#Edge Banding Machine for Wooden Furniture

Text

Manual Edge Banding Machine

Manual Edge Banding Machine is used to glue PVC edge bands on the plywod,, particle board, MDF and related materials. We can provide edge bander machine for gluing of pvc strips on the edges of the Honeycomb panels, wood and other variations as well as per client requirement.

Manual Edge Banding machine is capable of provide high strength glued strips. Manual Edge Banding Machine is suitable for Straight and Curved and so the Edge Banding Machine is also called Curvilinear Edge Banding Machine.

#Edge Banding Machine#Woodworking edge banding machine#Manual Edge Banding Machine#woodworking edge banding machine#Automatic edge banding machine#Edge banding equipment#Industrial edge banding machine#Edge banding machine price in india#automatic edge banding machine price in india#edge banding machine manufacturers in india#Manual Edge Bander Machine#Edge banding machine manufacturer near me#top edge banding machine manufacturers in india#Edge Banding Machine for Wooden Furniture#woodworking#wood#tools#furniture#manufacturer#machine#woodworker#edgebandingmachine#india#panelsaw

1 note

·

View note

Text

DIY Salvaged Spool Ottoman

Project by Shelly:

i know ottomans aren’t the most indispensable piece of furniture in the house, but is it criminal to say they bring me the most joy? i think upholstery maven shelly (aka ModHomeEcTeacher) would agree with me; she’s made a whole collection of smart looking ottomans using a range of found fabrics and materials. i am so excited to follow her instructions and craft an adorable plaid ottoman of my very own, just in time to welcome fall. click here to see more of shelly’s amazing work, including her tutorials on everything from upholstering with rugs to aligning atomic legs. thanks, shelly! –kate

When Lowes stopped selling the pre-cut wood circles I used to construct my ottoman frames, it was a dark day. I soon discovered that cutting perfect circles with a hand-held jigsaw wasn’t easy, or even really possible. Weeks later, while roaming the store searching for an alternative, I discovered the empty electrical spools that are routinely discarded. Two perfectly cut round pieces of 5/8” plywood with a removable cardboard cylinder in the middle? Now we’re talking. With a tiny bit of carpentry, I came up with a way to easily re-work these into frames for my upholstered ottomans. I would label this as a mid-level DIY project that you could complete in a weekend. Once you get the hang of it, you these would make fantastic handmade gifts for friends and family. –Shelly

Materials:

-1 20” diameter empty electrical wire spool (hardware stores usually throw these out, so ask about picking them up instead)

-8 pre cut 1”x 2”x 6” pieces of wood (a hardware store will cut these for you)

-Wood glue

-32 1 ¾” screws

-A piece of foam (anywhere from 3” to 6” thick and at least ½” larger all around than the wood)

-Spray adhesive (Elmers makes a spray adhesive available at the craft store)

-Scrap fabric ( this to attach around the ottoman frame measuring about 8” x 65”. An option would be to use a bendable piece of cardboard)

-1 ½ yard of cotton or dacron batting

-1 ½ yard of 54” wide fabric

-¾” yard of scrap fabric to cover the bottom of the finished ottoman

-Thread and straight pins

-Staples

-4 screw on leg plates (hardware store)

-4 fabulous ottoman legs (look around for good legs on cruddy, inexpensive Goodwill furniture)

Tools:

-Big marker

-Drill

-3/32” drill bit and a 3/8” drill bit

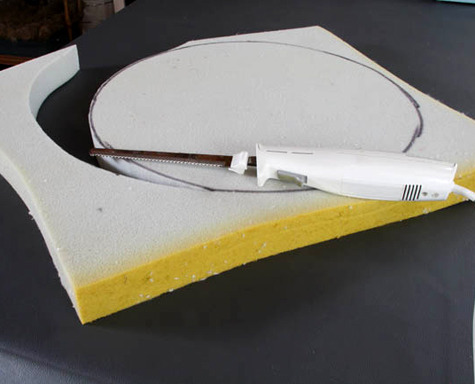

-Electric knife

-Electric stapler

-Scissors

-Measuring tape

-Flat head screwdriver

-Pliers (crescent or needle nose)

-Sewing machine

Instructions:

Making the frame:

1. Take the spool apart and make a pattern by tracing the circle on a large piece of paper, adding ½” all around for the seam allowance. The pattern will be used for cutting out the foam, batting, fabric and a dustcover for the bottom. Lay aside.

2. Glue and screw 6-8 posts evenly around the outside edge of one wooden circle, then add the other piece of wood on top of the posts and attach. Be sure to keep the wood circles aligned.

Padding:

1. Use the staple gun to attach the long piece of cotton muslin around the outside edges of the top and bottom circles. Keep fabric pulled taut. The fabric serves to fill in the open spaces between the support posts. Cut off excess fabric. (Option: use bendable cardboard)

2. Trace the pattern onto the foam and cut the foam using the electric knife. Keep the knife blades perpendicular to the foam to get a crisp, even cut.

3. Use spray adhesive to glue the foam to the top of the ottoman frame.

4. Trace the pattern onto the batting, cut out. Also, cut out a long strip of batting equal to the total height of the ottoman, from the top of the foam to the bottom edge, plus two extra inches.

5. Pin the batting strip to the batting circle, starting 1” from the short end of the strip and ending 1” from the other end. Stitch in place.

6. Remove from under the sewing machine and stitch the open seam closed and go back and complete stitching that section of the band to the batting top.

7. Trim off the excess seam allowance, turn the batting covering right side out and pull it down on top of the ottoman frame.

8. Measure and mark the batting band (all the way around the covering ) so that it will be stapled evenly from the top seam to the bottom EDGE of the frame. Do not attach the batting to the underneath side of the wood. Attach it to the edge and cut off the excess batting.

Sewing and Upholstering:

1. To make the fabric covering, which is a bit like a snug slipcover, trace the pattern onto the fabric and cut it out. You’ll need to cut a band of fabric 3” longer than the height of the ottoman and 5” wider than the circumference. If you need to stitch two pieces together to get a long enough piece for the band, split the circumference measurement in two and add 3 extra inches to each piece.

2. To prepare the fabric covering for stitching, fold one short end of the cut fabric band over 1” with wrong sides together. With the right side of the band to the right side of the fabric circle, patterns matching, pin and begin stitching at the folded short edge all the way around to the other short end. Overlap the excess fabric 2” past the folded short end. Cut off any excess fabric beyond the 2”. Pin and stitch the overlapping fabric to the seam.

3. Turn the fabric covering right side out and topstitch the folded seam closed from the bottom of the band to the top seam.

4. Pull the fabric covering down over the dacron covered ottoman. Adjust the fabric pattern and straighten so the pattern or plaid is aligned.

5. Pull the fabric down firmly and staple in place evenly and snugly.

Upholstery Tip: It works best to start with one section and attach with a few staples, move to the opposite side and do the same. Then repeat for the other sides. Attach the fabric between the set staples by smoothing and easing in the fabric.

Attach Legs:

1. Measure and mark the bottom of the ottoman base for leg attachment. Place the leg plates on the marks to make sure they are equidistant from each other. Mark the center hole of the plates. Use the 3/8”drill bit to drill out the center hole. You can also do this step prior to putting the fabric on (as shown below).

2. Cut out a dustcover from scrap fabric and attach it to the bottom of the ottoman by folding the edge under ½”.

3. Locate the drilled holes, line the leg plates up, screw the leg plates on using a Phillips head screwdriver or the drill. Attach the legs to the plates.

VOILA!

4 notes

·

View notes

Text

The Versatility of the Sawing Machine: Crafting Beauty from Wood

Woodworking is an art form that has stood the test of time, captivating generations with its timeless beauty and craftsmanship. At the heart of woodworking lies the sawing machine, a tool that transforms raw wood into intricate masterpieces. From rustic furniture to delicate carvings, the Sawing machine wood serves as the gateway to unlocking the potential of this versatile material.

One of the most remarkable qualities of the sawing machine is its ability to cater to both the novice hobbyist and the seasoned professional. With a range of models available, from simple hand saws to advanced power saws, there is a sawing machine suitable for every skill level and project requirement.

For beginners, the hand saw offers a hands-on approach to woodworking, allowing them to hone their skills and develop a deeper understanding of the craft. With patience and practice, novices can gradually progress to more complex techniques, such as using a jigsaw or band saw, to create intricate designs and precise cuts.

For the experienced woodworker, the sawing machine opens up a world of possibilities, enabling them to bring their creative visions to life with unparalleled precision and efficiency. Whether crafting custom furniture pieces or intricate wooden sculptures, the sawing machine empowers artisans to push the boundaries of their imagination and produce truly remarkable works of art.

Beyond its utility in traditional woodworking, the sawing machine has also found its place in modern design and fabrication processes. With advancements in technology, computer-controlled sawing machines, such as CNC routers and laser cutters, have revolutionized the way we approach woodworking, offering unparalleled precision and efficiency in cutting and shaping wood.

From architectural models to custom signage, these cutting-edge machines enable designers and fabricators to transform digital designs into tangible objects with ease. By harnessing the power of automation and digital fabrication, the sawing machine has become an indispensable tool in the world of design and manufacturing, paving the way for innovation and creativity in every industry.

However, it's not just the efficiency and precision of the sawing machine that make it such a valuable tool—it's also its ability to breathe new life into reclaimed and salvaged wood. With growing concerns about deforestation and environmental sustainability, many artisans are turning to reclaimed wood as a more eco-friendly alternative to virgin timber.

By repurposing old barn wood, salvaged pallets, and discarded lumber, craftsmen are able to create unique pieces with a rich history and character that cannot be replicated with new materials. With the help of the sawing machine, these reclaimed treasures are transformed into stunning works of art that celebrate the beauty of imperfection and the resilience of nature.

In conclusion, the Sawing machine wood is much more than just a tool—it is the cornerstone of woodworking, enabling artisans to unleash their creativity and craftsmanship in ways never before possible. From traditional hand saws to cutting-edge CNC routers, the versatility of the sawing machine knows no bounds, offering endless possibilities for innovation and expression in every project. Whether crafting a timeless heirloom or a modern masterpiece, the sawing machine remains an essential companion on the journey of woodworking excellence.

0 notes

Text

Innovating Woodworking: The Evolution of Soft Forming Edge Banding Machines

In the realm of woodworking, precision and efficiency are paramount. Whether crafting furniture, cabinetry, or other wooden structures, the quality of the finished product often hinges on the meticulousness of the edge banding process. In recent years, the advent of soft forming edge banding machines has revolutionized this critical aspect of woodworking, offering unparalleled versatility and precision.

Soft forming edge banding machines represent the pinnacle of technological innovation in the woodworking industry. Unlike traditional edge banding machines, which rely on rigid materials and fixed shapes, soft forming machines utilize flexible materials that can be molded to conform seamlessly to the contours of the workpiece. This flexibility allows for the creation of complex shapes and designs that were once thought impossible to achieve with traditional methods.

One of the key advantages of soft forming edge banding machines is their ability to produce smooth, seamless edges without the need for additional finishing processes. Traditional edge banding methods often result in visible seams or edges that require sanding or other finishing techniques to achieve a flawless appearance. With soft forming technology, however, edges are bonded with precision and uniformity, eliminating the need for extra work and saving valuable time and resources.

Moreover, soft forming edge banding machines offer unmatched versatility in terms of materials and finishes. Whether working with wood, plastic, or composite materials, these machines can apply edge banding with ease, accommodating a wide range of thicknesses and textures. Additionally, a variety of finishes, including matte, glossy, and textured surfaces, can be achieved to suit the specific aesthetic requirements of each project.

Beyond their technical capabilities, soft forming edge banding machines also streamline the woodworking process, increasing productivity and reducing waste. By automating the edge banding process, these machines eliminate the need for manual labor, allowing craftsmen to focus their time and energy on other aspects of the project. Furthermore, the precise application of edge banding reduces material waste, resulting in cost savings and environmental benefits.

The impact of soft forming edge banding machines extends beyond the workshop, influencing the broader landscape of design and architecture. With the ability to create intricate and customized edge profiles, designers are empowered to push the boundaries of creativity, incorporating curved edges and organic shapes into their creations. This newfound freedom opens up a world of possibilities for architects, interior designers, and furniture makers alike, inspiring innovative and visually stunning designs.

In conclusion, soft forming edge banding machines represent a quantum leap forward in the field of woodworking technology. With their unmatched precision, versatility, and efficiency, these machines are revolutionizing the way craftsmen approach edge banding, enabling them to achieve unparalleled levels of quality and craftsmanship. As the woodworking industry continues to evolve, soft forming technology promises to play a central role in shaping its future, driving innovation and pushing the boundaries of what is possible in woodworking design and fabrication.

0 notes

Text

Finishing Touch: The Art of Edge Banding

In the realm of furniture craftsmanship, there's a crucial yet often overlooked detail that can make or break the aesthetic appeal of a piece – the edge band. While it might not be the first thing that comes to mind when envisioning a finely crafted piece of furniture, the edge band plays a pivotal role in enhancing both the visual appeal and structural integrity of the finished product.

What is Edge Banding?

Edge banding, in its essence, is a method employed to cover the exposed and vulnerable edges of wood panels or boards. This technique not only serves a functional purpose by protecting the edges from moisture, wear, and tear but also contributes significantly to the overall design aesthetics of the furniture. The use of edge banding tape, a narrow strip of material designed for this purpose, has become a standard in the industry.

The Versatility of Edge Banding Tape:

Edge banding tape comes in various materials, each catering to specific needs and design preferences. Common materials include PVC, ABS, wood veneer, and melamine. The choice of material depends on factors such as the application, and desired visual outcome. PVC and ABS edge banding tapes, for instance, offer durability and resistance to moisture, making them ideal for kitchen and bathroom furniture.

Wood veneer edge banding, on the other hand, provides a natural and authentic look, seamlessly blending with the surface of wooden furniture. The wide array of colors and patterns available ensures that edge banding can complement any design style, from sleek and modern to classic and traditional.

Enhancing Aesthetics with Edge Banding:

Beyond its protective qualities, edge banding is a design element that allows for creative expression. The tape's application can add depth and dimension to a piece, giving it a polished and refined appearance. Clean lines, smooth transitions, and a cohesive finish are achievable with carefully selected edge banding options.

For those seeking a seamless and inconspicuous look, matching the edge banding tape to the surface material creates a unified appearance, eliminating visible edges and creating a visually appealing result. Conversely, contrasting edge banding can be used to highlight the edges, creating a bold and striking design statement.

Precision in Application:

The success of edge banding lies in the precision of its application. Modern machinery and techniques have elevated the process, allowing for seamless integration with the furniture manufacturing workflow. Automated edge banding machines ensure consistent and accurate application, reducing the margin for error and enhancing efficiency in production.

The Future of Edge Banding:

As technology advances, the world of edge banding continues to evolve. New materials, finishes, and application methods are constantly being developed to meet the ever-changing demands of the furniture industry. Edge banding is not just a functional necessity; it's a design element that has the potential to elevate furniture craftsmanship to new heights.

In conclusion, while edge banding might be a subtle detail in the grand scheme of furniture design, its impact is undeniable. The meticulous application of edge banding tape transforms raw materials into refined and sophisticated pieces of furniture. As the industry embraces innovation, edge banding remains a cornerstone of craftsmanship, proving that even the smallest details can make a significant difference in the world of furniture design.

0 notes

Text

CNC Router Machines for Furniture Making

CNC Furniture

Smart furniture CNC machine relies on a sophisticated array of machines and automation processes to create cutting-edge, functional, and user-friendly products. These machines work seamlessly together to transform raw materials into smart furniture pieces that enhance modern living spaces. CNC router machines are commonly used in the furniture-making industry for their precision, versatility, and efficiency. They can automate various woodworking processes, allowing for the production of high-quality furniture components.

Panel furniture production refers to the manufacturing process of furniture using panels or sheets of material, such as plywood, MDF (medium-density fiberboard), particleboard, or melamine-faced boards. Panel furniture is popular due to its cost-effectiveness, design flexibility, and ease of mass production.

Here are some key aspects of CNC furniture making

CNC Nesting Router Machine

A CNC nesting router machine is an industrial automatic wood cutting machine with computer numerical controller, which has the ability of feeding, cutting and unloading in furniture customization. The layout file is designed by CAD/CAM software, and the G-code command is generated by the computer, which is transmitted to the user friendly computer numerical control system, so as to control the machine to perform various operations. The CNC nesting machine drives the gantry to move through the stepper motor, cuts the panel through the tool in the high speed spindle. It is divided into single-process, double-process, three-process, and four-process based on the number of spindles, and is classified into single-table, double-table, and moving-table based on the different table structures. In addition, it can be customized and designed to meet the commercial woodworking plans.

It is mainly used to cut various wooden boards. In terms of processing functions, the cutting machine mainly includes cutting, punching, slotting and other processes. The CNC nesting machine is widely used in the furniture industry, such as cabinet doors, wardrobe doors, solid wood doors, paintless doors, solid wood composite doors, and suite doors.

Polishing machine:

Edge banding machine

Introduction: The edge banding machine is widely applied to panel furniture, customized furniture, cabinets, office furniture, wood furniture, tables & chairs, windows & doors, wood products and decorations. It is able to process a variety of panel materials, such as density fiberboard, ecological boards, composite boards, particle boards, plane wood boards, aluminum honeycomb panels etc.

Precision saw

Introduction: Precision saw is used for the longitudinal sectioning and cross-cutting work of various board materials, such as density fiberboard, particle boards, artificial boards, ABS boards, PVC boards, PMMA, solid wood panels and other panels with similar hardness.

Vacuum press machine

Introduction: The vacuum press machine can paste various PVC films on furniture, cabinets, speakers, paint-free doors and other materials in three dimensions, and can be used for thermal printing film and single-sided solid wood veneer after the addition of silicone plate.

Side drilling machine

Introduction: The side drilling machine is designed for panel furniture and cabinets, such as wardrobes, closets. It is capable for the side drilling work of three-in-one side holes/wood pinholes/blind holes/fixed groove/straight slot/four invisible parts.

Introduction: The polishing machine is used for rough and fine sanding, buffing and polishing the side surface, anisotropic surface, plane and curve surface of straight, L-shaped wood boards and door panels of various materials, such as solid wood, density fiberboard, tinplate etc. It is the ideal equipment for anisotropic polishing processing for doors, windows, cabinets and other furniture.

If you need to upgrade your panel furniture production line with a new nesting CNC machine to make cabinets, closets, wardrobes, home doors, home decorations, and other personalized panel furniture, we suggest starting your buying process sooner rather than later, as it can fully automate your panel furniture manufacturing process, which not only saves labor and production costs, but also improves production efficiency. Buy early and benefit early. CNC technology excels in custom furniture production. It allows for easy customization and personalization of furniture pieces to meet specific client requirements. CNC machines can quickly adapt to design changes, enabling furniture makers to create bespoke furniture items efficiently.

0 notes

Text

Finishing Touch: The Art of Edge Banding

In the realm of furniture craftsmanship, there’s a crucial yet often overlooked detail that can make or break the aesthetic appeal of a piece — the edge band. While it might not be the first thing that comes to mind when envisioning a finely crafted piece of furniture, the edge band plays a pivotal role in enhancing both the visual appeal and structural integrity of the finished product

What is Edge Banding?

Edge banding, in its essence, is a method employed to cover the exposed and vulnerable edges of wood panels or boards. This technique not only serves a functional purpose by protecting the edges from moisture, wear, and tear but also contributes significantly to the overall design aesthetics of the furniture. The use of edge banding tape, a narrow strip of material designed for this purpose, has become a standard in the industry.

The Versatility of Edge Banding Tape:

Edge banding tape comes in various materials, each catering to specific needs and design preferences. Common materials include PVC, ABS, wood veneer, and melamine. The choice of material depends on factors such as the application, and desired visual outcome. PVC and ABS edge banding tapes, for instance, offer durability and resistance to moisture, making them ideal for kitchen and bathroom furniture.

Wood veneer edge banding, on the other hand, provides a natural and authentic look, seamlessly blending with the surface of wooden furniture. The wide array of colors and patterns available ensures that edge banding can complement any design style, from sleek and modern to classic and traditional.

Enhancing Aesthetics with Edge Banding:

Beyond its protective qualities, edge banding is a design element that allows for creative expression. The tape’s application can add depth and dimension to a piece, giving it a polished and refined appearance. Clean lines, smooth transitions, and a cohesive finish are achievable with carefully selected edge banding options.

For those seeking a seamless and inconspicuous look, matching the edge banding tape to the surface material creates a unified appearance, eliminating visible edges and creating a visually appealing result. Conversely, contrasting edge banding can be used to highlight the edges, creating a bold and striking design statement.

Precision in Application:

The success of edge banding lies in the precision of its application. Modern machinery and techniques have elevated the process, allowing for seamless integration with the furniture manufacturing workflow. Automated edge banding machines ensure consistent and accurate application, reducing the margin for error and enhancing efficiency in production.

The Future of Edge Banding:

As technology advances, the world of edge banding continues to evolve. New materials, finishes, and application methods are constantly being developed to meet the ever-changing demands of the furniture industry. Edge banding is not just a functional necessity; it’s a design element that has the potential to elevate furniture craftsmanship to new heights.

In conclusion, while edge banding might be a subtle detail in the grand scheme of furniture design, its impact is undeniable. The meticulous application of edge banding tape transforms raw materials into refined and sophisticated pieces of furniture. As the industry embraces innovation, edge banding remains a cornerstone of craftsmanship, proving that even the smallest details can make a significant difference in the world of furniture design.

0 notes

Text

Heartstrings

Home for the Holidays 2019

Prompt: Admiration

Pairing: Sting x Rogue

A collaboration by @mdelpin and @oryu404

AO3 | FF.Net

September 29, 2012

Making new friends could seem like an intimidating challenge to many, but to Sting, it was a skill he had been gifted with from an early age. No matter where he went, he was always able to charm the people around him, both children and adults of any and all ages. His mother attributed it to his good looks and irresistible smile, his father accounted for it with his manners and friendliness, but Sting knew they were in no position to give an unbiased opinion. These were good qualities he had learned and inherited from them after all, they always said when the subject matter came up, and even though it was meant as a joke he could see the pride in their smiles.

While they probably weren’t really wrong, Sting believed that it all came down to radiating positive energy and having a good dose of confidence, but for the first time, the latter was hard to find. Nothing was familiar ever since he had come to Magnolia as an exchange student at the beginning of his sophomore year. Everything was new territory that he still had to find his place in, and although he did speak the language fluently enough to follow classes and hold his own in conversations, his flawed grammar and clearly present accent were the primary reasons for insecurity to raise its ugly head.

To enrich this unique experience of studying abroad for a year, he had to start making some friends, so on the recommendation of one of his roommates he’d decided to check out one of the most popular student bars downtown.

Oh, it was popular alright. That much became clear even before Sting entered the place. Live music could be heard from the beginning of the street, the terrace full of people socializing as they smoked their cigarettes, and when he peered through the window the place seemed to be bustling with life.

The first thing Sting did was find his way to the bar to order a drink, he could use some liquid courage if he was going to mingle. With so many people standing already, he figured that all the seats were taken. He found a spot of his own where he could stand, leaning against the side of a slot machine. Sipping his drink, he curiously took in the establishment’s interior.

Classic red brick walls were creatively decorated with graffiti murals, neon signs, and band posters. Aside from two black leather sofas in one corner, all of the furniture was wooden. Empty liquor bottles repurposed as oil lanterns graced every table.

But as appealing as it all was, none of it was the subject of his sudden interest. Instead, he was now focused on a small, elevated stage, where a band was responsible for the music he had heard earlier. Naturally, the lead singer had drawn his attention first, both for his center-stage position and his distinctive appearance. With his long black hair, a black leather jacket that had so many studs it must’ve weighed a ton, and a face covered in piercings, there was no way he could have missed him.

He played a mean set of riffs on his guitar, perfectly in sync with a girl with long blue curls that played the bass, and his voice was raw and raspy like you’d expect from a rock singer. The song ended and Sting’s focus shifted towards another occupant of the stage, the main guitarist.

Out of all the band members he was the least flashy, dressed in just a plain pair of black jeans and a band shirt that seemed at least a size too large. No piercings or tattoos either, no jewelry aside from a watch with a black leather strap. His black hair had been obscuring part of his face before, partially sticking to the sweat on his forehead. He was pulling it back into a small ponytail in preparation for the next song, frowning when it turned out to be in vain, as most of it fell right back into his face again.

The drummer- a guy who’s hair was part black and part white- signaled the start of their next song with four taps of his wooden sticks. This song was different, it had a softer edge to it and when it wasn’t the pierced guy who committed himself to the microphone it became clear why. The guitarist’s voice harmonized with the rest of the song perfectly, as if the two were made for each other.

As easy as it usually was for Sting to make friends, he would just as easily get infatuated. And that was exactly what happened as he watched the young man on the stage lose track of his surroundings. His hands were flying across the strings of his guitar in a way that made it look like child’s play, when Sting knew from a one-time experience that as as far from the truth as you could possibly get. Every note he produced was thick with emotion, and the only way Sting could describe the feelings it provoked was that it felt as if a soft, warm blanket was being wrapped around him.

With fluid motions, the guy moved through the song. The multi-colored stage lights painted rainbows on his skin and danced across his face along with alternating expressions. He was truly lost in a world of his own until the song came to a close, and Sting was convinced he was lost right there with him.

Needless to say he was too starstruck to even say hi when the guy walked past him to get a drink.

But days later he was still haunting Sting's mind as a bittersweet reminder of his lack of courage, so when he came to the campus library to escape the madness of his dorm floor and noticed him sitting at one of the tables, he wasn’t going to make that same mistake again.

And nervous as he was, he still managed to flash him what he was told was his brightest smile as he placed his hands on the backrest of the opposite chair and asked, “Hey, is this seat taken?

19 notes

·

View notes

Text

Everything you need to know about veneer and edge banding

A home without furniture is incomplete and it is difficult to imagine your house without furniture. In simple terms, we would say plywood, as it is used for making furniture. Plywood is the initial form and the only thing missing in it is the finished or covered edges. The completely covered and round-edged panel to the furniture is provided by edge banding. For the making of plywood, the veneer is used.

Owing to the increased demand in plywood in the economy there is enough scope for growth of for the teak wood suppliers in India. Veneer and edge banding are an integral part of it too.

Know everything you should know about veneer and edge banding. There is a lot more than people generally know.

What is Veneer?

The veneer is a thin piece of wood attached to the particle board or other types of manufactured woods. They are known to enhance the overall experience problem and decrease the cost on the same.

In simple terms, a thin piece of a hard word placed over a piece of manufactured wood is called a veneer. They are mainly used in furniture, floors, cabinets and other household materials. They are attached to piece of wood either with the use of nails, screws or adhesive.

Edge banding use:

For a real wood veneer, there are different techniques to apply edge banding. First, it can be done as a glueing method. Secondly, edge banding can be done by the iron-on-edge method. Lastly, edge banding can be done by edge banding machine and then flushing it to the top edge surface of the plywood.

Through the glueing method, the builder gets a variety to develop an attractive edge design. However, it is the most time-consuming method as compared to the other ones.

Edge banding is proven to solve the process and outcome of furniture making. Wooden boards when cut has raw edges which are rough. If left uncovered, they can be a major setback for the furniture or any wooden material and can pose problems in the future.

Raw and uncovered edges look unappealing and rough and also allow moisture to penetrate. This might lead to the warping of wood and reducing the lifespan of the wooden material significantly. Moreover, it is damaging to the appearance as well.

Veneers are used for the process of veneers edge banding that goes on the end of raw wooden boards and covers them up. Above all, they protect the wood from moisture by reducing atmospheric humidity and liquid spills effects and increase their lifespan.

No matter what advancements with engineered woods are made, it does not alter the tendency of wood to absorb water and moisture. Therefore, edge banding is necessary and the veneer is a great companion for that purpose.

#veneer edge banding#veneer edge banding india#teak wood suppliers in india#mosaic manufacturing#best veneer brands in india#best veneer company in india#veneer companies in india#veneer brands in india#veneer manufacturers#teak wood suppliers in mumbai

2 notes

·

View notes

Text

Edge Banding Machine

Manual Edge Banding Machine is used to glue PVC edge bands on the plywod,, particle board, MDF and related materials. We can provide edge bander machine for gluing of pvc strips on the edges of the Honeycomb panels, wood and other variations as well as per client requirement.

Manual Edge Banding machine is capable of provide high strength glued strips. Manual Edge Banding Machine is suitable for Straight and Curved and so the Edge Banding Machine is also called Curvilinear Edge Banding Machine.

Salient features of the Manual Edge Banding machine:

4 Feet wide table for easy processing of large boards

Easy setting of machine

Heaters for glue

Auto Cut-off of PVC Strip using Pneumatic pressure Machine tested and trial can be provided before delivery

Variable feed drive for feeding speed

Tilting of the side board also available (Optional)

Edge Banding Machine, Woodworking edge banding machine, Manual Edge Banding Machine, woodworking edge banding machine, Automatic edge banding machine, Edge banding equipment, Industrial edge banding machine, Edge banding machine price in india, automatic edge banding machine price in india, edge banding machine manufacturers in india, Manual Edge Bander Machine, Edge banding machine manufacturer near me, top edge banding machine manufacturers in india, Edge Banding Machine for Wooden Furniture

#Edge Banding Machine#Woodworking edge banding machine#Manual Edge Banding Machine#woodworking edge banding machine#Automatic edge banding machine#Edge banding equipment#Industrial edge banding machine#Edge banding machine price in india#automatic edge banding machine price in india#edge banding machine manufacturers in india#Manual Edge Bander Machine#Edge banding machine manufacturer near me#top edge banding machine manufacturers in india#Edge Banding Machine for Wooden Furniture

0 notes

Text

Global Decor Paper Market Scope in 2022

Global Decor Paper Market will exhibit a CAGR of 5.6% for the forecast period of 2022-2029

Global Decor Paper Market Analysis and Insights:

Decor paper is used in getting quality finishes on wooden materials after impregnating. They are available in a variety of colors and weights. Recently, the machine-smoothed décor paper has gathered some steam among consumers. Flooring, paneling, and furniture surfaces are just a few of the primary application areas for the décor paper. The need for light-resistant, chemically inert décor paper has increased significantly with the rising demand for home décor. Furthermore, changing certification and standards criteria for products in wood-working markets vary from country to country. This has made a large bearing on the growth trajectories in the decor paper market.

Accelerating urbanization and consumer preferences toward modern product designs in home décor acts as a driver in the growth of the global decor paper market. Shortage of raw materials for decor paper production prove to be a challenge. However, fundamental shift of demand for home décor amid the pandemic is expected to provide opportunities for the market. Stringent government norms & regulations regarding deforestation can prove to be a restrain for the market growth.

The global decor paper market report provides details of market share, new developments, and product pipeline analysis, the impact of domestic and localized market players, analyses opportunities in terms of emerging revenue pockets, changes in market regulations, product approvals, strategic decisions, product launches, geographic expansions, and technological innovations in the market. To understand the analysis and the global decor paper market scenario, contact Data Bridge Market Research for an Analyst Brief; our team will help you create a revenue impact solution to achieve your desired goal.

Get full report: https://www.databridgemarketresearch.com/reports/global-decor-paper-market

Global Decor Paper Market Scope and Market Size:

On the basis of product type, the global decor paper market is segmented into absorbent Kraft paper, print base paper, UNI paper, base paper for foil production, edge banding paper, and others. In 2022, the print base paper is expected to dominate the market because it is highly loaded with white and color pigments that provide high opacity, and also possesses good absorbency and better-wet strength.

On the basis of weight, the global decor paper market is segmented into less than 65 GSM, 65-80 GSM, 81- 100 GSM, and above 100 GSM. In 2022, less than 65 GSM is expected to dominate the market as they are economical and lightweight, which is perfect for fast printing.

On the basis of color, the global decor paper market is segmented into white, cream, beige, brown, grey, and black. In 2022, brown color is expected to dominate the market as it gives good surface finishing and more of a natural look in home décor.

Global Decor Paper Market Country Level Analysis:

The countries covered in the decor paper market report are the U.S., Canada and Mexico in North America, Germany, France, U.K., Netherlands, Switzerland, Belgium, Russia, Italy, Spain, Turkey, Rest of Europe in Europe, China, Japan, India, South Korea, Singapore, Malaysia, Australia, Thailand, Indonesia, Philippines, Rest of Asia-Pacific (APAC) in the Asia-Pacific (APAC), Saudi Arabia, U.A.E, South Africa, Egypt, Israel, Rest of Middle East and Africa (MEA) as a part of Middle East and Africa (MEA), Brazil, Argentina and Rest of South America as part of South America.

Get Sample Report here: https://www.databridgemarketresearch.com/request-a-sample/?dbmr=global-decor-paper-market

Competitive Landscape and Decor Paper Market Share Analysis:

The decor paper market competitive landscape provides details by competitor. Details included are company overview, company financials, revenue generated, market potential, investment in research and development, new market initiatives, global presence, production sites and facilities, production capacities, company strengths and weaknesses, product launch, product width and breadth, application dominance. The above data points provided are only related to the companies’ focus related to decor paper market.

Key Players:

Koehler Paper SE,

KÄMMERER Paper GmbH,

SURTECO GmbH,

Onyx Papers,

BMK GmbH,

Pura Group,

Felix Schoeller Holding GmbH & Co KG,

Impress Surfaces GmbH,

Ahlstrom-Munksjö,

Major TOC of the Report:

Chapter One: Introduction

Chapter Two: Market Segmentation

Chapter Three: Market Overview

Chapter Four: Executive Summary

Chapter Five: Premium Insight

Chapter Six: COVID-19 Impact on Global decor paper Market

Get TOC here: https://www.databridgemarketresearch.com/toc/?dbmr=global-decor-paper-market

About Us:

Data Bridge Market Research set forth itself as an unconventional and neoteric Market research and consulting firm with unparalleled level of resilience and integrated approaches. We are determined to unearth the best market opportunities and foster efficient information for your business to thrive in the market.

Contact:

Data Bridge Market Research

Tel: +1-888-387-2818

Email: [email protected]

0 notes

Text

PVC Edge Banding Solution: All Interesting facts & benefits you need to know on Edge Band!

I’m sure you have come across furniture with the most beautiful panel top but left the edges uncovered. This raw edge to beautiful panels makes entire furniture and other accessories look incomplete and ugly. The uncovered exposed edges also lead to early damage by allowing insects and moisture. Unmatching edges also create the problem by reducing the beauty of your home. To prevent these issues, PVC Edge Banding Solution is setting trends giving perfect finish matching with all kinds of plywood, laminates, panels, etc with exclusive features and easy to install. PVC Edge bands are placed on the edge of raw boards to cover the ends and thus seal them from moisture.

What is Edge Banding?

In simplest words, Edge Band is a strip of Plastic to cover the Wooden edges of the Furniture. It enhances the look of furniture and makes the edges smooth. The process of applying the PVC Edge Band in the raw edges of panels with a thin strip of PVC or resinous material is called edge banding. In India, the edge band is setting new designing trends with the fastest-growing market from the last 3 years. It is designed in wide variants of color, shade, finish, texture, etc.

History of PVC Edge Banding Tape

Let’s go back a few years. In the ’80s and ’90s when edge band was a rare concept, wooden beadings were the only edge covering product. So, whatever Laminate may be on the top, sides were covered by wooden strips called Margins which were polished or painted and never matched.

In India, at least 50% are still using traditional wooden strips, and the rest of them have converted to edge bands. You will be amazed to know that all Europeans & Americans use only edge bands. The new generation doesn’t even know that wooden beddings also exist. For the last 5 years, the edge band has been the fastest-growing product of our industry in India.

Why is using PVC Edge Band better than Wooden bit?

PVC Edge banding solution makes the furniture waterproof and termite-proof to a great extent. It increases the furniture life expectancy and protects the furniture from getting damaged due to water, termite, moisture, etc.

PVC Edge band does not require paint or polish like it’s required in a wooden bit, since the design does not fade or get damaged for years due to daily cleaning because of the UV Layer.

The wooden bit does not match with the tabletop or laminates but the edge band perfectly matches with all surfaces.

The price of the PVC edge band is comparatively much lower than the wooden bit. Wooden bit price is in running feet while the price of edge band is in the running meter. 1 meter is equal to 3.2 feet.

E3 edge band makes the sides of furniture soft. Adults and small kids do not get any cut or injury due to sharp edges by other coverings.

No use of nails. Sometimes, a small portion of nails comes out of bidding and damages our clothes. E3 edge band is a completely nailing-free product, hence no damage.

The minimum adhesive is used for pasting. Only a thin layer of good adhesive is required to paste.

E3 edge band is stronger than a wooden bit and most importantly it is 100% recyclable & eco-friendly products.

Why Should My Furniture Have an Edge Band?

These days, it is not easy to sell a Laminate or Panel if the matching edge band is not available, vice versa, Laminates with matching edge bands sell faster. In the retail market, the customer first chooses the laminate and then starts looking for the edge band. If the retail customer does not find a perfect match then either he goes with nearest matching or cuts strips from laminates which is a traditional way and fast fading. In projects and OEM’s, although they also first select the Laminate shade, they do not place an order or start the production till they perfectly match the edge band.

It is manufactured by mixing PVC Resin, Chemicals, and Pigments that are poured into the heating machine called an extruder. The Chemical mixture is heated to 200 degrees Celsius. At this temperature, PVC powder melts into liquid form in the extruder machine and comes out as shown in the picture. Then it is cooled where it takes the permanent shape of Edge Band. Then there are further processes like Printing & UV coating.

First choice of carpenter/Architect

E3 emerged as the Largest Edge band Manufacturer in India just within 5 years of establishment with distributorship in PAN India and a Capacity of 3 Lac running meters per day. E3 is now known for its high quality, wide-variant, exclusive features and for bringing PVC edge banding solution to the doorsteps of every retailer & every carpenter. The introduction of 50-meter rolls increased the robust demand. Later, E3 started its association with Greenlam adding new shades to the folder.

0 notes

Text

Revolutionizing Woodworking: The Advancements of Auto Edge Banding Machines

In the realm of woodworking, precision and efficiency are paramount. With the rapid advancements in technology, the traditional methods of edge banding have evolved significantly. One such innovation that has revolutionized the industry is the Auto Edge Banding Machine. This marvel of engineering has streamlined the process of applying edge banding to wooden panels, offering unparalleled accuracy and speed. In this article, we delve into the workings of auto edge banding machines, exploring their benefits, applications, and the future they herald for woodworking professionals.

Evolution of Edge Banding:

Traditionally, edge banding involved manual application of thin strips of veneer or PVC to the edges of wooden panels using adhesives and rollers. While effective, this method was labor-intensive and prone to human error. As demand for efficiency and precision grew, the need for automated solutions became apparent. Enter the auto edge banding machine.

How Auto Edge Banding Machines Work:

Auto edge banding machines automate the entire process of edge banding, from adhesive application to trimming and buffing. These machines are equipped with advanced mechanisms such as conveyor belts, glue application systems, pressure rollers, trimming units, and buffing wheels. The process begins with the feeding of the wooden panel into the machine, where it is guided along the conveyor belt. The machine applies adhesive to the edge of the panel and precisely attaches the edge banding material using pressure rollers. Subsequently, the excess banding material is trimmed and buffed to perfection, resulting in a seamless finish.

Advantages of Auto Edge Banding Machines:

Precision: Auto edge banding machines ensure consistent and precise application of edge banding material, eliminating human error.

Efficiency: These machines significantly reduce production time, allowing woodworking professionals to increase their output.

Versatility: Auto edge banding machines can handle various types of edge banding materials, including veneer, PVC, and ABS, making them versatile for different woodworking projects.

Quality: The automated process results in high-quality finishes that enhance the aesthetics and durability of the wooden panels.

Cost-effectiveness: While initial investment may be higher, the long-term cost savings from increased efficiency and reduced labor make auto edge banding machines a cost-effective solution.

Applications:

Auto edge banding machines find applications across various sectors of the woodworking industry, including furniture manufacturing, cabinetry, interior design, and architectural woodworking. Whether it’s producing custom furniture pieces or mass-manufacturing kitchen cabinets, these machines cater to the diverse needs of woodworking professionals.

Future Outlook:

The future of auto edge banding machines looks promising, with ongoing advancements in technology enhancing their capabilities further. Integration of artificial intelligence and machine learning algorithms may lead to even more precise and adaptive edge banding solutions. Additionally, advancements in materials science may result in the development of innovative edge banding materials with enhanced properties.

In conclusion, auto edge banding machines represent a significant leap forward in the field of woodworking. Their ability to automate and streamline the edge banding process offers numerous advantages, including increased precision, efficiency, and versatility. As technology continues to evolve, these machines will play a pivotal role in shaping the future of woodworking, empowering professionals to achieve new heights of craftsmanship and productivity.

0 notes

Text

Cabinet making machine?

The Cabinet making machine is suitable for kitchen cabinets making, cabinet door making, corner cabinets making, decorative cabinets making, home cabinets making, wall cabinets making, wood cabinets making, base cabinets making and other custom cabinets making in bathroom, garage, living room, office.

The complete cabinet production line is composed of optimized typesetting software, CNC cutting machine, edge banding machine, side hole machine, drilling machine, and edge banding machine. As the leader of the cabinet production line, iGOLDENCNC can provide double spindle & row drilling Cutting machine, multi-process cutting machine, six-sided drilling, edge banding machine, side hole machine, electric panel saw, profiling corner trimming machine, PTP machining center, three-row drill and other cabinet processing machines, and according to Customer needs and budget are equipped with the most cost-effective and efficient production line plan.

Custom and general cabinet manufacturing is one of the most popular applications for CNC routers. In addition, the size and configuration of the machine can also be customized according to the special needs of customers to achieve customized functions.

The cabinet making machine Applications

Woodworking Industry: Cabinet making CNC router is ideally suitable for furniture decorations, musical instruments, wooden crafts, solid wood furniture, MDF door, wood composite door, cabinet making, kitchen cabinet doors, windows, tables, etc.

Decoration Industry: Art model, wall art, screen relief engraving and cutting, decoration processing, gifts wrapping, waved plate, electrical cabinets panels, sports equipment, and other industrial wood works.

What is a Cabinet Maker?

Cabinet makers are woodworkers that specialize in designing and making built-in or customized cabinets. They also design and manufacture fine wood furniture that accompanies the cabinetry in homes or commercial offices. A cabinet maker also repairs or creates their products from flat panel, or solid timber materials, building many products individually for clients based on unique measurements, design elements or application.

From opening their own business to working for larger cabinet or woodworking manufacturers, today’s cabinet maker has multiple career paths they can follow. Some of the most common specialities include designing bedroom suites, kitchen cabinetry and furniture, antique furniture, dining, office, or entertainment-based wood furniture.

0 notes

Text

Interesting Facts About Edge Banding

If you’ve seen furniture being made, you might have noticed that wooden boards have a raw edge when cut. This raw wood edge banding, if left uncovered, can pose serious problems for the furniture.

Apart from looking unsightly and scratching the skin if someone bumps into them, these exposed edges allow moisture to seep in, which in turn makes the wood warp and become lumpy. To prevent these issues, edge bands were created. Edge bands are placed on the end of raw wood boards to cover the ends and thus seal it from moisture.

What is edge banding?

The process of covering the raw edges of wood panels with a thin strip of wood, PVC, or resinous material is called edge banding. The narrow strips themselves are known as edge bands. Commercially, edge banding is done using industry-grade heat applicators and a hot-melt adhesive. For modular furniture, the material used is mostly PVC which is easy to fix and has a long life.

Why should furnitures have an edge band?

Modular furniture is generally made using engineered wood veneers. As such, the wood is treated and made resistant to moisture by treatments. However, wood has a natural tendency to absorb water. This tendency cannot be removed completely – it can only be reduced.

Edge banding protects the wooden panels in your furniture from moisture, thus reducing the effects of atmospheric humidity and liquid spills. This means that the strength and durability of the wood increases. So, the next time you spill coffee on your table and it drips down the edge, thank the edge banding for protecting the wood.

Is PVC the only material for edge banding?

Conventional carpenters use teak wood bands to cover raw edges of wooden boards. Edge band tape can be made from PVC, acrylic, wood or wood veneer. However, most modular furnitures use PVC edge bands. That’s because PVC is impermeable which means that it reduces water absorption to a large extend.

Also, modular furniture comes in a much wider variety of colors and shades than the options available for real wood. PVC strips can be produced to match the exact shade and finish of your modular panel, thus creating a seamless look.

The main reason why PVC is such a popular choice is:

a. PVC edge bands are impermeable

b. PVC edge bands come in varying shades and color and can be custom made

c. It can be easily used on curved surfaces unlike real wood bands

How is edge banding applied?

Essentially, an edge band is a thin strip of impermeable PVC that is cut to fit the size of a wood panel. It is then applied to the raw edge using a strong adhesive. A heat roller is then used to melt the adhesive and glue the edge band over the wood.

The ends are trimmed flush and bent so that they cover the wood and do not have any sharp ends. Any surplus glue is scraped off and the finished edge is buffed to give a flawless finish. The machine that is used for this process is called an edge bander.

0 notes

Text

Field Equipment

6 Ton Light Duty Gantry Crane For Sale 1232131

Corrugated field design is the process of matching design factors for corrugated fiberboard bins with the practical bodily, processing and end-use requirements. The provided merchandise are tested by way of quality to deliver only defect less vary from our side. Since then, pulp processing, paper making, and corrugating operations have been developed to a high state of efficiency and productiveness. We hope that our worth for money merchandise will make it easier to in rising your enterprise for many years to come. This corrugated cardboard field making machine with excessive efficiency has passed the CE certification. We have been an brisk corporation with broad marketplace for Used Paper Egg Carton Making Machine, The product will supply to all over the world, reminiscent of: Suriname , Curacao , Rome , We warmly welcome home and overseas prospects to go to our firm and have business discuss. Explore the detailed product pages to search out all you might want to know about any box making machine. Kraft and Take a look at paper can be used to create the fluted paper in between liners which lastly create a strong board. We comprehend the truth that majority of import companies in are lively in sourcing distinct ranges of products together with raw supplies, machinery and consumer items and so on. Next, it’s important to procure equipment, which is able to differ depending on the type of box you wish to manufacture. offers fifty seven,111 carton box making machine products. There are 10,610 carton box making machine costs suppliers, primarily positioned in Asia. A quick information to cardboard bins by Kite Packaging. All Boxmatic machines can be outfitted with two or three-out production and as much as three sensible flexo print units. Recycling and different environmentally pleasant processes will proceed to grow in importance in the way forward for corrugated cardboard. In-home making of corrugated containers contributes to reduction of outsourcing prices. Our execs are lessen costs,dynamic gross sales group,specialised QC,sturdy factories,high-quality companies and products for Corrugated Carton Box Making Die Cutter Machine (ML-1600), The product will supply to all around the world, resembling: Albania , Sheffield , Swansea , “Make the women more enticing “is our sales philosophy. Most typical sorts of boxes in demand embody mono cartons, commonplace box, large field, packing containers in 2,three,5,7, ply. All kinds of carton box making machine costs options can be found to you, resembling beverage. One other 6 million tons of uncorrugated boxboard or paperboard were additionally produced to be used in folding cartons. Corrugated field making machine is a gear used to making corrugated packing containers. The machines find their option to various market sectors: from agricultural to industrial use in meals and non-meals sectors. At present, within the corrugated cardboard business, designers are creating innovative containers that require 4-colour printing and complicated die-reducing. At the fundamental of Corrugated Box Machine BM2508, it adds the function of die-cutting handle holes on both sides of the carton field. A semi-automated cardboard field producing machine will value your roughly $ a hundred and twenty,000, whereas full-scale manufacturing plan will cost you $ a hundred and eighty,000. Cardboard field making machines come with an enormous host of advantages that optimize your box-making course of. The lifetime of a carboard box by Kite Packaging. The know-how is fairly slicing-edge for the cardboard box trade. Other uncooked supplies are used to complete the corrugated cardboard after manufacturing. It can also present essentially the most appropriate corrugated packaging box on demand for furniture, hardware accessories, e-commerce logistics and different industries. It’s now quite common for these liners to also be made up of a considerable proportion of recycled content, sourced from old cardboard or other sources of second hand paper. I utterly suggest SPB equipment to anybody seeking to purchase machines. For extra data on corrugated containers, click on right here to browse our assets. 1 Manufacturing a corrugated cardboard field begins with the pulping of wooden chips within the kraft (sulfate) course of.

On account of their high quality, stable efficiency and lengthy service life, our products are wanted by prospects in Spain, Chile, Venezuela, Greece, Honduras, Malaysia,the Philippines, Russia, etc. Finally, the offcuts of paper is recycled and used to provide more packing containers and different paper products, many corrugators now produce bins in probably the most eco-friendly manner possible to make sure that their processes are carbon-neutral. The potential for cardboard field manufacturing is large; practically all industries want some time of cardboard packaging and the booming e-commerce industry might be the largest consumers of cardboard boxes. Almost 81% of the packaging in any trade is completed utilizing corrugated cardboard boxes and has the most important market share in e-commerce, logistics, cosmetics, prescribed drugs, and footwear business. The slowdown in the oil and gasoline business augmented the slowdown in demand for shopper and industrial merchandise, which in turn, hit the packaging industry on this region. Corrugated paperboard accounts for greater than half of all the paper recycled within the US. S & G Options is proud to deliver this exciting line of boxmaking machinery to the U.S. and Canada, offering a solution that’s precise, sturdy and simple to function. It’s designed on the premise of corrugated field machine BM2508, which removes the slotting operate, remains creasing and chopping capabilities. The size of a field might be measured for either internal (for product fit) or exterior (for dealing with machinery or palletizing) dimensions. View our sustainable box making machine solutions, software, consumables and companies below, and please contact us to talk with our corrugated field making machine producers with any questions you’ll have. Our cardboard field machines have only a sixty second setup time and are designed with the user in thoughts. 12 On the finish of corrugator, a slitter-scorer trims the cardboard and cuts it into large sheets called field blanks. SHH-B2 excessive speed computerized paste field machine possesses the SHH-800 and SHH-B all functions, Used imported electrical appliances, and accessories for export with a rubber curler Paper could be pressed collectively by the processes as well as possesses the features of beautiful modeling, high speed and might made extra broad boxes and so on, It is important equipment in packing printing trade. The demand for products from numerous industries that will gas the growth of the packaging industry is the major factor fueling the expansion of the distributors within the corrugated field making machines market. Allow us to enable you to make the most of our value-added merchandise choices to meet the demanding wants of your native market and prospects. About 28% of these are paper product making equipment, 16% are packaging line, and thirteen% are carton printing slotting die-chopping machine. The worldwide corrugated box making machine market is predicted to grow at a CAGR of greater than 2% through the forecast interval, 2017-2021. As an end-user, you may discover that our box making machines give companies of all sizes greater management over their packaging process. All our Boix tray forming machines with their specification for the best packaging options for your merchandise. Expertise is endlessly altering, and so are our suppliers and Carton Field Making Machine who all the time preserve their standards high and has fostered innovation in all the things they do. From their methods and finish products to how that are preserving and protecting the setting. Finished bins are then stacked and sent to a banding machine to be wrapped and shipped. Grain route of the paperboard – Right grain course will enable easy printing, automated gluing, scale back bulge, and cut back shrinkage. Our packaging will defend your merchandise, while taking care of the setting. With customized graphics for labels, folding cartons, corrugated displays and more, our group will guarantee your product stands out. Zhejiang Guangya Equipment Co.,Ltd is an expert manufacturers of scorching foil stamping and die reducing machine with lengthy history.Since its establish we have now at all times insisting on the coverage of Achieved success by high quality,Integrity is base,also pay attention to new product growth and continuous designing machine, we undertake high and new technology from house and merchandise may be very popular in home market and already exported to over 70counteirs or region resembling Europe,North America,Middle East and so forth.

Designed to be robust, they are comprised of corrugated paperboard, which accommodates air columns. We have now a gentle uncooked materials provide chain and produce most elements of the machines in-home. The paperboard and cardboard industry demand been relatively stable for the previous 5 years. The corrugator machine cuts each board various occasions, depending on the size of the field. Originally of this course of, kraft rolls from the paper mill are loaded into an enormous machine called a corrugator. The cardboard box manufacturing industry is the most important paper-converting industry in the USA. Corrugated bins are used for packaging consumer and industrial goods. It is not just , but other homegrown e-commerce corporations are also using cardboard packages over plastic packaging. Depending on the required strength of the box, corrugated bins may be made of 1, two, or three layers of flutes and liners. Integrated within the year 2009, we Krishna Gross sales Corporation” are counted as the reputed producer and trader of Corrugated Field Making Machine, Rotary Die Reducing Machine, Corrugated Carton Making Machine, Corrugated Board Plant, and so forth. Compack machines might be set up as a single feed, an inline feed (with up to 4 automatic, uncooked material sources feeding into the machine), or as a lateral (side by facet) feed with as much as 4 computerized corrugated feeds. In brief, it’s important to comply with the Air Pollution Prevention and Control Act, requirements and regulation and even food-related laws if you’re producing boxes for the meals industry. Design & Manufacturing of Corrugated Packaging & Displays. Whether you are a box plant, or an end-user trying to create custom containers in-house, our machinery is cutting-edge and will cater to your needs. When manufacturing packing containers we talk about two several types of liners, this is the fabric that lies on top and beneath the fluting and creates a corrugated board. The CORRUGATED FIELD MAKING EQUIPMENT import trade sector contributes considerably to the overall GDP proportion of India. Furthermore, with the sustainability difficulty on the rise, we are able to anticipate even more packaging firms sooner or later who will convey unique designs and produce a wide range of bins from quite a lot of paper material. Cardboard Help is a participant within the Amazon Providers LLC Associates Program, an affiliate promoting program designed to provide a way for websites to earn promoting charges by promoting and linking to Cardboard Help additionally participates in affiliate applications with Clickbank, CJ, ShareASale, Homedepot and different websites. Being a B2B business, you will have permanent prospects who will need packing containers on a regular basis. He named it the kraft course of because it produces a robust paper that resists tearing, splitting, and bursting. It has paper feeding unit, adjusted unit, glue unit, forming unit, completed products gathering unit and in addition counting unit. As a result of this machine is so fast to set up it ends in very low value packing containers of the very best grade for each small and huge runs. In case of continuous manufacturing it solely takes 30 seconds per box. The Corrugated & Paperboard Container Business: An Analysis of Current Markets & Prospects for Future Progress. We provide six totally different paper cup machines SPB seven hundred, SPB 750, SPB 850, SPB Super 850, SPB 950, SPB Tremendous 950. The growing consumption of food throughout globe that fuels the growth of the meals packaging industry and the growing demand for food and beverage products that may drive the demand for corrugated packing containers, will augment the expansion prospects of the market on this phase. Contemplating today’s state of affairs, it is safe to say that cardboard box manufacturing is a profitable business. In comparison with plastics, styrofoam and different materials, the folding carton and corrugated cardboard containers are thought-about to be a greater inexperienced packaging resolution by the customers. Over past four years, we have now invested over 1 Million dollars to develop our competitive field machines, it contains BM2506 small field making machine, BM1206 short run field making machine, and BM2508 cardboard box making machine.

The corrugated box making machine market in EMEA saw a decline in demand for corrugated bins during 2012-2015 within the wake of low crude oil costs, which led to the overall economic slowdown within the Middle East region. It’s now probably the most advanced and multifunctional field making machine, offering all types of personalized packaging options for finish users as well as box vegetation. The 2 liners are then adhered to the board by the machine; the cardboard is then lower each side with a round noticed to present the board straight sides. Well-liked for his or her energy, sturdiness, lightness, recyclability, and value-effectiveness, corrugated bins are used for the transport of a wide range of gadgets. If you’re planning to start a cardboard manufacturing enterprise, this text provides you with all the necessary details from machinery to legal permissions. As a result of our machines provide quick and medium run options, providing bins that meet area of interest customer demands is easy and does not take away out of your lengthy-run processes. As a result of rising manufacturing in Europe and China, cardboard costs within the USA dropped marginally. With a hundred and twenty+ Carton Sealing & Packaging Solutions with all kinds of excessive velocity Case Sealers, Carton Sealing Tape, Box Erectors, Field Formers and High Speed Box Tape Heads, BestPack is your one stop shop to automate your packaging course of. Essentially the most dominant participant within the industry is the single-wall corrugated board which accounts for over ninety percent of all production. Carton Box Machine BM2508-Plus is just like BM2508 to a big extent, which is a multifunctional carton field packing machine of horizontal slotting and scoring, vertical slitting and creasing, horizontal reducing. We offer global buyers with a complete useful resource for their packaging needs similar to low cost China Carton Field Making Machine. A wide variety of carton box making machine choices are available to you, resembling paper bowl machine, envelope making machine, and egg tray machine. Cardboard Help is compensated for referring traffic and business to those companies. SPB Equipment has one of the largest collection of paper product machines and I have all the time been amazed by their devoted help and after-sales service. It is a perfect equipment to supply paper field such like hamburger field, chips field. You not need to rely on third events, however can produce customized boxes, in small or medium runs, the second they’re required. These totally different grades of corrugated cardboard could be made by combining different grades of kraft paper. You can too select from ul, ce. In addition to from paper slitting and rewinding machine, winding machine, and printing machine. This report focuses on Skilled World Corrugated Box Making Machine Market 2019-2024 quantity and value at Global stage, regional degree and firm level. Glue energy, bursting strength, compression, and extremely accurate dimensional assessments determine the standard of the manufacturing course of. During 1992, greater than 25 million tons of corrugated cardboard had been produced in the United States. On this report, Technavio covers the market outlook and growth prospects of the global corrugated box making machine market for 2017-2021. As skilled staff run batches of box blanks by way of the flexo machines, individual containers are pulled and inspected. Amongst all elements of the cardboard box manufacturing trade, there has been an exponential enhance in the demand for inexperienced manufacturing both by the federal government and customers. The calls for of a number of guide handlings, automated sortation, and uncontrolled stacking in trucks or air containers put extreme stress on containers, field closures, and the contents. BM2508 is a completely automatic carton field making machine for corrugated cardboard, appropriate for box plant with small quantity orders and large dimension cartons, which effectively solves the problem of scattered orders. A complete one stop sourcing platform for packaging & printing suppliers, manufacturers and factories, we are large enough to have the ability to offer an expanded product line of labels and packaging design capabilities yet sufficiently small to have the ability to provide the private service that’s still so very important in business in the present day.

The post Field Equipment appeared first on Diy Script.

from WordPress https://ift.tt/32L0bVR

via IFTTT

0 notes