paper plates are produced. If you're looking to increase efficiency, reduce costs, and improve quality in your paper plate production process, look no further than the all-in-one paper plate machine. Make the switch today and experience the difference for yourself.

#all in one paper plate machine#double die paper plate machine#single die paper plate machine#asv engineering

0 notes

Text

Detergent Cake and Detergent Soap Manufacturer Machine

In the competitive world of soap manufacturing, having top-quality equipment can make or break a business. One essential machine that has been revolutionizing the soap industry is the detergent cake-making machine. This cutting-edge device streamlines the scrub production process, making it more efficient and cost-effective. In this article, we will delve into the innovative features of the detergent cake-making machine, its benefits, and how it is transforming the way scrub are produced.

Understanding the Detergent Cake Mixer Machine

The cake mixer machine is the cornerstone of cake manufacturing. This advanced equipment combines various ingredients such as oils, lye, and fragrances to create a homogeneous mixture that will eventually solidify into cake. With its high-speed mixing capabilities, the detergent cake mixer machine ensures that the ingredients are thoroughly blended, resulting in a consistent and high-quality product.

The Role of the Soap Making Machine

Once the soap mixture is ready, it is transferred to the scrub-making machine. This machine is responsible for shaping the cake mixture into cakes or bars, depending on the desired end product. The detergent cake-making machine uses moulds to shape the cake and can produce a large volume of soap cakes in a short amount of time. This not only increases productivity but also ensures uniformity in the shape and size of the cakes.

Enhancing Efficiency with the Soap Cutting Making Machine

After the scrub cakes have solidified, they are cut into individual bars by the cake-cutting-making machine. This machine cuts the cakes with precision, ensuring that each bar is uniform in size. By automating the cutting process, the scrub-cutting making machine eliminates human error and increases efficiency. This results in a higher production rate and consistent quality across all bars.

Benefits of Using Detergent Cake Making Machine

The cake-making machine offers numerous benefits to scrub manufacturers. Some of the key advantages include:

Increased Efficiency: By automating the cake production process, the detergent cake-making machine reduces the time and labour required to manufacture the scrub.

Cost-Effectiveness: The machine's high productivity and precision-cutting capabilities help reduce wastage and optimize resources, resulting in cost savings.

Consistent Quality: With its precise mixing, shaping, and cutting capabilities, the detergent cake-making machine ensures that every cake bar meets the same high standards of quality.

Customization: The machine can be easily adjusted to accommodate different scrub formulas and shapes, allowing manufacturers to tailor their products to meet customer demands.

Conclusion

detergent cake-making machine is a game-changer in the soap manufacturing industry. Its innovative features, such as high-speed mixing, precise shaping, and automated cutting, have revolutionized the way soaps are produced. By incorporating this advanced equipment into their production process, soap manufacturers can significantly improve efficiency, reduce costs, and maintain consistent quality. The detergent cake-making machine is truly a must-have tool for any soap manufacturer looking to stay ahead in the competitive market.

0 notes

Text

Paper plate making machine

A paper plate making machine is a mechanical device used to manufacture paper plates. These machines are designed to efficiently and rapidly produce disposable plates from raw materials such as paper pulp or other eco-friendly materials. The process typically involves the following steps:

Material Feeding: The raw material, usually paper pulp or a similar material is fed into the machine. The machine may also use pre-cut paper sheets or rolls.

Molding: The material is molded into the shape of a plate using a mold or a die. The size and shape of the plates can be adjusted based on the specifications of the machine.

Heating: The molded material is subjected to heat to dry and solidify it. This step is crucial to ensure that the plates are rigid and have the desired form.

Cutting and Shaping: Once the material has solidified, the machine cuts the plates into the desired size and shape. Some machines can produce different sizes or shapes based on the mold used.

Quality Control: Some machines may include quality control mechanisms to inspect the plates for defects or inconsistencies. This can involve visual inspections or automated sensors.

Stacking and Packaging: The finished plates are then stacked and may go through a packaging process. This can include counting, bundling, and wrapping the plates for transportation.

Paper plate making machines can vary in terms of production capacity, automation level, and the types of plates they can produce. Some machines are small and manually operated, while others are large and fully automated for mass production.

When considering a paper plate making machine, factors to take into account include the machine's production capacity, power consumption, and ease of operation, maintenance requirements, and the cost of raw materials. Additionally, it's essential to ensure that the machine complies with safety and environmental standards.

If you're interested in purchasing or learning more about specific paper plate making machines, you may want to contact manufacturers or suppliers in the industry for the latest information on available models and specifications.

Hydraulic paper plate making machine

A hydraulic paper plate making machine is a type of paper plate making machine that utilizes hydraulic pressure to carry out various processes involved in the production of paper plates. These machines are designed to provide efficient and reliable performance in manufacturing disposable plates. Here's a general overview of how a hydraulic paper plate making machine typically works:

Material Loading: The raw material, which is usually paper pulp or other eco-friendly materials, is loaded into the machine. This can be in the form of pre-cut paper sheets, rolls, or other suitable forms.

Hydraulic Pressing: The hydraulic system is employed to apply pressure on the raw material, forcing it into a mold or a die. This pressure helps in shaping the material into the desired form of the paper plate.

Heating: In some models, the hydraulic press may be combined with a heating element. The hydraulic pressure, along with heat, aids in the drying and solidification of the material. This ensures that the plates have the necessary strength and rigidity.

Cutting and Shaping: Once the material has solidified, the machine uses hydraulic power to cut and shape the plates. The mold or die determines the final size and design of the paper plates.

Quality Control: Some hydraulic paper plate making machines may include quality control features to inspect the plates for defects or inconsistencies. This can involve manual inspections or automated sensors.

Stacking and Packaging: After the plates are formed and cut, they are stacked and may go through a packaging process. This step involves counting, bundling, and wrapping the plates for storage or transportation.

Hydraulic paper plate making machines are known for their ability to provide high-pressure force, which can be advantageous in achieving precise and consistent results during the plate-making process. These machines are often chosen for their durability, reliability, and the ability to handle a variety of plate sizes and shapes.

When considering a hydraulic paper plate making machine, it's essential to take into account factors such as production capacity, power consumption, ease of operation, maintenance requirements, and compliance with safety standards. Additionally, you may want to explore the specific features and capabilities offered by different models in the market to find the one that best meets your production needs.

All in one paper plate making machine

An "all-in-one" paper plate making machine typically refers to a machine that combines multiple functionalities and processes within a single unit. These machines are designed to streamline the paper plate manufacturing process, providing efficiency and convenience. The specific features of an all-in-one paper plate making machine can vary based on the manufacturer and model, but here are some common functionalities that such a machine may incorporate:

Material Feeding: These machines often have a mechanism for loading the raw material, which could be paper pulp or other eco-friendly materials. The material may come in the form of pre-cut sheets, rolls, or other suitable forms.

Molding: The machine includes a molding or pressing mechanism that shapes the raw material into the form of paper plates. This could involve a hydraulic press or another method to achieve the desired shape and size.

Heating: Some all-in-one machines may have a heating element to aid in the drying and solidification of the material, ensuring that the plates have the necessary strength.

Cutting and Shaping: Integrated cutting and shaping mechanisms are typically part of the machine to cut the formed material into the final shape of the paper plates. The machine may offer flexibility in adjusting plate sizes and shapes.

Quality Control: These machines may include features for quality control, such as visual inspection systems or sensors to detect defects in the plates during or after the manufacturing process.

Stacking and Packaging: After the plates are formed and cut, the machine may have provisions for stacking and packaging the finished products. This can include counting, bundling, and wrapping the plates for storage or transportation.

Automation: Many all-in-one machines are designed with a high level of automation, reducing the need for manual intervention and increasing overall production efficiency.

When considering an all-in-one paper plate making machine, it's crucial to assess factors such as production capacity, power consumption, ease of operation, maintenance requirements, and compliance with safety standards. Additionally, specific features and customization options can vary, so it's important to review the specifications provided by the manufacturer to ensure that the machine meets your production needs.

If you are interested in purchasing an all-in-one paper plate making machine, you may want to contact manufacturers or suppliers in the industry to inquire about available models and obtain detailed information on their features and capabilities.

Fully automatic paper plate making machine

A fully automatic paper plate making machine is a sophisticated piece of equipment designed to efficiently produce paper plates with minimal human intervention. These machines are equipped with automated mechanisms for various stages of the paper plate manufacturing process. Here are the key features and processes typically associated with a fully automatic paper plate making machine:

Material Feeding:

The machine is designed to automatically feed the raw material, which can be paper pulp or other eco-friendly materials.

The material may come in the form of pre-cut sheets, rolls, or another suitable format.

Molding:

The machine includes an automated molding or pressing mechanism that shapes the raw material into the form of paper plates.

This process may involve a hydraulic press or another automated method to achieve precise and consistent plate shapes.

Heating:

Some fully automatic machines have integrated heating elements to assist in the drying and solidification of the material, ensuring the plates have the required strength.

Cutting and Shaping:

The machine is equipped with an automated cutting and shaping system that accurately cuts the formed material into the final shape of the paper plates.

It may offer flexibility in adjusting plate sizes and shapes based on programming or settings.

Quality Control:

Fully automatic paper plate making machines often include built-in quality control features.

This can involve visual inspection systems, sensors, or other mechanisms to detect and reject defective plates during or after the manufacturing process.

Stacking and Packaging:

After the plates are formed and cut, the machine automatically handles the stacking and packaging of the finished products.

This may include counting, bundling, and wrapping the plates for storage or transportation.

Automation:

These machines are designed for a high level of automation, reducing the need for manual intervention.

Automation can include material feeding, molding, cutting, stacking, and packaging processes.

Control Panel:

Fully automatic machines typically come with a user-friendly control panel where operators can set parameters, monitor the production process, and make adjustments as needed.

When considering a fully automatic paper plate making machine, it's important to assess factors such as production capacity, power consumption, ease of operation, maintenance requirements, and compliance with safety standards. Additionally, inquire about customization options and features offered by different models to ensure the machine meets your specific production requirements. If you are interested in purchasing such a machine, contacting manufacturers or suppliers in the industry for detailed specifications and pricing would be advisable.

#automatic paper plate making machine#Fully automatic paper plate making machine#all in one paper plate making machine#dona plate making machine

0 notes

Text

Paper plate making machine

A paper plate making machine is a piece of industrial equipment designed to produce paper plates in large quantities. These machines are commonly used in the food packaging industry, catering services, and other related businesses. The machine automates the process of forming, pressing, and cutting paper sheets into the shape of plates.

Here are some key features and components typically found in a paper plate making machine:

Raw Material Feeding Mechanism: This part of the machine is responsible for feeding the raw paper material. The raw material is usually paper pulp or coated paper.

Molding System: The molding system shapes the paper material into the desired form of the plate. It typically involves the use of molds and hydraulic or pneumatic systems.

Heating System: Some machines may include a heating system to dry and shape the plates effectively. This is especially important for machines that use wet pulp as the raw material.

Pressing Mechanism: The pressing mechanism ensures that the paper material is tightly pressed and takes the shape of the mold. This is crucial for forming sturdy and well-shaped plates.

Cutting System: After molding and pressing, the paper is cut into individual plates. This is usually done using a cutting mechanism that operates in coordination with the molding and pressing components.

Control Panel: A control panel is included for operators to set parameters, monitor the production process, and make adjustments as needed.

Output Conveyor: The finished paper plates are conveyed out of the machine for collection and packaging.

When choosing a paper plate making machine, businesses should consider factors such as production capacity, power consumption, ease of operation, maintenance requirements, and the type of raw material the machine can process.

It’s important to note that specific features may vary among different models and manufacturers. Additionally, advancements in technology may lead to improvements and innovations in paper plate making machines over time. If you are considering purchasing such a machine, it’s advisable to consult with manufacturers, review specifications, and possibly visit facilities where these machines are in operation to make an informed decision based on your business needs.

Fully automatic paper plate making machine

A fully automatic paper plate making machine is a sophisticated piece of equipment designed to handle the entire process of paper plate production automatically. These machines are commonly used in large-scale production environments where efficiency and speed are crucial. Here are some key features of a fully automatic paper plate making machine:

Automatic Raw Material Feeding: The machine is equipped with a system to automatically feed the raw material, which is typically paper pulp or coated paper.

Automatic Molding System: The molding system is automated to shape the paper material into the desired plate form. It may use molds and advanced automation mechanisms to ensure precision and consistency in plate formation.

Automatic Heating System: Some fully automatic machines come with an integrated heating system to dry the paper material effectively. This is particularly important when using wet pulp as the raw material.

Automatic Pressing Mechanism: The pressing mechanism is automated to ensure the paper material is tightly pressed and takes the shape of the mold without manual intervention.

Automatic Cutting System: The cutting system is automated to cut the formed paper plates into individual pieces. It operates in coordination with the molding and pressing components.

PLC Control Panel: Fully automatic paper plate making machines often feature a Programmable Logic Controller (PLC) control panel. This allows operators to set parameters, monitor the production process, and make adjustments easily.

High Production Capacity: These machines are designed for high production output, making them suitable for large-scale manufacturing operations.

Efficient Conveyor System: An efficient conveyor system is integrated to transport the finished paper plates from the machine to the collection point or packaging area.

Low Maintenance: Fully automatic machines are engineered for reliability and low maintenance requirements, minimizing downtime.

Energy Efficiency: Advanced technology is often employed to optimize energy consumption, making the machine more environmentally friendly and cost-effective to operate.

When considering the purchase of a fully automatic paper plate making machine, it’s important to assess factors such as production capacity, power consumption, the flexibility to handle different plate sizes, and the ease of operation. Additionally, potential buyers should inquire about after-sales support, warranty, and training provided by the manufacturer.

Paper plate making machine manufacturer

Online Directories: Explore online business directories and platforms that specialize in machinery and industrial equipment.

Trade Shows and Exhibitions: Attend industry-specific trade shows and exhibitions related to packaging and paper products. These events provide an opportunity to meet manufacturers, see their products in person, and discuss your specific requirements.

Local Industrial Associations: Contact local industrial associations related to paper and packaging in your region. They may have information about reliable manufacturers and can provide recommendations based on your location.

Referrals and Recommendations: Reach out to other businesses in your industry or region that use paper plate making machines. Ask for recommendations or referrals based on their experiences with manufacturers.

Online Research: Use search engines to find manufacturers based on your location or specific requirements. Check company websites, reviews, and testimonials to gather information about their reputation and the quality of their products.

Consult Distributors and Dealers: Contact distributors or dealers of industrial machinery in your area. They often have relationships with manufacturers and can guide you to reputable sources.

Industry Forums and Communities: Participate in online forums or communities related to paper product manufacturing, packaging, or industrial machinery. Members may share their experiences and recommendations for reliable manufacturers.

When evaluating manufacturers, consider factors such as the company’s reputation, years of experience, product quality, customer reviews, after-sales support, and warranty offerings. It’s also beneficial to communicate directly with the manufacturer to discuss your specific needs, production capacity requirements, and any customization you may require.

Always verify the latest information and reviews, as the manufacturing landscape can change, and new companies may emerge. Additionally, consider checking for updates or newer recommendations from industry sources in your region.

0 notes

Text

Asvr engineering

Asvr engineering is the best machine manufacturing and supplier company in Delhi. They are many types of machine in our company such as chapatti making machine, agarbatti making machine, notebook making machine, Detergent powder making machine, Bricks making machine, Chappal making machine, wire nail making machine, and many other kinds of machines are available. If you want to startup your business please contacts us on our contact no: 8800971968.

0 notes

Text

Bricks making machine

A brick-making machine is a piece of equipment designed to produce bricks from clay or other materials. These machines vary in complexity and size, ranging from small manual machines to large automated systems. Here's a brief overview of the types of brick-making machines:

Manual Brick Making Machine:

Simple and manually operated machines that require human effort to produce bricks.

Typically used for small-scale production or in areas with limited access to power.

Semi-Automatic Brick Making Machine:

Combines manual labor with automation to increase production efficiency.

May involve manual loading of raw materials, but some processes are automated, such as brick molding and removal.

Automatic Brick Making Machine:

Fully automated machines that handle the entire brick-making process from raw material preparation to brick stacking.

Can produce a large number of bricks in a short period with minimal human intervention.

Clay Brick Making Machine:

Specifically designed for molding and baking clay bricks.

Suitable for areas with abundant clay deposits.

Concrete Brick Making Machine:

Utilizes concrete as the primary raw material for brick production.

Often used in construction projects where concrete bricks are preferred.

Fly Ash Brick Making Machine:

Incorporates fly ash, a byproduct of coal combustion, as a raw material in the brick-making process.

Environmentally friendly option that utilizes industrial waste.

Hydraulic Brick Making Machine:

Utilizes hydraulic pressure to compress the raw materials and form bricks.

Offers precision and consistency in brick production.

Mobile Brick Making Machine:

Portable machines that can be moved to different locations for on-site brick production.

Useful for construction projects in remote areas.

When choosing a brick-making machine, factors to consider include the scale of production, available resources (such as raw materials and power supply), budget constraints, and the specific type of bricks needed. Additionally, understanding the local building regulations and standards is crucial to ensure that the produced bricks meet the required specifications.

Pover block making machine

It seems like there might be a small typo in your question. I assume you're asking about a "paver block making machine." A paver block making machine is a type of equipment used to produce concrete or interlocking pavers, which are commonly used in landscaping, road paving, and other outdoor applications. These machines play a crucial role in the construction industry, allowing for the efficient and consistent production of high-quality paver blocks. Here are some key features and aspects of paver block making machines:

Concrete or Interlocking Pavers:

Paver block making machines are designed to produce concrete pavers or interlocking blocks, which are widely used for creating pavements, driveways, walkways, and other outdoor surfaces.

Varying Capacities:

Paver block machines come in different capacities, ranging from small, manual machines suitable for small-scale projects to fully automatic machines for large-scale production.

Molding and Compression:

These machines typically use molds to shape the concrete into the desired paver block design. Hydraulic pressure or other mechanisms are employed to compress the concrete mixture into the mold.

Vibrations and Compaction:

Vibrators are often used to ensure proper compaction of the concrete mix within the mold, resulting in dense and durable paver blocks.

Coloring and Surface Finishing:

Some advanced machines allow for the addition of pigments or coloring agents to produce colored paver blocks. Additionally, surface finishing options can create various textures and patterns.

Automation Levels:

Paver block making machines range from manual or semi-automatic to fully automatic, depending on the level of automation required by the user.

Batching Systems:

In some cases, these machines may be integrated with concrete batching systems to ensure accurate mixing proportions and consistency in the quality of the blocks.

Versatility:

Paver block making machines can be versatile, producing different shapes, sizes, and designs of paver blocks to meet specific project requirements.

When considering a paver block making machine, it's important to assess factors such as the production capacity, the variety of designs it can produce, the level of automation, and the overall durability and reliability of the machine. It's also crucial to consider the availability of raw materials and the specific requirements of the projects you intend to undertake.

Fly ash brick making machine

A fly ash brick making machine is designed to manufacture bricks using fly ash, a byproduct of burning coal, as one of the main raw materials. Fly ash brick production is an environmentally friendly and sustainable alternative to traditional clay brick manufacturing. The process involves mixing fly ash with other materials, such as cement, sand, and sometimes lime, to create a concrete-like mixture. This mixture is then compacted and molded into bricks using a specialized machine. Here are some key features and aspects of fly ash brick making machines:

Raw Material Mixing:

Fly ash is typically mixed with cement, sand, and water to create a homogenous mixture. Lime may also be added to enhance the properties of the bricks.

Molding and Compaction:

The prepared mixture is fed into the brick making machine, which uses molds to shape the bricks. The compaction process ensures that the mixture is densely packed, resulting in strong and durable bricks.

Hydraulic Pressure:

Many fly ash brick making machines use hydraulic pressure to compress the mixture within the molds. This helps in achieving the desired brick density and strength.

Curing:

After molding, the bricks are typically subjected to a curing process. This involves keeping the bricks in a controlled environment with adequate moisture to allow them to gain strength over time.

Automation Levels:

Fly ash brick making machines come in various levels of automation. They can range from manual or semi-automatic machines, where some tasks are done manually, to fully automatic machines that handle the entire process automatically.

Production Capacity:

The production capacity of these machines can vary, and it's important to choose a machine that meets the specific production requirements of your project.

Brick Design and Size:

Fly ash brick making machines can produce bricks in different sizes and designs. Some machines allow for customization of the brick's surface texture and color.

Energy Efficiency:

Some modern fly ash brick making machines are designed to be energy-efficient, contributing to sustainability and cost-effectiveness.

Using fly ash in brick production not only helps in the proper disposal of a waste material but also reduces the demand for traditional clay bricks, conserving natural resources. Additionally, fly ash bricks often exhibit good insulation properties and are known for their strength and durability.

When considering a fly ash brick making machine, factors such as production capacity, automation features, energy efficiency, and the ability to produce bricks with specific characteristics should be taken into account.

Clay brick making machine

A clay brick making machine is designed to produce bricks using clay as the primary raw material. Clay bricks have been used in construction for centuries due to their durability and natural aesthetic appeal. These machines help automate the process of brick production, increasing efficiency and consistency. Here are some key features and aspects associated with clay brick making machines:

Clay Preparation:

The clay used in brick making needs to be prepared adequately. This involves refining and homogenizing the clay to ensure a consistent mixture.

Molding:

The prepared clay is then fed into molds within the machine. These molds shape the clay into individual bricks.

Drying:

After molding, the bricks are typically air-dried or dried in specialized chambers to reduce moisture content. Proper drying is crucial to prevent cracking during the firing process.

Firing or Burning:

The dried clay bricks are fired or burned in a kiln at high temperatures. This process, known as firing, transforms the clay into a hardened and durable material.

Cooling:

Once the firing process is complete, the bricks are cooled gradually to prevent thermal shock and ensure uniform strength.

Surface Finishing:

Some clay brick making machines may include features for adding texture or patterns to the brick surface during molding for aesthetic purposes.

Automation Levels:

Clay brick making machines are available in various levels of automation, ranging from manual or semi-automatic machines to fully automatic systems that handle the entire process.

Production Capacity:

Machines come in different production capacities to suit various project requirements, from small-scale production to large-scale industrial applications.

Energy Efficiency:

Some modern clay brick making machines are designed to be energy-efficient, utilizing advanced technologies to optimize the firing process.

Customization:

Depending on the machine model, there may be options for customizing the size, shape, and surface texture of the bricks.

Quality Control:

Ensuring the proper clay mixture, uniform molding, and controlled firing are essential for maintaining the quality and strength of the clay bricks.

Clay brick making machines are particularly well-suited for areas with abundant clay deposits. When choosing a clay brick making machine, factors to consider include the level of automation, production capacity, energy efficiency, and the specific requirements of the bricks for your construction projects. Understanding local building regulations and standards is also important to ensure that the produced clay bricks meet the necessary specifications.

0 notes