#Automatic edge banding machine manufacturers in india

Text

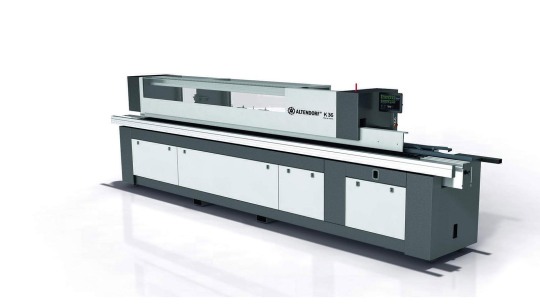

Automatic Edge Banding Machine

Automatic Edge Banding Machine

Automatic Edge Banding Machine using used to Glue PVC Edge Band on the Particle Board, plywood, MDF, Wood or similar materials Automatic Edge Banding Machine also finishes the edges of the PVC Edge Band Using various operations in the machine. Automatic Edge Banding Machine can have various functions as per requirement of finish, speed, production requirement.

We can provide variety of edge banding machines with various features. The usage and functions of the machines can be as mentioned below:

Functions of an Edge Bander Machine are

1. Gluing (Glue on board, PVC Band Cutting and Pressing of Edge Band on Board)

2. Rough trimming ( Required if thicker tapes are used regularly)

3. Fine Trimming

4. Scraping

5. Buffing

6. End Cutting

7. Pre-Milling (Custom applications)

8. Corner rounding (For thick edge bands)

9. Releasing and Cleaning Agents

10. Board Preheating

11. Conveyor Feeding

and machine can be customised as per customer requirement.

We would be happy to understand the details of your requirement and suggest a machine for the same.

Automatic Edge Banding Machine, Edge Banding Machine Price India, automatic edge banding machine price in india, Best automatic edge banding machine, automatic edge banding machine manufacturers, Automatic edge banding machine manufacturers in india,

#Automatic Edge Banding Machine#Edge Banding Machine Price India#automatic edge banding machine price in india#Best automatic edge banding machine#automatic edge banding machine manufacturers#Automatic edge banding machine manufacturers in india

0 notes

Text

Edge Banding Machine Manufacturer in Ahmedabad, India

Edge Banding Machine Manufacturer in Ahmedabad, India

Edge Banding Machine Manufacturer in Ahmedabad, India By Umisons Industries. Buy Automatic Edge Banders and Edge Banding Machines at Best Price in India.

Read More: https://www.umisons.com/services/edge-bander/

2 notes

·

View notes

Text

Troubleshooting Edge Banding Nightmares: Common Problems and How to Fix Them

Ah, the pursuit of the perfect edge. Edge banding, the process of applying a pre-veneered material to raw panel edges, elevates your woodworking projects with a touch of professionalism. But even the most seasoned woodworker can encounter occasional edge banding woes. Fear not, fellow crafters! This guide explores common edge banding problems and solutions, empowering you to troubleshoot these nightmares and achieve flawless results.

The Bane of Beautiful Edges: Common Edge Banding Nightmares

Let's delve into some of the most frequent edge banding challenges and how to overcome them:

Uneven Glue Application: This can lead to poor adhesion and visible gaps between the edging material and the panel.

Solution:

Manual Edge Banding: Ensure even glue spread with a dedicated glue spreader or a notched trowel.

Automatic Edge Banding Machines in India: Check the glue application settings and ensure proper roller pressure for consistent glue distribution.

Poor Adhesion: If the edging material peels off easily, the glue bond might be weak.

Solution:

General: Use a high-quality wood glue suitable for veneer application and ensure both surfaces are clean and free of dust before applying glue.

Manual Edge Banding: Apply sufficient clamping pressure to ensure a tight bond while the glue dries.

Rough or Chipped Edges: Uneven trimming can leave jagged edges or chipped veneer.

Solution:

Manual Edge Banding: Invest in a sharp, dedicated router bit for veneer trimming. Use a scrap piece of wood as a fence to guide your router for a straight cut.

Automatic Edge Banding Machines: Ensure the trimming blades are sharp and properly adjusted.

Wrinkles or Air Bubbles: These imperfections can detract from the overall finish.

Solution:

Manual Edge Banding: When using the glue and clamp method, carefully smooth out any air bubbles with a pressing tool before clamping.

Automatic Edge Banding Machines: Check the tension settings of the edging material feed system to avoid wrinkles.

Burning of Edging Material: Excess heat during trimming can scorch the veneer.

Solution:

Manual Edge Banding: Use a router with adjustable speed settings and a light touch while trimming.

Automatic Edge Banding Machines: Adjust the trimming speed or temperature settings to avoid burning the edging material.

Beyond Troubleshooting: Pro Tips for Flawless Edge Banding

Here are some additional tips to ensure a smooth edge banding experience:

Choose the Right Edging Material: Select a material compatible with your chosen glue and project requirements. Consider thickness and flexibility for curved edges.

Practice on Scrap Wood: Before tackling your final project, experiment with your edge banding technique on scrap pieces to perfect your application and trimming skills.

Clean Work Area: Dust and debris can interfere with glue adhesion. Maintain a clean workspace throughout the process.

Read the Manual (Seriously!): Whether using a manual or automatic edge banding machine, familiarizing yourself with the manufacturer's instructions ensures optimal machine performance and helps avoid common pitfalls.

Embrace the Challenge, Achieve Flawless Edges

Edge banding might present occasional challenges, but with the right knowledge and these troubleshooting tips, you can overcome these nightmares and achieve professional-looking results on your woodworking projects. Remember, whether you're using a manual edge banding machine, a high-tech automatic option in India, or a good old-fashioned DIY approach, patience, practice, and a touch of problem-solving go a long way in achieving flawless edges. So, don't let edge banding woes hold you back. Embrace the challenge, and watch your woodworking creations transform with the beauty of perfectly finished edges!

0 notes

Text

Top 5 Circular Saw Machine Manufacturer In India

Circular saw machines are essential tools in various industries, including woodworking, metalworking, and construction. In India, there are several manufacturers who specialize in producing high-quality circular saw machines. These manufacturers utilize advanced technology and innovative designs to meet the diverse cutting needs of industries.

With a focus on precision, durability, and efficiency, these manufacturers play a vital role in enhancing productivity and quality in the manufacturing sector. Their machines are known for their reliability, performance, and ability to handle different materials with ease.

As India continues to witness rapid industrial growth, these circular saw machine manufacturers are at the forefront, providing cutting-edge solutions to meet the evolving demands of the market.

1. Malwa Machine Tools India Private Limited

Malwa Machine Tools India Private Limited is a leading circular saw machine manufacturer in India, known for their cutting-edge technology and superior craftsmanship.

With a strong emphasis on quality and customer satisfaction, Malwa Machine Tools India Private Limited offers a wide range of durable and high-performance circular saw machines for various industrial applications.

Products: MMT-300 TCA Metal Band Saw Machine, Circular Saw Cutting Machine, Vertical Band Saw Machine

Address: 6-B/C, Ujjain Rd, opposite Sonal Enterprises, Industrial Area, Amlavati, Dewas, Madhya Pradesh 455001

Website: www.malwamachinetools.net

2. Zeal Tech Automation

Zeal Tech Automation is a top-notch Circular Saw Machine manufacturer in India, offering cutting-edge technology and precision cutting solutions.

With a strong focus on customer satisfaction and product excellence, Zeal Tech Automation has established itself as a trusted name in the industry, delivering reliable and high-performance circular saw machines.

Products: SPM Circular Saw Cutting Machine, Vertical Band Saw Machine (Manual), Vertical Band Saw Machine (Hydraulic), Semi-Automatic Circular Saw Machine

Address: 19/4, F-II Block, MIDC Pimpri, Pune: – 411018

Website: www.zealtechautomation.com

3. ITL Industries Limited

ITL Industries Limited is a well-established circular saw machine manufacturer in India, known for their cutting-edge technology and reliable performance.

With a commitment to quality and customer satisfaction, ITL Industries Limited offers a diverse range of circular saw machines that cater to different industrial needs.

Products: Band Saw And Circular Saw Machine, Circular Saw Cutter, Horizontal Band Saw Machine, Carbide Blade, Auto Loader

Address: 111, Sector B, Sanwer Road Industrial Area, Indore, Madhya Pradesh 452015, QR7V+VGC Indore, Madhya Pradesh

Website: www.itlindustries.co.in

4. TANNU TOOLS PVT. LTD.

TANNU TOOLS PVT. LTD. is a leading circular saw machine manufacturer in India, offering cutting-edge technology and reliable performance.

With a wide range of circular saw machines, TANNU TOOLS PVT. LTD. is committed to providing high-quality solutions for industrial cutting requirements.

Products: Double Column Semi-Automatic Band Saw Machine, Double Column Fully Automatic Band Saw Machine, Swing Type Fully Automatic Band Saw Machine, Swing Type Semi-Automatic Band Saw Machine, Band Saw Machines, Vertical Band Saw Machine, circular saw Machines

Address: Plot No-9, Gali No. 2, Near Shiv Mandir, Pyala Malwa Machine Tools India Private Limited

Road, Sikri, Ballabgarh, Faridabad - 121004, Haryana, India

Website: www.tannutools.com

5. Indotech Industries (I) Private Limited

Indotech Industries (I) Private Limited is a reputable circular saw machine manufacturer in India, specializing in high-quality machines for various cutting applications.

With a focus on precision and durability, Indotech Industries (I) Private Limited offers reliable and efficient circular saw machines that meet the demands of industries across the country.

Product: Metal Cutting Band Saw, Metal Cutting Horizontal Bandsaw, Circular Sawing Machine Auto-Loader, CNC Bandsaw Machine, Cutting Machines

Address: Gram Bardari Post, Hatod Sanwer Road, 47/2 & 47/3, Bardari, Indore, Madhya Pradesh 453111

Website: www.indotechmachines.com

Conclusion:

We have listed the top 5 Circular Saw Machine Manufacturers in India. India has several top-notch circular saw machine manufacturers that cater to the diverse needs of industries.

Whether it's for woodworking, metalworking, or other cutting applications, these manufacturers have established themselves as reliable suppliers in the Indian market. With their commitment to quality and customer satisfaction, they continue to play a significant role in the growth and development of the manufacturing sector in India.

0 notes

Text

Learn about SPINDLE MOTOR

Spindle

Changzhou Troy Machinery & Electric Co., Ltd. was established in 1998 and has since become a market leader in High-speed spindle motor design, production, and distribution.

We continually invest in new, cutting-edge production and testing equipment to make sure that our products are of the greatest calibre. Because of our cutting-edge technology and reliable quality, we have gained the trust of customers both domestically and internationally. Our “WHD” brand name is gaining popularity.

CNC spindle, engraving machines, drilling machines, edge banding machines, and other related devices frequently use products from our STZ, STF, STM, STL, and STX family. In addition, we may create unique spindle motors based on the demands of our clients. In order to uphold our company’s core philosophy of putting the customer first, we have shipped our products to many different nations throughout the world, including the United States, Russia, Europe, India, Brazil, and Iran.

To twist and wind thread from a pile of flax or wool carried on a distaff, a spindle is a narrow, rounded rod with tapered ends.

CNC Spindle motor

The geometrical tolerances of the workpiece surface are usually subjected to high demands when grinding. Hence, specifications for a minimum position change of the grinding discs due to external forces and bending moments are often included in the construction of grinding machine spindles.

Spindle ATC — Automatic Tool Change Spindler Motor Many tools can be used automatically by the motor. WHD offers water-cooled 5.5 kW ATC spindles, water-cooled 7.5 kW spindles, and air-cooled 9.0 kW spindles. With over 20 years of manufacturing and selling spindle motors, WHD offers High-Speed Air-Cooled Spindle motors for CNC engraving and CNC wood routing.WHD spindle motors have been delivered, among other locations, to the US, Europe, Brazil, India, and Russia.

ATC — Automatic Tool Change Spindle motor

Automated Tool Change Spindle Motor is referred to as ATC. The ATC Spindle Motor has a number of automatic tools. There are three alternatives provided by WHD: a water-cooled 5.5 kW ATC spindle, a water-cooled 7.5 kW ATC spindle, and an air-cooled 9.0 kW ATC spindle. With over 20 years of manufacturing and selling spindle motors, WHD offers High-Speed Air-Cooled Spindle motors for CNC engraving and CNC wood routing. WHD spindle motors have been delivered, among other locations, to the US, Europe, Brazil, India, and Russia. Woodworking, acrylic plastic, and light metal engravings like copper and aluminium are some of its applications.

0 notes

Link

About us

Based at Vadodara, Gujarat, India, we, "Multicut Machine Tools," are a prominent name engaged in the manufacturing of Bandsaw Machine. Our products are available in different models and the entire range includes Fully Automatic Double Column Band Saw Machine, Semi-Automatic Double Column Band Saw Machine, CNC Fully Automatic Bandsaw Machine, Swing Type Fully Hydraulic Bandsaw Machine, Swing type manual Bandsaw Machine, Mitre Cutting Bandsaw Machine, Hydraulic Power Packs, Hydraulic Cylinders and Vertical BandSaw Machine. Our machines are manufactured using cutting edge technologies and are customized according to the industry applications. The Band Saw Machines manufactured by us have a cutting capacity of 200 mm to 2000 mm, and may vary according to the models. We have a sound and sophisticated infrastructure that includes large production units.

http://multicut.in/

4 notes

·

View notes

Text

Bandsaw Machine – Definition, Types, Parts, Uses, Working & Advantages [Complete Guide]

Definition of Band Saw Machine

Band Saw – Definition, Types, Parts, Uses, Working, Advantages & Disadvantages :- A bandsaw machine, as the name of this machine suggests, is a saw that consists of a continuous metal band known as the bandsaw blade that rides on two wheels that are rotating in the same plane. A bandsaw machine consists of a round and serrated steel blade and can be employed to process wood, metal, and various other raw materials. A bandsaw machine can be employed for making straight, irregular, or curved shape cuts, depending upon the lateral flexibility and the width of the band. Bandsaws are mostly utilized for making irregular cuts. As the result of evenly distributed tooth load, bandsaw machines are capable of producing a uniform cutting action. The source of power for these bandsaw machines can be one of the many sources such as wind, steam, or electric power. Electric power is the most preferred source of power nowadays.

There are many manufacturers of band saw blades in India. However, only a few are known to produce high quality products. Among them, one of the most popular is Bandsaw Blades India. This company has been in the business for many years and has earned a good reputation for manufacturing high quality band saw blades.

Types of Bandsaw Machine

As well as being categorized elsewhere, bandsaw machines can also be categorized in a variety of ways. There are two types of bandsaw machines, vertical and horizontal, based on their mechanisms of mounting. This is the most basic and general way of classifying bandsaw machines.

1. Vertical Bandsaw Machine

Vertical bandsaws have toothed steel blades that cut vertically. They are usually powered by an electric motor via a belt transmission mechanism. This belt allows the blade speed to be adjusted. The steel blade in a vertical bandsaw machine rotates over a fixed track between the idler wheel, mounted above the worktable, and the drive wheel, mounted under the work table, which cuts into the sides of the stock material. Stocks are moved against the blade for cutting. The table can be tilted forward or sideways to allow mitered cutting. Internal cutting is also possible with vertical bandsaw machines since they can weld their own blades.

2. Horizontal Bandsaw Machine

In most cases, horizontal bandsaw machines are floor-mounted machines that are used to cut solid steel, tubing, and other odd-shaped raw materials. A belt and pulley mechanism drives the motor in horizontal bandsaw machines. The bandsaw blades are also driven by an electric motor. In this mechanism, the speed of the blades can be adjusted in discrete steps based on the requirements.

The cutting position of the bandsaw steel blade in a horizontal bandsaw machine is horizontal and it makes cuts into the stock with a downward motion. A machine frame pivots from a corner on the sawing machine bed and carries the drive and idler wheels along the length of the machine. On the bed of the machine is a vise that holds the material stock to be cut.

As well as cutting simple stock, a vertical bandsaw can also be used for contour cutting, filing, and polishing.

Working of Band Saw Machine

In a bandsaw machine, a continuous toothed metal band is drawn at high speed across workpieces to cut them. Workpieces are fed into the machine's cutting edge. A drive wheel drives the steel blade and an idler wheel supports it in a bandsaw machine. Since the bandsaw blade is made up of a precision cutting tool, machining at close tolerances is expected to be accurate.

Using the bandsaw machine eliminates or minimizes the need for a lot of secondary machining operations. The chip removal process is also very fast. When the bandsaw machine is turned on, the operator raises the saw and lowers the blade on the clamped material workpiece, cutting it through as the blade moves. Following the cutting operation, the bandsaw automatically shuts off.

For metal cutting jobs using a bandsaw machine, a constant flow of coolant is required as a lubricant to keep the blade cool and prevent it from becoming smeared. In addition to extending the life of the machine as well as the blade, cooling also increases accuracy. Sometimes brush wheels or brushes are used to remove cut chips. Band speeds on a bandsaw machine range from 40 ft per minute up to 5000 ft per minute.

Vertical bandsaw machines lower the blade onto the workpiece, while horizontal bandsaw machines feed the workpiece to the blade.

Parts of Band Saw Machine

Human health is adversely affected by the chips generated during the cutting process. Consequently, metal-cutting bandsaws are usually equipped with brushes or brush wheels to prevent chips from getting caught between the blade teeth and causing damage so that such impacts on human health are avoided.

To keep the saw blade cool and well lubricated, the band saw machine must be equipped with a cutting fluid circuit containing coolant liquid.

Furthermore, PLC or CNC-controlled band saw machines can also be partly automated.

Digitally controlled automatic band saw machines can not only cut faster, but also more precisely with higher accuracy, and eventually perform complex cutting operations like bevel cutting.

To adapt to today's manufacturing requirements and standards, most modern bandsaw machines are equipped with digital CNC controllers.

Applications of Band Saw

Modern manufacturing uses band sawing operations for a wide range of applications.

The processing of metal

Processing of wood

Other materials can also be cut.

Advantages of Band Saw

The advantages of a band saw machine include

Due to uniformly distributed tooth loads, cutting action is uniform and evenly distributed

As with a jigsaw machine, this machine can make irregular and curved cuts.

Having a band saw machine with a better load distribution ensures improved performance.

0 notes

Text

Edge Banding Machine Market by 2030 covers Size, Share, Upcoming Trends Segmentation, Opportunities and Forecast

Edge Banding Machine Market report provides in-depth statistics and analysis available on the market status of the Edge Banding Machine Manufacturers and is a valuable method of obtaining guidance and direction for companies and business enterprise insider considering the Edge Banding Machine market. It contains the analysis of drivers, challenges, and restraints impacting the industry.

Edge Banding Machine Market report also provide a thorough understanding of the cutting-edge competitive analysis of the emerging market trends along with the drivers, restraints, challenges, and opportunities in the Edge Banding Machine Market to offer worthwhile insights and current scenario for making right decision. The report covers the prominent players in the market with detailed SWOT analysis, financial overview, and key developments of the products/services from the past three years. Moreover, the report also offers a 360º outlook of the market through the competitive landscape of the global industry player and helps the companies to garner Edge Banding Machine Market revenue by understanding the strategic growth approaches.

Major Key Players of the Edge Banding Machine Market are:

Get sample copy of “Edge Banding Machine Market” at: https://www.alliedmarketresearch.com/request-sample/13293

Major Types of Edge Banding Machine covered are:

Major Applications of Edge Banding Machine covered are:

Adamik Company, BIESSE, Cantek, HOFFMANN, SCM Group, SIMCO Industrial Machinery Trd. Co. Ltd., Schnell Machine, Vector Systems, HOLZ-HER GmbH, BRANDT

Key Segments Covered

Market by Product Type

Full-automatic

Semi-automatic

Manual

Market by End-use

Furniture Industry

Building Material Industry

Other

Research objectives:-

- To study and analyze the global Edge Banding Machine consumption (value & volume) by key regions/countries, product type and application, history data.

- To understand the structure of the Edge Banding Machine market by identifying its various sub-segments.

- Focuses on the key global Edge Banding Machine manufacturers, to define, describe and analyze the sales volume, value, market share, market competitive landscape, SWOT analysis, and development plans in the next few years.

- To analyze the Edge Banding Machine with respect to individual growth trends, future prospects, and their contribution to the total market.

- To share detailed information about the key factors influencing the growth of the market (growth potential, opportunities, drivers, industry-specific challenges and risks).

- The scope of this report centers on key market analyses, market drivers & challenges, and competitive analysis & trends. Research report examines each market and its applications, regulatory scenario, technological innovations, Edge Banding Machine market projections, market sizes, and shares. Moreover, the Edge Banding Machine market report examines the most recent trends, pipeline products and developments in the Edge Banding Machine market. Complete profiles of leading organizations in the market are also mentioned in this report.

Go For Interesting Discount Here: https://www.alliedmarketresearch.com/request-for-customization/13293

Table of Content

1 Report Overview

1.1 Study Scope

1.2 Key Market Segments

1.3 Players Covered

1.4 Market Analysis by Type

1.5 Market by Application

1.6 Study Objectives

1.7 Years Considered

2 Global Growth Trends

2.1 Edge Banding Machine Market Size

2.2 Edge Banding Machine Growth Trends by Regions

2.3 Industry Trends

3 Market Share by Key Players

3.1 Edge Banding Machine Market Size by Manufacturers

3.2 Edge Banding Machine Key Players Head office and Area Served

3.3 Key Players Edge Banding Machine Product/Solution/Service

3.4 Date of Enter into Edge Banding Machine Market

3.5 Mergers & Acquisitions, Expansion Plans

4 Breakdown Data by Product

4.1 Global Edge Banding Machine Sales by Product

4.2 Global Edge Banding Machine Revenue by Product

4.3 Edge Banding Machine Price by Product

5 Breakdown Data by End User

5.1 Overview

5.2 Global Edge Banding Machine Breakdown Data by End User

Have any query? Inquiry about report at: https://www.alliedmarketresearch.com/connect-to-analyst/13293In the end, Edge Banding Machine industry report specifics the major regions, market scenarios with the product price, volume, supply, revenue, production, market growth rate, demand, forecast and so on. This report also presents SWOT analysis, investment feasibility analysis, and investment return analysis.

About Us-

Allied Market Research (AMR) is a full-service market research and business-consulting wing of Allied Analytics LLP based in Portland, Oregon. Allied Market Research provides global enterprises as well as medium and small businesses with unmatched quality of “Market Research Reports” and “Business Intelligence Solutions.” AMR has a targeted view to provide business insights and consulting to assist its clients to make strategic business decisions and achieve sustainable growth in their respective market domain.

Contact Us:

David Correa

Portland, OR, United States

USA/Canada (Toll Free): +1–800–792–5285, +1–503–894–6022, +1–503–446–1141

UK: +44–845–528–1300

Hong Kong: +852–301–84916

India (Pune): +91–20–346060

[email protected]

Web: https://www.alliedmarketresearch.com

Follow Us on LinkedIn: https://www.linkedin.com/company/allied-market-research

0 notes

Text

Automatic Edge Banding Machine Market May See a Big Move by 2026 Covid-19 Analysis

"

<a href=https://www.reporthive.com/request_sample/2802507 target=""""_blank"""" rel=""""noopener""""> Get Sample Report<a href=https://www.reporthive.com/checkout?currency=single-user-licence&reportid=2802507 target=""""_blank"""" rel=""""noopener""""> Buy Complete Report<a href=https://www.reporthive.com/request_customization/2802507 target=""""_blank"""" rel=""""noopener""""> Request for Customization

A new market study is released on Automatic Edge Banding Machine Market 2021 with data Tables for historical and forecast years represented with Chats & Graphs with easy to understand detailed analysis. The report also sheds light on present scenario and upcoming trends and developments that are contributing in the growth of the market. In addition, key market boomers and opportunities driving the market growth are provided that estimates for Global Automatic Edge Banding Machine Market till 2026. The authors of the Automatic Edge Banding Machine Market report have piled up a detailed study on crucial market dynamics, including growth drivers, restraints, and opportunities. Automatic Edge Banding Machine Market report carries out research and analysis of the market for a particular product/service which includes the investigation into customer inclinations. It performs the study of various customer capabilities such as investment attributes and buying potential. This market report involves feedback from the target audience to understand their characteristics, expectations, and requirements. The report provides new and exciting strategies for upcoming products by determining the category and features of products that the target audiences will readily accept. The global Automatic Edge Banding Machine market research report collects data about the target market such as pricing trends, customer requirements, competitor analysis, and other such details.

>>Get technical analysis | Request a FREE PDF Sample Copy @ https://www.reporthive.com/request_sample/2802507

Research objectives: Post-COVID analysis on market growth and size (growth potential, opportunities, drivers, industry specific challenges and risks). To study and analyze the global Automatic Edge Banding Machine market size by key regions / countries, product type and application, historical data from 2015 to 2021 and forecast to 2026. The study covers the current Automatic Edge Banding Machine market size and its growth rates based on 5-year records with a company overview of key players / manufacturers:

HOMAG, BIESSE, SCM Group, BRANDT, Vector Systems, HOLZ-HER GmbH, Cantek, BI-MATIC, Casadei Industria, HOFFMANN, OAV Equipment and Tools, KDT Woodworking Machinery, Nanxing, MAS, Unisunx, Schnell Machine, Jinjia

To understand the structure of Automatic Edge Banding Machine market by identifying its various subsegments. Focuses on the major players of the global Automatic Edge Banding Machine Market, to define, describe, and analyze the value, market share, market competitive landscape, SWOT analysis, and development plans in the coming years. To analyze the Automatic Edge Banding Machine Market with respect to individual growth trends, future prospects, and their contribution to the total market. Analyze competitive developments such as expansions, agreements, new product launches and acquisitions in the market to better understand the pre and post COVID scenario. Reporthive has released an updated research report highlighting the title Global Automatic Edge Banding Machine Market Research Report 2021, which presents a modern market growth outlook as well as the forecast forecast along with the Investment Rate (ROI) as a whole., with a developing CAGR close to XX% throughout the 2019-2026 period. The file studies the revenue of the Automatic Edge Banding Machine industry in the global market, especially in the North of the United States, China, Europe, Southeast Asia, Japan and India, with production, consumption, income, import and export in those areas. Market by Automatic Edge Banding Machine Type: Full-automatic, Semi-automatic Market by Automatic Edge Banding Machine Application: Furniture Industry, Building Material Industry, Other Automatic Edge Banding Machine Geographic Market Analysis: The report provides information on the Automatic Edge Banding Machine market area, which is subdivided into subregions and countries. In addition to the market share in each country and sub-region, this chapter of the report also provides information on profit / growth opportunities and also mentions the share according to the impact of COVID-19 for each region, country, and sub-region. * North America (Mexico, USA, Canada) * Europe (Netherlands, Germany, France, Belgium, UK, Russia, Spain, Switzerland) * Asia Pacific (China, Australia, Japan, Korea, India, Indonesia, Thailand, Philippines, Vietnam) * Middle East and Africa (Turkey, Saudi Arabia, Egypt, United Arab Emirates, South Africa, Israel, Nigeria) * Latin America (Brazil, Chile, Argentina, Colombia, Peru). Reason for purchasing this report: - It offers research and analysis of changing serious situations. - For the improvement of expert choices in organizations, it offers systematic information with essential organizational viewpoints - It helps to understand the important parts of the key elements. - The report explains the major key factors of the market, for example, drivers, limitations, models and openings. - It offers a provincial survey on the global Automatic Edge Banding Machine market along with the business profiles of some partners. - It offers tremendous information on the introduction of new elements that will impact the advancement of the Global Automatic Edge Banding Machine

>>> Direct purchase Our report (Edition 2021) Below @ https://www.reporthive.com/checkout?currency=single-user-licence&reportid=2802507

TOC Highlights: Chapter 1. Introduction: The Automatic Edge Banding Machine research work report covers a concise introduction to the global market. This segment provides assessments of key participants, a review of Automatic Edge Banding Machine industry, outlook across key areas, financial services, and various difficulties faced by Automatic Edge Banding Machine Market. This section depends on the Scope of the Study and Report Guidance. Chapter 2. Outstanding Report Scope: This is the second most significant chapter, which covers market segmentation along with a definition of Automatic Edge Banding Machine. It characterizes the whole scope of the Automatic Edge Banding Machine report and the various features it is describing. Chapter 3. Market Dynamics and Key Indicators: This chapter incorporates key elements focusing on drivers [Includes Globally Growing Automatic Edge Banding Machine frequency and Increasing Investments in Automatic Edge Banding Machine], Key Market Restraints[High Cost of Automatic Edge Banding Machine], opportunities [Arising Markets in Developing Countries] and introduced in detail the arising trends [Consistent Innovate of New Screening Products] development difficulties, and influence factors shared in this latest report. Chapter 4. Type Segments: This Automatic Edge Banding Machine market report shows the market development for different kinds of products showcased by the most far-reaching organizations. Chapter 5. Application Segments: The analysts who composed the report have completely assessed the market capability of key applications and perceived future freedoms. Chapter 6. Geographic Analysis: Each provincial market is deliberately examined to understand its current and future development, improvement, and request situations for this market. Chapter 7. Impact of COVID-19 Pandemic on Global Automatic Edge Banding Machine Market: 7.1 North America: Insight On COVID-19 Impact Study 2021-2026 7.2 Europe: Serves Complete Insight On COVID-19 Impact Study 2021-2026 7.3 Asia-Pacific: Potential Impact of COVID-19 (2021-2026) 7.4 Rest of the World: Impact Assessment of COVID-19 Pandemic Chapter 8. Manufacturing Profiles: The significant players in the Automatic Edge Banding Machine market are definite in the report based on their market size, market served, products, applications, regional development, and other variables. Chapter 9. Estimating Analysis: This chapter gives price point analysis by region and different forecasts. Chapter 10. North America Automatic Edge Banding Machine Market Analysis: This chapter includes an appraisal on Automatic Edge Banding Machine product sales across major countries of the United States and Canada along with a detailed segmental viewpoint across these countries for the forecasted period 2021-2026. Chapter 11. Latin America Automatic Edge Banding Machine Market Analysis: Significant countries of Brazil, Chile, Peru, Argentina, and Mexico are assessed apropos to the appropriation of Automatic Edge Banding Machine. Chapter 12. Europe Automatic Edge Banding Machine Market Analysis: Market Analysis of Automatic Edge Banding Machine report remembers insights on supply-demand and sales revenue of Automatic Edge Banding Machine across Germany, France, United Kingdom, Spain, BENELUX, Nordic, and Italy. Chapter 13. Asia Pacific Excluding Japan (APEJ) Automatic Edge Banding Machine Market Analysis: Countries of Greater China, ASEAN, India, and Australia & New Zealand are assessed, and sales evaluation of Automatic Edge Banding Machine in these countries is covered. Chapter 14. Middle East and Africa (MEA) Automatic Edge Banding Machine Market Analysis: This chapter centers around Automatic Edge Banding Machine market scenario across GCC countries, Israel, South Africa, and Turkey. Chapter 15. Research Methodology The research procedure chapter includes the accompanying primary realities, 15.1 Coverage 15.2 Secondary Research 15.3 Primary Research Chapter 16. Conclusion >> [With unrivaled insights into the Automatic Edge Banding Machine market, our industry research will help you take your Automatic Edge Banding Machine business to new heights.] <<

>>>> For more customization, connect with us at @ https://www.reporthive.com/2802507/enquiry_before_purchase

Why Report Hive Research: Report Hive Research delivers strategic market research reports, statistical surveys, industry analysis and forecast data on products and services, markets and companies. Our clientele ranges mix of global business leaders, government organizations, SME’s, individuals and Start-ups, top management consulting firms, universities, etc. Our library of 700,000 + reports targets high growth emerging markets in the USA, Europe Middle East, Africa, Asia Pacific covering industries like IT, Telecom, Semiconductor, Chemical, Healthcare, Pharmaceutical, Energy and Power, Manufacturing, Automotive and Transportation, Food and Beverages, etc. Contact Us: Report Hive Research 500, North Michigan Avenue, Suite 6014, Chicago, IL – 60611, United States Website: https://www.reporthive.com Email: [email protected] Phone: +1 312-604-7084"

0 notes

Text

Flat Face Mask Machines Market SWOT Analysis by Players Insights from 2020-2026 | Beijing Silk Road Enterprise Management Services, Broadfair Automation Equipment, Chang Hong Machinery

The worldwide Flat Face Mask Machines Market is conscientiously looked into inside the report while generally focusing on top players and their business strategies, topographical development, advertise sections, serious scene, assembling, and evaluating and value structures. Each area of the examination study is extraordinarily arranged to investigate key parts of the overall Flat Face Mask Machines Market. for instance the market elements segment dives profound into the drivers, limitations, patterns, and chances of the overall Flat Face Mask Machines Market. With subjective and quantitative synthetic investigation , we help you with intensive and extensive research on the overall Flat Face Mask Machines Market.

The Objective of Flat Face Mask Machines market:

The Flat Face Mask Machines market report has been fragmented into key sections, for example, item types, end-clients, prime areas, and vital players. The perusers can evaluate point by point and strategical data about each fragment. The Flat Face Mask Machines market report likewise incorporates a mix of measurements about deals, utilization rate, volume, esteem, net edge and the sky is the limit from there

Request Sample Report at: http://www.marketresearchglobe.com/request-sample/1290487

Key players of the Global Flat Face Mask Machines Market-

Beijing Silk Road Enterprise Management Services

Broadfair Automation Equipment

Chang Hong Machinery

DG SOUTH NEKON

Dongguan BangYin Machinery

Dongguan Chuangyu Ultrasonic Machinery

Dongguan Huitong Automation Equipment

Dongguan Li Cheng Machanical Equipment

Healthy Machinery

KYD Automatic Mask Machine

Mabotex Engineering (CERA MECA group)

NCM Nonwoven Converting Machinery

RI EXIM

RUIAN YONGTAI MACHINERY

TESTEX

Top Rank Machinery (TRM)

Types is divided into:

Inner Ear Mask Machine

External Ear Mask Machine

Band Mask Machine

Applications is divided into:

Personal Health Care

Medical

Pharmaceutical

Food-Processing

Cosmetics

Electronics

Others

The size of Flat Face Mask Machines market is split supported the merchandise type, purchaser, and application segments. The industry growth of every segment is assessed along side the prediction of their growth within the near future. The relevant data and statistics gathered from the regulatory authorities are portrayed within the report back to assess the event of segments.

Significant Regions covered in this report:

North America, China,Europe, Japan, Southeast Asia, India, Central & South America

Check Discount for Report: http://www.marketresearchglobe.com/check-discount/1290487

The research report renders comprehending insight supported several types and applications. the merchandise types are further collected with the most target being on the price , revenue, rate of growth , market share, etc. Similarly, supported the applications, the report aims the expansion rate, market share of Flat Face Mask Machines in each application.

The study objectives are:

To analyze and research the worldwide Flat Face Mask Machines capacity, production, value, consumption, status and forecast.

To specialise in the key Flat Face Mask Machines manufacturers and study the capacity, production, value, market share and development plans in next few years.

To focuses on the worldwide key manufacturers, to define, describe and analyze the market competition landscape, SWOT analysis.

Offers unique insights into the decision-making process for any category which will aid in strategic decision-making.

To analyze the worldwide and key regions market potential and advantage, opportunity and challenge, restraints and risks.

Market size estimate of the regionally and internationally focused infotainment marketplace for vehicles.

To analyze the opportunities within the marketplace for stakeholders by identifying the high growth segments.

Unique research methodology supported the dynamics of market.

Scope to hide all potential categories which will assist all stakeholders within the Flat Face Mask Machines market industry.

Enquire Additional Concerning the Report at: http://www.marketresearchglobe.com/send-an-enquiry/1290487

Customization of this Report: This Flat Face Mask Machines report could be customized to the customer's requirements. Please contact our sales professional ([email protected]), we will ensure you obtain the report which works for your needs.

0 notes

Text

Manual Edge Banding Machine

Manual Edge Banding Machine is used to glue PVC edge bands on the plywod,, particle board, MDF and related materials. We can provide edge bander machine for gluing of pvc strips on the edges of the Honeycomb panels, wood and other variations as well as per client requirement.

Manual Edge Banding machine is capable of provide high strength glued strips. Manual Edge Banding Machine is suitable for Straight and Curved and so the Edge Banding Machine is also called Curvilinear Edge Banding Machine.

#Edge Banding Machine#Woodworking edge banding machine#Manual Edge Banding Machine#woodworking edge banding machine#Automatic edge banding machine#Edge banding equipment#Industrial edge banding machine#Edge banding machine price in india#automatic edge banding machine price in india#edge banding machine manufacturers in india#Manual Edge Bander Machine#Edge banding machine manufacturer near me#top edge banding machine manufacturers in india#Edge Banding Machine for Wooden Furniture#woodworking#wood#tools#furniture#manufacturer#machine#woodworker#edgebandingmachine#india#panelsaw

1 note

·

View note

Text

Edge Banding Machine Market 2019 Global Trends, Size, Segment, Emerging Technologies

28 January 2019: Edge Banding Machine Market is expected to witness an exponential growth over forecast year. Edge banding is a type of process which is generally attached with a strip of narrow material majorly used for creation of aesthetically and durable fine trim edges in finish carpentry. Edge banding technology is used majorly to cover materials such as particle, particle board, plywood and MDF to cover the exposed sides owing to increasing strength and, appearance and durability for valuable material support. There are different substitutes for edge banding such as molding or face frames. The materials from which edge banding can be produced include melamine, ABS, acrylic, wood, PVC and wood veneer.

Easy availability of materials and ordinary tools for carpentry are mostly used for traditional edge banding owing to its manual process. However with advent of technology and advanced procurement process modern applications are majorly used for those processes which involve high in volume and recursive steps applied in manufacturing owing to alignment of cabinet doors. Using hot melt adhesive process edge banding has accounted high application by substrate automation process. These types of adhesives can be either solvent based which consists of many raw materials such as PUR, APOA, EVA, PA and PO or water based coupled with application oriented substrate based primer owing to its high usage as bonding agent between the substrate and the adhesives.

Request Sample Copy of This Market Research @ https://www.millioninsights.com/industry-reports/edge-banding-machine-market/request-sample

Global edge banding machine industry can be segmented on the basis of product type which includes manual edge banding machine and automatic edge banding machine. Based on size the global industry is segmented on the basis of portable edge banding machine and larger ambition edge banders and on the basis of application the global market is further divided into single-sided machine, double-sided machine and post forming. Application based edge banding machines are majorly used to produce a gamut of wood products with economy, utmost speed and quality. These widely diversified product portfolio have accounted high applications from wood working shop floors to high end process engineering plants and machines. Edge banding machines are coupled with several pioneering technologies such as synchronous and linear motors owing to its complete customer solutions from joining, trimming, sizing and to grooving and universal trimming of wood works.

The key industry players in this market include Felder Woodworking Machines Private Limited, Caple Industry solutions, Dellatecnica, Jai Industries, Printo, Biesse Manufacturing Co. Pvt. Ltd., Woodtech Consultants Pvt. Ltd., Sinic Electronics Private Limited., Atlas Machines, Novelty Implex, Shree – Umiya F-Tech Machines, Shanghai Zongtai Plastic Products Co., Ltd., Guangdong Firmy Machinery Co., Ltd., Luli Group Co., Ltd., Shanghai Peicheng Decoration Material Co. Ltd., Shanghai Jianhai Decorations Materials Co., Ltd., Shenzhen JYC Technology Ltd., Shouguang Yusen Wood Products Co., Ltd., Shenzhen Lian Da Sponge Product Co., Ltd., and others.

Browse Full Research Report @ https://www.millioninsights.com/industry-reports/edge-banding-machine-market

Edge Banding Machine Market by Geographical Regions:-

• North America

• Europe

• China

• Japan

• Southeast Asia

• India

Edge Banding Machine Market by Applications:-

• Furniture Industry

• Building Material Industry

• Other

Get in touch

At Million Insights, we work with the aim to reach the highest levels of customer satisfaction. Our representatives strive to understand diverse client requirements and cater to the same with the most innovative and functional solutions.

Contact Person:

Ryan Manuel

Research Support Specialist, USA

Email: [email protected]

Million Insights

Office No. 302, 3rd Floor, Manikchand Galleria,

Model Colony, Shivaji Nagar, Pune, MH, 411016 India

tel: 91-20-65300184

Email: [email protected]

Visit Our Blog: www.millioninsights.blogspot.com

0 notes

Text

Edge Banding Machines 101: An Introductory Guide for Woodworking Enthusiasts

Have you ever admired the flawless finish on professionally crafted cabinets or furniture? That seamless edge, where the material meets the core, is often the result of an ingenious tool called an edge banding machine. For woodworking enthusiasts, incorporating edge banding into your projects can significantly elevate their aesthetics, functionality, and overall quality. This beginner-friendly guide dives into the world of edge banding machines, empowering you to take your woodworking skills to the next level.

Understanding the Magic of Edge Banding

At its core, an edge banding machine applies pre-veneered edging material (think ABS, PVC, or melamine) to the raw edges of wood panels. This not only enhances the visual appeal by concealing the core material but also offers several practical benefits:

Improved Durability: Exposed edges are susceptible to moisture damage and chipping. Edge banding acts as a protective barrier, safeguarding the core material and extending the lifespan of your creations.

Enhanced Safety: Raw edges can be sharp and pose a splinter hazard. Edge banding eliminates this risk, creating a safer environment in your workshop.

Professional Finishing Touch: A flawlessly finished edge elevates the perceived value of your woodworking projects, making them stand out from the DIY crowd.

The Two Main Categories of Edge Banding Machines

As you embark on your edge banding journey, you'll encounter two primary machine types:

Manual Edge Banding Machines: These are ideal for hobbyists or workshops with occasional edge banding needs. The operator feeds the edging material and panel through the machine, offering greater control but requiring more physical effort.

Automatic Edge Banding Machines in India: Perfect for high-volume production environments, these machines automate most of the edging process. Features like automatic feeding, trimming, and buffing significantly enhance efficiency and consistency.

Choosing Your First Edge Banding Machine: Navigating the Options

The ideal edge banding machine for your needs depends on several factors:

Workshop Space and Budget: Manual machines are generally more affordable and require less space, making them suitable for smaller workshops. Automatic machines offer superior efficiency but require a larger budget and dedicated workspace.

Project Volume and Complexity: For occasional projects, a manual machine might suffice. However, if you envision high-volume production or intricate designs, an automatic machine might be a worthwhile investment.

Desired Level of Control: Manual machines offer greater control over the edge banding process. Automatic machines prioritize speed and consistency.

Portable Options: Edge Banding on the Go

For woodworking enthusiasts who require flexibility or work on-site installations, portable edge banding machines offer a compelling solution. These compact machines deliver surprisingly impressive results, often featuring functionalities like pre-milling and edge trimming.

Essential Considerations Before You Buy

Before diving headfirst into purchasing an edge banding machine, consider these additional factors:

Edging Material Compatibility: Ensure the machine you choose is compatible with the edging material you plan to use (thickness, type).

Safety Features: Look for machines with safety features like dust collection and emergency shut-off switches.

Availability of Replacement Parts and Customer Support: Reliable access to replacement parts and knowledgeable customer service can be invaluable in the long run.

The Learning Journey Begins: Resources for Budding Edge Banding Enthusiasts

The world of edge banding machines might seem intimidating at first. Here are some resources to equip you for success:

Manufacturer Manuals: Consult the user manual that comes with your chosen machine. It provides detailed instructions on operation, maintenance, and troubleshooting.

Online Tutorials: Numerous online tutorials demonstrate the edge banding process on various machines. These visual resources can be a great way to grasp the practical aspects.

Woodworking Communities: Online woodworking forums and communities are excellent platforms to connect with experienced woodworkers who can offer valuable advice and answer your specific questions.

Conclusion: Edge Banding – A Gateway to Professional Woodworking

By incorporating edge banding into your woodworking projects, you'll not only elevate their aesthetics and functionality but also demonstrate a commitment to detail and quality. With the knowledge gained from this guide and the vast array of edge banding machines available, from manual and portable options to automatic machines in India, there's a perfect machine waiting to empower you to achieve professional-grade finishes in your workshop. So, grab your woodworking tools, embrace the world of edge banding, and embark on a journey of creative exploration!

0 notes

Text

Advantages and Disadvantage Of Band Saw Cutting Machine

Precision Cutting

One of the most significant benefits of a band saw is its ability to create precise cuts. You can make complicated curves, clean edges, and accurate angles with the correct blade installed. As a result, it’s an ideal tool for making intricate woodworking projects.

Versatility

Another advantage of a band saw is its adaptability. This cutting tool is suitable for a wide range of materials, including wood, metal, plastic, and others. It can be used for a variety of purposes ranging from furniture making to metalworking.

Safety Features

Many contemporary band saws are equipped with safety measures that lower the possibility of mishaps. Blade guards, automatic shutoff, and safety switches fall within this category. Although these features don’t replace safe work practices, they can offer an additional degree of security.

Zeal Tech Automation is a leading Vertical Band saw Machine Manufacturer in Pune that provides advanced safety features to ensure the safety of the operator.

Efficiency

A band saw can help you operate more productively since it can make prompt, accurate cuts. If you’re working on a project that requires numerous complex cuts, this is especially true. You can achieve better results and save time using a band saw.

Flexible

Besides cutting lumber, you can cut meat, and even metal with bandsaw. Thicker blades are available for heavy cutting, while thinner blades are available for delicate and precise cuts.

Disadvantages of Band Saw Cutting

Cost

The price of a band saw is one of its main disadvantages. These devices can be pricey, especially if you want a high-end model. Even if the initial expenditure could be high, if you intend to use the equipment frequently, it might be worthwhile.

Space

A band saw’s potential for taking up a lot of room in your workshop is another drawback. Since these tools are frequently fairly large, a separate workspace is needed. There might be other solutions available if you have a little workspace than a band saw.

Maintenance

A band saw needs routine maintenance to stay in good operating order, just like any cutting tool. This may entail lubricating the mechanism, changing the blade, and adjusting the tension. There may be other options available than a band saw if you’re uncomfortable performing this upkeep.

Noise

It’s important to remember that band saws can be fairly loud. This might be acceptable if you have a separate workspace, but if you work in a shared environment or have noise sensitivity, a band saw might not be the ideal choice.

Conclusion

Zeal Tech Automation is a prominent producer of High Speed Circular Sawing Machines and Band Saw Machines. Please contact us for band saw machine pricing in India and high-speed band saw metal cutting machine expenses. We are the market leader in industrial band saws.

As with any tool, there are advantages and disadvantages to using a Horizontal Band saw For Metalworking and woodworking operations. However, there may be considerable constraints in terms of cost, space needs, maintenance, and noise level. Finally, you’ll need to carefully consider the benefits and drawbacks to determine whether a band saw is the best tool for your needs.

#circular saw machine#mechanicalmachines#vertical band saw machines#circularsawmachine#bandsawmachine#circularsawmachinebenefits#vertical band saw machine#mechanical services

0 notes

Text

Corrugated Box Making Machinery

This automatic BOXMATIC machine is good for the production of corrugated packing containers, trays, partitions and minimize-outs with the option of extra die-cuts and flexo printing. Designed to be strong, they are comprised of corrugated paperboard, paper straws making machine which accommodates air columns. Now we have a gradual raw material provide chain and produce most elements of the machines in-house. The paperboard and cardboard trade demand been comparatively steady for the previous 5 years. The corrugator machine cuts each board plenty of occasions, depending on the dimensions of the box. At the start of this process, kraft rolls from the paper mill are loaded into an enormous machine referred to as a corrugator. The cardboard box manufacturing trade is the biggest paper-changing trade within the USA. Corrugated packing containers are used for packaging shopper and industrial items. It's not simply , but other homegrown e-commerce companies are additionally using cardboard packages over plastic packaging. Depending on the required energy of the box, corrugated boxes could also be made of 1, two, or three layers of flutes and liners. Integrated in the year 2009, we Krishna Gross sales Corporation” are counted because the reputed manufacturer and dealer of Corrugated Field Making Machine, Rotary Die Reducing Machine, Corrugated Carton Making Machine, Corrugated Board Plant, and many others. Compack machines may be arrange as a single feed, an inline feed (with as much as 4 automated, raw material sources feeding into the machine), or as a lateral (side by facet) feed with as much as four automatic corrugated feeds. Briefly, you need to observe the Air Pollution Prevention and Management Act, requirements and regulation and even food-associated laws if you are producing boxes for the food trade. Design & Manufacturing of Corrugated Packaging & Displays. Whether or not you are a box plant, or an end-user looking to create customized bins in-home, our machinery is cutting-edge and will cater to your wants. When manufacturing boxes we speak about two various kinds of liners, that is the material that lies on top and beneath the fluting and creates a corrugated board. The CORRUGATED FIELD MAKING EQUIPMENT import commerce sector contributes significantly to the overall GDP proportion of India. Moreover, with the sustainability issue on the rise, we are able to expect much more packaging companies sooner or later who will bring distinctive designs and produce a variety of bins from quite a lot of paper materials. Cardboard Assistance is a participant within the Amazon Services LLC Associates Program, an affiliate advertising program designed to offer a method for websites to earn advertising charges by advertising and linking to Cardboard Assist additionally participates in affiliate packages with Clickbank, CJ, ShareASale, Homedepot and different websites. Being a B2B business, you will have everlasting clients who will want bins frequently. He named it the kraft process as a result of it produces a powerful paper that resists tearing, splitting, and bursting. It has paper feeding unit, adjusted unit, glue unit, forming unit, completed merchandise gathering unit and in addition counting unit. As a result of this machine is so quick to set up it results in very low price bins of the very best grade for each small and large runs. In case of continuous manufacturing it only takes 30 seconds per field. The Corrugated & Paperboard Container Trade: An Analysis of Current Markets & Prospects for Future Development. We offer six totally different paper cup machines SPB seven-hundred, SPB 750, SPB 850, SPB Tremendous 850, SPB 950, SPB Tremendous 950. The rising consumption of meals across globe that fuels the expansion of the food packaging business and the rising demand for meals and beverage products that will drive the demand for corrugated containers, will increase the expansion prospects of the market on this segment. Considering right this moment's scenario, it's secure to say that cardboard field manufacturing is a lucrative enterprise. In comparison with plastics, styrofoam and other supplies, the folding carton and corrugated cardboard containers are thought of to be a greater green packaging solution by the consumers. Over past 4 years, we now have invested over 1 Million dollars to develop our aggressive box machines, it consists of BM2506 small box making machine, BM1206 short run field making machine, and BM2508 cardboard box making machine.

Thanks for choosing BestPack, your complete tape sealing, carton erecting answer provider, field erector provider and case sealer solution supplier. Lastly, batches of completed boxes are banded together for delivery to the food processor, toy maker, automobile parts distributor, or any of the 1000's of businesses that depend upon corrugated cardboard packaging. MDPI assures nice effectivity for terribly small-amount corrugated packing containers of many different sizes. Corrugated cardboard is a stiff, robust, and lightweight material made up of three layers of brown kraft paper. The FEFCO (European Federation of Corrugated Board Producers) information is the bible of corrugated cartons, and outlines each style you would imagine - with several categories together with 01 categories for commercial rolls and sheets, 02 for slotted-kind bins utilizing one piece of glued board, 03 for telescope model containers consisting of multiple piece (often a bottom and lid design), 04 for folder kind packing containers similar to guide wrap mailers and 05, 06, 07, 08 and 09 which include more complicated styles. The key market driver for corrugated field making machines market arises from the rapid development in many African countries, which is expected to increase the demand for FMCG and electronics merchandise, owing to the fast progress in middle-class population and general disposable incomes. You get the advantages of over forty years of field and corrugated cardboard expertise, providing your company with the instruments it needs to satisfy buyer calls for - no matter the form of field, pallet or carton they require. We have provided the very best degree of equipment to a whole lot of field crops around the world, as well as enabling end-user businesses to take management over their packaging and lower your expenses. Accessible to cope with pressing calls for corrugated bins. Automatic Carton Erecting Machine with agency construction, top quality, low noise and excessive efficiency. The demand for retail-prepared corrugated boxes is anticipated to extend by 7 percent each year making up to $3 billion by 2020. The rising urbanization and the expansion in center class inhabitants that led to the increase in gross sales of merchandise from varied industries will subsequently rise the demand for corrugated containers. As short and medium-run machines, the AutoBox or Boxer take the load from high pace changing equipment, allowing long-run machines to work without interruption and with most efficiency. This shift among shopper demand has compelled producers to take vital measure to make their boxes atmosphere-pleasant, on the identical time letting consumers know of their efforts to attract prospects. Aside from the mentioned information,progress rateof Corrugated Field Making Machine market in 2025is additionally defined.Additionally, sort smart and application smart consumptiontables andfiguresof Corrugated Field Making Machine marketare additionally given. Having recently invested in further technological advances inside the manufacturing area CartonPack is properly poised to be able to meet the adjustments needs of your production requirements. Paperboard packaging is constituted of recycled products and is best than fossil gasoline-based mostly plastic packaging. We now have a leading organization in offering a supreme high quality assortment of Carton Box Making Machineto our customers. With increasing urbanization and growth of the middle-class inhabitants, the demand for varied products across totally different industries is expected to grow throughout the forecast period. Paper Board 200-600gsm; corrugated board paper with thickness not exceed 1.5MM. Gigantic, sq. buildings up to 600 feet long (182.88 meters), these machines include a wire mesh by which the paper is initially fashioned. World demand for cardboard bins is ever growing with almost 60% of all paperboard packaging products getting used in the meals segment including beverages, dairy merchandise, dry foods, frozen meals etc.

0 notes

Link

Based at Vadodara, Gujarat, India, we, "Multicut Machine Tools," are a prominent name engaged in the manufacturing of Bandsaw Machine. Our products are available in different models and the entire range includes Fully Automatic Double Column Band Saw Machine, Semi-Automatic Double Column Band Saw Machine, CNC Fully Automatic Bandsaw Machine, Swing Type Fully Hydraulic Bandsaw Machine, Swing type manual Bandsaw Machine, Mitre Cutting Bandsaw Machine, Hydraulic Power Packs, Hydraulic Cylinders and Vertical BandSaw Machine. Our machines are manufactured using cutting edge technologies and are customized according to the industry applications. The Band Saw Machines manufactured by us have a cutting capacity of 200 mm to 2000 mm, and may vary according to the models. We have a sound and sophisticated infrastructure that includes large production units.

http://multicut.in/

#bandsaw#bandsaw machine#Bandsaw_machine#band saw#bandsaw manufacturer#band saw manufacturer#india#Bandsaw_machine_manufacturer_vadodara#gujarat#vadodara

8 notes

·

View notes