#Coolants & Coolant Flow Control Valves

Text

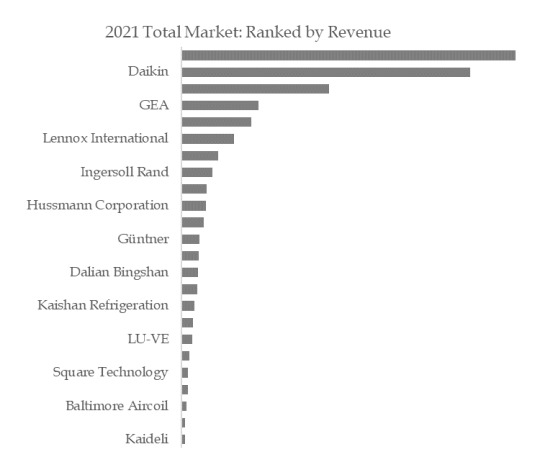

Global top 24 companies accounted for 45% of total Engine Cooling System, Refrigeration System, Coolants & Coolant Flow Control Valves market(qyresearch, 2021)

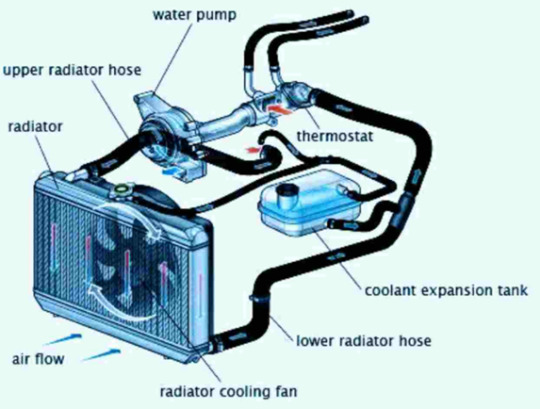

The engine-cooling system serves not just to keep the engine cool, but to also keep its temperature warm enough to ensure efficient, clean operation. System components include a radiator to dissipate heat, a fan or fans to ensure adequate airflow for radiator cooling, a thermostat valve that opens when the desired operating temperature is reached and a water pump (or coolant pump) to circulate coolant through the engine, hoses and other components.

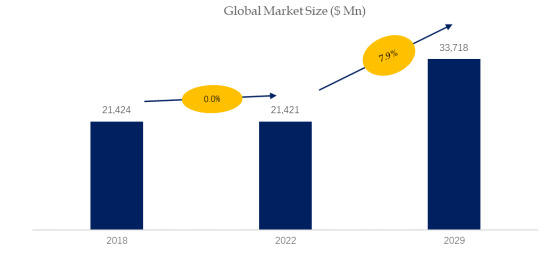

According to the new market research report “Global Engine Cooling System, Refrigeration System, Coolants & Coolant Flow Control Valves Market Report 2023-2029”, published by QYResearch, the global Engine Cooling System, Refrigeration System, Coolants & Coolant Flow Control Valves market size is projected to reach USD 33.72 billion by 2029, at a CAGR of 7.9% during the forecast period.

Figure. Global Engine Cooling System, Refrigeration System, Coolants & Coolant Flow Control Valves Market Size (US$ Mn), 2018-2029

Figure. Global Engine Cooling System, Refrigeration System, Coolants & Coolant Flow Control Valves Top 24 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Engine Cooling System, Refrigeration System, Coolants & Coolant Flow Control Valves include Kaideli, FRIGEL, Baltimore Aircoil, Star Refrigeration, Square Technology, Zhejiang Gaoxiang, LU-VE, Evapco, Johnson Controls, Hussmann Corporation, etc. In 2021, the global top five players had a share approximately 45.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

For more information, please contact the following e-mail address:

Email: [email protected]

Website: https://www.qyresearch.com

0 notes

Text

Engine Repair Instruction Full Guide

Engines are the heart of any vehicle, powering everything from your daily commute to long road trips. Knowing how to repair an engine can be a game-changer, whether you're an enthusiast who loves getting your hands dirty or someone looking to save money on mechanic bills. This guide will walk you through the entire process of engine repair, from diagnosing problems to reassembling your engine and ensuring it runs smoothly.

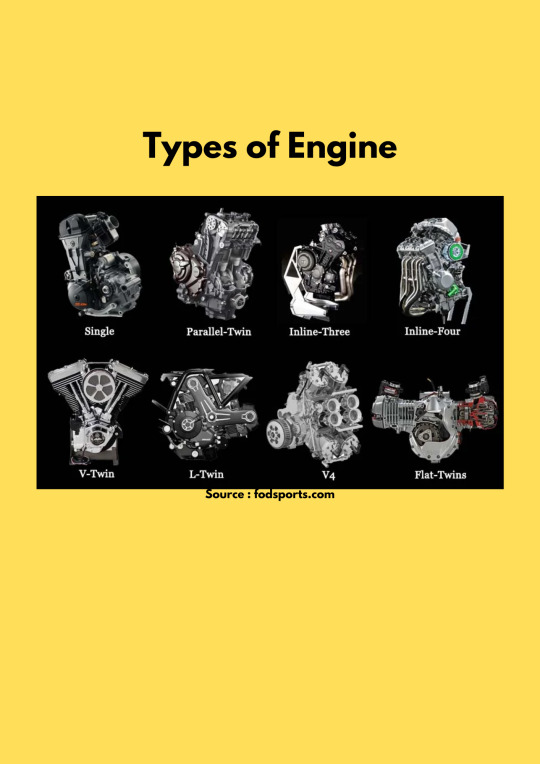

Understanding the Basics of an Engine

Before diving into the repair process, it’s crucial to understand how an engine works. Most vehicles use an internal combustion engine, which combines fuel and air, ignites it, and transforms that explosion into mechanical energy.

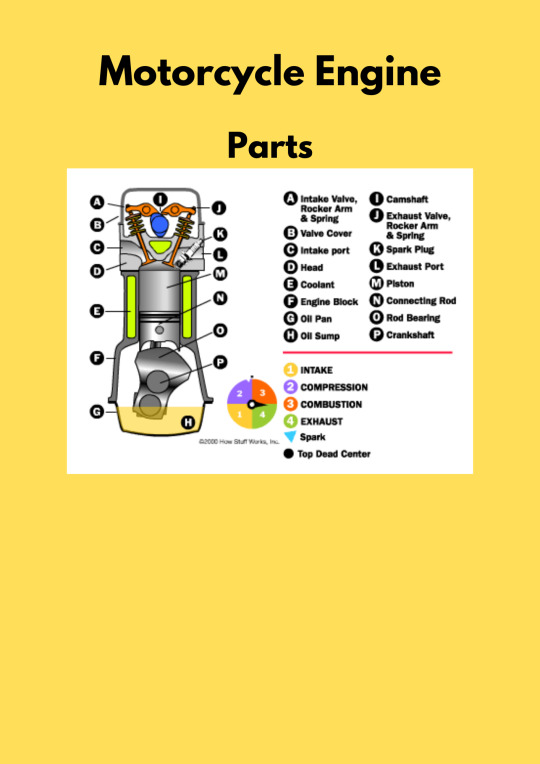

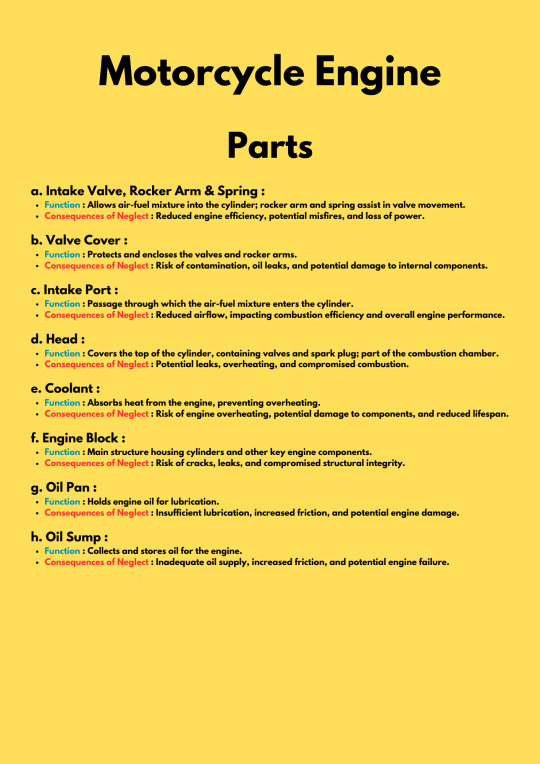

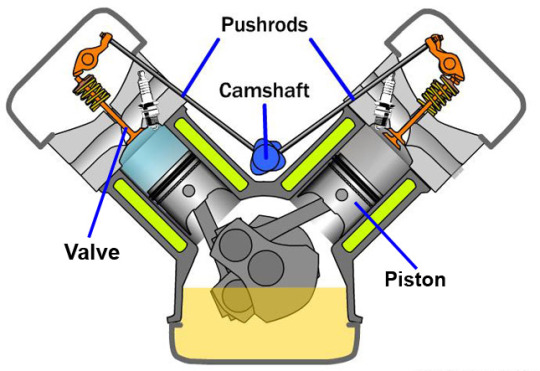

Components of an Internal Combustion Engine

The main components include:

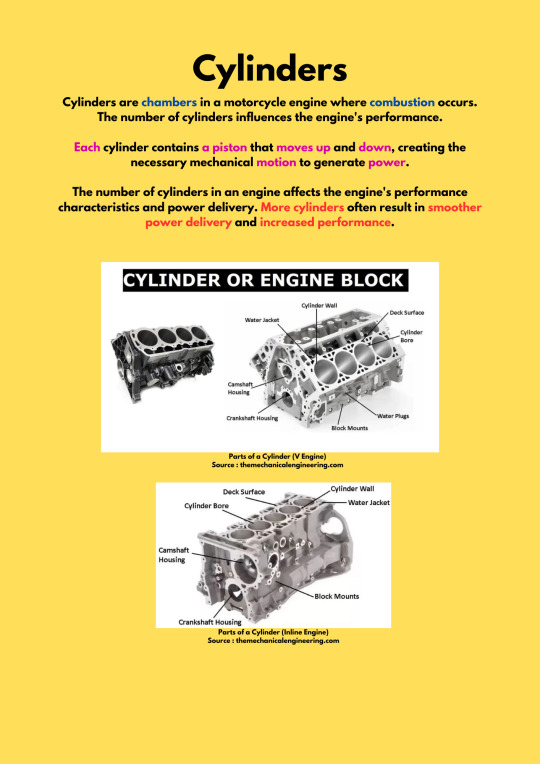

Cylinder Block: The engine's core where combustion occurs.

Cylinder Head: Houses the valves and spark plugs.

Pistons: Move up and down to create the force needed to turn the crankshaft.

Crankshaft: Converts the pistons' up-and-down movement into rotational motion.

Camshaft: Controls the opening and closing of the valves.

Valves: Regulate the flow of fuel and air into the engine and exhaust gases out.

How an Engine Works: A Simple Explanation

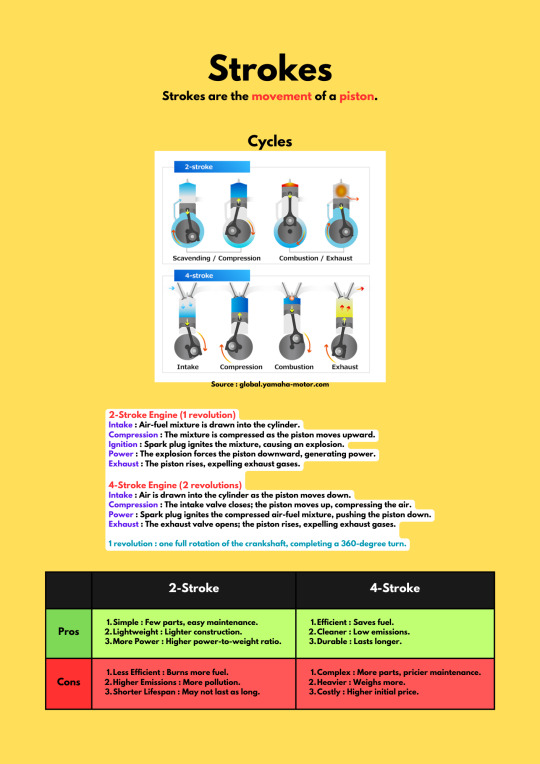

An engine works by pulling in a mixture of air and fuel, compressing it, igniting it with a spark (in gasoline engines), and then expelling the exhaust gases. This cycle—intake, compression, power, and exhaust—happens in each cylinder and repeats hundreds of times per minute.

Tools and Equipment Needed for Engine Repair

Whether you're performing a basic repair or diving into more complex work, having the right tools is essential.

Essential Tools for Basic Repairs

Socket Set: For removing and tightening bolts.

Wrenches: Different sizes for various engine parts.

Screwdrivers: Flathead and Phillips for screws and clips.

Pliers: For handling wires and small parts.

Torque Wrench: Ensures bolts are tightened to the correct specifications.

Specialized Equipment for Advanced Engine Work

Engine Hoist: For removing the engine from the vehicle.

Cylinder Hone: Prepares cylinders for new piston rings.

Compression Tester: Checks the health of each cylinder.

OBD-II Scanner: Diagnoses engine codes and issues.

Safety Gear and Precautions

Gloves: Protect your hands from cuts and chemicals.

Safety Glasses: Shield your eyes from debris.

Work Boots: Offer protection against heavy parts or tools.

Diagnosing Engine Problems

Accurately diagnosing engine problems is the first step in any repair process. Understanding the symptoms can save time and prevent unnecessary work.

Common Symptoms of Engine Issues

Check Engine Light: Indicates a problem detected by the car's computer.

Strange Noises: Knocking, tapping, or grinding sounds can signal internal damage.

Excessive Smoke: Blue smoke might mean burning oil, while white could suggest a coolant leak.

Loss of Power: Often linked to fuel or air delivery issues.

Step-by-Step Diagnostic Process

Listen and Observe: Note any unusual sounds, smells, or behaviors.

Check Engine Light Codes: Use an OBD-II scanner to retrieve error codes.

Perform Compression Test: Assesses the health of your engine’s cylinders.

Inspect Fluids: Look for contamination or leaks in oil, coolant, and other fluids.

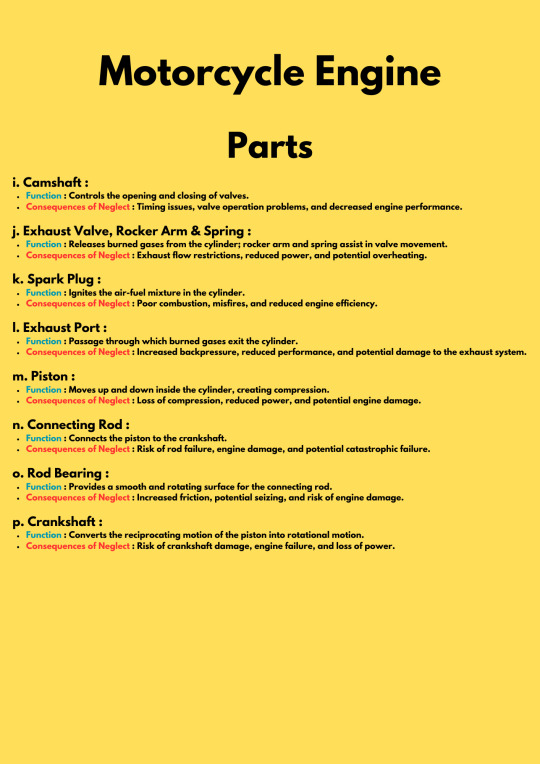

Step-by-Step Guide to Reassembly

Prepare Your Workspace: Ensure that your workspace is clean, organized, and well-lit. Lay out all the parts and tools you'll need in the order of reassembly. Keep the engine manual handy for specific torque specs and sequences.

Install the Crankshaft: Place the crankshaft back into the engine block, ensuring it is seated correctly. Use assembly lube on the main bearings to prevent damage during the initial startup. Torque the main caps to the manufacturer's specifications.

Insert the Pistons: Install the pistons and connecting rods. Be sure to align the piston rings correctly and use a ring compressor to insert the pistons into the cylinder bore. Attach the connecting rods to the crankshaft and torque the rod bolts to spec.

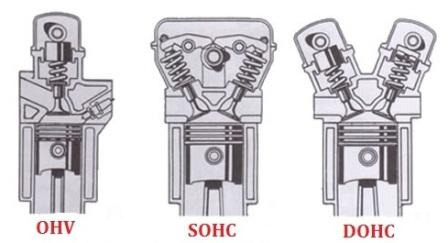

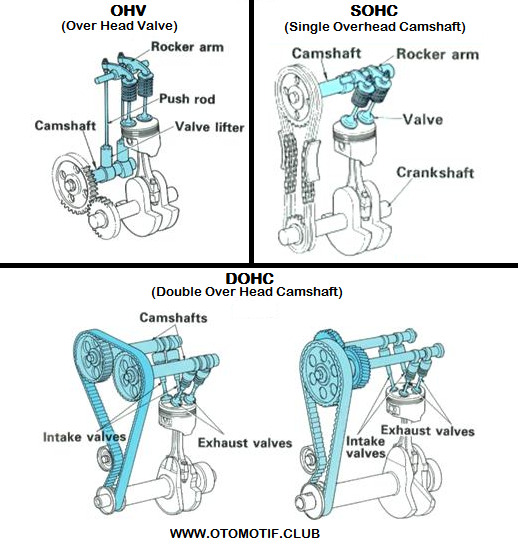

Install the Camshaft and Timing Components: If your engine uses a timing chain or belt, install it according to the timing marks on the camshaft and crankshaft gears. This step is crucial for ensuring the engine's valves open and close at the correct times.

Attach the Cylinder Head: Place the cylinder head gasket on the engine block, followed by the cylinder head. Torque the head bolts in the correct sequence and to the proper specifications. This ensures a good seal and prevents head gasket failure.

Install Valves, Lifters, and Pushrods: If applicable, install the engine's valves, lifters, and pushrods. Make sure they are properly aligned and that the lifters are seated correctly in their bores.

Reassemble the Valve Train: Install the rocker arms and adjust the valve lash according to the engine manual. Proper valve lash is critical for engine performance and longevity.

Reattach External Components: Begin reattaching external components like the water pump, oil pump, timing cover, oil pan, and intake manifold. Replace any gaskets and seals during this process to prevent leaks.

Reconnect the Fuel and Ignition Systems: Reinstall the fuel injectors, spark plugs, and ignition wires. Ensure all electrical connections are secure and properly routed to avoid short circuits or malfunctions.

Final Checks: Before moving on, double-check all connections, bolts, and components. Make sure nothing is left loose or unconnected.

Applying Proper Torques and Specifications

Every engine has specific torque settings for each bolt. Over-tightening can strip threads or warp components, while under-tightening can lead to leaks or parts coming loose. Use a torque wrench and follow the manufacturer's specifications closely.

Double-Checking Work for Mistakes

It's easy to miss a step or make a mistake during reassembly. Double-check your work:

Ensure all components are installed in the correct order.

Verify all bolts are torqued to spec.

Check for any leftover parts or tools in the engine bay.

Testing the Repaired Engine

With the engine reassembled, the next step is testing it to ensure everything is functioning properly.

Preparing for Initial Startup

Before starting the engine, perform a few preparatory checks:

Prime the oil system: This can be done by cranking the engine with the fuel system disabled until oil pressure is achieved.

Fill the engine with fresh oil and coolant.

Double-check all electrical connections and fuel lines.

Checking for Leaks and Unusual Noises

Once you start the engine, pay close attention to any unusual noises or leaks:

Oil Leaks: Check around the oil pan, valve covers, and front and rear seals.

Coolant Leaks: Inspect the radiator, hoses, and water pump area.

Unusual Noises: Listen for knocking, tapping, or whining sounds, which could indicate an issue with the timing components or internal parts.

Fine-Tuning and Adjusting the Engine

After the initial startup, the engine may require some adjustments:

Timing Adjustments: Use a timing light to set the ignition timing.

Idle Speed: Adjust the idle speed according to the manufacturer’s specifications.

Fuel Mixture: On carbureted engines, you may need to adjust the air-fuel mixture for optimal performance.

Common Engine Repair Mistakes to Avoid

Engine repair is complex, and mistakes can be costly. Here are some common errors to watch out for:

Misalignments and Incorrect Torques

Misaligned timing components can lead to poor engine performance or damage.

Incorrectly torqued bolts can cause leaks, parts failure, or engine damage.

Overlooking Small Parts and Connections

Small parts like washers, clips, or gaskets are easy to overlook but crucial for preventing leaks and ensuring proper function.

Electrical connections: Double-check that all sensors and connectors are properly seated.

Skipping Diagnostic Steps

Skipping steps in the diagnostic process can lead to unnecessary repairs or missed issues. Always perform thorough diagnostics before and after repairs.

Maintaining Your Engine After Repair

Proper maintenance is key to ensuring the longevity of your newly repaired engine.

Importance of Regular Maintenance

Regular maintenance, such as oil changes, air filter replacements, and coolant checks, is essential to keep your engine running smoothly and prevent future problems.

Tips for Extending Engine Life

Use high-quality oil and filters.

Avoid hard driving until the engine is fully warmed up.

Regularly check and maintain fluid levels.

When to Seek Professional Help

While DIY repairs can save money, some issues are best left to professionals, especially if you encounter complex problems or lack the necessary tools and expertise.

Dealing with Advanced Engine Repairs

Some engine repairs are too complex for the average DIYer. Here's when to consider professional help:

Understanding When It’s Beyond DIY

Extensive internal damage: Cracked blocks or severely worn bearings usually require professional expertise.

Advanced electrical issues: Problems with engine management systems often need specialized diagnostic tools and knowledge.

Overview of Complex Repairs: Timing Belt, Engine Rebuilds

Timing Belt Replacement: Involves precise alignment of engine components and is critical for preventing engine damage.

Engine Rebuilds: This is a time-consuming and complex task that often requires professional machining and specialized tools.

Working with a Professional Mechanic

When the repair is beyond your capabilities, working with a professional mechanic ensures that the job is done correctly and safely. They have the tools, experience, and resources to handle complex engine repairs.

Cost Considerations in Engine Repair

Engine repair costs can vary widely depending on the scope of work, parts required, and whether you do it yourself or hire a professional.

Estimating Costs for DIY vs Professional Repair

DIY Repairs: Typically cost less but require an investment in tools and time.

Professional Repairs: Can be expensive but come with the assurance of experience and often a warranty.

Budgeting for Tools, Parts, and Time

Consider the cost of any special tools or equipment you might need, as well as the cost of replacement parts. Factor in the time required, especially if the vehicle is your daily driver.

Understanding the Cost of Mistakes

Mistakes can be costly. Stripping a bolt, breaking a part, or incorrect assembly can lead to additional expenses. Always weigh the risks before starting a major repair.

Conclusion

Recap of Key Points

Engine repair is a rewarding but challenging task that requires careful planning, the right tools, and attention to detail. Whether you’re fixing a minor issue or performing a complete rebuild, following the correct procedures is crucial for success.

Encouragement for DIY Enthusiasts

For those who love working on their vehicles, engine repair can be a satisfying and cost-effective way to maintain your car. With patience and persistence, even complex repairs can be tackled with confidence.

Final Thoughts on Engine Repair

Always approach engine repair with a clear plan and the right resources. Don’t hesitate to seek professional help when needed, and remember that regular maintenance is the best way to avoid major repairs.

FAQs

How do I know if my engine needs repair?

Common signs include unusual noises, excessive smoke, loss of power, and a check engine light. Regular diagnostics can help catch issues early.

Can I repair my engine without professional help?

Basic repairs like replacing gaskets or sensors can often be done at home with the right tools. However, more complex tasks like engine rebuilds may require professional expertise.

What are the signs of a failing engine?

Signs include knocking noises, excessive oil consumption, smoke from the exhaust, and persistent overheating.

How long does it take to repair an engine?

The time required varies greatly depending on the complexity of the repair. Simple repairs might take a few hours, while a full rebuild could take several days or longer.

2 notes

·

View notes

Text

i am not gonna lie the only game I've been playing recently is Realistic Boiling Water Reactor Simulator on roblox and its so much fun. Im balancing coolant flows, meeting network demand, setting the recirculation to control reactivity in the reactor, opening deareator valves and such

1 note

·

View note

Text

Identifying and Resolving Issues with Truck Heater Cores and Valves

When it comes to maintaining a truck, one of the most overlooked yet vital systems is the heater. Often taken for granted, the heater core and valve in trucks ensure comfort during cold seasons by regulating the flow of warm air. However, like all mechanical parts, these components are prone to malfunction. Identifying and resolving issues with truck heater cores and valves is essential for ensuring not just comfort but safety during long hauls, especially in colder climates.

Whether you’re a truck owner, a fleet manager, or a mechanic, understanding how these parts work and recognizing when something is amiss will save you time and money. Let’s dive deep into the common symptoms, causes, and solutions for problems related to heater cores and valves in trucks.

Understanding the Heater Core: The Heart of the Truck’s Heating System

The heater core is a small, radiator-like device located in the dashboard of your truck. Its primary function is to transfer heat from the engine’s coolant to the air blowing through the HVAC (Heating, Ventilation, and Air Conditioning) system. By doing so, it provides the warmth needed to keep the cabin comfortable during cold weather.

The heater core operates by allowing hot engine coolant to flow through it. As air is blown over the heater core, the heat from the coolant warms the air, which is then directed into the cabin. Sounds simple, right? However, when things go wrong with this system, you’ll quickly notice discomfort, and possibly even damage, in other parts of the truck’s operation.

Symptoms of a Faulty Heater Core in Trucks

If you're experiencing cabin temperature inconsistencies, there’s a good chance your truck’s heater core might be the culprit. Here are some common symptoms of a faulty heater core:

Lack of Warm Air: If the air blowing from the vents remains cold despite the heater being on, it’s a strong indication that the heater core is not functioning properly.

Foggy Windows: A leaking heater core can cause excess moisture to enter the cabin, leading to fogging or misting of the windows.

Sweet Smell in the Cabin: This is a telltale sign of coolant leaking from the heater core into the cabin, as engine coolant often has a slightly sweet odor.

Coolant Levels Dropping: A malfunctioning heater core may cause coolant to leak, leading to a noticeable drop in coolant levels.

Overheating Engine: A failed heater core can affect the cooling system, causing the engine to overheat if coolant circulation is compromised.

Recognizing these symptoms early can prevent more significant issues, such as engine overheating or extensive HVAC damage.

Heater Valves: Controlling the Flow of Heat

While the heater core generates the heat, the heater control valve controls how much of it gets into the cabin. This valve regulates the flow of coolant to the heater core, essentially determining how much heat is produced. If the heater valve isn’t working properly, you’ll have either too much heat, too little, or none at all.

The heater valve is typically controlled by a thermostat or by the controls in the cabin. There are manual and vacuum-operated versions of this valve, both of which can experience wear and tear over time.

Signs of Heater Valve Problems in Trucks

Inconsistent Heating: If the cabin heat fluctuates or fails to reach the desired temperature, it could indicate that the heater valve is malfunctioning.

No Heat at All: A stuck heater valve could block the flow of coolant to the heater core, leading to no heat being generated.

Heat Always On: Conversely, if the valve is stuck open, the heater core may receive coolant constantly, making the cabin uncomfortably hot even when the heater is turned off.

Heater Control Knob Malfunction: If the temperature control on the dashboard doesn’t seem to affect the temperature in the cabin, the heater valve might be stuck or broken.

Just like the heater core, early detection of heater valve issues can save you from unnecessary repair bills and discomfort during long drives.

Common Causes of Heater Core and Valve Failures

Understanding what leads to heater core and valve failures can help in preventing them. Here are the most common causes:

Corrosion: Over time, the metal components of the heater core and valve can corrode, especially if the coolant isn’t changed regularly or if the wrong type of coolant is used.

Leaks: Leaks in the cooling system can reduce the amount of coolant flowing to the heater core, leading to reduced heating efficiency.

Clogs: Sediment buildup or debris in the coolant can cause blockages in the heater core, preventing proper heat transfer.

Wear and Tear: Like all mechanical components, heater cores and valves can wear out with age and heavy use, leading to failures.

Preventative maintenance is the key to avoiding these issues, and regular checks can keep your truck’s heating system running smoothly for longer.

How to Diagnose Heater Core and Valve Problems

Before you start replacing parts, it’s important to diagnose the issue accurately. Here's how you can identify the problem with the heater core or valve:

Check for Leaks: Inspect the heater core and surrounding hoses for any visible coolant leaks. Leaks are a sure sign that something isn’t right.

Monitor Coolant Levels: If the coolant level is consistently dropping, but you don’t notice any leaks under the truck, the heater core may be leaking internally.

Temperature Test: Start the truck and let it warm up. If the temperature inside the cabin doesn’t rise, or if it fluctuates, the heater valve might be at fault.

Pressure Test: Use a pressure tester to check the cooling system for leaks. A drop in pressure could indicate a heater core or valve problem.

Thermostat Test: Sometimes, the issue might not be with the heater core or valve but with the thermostat. A stuck thermostat can prevent the proper flow of coolant, affecting the heating system.

Steps to Fix a Faulty Heater Core

Once you've diagnosed the problem, you may need to replace the heater core. While it’s possible to fix a heater core, it often requires substantial work due to its location within the dashboard. Here’s a general step-by-step guide for fixing or replacing a heater core:

Step 1: Drain the Coolant: Before you start, ensure the engine is cool and drain the coolant to prevent spills.

Step 2: Remove the Dashboard: Accessing the heater core usually involves removing the dashboard or parts of it, depending on your truck model.

Step 3: Disconnect Heater Hoses: Disconnect the hoses attached to the heater core from under the hood.

Step 4: Remove the Heater Core: Carefully remove the heater core from its housing.

Step 5: Install the New Heater Core: Replace the old heater core with a new one, ensuring all seals and connections are secure.

Step 6: Reassemble the Dashboard: Reattach all the components of the dashboard and reconnect any electrical parts.

Step 7: Refill the Coolant: Once the new heater core is installed, refill the cooling system with fresh coolant and check for leaks.

While replacing a heater core can be a DIY job for those with mechanical knowledge, it’s often best left to a professional due to the labor-intensive nature of the task.

How to Fix a Stuck or Faulty Heater Valve

Repairing or replacing a heater valve is generally less complicated than replacing a heater core. Here’s how you can do it:

Step 1: Locate the Heater Valve: The heater valve is typically found along the heater hose that runs from the engine to the firewall.

Step 2: Disconnect the Hoses: Once located, disconnect the heater hoses from the valve.

Step 3: Remove the Heater Valve: Remove the faulty valve and replace it with a new one.

Step 4: Reconnect the Hoses: Attach the hoses back to the new heater valve.

Step 5: Test the System: Once the valve is in place, test the heating system to ensure it’s working correctly.

Preventative Maintenance for Truck Heater Cores and Valves

Preventative maintenance is the best way to avoid issues with your truck’s heater core and valve. Here are some tips to keep them in good shape:

Regularly Flush the Coolant System: Flushing the coolant system periodically removes sediment and debris that can clog the heater core.

Check Coolant Levels: Keep an eye on your coolant levels and top off when necessary. Low coolant levels can cause both the heater core and valve to malfunction.

Inspect Hoses and Connections: Regularly check hoses and connections for leaks or signs of wear.

Use the Correct Coolant: Always use the manufacturer-recommended coolant to prevent corrosion and damage to the heater core and valve.

By keeping up with these simple maintenance tasks, you can prolong the life of your truck’s heating system and avoid costly repairs.

Final Suggestion

To ensure your truck’s heater core and valve continue to function properly, it’s crucial to be aware of the common signs of failure and address them promptly. Routine maintenance, proper diagnosis, and timely repairs can prevent major issues down the road. Whether it's cold air blowing when you need warmth or a coolant leak flooding the cabin, understanding these components’ functions and potential issues will ensure you stay comfortable and safe on the road.

#heater cores#truck heater valves#heater control valve#automotive guide#automotive#truck heater troubleshooting#truck hvac

0 notes

Text

Exporter of Multi Effect Evaporator in Libya

Drytech Engineering Systems is an Exporter of Multi Effect Evaporator in Libya.

We are a Leading Manufacturer, Supplier, and Exporter of Flash Dryers, Spray Dryers, Spin Flash Dryers, Fluid Bed Dryers, and Evaporator Dryers, Rotary Valves, Rotary Atomizers, Hot Air Generators, Centrifugal Blowers, and Dust Collector Systems.

Drytech Engineering Systems Manufacturing Unit is in Ahmedabad, Gujarat, India.

We offer two types of Fully Automatic multi-effect-evaporators and semi-automatic multi-effect-evaporators.

Multi-effect evaporator is an advanced evaporator system designed with multiple stages arranged in series.

Each stage operates at progressively lower pressures, optimizing energy efficiency for the evaporation process.

The system uses steam to provide the necessary heat, making it a cost-effective method for concentrating liquids and recovering valuable substances.

Features:

Treatment of oily emulsions, coolant fluids, and mold release agents

Purging of compressors and water from washing floors

Removal of water from washing tanks and reactors

Processing of working and washing baths in galvanic processes and surface treatments

Handling of penetrating liquids

Rejection management in water treatment plants

Working Principle of Multi-Effect Evaporator:

Liquid Introduction: The liquid to be concentrated is fed into the first effect using a pump. It then flows through each subsequent effect in a controlled manner.

Heat Transfer: We introduce steam into the first effect, where it condenses, transferring heat to evaporate the liquid. The vapor then moves to the next effect.

Vapor Recompression: In each subsequent effect, the vapor generated from the previous effect serves as the heating medium. It condenses on the heat exchanger surface in the current effect, transferring heat and causing further evaporation.

Concentrated Liquid Collection: As the liquid passes through each effect, it becomes more concentrated. We collect the final liquid for further processing or storage.

Drytech Engineering Systems is an Exporter of Multi Effect Evaporator in Libya including locations

Tripoli, Benghazi, Misrata, Zawiya, Bayda, Gharyan, Tobruk, Ajdabiya, Zliten, Derna, Sirte, Sabha, Khoms, Bani Walid, Sabratha, Zuwara, Kufra, Marj, Tocra, Tarhuna.

For detailed information and inquiries, please feel free to contact us.

View Product: Click Here

Read the full article

0 notes

Text

Radiator Engine Flush: Essential Maintenance for a Healthy Cooling System

The radiator is a critical component of your vehicle’s cooling system, responsible for keeping the engine temperature in check and preventing overheating. Over time, however, the radiator and cooling system can accumulate debris, sludge, and scale that impede performance and efficiency. A radiator engine flush is a maintenance procedure designed to clean out these contaminants, ensuring optimal function and longevity of your cooling system. This article delves into the importance of radiator engine flushes, the process involved, and the benefits of regular maintenance.

What is a Radiator Engine Flush?

A radiator engine flush is a cleaning process that involves removing old coolant, debris, and contaminants from the radiator and the entire cooling system. The procedure typically involves adding a specialized cleaning solution to the radiator, running the engine to circulate the solution, and then flushing it out along with the old coolant and contaminants. Fresh coolant is then added to replace the old fluid.

Why is a Radiator Engine Flush Important?

Prevents Overheating:

Efficient Cooling: A clean radiator ensures that coolant flows freely and effectively, preventing the engine from overheating. Over time, sludge and scale can block coolant passages, leading to reduced cooling efficiency and potential engine damage.

Enhances Engine Performance:

Optimal Temperature Control: Proper cooling helps maintain the engine at the correct operating temperature, which is crucial for performance, fuel efficiency, and emissions control.

Extends Radiator and Engine Life:

Preventing Corrosion: Contaminants and old coolant can cause corrosion and rust in the radiator and other cooling system components. Regular flushing helps prevent corrosion and extends the lifespan of the radiator and engine.

Improves Cooling System Efficiency:

Clear Passages: Removing deposits and debris from the cooling system allows for more efficient heat transfer, improving overall cooling system performance and reliability.

Protects Against Coolant Contamination:

Fresh Coolant: Over time, coolant can become acidic and lose its effectiveness. Flushing the system removes old, contaminated coolant and replaces it with fresh fluid, ensuring optimal protection against freezing, boiling, and corrosion.

The Radiator Engine Flush Process

Preparation:

Safety First: Ensure the engine is cool before starting the flush process to avoid burns. Wear gloves and safety glasses to protect yourself from coolant and chemicals.

Drain the Old Coolant:

Locate Drain Valve: Find the radiator drain valve, typically located at the bottom of the radiator. Place a drain pan underneath the valve.

Open Valve: Open the drain valve and allow the old coolant to drain completely into the pan. Close the valve once all the coolant has drained.

Add Flush Solution:

Choose the Right Product: Select a radiator flush solution that is compatible with your vehicle’s cooling system. Follow the manufacturer’s instructions for the correct amount.

Add to Radiator: Pour the flush solution into the radiator or coolant reservoir as directed.

Run the Engine:

Circulate the Solution: Start the engine and let it run for the time specified on the flush product instructions. This allows the flush solution to circulate through the cooling system and loosen deposits and contaminants.

Flush the System:

Drain the Flush Solution: After the recommended time has elapsed, turn off the engine and allow it to cool. Open the drain valve again to drain the flush solution from the radiator.

Rinse (if needed): Some products may require a rinse with water to remove any remaining residues. If so, fill the radiator with water, run the engine again, and then drain the water.

Refill with Fresh Coolant:

Add New Coolant: Close the drain valve and refill the radiator with fresh coolant. Ensure that the coolant is the correct type and mixture for your vehicle (usually a 50/50 mix of antifreeze and water).

Check Levels: Fill the coolant reservoir to the recommended level and check for leaks.

Bleed the System:

Remove Air Pockets: Some vehicles require bleeding to remove air pockets from the cooling system. Consult your vehicle’s owner’s manual for the proper procedure.

Check for Leaks and Test Drive:

Inspect: After completing the flush, check for any leaks around the radiator and hoses.

Test Drive: Take your vehicle for a short drive to ensure that the cooling system is functioning properly and that the engine maintains the correct temperature.

When Should You Perform a Radiator Engine Flush?

Regular Maintenance:

Manufacturer’s Recommendations: Follow the maintenance schedule outlined in your vehicle’s owner’s manual. Typically, a radiator flush is recommended every 30,000 to 50,000 miles, or every 2 to 3 years.

Coolant Contamination:

Signs of Contamination: If you notice discolored or rusty coolant, a milky appearance, or sludge in the radiator, it’s time for a flush.

Overheating Issues:

Engine Temperature: If your engine is frequently overheating, it may be due to a clogged radiator or cooling system. A flush can help resolve these issues.

Prevention:

Preventive Maintenance: Regularly flushing the radiator as part of your vehicle’s maintenance routine can prevent buildup and potential problems before they arise.

Additional Tips

Professional Help: If you’re not comfortable performing a radiator flush yourself, or if you encounter any issues, consider having the service done by a professional mechanic.

Environmental Considerations: Dispose of old coolant and flush solutions properly. Many auto repair shops offer recycling services for used coolant.

Conclusion

A radiator engine flush is an essential maintenance task that helps ensure the efficiency and longevity of your vehicle’s cooling system. By removing contaminants and old coolant, you can prevent overheating, improve engine performance, and extend the life of your radiator and other cooling system components. Regular radiator flushes, as part of a comprehensive vehicle maintenance routine, will contribute to a healthier, more reliable vehicle and a smoother driving experience

0 notes

Text

Flow Control Valve Selection Guide: Factors to Consider for Different Applications

Flow control valves are crucial parts of many sectors, such as manufacturing, oil and gas extraction, chemical processing, and water treatment. These valves control the fluid flow rate, guaranteeing both safety and best performance in many applications.

To assist you in making an educated choice, this article will examine the important aspects to take into account when selecting a manifold valve Texas.

Being Aware of Flow Control Valves

Actuators can be used to automate or manually operate them. Among the primary varieties of flow control valves are:

Globe Valves: renowned for their accuracy in control.

Ball Valves: These are good for on/off control and provide a rapid shut-off.

Butterfly valves: Offer an equilibrium between price, dimensions, and effectiveness.

Diaphragm Valves: For viscous or corrosive liquids.

Needs for Flow Rates

Ascertain the flow rate that your application requires. The maximum flow rate that the valve can manage should not result in an unacceptable pressure decrease or turbulence. Flow rate computations can be used to choose the size and kind of valve as per industrial valve manufacturers.

Conditions of Pressure

Examine the differential pressure (the difference between the pressure at the intake and outflow) and the operating pressure. For the valve to remain functional and intact, it must be able to bear system pressure.

Method of Actuation

Think about the intended operation of the industrial valve manufacturers:

Manual: Simple and affordable, hand-operated valves.

Electric actuators: Offer exact automation and control.

Electric actuators are dangerous in explosive settings; pneumatic actuators are appropriate.

High-force applications employ hydraulic actuators.

Accurate Control

The type of valve will depend on how precise the flow rate control has to be. The necessary flow rate must also be ascertained. The valve must manage the highest possible flow rate while avoiding undue turbulence or pressure loss. Precise flow rate estimates may be used to choose the size and type of the valve. For the valve to remain functional and intact, it must be able to bear system pressure.

The surrounding environment significantly influences the choice of valve. Dust levels, corrosion potential, humidity, and ambient temperature all affect the decision. Materials that can survive such conditions are needed for ball valve manufacturers valves used at extremely cold temperatures.

Corrosion-resistant valves from industrial valve manufacturers are required for outdoor or maritime situations, and adequate sealing is necessary for dusty conditions to avoid contamination. These are the essential factors you must understand to consider.

Application-Specific Pointers

Water Purification

Valves in water treatment facilities must manage vast amounts of water with different degrees of impurities. Durability and resistance to corrosion are essential. Butterfly valves from industrial valve manufacturers are frequently utilized because they are economical and effectively regulate flow.

Gas and Oil

In the oil and gas sector, manifold valve Texas have to endure corrosive fluids, extreme temperatures, and pressures. Ball and globe valves made of stainless steel are favored due to their durability and dependability.

Chemical Reaction

Chemical factories need valves that are capable of withstanding caustic and aggressive chemicals. Teflon-lined and diaphragm valves are frequently used to stop chemical interactions with the valve material.

Air Conditioning Systems

Valves control the air and water flow in HVAC systems. Because of their dependability and speed of operation, ball and butterfly valves are frequently utilized.

Producing

Fluids used in manufacturing processes range from lubricants to coolants. The valve of choice needs to be accurate in its management and compatible with these fluids to guarantee product quality.

Choosing the appropriate manifold valve Texas requires taking into account a number of variables, such as the fluid's properties, flow rate, pressure levels, ambient circumstances, and more.

Comprehending the particular demands of your application guarantees the best possible performance, security, and durability for your flow control system. You may select a valve that satisfies your requirements and offers dependable service in your application by carefully weighing these considerations.

Summary: We have shared all the information here if you want to know about the flow control valves Texas. So, you may give it a read! For more information, checkout Arek Solutions with the flow control valves Texas. They are the best!

#flow control valves texas#manifold valve texas#flow valve texas#flow regulator valve texas#ball valve manufacturers#industrial valve manufacturers

0 notes

Text

What Are The Latest Advancements In Range Rover 2.0 Engine Technology?

In the realm of luxury SUVs, the Range Rover 2.0 engine stands as a pinnacle of engineering prowess, blending power with efficiency. Over recent years, significant advancements have transformed these engines, enhancing performance, fuel economy, and environmental sustainability. We delves into the cutting-edge technologies that define the latest Range Rover 2.0 engines, providing insights into how these innovations are shaping the future of automotive excellence.

Turbocharging and Power Efficiency

Turbocharging has been a cornerstone of Range Rover 2.0 engine advancements. By harnessing exhaust gases to drive a turbine, turbochargers increase air intake, boosting power without a significant increase in engine size. Modern variants employ twin-scroll turbochargers and advanced intercooling systems to optimize efficiency and minimize turbo lag, ensuring responsive acceleration across varying driving conditions.

Lightweight Construction and Material Innovations

Advancements in materials science have enabled Range Rover engineers to reduce engine weight while maintaining structural integrity and durability. High-strength alloys, carbon fiber components, and advanced composites are increasingly integrated into engine design, enhancing performance metrics such as power-to-weight ratio and overall efficiency. These lightweight materials also contribute to improved handling and reduced emissions, aligning with contemporary environmental standards.

Hybridization and Electrification

Embracing the shift towards electrification, Range Rover 2.0 engines have seen integration with hybrid powertrains. Mild hybrid systems utilize regenerative braking and start-stop technology to enhance fuel efficiency and reduce emissions during city driving. Meanwhile, plug-in hybrid variants offer extended electric-only driving ranges, leveraging electric motors in tandem with traditional combustion engines to deliver robust performance alongside enhanced environmental sustainability.

Advanced Fuel Injection Systems

Precision-engineered fuel injection systems play a pivotal role in optimizing combustion efficiency within Range Rover engines. Direct fuel injection techniques, coupled with variable valve timing and sophisticated engine management systems, ensure precise fuel delivery and combustion control. This results in improved fuel economy, reduced emissions, and heightened engine responsiveness across a wide range of driving scenarios.

Intelligent Thermal Management

Effective thermal management is critical to maximizing engine performance and longevity. Range Rover 2.0 engines feature advanced cooling systems that regulate temperatures dynamically, ensuring optimal operating conditions under varying loads and environmental conditions. Adaptive thermal management strategies, including active grille shutters and coolant flow optimization, contribute to improved efficiency and reliability while minimizing environmental impact.

Digitalization and Connectivity

The integration of digital technologies within Range Rover 2.0 engines has revolutionized vehicle connectivity and user experience. Enhanced onboard diagnostics, real-time performance monitoring, and over-the-air software updates enable proactive maintenance and customization options. Furthermore, connectivity features such as smartphone integration and remote vehicle management enhance convenience and accessibility for modern drivers, elevating the driving experience to new heights of sophistication.

Sustainable Practices and Emissions Reduction

In response to global environmental challenges, Range Rover 2.0 engines incorporate advanced emissions control technologies. Selective catalytic reduction (SCR) systems and particulate filters effectively reduce nitrogen oxide (NOx) and particulate matter emissions, ensuring compliance with stringent emissions regulations without compromising performance. Sustainable manufacturing practices and recyclable materials further underscore Range Rover's commitment to environmental stewardship across their vehicle lineup.

Conclusion

The evolution of Range Rover 2.0 engine technology exemplifies a dedication to innovation, performance excellence, and environmental responsibility. From turbocharged powertrains to hybrid-electric systems and advanced digital integration, these engines represent the forefront of automotive engineering. As technological advancements continue to shape the automotive landscape, Range Rover's commitment to pushing boundaries ensures that future iterations of their engines will redefine luxury SUV standards, offering drivers uncompromising performance with minimal environmental impact.

This comprehensive exploration highlights how Range Rover 2.0 engines are not just engines but embodiments of cutting-edge technology and sustainable innovation, driving towards a more efficient and connected automotive future.

Read the full article

#RangeRover2.0engine#RangeRover2.0Engines#RangeRover2.0EnginesForSale#reconditionedRangeRover2.0Engine#ReconditionedRangeRover2.0Engineforsale#ReconditionedRangeRover2.0Engines

0 notes

Video

youtube

Strange noises coming from your car's engine can be a sign of a variety of problems, ranging from minor to more serious. It is important to identify the source of the noise so you can repair it properly.**Here are some examples of strange noises and their possible causes:****Clicking or squeaking noises:*** **Low oil level or poor quality oil:** Insufficient oil level or the wrong oil for the engine can cause knocking in the pistons and other moving parts of the engine.* **Worn connecting rods or rings:** Connecting rods and rings are essential engine components that allow fuel combustion and piston movement. Their wear can cause dull clicking noises.* **Injectors not tightened:** The injectors inject fuel into the combustion chambers. If they are loose, they may produce a clicking noise.* **Worn valves or valve seals:** Valves control the flow of air and exhaust gases through the engine. Their wear or deterioration of their seals can generate clicking or clicking noises.* **Worn transfer case gears:** The transfer case distributes power from the engine to the wheels. Worn gears in the transfer case can produce a loud grinding noise.* **Poorly tightened exhaust:** A loose exhaust can vibrate and produce a clicking or grinding noise.**Whistles:*** **Oil line leaks:** An engine oil leak can produce a high-pitched whistling sound, especially when starting the engine.* **Leaks in the intake or exhaust air lines:** An air leak in the intake or exhaust system can cause a whistling sound, especially when accelerating.* **Coolant Line Leaks:** A coolant leak can produce a hissing sound when the coolant comes into contact with hot engine surfaces.* **Fuel line leaks:** A fuel leak is a serious problem that can be dangerous. It is generally signaled by a smell of gasoline and a whistling sound.* **Worn or loose belts:** Accessory belts, such as the timing belt, can produce a whining sound if they are worn, loose or defective.* **Poorly installed radiator fans:** An improperly mounted radiator fan can vibrate and produce a whistling sound.**Thud :*** **Worn wheel bearings:** Wheel bearings allow the wheels to turn smoothly. Their wear produces a dull rumble that intensifies with speed.* **Worn drive shaft:** The drive shaft transmits engine power to the rear wheels. A worn driveshaft can produce a dull rumbling noise, especially when accelerating or changing gears.* **Waste Water Pump:** The water pump circulates coolant through the engine. A worn water pump can produce a dull rumbling noise, especially when idling.**It is important to note that this list is not exhaustive and other strange noises may be coming from your car's engine.****If you hear a strange noise coming from your engine, it is important to have your vehicle checked by a qualified mechanic as soon as possible.** The mechanic will be able to identify the source of the noise and offer you the necessary repairs .**Failing to ignore strange noises coming from your engine can lead to more serious problems and more expensive repairs.****Here are some tips to help you identify the source of a strange noise:*** **Pay attention to the nature of the noise.** Is it high-pitched, low-pitched, clicking, grinding, hissing or rumbling?* **Note when you hear the noise.** Is it when starting, accelerating, idling, cornering, or all the time?* **Locate the noise.** Does it seem to be coming from the front, rear, right side, or left side of the engine?**Providing this information to a mechanic will help them diagnose the problem more quickly and accurately.**

0 notes

Text

What is the difference between an intake manifold and a fuel rail

The intake manifold plays a crucial role in the operation of an internal combustion engine by managing the flow of air (and sometimes fuel) into the engine's cylinders. The intake manifold is a critical component in the engine's intake system, responsible for delivering the air (and sometimes fuel) necessary for combustion while ensuring optimal performance and efficiency. Its design and configuration can vary depending on factors such as engine type, fuel delivery system, and performance requirements.

Air Distribution: The primary function of the intake manifold is to distribute air to each cylinder of the engine. It receives air from the air intake system, which may include components such as air filters and throttle bodies, and directs it to the intake ports of the engine cylinders.

Mixing Fuel and Air (in some designs): In certain types of fuel injection systems, such as port fuel injection, the intake manifold may also be responsible for mixing fuel with the incoming air. This mixture is then delivered to the cylinders for combustion. However, in other systems like direct fuel injection, fuel is injected directly into the cylinders rather than being mixed in the intake manifold.

Equalization of Airflow: The intake manifold is designed to ensure that each cylinder receives an equal amount of air (and fuel, if applicable) for optimal combustion. It may feature passages and runners that are carefully engineered to balance airflow and minimize turbulence.

Temperature Control: Some intake manifolds incorporate features for controlling the temperature of the incoming air. This can involve the use of coolant passages or heat exchangers to heat or cool the air as needed for improved engine performance and efficiency.

Mounting Point for Additional Components: The intake manifold often serves as a mounting point for various components, including fuel injectors, fuel pressure regulators, intake air temperature sensors, and idle air control valves.

The fuel rail is an essential component of the fuel delivery system in modern internal combustion engines, particularly those equipped with fuel injection. Fuel rail plays a critical role in the fuel delivery system of an engine, ensuring that fuel is delivered reliably and at the correct pressure to the fuel injectors for combustion. Its design and configuration may vary depending on factors such as engine type, fuel injection system, and performance requirements.

Fuel Distribution: The primary role of the fuel rail is to distribute pressurized fuel to each fuel injector mounted on the engine. It serves as a conduit that delivers fuel from the fuel pump to the injectors, ensuring each cylinder receives the proper amount of fuel for combustion.

Pressure Regulation: The fuel rail maintains the fuel at a consistent pressure before it reaches the injectors. This is crucial for achieving precise fuel delivery and ensuring consistent engine performance under varying operating conditions.

Mounting Point for Fuel Injectors: The fuel rail typically houses the fuel injectors and provides a secure mounting point for them. The injectors are connected to the fuel rail via injector ports or fittings, which allow fuel to flow from the rail into the injectors.

Return Line Connection (in some systems): In certain fuel injection systems, such as return-style fuel systems, the fuel rail also includes a connection point for a fuel return line. This line allows excess fuel not used by the engine to be returned to the fuel tank, helping to maintain consistent fuel pressure and prevent fuel overheating.

Pressure Sensor Integration: Some fuel rails may incorporate a pressure sensor or fuel pressure regulator to monitor and regulate fuel pressure within the rail. This sensor provides feedback to the engine control unit (ECU), allowing it to adjust fuel delivery as needed for optimal engine performance and efficiency.

Material and Design Considerations: Fuel rails are typically made of metal, such as aluminium or stainless steel, to withstand the high pressure and corrosive nature of automotive fuels. They are designed with smooth internal passages to minimize fuel flow restrictions and pressure losses.

The difference between an Intake Manifold and a Fuel Rail

An intake manifold and a fuel rail are both crucial components of an internal combustion engine, but they serve different purposes.

Intake Manifold: The intake manifold is responsible for distributing air (and sometimes fuel in certain types of fuel injection systems) to the cylinders of the engine. It is typically made of metal or plastic and is mounted on top of or to the side of the engine block. The intake manifold receives air from the air intake system and directs it into the combustion chambers of the engine. In some designs, it also mixes fuel with the incoming air before it enters the cylinders.

Fuel Rail: The fuel rail is part of the fuel delivery system in an engine equipped with fuel injection. It is a metal pipe or rail that delivers pressurized fuel to the fuel injectors, which then spray the fuel into the combustion chambers of the engine. The fuel rail receives fuel from the fuel pump and maintains the required pressure to ensure proper fuel delivery to the injectors. It typically sits on top of the engine or along the intake manifold.

In summary, while both components are involved in the engine's operation, the intake manifold deals with air distribution (and sometimes fuel), while the fuel rail deals specifically with delivering pressurized fuel to the injectors.

1 note

·

View note

Text

Under the Hood: Exploring Essential Toyota Car Parts

Introduction

When it comes to owning a Toyota car, understanding the essential parts under the hood is crucial for maintaining its performance and longevity. Whether you're a car enthusiast or a first-time Toyota owner, familiarizing yourself with these components will empower you to make informed decisions about maintenance, repairs, and upgrades. In this comprehensive guide, we will explore the essential Toyota car parts, their functions, and provide helpful tips to keep your Toyota running smoothly for years to come.

The Engine: The Heart of Your Toyota

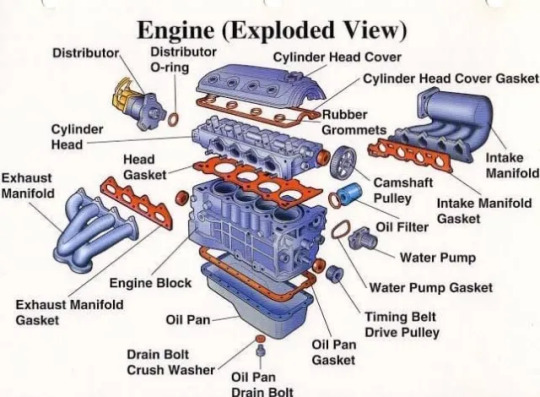

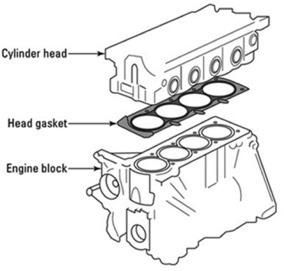

The Engine Block

At the core of your Toyota car is the engine block, also known as the cylinder block. This robust metal casing houses the engine's cylinders, pistons, and other internal components. The engine block provides structural support and acts as a foundation for the engine's operation.

The Pistons and Connecting Rods

The pistons and connecting rods work together to convert the energy generated by the combustion process into rotational motion. As the fuel-air mixture ignites, the pistons move up and down within the cylinders, transferring force to the connecting rods. These rods, in turn, transmit the energy to the crankshaft, which ultimately powers the wheels.

The Crankshaft

The crankshaft is a vital component responsible for converting the up-and-down motion of the pistons into rotational motion. It transfers power from the pistons to the transmission, allowing your Toyota to move forward. The crankshaft must be precisely balanced to minimize vibrations and ensure smooth engine operation.

The Cylinder Head

Located on top of the engine block, the cylinder head houses the intake and exhaust valves, spark plugs, and fuel injectors. It plays a crucial role in sealing the combustion chambers and controlling the flow of air, fuel, and exhaust gases. The cylinder head also houses the camshaft, which regulates the opening and closing of the valves.

The Timing Belt or Timing Chain

The timing belt or timing chain synchronizes the rotation of the crankshaft and the camshaft. It ensures that the valves open and close at the correct time, allowing for efficient combustion and optimal engine performance. Regular inspection and replacement of the timing belt or chain are essential to prevent potential engine damage.

The Fuel System: Powering Your Toyota

The Fuel Pump

The fuel pump is responsible for delivering fuel from the gas tank to the engine. It maintains the required fuel pressure for proper combustion and ensures a consistent flow of fuel to the injectors. A malfunctioning fuel pump can result in poor engine performance or even engine stalling.

The Fuel Injectors

Fuel injectors are responsible for precisely delivering fuel into the combustion chambers. They spray a fine mist of fuel, allowing for efficient combustion and optimal fuel economy. Over time, fuel injectors can become clogged or develop leaks, leading to decreased performance and fuel efficiency.

The Fuel Filter

The fuel filter plays a crucial role in ensuring that only clean fuel reaches the engine. It traps impurities and contaminants, preventing them from entering the fuel injectors and potentially causing damage. Regular replacement of the fuel filter is necessary to maintain optimal fuel system performance.

The Throttle Body

The throttle body controls the amount of air that enters the engine. It opens and closes a valve, known as the throttle plate, in response to driver input. The throttle body is electronically controlled in modern Toyota cars and works in conjunction with the engine's computer to optimize performance and fuel efficiency.

The Cooling System: Keeping Your Toyota Cool

The Radiator

The radiator is an essential component of the cooling system, responsible for dissipating heat generated by the engine. It uses a combination of coolant, air, and the radiator fan to regulate the engine's temperature. Regular maintenance, including coolant flushes and radiator cleanings, is necessary to prevent overheating and engine damage.

The Water Pump

The water pump circulates coolant throughout the engine, ensuring that it reaches all the necessary components. It is driven by the engine's crankshaft and plays a vital role in maintaining optimal operating temperatures. A faulty water pump can lead to coolant leaks, engine overheating, and potential engine damage.

The Thermostat

The thermostat is a temperature-sensitive valve located between the engine and the radiator. It regulates the flow of coolant based on the engine's temperature. The thermostat remains closed when the engine is cold, allowing it to warm up quickly. Once the engine reaches the optimal temperature, the thermostat opens, allowing coolant to flow and maintain a stable temperature.

The Cooling Fan

The cooling fan helps dissipate heat from the radiator by pulling air through the radiator fins. It is typically electrically controlled and turns on when the engine reaches a certain temperature. A malfunctioning cooling fan can result in overheating and potential engine damage.

Conclusion

Understanding the essential Toyota car parts under the hood is essential for every Toyota owner. From the engine components that power yourvehicle to the fuel system that keeps it running, and the cooling system that prevents overheating, each part plays a crucial role in maintaining optimal performance. By familiarizing yourself with these components and their functions, you can make informed decisions about maintenance, repairs, and upgrades for your Toyota.

Remember to regularly inspect and maintain these parts to ensure your Toyota continues to run smoothly. From checking the timing belt or chain to replacing the fuel filter and performing coolant flushes, proactive maintenance is key to preventing potential issues and extending the lifespan of your vehicle.

In conclusion, your Toyota car is a complex machine with various essential parts working together to provide a reliable and enjoyable driving experience. By understanding these components and their functions, you can take better care of your Toyota and ensure it serves you well for years to come.

FAQ

Q1: How often should I replace the timing belt or timing chain in my Toyota?

A1: It is recommended to replace the timing belt or timing chain in your Toyota every 60,000 to 100,000 miles, depending on the specific model and engine type. Regular inspection and replacement are crucial to prevent potential engine damage.

Q2: What are the signs of a failing fuel pump in a Toyota car?

A2: Some signs of a failing fuel pump in a Toyota car include engine misfires, difficulty starting the engine, decreased fuel efficiency, and engine stalling. If you experience any of these symptoms, it is advisable to have your fuel pump inspected and potentially replaced.

Q3: How often should I replace the fuel filter in my Toyota?

A3: The fuel filter in your Toyota should be replaced every 30,000 to 40,000 miles, or as recommended by the manufacturer. Regular replacement of the fuel filter helps maintain optimal fuel system performance and prevents potential damage to the injectors.

Q4: Can a faulty water pump cause engine overheating in a Toyota?

A4: Yes, a faulty water pump can cause engine overheating in a Toyota. The water pump is responsible for circulating coolant throughout the engine, and if it fails, coolant cannot reach the necessary components, leading to overheating. Regular inspection and maintenance of the water pump are crucial to prevent such issues.

Q5: How can I prevent overheating in my Toyota?

A5: To prevent overheating in your Toyota, ensure that the cooling system is properly maintained. Regularly check coolant levels, perform coolant flushes as recommended, inspect the radiator for debris, and ensure the cooling fan is functioning correctly. Additionally, avoid driving in extreme heat conditions and monitor the temperature gauge while driving.

Remember, proper maintenance and regular inspections are essential for keeping your Toyota in optimal condition and preventing potential issues. If you have any concerns or questions about specific parts or maintenance procedures, it is always advisable to consult your Toyota dealership or a qualified mechanic.

0 notes

Text

5 Possible Reasons Your Car Stalls When AC Is On From Certified Mechanics in Argyle

There are certain issues in your car that can be very frustrating to deal with as they leave you stranded in the middle of the road. One such common problem faced by the majority of drivers is related to stalling of the car when their car is running and the air conditioning system is on.

There are several factors that can cause your car to stall while running and it is important for you to know these hidden issues so that you can initiate remedial measures. Here are the 5 possible reasons.

Overheating Engine

One of the prominent reasons behind your car stalling when the AC is operational is related to the overheating of the engine of your vehicle. Most of the time people aren’t aware of the fact that continuous running of the air conditioning system in their car can put additional strain on the functioning of the engine.

As this leads to overheating of the engine your vehicle begins to stall when driving. Generally, the stalling problem is experienced during the summer months when the AC operates continuously and the engine faces tremendous pressure due to this and gets overheated beyond its cooling threshold.

In addition to that, there are certain parts and fluids in your car that help in preventing the engine from overheating like the radiator, thermostat, and coolant. However, if any of these components malfunction or there is the presence of inadequate levels of coolant in your car then the engine is going to overheat leading to stalling problems.

Engine Idling Control Issues

Most of the cars coming nowadays are equipped with advanced devices that help in the smooth running and better performance of the car. This is where the role of the idle air control valve or idle speed control comes to the fore because they help in maintaining a smooth idle process in your vehicle.

The idle air control valve is responsible for controlling the opening and closing of the throttle which helps in regulating the idle speed of your car. The operation of the air conditioning system draws in more power from the engine and this is when the idle speed control helps in maintaining a smooth idling speed for your vehicle.

However, if the valve has malfunctioned or there is a buildup of carbon in the throttle body of your vehicle which restricts the flow of air into the car then you will experience rough engine idle and stalling simultaneously. In addition to this, issues with the engine control unit (ECU) can also lead to stalling problems when driving.

Faulty Electrical System

The air conditioning system is part of the electrical system in your vehicle and there are a host of electrical components working in cohesion with the AC system of your vehicle. However, issues in the electrical system in the form of short circuits, loose connections, and bad relays can adversely affect the functioning of the engine.

There are several instances where issues with the functioning of the electrical components adversely affect the performance of the engine. Often it is observed that a malfunctioning AC relay disrupts the power supply to the compressor and this leads to stalling of the car when the AC is running.

Bad Compressor

The functioning of the compressor and the engine is related to a great extent because of the timing belt in your vehicle. The belt is connected to the crankshaft from where the compressed refrigerant is used to cool the cabin of your car when the AC blows.

Nevertheless, if the compressor starts encountering issues due to worn-out bearings or inadequate refrigerant levels then it affects the functioning of the engine causing it to stall when you are driving.

Issues in Fuel Delivery

The efficient functioning of the air conditioning system in your car requires an additional supply of fuel by the engine to keep up with the increase in demand from the AC. Nonetheless, problems in the delivery of fuel to the combustion chamber of your car can spell doom for both the engine & the air conditioning system.

Most of the issues in fuel delivery are caused due to blocked fuel filter, malfunctioning fuel pump, and bad fuel injectors and this adversely affects the capacity of the engine to maintain a smooth idle leading to stalling issues.

Finally

The above-discussed factors are some of the leading reasons behind your car stalling when the air conditioning system is operational. If you are facing these kinds of issues then it is time to get in touch with a certified mechanic to get your vehicle inspected and remedial measures initiated to bring it back on track.

0 notes

Text

Flowing Power: Exploring the Vital Role of Hydraulic Fluids

Hydraulic fluid, often referred to as hydraulic oil, is the lifeblood of hydraulic systems, powering a wide array of machinery and equipment across various industries. From construction and manufacturing to agriculture and aerospace, hydraulic systems rely on the properties of hydraulic fluid to transmit power, lubricate components, and ensure smooth operation. Let's delve into the vital role of hydraulic fluids and their impact on the efficiency and reliability of hydraulic systems.

Power Transmission

At the heart of hydraulic systems lies the principle of fluid power transmission. Hydraulic fluid is the medium through which force is transferred from one point to another within the system. When pressurized by a hydraulic pump, the fluid flows through hydraulic hoses and valves to actuate cylinders, motors, or other hydraulic components, converting mechanical energy into hydraulic force. This ability to transmit power efficiently and effectively makes hydraulic systems indispensable in applications where high force and precise control are required.

Lubrication and Cooling

In addition to power transmission, hydraulic fluid serves as a lubricant, reducing friction and wear between moving parts within hydraulic systems. As components such as pumps, valves, and cylinders operate, hydraulic fluid forms a protective film that prevents metal-to-metal contact, prolonging the life of critical components. Furthermore, hydraulic fluid absorbs heat generated during operation, acting as a coolant to dissipate excess heat and maintain optimal operating temperatures. Proper lubrication and cooling are essential for preventing equipment failure and maximizing the lifespan of hydraulic systems.

For More:

Contact: (03) 7002 6133

Email: [email protected]

Timings: Mon-Fri: 9am-5pm

Visit Us: https://oila.au/

0 notes

Text

Efficiency Redefined: Fuel Cell BOP Market Evolution 2023-2032

The fuel cell balance of plants (BOP) market is primarily driven by efficient power conversion, environmental benefits, and improved safety & control systems. Moreover, system optimization and improved flexibility drive the market growth for fuel cell balance of plants (BOP). However, the complex nature of the system and the additional costs of the balance of plants is expected to hamper the market growth. The fuel cell balance of plant (BOP) market was valued at $1.9 billion in 2022 and is estimated to reach $13.9 billion by 2032, growing at a CAGR of 22.2% from 2023 to 2032.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐑𝐞𝐬𝐞𝐚𝐫𝐜𝐡 𝐑𝐞𝐩𝐨𝐫𝐭 𝐒𝐚𝐦𝐩𝐥𝐞 & 𝐓𝐎𝐂: https://www.alliedmarketresearch.com/request-sample/14892

A fuel cell is an electrochemical device that converts the chemical energy of a fuel, typically hydrogen, directly into electrical energy without combustion. It is a clean and efficient power generation technology that offers several advantages over conventional combustion-based systems. The basic structure of a fuel cell consists of an electrolyte sandwiched between two electrodes, the anode, and the cathode. When hydrogen is supplied to the anode and oxygen (usually from the air) is supplied to the cathode, an electrochemical reaction occurs.

The balance of plants (BOP) in a fuel cell system plays a crucial role in supporting the operation and performance of the fuel cell stack. The BOP components and systems perform several functions. The BOP manages the storage, delivery, and conditioning of the fuel (such as hydrogen, natural gas, or methanol) to the fuel cell stack. It ensures a steady and controlled supply of fuel to the stack, maintaining the required flow rates and pressure. It provides the necessary air or oxygen to the fuel cell stack for the electrochemical reaction to occur.

It includes systems such as air compressors, filters, and humidifiers to ensure clean and properly humidified air is supplied to the stack, optimizing performance and longevity. Fuel cells generate heat during operation, and the BOP is responsible for managing and controlling the temperature within the stack. It includes heat exchangers, coolant systems, and temperature control mechanisms to dissipate excess heat, maintain optimal operating temperatures, and prevent overheating or thermal stress.

Depending on the type of fuel cell, water management is critical to maintain the proper hydration levels within the stack. The BOP includes systems such as humidifiers, condensers, and water removal systems to control water content, prevent flooding or dehydration of the fuel cell components, and ensure optimal performance.

The BOP includes components such as converters, inverters, and power electronics to condition the electrical output from the fuel cell stack. These systems convert the direct current (DC) produced by the fuel cell into the required form, whether it is alternating current (AC) for electrical grid integration or a specific voltage for powering devices or systems. The BOP incorporates sensors, control systems, and monitoring equipment to regulate and optimize the operation of the fuel cell system. It continuously monitors parameters such as fuel and airflow rates, temperature, pressure, and stack performance.

This enables feedback control and adjustment of operating conditions to maintain efficiency, reliability, and safety. The BOP includes systems to manage the exhaust gases produced during fuel cell operation. It may incorporate catalysts or other devices to reduce emissions or capture byproducts before discharge, ensuring compliance with environmental regulations and minimizing the environmental impact. The BOP incorporates safety features and mechanisms to ensure the safe operation of the fuel cell system. This may include gas sensors, pressure relief valves, emergency shutdown mechanisms, and other safety devices to prevent and mitigate potential hazards.

𝐆𝐞𝐭 𝐂𝐮𝐬𝐭𝐨𝐦𝐢𝐳𝐞𝐝 𝐑𝐞𝐩𝐨𝐫𝐭𝐬 𝐰𝐢𝐭𝐡 𝐲𝐨𝐮'𝐫𝐞 𝐑𝐞𝐪𝐮𝐢𝐫𝐞𝐦𝐞𝐧𝐭𝐬: https://www.alliedmarketresearch.com/request-for-customization/14892

BOP also plays a vital role in optimizing the price at which fuel cells are offered, therefore providing prospects for cost savings. The capital investment in fuel cell BOP is high, compared to that required for other power plants such as solar and wind. It also faces competition from other alternative sources of energy. These are the major restraints to the growth of the balance of plant (BOP) market. The fuel cell balance of the plant (BOP) market is governed by the prevalent costs of raw materials used in the manufacturing of the components. The selling price of a fuel cell is determined by the cost of BOP, which further relies upon the raw materials used in the production of these components.

The fuel cell balance of plants (BOP) market is studied based on material, component, and region. Based on material, the market is divided into structural plastics, elastomers, coolants, assembly aids, metals, and others. The fuel cell balance of plants (BOP) market share was dominated by the metals segment and the same is expected to grow at a higher pace during the fuel cell balance of plants (BOP) market forecast period.

𝐂𝐨𝐦𝐩𝐞𝐭𝐢𝐭𝐢𝐯𝐞 𝐀𝐧𝐚𝐥𝐲𝐬𝐢𝐬:

The Fuel Cell Balance of Plant (BOP) industry's key market players adopt various strategies such as product launches, product development, collaboration, partnership, and agreements to influence the market. It includes details about the key players in the market's strengths, product portfolio, market size and share analysis, operational results, and market positioning.

𝐒𝐨𝐦𝐞 𝐨𝐟 𝐭𝐡𝐞 𝐦𝐚𝐣𝐨𝐫 𝐤𝐞𝐲 𝐩𝐥𝐚𝐲𝐞𝐫𝐬 𝐢𝐧 𝐭𝐡𝐞 𝐠𝐥𝐨𝐛𝐚𝐥 𝐅𝐮𝐞𝐥 𝐂𝐞𝐥𝐥 𝐁𝐚𝐥𝐚𝐧𝐜𝐞 𝐨𝐟 𝐏𝐥𝐚𝐧𝐭 (𝐁𝐎𝐏) 𝐦𝐚𝐫𝐤𝐞𝐭 𝐢𝐧𝐜𝐥𝐮𝐝𝐞,

Bloom Energy

SFC Energy AG

INN Balance

Dana Limited

Ballard Power Systems

Elcogen AS

Doosan Fuel Cell Co., Ltd.

Cummins, Inc.

HORIBA FuelCon GmbH

Hydrogenics Corporation

Depending on the component, the fuel cell balance of plants (BOP) market is divided into power supply, water circulation, hydrogen processing, cooling, heat stabilizers, and others. The power supply segment dominated the fuel cell balance of plants (BOP) market share for 2022. However, the hydrogen processing segment is expected to grow at a significant CAGR during the projection years.

Region-wise, fuel cell balance of plants (BOP) market analysis is done across North America, Europe, Asia-Pacific, and LAMEA (Latin America, the Middle East, and Africa). Asia-Pacific region is expected to dominate the fuel cell BOP market, owing to the growth of end-use industries such as construction and automotive in countries, such as India, China, Japan, and South Korea.

The favorable regulations by the governments to reduce their carbon footprints by adopting cleaner and greener fuels are anticipated to enhance the demand for fuel cells during the forecast period. North America is expected to follow Asia-Pacific in the fuel cell balance of fuel (BOP) market due to the presence of well-established industrial and manufacturing sectors in the region that can incorporate fuel cells as a source of power.

𝐈𝐧𝐪𝐮𝐢𝐫𝐲 𝐛𝐞𝐟𝐨𝐫𝐞 𝐁𝐮𝐲𝐢𝐧𝐠: https://www.alliedmarketresearch.com/purchase-enquiry/14892

𝐊𝐞𝐲 𝐟𝐢𝐧𝐝𝐢𝐧𝐠𝐬 𝐨𝐟 𝐭𝐡𝐞 𝐬𝐭𝐮𝐝𝐲:

- By material, the metals segment is projected to grow at the highest CAGR of approximately 22.4%, in terms of during the fuel cell balance of plants (BOP) market forecast period.

- By component, the power supply segment dominated the fuel cell balance of plants (BOP) market share growing at a CAGR of 22.2% in 2021.

- By region, Asia-Pacific dominated the fuel cell balance of plants (BOP) market and is expected to grow at a high CAGR during the forecast period.

𝐓𝐫𝐞𝐧𝐝𝐢𝐧𝐠 𝐑𝐞𝐩𝐨𝐫𝐭𝐬 𝐢𝐧 𝐭𝐡𝐞 𝐄𝐧𝐞𝐫𝐠𝐲 𝐚𝐧𝐝 𝐏𝐨𝐰𝐞𝐫 𝐈𝐧𝐝𝐮𝐬𝐭𝐫𝐲:

𝟏. 𝐖𝐚𝐭𝐞𝐫 𝐚𝐬 𝐚 𝐅𝐮𝐞𝐥 ��𝐚𝐫𝐤𝐞𝐭 - https://www.globenewswire.com/en/news-release/2023/05/12/2667985/0/en/Water-as-a-Fuel-Market-to-Reach-13-4-Billion-Globally-by-2032-at-12-5-CAGR-Allied-Market-Research.html

𝟐. 𝐅𝐨𝐬𝐬𝐢𝐥 𝐅𝐮𝐞𝐥 𝐄𝐧𝐞𝐫𝐠𝐲 𝐌𝐚𝐫𝐤𝐞𝐭 - https://www.globenewswire.com/news-release/2023/04/19/2650021/0/en/Fossil-Fuel-Energy-Market-to-Reach-10-646-5-Billion-Globally-by-2031-at-5-3-CAGR-Allied-Market-Research.html

𝟑. 𝐁𝐢𝐨 𝐉𝐞𝐭 𝐅𝐮𝐞𝐥𝐬 𝐌𝐚𝐫𝐤𝐞𝐭 - https://www.globenewswire.com/news-release/2022/05/30/2452392/0/en/Bio-Jet-Fuel-Market-Is-Expected-to-Reach-837-7-Million-by-2030-Allied-Market-Research.html

𝐀𝐛𝐨𝐮𝐭 𝐔𝐬: