#Centrifugal Blower Market by Type

Text

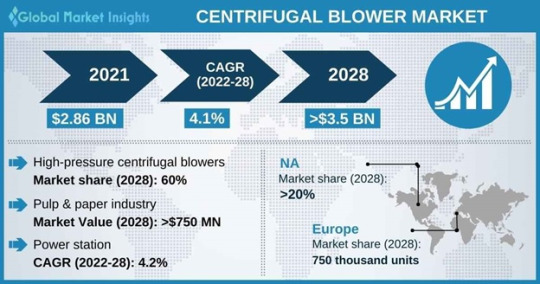

Centrifugal Blower Market Expansion Projected to Gain an Uptick During 2022-2028

The centrifugal blower market is estimated to grow significantly by 2028 primarily owing to rising product demand in cement production, petrochemicals, metal fabrication, and cryogenics.

Recently, burgeoning need for energy across virtually all industries globally has created an upsurge in the need for power producing units, such as nuclear power plants, coal power plants, thermal power plants, and hydro-power plants. These plants rely heavily on centrifugal fans and blowers to supply air for combustion and other types of heat transfers, which has been favorable for industry expansion.

Get sample copy of this research report @ https://www.gminsights.com/request-sample/detail/2602

Furthermore, centrifugal blowers have gained massive popularity in a number of industries, such as food and drinks, construction, and mining, particularly due to their efficiency and durability. In addition, escalating product requirement in regions with a high volume of air or gas has bolstered market uptake. Notably, industry players have increasingly been investing in product development and innovation in order to gain a competitive edge in the centrifugal blower market, thereby enhancing overall business dynamics.

For instance, in June 2021, Indian Space Research Organization (ISRO), the national space agency of India, introduced the Ventilation Assist Unit (VaU), an ICU grade positive pressure mechanical ventilator that has been designed to assist or replace spontaneous breathing in patients suffering from respiratory distress. The VaU has been designed based on a centrifugal blower that pulls in filtered ambient air, compresses it, and delivers it to the patient to provide ventilation, which allows it to function without a compressed pneumatic source.

The centrifugal blower market has been segmented on the basis of pressure, end-user, and region. In terms of end-user, the centrifugal market has been divided into cement plant, pulp & paper, chemical, steel plant, power station, mining, others. The cement plant end-user segment is foreseen to observe significant growth to garner a revenue share of more than 10% by 2028. The proliferating construction industry and mounting demand for cement and minerals are estimated to spur the growth of the segment.

The steel plant end-user segment is anticipated to witness substantial growth by 2028, registering approximately 3.6% CAGR by the forecast timeframe. Centrifugal blowers are used in steel plants to tackle problems like high temperatures and to cater to the need for a high output situation, which is likely to fuel segmental development in the upcoming years.

Request for customization @ https://www.gminsights.com/roc/2602

From the regional point of view, the Latin America centrifugal blower market is estimated to grow at a CAGR of over 3.7% through the forecast period. Meanwhile, the Middle East & Africa centrifugal blower industry held a volume share of around 7% in the overall market in 2021 and is projected to amass notable gains over 2022-2028.

Table of Contents (ToC) of the report:

Chapter 2 Executive Summary

2.1 Centrifugal blower industry 360° synopsis, 2018 – 2028

2.1.1 Business trends

2.1.2 Pressure by end-user trends

2.1.3 End-user trends

2.1.4 Regional trends

Chapter 3 Centrifugal Blowers Industry Insights

3.1 Industry segmentation

3.2 Industry size and forecast, 2018 – 2028

3.3 Industry ecosystem analysis

3.4 Innovation & sustainability

3.5 Industry impact forces

3.5.1 Growth drivers

3.5.1.1 Rapidly growing construction industry in the Asia Pacific

3.5.1.2 Strong product demand from power and mining industry in the U.S.

3.5.1.3 Growing food industry in the Asia Pacific

3.5.2 Industry pitfalls & challenges

3.5.2.1 High production and maintenance cost

3.6 Regulatory landscape

3.7 Growth potential analysis

3.8 Competitive landscape, 2020

3.9 Porter’s analysis

3.10 Regional price trends

3.11 PESTEL Analysis

Browse complete Table of Contents (ToC) of this research report @ https://www.gminsights.com/toc/detail/centrifugal-blower-market

HVAC & Construction Research Reports

Asphalt Mixing Plants Market

Painting Tools Market

Building Thermal Centrifugal Blower Market

About Global Market Insights:

Global Market Insights, Inc., headquartered in Delaware, U.S., is a global market research and consulting service provider; offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients with penetrative insights and actionable market data specially designed and presented to aid strategic decision making. These exhaustive reports are designed via a proprietary research methodology and are available for key industries such as chemicals, advanced materials, technology, renewable energy and biotechnology.

Contact Us:

Aashit Tiwari

Corporate Sales, USA

Global Market Insights Inc.

Toll Free: 1-888-689-0688

USA: +1-302-846-7766

Europe: +44-742-759-8484

APAC: +65-3129-7718

Email: [email protected]

#Centrifugal Blower Market Analysis#Centrifugal Blower Market by Type#Centrifugal Blower Market Share#Centrifugal Blower Market Development#Centrifugal Blower Market Growth

0 notes

Text

WHAT IS THE APPLICATION OF SCREW PUMPS IN THE COMMERCIAL SECTOR?

Screw pumps from India belong to the family of dry compressing gas transfer pumps. They are positive-displacement pumps that make use of two screw shaped intermeshing motors to move gas properly along the axis of the screw.

Different types of screw pumps are often used in industrial vacuum applications along with root blowers and as oil-free pumps in various high and ultrahigh vacuum systems.

The screw pump comes with a screw-like structure. The spindle of the pump is considered as in charge of the pump’s activity. This type of pump demands less maintenance. Like other pumps, screw pumps extract mechanical energy from a motor.

Diverse types of materials are used for manufacturing various elements of these pumps including high-speed steel for the bearings, cast iron for the casing, and top-quality carbon steel for the screw shafts.

Generally, screw pumps open and enclosed are demanded in the market for various applications. You can usually find them in wastewater treatment plants, where they help in transporting sludge and fluids from sewage lines or transported septage.

Commercial uses of screw pumps

Here are some commercial uses of screw pumps:

Beverage industry

The beverage industry is a major commercial firm that benefits from screw pumps. Beverage producers such as wineries, breweries, and bottled coffee producers transfer liquids around without any damage to the other ingredients.

Screw pumps for the industry of beverage demand low maintenance and can be easily equipped with a sealed precision type “E” bearing assembly.

Food preparation

The screw pump used in food preparation is great that demands sensitive speeds to avoid the problem of over-mixing or introducing material too early. screw pump is great for a canning firm that needs to get tomatoes chopped into a canning line without breaking tomato pieces.

Screw pump simply push the tomato combination at the right pace to avoid damage of tomatoes. Consistent flow rates help keep the lines operating smoothly without demanding more maintenance and increase the production.

Refineries and chemical plant

When it comes to screw pumps, they are an outstanding alternative to centrifugal pumps which are used in chemical plants. One common reason for this is saving money. Screw pumps are manufactured in a way so that they can work with liquids of different viscosities.

When pressure starts to rise, a centrifugal pump starts reducing the flow rate. To avoid problems, this requires modification on a regular basis. Screw pumps do not need such modifications which help to save your time and money as well.

In the oil and gas industry, screw pumps are proving the best choice. With more viscous crude oil coming in from countries such as South America, Canada, and Latin America, screw pumps can take more work to move oil from reservoirs to oil pipelines.

Theme parks

Theme parks use screw pumps to bring water to the top of a slide so that it can tumble down the slide to the pool below. This procedure is needed at every theme park which features a water attraction. A screw pump helps to move massive amounts of water continuously without any interruption.

It is important to know that the screw pump is good at carrying water from the pool back to the top of the ride again and again. This is especially helpful in water parks with log rides in a flume.

To ensure water moves non-stop from the bottom to the top, it is vital to have low-maintenance screw pumps.

Paper mills

During the process, several pulp and paper industry require screw pumps. Wood is first stripped of its bark and then broken into tiny bits. This is further steeped in a mixture of water and chemicals to help absorption.

Most of the liquid should be removed from the pulp before it is bleached and washed. After washing, there is a new wave of water removal. Before all this goes to the paper producing presses and drying room, the pulp needs to go through a procedure called refining. A screw pump is considered beneficial for each new stage that demands liquid separation.

Benefits of screw pumps

There are several benefits of installing screw pumps:

High pumping seeds

Excellent strength

Operational costs and maintenance needs are less

Scales to customer needs

No contamination of the medium being pumped

Highly efficient due to its internal compression

Frictionless rotation

High tolerance against water vapor

Summary

Therefore, screw pumps have become the best solution for almost every industrial process. If you are looking for the finest collection of screw pumps within your budget then Synopumps is the right place for you.

0 notes

Text

A Guide to Different Types of Industrial Roots Blower Machines:

Understanding Root Blower Technology:

Roots blower technology is a positive displacement blower that can be employed in a variety of industrial applications.

It uses a pair of meshing lobed rotors to transfer air or gas from the entrance to the outlet.

The rotors' lobes capture and transport air or gas around the housing, causing pressure and flow.

This technique is widely employed in various industries, including wastewater treatment, pneumatic conveying, and chemical processing.

Types of Blowers with Positive Displacement Roots:

Positive displacement roots blowers come in two primary varieties: single-stage and two-stage models.

Two rotors that are physically connected and spin in opposing directions are seen in single-stage blowers.

Applications requiring high flow rates and low pressure frequently use these blowers.

Two-stage blowers, on the other hand, feature an intercooler in between each stage and an extra set of rotors.

Applications requiring lower flow rates and higher pressure are served by these blowers.

ROOTS BLOWER MACHINE BENEFITS :

Blowers with roots have several advantages in industrial environments.

First of all, they offer a consistent and dependable supply of gas or compressed air.

This is crucial for procedures that need a steady stream of gas or air.

Furthermore, roots blowers can run at high speeds without using too much electricity and are energy-efficient.

Finally, because of their small size and low maintenance needs, these devices are affordable for use in industrial settings.

Applications of Centrifugal Roots Blowers:

Centrifugal roots blowers are commonly used in various applications.

One of the main applications is in wastewater treatment plants, where they are used for aeration.

They help to supply oxygen to the biological treatment process, promoting the growth of bacteria that break down organic matter.

Centrifugal roots blowers are also used in pneumatic conveying systems to transport bulk materials.

Additionally, they find application in chemical processing, food processing, and power generation industries.

Centrifugal Root Blower Applications:

Centrifugal roots blowers are frequently employed in many different contexts.

Aeration is one of the primary uses for them in wastewater treatment facilities.

They facilitate the growth of the bacteria that break down organic debris by contributing oxygen to the biological treatment process.

Bulk material transportation in pneumatic conveying systems also makes use of centrifugal roots blowers.

They are also used in the food processing, chemical processing, and power generation industries.

Various varieties of root blower machines:

The market is filled with a variety of roots blower machine models.

Claw blowers, screw blowers, and rotary lobe blowers are a few of the popular varieties.

The most popular kind of blowers are rotary lobe blowers, which can be used for a variety of purposes.

Wastewater treatment facilities frequently employ screw blowers because of their energy-efficient design.

Applications requiring oil-free gas or air, such the food and pharmaceutical sectors, use claw blowers.

Comparing Roots Blowers: Single-Stage and Two-Stage:

When selecting between single-stage and two-stage roots blowers, it's critical to take the application's particular requirements into account.

Applications requiring modest pressure differentials and large flow rates are better suited for single-stage blowers.

Pneumatic conveying, power generating, and the cement industry are among the industries that frequently use them.

Two-stage blowers, on the other hand, are perfect for situations requiring larger pressure differentials.

They are frequently employed in sectors including chemical processing, oil & gas, and wastewater treatment.

Selecting the Best Roots Blower for Your Commercial Requirements :

There are a number of things to take into account when choosing a roots blower for your industrial requirements.

To begin with, you must ascertain the necessary pressure difference and flow rate for your application.

This will assist you in deciding if a two-stage blower or a single-stage blower is better.

Second, think about the particular needs of your process or business, such the demand for oil-free gas or air.

Finally, consider the blower's energy efficiency, dependability, and maintenance needs.

Selecting the Best Roots Blower for Your Commercial Requirements :

There are a number of things to take into account when choosing a roots blower for your industrial requirements.

To begin with, you must ascertain the necessary pressure difference and flow rate for your application.

This will assist you in deciding if a two-stage blower or a single-stage blower is better.

Second, think about the particular needs of your process or business, such the demand for oil-free gas or air.

Finally, consider the blower's energy efficiency, dependability, and maintenance needs.

THE ROOTS BLOWERS MACHINE INNVONATIONS :

A number of advancements have been made in the realm of roots blower technology in recent years.

The creation of variable frequency drives (VFDs) for roots blowers is one noteworthy breakthrough.

Precise blower speed control is made possible by VFDs, which enhances process control and saves energy.

Using cutting-edge materials and coatings to increase the longevity and effectiveness of roots blowers is another innovation.

For instance, using rotors coated with Teflon can minimize friction and enhance blower performance.

FOR MORE VISIT: https://www.indiantradebird.com/

0 notes

Text

Electric Motor Market - Forecast(2024 - 2030)

Electric Motor Market Overview

Electric Motor Market Size is forecast to reach $169 billion by 2030, at a CAGR of 5.6% during 2024-2030. The increase in global electricity consumption and the use of electrical equipment and machines in different industries and the renewables sector are major factors driving the growth in the electric motor market during the forecast period. An increase in awareness of green vehicles among customers has been a key factor leading the market. Besides this, a rising number of government incentives to encourage sales of green vehicles for safeguarding the environment from carbon emissions is analysed to drive the market. The growing interest in sustainable transportation has driven the demand for electric vehicles. Electric motors play a crucial role in powering EVs, and advancements in motor technology contribute to increased efficiency and range. The industrial sector is witnessing the integration of electric motors with the Internet of Things (IoT) and Industry 4.0 technologies. This integration allows for real-time monitoring, predictive maintenance, and improved efficiency in industrial processes.

Smart motor technologies, incorporating features like connectivity, sensors, and advanced control systems, are becoming more prevalent. These innovations contribute to better performance, remote monitoring, and enhanced automation in various applications. Developments in motor control systems, including advanced algorithms and power electronics, contribute to improved motor performance, reduced energy losses, and enhanced control precision. There is an increasing emphasis on developing more energy-efficient electric motors to meet sustainability goals and reduce energy consumption. Regulations and standards promoting energy efficiency also influence the design and manufacturing of electric motors. Additionally, Electric motors have been observing several advancements in technology over the past few years, owing to which its demand is set to gain higher traction during the forecast period 2024-2030.

Report Coverage

The report: “Electric Motor Market Report– Forecast (2024-2030)”, by IndustryARC covers an in-depth analysis of the following segments of the Electric Motor market

By Product Type: AC Motor (Induction Motor, Synchronous Motor, Servo Motor, Stepper Motor), DC Motor (Brushed DC Motor, Brushless DC Motor, Servo Motor, Series Motor, Stepper motor, Compound Motor).

By Product Category: Permanent Magnet, Non-Permanent Magnet.

By Phase: Single Phase, Three Phase.

By Power Rating: Below 0.5W, 0.5W-1W, 1W to 100W, 100W to 1KW, 1KW to 10KW, 10KW and Above.

By Efficiency: IE1, IE2, IE3, IE4.

By Application: Commercial (Automated Doors, Elevators & Escalators, Blowers, Electric Sweepers, Hand Dryers, Data Center & UPS, Pumps, Power Tools, Water Coolers, Camera PTZ Control, Drones, Others), Consumer Products (Pumps, Hair Dryers, Lawn Mowers, Boilers, Dishwashers, Vacuum Cleaners, washing machine, Blenders & Mixers, Fans & Chimneys, Desktop & Laptops, Smartphones, Refrigerators, Others), Automotive (Body Control motors, EPS Motors, Brake Booster BLDC Motor, Seat Adjustment, Belt Tensioner, Car Window Motor, Door Lock Motors, Wiper Motor, Others), Medical & Healthcare (Diagnostic Equipment (CT Scanners, MRI, Biopsy Systems, Diagnostics Analyzers, Ultrasound Transducers, X-Ray, Others), Medical Centrifuges, Medical Pumps, Blowers and Compressors, Surgical Instruments (Saws, Drills, Surgical Robots, Others), Dental CAD/CAM Milling Machines, Exoskeleton & Prosthetics, Microscopes, Wheelchairs & Scooters, Stair Lifts, Hospital Beds & Exam Tables, Others).

By Geography: North America (U.S, Canada, Mexico), South America(Brazil, Argentina and others), Europe(Germany, UK, France, Italy, Spain, Russia, Netherlands, Poland, Czechia, Belgium, Sweden and Others), APAC(China, Japan India, SK, Aus and Others), and RoW (Middle East and Africa)

Request Sample

Key Takeaways

• The rising demand for efficient energy usage over concerns of environmental impact of energy generation from conventional sources such as coal and natural gas, is expected to help grow the electric motor market in APAC.

• The DC Motor segment is growing at a significant CAGR of 7.6% in the forecast period 2024-2030. A DC motor consists of a stator and a rotor.

• Medical & Healthcare sector is expected to witness a highest CAGR of 8.5% the forecast period 2024-2030, due to its extensive reliance on electrically powered devices and equipment. Diagnostic imaging equipment, such as MRI and CT scanners, demands high-performance electric motors for precise movements and accurate imaging.

• Electric Motor companies are strengthening their position through mergers & acquisitions and continuously investing in research and development (R&D) activities to come up with solutions to cater to the changing requirements of customers.

Electric Motor Market Segment Analysis - By Product Type

The DC Motor segment is expected to grow at a significant CAGR of 7.6% during the forecast period 2024-2030. Owing to the growing penetration of brushless DC motors across various industry verticals substituting brushed dc and even ac induction motors in certain applications such as home appliances. DC motors are used in electric vehicles in the automotive industry for various non-traction applications, contributing to the ongoing shift towards sustainable transportation. As the demand for electric vehicles grows, so does the demand for efficient and dependable DC motors. DC motors are also widely used in industrial automation, powering conveyor systems, robotics, and manufacturing equipment. Owing to the ease of control, they are suitable for accurate and regulated movements in automated processes.

Inquiry Before Buying

Electric Motor Market Segment Analysis - By Application

Medical & Healthcare sector is expected to witness a highest growth of CAGR 8.5% during the forecast period 2024-2030, owing to the increase in investments in healthcare and medical sector, along with growing penetration of advanced medical devices & equipment in the sector such as surgical robots, advanced imaging & diagnostic equipment, prosthetics and so on. Medical advances and technical improvements have resulted in the development of a wide range of medical instruments and gear that significantly rely on the precision and efficiency provided by electric motors. High-performance electric motors are required for precise motions and accurate imaging in diagnostic imaging equipment such as MRI and CT scanners. Electric motors provide stability and consistency to patient care and monitoring systems such as infusion pumps and monitoring equipment. Furthermore, the incorporation of electric motors in mobility aids such as electric wheelchairs and patient lifts improves accessibility for people who have mobility issues. Electric motors are used in laboratory equipment, robotic surgical systems, and a variety of medical tools, all of which contribute to the overall efficiency and improvement of healthcare techniques. The demand for electric motors is on the rise as the healthcare industry evolves and adopts more technologically sophisticated solutions, fueling additional innovation in this critical sector.

Electric Motor Market Segment Analysis - By Geography

Electric Motor market in Asia-Pacific region held significant market share of 38% in 2023. Increasing compliance for energy efficient motors and rising adoption of motor-driven electric vehicles are the key factors driving market growth. The rising demand for efficient energy usage over concerns of environmental impact of energy generation from conventional sources such as coal and natural gas, is expected to help grow the electric motor market. In addition, advancements in the agriculture sector and enormous investments in industrialization in countries such as China, India, South Korea, and Australia is driving the market growth. Further, the increasing production and sales of electric vehicles in countries including China and Japan is also analyzed to drive the market growth.

Schedule a Call

Electric Motor Market Drivers

Rise in demand for Electric Vehicles

The electric car market has witnessed rapid evolution with the ongoing developments in automotive sector and favorable government policies and support in terms of subsidies and grants, tax rebates. Major manufacturers such as General Motors, Toyota, and BMW plan to release a potential of 400 models and estimated global sales of 25 million by 2025. In 2022, Ford Motor has committed to increase its investments in electric vehicles to $50 billion by 2026, up from a previous spend of $30 billion by 2025. Similarly, in 2020, Volkswagen, Chinese ventures has committed to invest $17.5 billion in electric vehicles by 2025. As electric vehicles use various types of electric motors for traction & auxiliary applications, the rising demand for electric vehicles globally is set to assist the market growth for electric motors used in the same.

Growing R&D activities

Manufacturers are continuously focusing on R&D to develop new and effective electric motors to meet consumer demand. Increasing concerns, such as environmental pollution and regulations, are forcing manufacturers to develop electric motors that reduce vibration and increase efficiency. For instance, a synchronous electric motor is around 80% more efficient than an induction electric motor. Similarly, the development of a new type of steel for electric motors, which reduces the weight of the electric motor and makes it more efficient and powerful. This new type of electric motor will be small in size and cost effective, which will raise demand from residential and commercial applications. Moreover growing developments from various companies is also analysed to drive the market growth. Hence these factors are analysed to drive the market growth in the forecast period 2024-2030.

Electric Motor Market Challenges

Easy availability of low-quality electric motors

The market for electric motors is highly fragmented, with a significant number of domestic and international manufacturers. Product quality is a primary parameter for differentiation in this market. The organized sector in the market mainly targets industrial buyers and maintains excellent product quality, while the unorganized sector offers low-cost alternatives to tap local markets. Local manufacturers of electric motors in most countries target the unorganized sector and compete strongly with the global suppliers in the respective markets. Leading market players are currently exposed to intense competition from such unorganized players supplying inexpensive and low-quality electric motors. This acts as a key challenge for the growth of the market.

Buy Now

Market Landscape

Product launches, acquisitions, Partnerships and R&D activities are key strategies adopted by players in the Electric Motor market. Electric Motor top 10 companies include:

ABB Ltd

Johnson Electric Holdings Limited

Siemens AG

Rockwell Automation

Nidec Corporation

Bosch Electric

Regal Rexnord

Franklin Electric Company Inc.

Teco Electric & Machinery Co. Ltd.

Wolong Electric Group co. ltd.

Acquisitions/Product Launches

• In July 2023, Nidec Corporation announced that it has successfully developed a new electric power steering motor power pack*1 (“EPS-PP”).

• In July 2023, WEG announced new investments for its motor manufacturing plant located in Manaus, Brazil. The Company will invest R$ 48 million, in the next three years, to expand production capacity and adapt the plant to produce a new line of permanent magnet electric motors for split-type air conditioners

• In December 2023, Johnson Electric Launches 48-Volt Cooling Fan Module with High Power and Efficiency. Johnson Electric is pleased to announce the launch of the 48-Volt Cooling Fan Module with power up to 1.5kW to meet the most demanding cooling requirements. The need to reduce emissions and increase the electrification of the vehicle, requires higher cooling performance and efficiency.

#Electric Motor Market#Electric Motor Market size#Electric Motor industry#Electric Motor Market share#Electric Motor top 10 companies#Electric Motor Market report#Electric Motor industry outlook

0 notes

Text

Premier Ventilation System Suppliers in Saudi Arabia

JFTCO stands as the foremost ventilation system supplier Saudi Arabia, specializing in high-quality industrial fans and blowers, including centrifugal, ring blower, and advanced solutions for fume and smoke exhaust. Committed to excellence, they offer unparalleled service and competitive pricing, setting industry standards in ventilation solutions.

In the heart of Saudi Arabia's rapidly growing industrial sector, the demand for high-quality ventilation systems is more crucial than ever. Whether it's for manufacturing plants, commercial buildings, or residential areas, ensuring a steady flow of fresh air is pivotal for health, safety, and operational efficiency. JFTCO stands out as the leading supplier of industrial fans and blowers, offering an unparalleled selection of centrifugal fans, ring blowers, and exhaust systems tailored to meet the diverse needs of its clientele.

Unmatched Quality and Variety

JFTCO's commitment to quality and customer satisfaction is evident in its extensive range of ventilation solutions. As industry leaders, they understand the critical nature of air management in various environments. From centrifugal fans known for their durability and efficiency in moving air and gases in industrial applications to ring blowers that provide consistent performance for various low-pressure, high-volume applications, JFTCO ensures that every need is met with precision.

Their product lineup doesn't end there. Fume and smoke exhaust systems are also a significant part of their offerings, catering to industries where air quality is a major concern, such as manufacturing plants dealing with chemicals or spaces that require stringent air purity levels. By choosing JFTCO, customers are assured of a product that not only meets their specific requirements but also comes with the reliability and efficiency that modern businesses demand.

Tailored Solutions and Expert Support

What sets JFTCO apart in the competitive market of ventilation system suppliers in Saudi Arabia is not just their high-quality products but also their commitment to providing tailored solutions and expert support. Understanding that every project has its unique challenges and requirements, JFTCO works closely with its clients to identify the most suitable ventilation solution that aligns with their specific needs and budget.

Their team of experts is always ready to offer advice, from selecting the right type of fan or blower to designing a complete ventilation system that optimizes air flow, minimizes energy consumption, and ensures environmental compliance. With JFTCO, customers are not just buying a product; they're investing in a partnership that guarantees satisfaction and peace of mind.

Competitive Pricing and After-Sales Service

In addition to offering the best in class products, JFTCO prides itself on its competitive pricing and exceptional after-sales service. They understand that investment in a ventilation system is significant, and they strive to provide the best value for money without compromising on quality or performance. After-sales support, including maintenance and repair services, further ensures that their products continue to operate efficiently over time, maximizing the return on investment for their clients.

Conclusion

For businesses in Saudi Arabia looking for reliable, high-quality ventilation solutions, JFTCO is the go-to supplier. Their extensive range of industrial fans, blowers, and exhaust systems, combined with their expertise in offering customized solutions, makes them a preferred choice for industries across the board. Visit their dedicated page at https://www.jftco.com/industrial-fans/ to explore their offerings and discover why JFTCO is at the forefront of ventilation system suppliers in Saudi Arabia.

Read more: https://www.jftco.com/industrial-fans/

#Ventilation system suppliers saudi arabia#In line cabinet fan suppliers saudi arabia#Tunnel fan suppliers saudi arabia#Electronics

0 notes

Text

Whirling Success: Enhancing Efficiency and Comfort in HVAC Blower Technology | Future Market Insights,Inc.

Whirling Success: Enhancing Efficiency and Comfort in HVAC Blower Technology | Future Market Insights,Inc.

HVAC blower and fan systems are air ventilation systems that ensure efficient movement of air through various heating, ventilation, and air conditioning systems. These HVAC blower and fan systems are composed of an electric motor, modules, resistors, and fans. Ranging from the automotive industry, aviation industry, and residential sector, these HVAC fans and blower systems find applications across a diverse set of industries. The HVAC blower and fan systems market comprises a wide range of products and ancillaries depending upon the intended application. HVAC blower and fan systems are widely used in industrial applications such as those in power generation, mining, Oil & Gas, aviation, and automotive industries among others.

Gain expert insights and supercharge your growth strategies. Request our market overview sample now:https://www.futuremarketinsights.com/reports/sample/rep-gb-4674

Besides ensuring optimum movement of air, these HVAC fans and blower systems also play a vital role in ensuring safety of vital components such as engines. Thus, HVAC blower and fan systems are used in many industrial applications owing to which, HVAC blower and fan systems market is expected to witness significant growth during the forecast period.

HVAC Blower and Fan Systems Market: Dynamics

Anticipated steady growth in industrialization, especially in developing countries such as those in Asia Pacific, Latin America and Africa is expected to drive the growth of global HVAC blower and fan system market during the forecast period. Automotive industry accounts for a significant share in global HVAC blower and fan systems market. Anticipated steady growth in automotive production is expected to fuel the growth in demand for HVAC blowers and fans.

Moreover, growth in construction activity and infrastructure-related spending coupled with increasing urbanization, especially, in developing countries in Asia Pacific and MEA regions is another factor that is expected to drive the growth of HVAC fans and blowers market. Furthermore, efforts towards the development of efficient systems that adhere to standards such as LEED, and ASHRAE are expected to be witnessed over the forecast period. Demand for HVAC blower and fan systems is expected to register moderate single-digit growth over the forecast period.

However, the relatively high cost associated with the manufacture of some of these HVAC blowers and fan systems is expected to be one of the factors that are expected to act as impediments to growth of the market during forecast period. Furthermore, use of some of the harmful gases in certain systems and regulations and restrictions pertaining the same is another factor that is likely to impede the growth of market.

HVAC Blower and Fan Systems Market: Segmentation

The global HVAC blower and fan systems market is divided on the basis product type, and end users. On the basis of product type, HVAC blower and fan systems market can be segmented as axial, centrifugal, backward inclined fans, others. On the basis of end users, the global HVAC blower and fan systems market can be segmented as Industrial, residential and Commercial users.

HVAC Blower and Fan Systems Market: Regional Outlook

The global HVAC blowers and fan market is expected to register a steady CAGR over the forecast period. North America is expected to account for a significant share in global HVAC blowers and fan market in various industrial and commercial applications. Asia Pacific region is expected to witness relatively faster growth owing to growth across key application sectors for HVAC blowers and fan systems. Moreover, MEA and Eastern Europe regions are expected to witness steady growth owing to anticipated steady growth in construction activity in the region over the forecast period. Overall, the HVAC blowers and fan systems market is expected to witness steady growth during the forecast period owing to rising demand in various segments.

HVAC Blower and Fan Systems Market: Market Players

Examples of some of the market participants in the global HVAC blowers and Fan systems market identified across the value chain include:

CG Power and Industrial Solutions Limited

Acme Engineering and Manufacturing Corporation

Air systems component Inc.

Wuhan General Group (China) Co. Ltd.

Continental blower LLC

Air Master Fan company, Inc.

DongKun Industrial Co. Ltd.

Fläkt Woods Group SA

Greenheck Fan Corporation

Howden Group Ltd

Loren Cook Company

Gardner Denver, Inc.

CECO Environmental

The research report presents a comprehensive assessment of the market and contains thoughtful insights, facts, historical data, and statistically supported and industry-validated market data. It also contains projections using a suitable set of assumptions and methodologies. The research report provides analysis and information according to categories such as market segments, geographies, types, technology, and applications.

The report covers an exhaustive analysis on:

Market Segments

Market Dynamics

Market Size

Supply & Demand

Current Trends/Issues/Challenges

Competition and companies involved

Technology

Value Chain

Regional analysis includes

North America (U.S., Canada)

Latin America (Mexico, Brazil and Rest of Latin America)

Western Europe (Germany, Italy, France, U.K, Spain,)

Eastern Europe (Poland, Russia and Rest of Eastern Europe)

Asia Pacific (China, India, ASEAN, Australia & New Zealand)

Japan

Middle East and Africa (GCC, S. Africa, and Rest of MEA)

The report is a compilation of first-hand information, qualitative and quantitative assessment by industry analysts, inputs from industry experts and industry participants across the value chain. The report provides in-depth analysis of parent market trends, macro-economic indicators and governing factors along with market attractiveness as per segments. The report also maps the qualitative impact of various market factors on market segments and geographies.

Report Highlights:

Detailed overview of parent market

Changing market dynamics in the industry

In-depth market segmentation

Historical, current and projected market size in terms of volume and value

Recent industry trends and developments

Competitive landscape

Strategies of key players and products offered

Potential and niche segments, geographical regions exhibiting promising growth

A neutral perspective on market performance

Must-have information for market players to sustain and enhance their market footprint.

0 notes

Text

2024 - Top Quality Centrifugal Fans and Blowers Manufacturers in India

Centrifugal Fans and Blowers Manufacturers in India

Teral-Aerotech is a Top Centrifugal Fans and Blowers Manufacturers in India, offering a wide range of high-quality ventilation products. Their centrifugal blowers are engineered for high efficiency and low noise, making them suitable for various industrial and commercial applications. The company prides itself on its mission to develop, manufacture, and market top-notch ventilation products, with a focus on reliability, quality, and customer satisfaction.

Centrifugal Fans and Blowers

Centrifugal Fans and Blowers Manufacturers in India, Teral-Aerotech's centrifugal blower fans are precision designed to deliver efficient air movement and increase air or gas pressure. They offer a variety of fan types, including Double Inlet Double Width (DIDW) and Single Inlet fans, with features such as forward curved or backward curved impellers.

Teral

These fans are suitable for a wide range of applications, including general ventilation, pressurization, and various industrial processes, thanks to their high volume air displacement capabilities. The company's commitment to excellence is evident in its emphasis on trust, customer satisfaction, and continuous product development. They also prioritize timely delivery and aim to be the most reliable company for quality, availability, and delivery reliability.

Centrifugal Fans and Blowers

With a strong focus on customer relationships and community engagement, Teral-Aerotech is dedicated to providing the right products with the right performance characteristics, delivered at the right time. Their wide range of centrifugal blowers and fans, coupled with a commitment to quality and customer satisfaction, positions them as a leading manufacturer in the industry.

If you want to know more about our product how they are useful for your work , please contact us today . Our team is always here to help and find best solutions for your specific needs.

Visit:- https://www.blowers-fans.com/centrifugal-fan-blowers.html

Address : PLOT NO.188-89,ECOTECH EXTENSIONS-1, KASANA GREATER NOIDA-201301,(NEAR ASIAN PAINT) UTTAR PRADESH,INDIA

1 note

·

View note

Text

2024 - Top Quality Centrifugal Blower Manufacturers

Centrifugal Blower Manufacturers

AMCS Cooling Systems, a leading manufacturer in the field, has established a strong reputation as one of the best centrifugal blower manufacturers. With a focus on quality, customer service, and innovation, the company has become a trusted name in the market. Their dedication to product excellence is evident in the rigorous testing and quality checks that each centrifugal blower undergoes, ensuring optimal performance and reliability.

Centrifugal Blower

The company offers a wide range of centrifugal blowers, including direct driven and belt driven types, designed and manufactured by a team of skilled engineers and technicians. The products are used in various industrial applications such as air washers, air handling units, and air scrubbers, with a focus on high static pressure and high-pressure applications.

Airmake Cooling

Centrifugal Blower Manufacturers, AMCS Cooling Systems' commitment to quality and customer satisfaction sets them apart from the competition, making them a preferred choice for those in need of superior quality heating, ventilation, and air conditioning equipment and components. The company's unwavering focus on technological expertise and innovation, coupled with a strong customer-centric approach, has contributed to their status as a trusted manufacturer in the industry.

Centrifugal Blower

Centrifugal Blower Manufacturers, AMCS Cooling Systems has proven to be a reliable and innovative manufacturer of centrifugal blowers, with a strong focus on quality, customer satisfaction, and technological advancements.

If you want to know more about our product how they are useful for your work , please contact us today . Our team is always here to help and find best solutions for your specific needs.

Visit :- https://www.airmakecooling.com/centrifugal-blower.html

Address : PLOT NO. 49 UDYOG KENDRA - II, ECHOTECH-III Noida - 201306 (U.P.), (India)

Twitter :- https://twitter.com/make_air

#manufacturer#air quality#centrifugal blower suppliers#high quality#amcs#air filter#exhaust blower manufacturers in noida#air handling unit manufacturers#fan coil#air handling unit suppliers

0 notes

Text

Air Pump Manufacturers: A Guide to the Best Companies in the Industry

Air pumps are devices that compress air and distribute it in a variety of applications, such as inflating tires, mattresses, balloons, balls, pool beds, etc. Air pumps can also be used to circulate water in aquariums and ponds. Air pumps can be powered by electricity, batteries, or manual operation. They can have different designs and features depending on the purpose and choice of the customers.

There are many Air Pump Manufacturers on the market, offering a wide range of products and services. However, not all of them are reliable and trustworthy. Therefore, customers should consider some factors when choosing an air pump manufacturer, such as:

Quality and durability of products

Company reputation and experience

Customer service and after-sales support

Product price and warranty

Certification and recognition of the company

To help customers find the best air pump manufacturers in the industry, here is a list of some of the top companies that offer high-quality and innovative products:

1. VND Plastico Pumps Pvt. Ltd.: It is one of the oldest and leading air pump manufacturers in India, established in 1995. They produce a variety of air compressors including high-tech portable models for light and heavy-duty industrial applications. They also offer related accessories, such as Magnetic Pump Manufacturers, AODD Pump Manufacturers, and Centrifugal Pump Manufacturers. They use only the best materials and advanced machinery to ensure the efficiency and performance of their products. They also provide customized solutions as per the requirements of their clients.

2. Qianhu Aquastar India: It is one of the topmost manufacturers and distributors of Pumps and Blowers in India, established in 2009. They offer a wide range of products such as RO Pump, Air Pump, Pressure Pump, Submersible Pump, and Fountain Pump. , Etcetera. They use only the highest quality materials and state-of-the-art technology to manufacture their products. They also follow strict quality standards and ethical work practices to ensure customer satisfaction.

3. IDEX Corporation: It is a global leader in various markets, such as health and science technologies, fluid and metering technologies, fire and security, etc. established in 1987. They offer innovative and diversified products like Air Pumps, Diaphragms. Pump, piston pump, peristaltic pump, gear pump, etc. They use cutting-edge technology and engineering expertise to create solutions that improve lives and businesses. They also have a strong presence in more than 40 countries across the globe.

4. Sensen Group Co. Ltd.: It is a famous air pump manufacturer in China, founded in 1985. They specialize in aquarium products, such as air pumps, filters, heaters, lights, etc. They also make industrial products. Such as blowers, fans, compressors, etc. They have a large production capacity and a professional R&D team that can develop new products according to customers’ requirements. They also have a strict quality control system and good after-sales service.

5. Chen Yih Industrial Co. Ltd.: It is a professional manufacturer of air pumps in Taiwan, established in 1992. They provide different types of air pumps for different applications like bicycle pumps, car pumps, ball pumps, and electric pumps. , hand pump, etc. They also provide other related products, such as oil seals, packing seals, o-rings, etc. They use high-quality materials and advanced equipment to produce their products. They also have a good reputation in the industry and a large market share.

These are some of the best air pump manufacturers in the industry that customers can trust and rely on. They offer high-quality and innovative products that can meet the diverse needs of various industries. Customers can contact them for more details or visit their website for more details.

#air pump manufacturers#air pumps#aodd pump manufacturers#centrifugal pump manufacturers#magnetic pump manufacturers

0 notes

Text

Painting Tools Market Predicted to Witness Steady Growth by 2028

The painting tools market is expected to register notable gains by 2028 due to the expanding automotive industry across the globe.

Painting and coatings make products visually appealing and provide an added layer of protection and durability to products without adding any significant weight. Prevalent use of painting and coatings in varied applications has bolstered product uptake in recent years. Additionally, increasing adoption of flexible packaging solutions that utilize coated barrier systems, which enhance the recyclability and reusability of the packaging, has propelled market expansion.

Get sample copy of this research report @ https://www.gminsights.com/request-sample/detail/1843

The painting tools market has been segmented based on application, product, and region. With respect to product, the market has further been bifurcated into masking tapes, brushes, spray gun, rollers, trays, scrapers, knives, and others (extension poles, sanding tools, trowels).

The brushes sub-segment is projected to grow at a CAGR of around 5.4% in terms of revenue over the assessment period. Paint brushes are one of the most fundamental and oldest tools that are used for painting. Brushes are utilized to paint corners, walls, and ceilings, which is not possible with rollers and spray guns. Paint brushes are classified on the basis of types of bristles, shapes, and sizes. Surging demand for paint brushes with high-quality natural or synthetic bristles that deliver a smooth finish and provide a comfortable grip is likely to drive segmental growth in the forthcoming years.

From the application perspective, the painting tools market has been divided into packaging, construction, industrial machineries & equipment, residential, furniture, commercial, appliances, industrial, and automotive.

The packaging sub-segment is slated to reach a substantial valuation by 2028, expanding at a CAGR of approximately 3% through the review timeline. Paints and coatings provide all the features required for primary and secondary packing, including high performance, lightweight, low contamination, and airtightness. Packaging items use about 70% less plastic as well as take up lesser space than rigid packaging options. In addition, the use of improved paints and coatings on these packaging helps in protecting the goods from outside influences, which is estimated to boost product demand over the forthcoming years.

Request for customization @ https://www.gminsights.com/roc/1843

On the regional front, the Middle East & Africa painting tools market is poised to see robust expansion at a CAGR of more than 4.5% over the forecast period owing to high infrastructure spending and widespread post-war construction activities. The MEA painting tools market is dominated by Saudi Arabia and South Africa in terms of market share, with Saudi Arabia emerging as the fastest expanding market in the region. Notably, the booming domestic construction industry would bolster paint consumption, which is likely to drive regional market growth. Moreover, economic diversification and the growing tourism sector in the region are set to augment industry uptake over the upcoming years.

Table of Contents (ToC) of the report:

Chapter 1 Methodology and Scope

1.1 Market definitions

1.2 Base estimation & working

1.2.1 North America

1.2.2 Europe

1.2.3 Asia Pacific (APAC)

1.2.4 Latin America (LATAM)

1.2.5 Middle East & Africa (MEA)

1.3 Forecast calculations

1.3.1 COVID-19 impact calculations on industry forecast

1.4 Data Sources

1.4.1 Primary

1.4.2 Secondary

Chapter 2 Executive Summary

2.1 Global Painting Tools industry 360° synopsis, 2018 – 2028

2.1.1 Business trends

2.1.2 Product trends

2.1.3 Application trends

2.1.4 Regional trends

Browse complete Table of Contents (ToC) of this research report @ https://www.gminsights.com/toc/detail/painting-tools-market

HVAC & Construction Research Reports

Vacuum Pumps Market

Positive Displacement Blowers Market

Centrifugal Blower Market

About Global Market Insights:

Global Market Insights, Inc., headquartered in Delaware, U.S., is a global market research and consulting service provider; offering syndicated and custom research reports along with growth consulting services. Our business intelligence and industry research reports offer clients with penetrative insights and actionable market data specially designed and presented to aid strategic decision making. These exhaustive reports are designed via a proprietary research methodology and are available for key industries such as chemicals, advanced materials, technology, renewable energy and biotechnology.

Contact Us:

Aashit Tiwari

Corporate Sales, USA

Global Market Insights Inc.

Toll Free: 1-888-689-0688

USA: +1-302-846-7766

Europe: +44-742-759-8484

APAC: +65-3129-7718

Email: [email protected]

#Painting Tools Market Analysis#Painting Tools Market by Type#Painting Tools Market Share#Painting Tools Market Development

0 notes

Text

Portable Misting Fans Market Size and Share 2022 Industry Analysis by Future and Growth Forecast to 2028

The Portable Misting Fans Market size is projected to reach USD 1390 Million by 2028 from an estimated USD 852 Million in 2021, growing at a CAGR of 8.5% globally.

Misting fans blow water into the air intermittently, and this water helps cool the air as it evaporates. These fans may look like innocent little fans, but they are an innovation in energy efficient cooling fans among the many fans available today. Essentially, the mist fan cools the area around you by evaporating a small stream of water around you. Misting systems come in a variety of configurations, but portable fans offer the most versatility. These devices combine a powerful blower with a high-pressure water pump. Water is blown through misting nozzles or centrifugal misting systems, creating water droplets so fine they are barely visible. This mist is so fine that neither your skin nor your clothes will get wet.

The research presents a full analysis of the pandemic's influence on the whole industry, as well as an outline of market scenarios before and after COVID-19. All of our reports will be modified before distribution to account for the impact of COVID-19 in order to offer a more accurate market prediction. The research study looks at numerous market segments based on type, application, and geography. The research also includes a competitive analysis of the top Portable Misting Fans product providers, as well as their most recent advances. This study is divided into three sections: type, application, and region, with market size and forecasts for each area. For the predicted period, yearly compound growth rates for all segments have also been presented.

Read More: https://introspectivemarketresearch.com/reports/portable-misting-fans-market/

0 notes

Text

Industrial Motor Market - Forecast(2022 - 2027)

Industrial Motor Market Overview

The global Industrial Motor Market size is expected to reach $42.19 billion by 2027, growing at a CAGR of 4.20% during the forecast period from 2022 to 2027. Globally, increasing demand for industrial motors in the Automotive and Oil & Gas industries is set to drive the Industrial Motor Market during the forecast period. Increasing investments for the expansion of oil and gas production across the world owing to the rising energy demands also triggers the growth of the market. Moreover, increasing production ofelectric vehicleshas accelerated the demand for industrial motors for higher efficiency and good speed regulation during the forecast period is also boosting the growth of the market. Furthermore, rising number of government incentives to encourage use of energy efficient industrial motors for safeguarding the environment from carbon emissions is also expected to drive the market growth during the forecast period.

Request Sample

Industrial Motor Market Report Coverage

The report based on: “Industrial Motor Market-Forecast (2022-2027)”, by IndustryARC, covers an in-depth analysis of the following segments of Industrial Motor Market Industry Outlook.

By Product Type: AC (Phase Type: Single Phase, Three Phase; Operation: Asynchronous, Synchronous); DC (Brushed (BDC), Brushless (BLDC))

By Power Rating: <1kW, >1kW<2,2kW, >2,2kW < 3,5kW, 3.5-25 kW25-100 kW, Above 100 kW

By Voltage: Low Voltage (IE1, IE2, IE3, IE4); Medium Voltage (IE1, IE2, IE3, IE4);

High Voltage (IE1, IE2, IE3, IE4)

By Applications: Oil and Gas (Upstream, Midstream, Downstream); Aerospace

(Actuation, Air and Thermal System, Aircraft Engines, Auxiliary Power Unit, Wheels and Breaking System, Others); Automotive; HVAC (Heating, Ventilating, Air Conditioning); Paper and Pulp (Feed and Conveyor Systems, Fans and Blowers, Reeling and Rolling Machines, Mixers, Others); Food and Beverage (Milling, Grinding and Mixers, Conveyor Systems, Pumping Systems, Packaging, Others); Textile (Mixing and Beating Machines, Carding Machines, Winding Machines, Washers and Pumps, Blowers, Others); Transportation (Logistics and Warehousing (Manual Cranes and Hoists, ASRS Systems, Belt Conveyors, Others);Railways (Traction, Blowers, Others)); Power Generation (Coal, Gas and Oil-Fired Plants, Nuclear Power Plants, Geothermal Power Plants, Hydro Power Plants, Wind Mills, Others); Agriculture ( Pumping Systems, Grain Handling and Conveyor System, Aeration and Conditioning, Feed Delivery Systems, Others); Chemical (Pumps, Fans, Blowers and Compressors, Centrifuges, Agitators and Mixers, Others); Industrial Machinery (Machine Tools, Assembly Line and Conveyor Systems, Others); Plastics and Packaging; Industrial Automation; Others.

By Geography: North America (US, Canada, Mexico), South America (Brazil, Argentina,Chile, Colombia & Others),Europe (Germany, France, UK, Italy, Spain, Russia, Netherlands & Others), APAC (China, Japan, South Korea, India, Australia, Indonesia, Malaysia & Others) ,RoW (Middle East & Africa)

Key Takeaways

AC Motor dominated the global Industrial Motor market with a share of 84% in 2021 and is also anticipated to witness a significant growth during 2022-2027, owing to its use for various industrial applications such as in Appliances, Compressor drives and systems, Conveyor systems.

Industrial Automation dominated the global Industrial Motor market with a share of 24.61% in 2021, owing to growing use of motors in collaborative robots.

North America held the largest share of 30.65% in the global Industrial Motor market in 2021 and growing at CAGR of 3.64% during 2022-2027, owing to rising number of government incentives to encourage use of energy efficient industrial motors.

Increasing demand for industrial motors in chemical & petrochemical industries is set to be one of the major factor that is analyzed to drive the market during the forecast period.

Inquiry Before Buying

Industrial Motor Market Segment Analysis-By Product Type

Based on product type, AC Motor dominated the global Industrial Motor market with a share of 84% in 2021 and is also anticipated to witness a significant growth during 2022-2027, owing to its use for various industrial applications such as in Appliances, Compressor drives and systems, Conveyor systems. AC motors have been classified into induction or asynchronous and synchronous motors. Asynchronous motors held the share of 65.45% in the AC motor market in 2021 and growing at CAGR of 4.64% during 2022-2027. These motors are the major type of industrial motors used in industrial applications like used in conveyors, cranes, pumps, elevators, compressors, drilling machines, oil extracting mills and others. Asynchronous motors have lot of advantages such as less cost, easy to maintain, efficiency in partial-load operation and others. Owing to its advantages, the adoption rate is higher among industries, thus supporting the growth of the Industrial Motor Market. In 2020, ABB Ltd launched a new range of low voltage IEC induction motors i.e. M3BP motors for industries metals, cement, pulp & paper, water & wastewater in India. These motors are compactly designed for applications such as fan, pump, compressor, crusher and crane and helps the industrial customers to save space and cost. Such developments will positively impact the growth of the market.

Industrial Motor Market Segment Analysis-By Application

Based on Application, Oil and gas dominated the global Industrial Motor market with a share of 24.61% in 2021 and is also anticipated to witness highest growth during the forecast period 2022-2027. Industrial motors serve an extensive range of applications in industrial automation vertical including food, packaging, logistics systems, tool machines and robots, among others. Stepper, servo, ac, and dc motors are the ideal motors to meet most industrial automation requirements. In industrial automation, robotics is the major trend in recent years and coming years. Robots are used for various handling purposes for precise and better quality of production. In recent years, the need for industrial automation to mitigate labour shortages in the industrial sector has become a prime concern. In addition, COVID-19 pandemic has posed new risks for workers working in close proximity. Under these circumstances, there is an increasing demand for collaborative robots that can safely work side by side with humans at sites without safety barriers and can flexibly handle multiple tasks which in turn boost the demand for industrial motors. In October 2021, Japanese electronics manufacturer, Omron announced to invest in Tech-man Robot, a manufacturer of collaborative robots in Taiwan and a subsidiary of Quanta Computer. This investment will boost robot business which is the driving force behind the growth of industrial automation This will further create opportunities for the growth of the Industrial Motor market.

Schedule a Call

Industrial Motor Market Segment Analysis-By Geography

North America held the largest share of 30.65% in the global Industrial Motor market in 2020 and growing at CAGR of 3.64% during 2022-2027. The increasing adoption of industrial motors in power generation, aerospace, automotive and chemical industries is analyzed to expand Industrial Motor Market in this region. USA, Canada and Mexico are the top contributors in industrial motor market growth in this region. Moreover, a rising number of government incentives to encourage use of energy efficient industrial motors for safeguarding the environment from carbon emissions is expected to drive the market growth. For instance, USA has planned to increase carbon-free power generation from 27% to 35% of total by 2024, thus increasing the scope of adoption of energy efficient motors among industries. Similarly, In December 2020, Federal Electricity Commission planned to construct four nuclear reactors for power generation, thus creating opportunities for the use of energy efficient motors in nuclear power plants. Furthermore, the rising investments for the expansion of chemical industry also triggers the growth of the market in this region. In May 2020, ExxonMobil announced a $2billion investment in Baytown chemical plant expansion project. Such investments can increase the use of industrial motors for the need of handling toxic and aggressive acids, which can influence the market growth of Industrial Motor in the long run.

Industrial Motor Market Drivers

Growing demand for industrial motors in the Automotive and Oil and Gas industries will positively impact the market growth

Increasing demand for industrial motors in the Automotive and Oil and Gas industries will positively impact the market growth. In oil & gas industry, industrial motors are used for wide range of applications such as in off shore cranes, Compressors, Gas pumps, Winches and many others, thus raising its adoptability. Additionally, industrial motors play a vital role for drilling and bringing oil and natural gas resources to the surface and other applications in upstream part of this industry. Furthermore, rising investments for the expansion of oil and gas production across the world owing to the rising energy demands also triggers the growth of the market. In December 2021, the Government of India planned to invest $2.86 billion in the upstream oil and gas production to double natural gas production to 60 bcm and drill more than 120 exploration wells by the end of 2022. These major investments tend to bring significant growth in the demand of industrial motors for Upstream Oil and Gas industry, further driving its market growth during the forecast period. Increasing production of electric vehicles has accelerated the demand for industrial motors during the forecast period. The electric car market has witnessed rapid evolution with the ongoing developments in automotive sector and favorable government policies and support in terms of subsidies and grants, tax rebates. Increasing use of three phase induction motors in electric vehicles because of high efficiency and good speed regulation and absence is also anticipated to drive the growth of Industrial Motor Market. Additionally, increasing investments in production electric vehicles will increase the use of motors, thus contributing to the growth of the market. In 2021, Ford Motor announced to invest in production of electric vehicles to $30 billion by 2025, up from a previous spend of $22 billion by 2023. Such investments can increase the use of industrial motors for the need of good speed regulation, which can influence the market growth of Industrial Motor in the long run.

Buy Now

Growth of Chemicals & Petrochemicals industries leading to the adoption of industrial motors is analyzed to drive the market growth in the forecast period

Growing demand for industrial motors in chemical & petrochemical industries is set to be one of the major factors analyzed to drive the market during the forecast period. The Chemical & Petrochemical Industries have transformed tremendously at evolving several new technologies for processing chemicals along with automating these processes. The current challenge for the industries include to expand their market while maintaining optimum levels of profit. This has led to the rapid automation of the sector, particularly in the process automation segments which creates demand for industrial motors in the industry. The Chemical industry comprises of the facilities to process the raw materials derived from minerals, oil and natural gas, minerals and several other sources into industrial chemicals. This sector will be most influential in terms of growth prospects for LV and MV Industrial Motors in the forecast period as the chemicals are at the core of every demand either in industrial or consumer perspective. Moreover, induction motors are the major type of industrial motors that are used in wide variety of applications such as pumps, Compressors, Fans and blowers, centrifuges machines and mixers in chemical industry. The demand for pumps, compressors, fans and blowers, centrifuges machines and mixers in these industries are always high, owing to usage in handling toxic and aggressive acids, as well as highly flammable and explosive liquid. For instance, the chemical industry is a major sector that contributes towards the Spain’s GDP. In 2020, Spain's chemical sector accounted for 5.5% of their national gross domestic product (GDP) and 13.4% of the industrial GDP. The total revenue of the chemical sector was 64.519 billion euros, from which 36.57 billion were exported in 2020. This increasing growth was mostly due to rising local demand for chemicals coupled with engage in R&D cooperation with customers and institutes. These factors play significant role to develop higher demands for Industrial Motors in these industries resulting into the market growth.

Industrial Motor Market Challenges

High cost of raw materials to manufacture industrial motors can hamper the market growth

High cost of raw materials to manufacture industrial motors can act as a major challenge restraining the growth of Industrial Motor Market. The cost of raw material such as metals which includes steel, aluminium and insulation materials are quite expensive. Moreover, these industrial motors consume more electricity which results into rise of cost per unit. Furthermore, availability of low quality industrial motors is another factor that can hamper the market growth. Leading industrial motor manufacturing companies are facing intense competition from local motor manufacturers supplying inexpensive and low-quality AC and DC Motors to tap local markets, thus competing strongly with the global suppliers in the respective markets. Owing to the above mentioned factors, use of energy efficient industrial motor will be significantly impacted, thus hampering its market growth.

Industrial Motor Market Landscape

Partnership, Acquisitions, Collaboration, technology launches and R&D activities are key strategies adopted by players in the Industrial Motor Market. The Industrial Motor Market top 20 companies include:

ABB Ltd

Siemens AG

Nidec Corporation

Brook Crompton UK LIMITED

WEG S.A.

Emerson Electric Co

Rockwell Automation Inc

TECO Electric & Machinery Co., Ltd

Danfoss

Toshiba Corporation

Regal Rexnord Corporation

Parker-Hannifin Corporation

Fuji Electric Co., Ltd

Eaton Corporation plc

General Electric

FANUC CORPORATION

AMETEK, Inc

Allied Motion Technologies Inc

Hitachi, Ltd

Bosch Rexroth AG

Recent Developments

In December, 2021, WEG S.A , the traditional supplier of electric motors, frequency drives, automation systems, paints and digital solutions (IOT and IA), signed partnership with Marcopolo for the development of Attivi, which is the first electric bus manufactured with its own chassis. Thus, the partnership is formed as Marcopolo Attivi is equipped with a WEG Powertrain and consist of a 395 kW and 2800 Nm of torque three-phase motor and a frequency drive. The WEG Powertrain is designed with the environmental protection principles, and thus, partnership is developed to adapt the vehicle to the demands for urban and intercity transports.

In April 2021, Siemens announced the addition of the latest servo motors to its proven Sinamics S210 single-cable servo drive system. The Simotics S-1FS2 is a motor version with a stainless-steel housing, and featured with the highest degree of protection IP67/IP69, as well as high-resolution 22-bit absolute multi-turn encoders, resulting into the expansion of the range of applications across the food and beverage sector and pharmaceutical industry.

In March 2020, Rockwell Automation launched New Fanless Kinetix VPC Servo Motor to offer better performance and higher energy efficiencies. The new fanless version of the Allen-Bradley Kinetix VPC enables Printers and other industrial operators to enhance their energy efficiency and reduce machine complexity with a continuous-duty servo motor from Rockwell Automation.

#Industrial Motors Market#Industrial Motors Market size#Industrial Motors Market share#Industrial Motors Market trends

0 notes

Link

According to a research report “Blower Market by Product Type (Positive Displacement Blowers, Centrifugal Blowers, High-speed Turbo Blowers, Regenerative Blowers), Pressure (Up to 15 psi, 15-20 psi, Above 20 psi), Distribution Channel, End-Use Industry, & Region – Global Forecast to 2027″ published by MarketsandMarkets, the blower market size will grow to USD 4.3 billion by 2027 from USD 3.5 billion in 2022, at a CAGR of 4.3% during the forecast period.

0 notes

Text

What are the main advantages of axial or centrifugal fans?

Many companies are Axial Fan Manufacturer in India, but what are they used for? The phrase "industrial fan" does not have a clear meaning in reference markets, and in this post, we'll try to fill in some of the blanks by explaining what they are and answering some often asked questions.

Axial fans and centrifugal fans are the only two fundamental categories of industrial fans. Centrifugal fans and axial fans are the two most common types of fans and blowers, but there are many additional types that come under a wide variety of names, such as Industrial Blowers, Industrial Ventilation Fans, Exhaust Blowers, Industrial Exhaust Fans, HVAC fans and blowers, and many more.

Axial Fans

The first known use of an axial fan was in the horizontally oriented windmills of medieval Europe. Axial fans were the first to use electricity to propel air in the 1880s.

Axial fans conduct airflow on a single axis. A fan works because its blades spin around an axis, drawing in the air parallel to the axis and expelling it in the opposite direction.

Axial flow fans manufacturers made it to generate a lot of airflow because of the high flow rate they generate. However, the air currents they generate are weak. The amount of electricity needed to run them is little.

Best Uses of Axial Fans

It's safe to say that the vast majority of axial fans' applications are more broad in nature. Think about getting one any time you have a big air transfer to make.

Spaces, including houses and workplaces, benefit greatly from low-pressure, high-volume flow for cooling purposes. It also works well as a cooling mechanism for electronics like the PC you're using right now.

Condenser cooling in a refrigeration system makes use of an axial fan. It works wonderfully as a ventilation fan, too.

Axial fans have grown increasingly ubiquitous as technology has been integrated into more and more consumer goods. Modern vending machines employ them to keep the computers that process cashless payments at a safe temperature.

This design is probably what you need to solve airflow problems in non-ducted situations. Despite facing less resistance, axial fans are able to move large volumes of air.

Centrifugal Fans

Army engineer Lieutenant General Alexander Sablukov of the Russian Empire's Imperial Russian Army designed the centrifugal fan in 1832. Distinct from axial fans, centrifugal fans (also known as blowers) have a different design. A fan wheel consists of a number of blades attached to a central hub, and it is used to enhance the air pressure of an incoming airstream. When using a centrifugal fan, air is redirected such that it flows outward at an angle of 90 degrees with respect to the direction from which it entered.

Centrifugal fans generate airflow, which is then channeled through a network of ducts or tubes. This aids in producing airflow with greater pressure than axial fans. Centrifugal fans produce a more consistent airflow than axial fans do, albeit at the expense of flow velocity. Higher input of power is also needed by centrifugal fans.

Advantages of Using Centrifugal Fans

When a centrifugal fan is needed to push air through a duct system, it is the best option.

As a result of the higher resistance to airflow created by ductwork, the pressure is raised when ducts are present. You'll need a high-pressure fan to combat this increased pressure. A centrifugal fan is what you'll want to use.

Because of this, air conditioners and dryers can benefit greatly from using centrifugal fans. They excel in corrosive and acidic conditions as well. Their exceptional durability makes them an excellent choice for use in pollution filtering systems.

These gadgets are sturdy and hard to break since they are completely sealed and able to filter out dust and other particles.

Conclusion

A centrifugal fan is fundamentally different from an axial fan in both construction and operation. As a result of these distinctions, different types of fans are better suited to certain tasks, and consumers aren't always sure which one to choose. Choose the right axial fan manufacturer in India when you buy it! Sonika Engineers are one of the best axial flow fans manufacturers and their products like, Axial Flow Fans, Centrifugal Fans are the top most sellers in Gujarat.

0 notes

Text

American Blower LLC provides services for any brand or manufacturer of pumps

An industrial pump refers to heavy-duty process pumps that are used to move different types of products such as water, chemicals, petroleum, wastewater, oil, slurry, or food. There are mainly two types of pumps used in industrial verticals: centrifugal pumps and positive displacement pumps. Centrifugal pumps are extensively used as a result of its low cost, low maintenance, and longer lifespan.

These pumps are used in high-flow, low head applications with low viscosity. The positive displacement pumps are used in low-flow, high head with high viscosity fluids, and controlled flow applications. Some of the leading players in the market include pumps from Nash, Gardner Denver, Hoffman & Lamson, Sutorbilt, and Roots among others.

If you are interested in information please contact our American Blower certified service.

Web: http://americanblowerllc.com/

1 note

·

View note

Text

the tank ventilation jet fan can be used

The use of a tank ventilation jet fan at the industries is not a new thing. It&160MM Centrifugal In-line Duct Ventilation Fans39;s been a long time now, such high powered air driven is used at different industries where they need to deal with smoke, # fumes and hazardous gases on a regular interval. There are factories where the fumes and smokes can appear due to the work condition. And this cannot be avoided.

But on the other hand, these elements also produce real challenge for the workers and their health condition. Using the mask or any protective gear to stay away from the hazardous effects of smoke and fume cannot bring satisfactory result. There is always a need for a proper ventilation system that can exhaust such smoke and fume and can throw it into the outer atmosphere quickly. If you are using an exhaust fan for this purpose, then what about the blower and in case you can using the blower, then what about an exhauster! This can make you really confuse and you may not figure out that what you exactly need to do. Well, to eliminate your confusion tank ventilation jet fan has arrived in the market.