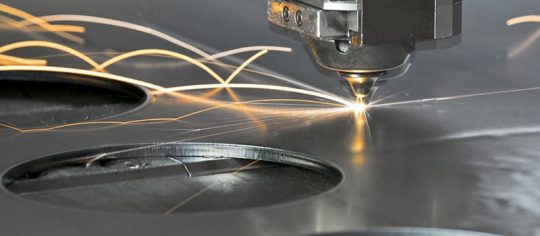

Laser cutting is a technology that uses a laser to slice materials. While typically used for industrial manufacturing applications, it is also starting to be used by ...

Don't wanna be here? Send us removal request.

Text

The Technology of Laser Cutting and Its Advantages

Implementing laser to cut materials is known as laser cutting and is ordinarily used by Industries. How does this work? A computer is used towards direct a high power laser for the material to be slice. Once the laser is used on the material it usually melted, molten melt or burns and a high quality surface finish is released. These are also known as Industrial laser cutters and they are used to trim flat sheet materials. There are different kinds of laser cutting: CARBON DIOXIDE laser is used for cutting, boring and engraving. It happens to be used for Industrial cutting of material. The CO2 lasers is commonly employed be passing a current through the gas mix or implementing Radio Frequency energy. The Radio Frequency (RF) method is most common as they are not prone to problems such as electrode erosion which happens to be prevalent in the other methods. The gas flow can affect performance. The neodymium Laser (ND): is also used by boring. But here high energy pulses are used using a decreased repetition speed. The Nd-YAG laser: here very high vigor pulses are used for boring and engraving as well as trimming.

Beam of light cutting is highly successful because it is a neater, cleaner and even faster way of cutting as compared to the traditional methods of cutting. The very laser beam is very precise and quick and is preferred across the traditional ways of cutting as some of the materials are very challenging cut. High energy is used to do this specialized way of cutting. Additionally, it is the most cost effective method of cutting high precision parts. Since the parts a good laser cut time is saved as parts don't need to be cut manually. This process is complex and implements a stimulating laser material by electrical discharges. Once the lasing material is stimulated using a partial mirror the order is reflected internally. Mirrors are used to direct the light to your lens so that the light is projected to the lens. Electrical power methods in cutting using the laser technology used to lower different material. They are vaporization, melt and blow, scribing, thermal stress cracking. The amount of cutting power needed for a task depends on the material type, thickness, the process used, and expected cutting rate. Laser Cutting Services are offered by a variety of agencies all over the world. Advantages of Laser cutting services are that they are suited to making custom parts quickly and economically.

0 notes

Text

Advantages Of Laser Cutting Vs Mechanical Cutting

Having the capability to control a broad range of laser parameters precisely helps renovate a flat sheet of metal into numerous parts by using a variety of characteristic without the need of tooling. Read on to learn around the advantages of laser cutting over mechanical cutting. Cleaner Designs Lasers allow for smaller and cleaner cuts, with sophisticated detail and good edge quality in sheet combination or round, square, rectangular, and/or triangular tubing. Compared with with mechanical cutting, cuts are burr-free and can be exceptionally intricate. Lasers can also be used to accurately cut wood, pockets, ceramics, or wax. 3D laser cutting is also readily available parts with unique hole geometries and CNC fractionated laser cutting is available for creating curves and creating intricate 3D structures. 6-axis laser cutting capabilities allow for designs at any desired angle for weld prep, plus realize the highest accuracy for easy fit-up of assemblies aid all in a single program cycle. Greater Accuracy - A smaller amount Wasted Metal Mechanical cutting involves contamination and corrosion of the blades on the cutting machines, but lasers haven't any actual surface to wear out, so they can cut as many the identical products as you need without wearing out. Laser cutting as well produces greater consistency from part to part. Plus laser cutting isn't just for cutting out parts. Lasers can trim holes straight through the metal, etch, or even counter-sink pockets. Additionally , because the laser is so precise there is less misused material surrounding the cut. And even furthermore, because there are a smaller amount wasted materials, you can cut down on the time and effort it takes to clean in place every day. Minimal Operator Intervention Laser machines are simple enough to use and don't require a large amount of skill or training. By using newer, modern day laser cutting machines the number of steps that demand human action have been dramatically reduced, allowing for more efficient section nesting capability due to greater programming flexibility. Quicker Output Most laser equipment also comes with automatic load/unload options, adding efficiency for the lasers to run while an employee can be on break or at lunch, and allowing for more speedily production of items. By using lasers you will have the precision portions you need much quicker and more cost effectively than with other types of units. Lasers can be used to cut carbon steel up to 1", s / s up to 0. 5", and aluminum up to 0. 375".

0 notes

Text

100 Watt Laser Cutter Makes Paper Wedding Invitation

youtube

1 note

·

View note