#Electrical Safety Compliance

Text

Enhance Your Electrical Systems with ThermoElite's Advanced Thermography Inspection

What is Electrical Thermography Inspection?

Electrical thermography inspection is a non-invasive diagnostic technique that uses infrared technology to detect abnormal heat patterns in electrical systems. By identifying hotspots, ThermoElite’s expert technicians can pinpoint areas of concern such as overloaded circuits, faulty connections, or failing components. This early detection helps in preventing equipment failure, reducing downtime, and enhancing overall safety.

Why Choose ThermoElite for Your Electrical Thermography Inspection?

Expertise and Experience: With years of experience in the field, ThermoElite’s certified thermographers provide accurate and reliable inspections.

Advanced Technology: We utilize the latest infrared cameras and software to deliver precise results.

Comprehensive Reports: Our detailed reports include thermal images, analysis, and actionable recommendations.

Preventative Maintenance: Regular inspections with ThermoElite can extend the lifespan of your equipment and reduce maintenance costs.

Safety Compliance: Ensure your business complies with industry safety standards and regulations.

How Does the Process Work?

Initial Consultation: Our team discusses your specific needs and sets up an inspection schedule.

On-Site Inspection: Using advanced infrared cameras, we conduct a thorough inspection of your electrical systems.

Analysis and Reporting: We analyze the thermal images and provide a detailed report highlighting any issues and recommended actions.

Follow-Up Support: ThermoElite offers ongoing support to help you implement our recommendations and maintain your systems in optimal condition.

Get Started with ThermoElite Today

Protect your business from unexpected electrical failures with ThermoElite’s electrical thermography inspection services. Contact us today to schedule your inspection and ensure the safety and efficiency of your electrical systems.

#Electrical Thermography Inspection#ThermoElite Thermography#Infrared Electrical Inspection#Preventative Electrical Maintenance#Electrical Safety Compliance

0 notes

Text

Comprehensive Engineering Solutions with Little P.Eng.: Catalyzing Innovation Across Engineering

Engineering challenges in contemporary industry demand sophisticated, multidisciplinary approaches. Little P.Eng., a rising name in the engineering sector, has positioned itself as a nexus for solutions spanning various specialized fields, including structural engineering, piping design, piping stress analysis, seismic bracing design, storage tank design, material handling engineering services, pressure vessel design, electrical design, and CRN registration services. This article delves into each of these areas, highlighting the complexities, methodologies, and cutting-edge strategies employed by Little P.Eng. to cater to the evolving needs of diverse sectors.

Engineering services are the cornerstone of modern industrial and infrastructural developments. From the conceptualization of a project to its final commissioning, various engineering disciplines come into play to ensure functionality, safety, compliance, and efficiency. Little P.Eng., with its array of engineering services, has etched its mark by offering comprehensive solutions under one roof. The company's commitment to technical excellence, precision, and continual innovation positions it at the forefront of engineering consultancy.

Structural Engineering: Structural engineering, a critical subset of civil engineering, involves the analysis, design, and planning of structural components and systems to achieve design goals and ensure the safety and comfort of users or occupants. The experts at Little P.Eng. undertake detailed analyses, considering factors such as geology of the site, environmental conditions, and materials to be used, ensuring structural soundness against static and dynamic loading, including human traffic and environmental stressors.

The service spectrum includes:

Building Design: Erection of residential, commercial, and industrial structures with considerations for material efficiency, safety regulations, and aesthetic aspects.

Structural Analysis and Inspection: Employing advanced tools to analyze stress, strain, and load distribution and conducting inspections to assure structural integrity and longevity.

Foundation Design: Creating robust foundations, including piles, rafts, and footings, customized to site conditions and building requirements.

Retrofitting and Rehabilitation: Strengthening existing structures through modernization techniques, enhancing our capacity to withstand additional or unanticipated loads.

Piping Design and Piping Stress Analysis: Piping systems are lifelines of process industries, influencing operational efficiency, safety, and economic feasibility. Little P.Eng. offers comprehensive solutions in piping design, ensuring optimal layout and functionality, accommodating project constraints, and adhering to international standards.

Key aspects include:

Piping Layout and 3D Modeling: Developing detailed piping system layouts, incorporating equipment placement, structural design, and safety compliance, facilitated through advanced 3D modeling for accuracy and visualization.

Stress Analysis: Utilizing software tools like CAESAR II for precise stress analysis, determining strain and stress levels within piping systems under various scenarios, including temperature changes, fluid dynamics, pressure variations, and external forces, thereby verifying system reliability and identifying necessary supports and reinforcements.

Seismic Bracing Design: In regions prone to seismic activity, designing structures with adequate bracing is crucial to prevent collapse and minimize damage during earthquakes. Little P.Eng.'s seismic bracing designs are tailored to enhance the resilience of structures, factoring in regional seismic activity, local regulations, and material specifications.

Services involve:

Seismic Risk Evaluations: Assessing seismic risks associated with specific locations, analyzing historical data, and geological conditions.

Bracing System Design: Engineering customized bracing systems, including base isolators, cross-bracing, and shear walls, to dissipate seismic forces and minimize structural vulnerability.

Post-Earthquake Assessments: Inspecting and evaluating structures post-seismic activity for damage assessment and further reinforcement recommendations.

Storage Tank Design: Storage tanks, essential for industries requiring liquid or gas storage, entail specialized design parameters. Little P.Eng. focuses on custom solutions, factoring in the stored substance's characteristics, environmental considerations, and industry regulations.

The design process encompasses:

Material Selection and Design: Choosing appropriate materials resistant to the stored contents and environmental conditions, and designing tanks based on capacity requirements, pressure ratings, and structural regulations.

Foundation and Settlement Analysis: Ensuring ground stability and accommodating potential settlement or shifts without compromising tank integrity.

Safety and Emission Controls: Integrating features to prevent leaks, limit emissions, and safeguard against potential hazards, including explosions or toxic releases.

Material Handling Engineering Services: Efficient material handling is pivotal to operational success in manufacturing, warehousing, and distribution facilities. Little P.Eng. offers engineering solutions optimizing the movement, storage, control, and protection of materials throughout the process.

These services include:

System Design and Integration: Developing comprehensive systems combining conveyors, automated storage and retrieval systems, and transfer equipment, ensuring seamless, efficient operations.

Equipment Selection and Procurement: Advising on the appropriate equipment tailored to specific operational needs and assisting with acquisition from reputable manufacturers.

Safety and Ergonomics: Designing systems prioritizing operator safety and ergonomics, reducing workplace hazards and potential for injury.

Pressure Vessel Design: Pressure vessels, used for holding gases or liquids at high pressures, require meticulous design to prevent failure and catastrophic results. Little P.Eng.'s expertise lies in crafting pressure vessels compliant with industry standards like the ASME Boiler and Pressure Vessel Code.

Specific services involve:

Design and Analysis: Performing detailed calculations for wall thickness, stress distribution, and overall vessel geometry, ensuring safety under various pressure conditions.

Material Specification and Fabrication Oversight: Specifying suitable materials able to withstand extreme pressures and overseeing the fabrication process for quality assurance.

Inspection and Certification: Conducting thorough inspections and facilitating necessary certifications, confirming adherence to safety and operational standards.

Electrical Design: Electrical design services encompass the planning and execution of electrical systems, vital for the operational integrity of residential, commercial, and industrial projects. Little P.Eng.'s electrical engineers are adept at crafting systems that meet energy efficiency, safety, and performance standards.

Critical offerings include:

System Layout and Design: Creating comprehensive electrical systems, including power distribution, lighting, and emergency backup systems, tailored to specific project requirements.

Compliance and Safety: Ensuring designs meet electrical codes and safety standards, incorporating protective measures to prevent system failures, electrical shocks, or fire hazards.

Energy Efficiency Solutions: Proposing energy-efficient technologies and methodologies, contributing to sustainable and cost-effective operations.

CRN Registration Services: The Canadian Registration Number (CRN) is a number issued by each province or territory of Canada for the design of a boiler, pressure vessel, or fitting. The CRN identifies that the design has been accepted and registered for use in that province or territory. Little P.Eng. assists with the complex process of obtaining CRN certifications, essential for legal and safe operation within Canada.

This process includes:

Design Evaluations: Reviewing pressure equipment designs to ensure they comply with pertinent regulations and standards.

Documentation Preparation: Compiling and preparing extensive documentation required for CRN applications, including drawings, calculations, and material test reports.

Liaison with Authorities: Acting as an intermediary between clients and regulatory bodies, facilitating communication and expediting the registration process.

Conclusion: Little P.Eng. has emerged as a one-stop solution for diverse engineering needs, driven by a team of experts dedicated to upholding the highest standards of engineering excellence. Our approach is not just about meeting the minimum regulatory requirements; it is about designing safe, efficient, and sustainable systems that stand the test of time. By embracing advanced technologies, up-to-date methodologies, and a customer-centric approach, Little P.Eng. is setting new benchmarks in the engineering domain, contributing significantly to industrial innovation and infrastructural advancement.

Tags:

CAESAR II

energy efficiency

structural engineering

material handling

3D modeling

safety standards

regulatory compliance

earthquake resilience

stress analysis

CRN registration

advanced technologies

engineering consultancy

fabrication oversight

rehabilitation

piping design

pressure vessel

project commissioning

retrofitting

electrical design

automated storage

operational excellence

system reliability

ASME compliance

seismic bracing

foundation design

storage tank

tank integrity

design evaluation

infrastructural advancement

industrial innovation

Engineering Services

Structural Engineering Consultancy

Pipe Stress Analysis Services

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#CAESAR II#energy efficiency#structural engineering#material handling#3D modeling#safety standards#regulatory compliance#earthquake resilience#stress analysis#CRN registration#advanced technologies#engineering consultancy#fabrication oversight#rehabilitation#piping design#pressure vessel#project commissioning#retrofitting#electrical design#automated storage#operational excellence#system reliability#ASME compliance#seismic bracing#foundation design#storage tank#tank integrity#design evaluation#infrastructural advancement#industrial innovation

0 notes

Text

Construction Safety Toolbox Topics

Understanding construction safety toolbox topics is crucial in the construction industry. This article covers key themes and explains why they are essential for maintaining a safe working environment. These topics not only ensure compliance with safety standards but also protect workers from potential hazards.

Essential Construction Safety Toolbox Topics

Personal Protective Equipment…

View On WordPress

#construction industry#Construction Safety#electrical safety#Fall Protection#hazard identification#industry standards#occupational safety#PPE#proactive safety#safety awareness#Safety Compliance#Safety Culture#safety meetings#safety protocols#Safety Regulations#Safety Training#Toolbox Talks#worker engagement#worker protection#Workplace Safety

0 notes

Text

Do FR4 and FR5 both contain bromine? Are there non-brominated G10 materials available?

As is widely known, in the realm of laminated materials, G10 and G11 sheets are non-flame-retardant, whereas FR4 and FR5 sheets are flame-retardant, with “FR” standing for “Flame-Retardant.” FR-4 and FR-5 materials were originally developed to prevent or mitigate the potential fire hazard caused by overheating or electrical faults in circuit sheets, making them commonly used in household…

View On WordPress

#Circuit Board Materials#Corrosion-Free#Corrosion-Resistant Laminates#Eco-Friendly Materials#Electrical Circuit Materials#Electrical Insulation#Fire Safety#Flame-Retardant Alternatives#FR4 and FR5 Alternatives#G10 Laminates#G11 Laminates#Household Appliances#Laminated Circuit Sheets#Laminated Materials#Non-brominated Sheets#Non-brominatedLaminates#Non-Flame-Retardant Materials#Overheating Prevention#RoHS Compliant Sheets#RoHS Requirements Compliance

1 note

·

View note

Text

Fixed Wire Testing

Fixed Wire Electrical Inspection & Testing, or Electrical Installation Condition Report (EICR) as its more commonly known is an essential part of the on going maintenance of your Building or Property.

Global Compliance specializes in providing comprehensive Fixed Wire Testing and Electrical Inspection services. With our team of highly skilled and certified electricians, we ensure that your electrical systems are thoroughly inspected and tested for compliance with safety regulations and standards.

Our services cover a wide range of industries, including commercial, industrial, and residential sectors. For more information visit us today.

#pat testing#Landlords Electrical Inspection#global compliance#portable appliance testing#Lightning Protection System Periodic Inspection#Landlords Electrical Safety Inspections#EICR#Fire Extinguisher Maintenance#Emergency Light Testing#Electrical Testing & Inspection

0 notes

Video

youtube

Ensuring Safe and Reliable Products with Regulatory Compliance Testing Consulting

https://approve-it.net/global-regulatory-compliance-testing/ - Are you a manufacturer or designer of electronic products? If so, you know that Electromagnetic Compatibility (EMC), Radio Frequency (RF), Electrical Safety and Environmental compliance, are a crucial consideration in product development. If your product does not comply with Electromagnetic Compatibility (EMC), Radio Frequency (RF), Electrical Safety and Environmental regulations, you risk losing market share, damaging your reputation, and even facing legal consequences.At Approve-IT, we provide global regulatory compliance testing consulting services to ensure that your products meet the necessary standards and requirements. Our experienced and highly trained engineers will work with you to identify potential issues and recommend solutions to ensure that your products meet the necessary Electromagnetic Compatibility (EMC), Radio Frequency (RF), Electrical Safety and Environmental standards. We provide detailed reports and documentation to help you understand the testing process and results, as well as recommendations for any necessary adjustments to your products. With our Electromagnetic Compatibility (EMC), Radio Frequency (RF), Electrical Safety and Environmental consulting services, you can be confident that your products will meet the necessary regulatory requirements, ensuring your success in the marketplace. Contact us at 651-647-5930.

Contact Us:

Approve-IT Inc.

8011 34th Ave S. Suite 342,

Bloomington, MN - 55425

Phone: +1 651-647-5930

Fax: +1 651-644-6057

E-mail Id: [email protected]

0 notes

Text

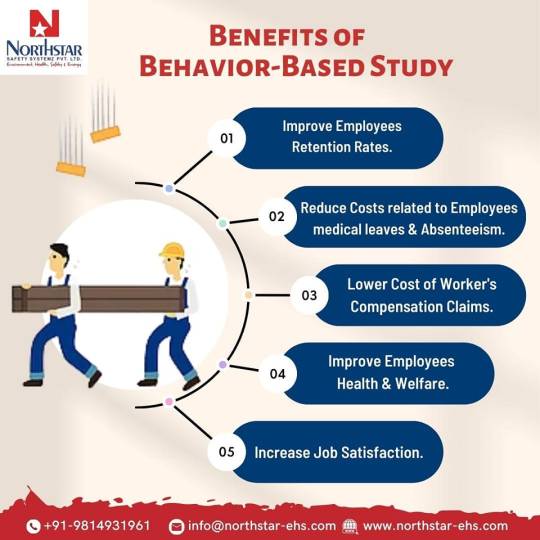

Behaviour Based Study is a technique of avoiding human error and enhancing workplace safety by observing and analyzing employees behaviour during their work time. It means that it also increase human and organisational performance.

There are many benefits of behaviour Based Study and safety. To get to know about these benefits, Check this post and for more details, Call at 9814931961

Follow us on Instagram & Facebook and subscribe YouTube

channel https://youtube.com/@northstarsafetysystemzpvt.9027

#process safety company in chandigarh#Safety Training company#Emvironment Health Safety Company in Chandigarh#Safety Audit#Safety Consultancy#Health and Safety#Safety and Energy and Risk Management#Best Electrical Safety Company#fire safety agency near me#safety training consultancy in Chandigarh#fire safety consultancy services#hazop process safety management#Fire Risk Assessment#environmental services company in chandigarh#Environmental Compliance#Arc Flash Study#EIA#Construction Safety company in chandigarh#Construction Safety#First Aid Training

0 notes

Text

(The Hague, February 26, 2024) – The Israeli government has failed to comply with at least one measure in the legally binding order from the International Court of Justice (ICJ) in South Africa’s genocide case, Human Rights Watch said today. Citing warnings about “catastrophic conditions” in Gaza, the court ordered Israel on January 26, 2024, to “take immediate and effective measures to enable the provision of urgently needed basic services and humanitarian aid,” and to report back on its compliance to the specific measures “within one month.”

One month later, however, Israel continues to obstruct the provision of basic services and the entry and distribution within Gaza of fuel and lifesaving aid, acts of collective punishment that amount to war crimes and include the use of starvation of civilians as a weapon of war. Fewer trucks have entered Gaza and fewer aid missions have been permitted to reach northern Gaza in the several weeks since the ruling than in the weeks preceding it, according to United Nations Office of the Coordination of Humanitarian Affairs (OCHA).

“The Israeli government is starving Gaza’s 2.3 million Palestinians, putting them in even more peril than before the World Court’s binding order,” said Omar Shakir, Israel and Palestine director at Human Rights Watch. “The Israeli government has simply ignored the court’s ruling, and in some ways even intensified its repression, including further blocking lifesaving aid.”

Other countries should use all forms of leverage, including sanctions and embargoes, to press the Israeli government to comply with the court’s binding orders in the genocide case, Human Rights Watch said.

Human Rights Watch found in December 2023 that Israeli authorities are using starvation as a weapon of war. Pursuant a policy set out by Israeli officials and carried out by Israeli forces, the Israeli authorities are deliberately blocking the delivery of water, food, and fuel, willfully impeding humanitarian assistance, apparently razing agricultural areas, and depriving the civilian population of objects indispensable to its survival.

Israeli authorities have kept its supply of electricity for Gaza shut off since the October 7 Hamas-led attacks. After initially cutting the entire supply of water that Israel provides to Gaza via three pipelines, Israel resumed piping on two of its three lines. However, due to the cuts and widespread destruction to water infrastructure amid unrelenting Israeli air and ground operations, only one of those lines remained operational at only 47 percent capacity as of February 20. Officials at the Gaza Coastal Municipalities Water Utility told Human Rights Watch on February 20 that Israeli authorities have obstructed efforts to repair the water infrastructure.

According to data published by OCHA and the UN Relief and Works Agency for Palestine Refugees in the Near East (UNRWA), the daily average number of trucks entering Gaza with food, aid, and medicine dropped by more than a third in the weeks following the ICJ ruling: 93 trucks between January 27 and February 21, 2024, compared to 147 trucks between January 1 and 26, and only 57 between February 9 and 21. A survey of impediments to the entry of aid faced by 24 humanitarian organizations operating in Gaza between January 26 and February 15 pointed to a lack of transparency around how aid trucks can enter Gaza, delays and denials at Israeli crossings and inspection points, and concerns about safety of trucks.

By comparison, an average of 500 trucks of food and goods entered Gaza each day before the escalation in hostilities in October, during which time 1.2 million people in Gaza were estimated to be facing acute food insecurity, and 80 percent of Gaza’s population were reliant on humanitarian aid amid Israel's more than 16-year-long unlawful closure.

High-ranking Israeli officials have articulated a policy to deprive civilians of food, water, and fuel, as Human Rights Watch has documented. The Israeli government spokesperson said more recently that there are “no limits” to aid entering Gaza, outside of security. Some Israeli officials blame the UN for distribution delays and accuse Hamas of diverting aid or Gaza police for failing to secure convoys.

The Israeli government cannot shift blame to evade responsibility, Human Rights Watch said. As the occupying power, Israel is obliged to provide for the welfare of the occupied population and ensure that the humanitarian needs of Gaza’s population are met. The Israeli human rights group Gisha challenged the Israeli government’s claims that it is not obstructing entry or distribution of aid and also found that it is not complying with the ICJ order.

Israeli authorities have also obstructed the aid that enters Gaza from reaching areas in the north. The survey of humanitarian organizations found that “almost no aid is distributed beyond Rafah,” Gaza’s southernmost governorate. On February 20, the World Food Programme paused deliveries of lifesaving food to the north, citing lack of safety and security. Israeli forces struck a food convoy on February 5, the UN said and CNN documented.

Between February 1 and 15, Israeli authorities only facilitated 2 of 21 planned missions to deliver fuel to the north of the Wadi Gaza area in central Gaza and none of the 16 planned fuel delivery or assessment missions to water and wastewater pumping stations in the north. Fewer than 20 percent of planned missions to deliver fuel and undertake assessments north of Wadi Gaza have been facilitated between January 1 and February 15, as compared with 86 percent of missions planned between October and December, according to OCHA.

“Israel’s ground forces are able to reach all parts of Gaza, so Israeli authorities clearly have the capacity to ensure that aid reaches all of Gaza,” Shakir said.

Since the ICJ order, Israeli authorities have also apparently destroyed the offices of at least two humanitarian organizations in Gaza and taken steps to undermine the work of UNRWA, the largest provider of humanitarian aid in Gaza, which more than half of other humanitarian organizations rely on to facilitate their operations. The head of UNWRA, Philippe Lazarini, said in a February 22 letter to the UN General Assembly president that the agency has reached a “breaking point” due to multiple government suspensions of funding and Israel’s campaign to shut the agency down.

Israel’s finance minister, Bezalel Smotrich, said on February 13 that he had blocked a US-funded flour shipment to Gaza, because it was going to UNRWA. Israel has alleged that at least 12 of the agency’s 30,000 employees participated in the October 7 attacks, which the UN is investigating.

In late December, the Integrated Food Security Phase Classification (IPC), a multi-partner initiative that regularly publishes information on the scale and severity of food insecurity and malnutrition globally, concluded that over 90 percent of Gaza’s population is at crisis level of acute food insecurity or worse. The IPC said that virtually all Palestinians in Gaza are skipping meals every day while many adults go hungry so children can eat, and that the population faced famine if current conditions persisted. “This is the highest share of people facing high levels of acute food insecurity that the IPC initiative has ever classified for any given area or country,” the group said.

On February 19, The United Nations Children’s Fund (UNICEF) found that 90 percent of children under age 2 and 95 percent of pregnant and breastfeeding women face “severe food poverty.” On February 22, Save the Children said families in Gaza “are forced to forage for scraps of food left by rats and eating leaves out of desperation to survive,” noting that “all 1.1 million children in Gaza [are] facing starvation.”

In response to a request by South Africa for additional provisional measures following Israeli Prime Minister Benjamin Netanyahu’s order for Israeli authorities to explore a possible plan to evacuate Rafah ahead of a ground incursion, the ICJ said that the “perilous situation demands immediate and effective implementation of the provisional measures” throughout Gaza – but not new measures – and highlighted Israel’s duty to ensure “the safety and security of the Palestinians in the Gaza Strip.”

Beyond enabling the provision of basic services and aid, the measures in the ICJ’s binding order require Israel to prevent genocide against Palestinians in Gaza and prevent and punish incitement to commit genocide. The ICJ issued these measures “to protect the rights claimed by South Africa that the Court has found to be plausible,” including “the right of the Palestinians in Gaza to be protected from acts of genocide.” Although South Africa asked the court in its oral arguments during January hearings on the provisional measures to make any report it ordered public, the court did not indicate that it has done so.

Between January 26 and February 23, more than 3,400 Palestinians were killed in Gaza, according to figures from Gaza’s Health Ministry compiled by OCHA.

South Africa’s case against Israel for genocide is distinct from the proceedings on the legal consequences of Israel’s 57-year-occupation, which began at the ICJ on February 19.

“Israel’s blatant disregard for the World Court’s order poses a direct challenge to the rules-based international order,” Shakir said. “Failure to ensure Israel’s compliance puts the lives of millions of Palestinians at risk and threatens to undermine the institutions charged with ensuring respect for international law and the system that ensures civilian protection worldwide.”

#palestine#free palestine#save palestine#gaza#free gaza#save gaza#world news#current events#israel palestine conflict#israeli apartheid#israel#middle east#war on gaza#gaza strip#gaza genocide#gazaunderattack#palestine genocide#genocide#stop the genocide#humanitarian crisis#human rights

40 notes

·

View notes

Text

Understanding RCD Load Banks: A Key Tool for Reliable Power Testing

In the world of power systems, reliability is non-negotiable. Whether you’re managing a data center, a hospital, or an industrial facility, ensuring that your backup power sources—like generators and Uninterruptible Power Supplies (UPS)—are always ready to perform is crucial. This is where RCD load banks come into play, offering a sophisticated solution for testing and maintaining these critical systems.

What Is an RCD Load Bank?

An RCD load bank is a specialized device used to simulate real-world electrical loads on power systems. Unlike standard resistive load banks that only provide a simple resistive load, RCD load banks combine Resistive (R), Capacitive (C), and Inductive (D) elements. This combination allows them to more accurately replicate the operational conditions that a power system might face in actual use.

For instance, when testing a generator or UPS, an RCD load bank can simulate the varying types of loads that these systems might encounter, such as those that combine heating elements (resistive), motors (inductive), and electronics (capacitive). By doing so, it provides a more comprehensive and realistic assessment of the power system's performance under different conditions.

Why Are RCD Load Banks Important?

The primary reason to use an RCD load bank is to ensure the reliability and efficiency of your power systems. By simulating real-world conditions, RCD load banks help identify potential weaknesses or failures in your equipment before they happen during an actual power outage. This proactive approach to maintenance not only enhances the reliability of your backup power but also extends the lifespan of your equipment.

Moreover, RCD load banks are essential for compliance with industry standards and regulations. Regular load testing with an RCD load bank ensures that your power systems meet the necessary requirements, providing peace of mind that your facility is prepared for any situation.

Choose EMAX Load Bank for Your Testing Needs

At EMAX Load Bank, we specialize in providing high-quality RCD load banks that deliver precise, reliable testing. Our products are designed to meet the rigorous demands of various industries, ensuring that your power systems are always up to the task. Whether you need to test a new installation or perform routine maintenance, our RCD load banks offer the accuracy and dependability you need to keep your operations running smoothly.

Invest in the reliability of your power systems with an RCD load bank from EMAX Load Bank, and rest easy knowing that your critical infrastructure is well-prepared for any challenge.

3 notes

·

View notes

Note

‘ you’re not going anywhere today. ’

You're Not Going Anywhere Today

The people have been asking for more Handler Smith/Jaime in training, so the people are gonna get it. Yeehaw for my first real writing post in like... months.

Takes place around 2 months into Jaime's initial training period.

WARNINGS: BBU/BBU adjacent, electric shock whump, restraints, burning, food deprivation, starvation, stress positions

The shock clip against Jaime’s throat is an impossible weight to ignore, but not nearly as insistent as the hunger thrumming through his body. While the instructor goes over the perfect blend of spices at the front of the room, Jaime tries to narrow his focus to the workspace in front of him. He doesn’t think about the two missed meals in a row, doesn’t let himself dwell on the staticky prickle of a handler’s presence at his back or the constriction around his wrists.

The restraints—like the shock clip—are a mandatory safety measure in all kitchen classes; a leather band around each wrist, secured to each designated work station. There’s just enough slack in the chain to allow him the range of motion to reach all of the utensils he needs, but not enough for him to bury one of the steak knives in the nearest handler.

Not that Jaime would do something like that.

Cooking lessons are one of the few bright spots of his days. They are a required part of domestic training, but also a privilege earned by a consistent show of compliance. It only took Jaime a month to gain access. Some part of him wants to feel ashamed for breaking so quickly, but the larger part of him can’t find fault in clinging to what little reprieve he can award himself in this place.

The culinary instructor is a young man who can’t be more than a handful of years older than Jaime, with curly hair and black-rim glasses and a kind smile. On Jaime’s first week in class, he told him he’s a natural in the kitchen, and he’s had something positive to say about his dishes in every class since. The praise warms him more than he ever wants to admit, and there are mornings when Jaime opens his eyes to the faintest flicker of excitement knowing that he will get to cook that day.

Sometimes the lessons can be hard, though. His training session from last night had run into his dinner block and Jaime went to bed hungry. This morning, one of the new trainees caused a disruption during the morning showers and the entire cell block was forced to skip breakfast. On days like this, when the smell of freshly diced pancetta and onions wafts up from the pan, it becomes difficult to push past the hunger.

He tries, though. They’re learning a new dish today and Jaime wants to do well. He pushes the ingredients around in the oil, making sure to turn the meat often enough that the surfaces crisp evenly. As he works, he tries to picture what life will be like when he gets his first home assignment. He wonders if his Keeper will want him to cook for them everyday, and thinks that might be okay. That he might actually be able to carve out some semblance of contentment in a life like that.

He tries, as often as he can, not to think about what else a contract will entail.

Desperate for a distraction, Jaime begins to paint a mental picture of his future Keeper’s kitchen. It will probably be big, he thinks—bigger than any of the foster homes he had seen growing up—with plenty of room to move around freely, and no cuffs on his wrist keeping him chained to a single counter. He imagines a large window over the kitchen sink, where Jaime can see the sky and the rain and the grass whenever he wants.

“Smells like something’s burning.” The low croon of a handler—suddenly standing much closer than he had been moments ago—sends a chill down his back.

In his alarm, Jaime barely feels the fingertip that traces the ridges of his spine. Instead, the familiar pool of despair rises to meet him as he looks down at the shriveled crisps of onion in his pan.

“You might want to take that off the burner now,” the handler murmurs, and the command prods Jaime into action.

“Yes, sir,” he whispers, quickly flipping off the heat switch and reaching for the hand towel each trainee kept tossed over their shoulders, but—

The moment his fingers brush the cloth, the towel is ripped away.

“Better hurry,” the handler says. “It’s starting to smoke.”

Jaime stares down at the exposed handle of the cast iron skillet—our trainees only work with the highest standard of cookware during their lessons—and realizes the cruel trick that’s been orchestrated against him.

He doesn’t bother begging. A few weeks ago, he might have tried it. He knows better now.

All he has time for is a deep inhale and the fleeting glance he tosses at his instructor, busy helping another trainee season his dish at a station across the room. If the instructor notices anything off about what’s happening at Jaime’s station, he doesn’t step in. He knows he is on his own, and there’s only one option ahead of him.

Jaime reaches forward and wraps his fingers around the bare handle. It takes one, two seconds for the pain to register, and when it does, it shoots through his palm and into his limb like lava has replaced his blood. As fast as he can without spilling, Jaime shoves the skillet to the back burner, but a heavy hand clamps down over his before he can pull away.

One hand keeps Jaime’s fingers pressed into the burning iron while the other twists around the chain keeping his other wrist confined. The handler presses into his space from behind, and Jaime is trapped. Again, he seeks out the instructor, but instead he lands on another trainee who looks up at just the wrong time. The wide, sallow eyes stare back at him, dart to the handler, to their overlapping hands on the skillet, then fall back to his own station.

Jaime’s jaw aches from the effort it takes to conceal it, but a small, strangled noise makes its way out anyway.

“Quiet,” the handler scolds, squeezing his hand in warning. Jaime seals his eyes shut and feels tears gathering at the corners.

He won’t beg. He won’t beg. He won’t—

Without warning, the grip on his hand releases. Jaime jerks back from the pain so fast he knocks into the handler’s chest, and, like a nightmare come to life, he watches as the pan knocks sideways off the backburner and clatters to the ground.

Every eye in the room is on him now, he can feel it in the sudden silence, and all he can do for a few endless seconds is stare down at the oil and food scattered around his shoes.

Then the shock comes.

His head jerks back, shoulder blades reaching for each other as every muscle in his body contracts. Pain is a bright, white light that momentarily wipes every other thought from his mind, even briefly tearing the attention from his burning palm.

When he recovers, the instructor is at his side. “Are you alright?” he asks. “What happened here?” His eyes show nothing but genuine concern, but Jaime feels a flash of rage toward him.

He stares at him, struggling to catch his breath. Where were you before? he wants to scream. You’re no fucking better than the rest of them.

“I’m sorry,” is what comes out instead.

“Just a tantrum.” The nameless handler steps forward. “Tried to take me out with a skillet and forgot to grab the towel first.” His hand wraps around Jaime’s wrist and twists so his red-hot palm is facing up for him to see.

The instructor doesn’t hide his wince. “Oh. Do you need—?”

“He’s coming with me to the clinic.” The handler is already unlatching his cuffs from the countertop. Jaime nearly slips in the olive oil, caught only by a rough grip around his bicep. “I’ll leave it to his primary to handle the consequences.”

****

“Time’s up.”

The sound of the beeping on Handler Smith’s watch sings through Jaime’s entire body, blanketing him in relief. Heavy footsteps trail up behind him, and Jaime tenses, but the latch on his cuffs releases and he crumbles to the ground after hours of being strung up in the same stress position.

Jaime allows himself only a few seconds to press his clammy forehead to the tile, letting the coolness of the surface pull the heat from his skin. “Thank you, sir,” he croaks out. The words burn even more than his aching muscles, but he knows he can only worsen the situation by failing to mind his manners.

“Up.” The toe of a boot nudges his hand. Jaime curls his fingers on instinct, trying to protect the burn.

The facility doctor had been cold and efficient in applying an antibacterial cream and bandaging the wound, but he had not been allowed painkillers. His time in the clinic had eclipsed his designated lunch block, so he had to endure his punishment on the tail of three skipped meals in a row. The immediate pain of the process had served as a distraction, but now that it was over, hunger clawed at his insides.

“Two,” Handler Smith says, and Jaime’s body slides on instinct into a knelt position with his hands clasped behind him, his chin on his chest. “You’re lucky I have to supervise dinner block or I might just extend this session.”

Hidden from his gaze, Jaime allows his eyes to close in relief. The flavorless, rubbery meat from the cafeteria had never sounded so appealing. Never wanting to keep Handler Smith waiting, Jaime scrambles onto his feet, ready to fall in line behind him, but an amused snort stops him short.

“Someone’s feeling bold today. Did I say you could move?” Handler Smith asks.

“No, sir.”

“No,” he agrees. “And I’m not going to. You’re not going anywhere today.”

Coldness spreads over him. “Sir?” he asks. Keep your head down, keep your eyes low. Squeeze your hands tighter to hide the shaking.

“You think you’re getting dinner after the stunt you pulled today?”

Don’t cry. It never helps to cry.

“I’m sorry, Handler Smith.”

Jaime doesn’t look up at the sound of the beep-and-whir of the opening cell door.

“Embarrass me like this again, and you will be.”

He doesn’t move a muscle until the door shuts behind him. Even then, the only movement he allows himself is the steady, compulsive brush of his thumb along the edge of the bandage. He can’t stop the tears this time.

Maybe tomorrow, he thinks. They can’t starve me forever.

****

TAG LIST: @whumpervescence @shiningstarofwinter @distinctlywhumpthing @whumptywhumpdump @nicolepascaline @anotherbluntpencil @hold-him-down @crystalquartzwhump @maracujatangerine @batfacedliar-yetagain @thecyrulik @finder-of-rings @melancholy-in-the-morning @insaneinthepaingame @skyhawkwolf @whump-for-all-and-all-for-whump @mylifeisonthebookshelf @dont-touch-my-soup @whump-world @inpainandsuffering @cicatrix-energy @quietly-by-myself @whumpsday @extemporary-whump @the-whumpers-grimm @thebirdsofgay @firewheeesky

94 notes

·

View notes

Text

last thing i have to say on the subject but so many people are making jokes about how titantic is what created SOLAS (safety of life at sea) regulations and the sub was in violation. but every single maritime company gets away with finding loopholes in SOLAS regulations look at the marine electric or estonia or conception or galaxy or edmund fitzgerald or the el faro! the el faro that still had open lifeboats and sailed into a hurricane at the companies request because they didn’t want to get off schedule and 33 people died. including some recent grads that my professors taught everyone says that maritime regulations are written in blood and we learned it day one of class and it’s just not funny to me. and yet i still see that joke post about the el faro and the grandcamp on here and i guess u guys can justify it this time with like “haha stupid rich people 😂” but my friends have gone out on ships with shitty safety regulations our training ship was a death trap and we all knew it. if something happened it would’ve been really bad but i’m sure everyone on here would’ve had a laugh cuz look that ship was so out of regulation haha 😂 what we’re they thinking 😝 so like haha yeah “it’s their fault for getting on a ship that’s not in compliance!” it’s funny now but it’s not funny when the rest of us have to work in an industry where the companies don’t care about human life and will get you killed and it’s dangerous and scary and to see everyone on here laugh about it when i know you guys don’t care about maritime safety normally is kind of sickening. okay!!!!

#oceangate#<- for blacklist#look man. i’m not trying to preach morality ofc if you’re making light of the situaiton.#but i have to see my friends go out in this industry and it’s scary because this stuff keeps happening. and it’s funny now.#but one day it won’t be

24 notes

·

View notes

Text

Residential & Industrial Electrical Contractor in Red Deer — Bryant’s Electrical Ltd.

Electrical work requires precision, expertise, and a deep understanding of safety protocols, whether it’s for a residential property or an industrial facility. In Red Deer, one name stands out for providing top-tier electrical solutions across residential and industrial sectors: Bryant’s Electrical Ltd. As a leading residential and industrial electrical contractor, Bryant’s Electrical Ltd. brings experience, professionalism, and high-quality workmanship to every project.

Comprehensive Residential Electrical Services

Your home’s electrical system is the heart of its functionality and safety. Whether you are building a new home, upgrading an older system, or making repairs, it’s essential to work with a trusted electrical contractor. Bryant’s Electrical Ltd. offers a range of residential electrical services designed to meet every homeowner’s needs.

1. New Construction Wiring

Building a new home requires detailed planning and professional electrical installations to ensure safety and long-term functionality. Bryant’s Electrical Ltd. works closely with contractors and homeowners to design and implement customized electrical systems that meet all modern standards and codes.

2. Electrical Panel Upgrades

As homes add more electrical devices, from smart home systems to modern appliances, older electrical panels can struggle to handle the increased load. Bryant’s Electrical Ltd. specializes in upgrading electrical panels, ensuring your home’s system can safely and efficiently meet its electrical needs.

3. Lighting Solutions

From interior lighting design to outdoor landscape lighting, Bryant’s Electrical Ltd. offers expert lighting installations. Whether you’re looking to create ambiance in your living space or improve your home’s security, they have the expertise to install energy-efficient lighting solutions.

4. Smart Home Installations

Smart home technology is more than a luxury; it’s an investment in convenience, energy efficiency, and security. Bryant’s Electrical Ltd. can help homeowners install and configure systems such as automated lighting, climate control, and security systems.

5. Electrical Safety Inspections

If you’re concerned about the safety of your home’s electrical system, Bryant’s Electrical Ltd. offers thorough inspections. They’ll check for faulty wiring, outdated panels, and other issues that could pose safety risks, ensuring peace of mind for homeowners.

Specialized Industrial Electrical Services

In the industrial sector, having a dependable electrical system is critical to the smooth operation of facilities. Bryant’s Electrical Ltd. is equipped to handle the unique challenges that come with industrial electrical work, offering services that ensure safety, compliance, and productivity for Red Deer’s industrial businesses.

1. Industrial Wiring and Electrical Installation

From manufacturing plants to warehouses, industrial facilities require complex and robust electrical systems. Bryant’s Electrical Ltd. specializes in designing and installing systems that meet the high demands of industrial operations. Their experienced electricians ensure that all installations are carried out to meet safety codes and provide maximum efficiency.

2. Machinery and Equipment Wiring

Industrial operations rely on heavy machinery and equipment, all of which need proper wiring and connections to function safely. Bryant’s Electrical Ltd. provides expert wiring services for machinery, ensuring that everything operates smoothly and efficiently.

3. Power Distribution Systems

Industrial facilities often require large-scale power distribution systems to meet their operational needs. Bryant’s Electrical Ltd. designs and installs power distribution systems that optimize energy usage while ensuring that all equipment and machinery receive a consistent and reliable power supply.

4. Maintenance and Repairs

Ongoing maintenance is essential in industrial settings to prevent electrical failures that could result in costly downtime. Bryant’s Electrical Ltd. offers routine maintenance services that ensure all electrical systems and equipment are in optimal working condition. They also provide emergency repair services, responding quickly to any electrical issues that may arise.

5. Energy-Efficient Upgrades

Industrial operations consume a significant amount of energy. Bryant’s Electrical Ltd. helps businesses reduce their energy consumption and lower operational costs by offering energy-efficient upgrades. From lighting retrofits to energy audits, they provide tailored solutions that enhance efficiency without compromising productivity.

Why Choose Bryant’s Electrical Ltd.?

As a trusted residential and industrial electrical contractor in Red Deer, Bryant’s Electrical Ltd. offers several advantages:

Licensed and Experienced Electricians: All their electricians are fully licensed, trained, and experienced in both residential and industrial electrical work. This ensures the highest standards of safety and quality on every project.

Safety-First Approach: Safety is paramount in all electrical work. Whether it’s a residential installation or a complex industrial setup, Bryant’s Electrical Ltd. follows strict safety protocols to protect clients and their property.

Timely and Reliable Service: Electrical issues can disrupt both homes and businesses. Bryant’s Electrical Ltd. prioritizes fast, efficient service, minimizing any inconvenience caused by electrical work or malfunctions.

Customized Solutions: Every project is unique, and Bryant’s Electrical Ltd. tailors their services to meet the specific needs of each client. Whether it’s designing a custom home electrical system or handling the electrical requirements of a large industrial facility, they provide personalized solutions.

Eco-Friendly Practices: Bryant’s Electrical Ltd. promotes energy-efficient solutions in both residential and industrial settings, helping clients reduce their environmental impact and save on energy costs.

Emergency Electrical Services

Electrical emergencies can occur at any time, whether in a home or an industrial facility. Bryant’s Electrical Ltd. offers 24/7 emergency services to ensure that clients receive prompt assistance when they need it most. Their team is equipped to handle urgent electrical issues, from power outages and wiring faults to equipment malfunctions, ensuring minimal disruption to your home or business.

Commitment to Customer Satisfaction

At Bryant’s Electrical Ltd., customer satisfaction is a top priority. Their team takes pride in delivering high-quality work, excellent customer service, and reliable results. Whether working on a residential renovation or a large-scale industrial project, they maintain open communication with clients, keeping them informed at every step of the process.

Conclusion

Whether you’re a homeowner looking for reliable electrical services or a business in need of specialized industrial solutions, Bryant’s Electrical Ltd. is your go-to industrial & residential electrical contractor in Red Deer. With a strong commitment to safety, quality, and customer satisfaction, they offer comprehensive electrical services that meet the unique needs of each client. From new home wiring to industrial equipment installations, Bryant’s Electrical Ltd. ensures that your electrical systems operate safely and efficiently.

For dependable residential and industrial electrical solutions in Red Deer, contact Bryant’s Electrical Ltd. today and experience the difference of working with a trusted, local electrical contractor.

#commercial electrician#red deer electrician#residential electrical services in red deer#electrician

3 notes

·

View notes

Text

Facility Management Companies in India

A Comprehensive Guide to Facility Management Companies in India: Elevating Operational Efficiency

Facility management is a critical component of successful business operations, ensuring that facilities run smoothly, efficiently, and safely. In India, a diverse and rapidly growing economy with numerous industries requires top-notch facility management services. From maintaining infrastructure to optimizing operational performance, facility management companies play a pivotal role. This blog explores some of the leading facility management companies in India , highlighting their services and what sets them apart.

Why Facility Management Matters

Facility management encompasses a wide range of services designed to ensure that buildings and infrastructures are safe, functional, and efficiently operated. Key areas include:

Maintenance: Regular upkeep of facilities to prevent breakdowns and ensure safety.

Cleaning: Maintaining cleanliness and hygiene in commercial and residential spaces.

Security: Protecting assets and ensuring safety through surveillance and access control.

Technical Services: Managing HVAC systems, electrical systems, and other technical infrastructure.

Energy Management: Implementing strategies to reduce energy consumption and costs.

Core Functions of Facility Management

Maintenance Management

Preventive Maintenance: Regular inspections and servicing to prevent equipment failures and ensure optimal performance.

Reactive Maintenance: Addressing repairs and issues as they arise to minimize downtime and disruptions.

2. Cleaning and Hygiene

Ensuring cleanliness and hygiene through regular cleaning schedules, waste management, and sanitation practices. This is vital for maintaining a healthy and productive environment.

3. Security and Safety

Implementing security measures such as surveillance, access control, and emergency preparedness. Ensuring the safety of occupants and protecting assets are key responsibilities.

4. Technical Services

Managing HVAC systems, electrical systems, plumbing, and other technical infrastructure to ensure they are functioning efficiently and reliably.

5. Space Management

Optimizing the use of space to improve functionality and accommodate changing needs. This includes layout planning, space allocation, and managing relocations.

6. Energy Management

Implementing strategies to reduce energy consumption and costs, such as energy-efficient systems, sustainable practices, and monitoring energy usage.

7. Project Management

Overseeing facility-related projects, such as renovations, upgrades, and new constructions, ensuring they are completed on time, within budget, and to the required standards.

8. Vendor Management

Coordinating with external service providers for specialized services such as landscaping, security, and janitorial services. Ensuring quality and compliance with service agreements.

Benefits of Effective Facility Management

Enhanced Operational Efficiency

Streamlined processes and well-maintained facilities lead to smoother operations and reduced downtime, allowing businesses to focus on their core activities.

2. Cost Savings

Proactive maintenance and energy management can result in significant cost savings by preventing costly repairs, reducing energy consumption, and extending the lifespan of assets.

3. Improved Safety and Compliance

Ensuring that safety protocols are followed and that facilities comply with regulations helps to create a safe environment for employees and visitors, reducing the risk of accidents and legal issues.

4. Increased Productivity

A well-maintained and comfortable environment contributes to employee satisfaction and productivity. Proper space management and ergonomic designs can enhance workplace efficiency.

5. Sustainability and Environmental Impact

Implementing sustainable practices and energy-efficient technologies contributes to environmental conservation and helps organizations meet their sustainability goals.

6. Enhanced Reputation

A well-managed facility reflects positively on the organization, enhancing its reputation among clients, partners, and employees.

Trends in Facility Management

Technology Integration

The use of smart building technologies, IoT devices, and advanced software solutions for real-time monitoring and management is on the rise.

2. Sustainability Focus

There is a growing emphasis on green building practices, energy efficiency, and reducing the environmental footprint of facilities.

3. Data-Driven Decision Making

Leveraging data analytics to optimize facility operations, track performance metrics, and make informed decisions is becoming increasingly important.

4. Employee Well-Being

There is a greater focus on creating environments that support employee well-being, including improved air quality, lighting, and ergonomic design.

5. Remote Management

The ability to manage facilities remotely through digital platforms and automation is becoming more prevalent, providing greater flexibility and efficiency.

Conclusion

Facility management is a multifaceted discipline that plays a vital role in the smooth operation of buildings and infrastructure. By encompassing a range of services from maintenance and cleaning to security and space management, facility management ensures that environments are functional, safe, and efficient. Embracing the latest trends and technologies can further enhance the effectiveness of facility management, leading to improved operational efficiency, cost savings, and overall success for organizations.

Whether you are managing a small office or a large industrial complex, understanding and implementing effective facility management practices can make a significant difference in achieving your operational goals.

2 notes

·

View notes

Text

Barcode

BBU Community Days: Day 8

@bbu-on-the-side

250 (aka Cass) gets his barcode.

Taglist: @littlespacecastle @whumpymirages @flowersarefreetherapy @painful-pooch

Finding Safety masterlist

CWs: BBU, pet whump, collared, non-con touch (non-sexual), discussion of future and past rape, amnesia, shock collar, electric shocks, humiliation, non-con nudity, crude language/sexual imagery and drawing on someone in Sharpie, sexual implications in body language, sexual harrassment, strapped down, gagged, muzzled, non-con photos, handcuffed, manhandling (brief, plus mentions of), non-con tattooing, dehumanisation, blindfold, sensory deprivation

"20 quid says he'll be a Guard Dog."

The other handler snorts. "Only 20? Not very certain, are you?"

"Well, what do you think he'll be?"

346250 sets his jaw best he can against the sharp pain as the needles prick against his skin, each one sending a pinpoint of ink into his arm. He doesn't know what they're drawing, his head's immovable like this, but he can guess. They tattoo it onto every pet, after all. He clenches his fist against the pain and receives a sharp slap on the knuckles for his troubles.

He can't see the handlers from this position, but he can swear he hears the shrug. "Could be a Guard Dog. The ladies would love those muscles though. And that scar... the heroic look's big this season. So, could be a Romantic."

346250 flinches as much as he can between the tight leather restraints as someone squeezes his arm, and there's two laughs. "Oh, yeah, I see what you mean about the muscles. Let me know if he gets assigned to your department. I want a turn."

"You always want a turn," says the handler, sounding exasperated.

"Boys, boys," says a woman, sounding amused. 'No touching the trainee until I've finished his barcode. You'll have plenty of time later."

"Sorry, boss."

"What do you mean, 'plenty of time later'? Do you know something we don't?"

"Just that Poppy says he's exceptionally defiant. He was the one who led 643 in the escape attempt, and he's resistant. So there'll be plenty of manhandling to be done."

346250 flinches again, his whole body this time. He was led in here by a choking hand on his collar and strapped in, ankles and legs and wrists and forearms, and torso and forehead too. Everywhere, in fact. The collar's too tight and he can't breathe properly, it's all he's wearing except for a black silicon gag that fits between his lips, pulling at his teeth, pinching the skin. And a blindfold, rendering everything completely black.

Clearly they want him to hear, though. At least for now.

A handler mentioned a fitted one. He doesn't want a fitted one. He wants to breathe.

He feels almost relaxed, though, like this. Like he's floating. As soon as the handlers stop talking he forgets what he's worrying about. He's sure there's something, it nags and worms at the back of his mind, but he doesn't remember what.

They said he's safe. He knows they're lying, they snigger behind their hands when they think he's not looking. He chose this. He didn't, he can see people in his mind that make him sad He can trust the handlers. He has to, he has to, he has to, or the electricity will come on again.

"Make the most of his compliance while it lasts, boys. I know you prefer the defiant ones, but best get him settled before he fights back."

"Right you are. I'm just about done. Anything you want to do to him?"

"Yeah, actually. Pass me that Sharpie."

346250 hears a pen uncapping and a strong smell of alcohol hits his nostrils. His chest tickles as someone draws on it.

"Mate, that might be a classic, but it won't win this week's competition. You know what Finn's prizes are like, you don't want to miss out."

"Yeah but, 643's untrained. No fun."

"I thought you boys liked the defiant ones. She's good enough without training, anyway." There's a stunned silence, and 346250's arm throbs. "What? You don't think no-one fucked her during her initial training? She was almost made into a Romantic then, after all. If it wasn't for 065 and the workers then messing it all up."

"See, this is why I'm adding you to the group chat. Like minds and all that." 346250 feels his face jostled as something metal is strapped over his mouth, and something is placed over his head that muffles all sounds. Noise-cancelling headphones, perhaps?

Someone undoes 346250's straps, leaving everything else in place. Then he's pulled to his feet and held tightly by his collar as the blindfold is removed.

There's a mirror in front of him, and he barely recognises the person in it. He doesn't remember himself, and yet it's possible not to recognise himself. He looks scared, smeared in blood, embarrassingly naked but one of the handlers cuffs his hands behind him, he can't cover himself. He sees his face go bright red. One of the handlers guffaws in the mirror, and the other makes a crude motion with his hands. The tattooist rolls her eyes.

346250 has scars he didn't know he had (and how does he know what scars he had?), injuries that he knows with a strange certainty weren't there before. The collar's black plastic, a small box attached to the front, metal prongs cold against his skin. It looks deceptively unthreatening. In his mouth is a gag, and over it, covering the lower half of his face, is a wire and leather muzzle. Like an animal. He hasn't been defiant for as long as he can remember, since they took him off that IV line. It must be a warning against misbehaviour. A threat. For fun.

He swallows a sob as he looks at his chest, a part of himself he'd been avoiding. He knew it was crude. Of course it was, they drew it in Sharpie and laughed. But somehow that's different to actually seeing it.

He has a penis drawn in black on his chest, semen spurting out of it. The words he can't make out, the handwriting's backwards and terrible and he has a splitting headache, but he assumes they're equally as crude.

It'll wash off eventually. It will. But that's the only comfort.

And on his arm... on his left arm is a tattoo. The tattoo. Black and bold against the tan of his skin, crisp, clean lines portray a barcode with a set of numbers below. 346250, he presumes. Marking him out forever as a pet.

It's okay though, he's safe here. He's not. It was his choice. It wasn't. It won't hurt too much. He doesn't know what they'll do to him.

He can survive. Whatever happens, he can.

Can he?

A handler steps in front of him, mobile phone in hand. He winks at 346250, pointing at a toy monkey on his head for the new trainee to look at. A flash goes off.

They're taking photos. Oh, god.

In the mirror, 346250 sees the other handler pull out the small black remote and turn the dial. Then he presses the button.

The trainee falls to his knees, attempting to claw at his neck as his vision goes white, gag-muffled screams reverberating in his ears, he can't hear them on the outside so they're all inside instead, shocks shaking his jaw and his limbs, sending them jerking and thrashing. All he can feel is pain, all he can think about is the pain of it, the sensation, he can barely breathe.

When he comes to, limbs twitching and jerking against the cold tile floor, he realises they're still taking photos.

#bbucommunity#day8#bbu#box boy universe#box boy#wru#whump#whump writing#sanctuary pigeonwhumps#cass oc#poor bb#i continue to fill prompts less than id like to#whumper and whumpee#multiple whumpers#pet whump#mind the tags

24 notes

·

View notes

Text

Avoid Costly Delays: How Scanning Utility Locating Saves You Time and Money

In today's fast-paced construction and infrastructure development landscape, time is money. Any unforeseen delays can significantly inflate costs and disrupt project timelines. One of the most effective ways to mitigate these risks is by employing advanced scanning utility locating techniques. Safe Scanners, a leader in this field, offers state-of-the-art GPR Services, GPR Scanning, Ground Penetrating Radar, and Concrete Scanning Services. These services ensure that projects proceed smoothly, without the costly interruptions caused by unforeseen utility line strikes or structural issues.

The Importance of Utility Locating Services

Before any excavation, drilling, or construction work begins, it's crucial to know what lies beneath the surface. Utility locating services help identify the presence of underground utilities such as water pipes, gas lines, electrical cables, and telecommunications infrastructure. Unintended strikes on these utilities can cause severe delays, legal liabilities, safety hazards, and increased costs.

Safe Scanners' Utility Locating Services use advanced technology to provide accurate and reliable subsurface information. This proactive approach not only prevents damage but also enhances project planning and efficiency.

How Ground Penetrating Radar (GPR) Works

Ground Penetrating Radar (GPR) is a non-destructive method that uses radar pulses to image the subsurface. GPR Scanning involves transmitting high-frequency radio waves into the ground. When these waves encounter a buried object or a boundary between different materials, they reflect back to the surface, where they are detected by a receiver. The time it takes for the radar waves to return is used to create a detailed image of the subsurface.

GPR Services provided by Safe Scanners are invaluable in detecting utilities, voids, rebar, and other structural components. This technology is highly effective in a variety of materials, including soil, rock, concrete, and asphalt, making it versatile for different construction needs.

Benefits of GPR Scanning and Concrete Scanning Services

Accuracy and Precision: GPR Scanning delivers highly accurate results, allowing construction teams to pinpoint the exact location and depth of utilities and other subsurface features. This precision reduces the risk of damaging existing infrastructure and ensures compliance with safety regulations.

Cost Savings: By identifying and avoiding utilities and other subsurface hazards, Safe Scanners' GPR Services prevent costly repairs, project delays, and potential legal issues. The upfront investment in scanning services can save significant amounts of money in the long run.

Safety Enhancement: Excavating without proper knowledge of underground utilities can lead to dangerous situations, including gas leaks, electrical hazards, and water main breaks. Using Ground Penetrating Radar and Concrete Scanning Services minimizes these risks, protecting workers and the public.

Non-Destructive Testing: GPR is a non-invasive method that does not disturb the surveyed area. This means that the site remains intact, avoiding the mess and potential damage associated with exploratory digging.

Versatility: GPR Scanning can be used in various environments and for multiple applications, from large-scale construction projects to smaller residential renovations. Safe Scanners' expertise ensures that each project benefits from tailored solutions.

Case Studies: Real-World Applications of GPR

Case Study 1: Urban Infrastructure Development

In a major city development project, Safe Scanners was enlisted to perform GPR Scanning before the installation of new utilities. The dense urban environment posed a challenge due to the existing network of underground utilities. Using advanced Ground Penetrating Radar, Safe Scanners successfully mapped out the complex subsurface layout, allowing the construction team to proceed without incident. This avoided potential delays and saved the city significant costs in rerouting and repairs.

Case Study 2: Historic Building Renovation

A historic building undergoing renovation required Concrete Scanning Services to locate rebar and voids within its foundation. Safe Scanners deployed its GPR technology to scan the concrete structure, providing detailed imagery of the rebar patterns and any hidden voids. This information was crucial in planning the renovation work, ensuring structural integrity and preserving the building's historical value. The project was completed on time and within budget, thanks to the accurate data provided by Safe Scanners.

Future Trends in Utility Locating and GPR Technology

As technology advances, the capabilities of GPR and utility locating services continue to expand. Innovations such as 3D GPR imaging and real-time data processing are enhancing the accuracy and speed of subsurface investigations. Safe Scanners is at the forefront of adopting these new technologies, ensuring that clients benefit from the latest advancements in the field.

Moreover, the integration of GPR data with Geographic Information Systems (GIS) allows for more comprehensive and accessible mapping of subsurface utilities. This integration provides a holistic view of the project site, further reducing risks and improving planning efficiency.

In the realm of construction and infrastructure development, avoiding costly delays is paramount. Safe Scanners' GPR Services, including GPR Scanning, Ground Penetrating Radar, and Concrete Scanning Services, offer a reliable and effective solution to this challenge. By accurately locating subsurface utilities and other features, these services save time, reduce costs, and enhance safety on job sites.

Investing in advanced utility locating services is a proactive step that pays off in both the short and long term. With Safe Scanners' expertise and cutting-edge technology, you can ensure your projects proceed without unexpected interruptions, keeping your timelines and budgets intact.

For more information on how Safe Scanners can assist with your next project, visit our website or contact us directly. Together, we can build a safer, more efficient future.

2 notes

·

View notes

Text

PINELLAS PARK, Fla. (WFLA) — A Florida camp powered by solar panels and a generator is home to about a dozen sex offenders who claim they were sent there by probation officers, but there is no indication the public was alerted.

Land records indicate the tents that sit under a structure made from branches are on land owned by the Florida Department of Transportation. An FDOT spokesperson said they were “not aware of this.”

Several sources, including a defense attorney, told Nexstar’s WFLA that anyone on probation is still “under sentence,” and they said that telling them to live outdoors violates state administrative code.

A DOC spokesperson denied offenders are told where to live by probation officers.

Biological parents want answers after Florida foster dad pleads guilty to sex crime charges

Several of the camp residents agreed to discuss their living conditions but asked to hide their identities to avoid possible retribution from the state employees they claim sent them there.

“Yes,” one of them said when asked if his probation officer told him to live there. “They actually brought me out here.”

“They told me there’s a spot that you need to go to,” another offender said. “So, I drove around for a while trying to find this place, and eventually, I did.”

The sex offender registration law was put on the books to let the public know where these types of offenders live.

But the registry website lists an intersection for the people who live in the camp — an intersection about a mile away from the tents.

“Exactly,” one offender said. “There’s no address.”

The camp is within walking distance of schools, homes and businesses. But it does not appear to violate the state law that restricts sex offenders from living within “1,000 feet of a school, child care facility, park, playground, or other place where children regularly congregate.”

Camp residents said their makeshift homes are well hidden from the public.

“They don’t even know we’re here,” one said. “They’re hiding us from society.”

All the offenders in the camp are wearing electronic monitoring devices, but they said they were not told how to charge them to avoid violating terms of their probation.

This prompted them to buy a solar-powered charging station and a generator, they say.

Department of Corrections spokesman Paul Walker denied the offenders were told to live in the woods.

“For purpose of your story, FDC does not assign residence locations,” Walker said in an email. “The FDC aims to protect the community by supervising offenders and reporting non-compliance to the sentencing court or sentencing authority.”

The camp is in House District 60, which is served by State Rep. Lindsay Cross.

“I think the first thing is being aware of the situation,” Cross said. “I think it’s very irresponsible to direct people to an open area and not alert the residents of that community.”

Cross said she plans on talking with other lawmakers about finding a way to avoid using the outdoors as housing for offenders on probation.

“We need to go back to the safety of the residents,” Cross said. “It’s also inhumane to have anyone live without running water, electricity, housing.”

Denise Rock, founder of inmate advocacy non-profit Florida Cares, said the state has to do more to find housing for offenders to ensure their safety and to protect the public.

Rock said several former inmates from other parts of the state have made similar claims about being sent to live in wooded areas by probation officers.

“I remember one case where they said they were told to go to an area behind a [fast-food restaurant],” said Rock. “The address on the registry was for the [restaurant.]”

14 notes

·

View notes