Don't wanna be here? Send us removal request.

Text

Walk-In Chamber

Effem Technologies is a leading manufacturer of high-quality Walk-in Chambers in India, designed to provide controlled environmental conditions for testing, storage, and research purposes. These chambers are ideal for applications in industries such as pharmaceuticals, electronics, and automotive, offering precise temperature, humidity, and light control. Built with advanced technology and durable materials, Effem Technologies' Walk-in Chambers ensure reliability and accuracy for a variety of testing needs. Customizable to meet specific requirements, these chambers provide optimal performance, making Effem Technologies a trusted name for environmental testing solutions in India. For more details contact us@+918750941116 , +919810186865 https://www.effemtechnologies.com/walk-in-chamber/

0 notes

Text

Stability Chamber Manufacturer

Are you looking for Stability Chamber Manufacturer in India? Look no further than Effem Technologies, We are a leading manufacturer and supplier of Stability Chamber in India. For more in info please contact us!

#stability chamber#effem technologies#stability test chamber manufacturer in india#stability test chamber manufacturer in ghaziabad

1 note

·

View note

Text

Stability Chamber Supplier in India

Are you looking for Stability Chamber Manufacturer in India? Look no further than Effem Technologies , We are a leading manufacturer, supplier and exporter of Stability Chamber�� in India.

For more details, please contact us!

#Stability Chamber Manufacturer#Stability Chamber Manufacturers#Stability Chamber Supplier#Stability Chamber Manufacturer in India#Stability Chamber Supplier in India#Stability Chamber Manufacturer in Delhi NCR#Stability Chamber Exporter in India

1 note

·

View note

Text

The Importance of Balances Accuracy in Lab Research

In industries ranging from pharmaceuticals to manufacturing, accurate measurement is crucial. Balances and balancing machines are essential tools for precision and efficiency in various applications. This blog explores the roles of these instruments, highlights prominent manufacturers, and provides insights into choosing the right equipment for your needs.

Understanding Balances and Balancing Machines

Balances are precision instruments used to measure mass or weight with high accuracy. They come in various types, each suited to different applications. Balancing machines are specialized equipment designed to measure and correct imbalances in rotating parts, crucial for ensuring smooth and efficient operation in machinery.

Key Types of Balances

1. Analytical Balances

Analytical balance manufacturers produce highly sensitive balances designed to measure small masses with extreme precision. These balances are used in laboratories and research settings where accuracy is critical. They offer readability to a fraction of a milligram, making them essential for chemical formulations, quality control, and scientific research.

2. Weighing Balances

Weighing balance manufacturers provide a range of balances designed for general weighing purposes. These include digital and mechanical balances that cater to various industries, including retail, manufacturing, and laboratories. They offer a range of capacities and precisions to suit different weighing needs.

The Role of Balancing Machines

Balancing machines are used to measure the balance and uniformity of rotating parts, such as wheels, shafts, and turbines. Proper balancing is crucial to prevent vibrations, reduce wear and tear, and ensure the efficient operation of machinery.

Balancing machine manufacturers offer a range of solutions for different applications, including:

Dynamic Balancing Machines: These are used to measure and correct imbalances in rotating parts dynamically, ensuring smooth operation.

Static Balancing Machines: These are designed for parts that do not rotate during measurement but require balancing to prevent future imbalances.

Leading Manufacturers in the Industry

Balances Manufacturers

Several companies specialize in producing high-quality balances, including analytical and weighing balances. These manufacturers focus on precision, reliability, and innovative technology to meet the diverse needs of their clients. Look for manufacturers with a strong reputation for quality and customer support to ensure you get the best equipment for your needs.

Balancing Machine Manufacturers

When it comes to balancing machines, various manufacturers provide advanced solutions for both dynamic and static balancing. These manufacturers offer robust, reliable machines that are essential for maintaining the performance and longevity of rotating equipment. Key features to look for include precision measurement, ease of use, and the ability to handle various part sizes and weights.

Choosing the Right Equipment

When selecting balances or balancing machines, consider the following factors:

Purpose: Identify the specific application, whether it’s precise mass measurement or balancing rotating parts.

Capacity and Precision: Ensure the equipment meets your requirements in terms of capacity and precision.

Technology: Look for advanced features such as digital displays, automated calibration, and integration with other systems.

Manufacturer Reputation: Choose manufacturers known for their quality, reliability, and customer support.

Conclusion

Balances and balancing machines are vital tools for accurate measurement and efficient operation in various industries. Understanding the different types of equipment, their applications, and leading manufacturers can help you make informed decisions and choose the right solutions for your needs. Whether you require an analytical balance for laboratory use or a balancing machine for machinery maintenance, selecting the right equipment will ensure precision, reliability, and optimal performance.

For more information on balances and balancing machines, including product specifications and manufacturer details, reach out to specialized suppliers to find the best solutions for your applications.

Website :- https://www.effemtechnologies.com/

Contact No. :- +91 8750941116

Email :- [email protected]

Address :- T-21, C- Block, Phase-2, Okhla Industrial Area, New Delhi -110020

1 note

·

View note

Text

Walk in Chamber Manufacturer in Faridabad

Are you looking for Walk in Chamber Manufacturer in India, look no further than Effem Technologies. We are a leading manufacturer and supplier of Walk in Test Chamber in India, For more details, please contact us!

#walk chamber manfacturer#walk in test chamber in india#walk in test chamber in delhi#walk in chamber#effem technologies#walk in chamber manufacturer in India

1 note

·

View note

Text

Features, Benefits of Walk in Test Chamber

Features and Benefits of Walk in Chamber:

Controlled Environment: The primary advantage of a walk-in test chamber is its ability to precisely control and monitor environmental conditions. This precision allows for accurate simulation of real-world scenarios that products might face in use.

Large Testing Capacity: These chambers can accommodate larger products or multiple items at once, making them ideal for testing large-scale systems or assemblies that cannot fit into standard-sized chambers.

Comprehensive Testing: The ability to test under varied conditions — temperature, humidity, pressure — ensures that products are thoroughly evaluated for reliability and safety, meeting stringent industry standards.

Data Collection and Analysis: Walk-in chambers are equipped with sophisticated sensors and data acquisition systems that record test conditions and results. This data is invaluable for understanding performance limits and identifying potential issues.

What is a Walk-In Test Chamber?

A walk-in test chamber is a large, enclosed space designed to create specific environmental conditions for testing purposes. Unlike smaller test chambers that are often bench-sized or compact, walk-in chambers are spacious enough for people to enter, facilitating the testing of larger objects, systems, or even full-scale prototypes.

These chambers can simulate a wide range of environmental conditions including:

Temperature Extremes: Testing how products perform under high heat or extreme cold.

Humidity Levels: Assessing the impact of moisture on materials and electronics.

Pressure Variations: Simulating different atmospheric pressures to test equipment performance in various altitudes.

Vibration and Shock: Evaluating the resilience of products to physical stresses and impacts.

Applications of Walk in Chamber in Industries:

1. Aerospace and Defense: In aerospace and defense, walk-in test chambers are used to simulate the extreme conditions that spacecraft and military equipment might encounter. This includes vacuum conditions, high altitudes, and intense temperatures. Ensuring that components can withstand such conditions is crucial for mission success and safety.

2. Automotive: Automobile manufacturers use walk-in test chambers to evaluate vehicle components and systems under various environmental conditions. For example, testing how engine parts perform at high temperatures or how electrical systems function in extreme cold helps improve vehicle reliability and safety.

3. Electronics: For electronics and consumer devices, walk-in chambers simulate conditions such as high humidity and temperature fluctuations. This testing helps in assessing the longevity and durability of gadgets, ensuring they perform reliably over time.

4. Pharmaceuticals: In the pharmaceutical industry, these chambers are used to test the stability of drugs under different environmental conditions. This ensures that medications maintain their efficacy and safety throughout their shelf life.

5. Construction and Materials: Builders and material scientists use walk-in chambers to test the durability of construction materials. Exposure to extreme weather conditions helps in assessing how materials like concrete or composites perform in real-world scenarios.

Conclusion

The walk-in test chamber is a cornerstone of modern testing and quality assurance. By providing a controlled environment for rigorous testing, it enables industries to innovate while ensuring safety, reliability, and performance. As technology advances and new materials and products emerge, the role of these chambers will continue to be integral in driving forward scientific discovery and industrial excellence. Whether it’s ensuring the next-generation spacecraft can withstand the harshness of space or testing the latest consumer electronics, walk-in test chambers remain a key tool in the quest for progress.

For more details, please contact us!

Website :- www.effemtechnologies.com

Contact No. :- +91 8750941116

Email us :- [email protected]

Address :- T-21, C- Block, Phase-2, Okhla Industrial Area, New Delhi -110020

#Walk in Chamber#Walk in Test Chamber#Effem Technologies#Walk in Chamber manufacturer in India#Walk in Chamber Manufacturer#Walk in Test Chamber Manufacturer

1 note

·

View note

Text

What is Stability Chamber and How does it work ?

Effem Technologies is a prominent name in the Indian industrial landscape, renowned for its expertise in manufacturing and supplying high-quality Stability Chambers. With a commitment to innovation and precision, Effem Technologies provides advanced solutions designed to meet the rigorous demands of the pharmaceutical, biotechnology, and research industries.

Their Stability Chambers are engineered to offer precise control over environmental conditions, including temperature, humidity, and light. This ensures the accurate simulation of storage and shelf-life conditions for various products, from pharmaceuticals to food items. Effem Technologies employs cutting-edge technology and adheres to international standards to guarantee the reliability and performance of their chambers.

The company's range of Stability Chambers includes both standard and custom models, tailored to specific customer requirements. These chambers are designed to provide stable and consistent conditions, crucial for product testing and quality assurance. Effem Technologies' dedication to quality and customer satisfaction makes them a preferred choice for businesses seeking reliable stability chamber solutions in India. With a focus on innovation and excellence, Effem Technologies continues to set the benchmark in the field of environmental testing equipment.

For more details, please contact us!

Website :- www.effemtechnologies.com

Contact No. :- +91–8750941116Email :- [email protected]

#stability chamber#stability test chamber manufacturer in ghaziabad#stability test chamber manufacturer in india#best stability test chamber manufacturer in india#top stability test chamber manufacturer in india#stability test chamber manufacturer in delhi#stability test chamber supplier in india

0 notes

Text

Everything You Should Know About Stability Chamber ?

Effem Technologies stands out as a premier manufacturer and supplier of Stability Chambers in India. With a reputation for precision and reliability, Effem Technologies delivers high-quality stability chambers designed to meet stringent industry standards. Their chambers are engineered to provide controlled environmental conditions, ensuring accurate and consistent testing for pharmaceuticals, cosmetics, and other sensitive products.

The company combines advanced technology with robust construction, offering a range of models tailored to various needs, including temperature and humidity control. Effem Technologies is committed to innovation and customer satisfaction, providing exceptional service and support. Their stability chambers are widely recognized for their durability, accuracy, and energy efficiency, making them a trusted choice for industries requiring rigorous stability testing solutions.

For more details, please contact us!

Website :- www.effemtechnologies.com

Contact No. :- +91–8750941116

Email :- [email protected]

#stability chamber#best stability chamber manufacturer in india#stability chamber supplier in india#stability chamber manufacturer in india#stability chamber manufacturer in ghaziabad#stability chamber manufacturer in delhi

0 notes

Text

What are the importance of Moisture Balance?

Importance of Moisture Balance:-

Indoor Air Quality: Proper moisture balance indoors helps maintain a healthy environment. Too much moisture can lead to mold growth, which can cause respiratory problems and damage to your home. Conversely, too little moisture can lead to dry skin, irritation, and other health issues.

Material Longevity: For many materials, including wood, paper, and textiles, maintaining appropriate moisture levels is crucial to avoid deterioration. Wood, for instance, can swell or shrink with moisture fluctuations, leading to structural issues or warping.

Product Quality: In manufacturing, especially in industries like pharmaceuticals or food processing, moisture balance is key to ensuring product quality. Excessive moisture can spoil products, while insufficient moisture can affect texture and taste.

Environmental Impact: In agriculture, moisture balance is vital for crop health. Both overwatering and underwatering can stress plants, affecting yields and the ecosystem.

Moisture balance refers to the equilibrium between moisture levels and the surrounding environment. It’s the fine line between too much and too little moisture, which can influence everything from the health of plants and people to the durability of buildings and products.

In essence, moisture balance involves understanding the dynamics of moisture input (such as humidity or water usage) and output (such as evaporation or absorption). Achieving the right moisture balance means maintaining conditions that prevent issues related to excessive moisture (like mold growth or material degradation) or insufficient moisture (like dryness or cracking).

Managing Moisture Balance

1. Monitoring: The first step in managing moisture balance is to monitor the moisture levels in your environment. This can be done using hygrometers for air humidity or moisture meters for materials and soil. Regular monitoring helps you detect imbalances early and take corrective action.

2. Ventilation: Adequate ventilation helps regulate moisture levels by allowing excess moisture to escape and bringing in fresh air. In homes, this means using exhaust fans in areas like bathrooms and kitchens. In industrial settings, proper ventilation systems are essential to control humidity.

3. Dehumidification and Humidification: Depending on your needs, you may require a dehumidifier to reduce excess moisture or a humidifier to increase moisture levels. For instance, in a damp basement, a dehumidifier can prevent mold growth, while in a dry climate, a humidifier can add necessary moisture to the air.

4. Insulation: Proper insulation in buildings helps maintain consistent temperatures and moisture levels, reducing the risk of condensation and associated problems.

5. Material Selection: In construction and manufacturing, choosing materials that are less prone to moisture-related issues can contribute to better moisture balance. For example, moisture-resistant paints and finishes can protect surfaces from damage.

6. Regular Maintenance: Routine checks and maintenance of HVAC systems, plumbing, and roofing can prevent leaks and other issues that disrupt moisture balance. Addressing these problems promptly helps maintain an optimal moisture environment.

Practical Tips for Different Scenarios

In Homes: Use a combination of dehumidifiers, air conditioners, and proper ventilation to keep indoor moisture levels in check. Be mindful of areas prone to dampness, such as basements and attics.

In Agriculture: Implement irrigation systems that match crop needs and use soil moisture sensors to optimize water usage. Mulching can also help retain soil moisture and reduce evaporation.

In Manufacturing: Invest in climate-controlled storage facilities and moisture-resistant packaging to protect products from moisture damage.

Conclusion

Achieving and maintaining moisture balance is a dynamic process that requires attention and management. By understanding the factors that influence moisture levels and employing strategies to regulate them, you can enhance indoor comfort, protect valuable materials, and ensure the quality of products. Whether you’re a homeowner, a professional in the manufacturing sector, or an agriculturalist, mastering moisture balance is a step towards a healthier, more sustainable environment.

For more details, please contact us!

Website :- www.effemtechnologies.com

Contact No. :- +91–8750941116

Email :- [email protected]

#Moisture Balance#effem technologies#Moisture Balance manufacturer in India#Moisture Balance supplier in India#Moisture Balance manufacturer in Delhi NCR#Moisture Balance manufacturer in Ghaziabad

1 note

·

View note

Text

What are the Functionalities of Stability Chamber?

Functionality of Stability Chambers

Stability chambers are designed with precision to maintain constant and accurate conditions:

Temperature Control: Chambers can simulate a wide range of temperatures, from extreme cold to high heat, depending on the product being tested. Temperature stability is crucial for assessing how heat-sensitive products will behave in different climates.

Humidity Control: Some products, like electronics or certain pharmaceuticals, are sensitive to moisture. Stability chambers can replicate different humidity levels to assess product stability under varying moisture conditions.

Lighting Conditions: In industries where exposure to light can degrade products (such as food and pharmaceuticals), stability chambers can simulate various lighting conditions to test product stability against light exposure.

Stability chambers are controlled environments used primarily in industries like pharmaceuticals, food, cosmetics, and even in scientific research. Their primary function is to replicate and maintain the environmental conditions under which a product is expected to be stored or used. This replication allows researchers and manufacturers to predict the product’s shelf life, efficacy, and safety under various environmental conditions.

Importance of Stability Chambers

Product Safety and Efficacy: For pharmaceuticals and biotech products, stability chambers help determine how temperature and humidity variations affect chemical composition and effectiveness. This information is critical for ensuring product safety and efficacy.

Regulatory Compliance: Regulatory bodies like the FDA (Food and Drug Administration) require stability testing as part of the approval process for drugs and medical devices. Stability chambers provide the necessary data to meet these regulatory standards.

Quality Assurance: Manufacturers use stability testing to guarantee product quality throughout its intended shelf life. It helps identify potential issues like degradation, contamination, or packaging failures that could affect product performance.

Research and Development: In research settings, stability chambers are essential for studying how environmental factors impact materials and products. This information guides the development of improved formulations and packaging.

Types of Stability Chambers

Stability chambers come in various types depending on the specific needs of the industry and the product being tested:

Walk-in Chambers: Large chambers that can accommodate substantial quantities of test samples or products.

Reach-in Chambers: Smaller chambers designed for easier access and monitoring of samples.

Environmental Chambers: Designed to replicate extreme conditions such as arctic cold or desert heat, useful for testing products intended for harsh environments.

Conclusion

Stability chambers are indispensable tools in ensuring product quality, safety, and regulatory compliance across industries. By replicating and controlling environmental conditions, these chambers provide valuable data that guide product development, quality assurance, and regulatory submissions. As technology advances, so too does the precision and capabilities of stability chambers, enabling industries to innovate and deliver safer, more effective products to consumers worldwide. Whether in pharmaceutical research labs or food manufacturing facilities, stability chambers remain a cornerstone of modern quality control and product development processes.

Top Stability Test Chamber Manufacturer in India

If you are looking for Best Stability Test Chamber Manufacturer in India, look no further than Effem Technologies, we are a leading manufacturer and supplier of Stability Test Chamber in India.

#Stability Chambers#Stability Chamber manufacturer#Stability Chambers manfuacturer in India#Stability Chambers Supplier in India#Effem Technologies

0 notes

Text

What are the Appplications of Viscometer?

Applications of Viscometers:

Chemical and Pharmaceutical Industries:

Formulation Development: Accurate viscosity measurements are crucial in developing consistent formulations for drugs and chemicals.

Quality Control: Ensures that the viscosity of products remains within specified limits during production.

2. Food and Beverage Industry:

Product Consistency: Monitoring viscosity helps maintain the desired texture and consistency of sauces, dressings, and beverages.

Process Control: Real-time viscosity measurements can be used to adjust processing conditions and ensure product quality.

3. Automotive Industry:

Lubricants Testing: Ensures that engine oils and other lubricants maintain appropriate viscosity for optimal performance and protection.

4. Paints and Coatings:

Application Properties: Viscosity affects how paints and coatings are applied and how they perform after application. Accurate measurement ensures the right consistency for application and drying.

5. Cosmetics Industry:

Product Texture: Viscosity measurements help in formulating products like lotions, creams, and gels to achieve the desired texture and feel.

What is a Viscometer?

A viscometer is a device used to measure the viscosity of a fluid. Viscosity is a measure of a fluid’s resistance to deformation or flow. It’s an essential property that indicates how “thick” or “thin” a fluid is. For instance, honey has a higher viscosity than water because it flows more slowly.

Viscometers are used to obtain precise viscosity measurements which can help in various applications, from formulating paints and coatings to manufacturing pharmaceuticals and food products.

Types of Viscometers

Capillary Viscometers:

How They Work: Capillary viscometers measure viscosity by observing the time it takes for a fluid to pass through a narrow tube (capillary). The longer it takes for the fluid to flow through the tube, the higher its viscosity.

Applications: Commonly used in laboratories for testing Newtonian fluids (fluids whose viscosity remains constant regardless of the applied stress).

2. Rotational Viscometers:

How They Work: These viscometers consist of a spindle or rotor that rotates within the fluid. The resistance to the spindle’s rotation is measured to determine viscosity.

Applications: Suitable for measuring the viscosity of both Newtonian and non-Newtonian fluids (fluids whose viscosity changes with the applied stress). They are often used in industries such as cosmetics, food and beverages, and chemicals.

3. Falling Ball Viscometers:

How They Work: A ball is dropped through a column of fluid, and the time it takes for the ball to fall a certain distance is used to calculate viscosity.

Applications: Often used in the oil and gas industry for measuring the viscosity of lubricants and crude oil.

4. Dynamic (or Rotational) Viscometers:

How They Work: This type measures the force required to rotate an object within the fluid at a constant speed. The resulting force gives an indication of viscosity.

Applications: Widely used for testing paints, adhesives, and polymers.

5. Vibrating Viscometers:

How They Work: These viscometers use a vibrating probe or rod immersed in the fluid. The changes in the frequency or amplitude of the vibration are used to measure viscosity.

Applications: Common in the food and beverage industry for real-time viscosity monitoring during production processes.

Choosing the Right Viscometer

Selecting the appropriate viscometer depends on several factors, including:

Type of Fluid: Newtonian vs. non-Newtonian fluids require different types of viscometers.

Viscosity Range: Ensure the viscometer can measure within the desired viscosity range.

Measurement Conditions: Consider the temperature and pressure conditions under which measurements will be taken.

Accuracy and Precision: Different applications require different levels of measurement accuracy.

Conclusion

Viscometers are indispensable tools in many industries, providing critical data that helps ensure the quality and performance of products. By understanding the different types of viscometers and their applications, industries can select the right instrument for their specific needs, leading to better product quality and more efficient processes. Whether you are involved in manufacturing, quality control, or research and development, a thorough grasp of viscometers and their functionality can make a significant difference in achieving optimal results.

Best Viscometer Manufacturer in India

If you are looking for Best Viscometer Manufacturer in India, look no further than Effem Technologies, we are a leading manufacturer and supplier of Viscometer in India.

For more details, please contact us!

Website :- www.effemtechnologies.com

Contact No. :- +91–8750941116

Email :- [email protected]

#Best Viscometer Manufacturer in India#Best Viscometer Manufacturer in Delhi#Viscometer Manufacturer in India#Viscometer Manufacturer in Ghaziabad#Viscometer Supplier in India#Viscometer Manufacturer in Faridabad#Effem Technologies

1 note

·

View note

Text

Stability Test Chamber Manufacturer from Delhi

Top Stability Test Chamber Manufacturer in India

If you are looking for Best Stability Test Chamber Manufacturer in India, look no further than Effem Technologies, we are a leading manufacturer and supplier of Stability Test Chamber in India.

What is a Stability Test Chamber?

A stability test chamber is a specialized piece of equipment designed to simulate and maintain specific environmental conditions such as temperature, humidity, light, and sometimes even vibration. These chambers are used primarily to test the stability and shelf-life of products over time. They provide a controlled environment that mimics real-world conditions to predict how products will behave, ensuring they meet regulatory requirements and consumer expectations.

Importance in Various Industries

Pharmaceuticals: In pharmaceuticals, stability chambers are used to test the stability of drugs and vaccines under different temperature and humidity conditions. This helps ensure that medications remain effective and safe throughout their shelf life.

Food and Beverage: Food manufacturers use stability chambers to evaluate the shelf life of products and to understand how different storage conditions affect freshness, taste, and nutritional value.

Electronics: Electronics companies test components and devices in stability chambers to assess their performance in various environmental conditions, ensuring reliability and durability.

Cosmetics: Stability chambers are employed to study the stability of cosmetic products, including creams, lotions, and makeup, under different temperature and humidity levels to maintain product quality.

Features and Capabilities

Stability test chambers come in various sizes and configurations to accommodate different testing needs. Key features often include:

Precise Control: They offer precise control over temperature, humidity, and sometimes light intensity to simulate real-world conditions accurately.

Uniformity: Chambers are designed to ensure uniform distribution of environmental factors throughout the testing area, minimizing variability in test results.

Monitoring and Recording: Advanced chambers are equipped with sensors and data logging capabilities to continuously monitor conditions and record data for analysis and regulatory compliance.

Safety and Compliance: Chambers are designed to meet stringent regulatory standards such as FDA, ICH (International Council for Harmonisation), and WHO (World Health Organization) guidelines to ensure the reliability and reproducibility of test results.

Applications and Benefits

Quality Assurance: By subjecting products to rigorous testing in stability chambers, manufacturers can ensure that their products meet quality standards and regulatory requirements.

Risk Mitigation: Identifying potential issues early in the development process helps companies mitigate risks associated with product stability and shelf life.

Cost Efficiency: Conducting stability testing early in product development can save time and costs associated with potential recalls or product failures later on.

Research and Development: Stability chambers are also invaluable in research and development, providing insights into how different formulations or materials react to environmental stresses over time.

Future Trends

As technology advances, stability test chambers are evolving to meet the increasingly complex demands of various industries. Key trends include:

Integration with IoT: Chambers may be equipped with IoT (Internet of Things) capabilities for remote monitoring and control.

Advanced Data Analytics: Utilizing big data and AI to analyze vast amounts of stability testing data for predictive modeling and optimization.

Environmental Sustainability: Designing chambers with energy-efficient features and sustainable materials to minimize environmental impact.

In conclusion, stability test chambers are indispensable tools across industries where product reliability and quality are paramount. By providing controlled environments to simulate real-world conditions, these chambers play a crucial role in ensuring that products meet safety, efficacy, and durability standards. As technology continues to advance, the capabilities of stability test chambers will undoubtedly expand, further enhancing their role in product development and quality assurance processes worldwide.

For more details, please contact us!

Website :- www.effemtechnologies.com

Contact No. :- +91–8750941116

Email :- [email protected]

#Stability Test Chamber Manufacturer in India#Stability Test Chamber Manufacturer in Delhi#Stability Test Chamber Manufacturer in Ghaziabad#Stability Test Chamber Manufacturer in faridabad#Stability Test Chamber Manufacturer in noida#Stability Test Chamber Manufacturer in Gurugram#Top Stability Test Chamber Manufacturer in India#Best Stability Test Chamber Manufacturer in India

1 note

·

View note

Text

What is the Importance of Stability Chamber?

The Purpose and Importance of Stability Chamber

The primary purpose of stability chambers is to evaluate the long-term effects of various environmental conditions on products. This testing is essential for several reasons:

Quality Assurance: Stability testing ensures that products maintain their quality, efficacy, and safety throughout their intended shelf life. For instance, pharmaceutical companies use stability chambers to test drug formulations to ensure they remain effective and safe from degradation over time.

Regulatory Compliance: Many industries, such as pharmaceuticals and food production, are required by regulatory agencies (like the FDA in the United States) to conduct stability testing as part of the approval process. This ensures that products meet stringent quality and safety standards.

Research and Development: Stability chambers are invaluable in research and development (R&D) phases, allowing scientists to study how different environmental conditions affect materials. This knowledge helps in optimizing formulations, packaging, and storage conditions to enhance product stability.

Predictive Analysis: By subjecting products to accelerated aging conditions within stability chambers, researchers can predict their shelf life more accurately. This information is critical for manufacturers to determine appropriate storage recommendations and expiration dates.

What is a Stability Chamber?

A stability chamber, often referred to as a stability testing chamber or environmental chamber, is a controlled environment designed to simulate and maintain specific conditions of temperature, humidity, light, and other environmental factors. These chambers are used extensively to test the stability of substances, products, or materials under controlled conditions that mimic real-world storage environments.

Key Features of Stability Chambers

Modern stability chambers are equipped with advanced features to provide precise and consistent testing conditions:

Temperature Control: Chambers can maintain temperatures ranging from sub-zero to high temperatures, depending on the product being tested.

Humidity Control: Some chambers allow for precise control of humidity levels, which is crucial for testing products sensitive to moisture.

Lighting Conditions: For products sensitive to light, such as pharmaceuticals, chambers can replicate different lighting conditions to assess light-induced degradation.

Monitoring and Data Logging: Chambers are equipped with sensors and data logging systems to continuously monitor and record environmental parameters. This data is analyzed to ensure compliance with testing protocols and to generate reports.

Applications of Stability Chamber Across Industries:

Stability chambers find applications in various industries:

Pharmaceuticals: Testing drug stability to ensure safety and efficacy.

Food and Beverage: Evaluating the shelf life and quality of food products.

Cosmetics: Assessing the stability and performance of cosmetic formulations.

Biotechnology: Studying the stability of biological materials such as vaccines and enzymes.

Conclusion

In conclusion, stability chambers are indispensable tools in scientific research and industrial applications where maintaining product quality and safety over time is critical. By providing controlled environments that mimic real-world conditions, these chambers enable researchers and manufacturers to ensure compliance with regulatory standards, optimize product formulations, and deliver reliable products to consumers. As technology continues to advance, stability chambers will play an increasingly vital role in ensuring the stability and longevity of a wide range of products across industries worldwide.

Top Stability Test Chamber Manufacturer in India

If you are looking for Best Stability Test Chamber Manufacturer in India, look no further than Effem Technologies, we are a leading manufacturer and supplier of Stability Test Chamber in India.

For more details, please contact us!

Website :- www.effemtechnologies.com

Contact No. :- +91–8750941116

Email :- [email protected]

#Stability Test Chamber Manufacturer in India#Stability Test Chamber Supplier in India#Stability Test Chamber Manufacturer in Ghaziabad#Stability Test Chamber Manufacturer in Delhi#Effem Technologies

1 note

·

View note

Text

What are the main Functions of Stability Test Chamber?

What is a Stability Test Chamber?

A stability test chamber, often referred to simply as a stability chamber, is a specialized piece of equipment designed to simulate environmental conditions to which products may be exposed during their lifecycle. These chambers provide controlled environments of temperature, humidity, and sometimes light to evaluate the stability and shelf-life of products.

Understanding the Purpose

The primary purpose of stability test chambers is to mimic and accelerate real-world conditions under which products are stored, transported, or used. By subjecting products to these controlled environments over extended periods, researchers and quality assurance professionals can:

Assess Shelf Life: Determine how long a product can maintain its efficacy, safety, and quality under specified conditions.

Identify Degradation: Monitor changes in physical, chemical, and biological attributes of products such as color, texture, potency, and microbial growth.

Ensure Regulatory Compliance: Many industries, particularly pharmaceuticals and food, have strict regulations requiring stability testing to ensure consumer safety and product efficacy.

Key Features and Capabilities of Stability Test Chamber

Stability test chambers come in various sizes and configurations, depending on the specific needs of the industry and the type of products being tested. Key features typically include:

Temperature Control: Chambers can maintain precise temperature levels, often ranging from sub-zero to high temperatures, ensuring products are tested across their intended storage conditions.

Humidity Control: Some chambers offer humidity control, crucial for products sensitive to moisture levels.

Light Exposure: Light-controlled chambers simulate exposure to natural or artificial light, important for products susceptible to photodegradation.

Monitoring and Data Logging: Advanced chambers include monitoring systems to track environmental conditions continuously, providing data for analysis and compliance reporting.

Applications of Stability Test Chamber in Industries

Pharmaceuticals: Stability testing ensures drugs remain potent and safe throughout their shelf life, meeting regulatory requirements from agencies like the FDA.

Food and Beverages: Ensures food products maintain taste, texture, and nutritional value, particularly under various storage conditions.

Cosmetics: Evaluates product stability and shelf life, preventing issues like color changes or separation.

Electronics: Tests components and devices to ensure they can withstand temperature variations and humidity without performance degradation.

Advances in Technology

Recent advancements in stability chamber technology have improved accuracy, reliability, and efficiency:

Smart Controls: Integration with IoT (Internet of Things) enables remote monitoring and control of chambers, enhancing accessibility and data integrity.

Energy Efficiency: Chambers are designed with energy-saving features, reducing operational costs and environmental impact.

Compliance and Validation: Automated systems streamline compliance with regulatory standards, ensuring consistent results and audit readiness.

Conclusion

In essence, stability test chambers are indispensable tools for industries focused on delivering reliable, safe, and effective products to consumers. Their ability to replicate and monitor environmental conditions helps companies make informed decisions about product formulations, packaging, and storage requirements. As technology continues to advance, these chambers will play an even more critical role in ensuring product quality and regulatory compliance across global markets.

Top Stability Test Chamber Manufacturer in India

If you are looking for Best Stability Test Chamber Manufacturer in India, look no further than Effem Technologies, we are a leading manufacturer and supplier of Stability Test Chamber in India.

For more details, please contact us!

Website :- www.effemtechnologies.com

Contact No. :- +91–8750941116

Email :- [email protected]

#Top Stability Test Chamber Manufacturer in India#Best Stability Test Chamber Manufacturer in India#Stability Test Chamber Manufacturer in India#Stability Test Chamber Supplier in India#Best Stability Test Chamber Supplier in India#Effem Technologies#Stability Test Chamber Manufacturer in Delhi NCR#Stability Test Chamber Manufacturer in Ghaziabad

1 note

·

View note

Text

Are you Looking For a Stability Chamber Manufacturing Company in India? Effem Technologies

In the realm of pharmaceuticals, biotechnology, and food industries, maintaining product stability is paramount. This necessity birthed the innovation of stability chambers, indispensable tools ensuring the integrity and longevity of various products subjected to diverse environmental conditions.Stability Chamber

Effem Technologies stands as a beacon in this critical domain, offering top-notch stability chambers tailored to meet industry-specific requirements. Situated at T-21, C-Block, Phase-2, Okhla Industrial Area, New Delhi, Effem Technologies epitomizes reliability and technological prowess in every aspect of its operations.

At Effem Technologies, we understand the intricacies involved in preserving product efficacy and safety. Hence, our stability chambers are meticulously designed and engineered to simulate a spectrum of environmental conditions including temperature, humidity, light, and more. These chambers serve as controlled environments where products undergo rigorous testing to ascertain their shelf-life, potency, and quality under varying circumstances.

Effem Technologies takes pride in its unwavering commitment to customer satisfaction and product excellence. Our team of experts is dedicated to providing comprehensive support, ensuring seamless integration and optimal performance of our stability chambers within diverse industrial settings.

For inquiries, reach out to us at +91 8750941116 or via email at [email protected]. Experience the pinnacle of product stability and integrity with Effem Technologies, your trusted partner in quality assurance.

0 notes

Text

Are you looking for a Stability Chamber? | Effem Technologies

Are you in need of a top-quality Stability Chamber? Look no further, because we have the perfect solution for you! As a leading Stability Chamber manufacturer, we take pride in delivering exceptional products that meet the highest industry standards. Whether you are conducting research or need a controlled environment to test the stability of your products, our Stability Chambers are designed to provide reliable and accurate results. With our state-of-the-art technology and expertise, you can trust that our Stability Chambers will meet all your requirements and exceed your expectations.

When it comes to choosing a Stability Chamber manufacturer, it is crucial to select a company that has a proven track record of excellence. With years of experience in the industry, we have established ourselves as a trusted name in the field of Stability Chamber manufacturing. Our team of experts works tirelessly to ensure that each chamber is built with precision and adheres to the highest quality standards. We understand the importance of maintaining stability and consistency in your experiments, which is why we go above and beyond to deliver chambers that are reliable and durable.

What sets our Stability Chambers apart from the rest is our commitment to innovation. We continuously strive to improve and enhance our products to meet the ever-changing needs of our customers. Our research and development team works diligently to incorporate the latest technological advancements into our chambers, ensuring that you have access to cutting-edge equipment. With our Stability Chambers, you can stay ahead of the curve and conduct experiments with confidence, knowing that you have the most advanced tools at your disposal.

Not only do we offer top-notch Stability Chambers, but we also provide exceptional customer service. We understand that purchasing a Stability Chamber is a significant investment, and we are here to guide you every step of the way. Our knowledgeable and friendly team is always available to answer any questions you may have and provide expert advice tailored to your specific needs. We believe in building long-term relationships with our customers, and we are committed to ensuring your satisfaction.

In addition to our exceptional products and customer service, we also offer competitive pricing. We believe that high-quality Stability Chambers should be accessible to all researchers and industries, which is why we strive to keep our prices reasonable without compromising on quality. When you choose us as your Stability Chamber manufacturer, you can rest assured knowing that you are getting the best value for your money.

So why wait? If you are in need of a Stability Chamber, look no further than us. As a leading Stability Chamber manufacturer, we have the expertise, technology, and commitment to deliver top-quality products that will meet all your needs. Contact us today to discuss your requirements and let us help you find the perfect Stability Chamber for your research or testing needs. If you are interested in buying it, Visit us - www.effemtechnologies.com. Our Address : 21, C Block Rd, Pocket C, Okhla Phase II, Okhla Industrial Estate, New Delhi, Delhi 110020

#StabilityChamberSolutions#LeadingStabilityChamber#TopQualityStabilityChamber#StabilityChamberManufacturer#ChamberExpertise#AdvancedTechnologyChamber#StabilityChamberCommitment#QualityChamberProducts#ChamberInnovation#ReliableStabilityChamber

0 notes

Text

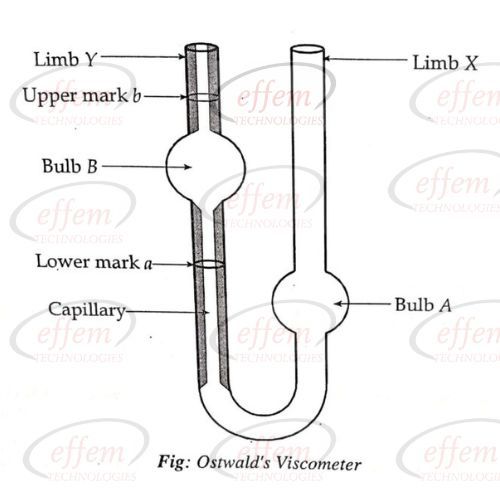

What Is an Ostwald Viscometer?

An Ostwald Viscometer is a type of viscometer used to measure the viscosity of liquids. It is named after its inventor, Wilhelm Ostwald, a German chemist who developed the device in the late 19th century. The Ostwald Viscometer is widely used in industries such as pharmaceuticals, food and beverages, and petrochemicals to determine the flow properties of fluids.

The Ostwald Viscometer consists of a glass capillary tube with a bulb at one end. The capillary tube is filled with the liquid to be tested, and the viscosity of the liquid is determined by measuring the time it takes for a fixed volume of the liquid to flow through the capillary under gravity. The viscosity is calculated using the formula derived by Ostwald, which relates the flow time to the viscosity of the liquid.

As a viscometer manufacturer, it is important to produce high-quality and accurate Ostwald Viscometers. The manufacturing process involves carefully selecting and shaping the glass capillary tubes to ensure precise measurements. The bulbs are also made with precision to ensure proper flow of the liquid through the capillary. The viscometer is calibrated using standard reference fluids with known viscosities, and adjustments are made to ensure accurate measurements.

Viscometer manufacturers also need to consider factors such as temperature control and sample handling. The viscosity of a fluid can be affected by temperature, so it is important to provide a temperature-controlled environment for accurate measurements. Some Ostwald Viscometers are equipped with a water bath or temperature control system to maintain a constant temperature during testing. Proper sample handling techniques should also be followed to prevent contamination or alteration of the fluid’s viscosity.

In addition to manufacturing Ostwald Viscometers, viscometer manufacturers may also offer related services such as maintenance, calibration, and repair. Regular maintenance and calibration are necessary to ensure that the viscometer continues to provide accurate measurements over time. Manufacturers may provide guidelines and recommendations for proper care and handling of the viscometer to ensure its longevity and reliability.In conclusion, an Ostwald Viscometer is a valuable tool for measuring the viscosity of liquids in various industries.

As a viscometer manufacturer, it is important to produce high-quality and accurate viscometers that meet industry standards. Proper manufacturing techniques, calibration, and maintenance are essential to ensure reliable measurements and customer satisfaction. Viscometer manufacturers play a crucial role in providing reliable instruments for viscosity testing and contribute to the overall quality control processes in industries that rely on accurate viscosity measurements.

#viscometer#Laboratory Viscometers#Brookfield Viscosity#Ostwald Viscometer#viscometer manufacturer#stability chamber

0 notes