KP Green Engineering Ltd. ( Formerly Known as KP Buildcon Pvt. Ltd. ) is the parent company among all the existing Companies of the group. It was established by Dr. Faruk G. Patel in 1994, with an aim to provide single-window solutions to all infrastructural requirements of the telecom service providers.

Don't wanna be here? Send us removal request.

Text

Different Types of Crash Barriers and Where They’re Used

Crash barriers are vital components of road safety infrastructure, designed to mitigate the impact of vehicle collisions and prevent accidents. Understanding the various types of crash barriers and their appropriate applications is crucial for ensuring optimal safety on roads and highways. This comprehensive guide delves into the different crash barrier types, their functionalities, and the specific scenarios where each is most effective.

1. Concrete Barriers

Overview:

Concrete barriers are rigid, non-deformable structures made from reinforced concrete. They are designed to absorb and dissipate the energy from a collision, thereby reducing the severity of accidents.

Applications:

High-Speed Roads: Concrete barriers are commonly used on highways and expressways where vehicles travel at high speeds.

Medians: They are placed in the center of divided highways to prevent vehicles from crossing into oncoming traffic lanes.

Bridges and Overpasses: Concrete barriers provide additional safety on elevated structures, preventing vehicles from falling off.

Advantages:

High impact resistance

Durability and low maintenance

Effective in preventing vehicle crossover accidents

2. W-Beam Guardrails

Overview:

W-Beam guardrails are semi-rigid barriers made from corrugated steel sheets, shaped in a "W" profile. They are supported by posts and are designed to redirect vehicles back onto the roadway after a collision.

Applications:

Rural Roads: Ideal for roads with lower traffic volumes and speeds.

Curves and Slopes: Effective in areas where vehicles are at risk of veering off the road.

Construction Zones: Used to protect workers and equipment in temporary work areas.

Advantages:

Cost-effective installation

Flexibility to absorb impact energy

Easy to repair and maintain

3. Thrie-Beam Guardrails

Overview:

Thrie-Beam guardrails are similar to W-Beam guardrails but feature an additional beam, providing increased strength and impact resistance. The extra beam enhances the barrier's ability to contain and redirect vehicles.

Applications:

High-Speed Highways: Suitable for roads with higher traffic volumes and speeds.

Areas with Heavy Vehicles: Effective in locations where large trucks and buses are common.

Bridges and Overpasses: Provides additional safety on elevated structures.

Advantages:

Higher containment level

Enhanced durability

Improved safety for vehicles and occupants

4. Cable Barriers

Overview:

Cable barriers consist of high-tensile steel cables strung between posts. They are designed to absorb and dissipate the energy from a collision, reducing the severity of accidents.

Applications:

Medians: Commonly used in the center of divided highways to prevent vehicles from crossing into oncoming traffic lanes.

Curves and Slopes: Effective in areas where vehicles are at risk of veering off the road.

Temporary Installations: Suitable for construction zones and areas requiring temporary safety measures.

Advantages:

Cost-effective installation

Flexibility to absorb impact energy

Minimal space requirement

5. Crash Cushions

Overview:

Crash cushions, also known as impact attenuators, are devices designed to absorb the kinetic energy of a colliding vehicle, reducing the severity of the crash.

Applications:

End Terminals: Placed at the ends of guardrails and barriers to prevent vehicles from penetrating the barrier.

Fixed Objects: Used to shield fixed objects such as bridge piers and signposts.

Construction Zones: Provides protection in areas with temporary hazards.

Advantages:

Effective in reducing crash severity

Versatile applications

Enhances safety for vehicles and occupants

Conclusion

Selecting the appropriate crash barrier type is essential for ensuring road safety. Factors such as traffic volume, vehicle speeds, road geometry, and environmental conditions should be considered when choosing the most suitable barrier. By understanding the different types of crash barriers and their applications, infrastructure planners and engineers can make informed decisions to enhance road safety and reduce the risk of accidents.

For more detailed information on crash barriers and their applications, refer to the expert insights provided by KP Green Engineering Limited in their comprehensive guide here.

0 notes

Text

Monopole towers are one of the important aspects of advanced structures. They are known for their simple design and multifunctional abilities. They improve the performance of electricity transmission lines and telecommunication networks with innovation. They have wide-ranging uses and many benefits that help various industries function well.

0 notes

Text

As the use of technology is growing, the need for green energy production is also in demand. Smart grids are helping with that. They are changing the way traditional power systems work.

0 notes

Text

Windmill lattice towers are vital components of wind turbine systems, providing the basic foundation of the turbines and being specifically engineered for strength, flexibility, and efficiency. Their lightweight lattice tower construction with an open framework makes them suitable for use in various terrains and high-wind areas.

0 notes

Text

Windmill Lattice Towers: Installation and Maintenance Guide

Windmill lattice towers are vital components of wind turbine systems, providing the basic foundation of the turbines and being specifically engineered for strength, flexibility, and efficiency. Their lightweight lattice tower construction with an open framework makes them suitable for use in various terrains and high-wind areas.

In this guide, we explore the installation process of windmill lattice towers, as well as their maintenance, after which we hope for their safe, efficient and long-lasting energy generation.

What is a Lattice Tower?

Before we get into the installation and maintenance process, it is vital to understand: what is a lattice tower? A lattice tower is simply a steel structure made up of many components crossed by others formed typically into a triangular or square base tapering toward the top.

With this design, the wind load impact is drastically reduced, which also helps to lighten and improve material efficiency. It is most often applied in communication towers, transmission lines, and, above all, wind turbines.

Installation Steps of Windmill Lattice Towers

1. Site Assessment and Feasibility

This includes the geography, wind speed data, soil test, and accessibility. Engineers must ensure that the site can take the load of the tower and wind turbine in general, environmental, and safety terms.

2. Design and Engineering

The engineering cycle of the lattice tower consists of making designs to suit demands of height, weight, and wind resistance to meet load requirements on the basis of concern for load distribution, vibrations, and torque balancing. Custom solutions adhering to industry standards and optimizing the structural performance are therefore the forte of KP Green Engineering Limited, a reputed provider of windmill lattice towers in India.

3. Foundation Work

Any lattice steel tower needs a strong foundation. Depending upon the soil condition, the engineers may provide either a reinforced concrete pad type of foundation if the foundation soil is strong or, if the soil is relatively weaker, a pile type of foundation. The depth and width of the foundation would be determined by the height of the tower and the expected wind loads. Leveling and alignment will be done accurately for easy assembly of the tower.

4. Tower Assembly

Windmill lattice towers are assembled in a few modular sections. These prefabricated sections may be assembled either on the ground and lifted or constructed piece-by-piece in a vertical stress arrangement by a crane. The modular nature of lattice towers allows easy transportation and on-site assembly, especially in remote locations.

5. Erection of the Tower

Mechanical jacks or cranes have been used to hoist the tower segments. Once mounted, every component is bolted down and aligned for accuracy in vertical and structural integrity. Because lifting and alignment operations are hazardous, strict safety practices are followed by workers.

6. Wind Turbine Installation

Also, described above, when the lattice tower is completely assembled, nacelle and rotor hub and rotor blades are placed at the top. This phase requires quite high accuracy and favorable weather to prevent accidents or damages to such parts.

For further benefits and uses of wind lattice towers in energy projects, Visit: How Wind Lattice Towers Empower Wind Farms and Impact Energy Production.

Maintenance Guide for Windmill Lattice Towers

Good and proper maintenance extends windmill lattice towers life and efficiency. Regular inspections and prompt actions really help in the early detection of wear, corrosion, or structural problems.

1. Routine Visual Inspections

These inspections will include rust spots, paint wear, loosened bolts, and metal fatigue on the lattice tower structures periodically scheduled by the operators for checks. Normally, these inspections are made either quarterly or biannually, depending on environmental exposure.

2. Corrosion Control

Especially along shorelines and within high-moisture areas, corrosion poses as severe a threat as any to steel lattice towers. Galvanization, epoxy coating, or weatherproof paint should be applied, and regularly renewed. Check weld joints, bolt states, and base sections for any signs of rust.

3. Bolt Tightening and Component Alignment

The many high-strength bolts used for assembling lattice towers have to be periodically checked regarding their tightness by a torque wrench. Improperly tightened joints may misalign the components or even cause structural failure, thereby affecting the performance of the wind turbine.

4. Structural Load Checks

Windmill towers experience dynamic loads that may lead to fatigue cracks or deformation. The use of either drone surveys or SHM (structural health monitoring) systems could reveal whatever signs of stresses or cracks present- particularly at the anchor points and mid-sections.

5. Access System Maintenance

Technicians gain access to lattice towers by using ladders for staircases. Such access systems also need to be inspected and maintained.

6. Documentation and Audits

Keeping a detailed log of all inspection, repair, and service activities ensures consistent performance over the years. The log supports possible warranty claim back, future audits, and well-researched decision-making for upgrades.

Ready to elevate your wind project? Contact KP Green Engineering Limited today!

Advantages of Windmill Lattice Towers

windmill lattice towers offer engineering and economic advantages over the tubular towers:

Cost-Effective: The lattice tower structures require less steel, hence, material and fabrication costs are lower.

Modular Design: More easily transported and erected in rugged or remote areas.

Superior Airflow: The open-frame design allows wind to pass through, reduces the wind drag and load stress.

Flexibility in Height: Easily scalable for projects requiring tall structures without sacrificing stability.

Conclusion

Installation and maintenance of windmill lattice towers are strategic processes involving one-off expert planning, precision engineering, and continued maintenance. Well-executed, it leads to sustainably and efficiently generating wind energy. KP Green Engineering Limited, makes all the difference with respect to project success and long-term reliability.

Whether you are a developer, EPC contractor, or investor in wind energy, understanding the details of lattice steel towers and their maintenance protocols ensures that your infrastructure will be built to last, performing optimally for decades.

0 notes

Text

Monopole towers, characterized by their single-pole design, have become a preferred choice in various infrastructure projects worldwide. Their streamlined structure offers numerous advantages over traditional lattice towers, making them suitable for a range of applications from power transmission to telecommunications.

0 notes

Text

Monopole Towers: Key Benefits & Common Applications

Monopole towers, characterized by their single-pole design, have become a preferred choice in various infrastructure projects worldwide. Their streamlined structure offers numerous advantages over traditional lattice towers, making them suitable for a range of applications from power transmission to telecommunications.

What Is a Monopole Tower?

A monopole tower is a vertical, single-pole structure designed to support various equipment such as antennas, power lines, or lighting fixtures. Unlike lattice towers, which consist of multiple interconnected steel members, monopoles offer a more compact and aesthetically pleasing alternative.

Key Benefits of Monopole Towers

Space Efficiency

Monopole towers require significantly less ground space compared to lattice towers. This compact design makes them ideal for urban environments where land availability is limited. Their smaller footprint also reduces the environmental impact during installation.

Aesthetic Appeal

The sleek, single-pole design of monopoles is less visually intrusive than the bulky, multi-legged structure of lattice towers. This makes them more acceptable in residential and commercial areas where visual impact is a concern.

Durability and Low Maintenance

Monopole towers are typically constructed from galvanized steel, which provides resistance to corrosion and extends the tower's lifespan. Their simple design also means fewer joints and connections, reducing maintenance needs.

Quick and Easy Installation

The design of monopole towers allows for faster assembly and erection compared to lattice towers. This efficiency leads to reduced labor costs and shorter project timelines.

Versatility

Monopole towers can support a variety of applications, including high-voltage power lines, telecommunications antennas, and lighting fixtures. Their adaptability makes them a versatile choice for different infrastructure projects.

Common Applications of Monopole Towers

1. Power Transmission

Monopole transmission towers are widely used in power distribution networks. Their compact design allows for installation in areas with limited space, such as urban environments or along highways. They are suitable for both overhead and underground power lines.

2. Telecommunications

Monopole cell towers are commonly employed in the telecommunications industry to support antennas for mobile networks. Their slim profile and height flexibility make them ideal for urban and suburban areas where space is at a premium.

3. Lighting and Surveillance

Monopole towers are also used to mount street lighting and surveillance cameras. Their sturdy construction ensures reliable performance in various weather conditions, making them suitable for public safety applications.

4. Renewable Energy Integration

In renewable energy projects, monopole towers can support wind turbines and solar panel arrays. Their ability to withstand environmental stresses makes them a good fit for such applications.

Monopole Tower Height Considerations

The height of a monopole tower depends on its intended application. For instance, monopole cell towers typically range from 80 to 160 feet, while monopole transmission towers can exceed 130 feet, depending on the voltage requirements and geographical factors. It's essential to consider local regulations and environmental factors when determining the appropriate height.

Monopole Tower Manufacturers in India

India has seen a growing demand for monopole towers, driven by urbanization and infrastructure development. Several manufacturers in India specialize in producing high-quality monopole towers tailored to meet the country's specific requirements. These manufacturers adhere to international standards and offer customized solutions to cater to diverse applications.

Conclusion

Monopole towers offer a range of benefits, including space efficiency, aesthetic appeal, durability, and versatility, making them a preferred choice for various infrastructure projects. Their applications span power transmission, telecommunications, lighting, surveillance, and renewable energy integration. In India, leading manufacturers are providing high-quality monopole towers to meet the growing demand.

For those seeking reliable and innovative monopole tower solutions, KP Green Engineering Limited, based in Vadodara, Gujarat, stands out as a trusted provider. With a commitment to quality and customer satisfaction, KP Green Engineering Limited offers a range of monopole towers designed to meet diverse needs and specifications.

#Monopole tower#monopole transmission tower#monopole tower height#monopole cell tower#monopole tower manufacturers in india#monopole electric tower

0 notes

Text

Why Solar Trackers Are Key to Efficient Solar Farms

In the rapidly growing world of renewable energy, solar power continues to emerge as one of the most efficient and sustainable sources of electricity. As demand for solar energy increases, maximizing the efficiency of solar installations becomes crucial. One of the key innovations that has greatly contributed to the efficiency of large-scale solar farms is the solar tracker. In this blog, we will explore the role of solar trackers in enhancing the performance of solar farms.

What is a Solar Tracker?

A solar tracker is a device that adjusts the orientation of solar panels to follow the sun's movement throughout the day. By doing so, it ensures that the panels are always positioned to capture the maximum amount of sunlight. This simple yet effective technology helps improve the energy output of solar panels, making solar farms more productive and cost-efficient.

How Does a Solar Tracker Work?

The main function of a solar tracker is to adjust the tilt and rotation of solar panels to ensure they are always facing the sun. There are two primary types of solar tracking systems used in large-scale solar farms: the single axis solar tracker and the dual axis solar tracker.

Single axis solar trackers rotate on one axis (usually north-south), allowing panels to follow the sun from east to west.

Dual axis solar trackers can rotate on two axes, enabling them to adjust both vertically and horizontally, following the sun's movement more precisely throughout the day and across seasons.

Both types of solar trackers increase the amount of sunlight captured by solar panels, which translates into greater energy production.

Automatic Solar Tracker: The Future of Solar Efficiency

One of the biggest advancements in solar tracking technology is the development of automatic solar trackers. These trackers are equipped with sensors that detect the position of the sun in the sky, adjusting the panels automatically without human intervention. By optimizing the solar panel's orientation in real-time, automatic solar trackers can significantly increase the overall efficiency of a solar farm, leading to higher energy output and a quicker return on investment.

Single Axis Solar Tracker: Simplifying Solar Tracking

The single axis solar tracker is one of the most widely used tracking systems in solar farms due to its cost-effectiveness and reliability. With a single axis tracker, solar panels follow the sun as it moves from east to west throughout the day. This type of tracker is relatively simple, requiring less maintenance and offering excellent performance in regions with high sunlight exposure.

Dual Axis Solar Tracker: Maximizing Sunlight Capture

For locations where maximizing solar energy capture is essential, the dual axis solar tracker offers superior performance. This system allows the solar panels to follow the sun's path both throughout the day (east to west) and across seasons (north to south). The ability to capture sunlight at any angle results in significant gains in energy production, making dual axis solar trackers ideal for large-scale solar farms in regions with variable sun angles or in areas requiring high energy output.

Solar Tracking Systems in Large-Scale Solar Farms

In large-scale solar farms, solar tracking systems are crucial for optimizing the layout and ensuring maximum energy efficiency. By integrating solar trackers into the design, these farms can significantly increase their overall energy yield. The cost of implementing tracking systems has dropped in recent years, making it more feasible for solar farms to adopt this technology and improve their return on investment.

As solar energy continues to grow as a key player in the global renewable energy market, innovations like solar trackers are helping to push the boundaries of what is possible. By ensuring that solar panels are always oriented to receive the maximum sunlight, solar tracking systems offer a simple yet effective way to increase the efficiency of solar farms and reduce the levelized cost of electricity (LCOE).

Conclusion

Incorporating solar trackers in large-scale solar farms boosts efficiency and energy production. Whether using single axis or dual axis solar trackers, these systems optimize panel orientation, maximizing sunlight capture. At KP Green Engineering Limited, we offer advanced solar tracking solutions to ensure your projects are efficient and successful. Partner with us to optimize your solar energy potential.

0 notes

Text

Large-scale solar farms are transforming the world towards sustainable energy solutions. They absorb the sunlight on a large scale, improving the way electricity is produced. It also reduces dependence on nonrenewable energy. Solar trackers play a major role in improving the solar panel's performance in farms, including ground-mounted solar plants.

0 notes

Text

Transmission towers, also known as electrical towers or power towers, play a crucial role in the modern power distribution and transmission system. These towering structures are responsible for carrying high-voltage transmission lines that transfer electricity over long distances, ensuring that power generated at a power plant reaches homes, businesses, and industries.

0 notes

Text

Exploring the Different Types of Transmission Towers and Their Functions

Transmission towers, also known as electrical towers or power towers, play a crucial role in the modern power distribution and transmission system. These towering structures are responsible for carrying high-voltage transmission lines that transfer electricity over long distances, ensuring that power generated at a power plant reaches homes, businesses, and industries. Transmission towers are essential components of the energy infrastructure, enabling the delivery of electrical power across vast distances with minimal loss of energy.

In this article, we will delve into the different types of transmission towers, their functions, and the vital role they play in the electrical transmission system. We will also explore the role of transmission line tower manufacturers in India, which is one of the largest markets for these essential structures.

What Are Transmission Towers?

Transmission towers are large steel structures designed to support and suspend electrical transmission lines. These lines carry electricity from power plants to substations and then to local distribution networks, supplying homes and industries with the electrical power they need. Transmission towers are built to withstand harsh environmental conditions, including wind, rain, snow, and even seismic activity, to ensure uninterrupted power delivery.

The towers are designed to support conductors (wires) at a height that minimizes the risk of contact with people, animals, or objects on the ground. They are essential in maintaining the integrity and efficiency of the entire power grid. These towers vary in size, design, and material depending on the type of transmission line, the voltage of the electricity being carried, and the geographical environment in which they are placed.

Types of Transmission Towers

Transmission towers come in various shapes and sizes, and each type serves a specific function within the power transmission system. Let’s explore the different types of towers that are used for power transmission.

1. Lattice Towers

Lattice towers are one of the most common types of transmission towers. They have a framework-like structure made of steel, which gives them the name “lattice.” These towers are widely used in high-voltage transmission lines because they offer a high level of stability and strength. The lattice design allows for a lightweight yet durable structure, making it easier to transport and install.

Lattice transmission towers are typically used for long-distance transmission lines that require a high level of support to carry heavy electrical cables. They are designed to withstand harsh weather conditions and are capable of supporting large numbers of transmission conductors.

2. Monopole Towers

Monopole towers are another type of transmission tower that is often used for medium and low-voltage transmission lines. These towers consist of a single, vertical pole structure that supports the conductors. Monopole towers are typically made of steel or concrete, and they are often used in urban areas or locations where space is limited, as their smaller footprint is more suitable for such environments.

Monopole towers are lightweight and cost-effective compared to lattice towers, making them an attractive option for certain types of power transmission. However, they are generally not suitable for high-voltage lines or areas with extreme weather conditions due to their reduced strength compared to lattice towers.

3. Guyed Towers

Guyed towers are a type of transmission tower that relies on external supports, or guy wires, to stabilize the structure. These wires are tensioned to hold the tower upright, providing additional stability and strength. Guyed towers are typically used for medium to high-voltage transmission lines, especially in areas with limited access or difficult terrain.

The primary advantage of guyed towers is their lower cost compared to other types of transmission towers. They are often used in remote areas where it is difficult to transport or install larger, more complex towers. However, the use of guy wires requires careful planning and maintenance, as they can pose a hazard to nearby activities.

4. Tubular Towers

Tubular towers, also known as tubular steel transmission towers, are made from hollow steel tubes. These towers are lightweight, durable, and resistant to corrosion, making them ideal for use in coastal or industrial areas where environmental factors can significantly impact the lifespan of the towers.

Tubular towers are designed to support high-voltage transmission lines, and they can be used for both overhead and underground power transmission. They are also commonly used for applications such as communication towers or wind turbine towers due to their robust structure and ability to withstand high winds and heavy loads.

5. Double Circuit Towers

Double circuit towers are designed to carry two separate circuits of transmission lines on the same tower. These towers are used in situations where space is limited or where it is more cost-effective to install two circuits on a single tower rather than multiple separate towers.

Double circuit transmission towers are often used for medium- to high-voltage transmission lines and are commonly found in urban areas or regions with limited land availability. They help maximize the efficiency of the transmission network while reducing the environmental impact of additional tower installations.

Functions of Transmission Towers

Transmission towers serve several critical functions in the power transmission system. Some of the key roles of transmission towers include:

1. Supporting Transmission Lines

The primary function of transmission towers is to support electrical transmission lines. These lines carry electricity from power plants to substations and eventually to homes and businesses. Without transmission towers, it would be impossible to maintain the height and distance required for these high-voltage lines to safely carry electricity over long distances.

2. Maintaining Safety

Transmission towers are built to ensure the safe transmission of electricity. The towers keep the high-voltage conductors elevated above the ground, preventing accidental contact with people, animals, or other objects. This helps avoid electrical hazards and ensures the safety of both people and the environment.

3. Minimizing Power Loss

Transmission towers also play a vital role in minimizing power loss. By supporting the electrical conductors at the appropriate height and distance, they help reduce the amount of energy lost during the transmission process. The design and placement of transmission towers are carefully considered to ensure the most efficient transfer of electricity.

4. Enhancing System Reliability

The use of transmission towers helps ensure the reliability of the electrical power grid. They are designed to withstand a variety of environmental factors, including strong winds, heavy snow, and earthquakes. By maintaining the stability and integrity of the transmission lines, transmission towers help prevent power outages and disruptions to the electrical grid.

Transmission Line Tower Manufacturers in India

India is one of the largest and fastest-growing markets for transmission line towers due to its rapidly expanding power generation and transmission infrastructure. Transmission line tower manufacturers in India play a key role in meeting the demand for these essential structures.

Indian manufacturers are known for producing a wide range of transmission towers, including lattice towers, monopole towers, and tubular towers, to suit the diverse needs of the power transmission sector. They also produce custom-designed towers based on specific project requirements, ensuring that the towers are tailored to the unique environmental and technical conditions of the project.

With a focus on quality, durability, and cost-effectiveness, transmission line tower manufacturers in India contribute significantly to the development of the country’s energy infrastructure. They are constantly innovating and adopting new technologies to improve the design and functionality of transmission towers, ensuring that they meet international standards for safety and performance.

Conclusion

Transmission towers are indispensable elements of the power transmission system, ensuring the efficient and safe transfer of electricity over long distances. Understanding the different types of transmission towers, such as lattice towers, monopole towers, and guyed towers, is essential for recognizing their unique functions and importance in maintaining the reliability of the electrical grid.

Transmission towers not only support the transmission lines but also play a critical role in minimizing power loss, enhancing system reliability, and ensuring safety. Transmission line tower manufacturers in India are vital contributors to the country's growing energy infrastructure, providing high-quality, durable towers that support the expanding demand for electricity.

At KP Green Engineering Limited, we specialize in the design and manufacturing of high-quality transmission towers. Our products are built to meet international standards for safety, durability, and performance, ensuring that they support the efficient transmission of power. As a trusted leader in the industry, KP Green Engineering Limited is committed to delivering innovative solutions to help enhance the energy infrastructure, both in India and beyond.

By understanding the different types of transmission towers and their functions, we gain a deeper appreciation for the complex systems that power our modern lives.

#transmission line tower#Types of towers#electrical tower#transmission line tower manufacturers in India

0 notes

Text

Well, the secret is often in Pre-Engineered Buildings (PEBs). But what exactly is a PEB?

We are sure you might have come across the term PEB structure if you are working in industries like warehousing, industrial plants, retail, or commercial buildings.

0 notes

Text

A cable tray is an essential component of electrical infrastructure, used to organize and protect wires and cables as they run throughout buildings and facilities. Whether you are building a new electrical system or upgrading an existing one, understanding the benefits of cable trays for electrical systems is essential for making an informed decision.

0 notes

Text

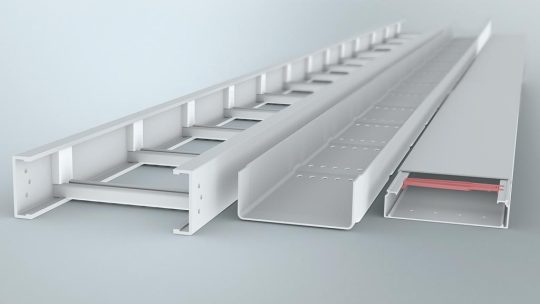

Exploring the Benefits of Cable Trays for Electrical Systems

When it comes to managing and supporting electrical cables in commercial, industrial, and residential installations, cable trays play a critical role in ensuring safety, organization, and efficiency. A cable tray is an essential component of electrical infrastructure, used to organize and protect wires and cables as they run throughout buildings and facilities. Whether you are building a new electrical system or upgrading an existing one, understanding the benefits of cable trays for electrical systems is essential for making an informed decision.

In this article, we will explore the different cable tray types, the importance of cable tray electrical systems, and the advantages of using ladder cable trays, perforated cable trays, and other electrical tray solutions. We’ll also discuss the best cable tray manufacturers in Gujarat and what to look for when selecting the right tray for your electrical system.

What Is a Cable Tray?

A cable tray is a structural system used to support and organize electrical wiring, communication cables, and other types of power distribution systems. Made from various materials such as steel, aluminum, or fiberglass, cable trays provide a safe, efficient, and cost-effective way to run electrical cables throughout a building or industrial setup.

Typically installed in the ceiling, walls, or floors, cable trays for electrical systems prevent cable damage by keeping cables properly aligned, reducing strain, and minimizing the risk of fire hazards. They also allow easy access for maintenance and future upgrades.

Different Types of Cable Trays

When selecting a cable tray, understanding the various cable tray types is crucial to choosing the right one for your project. Below are the most commonly used types of cable trays:

1. Ladder Cable Tray

Ladder cable trays are one of the most popular types of cable trays for electrical systems. They have a "ladder-like" structure with two longitudinal side rails and rungs that provide support for cables. This design allows for better air circulation around the cables, making them ideal for high-voltage applications or where heat dissipation is a priority.

The ladder cable tray is particularly effective for large, heavy-duty cables, as it provides ample space for cables to rest without bending or crimping. These trays are often used in commercial and industrial environments, such as data centers, factories, and large office buildings.

2. Perforated Cable Tray

A perforated cable tray is similar to a ladder tray but features side rails with perforations (holes) instead of solid metal. This design allows for greater flexibility when installing cables and reduces the tray's overall weight. The perforations also provide ventilation, helping to keep the cables cool.

Perforated trays are ideal for environments where moderate to light cable loads are used, and they can be easily adjusted or expanded if additional cables need to be added later. These trays are also commonly used in offices, telecommunications facilities, and smaller commercial buildings.

3. Solid Bottom Cable Tray

Solid bottom cable trays are designed with a solid base that provides full protection to the cables from dust, dirt, and debris. These trays are used in environments where cables need to be protected from external elements or potential mechanical damage. They are commonly used in industries that require a high level of protection, such as chemical plants or food processing facilities.

While solid bottom trays may restrict airflow compared to ladder or perforated trays, they provide a higher degree of cable protection.

4. Trough Cable Tray

A trough cable tray is similar to a solid-bottom tray but has an open-top design, allowing easy access to cables. This tray type is typically used for lighter applications or where cables need to be supported but not completely enclosed. The trough design allows for easier cable management and future upgrades.

Benefits of Cable Trays for Electrical Systems

1. Safety and Protection

One of the primary benefits of using a cable tray electrical system is the safety it provides. Cables that are loosely hanging or improperly supported can become damaged, which may lead to electrical shorts, fires, or other hazardous situations. By using cable trays, electrical cables are securely supported, reducing the likelihood of these issues occurring.

In addition, cable trays are typically made of fire-resistant materials, helping prevent the spread of fire in case of an emergency.

2. Ease of Installation and Maintenance

Installing a cable tray is much quicker and more efficient than running individual cables through walls or conduit systems. Cable trays provide a modular and organized framework that allows for easy installation and adjustments to accommodate new cables or electrical components.

Maintenance and troubleshooting are also simpler when using a cable tray system. Technicians can easily access the cables in the tray, inspect them for damage, and replace or upgrade cables as needed without having to dismantle entire sections of the electrical system.

3. Cost-Effectiveness

In the long run, using cable trays for electrical systems can be more cost-effective than traditional conduit systems. Cable trays reduce the need for costly and labor-intensive installations while also providing easy scalability. As new cables are added or changes are made to the system, cable trays can be easily modified without requiring significant alterations to the overall infrastructure.

Additionally, cable tray manufacturers in Gujarat offer a wide range of tray options at competitive prices, making them a great option for businesses looking to manage their electrical systems more affordably.

4. Organization and Flexibility

A well-organized electrical system is crucial for smooth operation. Cable trays help keep cables neatly organized, reducing clutter and allowing for better airflow. This organization also makes it easier to identify and resolve issues quickly when they arise.

Cable trays are incredibly flexible and adaptable, which is important for expanding or upgrading an electrical system. As your business grows and additional cables are required, cable trays can be extended or adjusted without disrupting the entire setup.

5. Improved Aesthetics

In large commercial and industrial facilities, exposed cables can look messy and unprofessional. Cable trays provide a sleek and organized appearance, helping improve the overall aesthetics of a space while maintaining functionality. This is particularly important in office buildings, shopping malls, and data centers.

Selecting the Right Cable Tray Manufacturer in Gujarat

When looking for a cable tray manufacturer in Gujarat, it is essential to choose a reputable company that offers high-quality products and excellent customer service. Gujarat is home to numerous manufacturers specializing in cable trays, and many of them offer custom designs based on your specific needs.

To ensure you are purchasing the best cable trays for electrical systems, consider the following factors when selecting a manufacturer:

Product Quality: Look for manufacturers who use high-quality materials such as galvanized steel or aluminum to ensure durability and longevity.

Customization: Many businesses have unique cable management needs, so working with a manufacturer who can provide customized solutions is key.

Industry Experience: A manufacturer with a proven track record of working with electrical systems can ensure that your cable tray will meet industry standards and regulations.

Timely Delivery: A reliable manufacturer will be able to deliver products on time and support you with installation and maintenance needs.

Conclusion

In conclusion, cable trays for electrical systems are an essential part of modern electrical infrastructure, offering numerous benefits such as improved safety, ease of installation, cost-effectiveness, and organization. Whether you are installing ladder cable trays, perforated cable trays, or any other electrical tray, these systems help ensure that cables are properly supported, protected, and maintained.

For those in Gujarat, working with a reputable cable tray manufacturer in Gujarat is crucial to obtaining high-quality and durable products. KP Green Engineering Limited is a trusted name in the industry, providing reliable and robust cable trays designed to meet your specific electrical system requirements. By choosing the right cable tray for your needs, you can enhance the performance and safety of your electrical system, ensuring reliable and efficient operations for years to come.

#cable tray#cable tray manufacturers#cable tray types#cable tray manufacturer in india#ladder cable trays#perforated cable trays

0 notes

Text

Guarding the roads with high-quality crash barriers can enhance road safety by minimizing risks of motorists from steep drops, medians, and roadside hazards. Built for durability and resistance to harsh weather conditions, they are an inseparable part of modern highway infrastructure, ensuring safer journeys for everyone on the road.

0 notes

Text

Galvanized crash barriers are essential for road safety, offering robust protection against vehicle collisions. Coated with zinc, these steel barriers resist rust and environmental damage, ensuring long-lasting durability. Their installation on highways, bridges, and urban roads helps prevent vehicles from veering off, reducing accident severity and enhancing safety for all road users.

#galvanized crash barriers#road safety barriers#metal crash barriers#highway safety#W beam crash barrier#crash barrier#galvanized steel barriers

0 notes

Text

Why Galvanized Crash Barriers Matter for Road Safety

Keeping Roads Safe with Strong Barriers

Road safety is a big deal. Highways, bridges, and city roads need solid protection to prevent accidents. One of the best solutions? Crash Barriers. These sturdy steel barriers are coated with zinc to make them tough, rust-resistant, and long-lasting. They help keep cars on the road and reduce the damage from crashes, making roads safer for everyone.

As more vehicles hit the road and infrastructure grows, the demand for road crash barriers has skyrocketed. These barriers don’t just stop vehicles from going off the road - they also reduce the impact of accidents. Their strength and durability make them a must-have for modern road safety.

What Are Galvanized Crash Barriers?

A galvanized crash barrier is a protective steel structure covered in a layer of zinc. This zinc coating protects against rust and damage from the environment. You’ll often see these barriers on highways, bridges, and flyovers, keeping vehicles safely on track.

How Does Galvanization Work?

The process, called hot-dip galvanizing, coats steel with a protective zinc layer. This makes the barrier resistant to rust and corrosion, ensuring it lasts for years—even in harsh weather. The zinc coating acts like a shield against moisture, chemicals, and other elements that can wear down regular steel.

Why Galvanized Crash Barriers Are a Smart Choice

1. They Resist Corrosion

One of the best things about galvanized crash barriers is their ability to fight off rust. The zinc layer protects the steel from rain, salt, and chemicals, making these barriers perfect for any climate.

They’re especially useful in coastal areas, where the salty air would normally speed up rust. Thanks to their corrosion resistance, these barriers last for years without needing constant repairs.

2. They’re Strong and Built to Last

These barriers are designed to handle heavy impacts. Whether on highways or city streets, a road crash barrier made of galvanized steel helps absorb and redirect crash forces, reducing serious injuries. Their tough build ensures they stay intact even after minor collisions.

3. They Save Money on Maintenance

Unlike regular metal crash barriers, galvanized ones don’t need constant upkeep. The zinc coating prevents rust and damage, cutting down on maintenance costs. That means fewer replacements and repainting jobs - making them a budget-friendly choice for road safety projects.

4. They’re Eco-Friendly

Choosing galvanized crash barriers is also good for the environment. Since the zinc coating extends the life of the steel, there’s less need for frequent replacements. Plus, galvanized steel is recyclable, making it a sustainable choice for modern infrastructure projects.

5. They Keep Drivers Safe

A well-placed W beam crash barrier helps keep vehicles on the road, preventing accidents caused by sudden swerves or lane departures. These barriers are installed on highways, flyovers, and accident-prone spots to reduce the risk of serious injuries.

The way these barriers are designed helps absorb the impact of a crash, making accidents less severe. That’s why they’re a key part of modern road safety.

6. They’re Quick and Affordable to Install

Compared to concrete barriers, crash barrier installation is faster and more cost-effective. Galvanized steel is lightweight, making transportation and installation easier. Plus, W beam crash barriers come in prefabricated sections, meaning they can be set up quickly - even on busy roads.

7. They Work in Many Places

These barriers aren’t just for highways. They’re also used in parking lots, industrial areas, and even private properties to improve safety. Since they can be customized for different needs, they’re a great option for all kinds of safety applications.

Choosing the Right Manufacturer

When picking a crash barrier manufacturer, it’s important to look at material quality, production standards, and customization options. KP Green Engineering makes high-quality road safety solutions, ensuring every barrier meets industry standards for maximum protection.

What to Look for in a Manufacturer:

Quality Materials: High-grade galvanized steel lasts longer.

Custom Options: Different roads need different barrier designs.

Industry Certifications: Make sure the barriers meet safety standards.

Reputation & Experience: Trusted manufacturers offer better reliability.

Installing and Maintaining Crash Barriers

Proper crash barrier installation is crucial for safety. Engineers assess the site and place barriers in the best spots for impact absorption. Regular checks and maintenance keep the barriers in top shape.

If you need guidance on choosing or installing the right barriers, the team at KP Green Engineering can help.

Simple Maintenance Tips:

Regular Inspections: Check for damage or wear.

Keep Them Clean: Remove dirt and debris to maintain visibility.

Replace Damaged Sections: If a barrier is seriously damaged, swap it out right away.

Final Thoughts

Galvanized crash barriers play a huge role in modern infrastructure. They’re strong, cost-effective, and great at preventing accidents. Investing in high-quality road crash barriers helps reduce fatalities and makes roads safer for everyone.

As road safety technology improves, crash barrier installations are getting even better—offering stronger protection and longer service life. Using galvanized barriers in infrastructure projects ensures reliable safety solutions with minimal environmental impact.

#galvanized crash barriers#road safety barriers#metal crash barriers#highway safety#W beam crash barrier#crash barrier#galvanized steel barriers

0 notes