#1 jaw crusher manufacturer

Text

youtube

Jaw Crusher Gold-Crush: Best Jaw Crusher Machine Manufacturer & Supplier in Indore Buy the best stone crusher plant, vibrating screen, and more at best price

#doubletogglejawcrusheratbestprice#singletogglejawcrusheratbestprice#verticalshaftimpactor#stonecrusherplant#buysandmakingmachine#stonecrushermachine#bestvibratingscreenmanufacturer#bestvibratingscreensupplier#BiggestBeltConveyorsManufacturer#BestBeltConveyorsIndore#stonecrushermachinemanufacturer#jawcrushermachinemanufacturer#bestjawcrushermachine#best jaw crusher machine#best jaw crusher#buybeststonecrusherplant#singletogglejawcrusher#1 jaw crusher manufacturer#best jaw crusher machine in indore#jawcrushermanufacturer#1 jaw crusher machines#doubletogglejawcrusher#Youtube

0 notes

Text

BDI Wear Parts: Your Trusted Source for High-Quality Crusher Components

Amid the demanding and competitive world of heavy-duty crushing equipment, BDI Wear Parts shines as a symbol of quality and dependability. As a top supplier of crusher parts, we serve the mining, quarrying, construction, and recycling industries, providing a wide range of components designed to improve the efficiency and longevity of crushing machinery.

Our Key Solutions: Complete Range of Crusher Components

1. Jaw Crusher Parts: Durability Combined with Precision

At the heart of our product portfolio are jaw crusher parts, essential for primary crushing applications. Our jaw plates, available in various profiles and materials including high-manganese steel, are engineered to withstand extreme compressive forces and abrasive wear. Precision-machined to ensure a seamless fit, these parts minimize downtime and optimize crushing efficiency. Our commitment to durability ensures that you can rely on BDI Wear Parts to keep your jaw crushers running smoothly for longer.

2. Cone Crusher Parts: Power in Simplicity

Moving further down the crushing line, our cone crusher parts represent the epitome of engineering excellence. From bowl liners and mantles to concaves and adjusting rings, every component is crafted from premium materials such as high-chrome iron and manganese steel. These parts are designed to balance wear resistance with cost-effectiveness, ensuring maximum production with minimal downtime. With BDI Wear Parts, you can count on precise fitment, enhanced performance, and a lower total cost of ownership.

3. Impact Crusher Parts: Versatility Meets Durability

For applications requiring high throughput and versatility, our impact crusher parts are the ultimate solution. Our blow bars, hammers, and impact plates are constructed from the toughest alloys available, withstanding the intense impacts and abrasive wear characteristic of impact crushing. By utilizing advanced heat treatment and surface finishing techniques, we enhance the durability of these crusher parts for sale, extending their service life and reducing the need for frequent replacements.

4. Cutting Edge Components: Leading the Way in Innovation

BDI Wear Parts is constantly pushing the boundaries of innovation with our cutting-edge components. Our cutting edges, designed for screen decks, conveyor belts, and other applications, incorporate advanced materials like tungsten carbide to improve wear resistance and performance. Whether you’re looking to increase the throughput of your screening system or prolong the life of your conveyor components, our cutting-edge products offer the perfect solution.

In-House Manufacturing & Streamlined Logistics: Your Edge in the Market

What sets BDI Wear Parts apart is our advanced in-house manufacturing and efficient logistics network. Equipped with state-of-the-art machinery and skilled technicians, our facilities ensure that every component meets the highest standards of quality and precision. Coupled with our optimized logistics system, we deliver parts swiftly to customers around the globe, reducing downtime and boosting operational efficiency.

Conclusion

In summary, BDI Wear Parts is the go-to source for premium crusher components that enhance the performance and longevity of your crushing equipment. From jaw crusher parts to cone crusher parts for sale Canada, impact parts, and cutting-edge components, our extensive product range caters to the diverse needs of the mining, quarrying, construction, and recycling industries. With our in-house manufacturing and streamlined logistics, we are dedicated to delivering the best solutions for your crushing needs. Choose BDI Wear Parts today and discover the impact that quality and reliability can have on your operations.

0 notes

Text

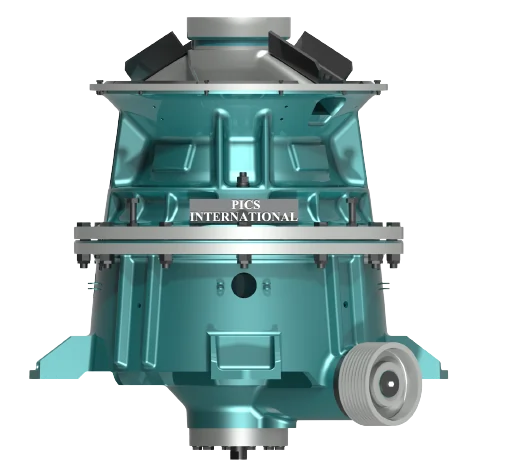

Cone Crusher Manufacturer -Picson

PICS INTERNATIONAL introduces the latest technology Hydro Cone Crusher Manufacturer. PICS INTERNATIONAL cone crushers are suitable for a wide range of applications to get excellently shaped product in polyhydric shape.

GC Series:-

The high crushing ratio of the PICS INTERNATIONAL Hydro Cone Crusher Manufacturer In India makes it ideal for secondary and tertiary stage crushing of hard rocks, perlite, corundum, bauxite, basalt, iron ores, etc. With the PICS INTERNATIONAL Hydro-cone series, you can run your crusher at its peak efficiency under varying feed conditions without worrying about overloading the cone crusher. Its design promotes maximum productivity and performance with high outputs, dependability, and low operating costs.

HP Series:-

A standard jaw crusher combined with an HP Series Cone crusher from PICS International is a great secondary crusher option. They reduce your investment cost and save energy by producing finer goods through fewer crushing processes. Greater product form, a high reduction ratio, and a high capacity are the outcomes of improved inter-particle crushing action in the crushing chamber, which is caused by increased density and pressure.

Maximizing Efficiency and Productivity: The Benefits of Choosing a Cone Crusher Manufacture

1. Quality Assurance: Selecting an experienced cone crusher manufacturer is like making an investment in quality control. Through the production process, reputable manufacturers maintain strict quality control procedures to guarantee that every component satisfies or exceeds industry requirements.

2. Customization and Innovation: cone crusher manufacturer that welcomes innovation and provides customizing choices. Prominent producers allocate resources towards research and development in order to continually improve their product's quality and modify it to suit changing market demands.

3. Comprehensive Support and Service: Choosing to buy a cone crusher is more than just the money spent on it initially. Maintaining uninterrupted operations and reducing downtime requires constant support and maintenance.

4. Access to Expertise: When you work with a respectable cone crusher manufacturer, you may benefit from their extensive experience and industry understanding. Technicians educated by the manufacturer are highly acquainted with their equipment, which allows them to offer insightful advice, help with investigating, and proactive maintenance suggestions.

In conclusion, the benefits of choosing a reputable cone crusher manufacturer extend far beyond the equipment itself. From quality assurance and customization to comprehensive support and long-term value, the advantages are clear. When selecting a cone crusher manufacturer, prioritize reliability, innovation, and expertise to unlock the full potential of your crushing operations. By making an informed decision today, you're laying the groundwork for success tomorrow and beyond.

Contact: - +919081777945 , [email protected]

Address: - 986, 986/1, Near Getco Substation, GIDC, Por Ramangamdi, Por, Vadodara - 391243, Gujarat

Visit for More Information: - https://www.picsinternational.com/cone-crusher

0 notes

Text

The Importance of Jaw Plates in Industrial Applications

When it comes to heavy-duty industrial machinery, one component that plays a critical role in ensuring efficient operation is the jaw plates. These plates serve as a vital component in various industries, including mining, construction, and recycling. In this blog post, we will explore the significance of jaw plates and shed light on how Jalpa Devi, a leading manufacturer in this field, is revolutionizing the industry.

What are Jaw Plates?

Jaw plates are critical components used in jaw crushers, also known as rock crushers. These crushers are used in the primary stage of crushing various types of materials, such as rocks, ores, and minerals. The jaw plates are fixed to the crusher's frame and consist of two main parts: the moving jaw plate and the static jaw plate. They work together to compress and crush the materials, allowing for the desired size reduction.

Importance in Industrial Applications

1. Durability and Strength

In industrial applications, jaw plates are subjected to extreme wear and tear due to the constant crushing of hard materials. Therefore, these plates must be made from high-quality materials that exhibit exceptional durability and strength. Jalpa Devi understands this need and utilizes advanced techniques to manufacture jaw plates with superior longevity and resistance to impact and abrasion.

2. Crushing Efficiency

Efficient crushing is a cornerstone of productivity in industrial applications. The design and quality of jaw plates greatly influence the crushing efficiency of the crushers. A well-designed jaw plate profile ensures an even distribution of materials across the crushing chamber, allowing for efficient crushing and reducing the risk of blockages. Jalpa Devi's engineering expertise and commitment to precision craftsmanship enable them to produce jaw plates with optimal crushing efficiency.

3. Customization and Compatibility

Different industries require different specifications and designs when it comes to jaw plates. Jalpa Devi recognizes this diversity and offers a wide range of customized jaw plate solutions to suit specific industrial requirements. By working closely with their customers, Jalpa Devi ensures that their jaw plates are compatible with various crusher models, making them a versatile choice for different applications.

4. Cost-effectiveness

The durability and reliability of jaw plates directly impact the cost-effectiveness of industrial operations. By investing in high-quality jaw plates from Jalpa Devi, industrial companies can reduce maintenance and replacement costs. Jalpa Devi's jaw plates are known for their long lifespan, minimizing downtime, and improving overall cost efficiency for their customers.

Jalpa Devi: Revolutionizing the Industry

With years of experience and a commitment to innovation, Jalpa Devi has become a leading manufacturer of jaw plates. Their team of experts constantly works towards developing new materials and refining manufacturing techniques to stay at the forefront of the industry. By incorporating the latest technology and employing skilled craftsmanship, Jalpa Devi ensures that their jaw plates deliver unparalleled performance, durability, and cost-effectiveness.

Conclusion

Jaw plates are a crucial component in industrial applications, ensuring efficient crushing and reducing maintenance costs. Choosing high-quality jaw plates from Jalpa Devi can significantly improve productivity and extend the lifespan of crushers, benefiting companies across various industries.

0 notes

Text

Top 5 stone crusher manufacturer in Udaipur

When it comes to selecting the best stone crusher manufacturer in Udaipur, Craftsmen Crusher emerges as the unrivaled leader, delivering top-notch quality and cutting-edge technology. Udaipur, known for its architectural splendor, demands stone crushers that reflect precision and durability, and Craftsmen Crusher stands tall as the epitome of excellence in this domain.

1. Craftsmanship Redefined: Craftsmen Crusher

Craftsmen Crusher, a prominent name in the stone crushing industry, takes pride in its commitment to unmatched craftsmanship. Each crusher is a masterpiece, meticulously designed to ensure optimal performance, longevity, and efficiency. Craftsmen Crusher's dedication to precision sets it apart as a reliable choice for those seeking top-tier stone crushing solutions.

2. Cutting-Edge Technology: Pioneering Innovation

In a world driven by technological advancements, Craftsmen Crusher embraces innovation. The top-of-the-line crushers from Craftsmen incorporate cutting-edge technology, enhancing the crushing process and setting new benchmarks for efficiency. Investing in Craftsmen Crusher means embracing the future of stone crushing technology.

3. Comprehensive Product Range: Tailored to Perfection

Craftsmen Crusher understands the diverse needs of its clients. The product range encompasses a variety of crushers, each catering to specific requirements. From robust jaw crushers to efficient cone crushers, Craftsmen ensures that their lineup meets the demands of various applications, making them a versatile choice for any stone crushing project.

4. Unrivaled Durability: Built to Last

Durability is non-negotiable in the stone crushing industry, and Craftsmen Crusher excels in this aspect. Crafted from premium materials and subjected to rigorous quality checks, their crushers withstand the test of time, ensuring a reliable and long-lasting solution for your stone crushing needs.

5. Client-Centric Approach: Beyond Business

Craftsmen Crusher goes beyond being just a manufacturer; they foster lasting relationships. With a client-centric approach, Craftsmen prioritizes customer satisfaction, offering personalized solutions and comprehensive support throughout the purchasing and operational phases. Choosing Craftsmen Crusher means choosing a partner invested in your success.

In conclusion, the quest for the top 5 stone crusher manufacturer in Udaipur culminates with Craftsmen Crusher, a brand synonymous with excellence, innovation, and unwavering commitment. Elevate your stone crushing experience with Craftsmen Crusher – where precision meets performance, and each crusher is a testament to the dedication of Udaipur's finest craftsmen. Choose Craftsmen Crusher for stone crushing solutions that stand the test of time.

0 notes

Text

Forecast of the Global Glass Crusher Market: 2022-2032

The global glass crusher market size has reached US$ 590.3 million in 2022 and is expected to increase at a CAGR of 5.8% to reach a market valuation of US$ 1 billion by the end of 2032.

Sales of glass crushers accounted for nearly 17% share of the global glass recycling market at the end of 2021.

Download Sample Copy of This Report:

The readability score of the Glass crusher market Demand report is good as it offers chapter-wise layout with each section divided into a smaller sections.

The report encompasses graphs and tables to show the entire assembling. Pictorial demonstration of the definite and estimated values of key segments is visually appealing to readers.

This Glass crusher market outlook report explicates on vital dynamics such as the drivers, restraints and opportunities for key players and competitive analysis of Glass crusher market along with key stakeholders as well as emerging players associated with the manufacturing of product.

The Key trends Analysis of Glass crusher market also provides dynamics that are responsible for influencing the future Sales and Demand of over the forecast period.

What differences can the Glass crusher market report make on the revenue impacts and strategies of businesses?

Fact.MR strives to provide comprehensive assessments of opportunities in various regions and technology segments. The study also offers an uncluttered data-driven insights into the growth avenues of the Glass crusher market and all its segments. Some of the ways the study can make a discernible impact are by offering evidence-based perspectives on:

Attractiveness quotient of emerging product/technology types in various products in the Glass crusher market.

Micro-economics factors that may hamper the prospects of some of the key segments

Recent spate of research and development (R&D) funding on key Glass crusher market

New business models paving way for disruptions in demand dynamic of key segments

Regional markets that will be future engine of growth and the industry trends that will support these markets

Challenges overcoming which may offer industry players competitive edge

The key market players in the global Glass crusher market include:

HARDEN

Ampulverizer (Hustler Conveyor Company)

American Pulverizer

McLanahan

Techna-Flo IMI plc

BottleCycler

Krysteline Group Ltd

Sesotec GmbH

Krause Manufacturing Watts Water Technologies Inc.

Segmentation of Glass Crusher Industry Research

· By Type :

Jaw Crushers

Hammer Crushers

Roll Crushers

Impact Crushers

Compound Crushers

· By Capacity :

Below 25 Tons/Hr

25-50 Tons/Hr

50-100 Tons/Hr

Above 100 Tons/Hr

· By Output Type :

Glass to Sand

Glass to Cullets

· By Feed Size :

Less than 150 mm

150-250 mm

Above 250 mm

· By Noise Level :

Low (below 70 db)

Medium (70-85 db)

High (Above 85 db)

· By Application :

Food & Beverage Industry

Medical Industry

Automotive

Interior & Construction

Labs and Research Centers

Others

· By Region :

North America

Latin America

Europe

East Asia

South Asia & Oceania

MEA

Get Full Access of Complete Report:

Questionnaire answered in the Market outlook Report of Glass crusher market include:

What is the key strategy deployed by large players to maximize Glass crusher marketgrowth?

What are the main challenges faced by players in the Glass crusher market Demand?

With the advent of technological advancement, how will the Glass crusher market landscape change over the forecast period?

What does player bring to the table which is unique as a strategy, and is easy to emulate for new investors in the Glass crusher market size?

How will be insights and market estimations provided in the Fact.MR report on the Demand of Glass crusher make a difference?

The study takes a closer look at the major economic turmoil, with a focus on the recent COVID-19 pandemic disruptions

The assessment of key growth dynamics highlights the attractiveness of new automation technologies and offers readers insight on the prospect of these during the forecast period

The study tries to offer a balance perspective of the opportunities in mature and the most lackluster markets

Provides scrutiny of the industry trends that have shaped recent government policies

Provides an account of major breakthroughs in all segments that might change the course of the market considerably

Provides an incisive analysis of socio-political milieu in which the key markets operate, and how will that influence the lucrativeness of the overall Automated External Defibrillators Market

Analyzes how collaborations and partnerships among players from different industries shape the key growth dynamics in the near future

Evaluates the role of various stages of funding on new growth avenues in key regional markets

Contact:

US Sales Office :

11140 Rockville Pike

Suite 400

Rockville, MD 20852

United States

Tel: +1 (628) 251-1583

E-Mail: [email protected]

0 notes

Text

How Cone Crusher works and Why It is essential for Crushing Needs?

A Cone crusher is a type of heavy-duty machinery used in mining, construction, and other industries to crush materials. It consists of a cone-shaped crushing chamber that is lined with wear-resistant plates, and a rotating mantle that gyrates within the chamber, creating a compressive force that breaks down the materials.

Cone crushers are designed to handle a wide range of materials, including hard and abrasive rocks, ores, and minerals. They are typically used as secondary or tertiary crushers, after primary crushers such as jaw crushers or gyratory crushers.

How Cone Crusher Works?

A cone crusher is a type of crushing equipment used to reduce the size of large rocks into smaller ones. It works by compressing the material between an eccentrically gyrating cone and a stationary chamber. Here is a step-by-step explanation of how a cone crusher works:

1. The material enters the crushing chamber through the top of the cone crusher.

2. The cone rotates around its axis, which causes the eccentrically mounted mantle to gyrate. The mantle is located beneath the concave, or bowl-shaped, lining of the chamber.

3. As the mantle gyrates, it creates a compressive force on the material that is being crushed. The force is transferred to the concave, which also has a gyrating motion, and the material is crushed between the mantle and concave.

4. The crushed material falls through the opening at the bottom of the chamber and is discharged.

5. The size of the crushed material can be controlled by adjusting the gap between the mantle and the concave. This is achieved by moving the mantle up or down using a hydraulic system.

6. The hydraulic system also helps to protect the crusher from damage by releasing the pressure if the crushing chamber becomes overloaded.

Why Cone Crusher is essential for crushing needs?

Cone crushers are essential for many industries, including mining, construction, and demolition. They are used to crush a variety of materials, including rocks, ores, and minerals, to produce a consistent and high-quality end product. We'll explore why cone crushers are essential for your crushing needs.

1. Versatility: Cone crushers can handle a wide range of materials, from hard and abrasive rocks to soft and friable materials. This makes them ideal for use in a variety of industries, including mining, construction, and demolition.

2. Efficiency: Cone crushers are designed to crush materials with efficiency and speed. Their unique design allows for the efficient use of energy, reducing the amount of power needed to crush materials.

3. Consistency: Cone crushers produce a consistent and high-quality end product, which is essential for many industries. This ensures that the materials produced meet the required specifications and are of a consistent quality.

4. Reliability: Cone crushers are designed to be reliable and durable, ensuring that they can withstand the rigors of heavy-duty use. This makes them ideal for use in demanding environments, such as mines and construction sites.

5. Low maintenance: Cone crushers are designed to be low maintenance, with minimal downtime required for maintenance and repairs. This means that they can be used for longer periods without the need for costly repairs or replacements.

6. Safety: Cone crushers are designed with safety in mind, with features such as a hydraulic overload protection system and a safety toggle plate. This ensures that the crusher can be operated safely and efficiently, reducing the risk of accidents and injuries.

Cone crushers are essential for many industries, offering versatility, efficiency, consistency, reliability, low maintenance, and safety. Proman is a leading Cone crusher manufacturer in India. Our cone crusher can be the perfect choice for your crushing needs.

1 note

·

View note

Text

Leading Manufacturer of gc vsi 75 vertical shaft impactor, gc vsi 300 vertical shaft impactor, gc vsi 200 vertical shaft impactor and gc vsi 100 vertical shaft impactor from Indore

#double toggle jaw crusher#jawcrushermanufacturer#single toggle jaw crusher#best jaw crusher machine#best jaw crusher#best jaw crusher machine in indore#1 jaw crusher manufacturer#jaw crusher machine manufacturer#jaw crusher manufacturer#1 jaw crusher machines

0 notes

Text

Unmatched Strength and Reliability of BDI Crusher Parts

In the demanding world of mining and construction, reliable and high-performance crusher parts are crucial for maintaining optimal equipment efficiency and minimizing downtime. BDI Wear Parts stands out as a leading supplier of customized and high-quality crusher parts, offering a comprehensive range that caters to the unique needs of various industries.

What Makes BDI Crusher Parts the Best Choice?

BDI Wear Parts is renowned for its commitment to quality and customer satisfaction. Our products are meticulously crafted to ensure maximum durability and performance, even in the toughest operating conditions. Our focus on innovation and the use of cutting-edge wear technology sets new standards for reliability, efficiency, and productivity. With a one-year warranty against manufacturing defects and 24/7 customer support, BDI Wear Parts is your trusted partner for all your crusher parts Canada needs.

Our Comprehensive Product Range

1. Jaw Crusher Parts

BDI Wear Parts offers a wide array of jaw crusher parts for sale, designed to withstand the rigors of heavy-duty applications. Our jaw plates, crafted from high-quality materials like ZGMn13Cr2 and ZGMn18Cr2, offer outstanding wear resistance and durability. These parts are precisely engineered for an exact fit with a wide range of jaw crusher models, including the widely-used CJ and C series from leading brands. This ensures less downtime, enhanced productivity, and substantial cost savings for our customers.

2. Cone Crusher Parts

For cone crushers, BDI Wear Parts provides an extensive selection of mantles, concaves, and other essential components. Our cone crusher parts for sale are precision-engineered to optimize crushing performance and minimize wear. High-manganese steel and high-chromium iron are among the materials used in our mantles and concaves, ensuring exceptional strength and durability. We offer parts for popular cone crusher series like the H, S, CS, GP, and HP, ensuring compatibility with a wide range of equipment.

3. Impact Parts

BDI Wear Parts also specializes in impact crusher parts, including blow bars, impact plates, and hammer mill hammers. These parts are subject to intense impact and abrasion, making material selection and design crucial. We offer high-chrome and high-manganese steel blow bars, as well as customized materials to suit specific application requirements. Our impact parts are designed to increase productivity, reduce maintenance costs, and extend equipment life.

4. Cutting Edge

The cutting edge of crusher parts for sale, particularly in bucket teeth and jaw plates, is critical to maintaining optimal crushing efficiency. BDI Wear Parts offers cutting edges that are hard-wearing and precision-ground to ensure sharp, consistent performance. These cutting edges are available in various materials, including high-manganese steel, high-chrome iron, and customized alloys, to suit different applications and operating conditions. Regular replacement and maintenance of cutting edges Canada can significantly improve overall crushing performance and reduce machine stress.

ConclusionBDI Wear Parts is your go-to source for high-quality, customized crusher parts. Our comprehensive range of jaw crusher parts, cone crusher parts, impact parts, and cutting edges is designed to meet the unique demands of various industries. Dedicated to innovation, quality, and customer satisfaction, we aim to deliver dependable products that boost productivity and reduce downtime. Whether you require parts for Metso, Sandvik, Terex, or other brands, BDI Wear Parts is your go-to source. Reach out to us today to explore our products and services.

0 notes

Text

Crushing Equipment Market is Booming Worldwide | Gaining Revolution In Eyes of Global Exposure

Global Crushing Equipment Market Report from AMA Research highlights deep analysis on market characteristics, sizing, estimates and growth by segmentation, regional breakdowns & country along with competitive landscape, players market shares, and strategies that are key in the market. The exploration provides a 360° view and insights, highlighting major outcomes of the industry. These insights help the business decision-makers to formulate better business plans and make informed decisions to improved profitability. In addition, the study helps venture or private players in understanding the companies in more detail to make better informed decisions.

Major Players in This Report Include:

Metso (Finland)

Sandvik (Sweden)

IROCK Crusher (United States)

Terex Corporation (United States)

Caterpillar Inc. (United States)

Komatsu Ltd. (Japan)

Joy Global Inc. (United States)

ThyssenKrupp (Germany)

Eagle Crusher Company Inc. (United States)

R.R. EQUIPMENT (United States)

Crusher equipment is heavy machinery designed to break the stone into small fragments called aggregates. It may be used to reduce the size or change the form of waste materials so they can be more easily disposed of or recycled or to reduce the size of a solid mix. It holds material that is going to crushed between two parallel or tangent solid surfaces and applies sufficient force to bring the surfaces together to generate enough energy within the material being crushed so that its molecules separate from or change alignment in relation to each other. It has demand in the construction and mining industry due to the low cost of transportation. Crusher equipment manufacturers are focusing to design electric crushers.

Market Drivers Increasing Demand from Construction Industry

Development of Construction Industry Worldwide

Market Trend Automation of Crushing Equipment

Demand for Crushing Equipment with Less Carbon Emissions

Opportunities Expansion of Sand Manufacturing Industry Worldwide

Increasing Demand from End-user Industry

Technological Advancements in the Crushing Equipment

Challenges Emissions during the Mining, Screening and Crushing Operations Creates Environmental Issues

The Crushing Equipment market study is being classified by Type (Jaw Crusher, Cone Crusher, Impact Crusher, Gyratory crushers, Compound crusher, Others), Application (Mining, Rock Quarries, Mineral Processing, Recycling, Others), Reduction Ratio (3/1 to 5/1 ratio, 4/1 to 7/1 ratio, Others)

Presented By

AMA Research & Media LLP

0 notes

Text

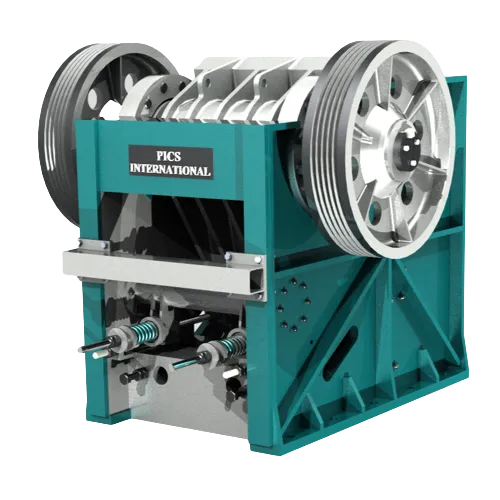

Pics International

We Engineer, We Manufacture,

We Deliver..... Worldwide

Picson Construction Equipments Pvt. Ltd.

PICS INTERNATIONAL is a leading global engineering and manufacturing unit engaged in supplying cutting-edge crushing and screening equipment for applications in mining, quarrying, and infrastructure projects, Construction and Demolition and waste recycling.

We have more than three decades of experience in supplying a robust range of crushing, screening and washing equipment, including varying sizes of stationary and mobile jaw, cone and impact crushers; heavy duty screens and mobile plants for recycling construction and demolition waste. These high-quality industrial equipments ensures a fine and precise performance promises an end result which is nothing less than the best.

Our Quality Products

1.CRUSHER

2.IMPACTORS

3.WASHING SYSYTEM

4.SCREENS

5.FEEDERS

6.MIXING

OUR PRODUCTS

1.Single Toggle Jaw Crusher

2 Double Toggle Jaw Crusher

3 Cone Crusher HC Series

4 Cone Crusher GC Series

Our Products

Crusher

Sand Making Machine

C & D Waste Recycling Plant

Washing System

Semi Mobile Series

Applications

Quarrying & Aggregate

Sand Processing

C & D Waste Recycling

Mining

Industrial Sand

Supports

Parts

Service

Operator Training

Dealer Portal

Manuals

Get In Touch

986, 986/1, Near Getco Substation, GIDC, Por Ramangamdi, Por, Vadodara - 391243, Gujarat, India.

9081777945

https://www.picsinternational.com/

#Stone Crusher#Cone Crusher#Jaw Crusher#C&D Waste#C&D Waste Recycling#C&D Waste Recycling Plant#C&D Waste Recycling Plant Manufacturer#C&D Waste Recycling Plant Manufacturer in India#Construction & Demolition Waste Recycling#Construction & Demolition Waste#Stone Crusher Manufacturers

0 notes

Text

On Corporate Desperation

I'd love to tell someone at one of the major manufacturers that wagging a 1% rebate for the interest rate in a pandemic and during a chip shortage does not send particularly kind "Hey, I know you're struggling, so here's a bit of a leg-up" vibes.

This is more the manufacturers saying "Yeah, we know you're struggling, but - guess what? Our profit margin matters more, and our workers can't respec out of the automotive industry. So fuck your feelings, screw your budget, and pay the fuck up."

I'd maybe have an easier time sitting with it if I hadn't argued against this with regional sales reps personally, but most Canadian offices are dead-set on meeting sales quotas for the end of the fiscal year.

Guess what: they won't.

I'm also likely to be shelved for the rest of the week, starting tomorrow. My colleagues and I keep telling the sales directors that any blitzes, big-top sales, private events and mail-in offers are generally perceived as being inappropriate by the general public in times like these, and their response usually amounts to "Welp, it's that or we send all of 2021 and 2022's lineups to the crusher..."

Considering how the demand for EVs is growing at an astonishing rate across Quebec, I'm actually in favor of shuttering SUV production lines and actually weaning the public off of the stereotypical suburban mommy-mobiles. Predictably enough, that line of thought makes shareholders piss their pants.

People got scared shitless, this summer. Forest fires, heat waves - I'm seeing more and more people effectively wake up, leaving their slack-jawed and half-hearted recycling attempts and going all-in on it, on reuse platforms or various rental services. I'm seeing community compost bins pop up everywhere.

What's baffling is that in the midst of all this, there's still fifty and sixtysomething guys in their second adolescence who really want that gas-guzzling V8 for the sake of fulfilling some boyhood fantasy...

There's a sales ban on gas vehicles being projected for seven or eight years from now - I don't remember when, exactly. I work in the fucking automotive industry and I can't wait for that to rear its head. It'll make Saudi Arabia's ballsack shrivel and it'll shake the Prairies into investing in something more sustainable than their black sands.

I'm just hoping recycling centers will be more adequately financed, by that point. I'd hate to see Canada get weaned off of gas and moving on to poisoning whole water tables with nickel-hydride runoffs...

1 note

·

View note

Photo

Aggregate Crushing in India

Puzzolana

Puzzolana with five decades of enviable history has the reputation of delivering effective, economic & environmentally compatible engineering solutions to infrastructure challenges. A truly ‘Make in India’ organization, it made great progress & success in Multi engineering disciplines like Design, Metallurgy, Fabrication, Machining, Infrastructure & Turnkey solutions for varied business needs. Puzzolana brand is known for its uncompromising quality, Indigenous technology & innovation through its dedicated service. Puzzolana is the market leader in Aggregate Crushers in India and has adapted state-of-the-art technologies in engineering catering to infrastructure needs of our country and global market.

Services: Sand Manufacturer, Waste Recycling Machine Manufacturer, Crusher Spares Manufacturer, Crusher Gearbox Manufacturer, Vibrating Screen Manufacturer, Aggregate Crushing, M Sand Plant Manufacturer, Dry Classifier Manufacturer, Cone Crusher Manufacturer, Surface Miner Manufacturer, Jaw Crusher Manufacturer, VSI Crusher Manufacturer, Mobile Crushing Plant Manufacturer & Supplier in India

Address: Puzzolana Towers Sumedha Estates, Avenue -4 Street No.1, Road No.10 Banjara Hills, Hyderabad, TS 500034, India

Phone: +91 40 2335 0409

Website: Aggregate Crushing in India

#Sand Manufacturer & Supplier in India#Dry Classifier Manufacturer & Supplier in India#Crusher Spares Manufacturer & Supplier in India#Aggregate Crushing in India

1 note

·

View note

Text

Just How Carry Out Jaw Crushers Work?

A jaw-crusher can be actually a compression style crusher, comprised of a jaw and jaw located in a V-shape. The jaw protects material contrary to the jaw, crushing the material. The material exits the jaw throughout the base of the rock crusher differently called the discharge launching. Changing the discharge launching controls the item size manufactured by the crusher.

Jaw crushers are mainly applied at the stage of substance reduction for example stone quarries, sand and gravel, mining, building and demolition recycling, structure aggregates, metallurgy, and chemical industries. In the event you desire sandvik jaw crusher parts on the jaw-crushers, you may take into account to see qimingmachinery site.

A jaw-crusher's flywheel, toggle plates, pitman rotating shaft, and driving engine provide the power required to crack up the stuff and make the devastating action.

The mechanical strain employed in jaw crushers for wearing down rock is accomplished by the 2 jaws of the crusher. One jaw is repaired while the other moves forth and back and forth can be understand being a swing jaw. The swing jaw is transferred by a cam or pitman mechanism, behaving in the manner of a lever. The distance between your two jaws is called the space. The movements of the swing jaw can be smaller, and can be repeated as crucial to divide the issue down. A rotating shaft developing is moved by A flywheel. Qimingmachinery may be your top reputable provider of jaw crusher plates. You can buy this devices without any doubt.

Jaw-crushers are duty machines that are heavy also will need to be more strongly constructed. The framework is built from cast steel or iron. The jaws by on their own usually are assembled from cast metal. They're fitted with liners that are made of manganese steel.

A click jaw crusher is larger, with much more moving pieces and decreased productivity than single toggle jaw-crushers. In a double click jaw-crusher, the bizarre is located from the swinging jaw. This has two effects, when stone continues to be rich, it keeps the bizarre out of harms way and one effect can be just a plane of motion to get the swinging jaw which leads to its deficiency of productivity. The jaw motions just like a swinging door that is hinged on top and can be getting pushed open and pulled closed. 1 plate extends contrary to the bottom of the eccentric arm to the underparts of the the swinging jawand also the toggle plate goes contrary to the side of the base of the bizarre arm into your point at the very back of their jaw crusher frame. For find out jaw crusher wear parts you could search internet.

In contrast, the single toggle jaw-crusher contains fewer shafts and bearings and only one toggle that goes from the bottom of the swinging jaw into a position in the back part of the jaw crusher. The eccentric is situated on top of the swinging jaw and also can be part of this rotating shaft. The benefit of this is the jaw includes two movements that are taking place at the same time. It even gets the swinging door motion that the double tap includes, but also includes up the up and down motion from the eccentric. It offers a high productivity rate.

1 note

·

View note

Text

Top 4 Crucial Tips to Ensure Efficient Cone Crushing Operation

The cone crushing machine is a piece of important machinery suitable for crushing raw materials such as metal ores and medium-sized rocks. Compared to a jaw crusher or rock crusher, the cone crusher is an effective and widely used machine – it adopts innovative methods that ensure smooth crushing while saving time.

The innovative technology functioned the cone crusher can boost work efficiency. However, when crusher maintenance is neglected, it can damage internal parts, and constrainedly need to purchase Cone crusher spare parts to ensure great performance. Let's understand the key tips to maximize cone-crushing operation.

#1 Choose Automation to Extend Cone Crusher Parts life

Using automation greatly boosts cone crusher performance, but it shouldn't be complicated; rather, it is easy to use and control. One of the greatest things that automation offers is protecting the crusher parts from damage; it gives a warning system and alerts the operation before the parts become out of order.

Generally, when the crushing operation surpasses the pressure, it causes a bowl float or ring bounce, ultimately reducing the operation's efficiency.

#2 Operate at a regular "choke-fed" cavity level

When a crusher operates at different cavity levels during a shift – it will operate at inconsistent product shapes and production rates. A cone crusher operating at half the cavity level will produce a much rough product. Also, the low cavity level produces smaller and more elongated product particles.

It is important to ensure that the crusher operates at the correct choke-fed cavity level because this will result in a higher crusher throughput and a cubical-shaped product. This is especially important for the circuit's tertiary (short-head) crushers as they produce most of the aggregate operations' saleable products.

#3 Hydraulic Power Maintenance

Poor maintenance of the hydraulic power unit can damage the motor and pump assembly, which is important for the cone crusher to perform crushing operations. Using higher horsepower for performing hard operations can result in higher energy costs per ton of material (kW/hr/ton).

Thus, using higher horsepower result in shorter life cycles for hydraulic power unit ancillary parts, such as the pump, motor and coupling, starter, pressure switches, solenoid valve seals, packings, and pressure switches. So, to ensure larger efficiency, inspect the hydraulic power unit for filter condition, breather condition, and leaks.

#4 Avoid Excess Feed

To ensure smooth working of crusher parts, avoid trickle-feeding cone crushers. This practice can damage the parts in the long run, which results in low productivity and poor product shape. Also, overfeeding can affect the bearing alignment of the crusher and make you purchase Cone crusher spare parts.

A cone crusher's operational characteristics indicate that it shouldn't be utilised below 40 percent of its rated horsepower while crushing. Experts suggest that the crusher should run at 40 percent of its ideal horsepower. This practice will help obtain correct bearing alignment that ultimately maximizes productivity and allows for optimum load-bearing.

Partner with John Heine for Broad Range of Crushers

We are a renowned Machining shop and Mining pump casting manufacturers in Australia. Over the years, we have developed a high reputation of manufacturing highly precision products, mining tools, lathe machine, and many more. Our technical team is well trained and have experienced in supplying crushing equipment direct to mine sites of some of the largest coal, gold and iron ore companies in Australia and SE Asia.

Since 1886, John Heine and Sons under Heine hard brand has been catered several industries such as mining, quarrying, power generation, and general engineering sector. We are well known for supplying high quality, low volume ferrous casting for these industries.

We also supply cost efficient and durable jaws for BL-Pegson, Goodwin Barsby, Kemco, Parker, Kue Ken, Hadfield, Pioneer and Nordberg machines. So, to get durable Small Jaw Crusher for Sale in Australia, Look no further than John Heine.

Contact John Heine’s customer representative to get the best quality cone crusher parts at budget friendly rate.

SOURCE URL: https://medium.com/@seoo3digital/top-4-crucial-tips-to-ensure-efficient-cone-crushing-operation-b6f4d362193d

0 notes

Text

Properties of M Sand | Advantages of Manufactured Sand

What is MSand?

Manufactured sand also known as M-Sand, is an effective alternative to natural or river sand used in construction and other infrastructure.

Manufactured Sand or M-Sand is made by crushing hard natural stones into small granules and further washed then graded for multiple uses in construction work.

Why manufactured sand is used?

Manufactured sand is an alternative to river sand. Due to the fast-growing construction Industry. the demand for it has increased tremendously causing a deficiency of suitable river sand in most of the world.

Advantages of M-Sand:

1. Greater Durability

2. High Strength

3. Greater workability

4. Offsets Construction Defects

5. Economy

6. Eco-Friendly

Disadvantages of M-Sand:

Crushed Sand can be of coarser and angular surface this can prompt more water and concrete necessary to accomplish the normal functionality.

1. Cost

2. Texture and Shape

3. Workability

How M-Sand is Manufactured:

M-Sand is Manufactured by multiple techniques and numerous stages to achieve the perfect consistency, texture, and quality.

Steps:

1. Jaw Crushing

2. Cone Crushing

3. Vertical Shaft Impact Crusher

4. Screening

5. Classification

Where is M-Sand is used in Construction:

1. Residential Construction

2. Concrete Mixing

3. Plastering

4. RCC Reinforced Cement Concrete

5. Earthen Embankments

6. Backfilling

For more information visit now: https://www.buildersmart.in/blogs/M-sand/

#hyderabad#ecommerce#onlineshopping#buildingmaterialsonline#construction#secunderabad#constructionmaterials#realestate#builders#contractors#cement#sand#msand#aggregates#riversand

0 notes