Don't wanna be here? Send us removal request.

Text

Granulation vs. Mixing: Which Matters More in Fertilizer Production?

When setting up a fertilizer production line, manufacturers often debate: Is granulation equipment or mixing equipment more crucial? The truth is, both play indispensable roles—but their advantages differ. Let's break it down.

In fertilizer production, both granulation and mixing are critical processes, but their importance depends on the desired product characteristics. Granulation ensures uniform particle size and improved nutrient release, while mixing guarantees homogeneity of raw materials. Fertilizer manufacturing equipment, such as granulators and mixers, plays a key role in these processes. Fertilizer machine manufacturers design and supply these specialized machines, ensuring efficiency and scalability in production lines. The choice between granulation-focused or mixing-centric equipment depends on the specific formulation and end-use requirements of the fertilizer.

The Role of Fertilizer Mixing Equipment

Mixing is the foundation. Before granulation, raw materials—whether compost, minerals, or additives—must be uniformly blended. Inconsistent mixing leads to nutrient imbalances, reducing fertilizer effectiveness.

Key advantages:

✔ Ensures homogeneity – No clumps, no weak spots.

✔ Boosts efficiency – Well-mixed materials granulate smoothly.

✔ Customizable blends – Adjust NPK ratios easily for tailored fertilizers.

Without proper mixing, even the best granulation process can't compensate for poor distribution of nutrients.

The Power of Granulation Equipment

Granulation transforms mixed powder into easy-to-handle, slow-release pellets. This step enhances marketability, reduces dust, and improves nutrient delivery.

Why it shines:

✔ Better usability – Pellets are easier to store, transport, and apply.

✔ Controlled release – Granules break down gradually, improving soil absorption.

✔ Reduces waste – Less runoff and dust compared to powdered fertilizers.

Which One Should You Prioritize?

Both are essential, but their importance depends on your goals. Need a versatile base product? Focus on mixing. Selling commercial-grade fertilizer? Granulation is key.

Ultimately, a well-balanced fertilizer production line integrates both seamlessly—mixing for consistency, granulation for performance.

0 notes

Text

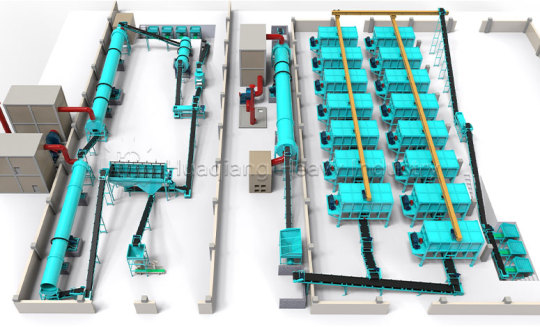

Bio-organic Fertilizer Production Line: Technical Pathway for Waste Resource Utilization

The Urgent Need for Waste Resource Utilization

With the increasing accumulation of agricultural and urban organic waste, the resource utilization of these materials has become a critical issue for environmental protection and sustainable agricultural development. Bio-organic fertilizer production lines systematically process organic wastes such as livestock manure, crop straw, and food waste into high-value bio-organic fertilizers, realizing a circular economy model that "turns waste into treasure".

Modern bio-organic fertilizer production lines typically include core processes such as raw material pretreatment, fermentation and composting, ingredient mixing, granulation, drying and cooling, screening and packaging, forming a complete technical loop from waste treatment to fertilizer production and agricultural application.

Key Technical Components

The core technical pathway for efficient bio-organic fertilizer production includes:

Efficient Fermentation Technology: Using microbial inoculants to accelerate organic matter decomposition while controlling temperature, humidity and aeration

Deodorization and Sterilization Process: Eliminating pathogens and odors through high-temperature fermentation and biofiltration

Precision Formulation System: Adding functional microorganisms and nutrients according to crop needs

Intelligent Control System: Automatically monitoring process parameters to ensure product quality consistency

Environmental and Economic Benefits

Bio-organic fertilizer production lines not only address the environmental pollution caused by organic waste but also produce fertilizers that improve soil structure, enhance fertilizer efficiency, and promote crop growth. Statistics show that a medium-sized production line can process 30,000-50,000 tons of organic waste annually, reducing carbon emissions by approximately 12,000 tons while producing 20,000-30,000 tons of high-quality organic fertilizer, achieving both environmental and economic benefits.

0 notes

Text

Organic Fertilizer Granulator Guide: Which Type Suits You Best?

Choosing the right granulator for your organic fertilizer production can be tricky - there are several options out there, each with its own personality. Let me walk you through the five main types, their quirks, and where they shine.

Quick tip before we dive in: The granulator is like the heart of your organic fertilizer production line. It takes all that prepared material and shapes it into market-ready pellets, affecting everything from nutrient content to how easy the fertilizer is to spread.

1. Ring Die Granulator - The Heavyweight Champion

How it works: Uses a rotating ring die with internal rollers to squeeze material through holes - think of it like a giant playdough machine

Pros: High output (we're talking tons per hour), produces super uniform pellets, handles moderate moisture well

Cons: Big footprint, higher power consumption, not great for sticky materials

Best for: Commercial-scale operations where consistency and volume matter most

2. New Type Organic Fertilizer Granulator - The Versatile Performer

How it works: Combines crushing and granulating in one unit using a unique stirring and shearing action

Pros: Handles diverse materials (even fibrous stuff), lower energy use, compact design

Cons: Slightly less uniform particle size than ring die, not ideal for very wet materials

Best for: Medium operations processing mixed organic wastes (like farm waste + food scraps)

3.New Type Stirring Tooth-Drum Granulator- The Space Saver

How it works: Integrates fermentation and granulation in a single drum - basically does two jobs at once

Pros: Saves floor space, reduces handling between processes, good for continuous production

Cons: Requires careful moisture control, smaller batches than dedicated granulators

Best for: Startups or urban farms where space is tight but you want complete processing

4. Flat Die Granulator - The Reliable Workhorse

How it works: Material gets compressed between a flat die and rollers - simpler version of ring die

Pros: Affordable, easy to maintain, good for small batches

Cons: Lower output, dies wear faster than ring types

Best for: Small farms making fertilizer for own use or local sales

5. Disc Granulator - The Gentle Giant

How it works: Material tumbles in an inclined rotating disc, forming perfect little spheres

Pros: Produces beautiful round pellets, gentle on delicate materials, adjustable disc angle controls size

Cons: Needs binder for some materials, not as compact as other types

Best for: Premium organic fertilizers where pellet appearance matters (think horticulture or retail products)

Where Granulators Fit in the Big Picture

In a typical organic fertilizer production line, granulation happens after composting and material prep but before drying and packaging. The machine you choose affects:

How you prepare materials beforehand (crushing size, moisture content)

Your drying requirements (some granulators handle wetter materials better)

Final product quality (density, crush resistance, dissolution rate)

At the end of the day, there's no "best" granulator - just the one that best fits your specific materials, production goals, and budget. The good news? With these five options, you're almost guaranteed to find your perfect match!

0 notes

Text

Flat Die Granulator: The Ideal Choice for Organic Fertilizer Production?

In the field of organic and bio-fertilizer production, flat die granulators are widely popular due to their unique working principle and excellent adaptability. But what exactly are the characteristics of this equipment? What types of raw materials is it suitable for processing? Which fertilizer manufacturers should consider choosing it? And what are the features of the fertilizer granules it produces?

Flat die pellet mills are key equipment in both organic production lines and biofertilizer production lines, converting powdered organic materials or microbial-enriched mixtures into uniform pellets. They ensure efficient granulation while preserving nutrient content and microbial viability, making them essential for sustainable fertilizer manufacturing.

The flat die granulator plays a crucial role in the organic fertilizer production process by converting powdered organic materials into uniform granules. Using a flat die and rollers, it compresses the raw mixture under high pressure, forming dense, evenly sized pellets. This improves fertilizer handling, storage, and slow-release properties while reducing dust and waste. The granulator operates efficiently at room temperature, preserving nutrient content, and is ideal for small to medium-scale organic fertilizer production.

Core Characteristics of Flat Die Granulators

Flat die granulators use vertical pressure granulation principle and have the following notable features:

Gentle granulation process: Low-temperature and low-pressure operation, especially suitable for raw materials containing active microorganisms or heat-sensitive components

High adaptability: Can process raw materials with higher moisture content (20-40%), reducing pre-drying steps

Low energy consumption: 30-50% less energy consumption compared to other granulation methods

Simple operation: Concise structural design, easy maintenance, suitable for continuous production

Most Suitable Raw Material Types

Flat die granulators are particularly suitable for the following types of raw materials:

High organic content: Livestock manure, food waste, agricultural waste, etc.

Fibrous materials: Straw, wood chips, mushroom residue, etc.

Materials with moderate viscosity: Neither requiring additional binders nor excessively sticking to the mold

Containing active ingredients: Such as microbial agents, enzyme preparations and other bioactive substances

Suitable Manufacturer Types

The following types of fertilizer production enterprises should most consider flat die granulators:

Specialized organic fertilizer producers: Especially those focusing on high-quality organic fertilizers

Small and medium-sized bio-fertilizer plants: Relatively low investment threshold, suitable for startups

Manufacturers emphasizing product bioactivity: Need to preserve beneficial microorganisms in raw materials

Enterprises with diversified production needs: The same equipment can produce multiple formula products

Finished Granule Characteristics

Fertilizer granules produced by flat die granulators have the following unique advantages:

Good granule uniformity: Typically 3-8mm in diameter, adjustable length

Moderate hardness: Maintains transport integrity while being easy to decompose in soil

Appropriate porosity: Beneficial for microbial activity and moisture exchange

Relatively rough surface: Increases contact area with soil, improving application effectiveness

Complete nutrient retention: Low-temperature process maximizes retention of raw material nutrients

With its gentle processing method and excellent raw material adaptability, the flat die granulator has become the ideal choice for organic and bio-fertilizer production. For producers pursuing product quality, emphasizing bioactivity preservation and with limited budgets, this equipment provides a perfect solution. With the rapid development of global organic agriculture, flat die granulation technology is bound to gain broader market space.

0 notes

Text

Which Organic Fertilizer Granulator is Most Popular?

In the organic fertilizer production industry, choosing the right granulator is crucial for product quality and production efficiency. The common organic fertilizer granulators on the market mainly include rotary drum granulators, disc granulators, extrusion granulators, and double roller press granulators, each with its unique application scenarios and advantages.

Main Types of Organic Fertilizer Granulators and Their Applications

Rotary Drum Granulator is suitable for large-scale production, especially for raw materials with high moisture content, forming uniform particles through rotational movement. This equipment has high output but requires large floor space.

Disc Granulator has simple structure and easy operation, suitable for small and medium-sized fertilizer plants, capable of producing spherical particles with uniform size, but has higher requirements for raw material humidity.

Extrusion Granulator uses mechanical pressure to directly compress dry powder materials into shape without drying process, suitable for producing high-density organic fertilizer, but the particle shape is not as round as the former two.

Double Roller Press Granulator is a popular new equipment in recent years, which compresses materials into particles through two relatively rotating rollers, with low energy consumption and simple maintenance, especially suitable for small and medium-sized organic fertilizer production lines.

The Most Popular Granulator: Double Roller Press Granulator

Market research shows that the double roller press granulator has become the first choice of fertilizer manufacturers, and its advantages are mainly reflected in:

Low energy consumption: 30-50% energy saving compared with traditional granulation methods

Strong adaptability: Can process various organic raw materials, including livestock manure, straw, sludge, etc.

Simple maintenance: Simple structural design, low failure rate, low maintenance cost

Environmentally friendly and efficient: No drying process, reducing exhaust emissions

Fast return on investment: Moderate equipment price and short payback period

How to Choose the Right Granulator?

When selecting a granulator, comprehensive consideration should be given to raw material characteristics, production scale, product requirements and budget. Although the double roller press granulator is widely popular, large enterprises may still need rotary drum granulators to meet mass production needs, while manufacturers pursuing particle aesthetics may tend to choose disc granulators.

With the global rise of organic agriculture, efficient and environmentally friendly granulation equipment will become the core competitiveness of fertilizer enterprises. The double roller press granulator, with its comprehensive advantages, is leading the new trend of organic fertilizer production equipment.

0 notes

Text

Disc Granulation: The Intelligent Choice for Organic Fertilizer Production

Core Advantages of Disc Granulation Production Line

The Organic Fertilizer Disc Granulation Production Line holds a prominent position in organic fertilizer manufacturing due to its unique granulation method. Its most notable advantage is the gentle granulation process, particularly suitable for organic materials containing live microorganisms. With adjustable inclination (45-60°) and rotational speed (30-50rpm), it can handle various organic materials from powdery to viscous while preserving microbial activity.

Standard disc granulation lines typically process 1-10 tons/hour with granulation rates reaching 85-92%, producing more spherical granules than other methods.

Key Efficiency Improvement Measures

Enhancing production line efficiency requires focus on: raw material pretreatment (25-35% moisture content), dynamic adjustment of disc speed/angle, regular cleaning (every 8 hours), and automated control systems. Adding 5-10% binders (like bentonite) significantly improves pelletization, while variable frequency drives adapt to different materials.

Unique Characteristics of the Production Line

Disc granulation produces organic fertilizer with uniform particle size (2-5mm), smooth surfaces, and moderate strength (10-20N/granule). This open granulation method allows real-time process observation and adjustment, with 30-40% lower energy consumption than extrusion granulation. Crucially, it perfectly preserves active components in organic matter - essential for premium bio-organic fertilizers.

With organic agriculture's rapid growth, disc granulation technology is evolving toward intelligent systems. Integrated sensors and AI controls now automatically adjust parameters for varying materials, elevating the efficiency of converting organic waste into high-value fertilizers to unprecedented levels.

0 notes

Text

Organic Fertilizer Production: How to Build an Efficient and Eco-Friendly Process?

The Relationship Between Production Process and Manufacturing Technology

The terms "organic fertilizer production process" and "organic fertilizer manufacturing process" are often used interchangeably in practice, but there are subtle differences. The production process emphasizes the complete chain from raw materials to finished products, while the manufacturing process focuses more on specific technical methods and operational details.

Key Stages of Organic Fertilizer Production

A typical organic fertilizer production line includes these core stages:

Raw Material Pretreatment: Sorting, crushing, moisture adjustment

Fermentation: Aerobic composting or anaerobic fermentation (usually takes 15-30 days)

Secondary Processing: Adding supplements, adjusting nutrient ratios

Granulation: Disc granulation, extrusion granulation or rotary drum granulation

Drying and Cooling: Controlling final moisture content at 10-15%

Screening and Packaging: Grading and final packaging

Five Strategies to Improve Production Line Efficiency

1. Optimize Fermentation Process: Trough fermentation systems can improve efficiency by 40% compared to traditional windrow methods, reducing fermentation period to 7-10 days[1].

2. Automated Control Systems: Install temperature, humidity and oxygen sensors for intelligent monitoring of fermentation process.

3. Modular Equipment Layout: U-shaped production line design reduces material transfer distance, saving 15-20% energy consumption.

4. Heat Energy Recovery: Heat recovery systems in drying section can reduce energy consumption by 30%.

5. Preventive Maintenance Program: Regular inspection of key equipment (like granulator molds, conveyor bearings) reduces unplanned downtime.

Win-Win Solutions for Ecology and Efficiency

Modern organic fertilizer production increasingly focuses on balancing ecology and efficiency:

Adopt enclosed fermentation systems to reduce odor emissions

Install dust removal equipment to control particulate pollution

Utilize solar-assisted drying to reduce carbon footprint

Implement water recycling systems

0 notes

Text

What Key Equipment is Needed for Fertilizer Production Lines?

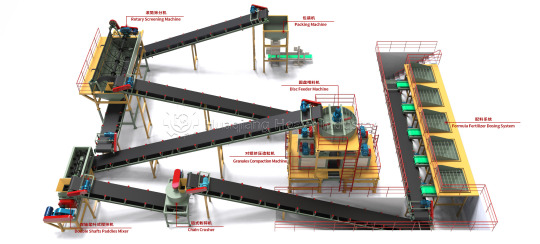

Modern fertilizer production integrates both general-purpose equipment and specialized machinery, with granulation technology being particularly critical. Drum granulators utilize a rotating cylinder to form spherical granules through a combination of agglomeration and layering mechanisms, ideal for high-capacity NPK production. Disc granulators employ an inclined rotating pan to produce uniform granules via a controlled cascading motion, offering precise particle size control. These core granulation units work in conjunction with auxiliary systems including:

Precision batching systems for raw material formulation

Thermal processing units for drying/cooling

Surface coating systems for enhanced product performance

Automated packaging lines for final product handling

Proper equipment selection directly impacts production efficiency, product quality, and operational costs in fertilizer manufacturing.

General Equipment in Fertilizer Production

All fertilizer production lines share certain fundamental equipment that handles the basic processing stages:

Specialized Fertilizer Equipment

Beyond general equipment, specialized fertilizer production requires additional machinery tailored to specific product types:

Global Fertilizer Production by Type (2022)

Selecting the Right Equipment

Choosing appropriate equipment depends on several factors:

Production capacity: Small (1-5 tons/hour), medium (5-20 tons/hour), or large-scale (20+ tons/hour)

Fertilizer type: Organic, inorganic, compound, or specialty fertilizers

Automation level: Manual, semi-automatic, or fully automatic systems

Budget: Initial investment versus long-term operational costs

Modern fertilizer production lines increasingly incorporate smart technologies such as IoT sensors for real-time monitoring and AI-driven optimization systems to improve efficiency and product consistency [1].

[1] Data from International Fertilizer Association 2022 Report

Note: Equipment specifications may vary by manufacturer and application requirements.

0 notes

Text

Drying and Cooling 1+1>2: The Temperature Control Code for Improving Efficiency of Organic Fertilizers

In organic fertilizer production lines, dryers and coolers serve as key temperature regulation equipment, working together to transform wet materials into finished products. While complementary in function, their coordinated operation is essential for ensuring fertilizer quality.

Core Functions

Synergistic Relationship

Process Connection: Materials must be cooled immediately after drying to prevent caking

Energy Utilization: Modern systems often recycle cooling air for dryer preheating

Quality Assurance: Inadequate drying reduces cooling efficiency, while delayed cooling affects packaging

System Balance: Capacity must match (typically 1:1 ratio)

Selection Recommendations

Dryer Selection: Rotary dryers for large-scale, belt dryers for heat-sensitive materials

Cooler Selection: Counter-flow coolers offer 15-20% higher efficiency

Integrated Control: Prefer systems with coordinated drying-cooling control

Heat Recovery: Can reduce total energy consumption by 25-30%

References:

International Organic Fertilizer Association "Organic Fertilizer Equipment Guide" (2023)

Zhang et al. "Energy optimization in fertilizer drying and cooling systems" (2021)

0 notes

Text

Food Waste to Treasure: The Art of Pretreatment

Food industry by-products such as soybean residue, fruit peel residue, and brewer's grains are rich in organic matter and nutrients, making them ideal raw materials for producing high-quality organic fertilizers. However, the special characteristics of these materials mean they must undergo scientific pretreatment before entering the production line. This article reveals the key technologies and precautions for pretreating food industry waste.

Pretreatment Requirements for Different Wastes

Microbial Inoculants: Necessity and Selection

According to the characteristics of food industry waste, the following inoculants are usually needed:

Thermophilic cellulose-decomposing bacteria: Such as Streptomyces thermophilus to accelerate fiber decomposition

Protein-decomposing bacteria: Such as Bacillus subtilis to prevent protein spoilage and odor

Yeast: Such as Saccharomyces cerevisiae to quickly consume sugar and prevent acidification

Compound inoculants: Multiple functional bacteria work synergistically to improve fermentation efficiency

The inoculation amount is generally 0.2-0.5% of the raw material weight, and should be adjusted according to material characteristics and ambient temperature.

Precautions After Pretreatment

When pretreated materials enter the production line, pay attention to:

Mixing uniformity: Different materials should be thoroughly mixed according to formula ratio

Moisture control: Overall moisture content should be maintained between 50-60%

C/N ratio adjustment: Optimal range is 25:1 to 30:1

Temperature monitoring: Feeding temperature should not exceed 45℃

Sanitation management: Prevent secondary pollution and ensure pure fermentation process

Note: Pretreatment process parameters need to be adjusted and optimized according to specific material characteristics and production conditions.

0 notes

Text

How to improve the automation level of fertilizer production line and reduce labor costs?

In modern agricultural production, the demand for fertilizer is growing, and enterprises need to improve production efficiency while reducing labor costs. The degree of automation of fertilizer production line directly affects the production efficiency, and the intelligent upgrading of key machine such as fertilizer pelletizer can effectively optimize the production process, increase output and reduce manual intervention.

1. Automation machine to improve production efficiency

Traditional fertilizer production relies on manual operation, which is not only inefficient, but also prone to human error. The NPK fertilizer production line with automatic control system can realize the automation of material handling, batching, granulation, screener, packaging and other links, greatly improving production efficiency.

2. Intelligent control of granulator to ensure particle quality

In the process of fertilizer production, fertilizer granulator is one of the key machine. Modern pelletizer can be equipped with intelligent temperature control system and material testing device to ensure uniform particle molding, reduce the material return rate, reduce unnecessary manual intervention, thereby reducing costs.

3. Automatic optimization of material handling and screener

In the NPK fertilizer production line, the raw material handling and screenerlinks often require a lot of manpower. Using machine such as automatic feeding systems, drum screens or vibrating screens, materials can be accurately graded and seamlessly transported, reducing manual operations and improving production continuity.

4. Remote monitoring and intelligent maintenance

The intelligent fertilizer production line can be equipped with a remote monitoring system, and enterprise managers can check the operating status of the machine at any time through the computer or mobile phone, advance warning of machine failure, reduce downtime losses, and reduce the workload of maintenance personnel.

Conclusion

Improving the automation level of fertilizer production lines can not only reduce labor costs, but also improve production efficiency and product quality. By intelligently upgrading core machine such as fertilizer granulator and optimizing the production process, enterprises can respond to market demand more efficiently and occupy an advantage in the fierce competition.

#organic fertilizer production line#rotary drum granulator#disc granulator#npk fertilizer production line#organic fertilizer compost turning machine

0 notes

Text

How does the accuracy of the screenermachine affect the quality of the finished fertilizer?

In the fertilizer production line, the main role of the screen is to grade the fertilizer after granulation, ensure the uniform size of the finished particles, remove too large or too small particles, and improve product quality. The accuracy of the screenermachine directly affects the production effect of the fertilizer granulator and the market competitiveness of the final fertilizer.

1. The screeneraccuracy affects the uniformity of fertilizer particles

In the NPK fertilizer production line, the particle size of the fertilizer is directly related to the fertilization effect. If the accuracy of the screenermachine is too low, a large number of particles that do not meet the standard will be mixed into the finished product, resulting in uneven particle size, affecting the dissolution rate of fertilizer and nutrient release, and ultimately affecting crop absorption.

2. Low precision screenerleads to high return rate

If the screeneraccuracy is insufficient, too many unqualified particles need to re-enter the fertilizer granulator for secondary granulation, which not only increases energy consumption, but also reduces production efficiency. At the same time, too many times of return may lead to uneven water content of the material, affect particle strength, and even cause the granulator to block the material.

3. Affect the appearance and market competitiveness of fertilizers

High quality compound fertilizer products need to have a uniform appearance and round particles. If the screeneraccuracy is not enough, it will lead to the inclusion of powder or debris in the finished product, which will reduce the appearance quality of the product and affect the market sales. Especially in the export or high-end market, customers have higher requirements for the consistency of fertilizer particles, and the quality of screeneraccuracy directly determines the competitiveness of the product.

4. Select the right screenermachine to improve the screeneraccuracy

Common fertilizer screenermachine includes drum screenermachine and vibrating screenermachine. Roller screen is suitable for large-scale production, high screenerefficiency, suitable for NPK and other compound fertilizer production. The vibrating screen is suitable for fine screener, which can effectively remove the fine powder and improve the quality of the finished product. When selecting the screenermachine, enterprises should choose the appropriate screenermethod according to the production capacity requirements and particle specifications, improve the screeneraccuracy and optimize the quality of fertilizer.

#organic fertilizer production line#rotary drum granulator#disc granulator#npk fertilizer production line#organic fertilizer compost turning machine

0 notes

Text

How does the accuracy of the screener machine affect the quality of the finished fertilizer?

In the fertilizer production line, the main role of the screen is to grade the fertilizer after granulation, ensure the uniform size of the finished particles, remove too large or too small particles, and improve product quality. The accuracy of the screenermachine directly affects the production effect of the fertilizer granulator and the market competitiveness of the final fertilizer.

1. The screeneraccuracy affects the uniformity of fertilizer particles

In the NPK fertilizer production line, the particle size of the fertilizer is directly related to the fertilization effect. If the accuracy of the screenermachine is too low, a large number of particles that do not meet the standard will be mixed into the finished product, resulting in uneven particle size, affecting the dissolution rate of fertilizer and nutrient release, and ultimately affecting crop absorption.

2. Low precision screenerleads to high return rate

If the screeneraccuracy is insufficient, too many unqualified particles need to re-enter the fertilizer granulator for secondary granulation, which not only increases energy consumption, but also reduces production efficiency. At the same time, too many times of return may lead to uneven water content of the material, affect particle strength, and even cause the granulator to block the material.

3. Affect the appearance and market competitiveness of fertilizers

High quality compound fertilizer products need to have a uniform appearance and round particles. If the screeneraccuracy is not enough, it will lead to the inclusion of powder or debris in the finished product, which will reduce the appearance quality of the product and affect the market sales. Especially in the export or high-end market, customers have higher requirements for the consistency of fertilizer particles, and the quality of screeneraccuracy directly determines the competitiveness of the product.

4. Select the right screenermachine to improve the screeneraccuracy

Common fertilizer screenermachine includes drum screenermachine and vibrating screenermachine. Roller screen is suitable for large-scale production, high screenerefficiency, suitable for NPK and other compound fertilizer production. The vibrating screen is suitable for fine screener, which can effectively remove the fine powder and improve the quality of the finished product. When selecting the screenermachine, enterprises should choose the appropriate screenermethod according to the production capacity requirements and particle specifications, improve the screeneraccuracy and optimize the quality of fertilizer.

#organic fertilizer production line#rotary drum granulator#disc granulator#npk fertilizer production line#organic fertilizer compost turning machine

0 notes

Text

How to improve the automation level of fertilizer production line and reduce labor costs?

In modern agricultural production, the demand for fertilizer is growing, and enterprises need to improve production efficiency while reducing labor costs……

#organic fertilizer production line#rotary drum granulator#disc granulator#npk fertilizer production line

0 notes

Text

How does the accuracy of the screenermachine affect the quality of the finished fertilizer?

In the fertilizer production line, the main role of the screen is to grade the fertilizer after granulation, ensure the uniform size of the finished particles, remove too large or too small particles, and improve product quality……

https://www.fertilizerproductionprocess.com/

#organic fertilizer production line#rotary drum granulator#disc granulator#npk fertilizer production line#organic fertilizer compost turning machine

0 notes

Text

How does the accuracy of the screener machine affect the quality of the finished fertilizer?

In the fertilizer production line, the main role of the screen is to grade the fertilizer after granulation, ensure the uniform size of the finished particles, remove too large or too small particles, and improve product quality……

#organic fertilizer production line#rotary drum granulator#disc granulator#npk fertilizer production line#organic fertilizer compost turning machine

0 notes

Text

There are three reasons why the production capacity in the fertilizer production line is not up to expectations

In the operation of the fertilizer production line, many companies will encounter production capacity that is not up to expectations. This not only affects production efficiency, but also may lead to higher costs, order delays, and even affect market competitiveness. Especially in NPK fertilizer production lines, the reasons for insufficient capacity are usually related to factors such as machine, process and raw materials. Here are the three main reasons and the corresponding optimization suggestions.

1. The device running efficiency is low

The core machine of the production line, such as the fertilizer granulator, if the operating state is unstable or inefficient, it will directly affect the overall production capacity. For example, pelletizer mold wear, speed mismatch, discharge port blockage and other problems will reduce production. The solution is to check the machine regularly, replace the wearing parts in time, and adjust the operating parameters of the pelletizer according to the production needs to ensure the best working condition of the machine.

2. The quality and ratio of raw materials are unreasonable

Raw material is an important factor affecting production efficiency. If the water content of the raw material is too high or too low, or the granularity is not uniform, it will affect the granulation effect, resulting in a decrease in output. In addition, improper ratio may cause problems of caking, adhesion or difficult molding. Therefore, before production, the moisture and granularity of raw materials should be strictly controlled, and the formula should be optimized to ensure that the material is suitable for the operation requirements of the granulator.

3. The production process is not well connected

The NPK fertilizer production line consists of several stages, including crushing, mixing, granulation, drying, screenerand packaging. If the connection between the links is not smooth, the material speed is too slow, the drying time is too long or the screeneris not thorough, it will cause the efficiency of the production line to be reduced. The optimization method is to achieve the accurate coordination of various machine through the automatic control system, and rationally arrange the process flow, reduce the waiting time, and improve the overall production efficiency.

#organic fertilizer production line#rotary drum granulator#disc granulator#organic fertilizer compost turning machine#npk fertilizer production line

0 notes