#CNCmachine

Text

How do you process carbon fiber brake discs?#carbonfiber #brakedisc #cncmachine #cncmachining #cnc #machine #cncmachinist #cncmillingmachine #cncrouter #cncporn #cncmill #cncmilling #cncplasma #cnclathe #cnccutting #cnclaser #cnctools #machinist #tools #cncprogramming #mold #components #machinetools #jinsucnc #5axis #cncoperator #factory #machining #fyp

#cnc milling#cncmachine#cncmachine tools#cncmachining#cncmill#cncrouter#cnctool#machine#cnc lathe#tool

5 notes

·

View notes

Text

What is a difficult-to-process material?

When difficult-to-process materials are mentioned, different images of materials come to mind. Among them are materials with low thermal conductivity such as titanium alloys. So far, we have been working on hard-to-cut materials such as titanium alloys processing dozens of products every year, and have accumulated daily processing experience.

And based on these records, we provide the best processing conditions for each product. In addition, special tools from our tool suppliers have solved the challenges of machining accuracy and productivity for us. Now, TPV Precision Machining can achieve high precision machining with tolerance width ± 0.003mm, low thermal expansion material area of 1000mm x 1000mm, and flatness of 0.02mm or less.

In the field of machined parts, we are engaged in a wide range of fields such as aircraft, automobiles, semiconductor manufacturing equipment, liquid crystal exposure equipment, and medical equipment, and have contributed greatly to supporting cutting-edge technology. And we have received high praise from our customers.

#machining#sales#communication#cncmachining#cncmanufacturing#cncmilling#cncmachine#cncmachinist#cncmachiningparts#cncgrinding#precisionmachining#precisionengineering#precision#precisionmanufacturing#3axis#4axis#5axis#5axismachining#5axiscnc#rapidprototyping#rapidtooling#rapid#automaticmachine#automative#medical#energi#car#millingmachine#turning#elections

2 notes

·

View notes

Text

The Benefits and Applications of CNC Plasma Cutting Machines in Present day Assembling

In the present assembling landscape, precision, speed, and versatility are urgent for progress. One device that has reformed the metalworking industry is the CNC plasma cutting machine. With its capacity to slice through different metals with unrivaled accuracy and proficiency, CNC plasma cutting machines have become fundamental in industries like automotive, construction, and fabrication.

This blog will investigate the key features, benefits, and applications of CNC plasma cutting machines and why they are an important resource for organizations.

What is a CNC Plasma Cutting Machine?

CNC stands for "Computer Numerical Control," an innovation that robotizes the control of machining instruments utilizing a computer. In a CNC plasma cutting machine, a plasma light is used to slice through metals like steel, aluminum, and copper. Plasma is made when an electrically conductive gas (like compacted air or oxygen) is ionized, creating a hot, high-energy stream fit for cutting through metal.

The cutting system is controlled by computer software, which coordinates the development of the plasma light with unbelievable precision. This computerization takes into account highly exact cuts that are repeatable, making CNC plasma cutting machines ideal for both limited scope ventures and large scale manufacturing.

Key Benefits of CNC Plasma Cutting Machines

1. High Precision and Accuracy

One of the greatest benefits of CNC plasma cutting machines is their capacity to convey highly exact cuts. By adhering to advanced guidelines, the machine can cut complex shapes and perplexing plans with predictable accuracy. This precision is crucial for industries that require point by point parts, for example, the automotive or aerospace areas.

2. Faster Cutting Speeds

CNC plasma cutting machines work at a lot higher speeds contrasted with customary cutting techniques like oxy-fuel or mechanical cutting. This outcomes in faster venture completion times and higher creation proficiency. For organizations handling enormous volumes of metal fabrication, this speed can essentially decrease work costs and work on in general efficiency.

3. Versatility Across Multiple Metals

A CNC plasma cutting machine is highly flexible, fit for cutting through many conductive metals, including gentle steel, treated steel, metal, copper, and aluminum. Whether you're chipping away at modern parts or artistic metalwork, this machine can handle different materials and thicknesses effortlessly.

4. Cost-Effective and Efficient

Albeit the underlying interest in a CNC plasma cutting machine might appear to be high, the drawn out benefits offset the costs. These machines are energy-efficient, and their high speed implies less time and work are expected to finish projects. Also, their precision diminishes material waste, setting aside organizations cash over the long haul.

5. Smaller Heat-Affected Zones

CNC plasma cutting produces less heat contrasted with different strategies, bringing about smaller heat-affected zones (HAZ). This is significant because overabundance heat can twist or contort the metal, influencing the nature of the eventual outcome. By limiting the HAZ, CNC plasma cutting guarantees that the material holds its trustworthiness, making it ideal for high-quality completions.

6. Ease of Use

Present day CNC plasma cutting machines accompany user-accommodating points of interaction and software that permit administrators to stack and adjust cutting projects without any problem. With essential preparation, administrators can immediately become proficient in utilizing these machines, further expanding productivity and diminishing the requirement for particular work.

Applications of CNC Plasma Cutting Machines

Because of their precision, speed, and versatility, CNC plasma cutting machines are generally used in different industries. Probably the most widely recognized applications include:

1. Automotive Industry

CNC plasma cutting machines are much of the time used in the automotive industry for making and fixing metal parts. The precision of CNC plasma cutters permits makers to deliver custom vehicle parts and models rapidly and efficiently. Moreover, they are used for cutting complex shapes required in vehicle casings, sections, and boards.

2. Construction and Fabrication

In construction and general metal fabrication, CNC plasma cutters are used to make primary parts, metal structures, and custom parts for different tasks. Their capacity to handle both huge scope and complicated plans makes them fundamental for all that from building construction to custom metal establishments.

3. Artistic Metalwork and Signage

Past modern applications, CNC plasma cutting machines are additionally well known in the realm of artistic metalwork. Specialists and originators use these machines to create itemized models, improving pieces, and custom signs. The capacity to definitively cut complex plans makes CNC plasma cutting ideal for making artistic and structural features.

4. Shipbuilding and Aerospace

In industries like shipbuilding and aerospace, where high precision and strength are required, CNC plasma cutting machines are imperative. The capacity to precisely slice through thick steel and aluminum with negligible bending guarantees that basic parts satisfy security and performance guidelines.

5. Salvage and Recycling Operations

CNC plasma cutting machines are additionally used in salvage and recycling yards to immediately slice through metal for reusing or removal. Their speed and proficiency make them ideal for stalling enormous metal designs, vehicles, or hardware for recycling purposes.

Variables to Consider While Picking a CNC Plasma Cutting Machine

While putting resources into a CNC plasma cutting machine, there are a few variables to consider to guarantee you select the right hardware for your necessities:

Cutting Capacity: Decide the thickness and kinds of metals you'll work with to guarantee the machine can handle your necessities.

Software Compatibility: Ensure the machine is viable with the plan software you intend to use. Most CNC plasma cutters accompany pre-introduced software, yet guarantee it suits your work process.

Machine Size: Think about the size of the machine corresponding to your work area. Bigger machines might offer greater adaptability yet require more space.

Backing and Upkeep: Settle on a maker that gives fantastic after-deals backing and support administrations to guarantee the life span of your machine.

Conclusion

CNC plasma cutting machines have transformed metal fabrication by offering a mix of high precision, speed, and versatility. Their capacity to handle different metals and their cost-productivity make them an important resource for industries going from automotive and construction to artistic metalwork and recycling.

For organizations hoping to smooth out their assembling cycle, decrease costs, and further develop efficiency, putting resources into a CNC plasma cutting machine is a shrewd move. With mechanical headways proceeding to push the abilities of these machines, they are ready to stay a fundamental device coming soon for present day metalworking.

#cncplasmacuttingmachine#cncplasmacuttingmachinemanufacturer#Manufacturers#Metweld#cncmachine#cncplasmacutter

0 notes

Text

HUNSONE Precision Bending 2mm Steel Plate

0 notes

Text

👏👏Today we are thrilled to announce the latest addition to CNC Pro team @felipeandradetattooink in Lisboa, Portugal.

We hope more tattoo artists will join our pro team. 🤝🤝

Online shop: https://bit.ly/3UP3erA

0 notes

Text

What are the main components of a CNC Vertical Machine? | SBV Engineering Works Coimbatore

Main Components of a CNC Vertical Machine

A CNC Vertical Machine is an advanced manufacturing tool widely used in industries for its precision, efficiency, and versatility. These machines automate complex tasks such as cutting, milling, drilling, and shaping materials, mainly metals and plastics. To understand the functionality and importance of CNC vertical machines, it is crucial to explore their main components.

Machine Frame

The machine frame is the backbone of a CNC vertical machine. Typically made from cast iron or steel, it provides structural integrity and stability to the entire setup. The rigidity of the frame is vital as it minimizes vibrations and ensures precision during machining operations. The frame houses and supports other critical components, such as the spindle, worktable, and guideways.

Spindle

The spindle is one of the most critical components of a CNC vertical machine. It is responsible for holding and rotating the cutting tool at various speeds, depending on the material and operation being performed. Spindles in CNC machines are typically powered by electric motors and can achieve very high rotational speeds, enabling precise and efficient material removal. The quality and performance of the spindle directly impact the machine’s accuracy and surface finish of the workpiece.

Worktable

The worktable, also known as the bed or table, is the platform where the workpiece is securely clamped or fixtured during machining. The worktable moves along the X and Y axes to position the workpiece under the spindle for machining operations. Many CNC vertical machines feature T-slots or grid patterns on the worktable, allowing flexible and secure clamping of various workpieces. The worktable's movement is controlled by precision ball screws and linear guideways, ensuring smooth and accurate positioning.

Control System

The control system is the brain of a CNC vertical machine. It interprets the G-code or machine instructions, which are programmed commands that dictate the movement and operations of the machine. Modern CNC machines utilize advanced computer control systems equipped with user-friendly interfaces, allowing operators to input, modify, and monitor machining parameters easily. The control system coordinates the movement of the spindle, worktable, and other components to execute complex machining tasks with high precision.

Motors and Drives

Motors and drives are essential for the movement of various machine components. Stepper motors or servo motors, coupled with precision ball screws and linear guideways, enable the controlled movement of the spindle, worktable, and other axes. Servo motors, known for their high torque and accuracy, are commonly used in CNC machines. These motors receive signals from the control system and translate them into precise mechanical movements, ensuring accurate positioning and repeatability.

Tool Changer

Many CNC vertical machines are equipped with an automatic tool changer (ATC). The ATC allows the machine to switch between different cutting tools without manual intervention, significantly increasing productivity and reducing downtime. The tool changer typically consists of a carousel or linear magazine that holds multiple tools, and a robotic arm or similar mechanism that exchanges tools as needed during the machining process.

Coolant System

The coolant system plays a crucial role in maintaining the temperature of the cutting tools and workpiece. During machining, cutting tools generate significant heat due to friction. The coolant system delivers a steady flow of coolant, usually a mixture of water and soluble oil, to the cutting zone. This not only reduces heat but also lubricates the cutting process, prolonging tool life and ensuring a better surface finish.

Enclosure

The enclosure, or machine cabinet, serves multiple purposes. It contains the machining area, protecting the operator from flying debris, coolant splash, and noise. The enclosure also helps in containing the coolant within the machine, reducing wastage and maintaining a cleaner work environment. Many CNC machines feature transparent panels in the enclosure, allowing operators to monitor the machining process safely.

Sensors and Feedback Systems

Modern CNC vertical machines are equipped with various sensors and feedback systems that enhance accuracy and reliability. These sensors monitor parameters such as tool position, spindle speed, temperature, and vibration. Feedback systems provide real-time data to the control system, enabling dynamic adjustments to optimize machining performance and prevent errors.

conclusion

CNC vertical machines are sophisticated tools composed of several integral components working in harmony. Each component plays a vital role in ensuring precision, efficiency, and productivity in modern manufacturing processes. Understanding these components provides insight into the complex yet fascinating world of CNC machining.

See more: https://www.sbvengineering.com/

#cncmachine#cncturningmachinejobwork#cnccompany#cncmachinejobwork#cncverticalmachining#cncmachineshop#horizontal milling and boring machine#commercial

0 notes

Text

Renishaw FORTiS-S™ enclosed linear encoders

Next-generation enclosed linear absolute encoders for use in harsh environments.

🔹High Accuracy

🔹Easy to Installation

🔹Superior reliability

#encoders#linearencoders#harshenvironments#cncmachine#machinespart#importantpart#machine#industries#installation#Accuracy

0 notes

Text

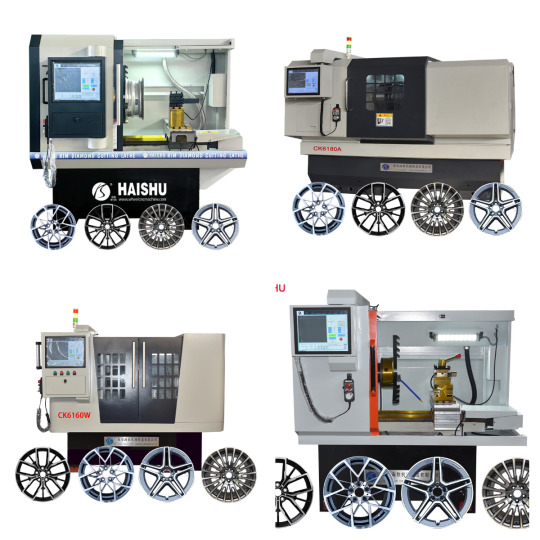

Car wheel rim repair cnc lathe machine equipment#wheelrepair#wheellathe#wheelmachine

0 notes

Text

Copper mold sample test made by CNC milling machine. #copper #cncmachine #cncmachining #cnc #machine #cncmachinist #cncmillingmachine #cncrouter #cncporn #cncmill #cncmilling #cncplasma #cnclathe #cnccutting #cnctools #machinist #tools #cncprogramming #mold #components #machinetools #jinsucnc #5axis #cncoperator #factory #machining #aluminum #instagram #fyp

#cnc milling#cncmachine#cncmachine tools#cncmachining#cncmill#cncrouter#cnctool#machine#cnc lathe#tool

4 notes

·

View notes

Text

Discover how CNC machined components drive India's industrial development! Precision, efficiency, and innovation are transforming manufacturing and boosting growth.

Read More at - https://www.parulinduscorp.com/blogs/india-development-through-cnc-machined-components

0 notes

Text

Opening Accuracy and Efficiency with CNC Plasma Cutting Machines

Opening Accuracy and Efficiency with CNC Plasma Cutting Machines

In the advanced landscape of assembling and metal manufacture, accuracy and efficiency are non-debatable. The CNC plasma cutting machine has arisen as a groundbreaking device, changing how we approach metal cutting. Joining trend setting innovation with outstanding exactness, these machines have become crucial in different businesses. This blog investigates the various benefits of CNC plasma cutting machines and their wide applications.

What is a CNC Plasma Cutting Machine?

A CNC (Computer Numerical Control) plasma cutting machine is a mechanized framework intended to cut metals with high accuracy. The interaction includes utilizing a plasma light that creates a hot plasma bend to soften through the metal. This light is directed by a computer-controlled framework, taking into consideration unpredictable cuts and complex shapes with insignificant manual mediation.

The CNC part of the machine alludes to its capacity to adhere to exact directions encoded in a computer program. This robotization guarantees that each cut is reliable and exact, fundamentally diminishing the potential for human mistake.

Advantages of CNC Plasma Cutting Machines

1. Remarkable Accuracy and Precision

One of the standout highlights of CNC plasma cutting machines is their accuracy. Dissimilar to customary cutting techniques, which can be inclined to irregularities, CNC plasma cutters work in light of accurate numerical information. This takes into account complex plans and nitty gritty cuts, guaranteeing that each piece fulfills rigid quality guidelines. Whether you're dealing with complex modern parts or fragile creative plans, CNC plasma cutting machines convey unparalleled exactness.

2. Speed and Efficiency

In this present reality where time is cash, CNC plasma cutting machines succeed by conveying fast outcomes. These machines can slice through metals at high speeds, which is especially useful for enormous scope creation runs. The efficiency of CNC plasma cutting converts into quicker completion times and reduced work costs. Projects that could have required hours or even days with manual techniques can be finished in a small part of the time.

3. Versatility Across Materials

CNC plasma cutting machines are famous for their versatility. They can handle a great many metals, including steel, treated steel, aluminum, metal, and copper. This makes them appropriate for different applications, from modern assembling and development to imaginative metalwork and custom creation. The capacity to work with various materials expands the scope of tasks that can be attempted, taking care of assorted needs and enterprises.

4. Cost-Effectiveness

While the underlying interest in a CNC plasma cutting machine can be huge, the drawn out cost benefits are impressive. These machines diminish the requirement for physical work, limiting human mistake and related costs. Furthermore, the rapid cutting ability diminishes creation time, prompting by and large cost reserve funds. The decrease in material wastage and the machine's capacity to handle numerous errands productively add to its cost-effectiveness.

5. Reduced Heat-Affected Zones

Plasma cutting produces less heat contrasted with other cutting strategies, bringing about more modest heat-affected zones (HAZ). This is pivotal for keeping up with the respectability of the metal and forestalling twisting or bending. The controlled use of heat guarantees that the eventual outcome holds its ideal properties, which is especially significant for accuracy parts and top notch wraps up.

Uses of CNC Plasma Cutting Machines

The versatility of CNC plasma cutting machines makes them significant across a large number of businesses:

Automotive Industry: CNC plasma cutters are utilized for creating and fixing automotive parts. Their accuracy takes into account the production of complicated parts and hand crafts, improving both usefulness and style.

Development and Modern Assembling: In development and assembling, CNC plasma cutting machines are utilized to make underlying parts, machinery parts, and hardware. Their capacity to handle huge scope projects with accuracy makes them fundamental for modern applications.

Creative and Beautiful Metalwork: Specialists and architects use CNC plasma cutting machines to make many-sided metal figures, signs, and other enhancing things. The machine's accuracy and versatility empower the production of itemized and specially crafts that would be trying to accomplish with manual techniques.

Rescue and Reusing: In rescue activities, CNC plasma cutters are utilized to proficiently deal with salvaged material. The capacity to slice through different metals rapidly makes them ideal for reusing and reusing materials.

Picking the Right CNC Plasma Cutting Machine

Choosing the proper CNC plasma cutting machine includes a few contemplations:

Cutting Capacity: Survey the thickness of materials you will be working with and guarantee the machine can oblige it. Substantial activities require all the more impressive machines.

Software and Compatibility: Guarantee that the machine is viable with your plan software. Easy to use software can work on the cutting system and further develop efficiency.

Support and Service: Select a producer that offers far reaching support and after-deals service. Dependable support is critical for keeping up with machine execution and resolving any issues that might emerge.

Conclusion

CNC plasma cutting machines have set another standard in metal manufacture by joining accuracy, speed, and versatility. Their capacity to convey precise cuts across different metals makes them a significant resource in various businesses. Whether for modern assembling, imaginative undertakings, or reusing tasks, CNC plasma cutting machines offer critical advantages that can upgrade efficiency, diminish costs, and work on by and large quality.

Putting resources into a CNC plasma cutting machine addresses a promise to propelling your capacities in metalworking. As innovation keeps on developing, these machines will assume an undeniably significant part in forming the fate of assembling and creation.

#cncplasmacuttingmachine#cncplasmacuttingmachinemanufacturer#Manufacturers#Metweld#cncmachine#cncplasmacutter

0 notes

Text

Maximizing Efficiency and Precision: The Power of 5 Axis CNC Machines

In the realm of modern manufacturing, precision and efficiency are paramount. Whether you're a seasoned industry professional or a budding entrepreneur, harnessing the power of cutting-edge technology can elevate your production capabilities to new heights. One such technology that continues to revolutionize the manufacturing landscape is the 5 axis CNC machine.

#5axiscncmachines#5axismachine#aboutcncmachine#basiccncmachine#buyacncmachine#cncmachine#cncmachineapplication#cncmachineforsale#cncmachineforsaleused#cncmachinemill#cncmachinesecondhand#cncmachineused#cncmachineusedfor#cncmachinevmc#cncmachiningturning#cncmill#cncmillingmachineoperation#cncturn#cncvmc

0 notes

Text

HUNSONE DELEM DA-53T 130T/3200 Press Brake With Brazilian NR-12

0 notes

Text

👏👏Today we are thrilled to announce the latest addition to CNC Pro team in Florida, US.

We hope more tattoo artists will join our pro team. 🤝🤝

Online shop:

0 notes

Text

Applications of CNC Machines | SBV Engineering Works Coimbatore

CNC machines are integral to various industries, including:

Aerospace: Manufacturing high-precision components for aircraft engines and structural parts.

Automotive: Producing engine components, transmission parts, and custom modifications.

Medical: Creating surgical instruments, prosthetics, and implants with exacting standards.

Electronics: Fabricating circuit boards and enclosures for electronic devices.

Furniture: Designing intricate patterns and shapes in wood and other materials.

Our machines are:

CNC Vertical Machine

CNC Turning Machine

VMC Machine

Horizontal Boring Machine

Radial Drilling Machine

See more about our machines and services: https://www.sbvengineering.com/

#cncmachine#cncturningmachinejobwork#cnccompany#cncmachinejobwork#cncverticalmachining#horizontal milling and boring machine#cncmachineshop

0 notes

Video

youtube

Gedee Weiler Turn Mill Machine

#youtube#cncmachine#gedee weiler#industrialmachine parts making machine#heavy machine#milling machine#drilling machine#turn mill#manufacturer

0 notes