Please follow me on Facebook: https://www.facebook.com/profile.php?id=61550896354144

Don't wanna be here? Send us removal request.

Text

SUPPLY CHAIN TERMS AND GLOSSARY

Grate to Learn

#8 - Week 2 - Supply Chain Management: Be Global

SUPPLY CHAIN TERMS AND GLOSSARY

Hello everyone, today, I will bring you an interesting topic that I learned on Coursera: Supply Chain Management: Be Global by Dr. Mehrdokht Pournader from Macquarie University.

This series will last for 6 weeks corresponding to the content learned in the course. I will experience and write down what I learn through each subject bilingually. Hopefully, my sharing will help you, especially those interested in Supply Chain!

#8 - Week 2:

Download the CSCMP glossary: Here

Definitions of Supply Chain Management

The supply chain management (SCM) profession has continued to change and evolve to fit the needs of the growing global supply chain. With the supply chain covering a broad range of disciplines, the definition of what is a supply chain can be unclear. Often times SCM can be confused with the term logistics management. CSCMP and the board of directors, comprised of industry experts, created official definitions for the following terms.

CSCMP’s Definition of Supply Chain Management

Supply chain management encompasses the planning and management of all activities involved in sourcing and procurement, conversion, and all logistics management activities. Importantly, it also includes coordination and collaboration with channel partners, which can be suppliers, intermediaries, third party service providers, and customers. In essence, supply chain management integrates supply and demand management within and across companies.

Supply Chain Management – Boundaries and Relationships

Supply chain management is an integrating function with primary responsibility for linking major business functions and business processes within and across companies into a cohesive and high-performing business model. It includes all of the logistics management activities noted above, as well as manufacturing operations, and it drives coordination of processes and activities with and across marketing, sales, product design, finance, and information technology.

CSCMP’s Definition of Logistics Management

Logistics management is that part of supply chain management that plans, implements, and controls the efficient, effective forward and reverse flow and storage of goods, services and related information between the point of origin and the point of consumption in order to meet customers' requirements.

Logistics Management – Boundaries and Relationships

Logistics management activities typically include inbound and outbound transportation management, fleet management, warehousing, materials handling, order fulfillment, logistics network design, inventory management, supply/demand planning, and management of third party logistics services providers. To varying degrees, the logistics function also includes sourcing and procurement, production planning and scheduling, packaging and assembly, and customer service. It is involved in all levels of planning and execution--strategic, operational and tactical. Logistics management is an integrating function, which coordinates and optimizes all logistics activities, as well as integrates logistics activities with other functions including marketing, sales manufacturing, finance, and information technology. (Vitasek, 2013).

Creating value in transportation and logistics

Resolve the asset dilemma. Our analysis suggests that the flexibility provided by financial leases rarely justifies the premium that asset-intensive companies pay for them, implying that many transport companies could outperform competitors by owning a larger part of their core fleet. A through-cycle procurement strategy is also required to overcome pro-cyclical asset purchases that create vicious cycles of capacity influx in times of lower demand. An understanding of the enormous efficiency gains in the newest equipment models helps avoid the “asset trap” (that is, sinking money into transport equipment or infrastructure that rapidly loses value and/or becomes obsolete). A shipping line has saved five percentage points on the costs of adding new asset capacity relative to competitors by consistently better timing its vessel purchases through the cycle for the last 15 years, thereby avoiding having to pay the substantial price premium that is charged during “order booms.” Also, the first movers into innovative asset-pooling concepts, starting with aircraft-engine pools, have been rewarded with higher capital efficiency.

Make your digital transformation a success story. Almost every company is facing the pressure of digitally enabled change from customers, new competitors, and shareholders. Turning a potential threat into an opportunity will require each company to define a digital strategy tailored to its own value drivers, and to make its transformation a success on its own terms. Instead of just “adding” digital outside of existing structures, corporations can create much more value from digitization if they build on their existing assets and strengths (product portfolio and product-development team, existing customer relationships, company assets, and business-building approaches). For most companies, this will mean defining and executing objectives that digitize their core processes, reinforce the IT foundations of their business model, and stake a claim along new frontiers. The latter could reach from digital auxiliary products to partnering with digital giants to develop completely new solutions.

What will the logistics marketplace look like in five to ten years?

Digital is still a challenge for the sector There is no other industry where so many industry experts ascribe a high importance to data and analytics in the next five years than transportation and logistics – 90% in T&L compared to an average of 83%.8 The sector has never had access to more data. There are vast opportunities here to improve performance and serve customers better, and LSPs who are part of a digitally integrated value chain can benefit from significantly improved forecasting to scale capacity up or down and plan routes. Adding machine learning and artificial intelligence techniques to data analytics can deliver truly dynamic routing.

What are the implications for logistics companies? Forwarding becomes more fragmented, as newly emerging ‘hub specialists’ begin to dominate specific legs of trade routes. In the contract logistics space, start-ups (including 4PL start-ups) complement and enhance the services provided by 3PLs, focusing on their most profitable customer segments. Operators in CEP (carriers, and courier / express / parcel (CEP) companies) have to compete with start-ups which may have a clear cost advantage if their people are independent contractors rather than employees. Transportation and logistics is among the top industries to replace labour with automation – but the time frames for implementation vary. Sortation and picking, for example, will be automated much quicker than last-mile delivery. Blockchain technology also fosters automation and efficiency through its trustless peer-to-peer network, thereby reducing delays, human error, and transaction costs for interactions between supply chain partners – for example, in the processing of international trade documents.

What are the implications for customers? Industrial customers benefit from advanced logistics services based on high-end technology, provided by collaborating incumbent 3PLs and startups. Retail customers enjoy greater choice of last-mile providers, and lower delivery costs as a result. At the same time, service offers based on the sharing economy might result in lower costs as well as lower service levels, though the idea is more likely to be accepted by B2C than B2B customers. Consumers who participate in crowdsourcing solutions earn extra cash for trips they take anyway. They have a high flexibility in how they can contribute to platform-based logistics solutions – with opportunities from a temporary part time role all the way to a full-time job. Supply chains become more transparent, with blockchain-backed services offering easy authentication of shipments.

See you in next week

Grate To Learn,

0 notes

Text

PUSH AND PULL STRATEGY IN SUPPLY CHAIN

Grate to Learn

PUSH AND PULL STRATEGY IN SUPPLY CHAIN

#7 - Week 2

Hello everyone, today, I will bring you an interesting topic that I learned on Coursera: Supply Chain Management: Be Global by Dr. Mehrdokht Pournader from Macquarie University.

This series will last for 6 weeks corresponding to the content learned in the course. I will experience and write down what I learn through each subject bilingually. Hopefully, my sharing will help you, especially those interested in Supply Chain!

#7 - Week 2:

A good supply chain manager knows how to use different tactics and understand Trade-offs (lesson #6) in a certain supply chain to help the supply chain achieve balance in terms of value. cost efficiency and responsiveness at all times. One such effective strategy is: Pull and Push strategies focus on Demand Forecast and Align to customer preferences (Suitable to customer needs) through three application examples in the lesson.

Imagine, you are working near a shopping mall, you are on your lunch break and are planning to buy them, what are your options? First, if you are in a hurry, you will choose fast food like a sandwich from the nearest store. Second, if you want to eat more, you can choose to eat sushi at a food court. Third, you can choose a restaurant that you love and choose a plate of steak. As a supply chain manager, think about the differences between the three options above:

Which one has the most impact by logistics and strategies.

Which one belongs to the Market-responsive supply chain?

Which one belongs to the Physically-efficient supply chain?

For the sandwich supply chain, in the manufacturing plant, its production, packaging and distribution are calculated based on long-term forecast of demand. In short, sandwiches are pushed to market based on long-term forecasts. This is called Push strategy or called production method Make-to-stock strategy.

The advantage of this Push strategy is that logistics plans aim at cost efficiency and economies of scale such as purchasing (buying in large quantities will get discounts on products, pickles, side lettuce from farmers), produce and transport large quantities of inventory (full truckload), minimizing inbound and outbound transportation costs.

The disadvantage of the Push strategy is that once customers change their tastes or some other factors change, affecting preferences or changing needs, the supply chain will be very slow to respond to those changes. That change causes significant damage

For the third option, fancy restaurant, preparation and delivery are done after you order from ingredients bought, order placed, prepared and food delivered. They are completely dependent on need,daily forecast and, they are demand-driven. This is called Pull Strategy or Make-to-order strategy.

The advantage of Pull strategy is that production and distribution are based on actual customer needs, final products or final services are personalized. Inventory or in this example other food waste is minimized. By personalizing, we improve quality and customer satisfaction.

The biggest disadvantage of the Pull strategy is that it is difficult to achieve economies of scale, and the cost to complete the final product is often quite high. The challenge is that the delivery speed (lead times) to the end user is often longer, causing customers to wait to get their food instead of choosing a sandwich with almost no wait.

Thus, Push strategy will be suitable for Physically-efficient supply chains and Pull Strategy will be suitable for Market-responsive supply chains.

The question is how can we take advantage of both Pull and Push strategies in the supply chain? The second example of sushi is a Push strategy, but the biggest difference is that you can choose multiple types of sushi, creating custom and delicious sushi plates of your choice according to a Pull strategy. A sushi restaurant needs to synthesize customer demand forecasts, then prepare a certain amount of sushi from each forecast (Aggregated demands). Aggregate forecasts are often more accurate than forecasts for each individual product or service. Sushi restaurants not only ensure and enhance customer satisfaction with personalized sushi plates, but also enjoy cost-effectiveness in aggregate forecasting and benefit from economies of scale. This is called Push Pull Strategy.

Supply chain managers are experts at drawing the line between two strategies based on the speed at which sushi is created and delivered to the final consumer in order to achieve cost-effective, increased responsiveness in the process. supply chain.

See you on topic Supply chain Terms will be very useful for your career in post #8.

Grate To Learn,

#supplychainmanagement#business#gratetolearn#supplychainsolutions#food supply#sushi#sandwich#supplychain

2 notes

·

View notes

Text

TRADE-OFF BETWEEN REDUCED DELIVERY TIME AND INCREASED INVENTORY OR TRANSPORTATION COSTS

Grate To Learn

#6 Week 2 - Supply Chain Management: Be Global

Hello everyone, today, I will bring you an interesting topic that I learned on Coursera: Supply Chain Management: Be Global by Dr. Mehrdokht Pournader from Macquarie University.

This series will last for 6 weeks corresponding to the content learned in the course. I will experience and write down what I learn through each subject bilingually. Hopefully, my sharing will be helpful to you, especially those interested in Supply Chain!

#6 - Week 2:

We have discussed two main types of supply chains: Market-responsive and Physically-efficient. Throughout the course, we will discuss tools and techniques to achieve the directions of those two supply chains. And today, we will mention one of those tools: Distribution Network Design (Design of Distribution networks) through the example of online orderingAmazon, balancing factors in logistics to achievestrategic fit.

What is Distribution?

Distribution is the movement of inventory from suppliers to final customers. This is an important element in effective logistics management in minimizing inventory costs and transportation costs in the future. supply chain.

Going back to the example of ordering books online in lesson #5, you ordered the book on Amazon, then the book was shipped from the US to Australia. We have not discussed the trade-offs between these logistics drivers. Imagine, Amazon decides to reduce local couriers' delivery times even further, what options does Amazon have?

Trade-offs between logistics drivers

To reduce delivery times, instead of storing parcels in distribution centers and then waiting for another parcel to be filled on the truck, they can send directly to customers, they can reduce Facilities (facilities) such as distribution centers and warehouses. In exchange, shipping costs will increase due to many other reasons such as choosing a faster shipping unit, transporting goods even when the truck is not fully loaded, increasing fuel costs, etc.

Another option is that Amazon could increase the number of local distribution centers, warehouses in Australia and then stock books until customers order them, helping to increase delivery of books to users. Amazon will save on international shipping costs between the US and Australia, but its inventory will increase. Other costs that have increased are the costs of renting and operating the center (utilities, staff, and center operating equipment).

The main element that determines the cost-efficiency of supply chains is: Distribution networks - Distribution networks contain all the elements of logistics drivers and determine how cost-efficient and responsive a supply chain is going to be.

Amazon needs to decide whether it is willing to increase its costs Facilities or increase the will of Transportation for response Response Time:

For each strategy in the supply chain, managers must carefully consider the costs and benefits of trade-offs between logistics elements and how to optimize them. Then we need to plan the actual design of your network in detail in another lesson.

See you on topicPull and Push strategies in post #7.

Grate To Learn,

1 note

·

View note

Text

LOGISTICS - WHY DOES IT CRITICAL?

Grate to Learn

#5 Week 2 - Supply Chain Management: Be Global

Hello everyone, today, I will bring you an interesting topic that I learned on Coursera: Supply Chain Management: Be Global by Dr. Mehrdokht Pournader from Macquarie University.

This series will last for 6 weeks corresponding to the content learned in the course. I will experience and write down what I learn through each subject bilingually. Hopefully, my sharing will help you, especially those interested in Supply Chain!

#5 - Week 2:

Logistics is a very common issue that appears in the media such as ways to improve company A's operations or logistics development issues to complete project B. So what does logistics mean in this context? Supply chain management, why is it important? We will discuss about facilities (Facilities), inventory (Inventory) and shipping (Transportation), these are the three main drivers that suppliers rely on to develop their supply chain network

This week, we talk aboutLogistics to learn about the main components, their strategies in the supply chain, how to balance those components when designing distribution channels, and how to coordinate Pull and Push strategies to help reduce costs, Maximize flexibility and speed in logistics operations. Today, we discuss together Logistics of Online Ordering.

Let's say you live in Sydney and the book is shipped from a bookstore in the US. The time it takes for the book to reach you is only 4 days. It's surprising, isn't it? That journey was more than 14,000km long, in less than a week, it arrived to you. More than 30-40 years ago, a book would have taken weeks or even months. That will cost us hundreds of dollars in shipping and delivery costs, the risk of losing goods is always potential, and we cannot track where the product is currently. In recent years, logistics has made a major impact on global trade (Global Trade) allows online ordering and delivery to help save time and costs. Improving online Logistics management is key to creating that impact.

When you place an order, the goods are first processed by the seller, and then the seller through its businesses delivers them to the service providers. If the destination requires an ocean crossing, your goods will need to pass through a distribution center (Distribution center) near the port of delivery such as seaport or airport and be aggregated with the goods of other customers. Goods are continued to be transported by means of transport such as planes, ships and then trucks to the distribution center (Distribution center) where goods are classified according to the receiving area. Finally, local carriers take care of the last-mile delivery and the goods are delivered to you. RFID tags and RFID readers at the entry and exit points of distribution centers are used to help us easily track the distribution process.

What is logistics?

What are the key ingredients that make this process work? What are the requirements to execute this complex operation? Logistics makes these activities visible including:

Carrier: Delivered the parcels =Transport driver

Distribution centers: Warehousing and reassigning parcels = Facilities driver

Parcels = Inventory driver

This program also has many important components, but three basic components (Facilities), inventory (Inventory) And shipping (Transportation) will take more cost, time and effort to optimize. Let's discuss those concepts and establish KPIs to evaluate performance indicators and measure their effectiveness in the supply chain:

Facilities: Are the means and tools to manage production or inventory storage. Examples of Facilities are Warehouse, Distribution Center, Factory and Retail store. Depending on the supply chain, Market-responsive will have more quantity (Capacity) and excess capacity of facilities (Facilities) than Physically-efficient. Capacity ensures changes in customer needs. KPIs to evaluate efficiency such as: Total capacity (Capacity), Capacity Loss (due to changes or machine failure), Cube utilization (If the company can increase the average number of blocks (or weight) per load, additional products will be free), Availability for production and production service level.

Inventory: There are three main types: raw material (materials),work-in-process (work in progress) and finished products (finished product). In a market-responsive supply chain, due to the short product life cycle, raw material inventory with more work-in-process is not limited, making inventory more accessible and flexible to customers. customer needs versus a Physically-efficient supply chain. KPIs to evaluate effectiveness such as Average inventory, Average safety stock, obsolete components (when the manufacturer stops producing them), Finished products obsoletes (finished products obsolete due to not being sold out), Stock value (Price). inventory value - book value of inventory, shown on the enterprise's balance sheet), Fill rate.

Transportation: Is the process of transporting inventory from facilities to final customers. In Physically-efficient supply chains, they often use faster transportation vehicles with full inventory, but with Market-responsive, they do not need to consider sending full trucks with full inventory. Transportation costs are considered by Outbound and Inbound transportation costs. Outbound is the cost of shipping goods to customers, while Inbound is the cost of receiving goods for the manufacturer from the supplier.

See you in the next part with the How to Design Distribution channels topic.

Grate To Learn,

#supplychainmanagement#business#supplychain#gratetolearn#logistics#inventory#facilities#transportation

1 note

·

View note

Text

"As long as you are grateful, you will be happy“ _Thich Nhat Hanh (Zen Master)_

1 note

·

View note

Text

ARTICLE ABOUT SUPPLY CHAIN MANAGEMENT: Be Global

Grate To Learn

#4 Week 1 - Supply Chain Management: Be Global

Hello friends, today, I will bring you an interesting topic that I learned on Coursera, Supply Chain Management: Be Global by Dr. Mehrdokht Pournader from Macquarie University.

This series will last for 6 weeks corresponding to the content of the course. I will experience and rewrite what I learn through each subject in a bilingual manner. Hopefully, my sharing will help you, especially those who are interested in Supply Chain!

#4 - Week 1:

This thought leadership paper provides a general understanding of excellence in supply chain management planning as well as logistics management in supply chains:

Glatazel, C. & Niemeyer, A. (n.d.). Operations practice: Excellence in supply chain management. McKinsey & Company.

“In this battle for customers, our supply chain and distribution network gives us a key advantage.”– Meg Whitman, CEO of HP.

Questions a CEO should ask about the supply chain Check your current understanding of your organization’s supply chain needs and capabilities. Can you answer these questions?

What is your customers’ experience of your supply chain? How does it stand out from your competitors?

What is your supply chain strategy, and how does it support your business strategy? For which customers, products, and segments does your supply chain target the best performance? Where does it optimize for cost rather than for service?

Do you have clear supply chain performance and cost targets? Which KPIs do you use to measure these?

Who is ultimately responsible to deliver against these performance targets? How do you ensure every function in your business supports those efforts?

How quickly can you ramp up production of a new product or a new sales region? Is your supply chain agile enough to flexibly respond to external changes?

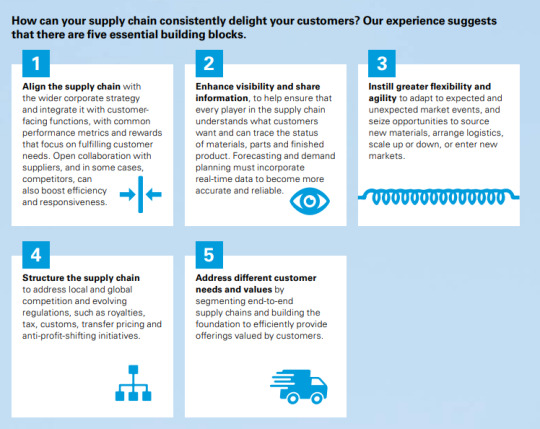

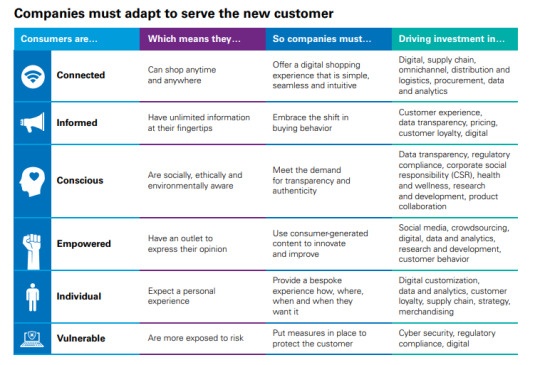

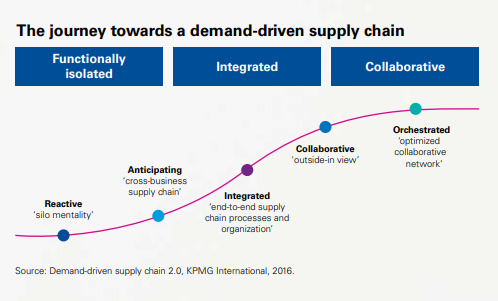

2. This thought leadership paper by KPMG is a great supplement to the discussions on developing market-responsive supply chains. It provides explanations on what it means for supply chains to be demand-driven and improve customer experience:

Gampenrieder, E.L. (2016). Demand-driven supply chain 2.0: A direct link to profitability. KPMG International.

Drones will soon be delivering everything from consumer goods in cities to vital medical supplies in remote areas.

3. This article skillfully elaborate's on Fisher's framework and provides six (6) types of supply chain strategies that could fit an organisation:

Perez, H.D. (2013). Supply chain strategies: Which one hits the mark? Supply chain quarterly. Council of supply chain management professionals (CSCMP).

The fast supply chain model is most suitable for companies that manufacture trendy products with a brief product lifespan. From the customer's perspective, the key differentiator among competitors' value propositions lies in their ability to promptly update their product offerings to align with current trends. This intensifies competition in the market, emphasizing manufacturers' capacity to continually innovate and offer new products at competitive prices. Consequently, the primary driver of competitiveness revolves around reducing market intermediation costs. While this may seem challenging in an industry characterized by short product lifecycles, it is achievable through a keen understanding of market trends and consumer behaviors.

To address this challenge, production should be organized into a single batch per Stock Keeping Unit (SKU), with batch size determined by sales forecasts for the upcoming sales season (or collection, in the fashion industry). This approach aligns with a "make to forecast" decoupling point. As the sales season for a product line becomes progressively shorter, producing a second batch of the best-selling items from the collection and restocking store shelves before the products lose their appeal to consumers becomes increasingly challenging.

The "agile" supply chain model The agile type of supply chain is useful for companies that manufacture products under unique specifications for each customer. This is typically seen in industries that are characterized by unpredictable demand. They use a "make to order" decoupling point, producing the item after receiving the customer's purchase order to avoid manufacturing products that have no certainty of future sales.

As a result, the main driver of competitiveness is agility—the ability to meet unpredictable demand, in quantities exceeding the customer's forecast and/or within a shorter lead time than agreed. The ability to be agile is proportional to the ratio between excess capacity and the average rate of asset usage. In strict terms, there can be no agility without excess capacity.

Organizations tend to want their supply chains to have simultaneous capabilities: efficient, fast, agile, custom-configured, and flexible, among others.

See you in the next part.

Grate to Learn,

#business#supplychainmanagement#supplychainsolutions#production#article#reading#gratetolearn#supplychain

1 note

·

View note

Text

HOW TO CHOOSE THE SUPPLY CHAIN OF MY PRODUCTS

Grate to Learn

#3 Week 1 - Supply Chain Management: Be Global

Hello friends, today, I will bring you an interesting topic that I learned on Coursera, Supply Chain Management: Be Global by Dr. Mehrdokht Pournader from Macquarie University.

This series will last for 6 weeks corresponding to the content of the course. I will experience and rewrite what I learn through each subject in a bilingual manner. Hopefully, my sharing will help you, especially those who are interested in Supply Chain!

#3 - Week 1:

Today we are talking aboutAchieve strategic fit to better understand how to choose the right strategy for the supply chain, the importance of that.

Cooking Competition

Imagine, you are passionate about cooking and are participating in a cooking competition in Italy for 3 months, the goal is that you make the most of your time to win. Your plan should not only outline the milestones you need to do but also include detailed activities for each milestone. Milestones can be 1-Learning different types of Italian dishes, cooking styles, 2-Learning how to choose the right food, recipes and experimenting with cooking for a competition. With milestone 1, you will have to search for online information such as videos, recipes, cooking courses. The second milestone, you need time to actually practice the recipes, test them and pick the ones you love the most and make them your own. Of course, you need money, a little help from family, friends. But is that enough for you to win? The answer is no, because if you want to win, it depends on your skills and other contestants, the criteria of the competition. During the game day, you have to face unexpected situations such as suddenly you are late, or feel uncomfortable when you have a runny nose, sneezing. It all affects your performance as judged by the judges in this Italian cooking contest.

A strategic perspective to global supply chains

Now, replace yourself in the above competition into an international business, the customer will be the judge, the participant will be your opponent. To win, in the international business context, you need to gain and maintain market share with a competitive strategy that sets you apart from the competition.

This differentiating factor could be cost, product quality, product availability, superior customer service, or any other winning factor. To have a good competitive strategy requires the alignment between product development strategy (Product Development strategy), sales and marketing strategy (Marketing and Sale strategy) and also supply chain strategy (Supply Chain strategy):

Product Development strategy: Interested in new product category (Product portfolio) that the company is aiming for.

Marketing and Sale strategy: Concerning customer segmentation, pricing strategy, broader strategy4Ps (Product, Price, Place, Promotion) approach by advertising, communication to the end user.

Supply Chain strategy: This strategy goes into defining operational and logistics requirements from the end-to-end supply chain to meet customer needs such as determining safety stock (Safety stock) for a particular product, a high level of safety stock to increase production flexibility or reduce it to reduce costs; Who will be your supplier?Suppliers), how can you choose them, do you choose them for flexibility, availability of materials or to reduce costs; What is your current production capacity (Capacity), do you maximize to enjoy economies of scale or do you just produce to chase customer demand (Chase demand strategy), that is the story of production planning strategies. The choice depends on what your product is, in the following articles we will go into more detail about supply chain strategy decisions and their impact on operations and logistics.

Now, let's discuss, how to choose the strategyFit?

Strategic fit

Strategy fit is achieved when there is an alignment between competitive strategies and supply chain strategies. Some of the problems businesses face are your not being able to promise the variety and high quality of your products with choosing a supplier just because of low costs or you can't be ambitious to achieve your savings goals. Cost savings when you create products where demand is unpredictable (Remedy & Meindl, 2016). To achieve strategic fit, you need to determine whether your product is in a Responsive or Efficient supply chain (See lesson #2), you must know who your customers are, your supply capabilities, your promises. appointments you can make for clients. See the model below to understand better. You should align with the Competitive Strategy and your Supply Chain Strategy.

In the end, how do you win the Italian cooking contest, that's when you have some recipes that many people love to taste.

See you soon.

Grate To Learn,

#business#supplychainmanagement#supplychainsolutions#strategy#manager#goal setting#production#supplychain#gratetolearn

1 note

·

View note

Text

Hope you guys follow me on this platform.

Grateful for all

1 note

·

View note

Text

Grateful

Grateful

Hello! Thank you very much for visiting our blogs. The journey of this blog will officially start from September 2, 2023, a happy day for all of Vietnam, on that occasion, I would like to mark the beginning of "Grate Journey"Like a diary recording the imprints, lessons, memories, the journey that I have gone through is always full of gratitude.

Inspired by the fact that, I want to record the process and things I have learned when I was a student and about to go to work, most of all, I want to share my experiences as a part of giving, a part of giving, is a part of being grateful for the lessons that life has given me. In the process of being fortunate to have the opportunity to study at the University, through the Coach training program ofIAG Academy, I know Zen Master Thich Nhat Hanh, I gradually learn and know the saying "As long as you are grateful, you will be happy“. That quote always motivates me, always gives me a depth of awareness about all the joys and sorrows that happen in life, always makes me appreciate every moment and everything, no matter how small or big. I am also impressed by the Zen master's saying that flowers are made of things that are not flowers, children are not only the crystallization of parents but also the contribution of heaven and earth. Everything that we have is created by things that we do not configure, so our gratitude should always be permanent, there is always an extension to everything, everything should be.“who have exhausted their gratitude, happiness can no longer be found”. Based on the Buddhist philosophy (Buddha), he said that the giver is also the receiver, the receiver is also the giver. I am also on a journey of contemplating that Non-Dualistic view, so that I can fully realize that, in this present moment, we are still alive, being tolerated by heaven and earth, living in this life. There is suffering to see happiness.

In the past, I was fortunate to have the opportunity to hear an excerpt from a lecture by Thich Minh Niem about the saying "The lotus flower is close to the mud but doesn't smell like mud". I often deny the contribution of something small and dirty like mud, but he gave me a new perspective, if it weren't for the mud, would there be such a fragrant lotus flower. If that lotus is ungrateful to the foul-smelling mud, it may have lost its chance to shine and bloom.

In my opinion, the things that we are enjoying for free in life such as light, air, or love from family, teachers, and friends are priceless, impossible things. is lacking, but it is also the thing that we ignore and take for granted the most. When we lose one of them, we suddenly realize their value and secretly wish they would return. On the journey of building gratitude, I learned that cultivating gratitude always shows me the importance of everything around me, always respects and loves those who have been helping me, accepting Accept all the lessons that heaven and earth bring, no matter how difficult it is, we must always live fully for the present moment.

Gratitude is not asking for somethingGratitude is to nourish the body and mind, to give more. And I am also on a journey to build deep gratitude to everyone, everything that I have the grace to meet andGrate Journey is an effective means of support so that I can share good things and stories that I have the opportunity to receive.

Thank you so much for taking the time to read my first post. I always appreciate everyone's contributions to Grate Journey will get better every day.

Grate for all,

2 notes

·

View notes

Text

HOW TO CHOOSE THE SUPPLY CHAIN OF MY PRODUCTS

Grate to Learn

#2 Week 1 - Supply Chain Management: Be Global

Hello friends, today, I will bring you an interesting topic that I learned on Coursera, Supply Chain Management: Be Global by Dr. Mehrdokht Pournader from Macquarie University.

This series will last for 6 weeks corresponding to the content of the course. I will experience and rewrite what I learn through each subject in a bilingual manner. Hopefully, my sharing will help you, especially those who are interested in Supply Chain!

#2 - Week 1:

Today we are talking aboutChoosing the right supply chain

When working in the Global Supply Chain, one may encounter problems with poor coordination between the company and its suppliers or the quality and quantity must be correct when the customer places an order, at the same time, the inventory of the company must be correct. We are missing or redundant leading to many unnecessary costs. These are just the tip of the iceberg, the problem will increase when we do not identify the right supply chain for our products and services as well as the overall strategy of our business.

Fisher’s framework

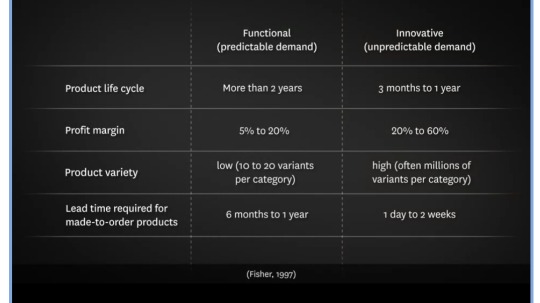

Fisher's framework is a tool to help you quickly and efficiently identify the right properties for your supply chain, helping to avoid problems. About tools, in 1997, Marshall Fisher introduced innovative products on Harvard Business Review as "What is right supply chain for your product". Fisher (1997) argues that almost all products can be placed in the spectrum from functional to innovative. Products and services will be classified and located in that range.

Imagine you are going to a mall with a list of things to buy for the next week. Looking at the shelves outside your list, you seem to forget that you are buying things on the list, you immediately visit the shelves of clothes, electronics, or try fruit and vegetables.

Back to Fisher, think about how often you shop, it's normal if you buy vegetables and food every 1-2 weeks, but with TVs and expensive headphones, it's less often right Are not? Almost all of us follow that buying behavior. That is also the biggest difference between the function (Functional) and creativity (Innovative) of the product. Functional products are products that meet your basic needs such as fruits, vegetables, food, these products are easily predictable with fairly stable demand and long product cycle (Product Life Cycle). Demand for innovative products such as electronics is less predictable with a shorter product life cycle because it requires continuous improvement to serve customers. As a matter of fact, many people often change their Iphone to higher-end models every year to enjoy the latest technology services.

The Innovative model is difficult to predict in terms of demand, but it offers a higher profit value than Functional. Based on Fisher's statement, we can compare Product Life Cycle, Profit Margin, Variety and Lead time to make-to-order products of two types of products (See more in the image below).

Innovative Product: Shorter Lifecycle, Higher Profit Margins, More Product Types, and Shorter Product Creation Time.

Functional Product: Long life cycle, Low profit margin, similar looking products, not much difference, quite long time to create

Fisher divides the two types of products into two different supply chains, which he calls Functional Product a supply chain that is physically-efficient. Innovative product is a market-responsive supply chain.

Physically-efficient supply chains, with a focus on the supply chain manager's need to reduce costs. For example, for dairy products (Dairy supply chain), we need to reduce the cost of milk production, reduce the cost of storing milk in the warehouse because this is a commodity with a limited shelf life and a perishable commodity. Perishable goods).

Market-responsive supply chain, the focus is on supply chain managers to respond quickly and promptly to market changes, minimize inventory, even no inventory, reduce inventory product prices to avoid inventory of obsolete products. For example, Smart TVs, manufacturers can only use the same production technology for a limited period of time. They need to make sure assembly lines and inventory levels are responsive to short-term fluctuations in customer demand. They must minimize the appearance and distribution of older TVs that are in less demand and when new product lines are produced. With the new TV line, manufacturers need technology suppliers who have components and spare parts at the time they need to be produced. The new supplier needs to ensure the expected quality and specifications. Manufacturers also need to redesign their production lines for the new TV product. This cycle repeats every time the company releases a new product.

Fisher is the starting point that provides you with an arrangement of strategies to suit each product type, Functional or Innovative.

How to do this, I will see you in the next post #3 Week 1!

Grate to Learn,

1 note

·

View note

Text

SUPPLY CHAIN MANAGEMENT: BE GLOBAL

Grate to Learn,

#1 Week 1 - Supply Chain Management: Be Global

Hello friends, today, I will bring you an interesting topic that I learned on Coursera, Supply Chain Management: Be Global by Dr. Mehrdokht Pournader from Macquarie University.

This series will last for 6 weeks corresponding to the content of the course. I will experience and rewrite what I learn through each subject in a bilingual manner. Hopefully, my sharing will help you, especially those who are interested in Supply Chain!

#1 - Week 1:

WEEK 1: Welcome - Strategic supply chain management in global markets

• Warm-up:

PizzaGlobal: Imagine you are opening and running a Pizza shop called PizzaGlobal. Your challenge is about producing the cake, managing the store and delivering the cake to the customer. In addition, the challenge is to increase revenue and increase the rate of customer return. On top of that, it becomes challenging to do business with running multiple stores in the chain and operating all of the stores worldwide. All are central tasks of Global Supply Chain Management.

* Course Map:

Throughout this course, we will learn about the tools supply chain managers use to improve their supply chains on a global scale.

Week 1 - Strategic Supply Chain Management in Global market; We will discuss together the definition of Supply Chain, review, evaluate Supply Chain strategies in terms of supply chain relevance. Study two key Supply Chain issues and how they affect supply chain decisions.

Week 2 - Logistics drivers: Learn how to apply supply chain strategy to solve logistics problems such as minimizing costs, maximizing flexibility.

Week 3 - Principle of Global Supply Chain network design: Identify the factors that help the supply chain to expand, expand the scope of operations to a new country or create a new brand. We will learn frameworks when laying out a supply chain in a new country to enhance supply chain coordination.

Week 4 - Sourcing decisions in global markets: Sourcing is VERY IMPORTANT to answer two questions: 1. Should Outsourcing (outsource) not; 2. What and from whom should we buy (Procurement)?

Week 5 - Risks and Sustainability in global Supply Chain: Identify risks and challenges in the Global Supply Chain, and how we evaluate and prioritize those decisions. How to increase the resilience of Supply Chain to avoid the risk of Supply Chain disruption. In addition, we will take a look at how to operate a sustainable supply chain that is oriented to people and the planet.

Week 6 - Supply Chain diagnostic framework: We will go into practice through case studies (with 3 cases), the importance of technology, modern supply chain management

Figure 1: Research and learning process of the entire course in 6 weeks

Full course knowledge goals: Improve and manage the GLOBAL supply chain effectively.

The course will be narrated by me in bilingual.

* Topic of Week 1:

Supply Chain Management (SCM)

SCM selection

SCM and strategic fit

* Learning outcome:

Apply a strategic perspective to supply chain management

Select the supply chain type that best matches the business and supply chain strategies

Assess the strategic fit of global supply chains using Fisher's framework

-MAIN CONTENT-

Opening:

MissMehrdokht As a shopaholic, she spends a lot of time looking for beautiful, trendy designs that fit her personal size. When shopping, we realize the speed at which the clothing stores are constantly changing, the models that have just been released on the runways immediately appear on the shelves of Zara, H&M or Uniqlo. That situation we call fast fashion, this makes customers always have many choices, makes us more inclined to buy more to hope to catch up with the trend, leading to these brands selling. in large quantities but at low prices, triggered by customer demand. This is also their core competitive strategy. To operate such a strategy well, it requires managers to have a deep understanding of the supply chain and business strategy.

Beef supply chain: From Australia to Asia

Who made your purchase of beef, access to beef convenient? In 1788, when cattle were first brought to Australia, the gold rush of the 1850s in this country brought a fever for beef, plus the purpose of raising cows made this industry go. long stride. Today, Australia leads the world in exports of live cattle to 77 countries (2016-2017) with $1 billion in income with 13,000 employees.

Supply Chain Requirement:

Rising demand in leading economies such as China, which requires high quality meat, increases the demand for high quality beef supply in Australia. This is an opportunity for the industry to promote and develop into Asia. What the industry cares about is the end-to-end beef supply chain and how it affects the overall policy of the economy such as welfare, production costs, transportation.

Australian beef supply chain:

Starting from Producer: meat producers scattered throughout the country.

Exporter: After production, they sell to the exporter, through Transport.

Feedlot: The beef is then tested for health and nutrition by veterinarians at Feedlot to ensure compliance with Australian government food standards and Chinese standards. For traceability, exporters often use RFID tags to track livestock throughout the supply chain leading to overseas slaughter.

Feedlot: After going through customs clearance and transportation procedures, cows are checked for food safety and hygiene for consumption in China,

Distributor: If satisfactory, cows are brought to the slaughterhouse (Slaughterhouse), then to wholesaler, retailer.

Consumer: Ultimately, beef is purchased by consumers from those stores.

Definition of Supply Chain and Supply Chain Management

Components of the beef supply chain include: Producers, Exporter, Feedlots, Distributors, Slaughterhouse, Wholesalers, Retailer of meat.

Types of costs: Cattle production costs, farm operations, transportation costs, health care costs, cow quality

The flow of this cow commodity is a supply chain. Upstream Supply Chain is the producers, feedlot in Australia, and Downstream Supply Chain is the slaughterhouse, feedlots, retailers and consumers in China.

Simple supply chain model:

Supplier: Supply inventory to Manufacturer - Distributor - Retailer - Customers

Modern supply chain model: Will include more Suppliers, more Manufacturers and similar with other components. They are linked together with many links.

Objectives of Supply Chain Management:

Using a set of approaches and frameworks to effectively integrate the upstream and downstream supply chain tiers to save costs and meet customer needs. Or we can say to increase revenue and service

Challenge in Beef Supply Chain:

- The challenge comes from the requirements of the Chinese market: Changing regulations and standards for beef import and export

- Concerns with components in the supply chain

- Climate change, extreme weather leading to epidemics, scarce grasslands, depending on some other specific markets.

Internal risks can be optimized and rearranged, but external factors make it difficult to control.

Grate to learn,

1 note

·

View note

Link

1 note

·

View note

Link

1 note

·

View note