#Conformal Coatings Market for PCBs

Text

Optimized SMT Circuit Board and PCB Assembly Manufacturing: A Guide to Modern Electronics Production

In the ever-evolving world of hardware, the SMT (Surface Mount Technology) circuit board and PCB (Printed Circuit Board) assembly fabricating forms have gotten to be progressively vital. These advances not as it were empower the creation of smooth, compact, and high-performance electronic gadgets but moreover play an imperative part in the victory of different businesses, from shopper hardware to aviation and beyond.

Understanding the SMT Circuit Board Manufacturing Process

The SMT circuit board fabricating prepare includes the situation and fastening of electronic components specifically onto the surface of a printed circuit board. This approach offers a few focal points over conventional through-hole innovation, including:

1. Miniaturization: SMT components are by and large littler and more compact than their through-hole partners, permitting for the creation of littler and more lightweight electronic devices.

2. Increased Productivity: The robotized pick-and-place machines utilized in SMT fabricating can collect components on a circuit board much quicker than manual patching, moving forward generation efficiency.

3. Enhanced Unwavering quality: The patch joints in SMT gatherings are regularly more dependable and less inclined to disappointment than those in through-hole designs.

4. Cost Investment funds: SMT fabricating frequently decreases the in general fetched of electronic components and congregations, making them more open to a more extensive run of businesses and consumers.

The PCB Assembly Manufacturing Process

The PCB Assembly Manufacturing includes the integration of different electronic components onto a printed circuit board to make a useful electronic gadget. This prepare ordinarily incorporates the taking after steps:

1. PCB Manufacture: The to begin with step is the generation of the printed circuit board itself, which includes the creation of copper follows, cushions, and other highlights on a non-conductive substrate, such as fiberglass or ceramic.

2. Component Situation: Once the PCB is manufactured, electronic components, such as resistors, capacitors, coordinates circuits, and connectors, are put onto the board utilizing computerized pick-and-place machines or manual assembly methods.

3. Soldering: After the components are set, they are fastened onto the PCB utilizing procedures like wave patching, reflow patching, or specific fastening, depending on the particular necessities of the assembly.

4. Inspection and Testing: The amassed PCB is at that point assessed and tried to guarantee that all components are legitimately associated, and the circuit is working as intended.

5. Finishing Forms: Depending on the application, the PCB may experience extra wrapping up forms, such as conformal coating, embodiment, or the expansion of warm sinks or shielding.

The Significance of SMT Circuit Board andPCB Assembly Manufacturing

The SMT Circuit Board and PCB assemblyfabricating forms are basic for the generation of a wide run of electronic gadgets, from shopper hardware to mechanical hardware and past. These advances empower the creation of compact, lightweight, and profoundly solid electronic components and congregations, which are basic for assembly the ever-increasing request for progressed, feature-rich electronic devices.

Furthermore, the SMT circuit board and PCB gathering fabricating forms play a pivotal part in the competitiveness of different businesses, as they permit for the quick and cost-effective generation of electronic items. This, in turn, leads to progressed time-to-market, diminished fabricating costs, and upgraded item quality, all of which are basic for keeping up a competitive edge in today's worldwide marketplace.

Conclusion

The SMT circuit board and PCB assemblyfabricating forms are at the heart of the advanced gadgets industry, empowering the creation of imaginative and mechanically progressed items that proceed to change our world. By understanding the complexities and benefits of these forms, producers and originators can use these advances to make items that are not as it were outwardly engaging and profoundly useful but too cost-effective and dependable.

0 notes

Text

Electronic Protection Device Coatings Market Growing Technology Opportunities and Future Business Trends to 2032

Allied Market Research, titled, “Electronic Protection Device Coatings Market," The electronic protection device coatings market size was valued at $1.1 billion in 2022, and is estimated to reach $1.9 billion by 2032, growing at a CAGR of 5.6% from 2023 to 2032.

Electronic protection device coatings refer to specialized coatings or films applied to electronic devices or components to offer protection against various environmental and operational factors. These coatings are designed to enhance the durability, reliability, and performance of electronic devices by safeguarding them from moisture, dust, chemicals, heat, electrical interference, and different potential hazards. These coatings are thin and transparent films that conform to the structure of the device. They protect against moisture, dust, chemicals, and corrosion. Conformal coatings are commonly used in printed circuit boards (PCBs), connectors, and other electronic components.

The rising demand for electronic devices such as smartphones, tablets, laptops, and wearable devices has significantly boosted the electronic protection device coatings market growth. These coatings are used to protect electronic components from environmental factors like moisture, dust, chemicals, and corrosion, thereby extending the lifespan and reliability of the devices. Moisture and dirt can cause short circuits and different electrical malfunctions, whilst chemicals and corrosion can degrade the performance and lifespan of electronic components. By applying protective coatings, producers can enhance the durability and reliability of their devices, ensuring that they continue to function optimally even in challenging environments. The increasing demand for electronic devices, along with the need for better device durability and reliability, has been a key driver of the electronic protection device coatings market.

The electronic protection device coatings market lacks standardized testing methods and performance criteria. The absence of widely accepted standards can create uncertainty and make it difficult for customers to evaluate and compare different coating options. This can slow down the adoption of coatings and hinder electronic protection device coatings market growth. Without standardized testing methods and performance criteria, it becomes difficult to assess and compare the effectiveness of different coatings. Customers may lack confidence in the claims made by coating manufacturers, leading to hesitation in adopting new products. The absence of standardized quality control measures may result in variations in coating performance across different manufacturers. Customers may find it challenging to determine the reliability and consistency of coatings, making it harder for them to make informed decisions.

Owing to the increasing reliance on electronic devices in various sectors such as consumer electronics, automotive, aerospace, and healthcare, there is a rising demand for effective protection of these devices. Electronic protection device coatings play a vital role in safeguarding electronic components from environmental factors such as moisture, chemicals, UV radiation, and mechanical stress. The consumer electronics sector, including smartphones, tablets, laptops, and gaming consoles, continues to experience robust growth. These devices are exposed to various external factors that can potentially damage their electronic components. Electronic protection device coatings offer enhanced protection against moisture, dust, scratches, and other environmental factors, thereby extending the lifespan and reliability of these devices. The expanding market for electronic devices presents a significant opportunity for the growth of the electronic protection device coatings market.

The global electronic protection device coatings market share is segmented based on chemistry, application, and region. By chemistry, it is classified into parylene, urethane, acrylic, silicone, and epoxy. By application, it is classified into aerospace & defense, automotive, power & renewable energy, consumer electronics, industrial, medical, and others. By region, the electronic protection device coatings market is analyzed across North America, Europe, Asia-Pacific, and LAMEA.

The key players profiled in the electronic protection device coatings market analysis report include 3M, Henkel Corporation, P2i Ltd., ENDURA, Specialty Coating Systems Inc., Electronic Coating Technologies, MATERIAL SCIENCES CORPORATION, Aculon, ABB, Electrolube.

The report offers a comprehensive analysis of the global electronic protection device coatings market trends by thoroughly studying different aspects of the market including major segments, market statistics, market dynamics, regional market outlook, investment opportunities, and top players working towards the growth of the electronic protection device coatingsmarket. The report also sheds light on the present scenario and upcoming trends & developments that are contributing to the growth of the electronic protection device coatings market. Moreover, restraints and challenges that hold power to obstruct the market growth are also profiled in the report along with the Porter’s five forces analysis of the market to elucidate factors such as competitive landscape, bargaining power of buyers and suppliers, threats of new players, and emergence of substitutes in the electronic protection device coatings market.

Impact of COVID-19 on the Global Electronic Protection Device Coatings Industry

The pandemic disrupted global supply chains, including the availability of raw materials and transportation. This led to delays in production and potentially impacted the availability of electronic protection device coatings.

The economic slowdown caused by the pandemic affected various industries, including consumer electronics, automotive, and aerospace, which are major consumers of electronic protection device coatings. Reduced consumer spending and business investments in these sectors resulted in lower demand for coatings.

With the increased adoption of remote work and online learning, there has been a surge in the demand for electronic devices such as laptops, tablets, and smartphones. This increase in demand for electronic devices led to rise in the need for electronic protection coatings to safeguard these devices from environmental factors.

Key Findings of the Study

Based on chemistry, the acrylic sub-segment emerged as the global leader in 2022 and is expected to grow with the highest CAGR during the forecast period.

Based on application, the automotive sub-segment emerged as the global leader in 2022 and is predicted to have the fastest growth rate.

Based on region, the Asia-Pacific electronic protection device coatings market registered the highest market share in 2022 and is projected to show the fastest growth during the forecast period.

0 notes

Text

PCB Assembly at inYantra Technolgies

In the fast-paced world of electronics, finding a reliable partner for Printed Circuit Board (PCB) Assembly and related services is crucial. inYantra, a leading Electronics Design and Manufacturing Services (EDMS) company in India, has established itself as a premier provider of comprehensive PCB Assembly services.

Why Choose inYantra for PCB Assembly Services?

At inYantra, we understand that our customers’ success depends on the quality and reliability of their products. That’s why we offer end-to-end electronics services, from Printed Circuit Assembly to complete system integration and box build. Our goal is to ensure that our customers’ objectives are met through on-time delivery, superior quality, and cutting-edge manufacturing processes.

Quick-Turnaround for Complex and Advanced Needs

In today’s dynamic business environment, the ability to adapt quickly is key to staying competitive. We specialize in quick-turnaround services for highly complex and advanced PCB assembly and systems manufacturing. Whether you need a small batch of prototype boards or a large-scale production run, our flexible approach ensures that we meet your deadlines without compromising on quality.

Expertise in Latest Technologies

Our highly skilled and competent engineering and manufacturing team is at the forefront of the latest technology and processes in the industry. We are well-equipped to provide complete solutions for all kinds of PCB assembly requirements, ensuring that every project is handled with the highest level of expertise and precision.

Highlights of Our PCB Assembly Services

At inYantra, we offer a wide range of PCB Assembly services to meet the diverse needs of our customers. Here are some of the key highlights:

SMD Assembly: We offer Surface Mount Device (SMD) assembly services, ensuring precision and reliability for complex PCB designs.

Through Hole Assembly (Auto MI): Our automated through-hole assembly services are designed for high-volume production with consistent quality.

Hybrid Board (SMD + Through Hole): For products that require both SMD and through-hole components, we provide hybrid board assembly services.

Conformal Coating: To protect your PCBAs from environmental factors, we offer conformal coating services that enhance durability and performance.

3D X-Ray: Our state-of-the-art 3D X-Ray inspection technology ensures that even the most complex assemblies are free from defects.

Programming: We provide programming services for microcontrollers and other programmable components, ensuring that your PCBs are ready for deployment.

Testing: Comprehensive testing services are available to verify the functionality and reliability of your assembled PCBs.

Sub-Level Assembly: We offer sub-level assembly services, integrating your PCBs into larger systems with precision and care.

Conclusion

When it comes to PCB Assembly services in India, inYantra stands out as a leader in the industry. Our focus on quality, quick-turnaround, and advanced technology ensures that we can meet the needs of even the most demanding projects. Whether you are looking for a reliable partner for your next product launch or need ongoing support for your manufacturing processes, inYantra is here to help. Trust us to deliver the high-quality PCB Assembly services you need to succeed in today’s competitive market.

1 note

·

View note

Text

Global Conformal Coating Machine Market Size, Growth Rate, Industry opportunities 2024-2030

On 2024-7-18, the latest report 【Global Conformal Coating Machine Market 2024 by Manufacturers, Regions, Types and Applications, Forecast to 2030】from Global Info Research provides a detailed and comprehensive analysis of the global Conformal Coating Machine market. The report provides both quantitative and qualitative analysis by manufacturers, regions and countries, types and applications. As the market is constantly changing, this report explores market competition, supply and demand trends, and key factors that are causing many market demand changes. The report also provides company profiles and product examples of some of the competitors, as well as market share estimates for some of the leading players in 2024.

According to our (Global Info Research) latest study, the global Conformal Coating Machine market size was valued at USD million in 2023 and is forecast to a readjusted size of USD million by 2030 with a CAGR of % during review period.

Conformal Coating Machine is to achieve conformal coating in equipment or other electronic components. A conformal coating is a thin polymeric film applied to a printed circuit board (PCB) in order to protect the board and its components from the environment and corrosion. The film is typically applied at 25-250µm and ‘conforms’ to the shape of the board and its components, covering and protecting solder joints, the leads of electronic components, exposed traces, and other metallised areas from corrosion, ultimately extending the working life of the PCB.

The Global Info Research report includes an overview of the development of the Conformal Coating Machine industry chain, the market status of Automotive Board (Fully Automated Conformal Coatings Equipment, Semi Automated Conformal Coatings Equipment), Home Appliances (Fully Automated Conformal Coatings Equipment, Semi Automated Conformal Coatings Equipment), and key enterprises in developed and developing market, and analysed the cutting-edge technology, patent, hot applications and market trends of Conformal Coating Machine.

Regionally, the report analyzes the Conformal Coating Machine markets in key regions. North America and Europe are experiencing steady growth, driven by government initiatives and increasing consumer awareness. Asia-Pacific, particularly China, leads the global Conformal Coating Machine market, with robust domestic demand, supportive policies, and a strong manufacturing base.

This report also provides key insights about market drivers, restraints, opportunities, new product launches or approval.

Conformal Coating Machine market is split by Type and by Application. For the period 2019-2030, the growth among segments provides accurate calculations and forecasts for consumption value by Type, and by Application in terms of volume and value. This analysis can help you expand your business by targeting qualified niche markets.

Market segment by Type: Fully Automated Conformal Coatings Equipment、Semi Automated Conformal Coatings Equipment

Market segment by Application:Automotive Board、Home Appliances、Industrial、Medical、Aerospace & Aviation、Others

Major players covered:Nordson、(USI) Ultrasonic Systems、Precision Valve & Automation、GLENRO INC、Specialty Coating Systems、Para Tech、Hitachi High-Technologies、SCH Technologies、TTnS

The content of the study subjects, includes a total of 15 chapters:

Chapter 1, to describe Conformal Coating Machine product scope, market overview, market estimation caveats and base year.

Chapter 2, to profile the top manufacturers of Conformal Coating Machine, with price, sales quantity, revenue, and global market share of Conformal Coating Machine from 2019 to 2024.

Chapter 3, the Conformal Coating Machine competitive situation, sales quantity, revenue, and global market share of top manufacturers are analyzed emphatically by landscape contrast.

Chapter 4, the Conformal Coating Machine breakdown data are shown at the regional level, to show the sales quantity, consumption value, and growth by regions, from 2019 to 2030.

Chapter 5 and 6, to segment Conformal Coating Machine the sales by Type and by Application, with sales market share and growth rate by Type, by Application, from 2019 to 2030.

Chapter 7, 8, 9, 10 and 11, to break the Conformal Coating Machine sales data at the country level, with sales quantity, consumption value, and market share for key countries in the world, from 2019 to 2024.and Conformal Coating Machine market forecast, by regions, by Type, and by Application, with sales and revenue, from 2025 to 2030.

Chapter 12, market dynamics, drivers, restraints, trends, and Porters Five Forces analysis.

Chapter 13, the key raw materials and key suppliers, and industry chain of Conformal Coating Machine.

Chapter 14 and 15, to describe Conformal Coating Machine sales channel, distributors, customers, research findings and conclusion.

The Primary Objectives in This Report Are:

To determine the size of the total market opportunity of global and key countries

To assess the growth potential for Conformal Coating Machine

To forecast future growth in each product and end-use market

To assess competitive factors affecting the marketplace

Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

Sustainable Practices in Coating Operations - A Comprehensive Overview

As the global landscape increasingly shifts toward sustainability, industries across the board are reevaluating their processes to meet environmentally-friendly standards. In the domain of electronics manufacturing, coating operations are pivotal for product longevity and functionality. Particularly, the utilization of various sophisticated machines such as conformal coating PCB coating machine spray coating machines, and SMT conformal coating machines is essential. This article delves into how adopting sustainable practices in these operations not only benefits the environment but also enhances efficiency and compliance with international regulations.

Embracing Eco-Friendly Technologies

The introduction of the conformal coating machine marked a significant advancement in electronic production. This machine meticulously applies a protective chemical coating to printed circuit boards (PCBs), safeguarding them against moisture, dust, and thermal variations. Enhancing this process, the selective conformal coating machine allows for precise application on specified areas, significantly reducing waste and volatile organic compound (VOC) emissions.

Further refining coating precision, PCB glue coating machines and PCB conformal coating machines cater specifically to intricate designs and high-density component populations. They ensure optimal coverage without excess, adhering strictly to the required areas, thus minimizing material usage and spillage.

Integrated Automation in Coating Lines

The development of automated conformal coating lines epitomizes efficiency in modern production setups. By integrating systems such as the Coating spraying gluing machine for PCB LED, manufacturers can achieve a uniform high-quality coat across large volumes of boards while dramatically cutting down on manual labor and associated errors. The reduced need for touch-ups and rework conserves resources and leads to a substantial decline in raw material consumption.

For surface-mount technology (SMT), specific machines like the SMT coating machine and SMT conformal coating machine have been tailored to address the unique needs of SMT components and assemblies. These specialized devices ensure that environmentally sensitive applications can be completed with precision, adhering to stringent environmental standards.

Reducing Environmental Footprint

Adopting machines like the PCB spray coating machine also plays a crucial role in reducing the ecological footprint of manufacturing operations. By implementing targeted spraying technologies, these machines lower overspray and solvent use, leading directly to fewer emissions. This not only helps companies comply with stricter environmental regulations but also fosters goodwill among environmentally conscious consumers.

Moreover, advanced filtration systems can be integrated into these machines to capture contaminants before they enter the atmosphere, adding an additional layer of environmental protection. Enhanced maintenance protocols contribute further by extending machine life spans and optimizing their performance, thereby reducing waste and the need for frequent replacements.

The pivot toward sustainable practices in coating operations is not merely a response to regulatory demands but a strategic move towards greater economic efficiency and market positioning. As technology continues to evolve, the potential for fully sustainable coating operations becomes increasingly tangible. With continued innovation and commitment, the coatings industry can expect to see significant advancements in both environmental stewardship and operational prowess.

By aligning with green initiatives through sophisticated machinery and processes, companies not only contribute to the health of our planet but also position themselves as leaders in a competitive industry where sustainability has become a benchmark of success and integrity.

1 note

·

View note

Text

Understanding PCB Quotes: What to Expect and How to Get the Best Value

Printed Circuit Boards (PCBs) are the backbone of modern electronics, serving as the foundation for virtually every electronic device. When embarking on a project that requires PCBs, obtaining a PCB quote is a crucial step in the planning process. This blog will guide you through the essentials of PCB quotes, what to expect, and how to ensure you get the best value for your investment.

What is a PCB Quote?

A PCB quote is a detailed estimate provided by a PCB manufacturer or supplier outlining the costs associated with producing your PCBs. This quote includes various elements such as material costs, manufacturing processes, assembly, testing, and any additional services required. Understanding the components of a PCB quote can help you make informed decisions and manage your project's budget effectively.

Key Components of a PCB Quote

Design and Prototyping Costs:

Design Services: If you need assistance with the PCB design, the quote will include costs for design services. This can range from layout design to schematic capture.

Prototyping: Before full-scale production, prototypes are often necessary to test the design. The cost of creating these prototypes is included in the quote.

Material Costs:

Base Materials: The type of materials used, such as FR4, aluminum, or copper, significantly affects the cost. High-performance materials for specialized applications will be more expensive.

Components: The quote will list the components needed for the PCB, including resistors, capacitors, ICs, and connectors.

Manufacturing Processes:

PCB Fabrication: This includes costs for drilling, plating, and etching to create the circuit patterns on the board.

Layer Count: PCBs can be single-layer, double-layer, or multi-layer. The number of layers directly impacts the manufacturing cost.

Assembly and Soldering:

Component Placement: Automated or manual placement of components onto the PCB incurs additional costs.

Soldering: Different soldering techniques (wave soldering, reflow soldering) can influence the overall price.

Testing and Quality Control:

Inspection and Testing: Ensuring the PCB functions correctly through various testing methods (AOI, X-ray inspection, functional testing) is crucial for quality assurance.

Quality Standards: Adherence to industry standards such as IPC-A-600 or ISO certifications can add to the cost but guarantee a higher quality product.

Additional Services:

Turnkey Solutions: Full turnkey services, including component sourcing, assembly, and testing, provide a hassle-free experience but come at a premium.

Custom Features: Specialized requirements like conformal coating, specific surface finishes (ENIG, HASL), or unique board shapes may also be reflected in the quote.

Factors Influencing PCB Quotes

Several factors can affect the pricing of a PCB quote:

Order Volume: Larger orders typically benefit from economies of scale, reducing the per-unit cost.

Lead Time: Expedited services for quicker turnaround times will generally be more expensive.

Complexity: More complex designs with higher layer counts, finer pitches, or specific material requirements will increase the overall cost.

Geographic Location: Manufacturing costs can vary significantly by region, with some countries offering lower labor and material costs.

How to Obtain an Accurate PCB Quote

Provide Detailed Specifications: Clearly outline your design requirements, including dimensions, layer count, materials, and any special instructions. The more detailed your information, the more accurate the quote will be.

Request Multiple Quotes: Contact several manufacturers to compare quotes. This will give you a better understanding of the market rate and help you identify any outliers.

Check for Hidden Costs: Ensure that the quote includes all potential costs. Ask about any fees that may not be immediately apparent, such as setup charges, tooling costs, or additional testing fees.

Evaluate Manufacturer Capabilities: Choose a manufacturer with a proven track record and the necessary certifications. Quality should not be compromised for the sake of lower costs.

Consider Value-Added Services: Evaluate the benefits of additional services like turnkey solutions, which can save time and reduce the complexity of managing multiple suppliers.

Conclusion

Obtaining a PCB quote is a vital step in the development of any electronic project. By understanding the components and factors that influence the cost, you can make informed decisions and ensure that you receive a fair and comprehensive quote. Remember to provide detailed specifications, compare multiple quotes, and consider the overall value offered by the manufacturer to get the best return on your investment. With the right approach, you can secure high-quality PCBs that meet your project’s requirements without exceeding your budget. For more details visit our website www.crimpcircuits.com

#pcb manufacturing toronto#printed circuit board design#metal clad pcb#printed circuits#rigid flex pcb#full turnkey pcb services#turnkey pcb services#pcb parts#eagle software#pcb designing#flexible pcb#pcb assembly#printed circuit board manufacturers#pcb manufacturers in canada#circuit board manufacturers in canada#pcb quote#pcb prototype services in canada

0 notes

Text

0 notes

Text

Conformal Coatings Market for PCBs to Reach USD 5.3 billion, Growing 5.5% CAGR

The global conformal coatings market for PCBs is estimated to flourish at a CAGR of 5.5% from 2023 to 2031. Transparency Market Research projects that the overall sales revenue conformal coatings market for PCBs is estimated to reach US$ 5.3 billion by the end of 2031.

The increasing adoption of PCBs in medical devices necessitates conformal coatings that meet stringent regulatory requirements for biocompatibility, sterilization, and long-term reliability in harsh medical environments. The proliferation of renewable energy technologies such as solar panels and wind turbines requires PCBs with durable conformal coatings to withstand outdoor exposure to UV radiation, moisture, and temperature fluctuations.

The expansion of telecommunications infrastructure, including 5G networks and satellite communication systems, drives demand for high-performance PCBs with conformal coatings optimized for reliability and longevity in demanding outdoor environments. The growing interest in space exploration and satellite technology necessitates PCBs equipped with conformal coatings capable of withstanding extreme temperature variations, vacuum conditions, and radiation exposure in space environments.

Download Sample Copy of the Report: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=44288

Market Segmentation

By Service Type: Segmented into coating application services, consulting, and customization services catering to diverse industry needs.

By Sourcing Type: Includes acrylics, silicones, urethanes, perylene, and other material variants, reflecting different performance characteristics and application requirements.

By Application: Covers PCB protection, automotive electronics, aerospace components, industrial equipment, medical devices, and consumer electronics.

By Industry Vertical: Encompasses electronics manufacturing, automotive, aerospace & defense, healthcare, industrial machinery, and telecommunications.

By Region: Analysis based on geographical regions such as North America, Europe, Asia Pacific, Latin America, and Middle East & Africa, considering regional demand dynamics and regulatory frameworks.

Regional Analysis

North America: Technological advancements in electronics, automotive innovations, and aerospace developments drive significant demand for conformal coatings in the region.

Europe: Strict regulatory standards for electronic devices and automotive components boost adoption of high-performance conformal coatings.

Asia Pacific: Dominant region in electronics manufacturing, automotive production, and consumer electronics, fueling market growth for conformal coatings.

Latin America, Middle East & Africa: Emerging markets witnessing increased industrialization and infrastructure development contribute to market opportunities for conformal coatings.

Market Drivers and Challenges

Drivers:

Electronic Device Miniaturization: Shrinking electronic components require advanced protection against environmental factors, driving demand for conformal coatings.

Automotive and Aerospace Innovations: Complex electronic systems in vehicles and aircraft demand reliable protection solutions, boosting coating market growth.

Stringent Quality Standards: Compliance with industry standards and regulations mandates the use of reliable conformal coatings for critical applications.

Challenges:

Technological Complexity: Evolving electronics and materials require continuous innovation in coating formulations and application methods.

Environmental Concerns: Proper handling, disposal, and recycling of coating materials pose sustainability challenges for the industry.

Cost Pressures: Balancing performance requirements with cost-effectiveness remains a challenge for coating manufacturers and end-users.

Market Trends

Emergence of Nano-coatings: Development of nano-scale conformal coatings for enhanced protection, moisture resistance, and electrical insulation.

Environmentally Friendly Formulations: Adoption of eco-friendly materials, solvent-free coatings, and recycling initiatives to address sustainability concerns.

Smart Coatings: Integration of functional properties such as self-healing, anti-corrosion, and antimicrobial features in conformal coatings for specialized applications.

Future Outlook

The conformal coatings market is poised for continued growth driven by technological advancements, expanding applications across industries, and regulatory imperatives for product reliability and performance. Market players focusing on innovation, sustainability, and strategic partnerships will be well-positioned to capitalize on emerging opportunities and address evolving customer needs.

Key Market Study Points

Market size and growth projections for conformal coatings

Segmentation analysis based on service type, sourcing type, application, industry vertical, and region

Regional dynamics, regulatory landscapes, and market trends

Drivers, challenges, and opportunities shaping the market landscape

Future outlook and growth strategies for stakeholders

Conformal Coatings Market for PCBs: Competitive Landscape

The Conformal Coatings Market for PCBs is fiercely competitive, characterized by key players like Henkel AG & Co. KGaA, Dow Chemical Company, and Chase Corporation. These industry giants dominate with extensive product portfolios and global presence. Emerging players such as MG Chemicals and Electrolube are rapidly gaining traction, offering innovative formulations and tailored solutions to meet specific customer needs.

Buy this Premium Research Report @ https://www.transparencymarketresearch.com/checkout.php?rep_id=44288<ype=S

Competition is driven by factors like product performance, environmental regulations, and technological advancements. As electronics become more pervasive across industries, the demand for high-quality conformal coatings continues to rise, intensifying competition and spurring innovation in the market. Some prominent players are as follows:

Henkel AG & Co. KGaA

Dow

Chase Corporation

Electrolube

Shin-Etsu Chemical Co. Ltd.

Europlasma N.V.

B. Fuller Company

MG Chemicals

Al Technology Inc.

Chemtronics

Aalpha Conformal Coatings

KISCO Ltd.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

Electronic Adhesives Market| Market Size, Share, Trends, Analysis, Growth and Forecast, 2023 – 2027

Originally published on Technavio: Electronic Adhesives Market by Application, Product and Geography- Forecast and Analysis 2023-2027

The Electronic Adhesives Market is poised for comprehensive analysis and anticipated growth during the forecast period from 2023 to 2027. This market, integral to the electronics manufacturing industry, will be examined based on its applications, product variations, and geographical trends influencing its trajectory.

In terms of applications, the Electronic Adhesives Market serves a critical role in various segments of the electronics industry. These adhesives are widely used in applications such as surface mounting, conformal coatings, wire tacking, encapsulation, and bonding of electronic components. In surface mounting, electronic adhesives are essential for attaching components to printed circuit boards (PCBs), ensuring secure and reliable connections. Conformal coatings protect electronic assemblies from environmental factors such as moisture, dust, and chemicals. Wire tacking involves securing wires and cables within electronic devices, preventing movement and potential damage. Encapsulation is employed to protect sensitive electronic components from mechanical stress and environmental hazards. The versatility of electronic adhesives supports the intricate and diverse needs of modern electronics manufacturing.

The Electronic Adhesives Market offers various product formulations to cater to the specific requirements of different applications. Common types of electronic adhesives include conductive adhesives, thermally conductive adhesives, UV-curable adhesives, and epoxy adhesives. Conductive adhesives facilitate the electrical connection between components, contributing to the efficient functioning of electronic devices. Thermally conductive adhesives aid in heat dissipation, crucial for electronic components with heat-sensitive requirements. UV-curable adhesives offer rapid curing and bonding for applications demanding speed and precision. Epoxy adhesives provide strong and durable bonds, making them suitable for a wide range of electronic assembly applications.

Geographically, the global Electronic Adhesives Market demonstrates a widespread presence, with significant contributions from regions such as North America, Europe, Asia-Pacific, and South America. North America, particularly the United States, is a major player in the market, driven by a robust electronics manufacturing sector and ongoing technological advancements. Europe, with countries like Germany and the United Kingdom, is another key contributor, benefitting from a focus on research and development in electronics. The Asia-Pacific region, led by countries such as China, Japan, and South Korea, is experiencing notable growth, reflecting its status as a global hub for electronics manufacturing. South America, with its expanding electronics industry, also contributes significantly to the global market.

To Learn deeper into this report , View Sample PDF

The forecasted period for the Electronic Adhesives Market underscores the critical role these materials play in the fast-paced and ever-evolving electronics manufacturing landscape. As electronics continue to advance in complexity and functionality, manufacturers and stakeholders in the adhesives sector must stay attuned to evolving technological requirements, environmental considerations, and global market dynamics to capitalize on the expanding opportunities within this dynamic market.

For more information please contact.

0 notes

Text

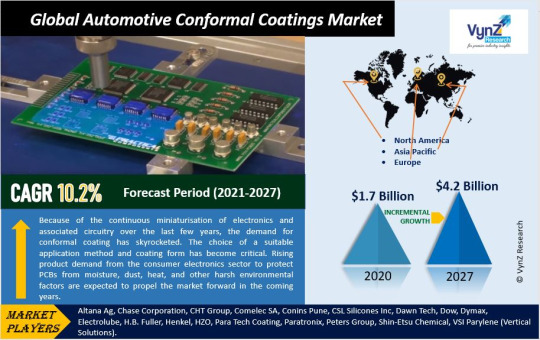

Global Automotive Conformal Coatings Market - Growth, Trends, COVID-19 Impact, and Forecasts (2021-2027)

The global automotive conformal coatings market is expected to reach USD 4.2 billion by 2027, from USD 1.7 billion in 2020. The market is growing at a CAGR of 10.2%, driven by the increasing adoption of electronics in vehicles and the development of new technology.

Market Overview

The global automotive conformal coatings market is segmented by material, component, vehicle type, application, and region.

By material: The market is segmented into acrylic, silicone, epoxy, polyurethane, and parylene. Acrylic is the most widely used material, followed by silicone.

By component: The market is segmented into ECU, PCB, sensor, battery casing, LED, and infotainment system. ECUs are the largest application segment, followed by PCBs and sensors.

By vehicle type: The market is segmented into passenger vehicles, light commercial vehicles, and heavy commercial vehicles. Passenger vehicles are the largest application segment, followed by light commercial vehicles and heavy commercial vehicles.

By application: The market is segmented into brush coating, dipping, spray coating, selective coating, and vapor deposition. Brush coating is the most widely used application method, followed by dipping and spray coating.

By region: The market is segmented into North America, Europe, Asia Pacific, Middle East & Africa, and South America. Asia Pacific is the largest market for automotive conformal coatings, followed by Europe and North America.

Get a free sample copy of the research report: https://www.vynzresearch.com/automotive-transportation/automotive-conformal-coatings-market/request-sample

Key Players

The key players in the global automotive conformal coatings market are:

• Altana Ag

• Chase Corporation

• CHT Group

• Comelec SA

• Conins Pune

• CSL Silicones Inc

• Dawn Tech

• Dow

• Dymax

• Electrolube

• H.B. Fuller

• Henkel

• HZO

• Para Tech Coating

• Paratronix

• Peters Group

• Shin-Etsu Chemical

• VSI Parylene (Vertical Solutions)

Trends and Opportunities

The global automotive conformal coatings market is expected to witness significant growth in the coming years. This growth will be driven by a number of factors, including:

The increasing adoption of electronics in vehicles

The development of new technology, such as self-driving cars and electric vehicles

The growing demand for conformal coatings in harsh environments

Challenges

The automotive conformal coatings market faces a number of challenges, including:

The high cost of conformal coatings

The complexity of the application process

The need for regular maintenance

Conclusion

The global automotive conformal coatings market is expected to grow significantly in the coming years. This growth will be driven by a number of factors, including the increasing adoption of electronics in vehicles, the development of new technology, and the growing demand for conformal coatings in harsh environments. The key players in the market are major suppliers of conformal coatings to OEMs and aftermarket distributors. The market faces a number of challenges, including the high cost of conformal coatings, the complexity of the application process, and the need for regular maintenance.

About Us:

VynZ Research is a global market research firm offering research, analytics, and consulting services on business strategies. We have a recognized trajectory record and our research database is used by many renowned companies and institutions in the world to strategize and revolutionize business opportunities.

Source: VynZ Research

0 notes

Text

Electronics Conformal Coating Market Size, Share, Growth Trends, and Forecast Analysis to 2032

The Electronics Conformal Coating Market is a rapidly growing sector within the electronics industry. Conformal coating refers to a protective layer applied to electronic components and printed circuit boards (PCBs) to safeguard them from environmental factors such as moisture, dust, chemicals, and temperature variations. The demand for conformal coatings has surged due to the increasing complexity and miniaturization of electronic devices, coupled with the need for enhanced reliability and longevity of these products in harsh operating conditions.

One of the primary drivers of the Electronics Conformal Coating Market is the escalating adoption of electronic components in various industries, including automotive, aerospace, consumer electronics, and medical devices. These industries heavily rely on electronics that can withstand demanding environments, driving the demand for effective conformal coatings. Additionally, the rise in Internet of Things (IoT) devices and smart connected devices has further fueled the growth of the conformal coating market, as these gadgets often operate in diverse environments.

Moreover, the advancement of conformal coating technologies has led to the development of environmentally friendly and more efficient coatings, further propelling market growth. Manufacturers are investing in research and development to create new formulations that provide better protection while being easier to apply and more sustainable. This push towards eco-friendly solutions aligns with the growing global awareness of environmental concerns.

Furthermore, the Asia-Pacific region has emerged as a significant player in the Electronics Conformal Coating Market. The region's robust electronics manufacturing industry, particularly in countries like China, South Korea, and Japan, has driven the demand for conformal coatings. Additionally, the region's increasing investments in infrastructure and rising consumer disposable income have contributed to the growth of the consumer electronics sector, further bolstering the market.

For More Info@ https://www.globenewswire.com/en/news-release/2023/03/31/2638740/0/en/Electronics-Conformal-Coating-Market-to-Surpass-US-1-7-Billion-by-2032-as-Demand-from-Automobile-and-Consumer-Electronics-Industries-Rises-says-Persistence-Market-Research.html

Overall, the Electronics Conformal Coating Market is expected to witness substantial growth in the coming years as the demand for reliable and durable electronic devices continues to rise across various industries. The development of advanced conformal coating technologies and the market's expansion in the Asia-Pacific region are likely to be significant factors shaping the future of this industry.

0 notes

Text

0 notes

Text

0 notes

Text

Automotive Conformal Coatings Market Expected to Witness a Sustainable Growth Over 2031

New York, Global Automotive Conformal Coatings Market report from Global Insight Services is the single authoritative source of intelligence on Automotive Conformal Coatings Market. The report will provide you with analysis of impact of latest market disruptions such as Russia-Ukraine war and Covid-19 on the market. Report provides qualitative analysis of the market using various frameworks such as Porters’ and PESTLE analysis. Report includes in-depth segmentation and market size data by categories, product types, applications, and geographies. Report also includes comprehensive analysis of key issues, trends and drivers, restraints and challenges, competitive landscape, as well as recent events such as M&A activities in the market.

Get Access to A Free Sample Copy of Our Latest Report : https://www.globalinsightservices.com/request-sample/GIS20997

Automotive Conformal Coatings are thin films that are applied to the surface of electronic components and printed circuit boards (PCBs) for protection from the environment. The coatings are applied in a thin layer and conform to the shape of the component, providing a barrier against moisture, dust, chemicals, and other contaminants. Conformal coatings are used in a variety of automotive applications, including engine control units (ECUs), body control modules (BCMs), infotainment systems, and sensor modules.

Key Players

The Automotive Conformal Coatings Market report includes players such as Altana Ag, Chase Corporation, CHT Group, Comelec SA, ConinsPune, CSLSilicones Inc, Dawn Tech, Dow, Dymax and Electrolube.

Key Trends

There are several key trends in automotive conformal coatings technology. One is the move towards more environmentally friendly coatings. This is being driven by regulations in many countries that are becoming more stringent. Another trend is the development of coatings that are more resistant to thermal shock. This is important for applications where the coated parts are exposed to extreme temperatures. Finally, there is a trend towards coatings that have better adhesion to substrate materials. This is important for preventing delamination and ensuring that the coating lasts for the intended lifetime of the part.

Free Customization Available : https://www.globalinsightservices.com/request-customization/GIS20997

Key Drivers

Automotive Conformal Coatings are an important part of the automotive industry and are used in a variety of applications. They are used to protect electronic components from the harsh environment inside a vehicle, and also to improve the reliability of those components. The main drivers of the Automotive Conformal Coatings market are the increasing demand for vehicles with higher levels of electronic content, and the need to protect those electronic components from the harsh environment inside a vehicle.

The automotive industry is increasingly relying on electronic components to improve the performance of vehicles. This trend is being driven by the need to meet stricter emissions regulations, and the desire to improve fuel efficiency. The electronic content of a vehicle can include items such as engine management systems, infotainment systems, and active safety systems. The increasing demand for vehicles with higher levels of electronic content is driving the demand for Automotive Conformal Coatings.

The harsh environment inside a vehicle can cause problems for electronic components. The temperature inside a vehicle can vary widely, from the freezing cold of winter to the scorching heat of summer. The humidity inside a vehicle can also be high, which can cause corrosion of electronic components. The vibration and shock that a vehicle experiences during driving can also damage electronic components. The main driver of the Automotive Conformal Coatings market is the need to protect electronic components from the harsh environment inside a vehicle.

Automotive Conformal Coatings are used to improve the reliability of electronic components. The coatings can protect components from the environment inside a vehicle, and they can also improve the connection between components. The coatings can also help to dissipate heat, which can improve the reliability of electronic components. The main driver of the Automotive Conformal Coatings market is the need to improve the reliability of electronic components.

Market Segments

By Material

Acrylic

Silicone

Epoxy

Others

By Application

Brush Coating

Dipping

Spray Coating

Selective Coating

By Component

ECU

PCB

Sensors

Battery Casing

Others

By Region

North America

The U.S.

Canada

Mexico

Europe

The UK

Germany

France

Spain

Rest of Europe

The Asia Pacific

China

India

Japan

South Korea

Rest of Asia-Pacific

Rest of the World

Latin America

The Middle East

Purchase This Market Research Report – https://www.globalinsightservices.com/checkout/single_user/GIS20997

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Excel data pack included with all report purchases

Robust and transparent research methodology

About Global Insight Services:

Global Insight Services (GIS) is a leading multi-industry market research firm headquartered in Delaware, US. We are committed to providing our clients with highest quality data, analysis, and tools to meet all their market research needs. With GIS, you can be assured of the quality of the deliverables, robust & transparent research methodology, and superior service.

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1-833-761-1700

Website: https://www.globalinsightservices.com/

#Automotive Conformal Coatings Market#Automotive Conformal Coatings Market Demand#Automotive Conformal Coatings Market Forecast#Automotive Conformal Coatings Market Growth#Automotive Conformal Coatings Market Overview#Automotive Conformal Coatings Market Share And Size#Automotive Conformal Coatings Market Trend#Impact of COVID-19 on Automotive Conformal Coatings Market

0 notes

Text

Conformal Coatings Market Driven By Aerospace, Automotive, Consumer Electronics, And Medical Applications

The global conformal coatings market size is anticipated to reach USD 1,493.46 million by 2030, according to a new report by Grand View Research, Inc., advancing at a CAGR of 5.9% during the forecast period. The global conformal coatings market is anticipated to grow with the development in aerospace, automotive, consumer electronics, and medical applications across the globe. Rising expectations regarding automation in the abovementioned applications have driven the demand for electronic devices & equipment.

The conformal coatings provide improved product characteristics, including high heat, dust, moisture resistance, corrosion resistance, and improved overall durability. The use of conformal coating has driven the demand for high-quality dispensing mechanisms to dispense conformal coatings effectively, since poor dispersion results in cracks in the coating layer and affects PCB functions. In January 2021, Delta Electronics, Inc. provided a PCB conformal coating dispensing and inspection solution to an electronic automotive component manufacturer in Tianjin, China. The mechanism dispenses coatings through a nozzle and triggers an alarm in case of insufficient or improper dispensing.

Gain deeper insights on the market and receive your free copy with TOC now @: Conformal Coatings Market Report

Players in the conformal coatings market are adopting merger & acquisition initiatives to expand their reach. For instance, in May 2021, Element Solutions, Inc. acquired H.K. Wentworth Limited, a U.K.-based company involved in manufacturing conformal coatings, thermal management materials, electronic cleaning solutions, and encapsulation resins. The company has a presence in over 55 countries and caters to end-user markets, including aerospace & defense, medical, telecommunications, and consumer electronics. This acquisition can help Element Solutions, Inc. to expand its conformal coatings manufacturing capacity in various end-use markets.

Due to the presence of several players in the conformal coatings market, the competitive rivalry is high. Conformal coating manufacturers collaborate with other market players to increase their market share. For instance, in May 2021, Dymax and HZO, Inc. entered into a strategic alliance to facilitate joint product development, formulate existing coating solutions, and accelerate market reach. Dymax is involved in producing conformal coatings, and such initiatives can strengthen its position in the conformal coatings market.

#Conformal Coatings Market Size & Share#Conformal Coatings Market Latest Trends#Conformal Coatings Market Growth Forecast#Conformal Coatings Industry Insights#COVID-19 Impacts On Conformal Coatings Market#Conformal Coatings Market Revenue Value#Global Conformal Coatings Market

0 notes

Link

0 notes