#Electronics Circuit Designer

Explore tagged Tumblr posts

Text

#book cover#cover design#technology#engineering#physics#computational lithography#lithography#electronics#integrated circuits#Gonzalo R. Arce#Xu Ma#circuits#science#computers

15 notes

·

View notes

Text

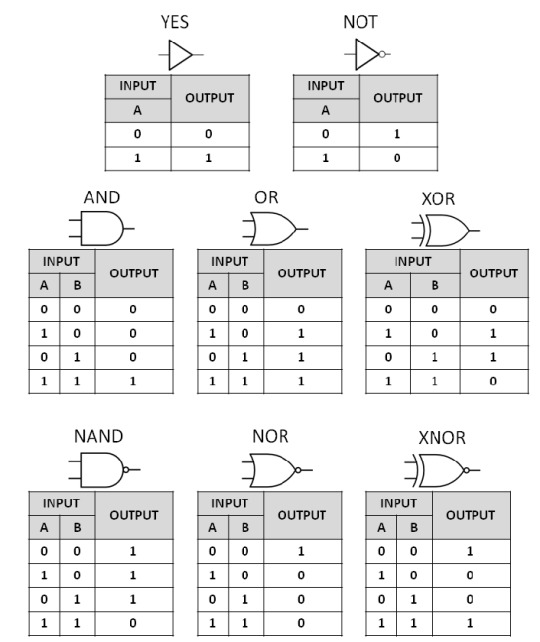

Why does digital elecronics is important for engineering?

Digital electronics is super important in engineering for a bunch of reasons—it's pretty much the backbone of modern technology. Digital electronics powers everything from smartphones and computers to cars and medical devices. Engineers across disciplines need to understand it to design, troubleshoot, or innovate with modern systems.

GET CIRCUIT DESIGNING VIDEO TUTORIAL 👈.

Digital tech allows for very large-scale integration (VLSI), meaning engineers can cram millions of logic gates into a single chip (like microprocessors or memory). It enables powerful, compact, and cost-effective designs.

#digital electronics#engine mechanism#electronics circuit#crank shaft#mechanical arms#mechanical engineering#mechanical parts#two stroke engine#technology#electronics#computing#and gate#digital chip#or gate#not gate#nand gate#nor gate#xor gate#electronic gate#embedded circuit design

2 notes

·

View notes

Text

youtube

Music video I made for my good friend Raif for his song "Ratter"

2 notes

·

View notes

Text

The Benefits of Ordering Printed Circuit Boards Online: A Guide to Choosing the Right PCB Manufacturer

In today's rapidly advancing technological landscape, printed circuit boards (PCBs) play a crucial role in various electronic devices, from smartphones to industrial machinery. As demand for these essential components grows, businesses and hobbyists alike seek efficient and cost-effective solutions for obtaining high-quality PCBs. One of the most convenient methods is to order printed circuit boards online. In this article, we will explore the advantages of ordering PCBs online and provide insights into selecting a reputable PCB manufacturer.

Why Order Printed Circuit Boards Online?

Ordering printed circuit boards online offers several benefits, making it an attractive option for many businesses and individuals:

Convenience: The ability to order PCBs from the comfort of your home or office eliminates the need for in-person visits to manufacturers or suppliers. This convenience saves time and effort, allowing you to focus on your projects or business operations.

Wide Range of Options: Online PCB manufacturers offer a variety of options in terms of materials, layer counts, finishes, and more. This flexibility allows you to customize your PCBs according to your specific requirements and budget.

Cost-Effectiveness: Many online PCB manufacturers provide competitive pricing, especially for bulk orders. Additionally, you can easily compare prices and services from different providers, ensuring you get the best value for your money.

Quick Turnaround Times: Online ordering often comes with expedited production and shipping options, allowing you to receive your PCBs faster. This is particularly beneficial for projects with tight deadlines or when you need quick prototypes.

Access to Advanced Technologies: Many online PCB manufacturers offer advanced technologies such as high-frequency PCBs, flexible PCBs, and more. This access to cutting-edge technology ensures your designs are compatible with the latest industry standards.

Choosing the Right PCB Manufacturer

Selecting the right PCB manufacturer is crucial to ensuring the quality and reliability of your printed circuit boards. Here are some key factors to consider when choosing a PCB manufacturer:

Experience and Reputation: Look for a manufacturer with a solid track record and positive reviews from previous customers. Experienced manufacturers are more likely to produce high-quality PCBs and provide reliable service.

Quality Assurance: Ensure the manufacturer follows strict quality control measures, such as ISO certification and regular testing. High-quality PCBs are essential for the proper functioning and longevity of your electronic devices.

Customer Support: Good customer support is vital, especially if you encounter issues during the ordering process or with the final product. Choose a manufacturer that offers responsive and helpful customer service.

Manufacturing Capabilities: Check the manufacturer’s capabilities, including the types of PCBs they can produce, their layer count capacity, and the materials they use. Make sure they can meet your specific design requirements.

Lead Times and Shipping: Consider the manufacturer’s production lead times and shipping options. Quick turnaround times are crucial for meeting project deadlines, so choose a manufacturer that can deliver within your required timeframe.

Pricing and Payment Terms: While cost is an important factor, it should not be the sole consideration. Ensure the manufacturer offers transparent pricing and flexible payment terms that suit your budget.

Conclusion

Ordering printed circuit boards online is a convenient and cost-effective way to obtain high-quality PCBs for your projects. By choosing a reputable PCB manufacturer, you can ensure the reliability and performance of your electronic devices. Whether you are a business looking to streamline your supply chain or a hobbyist working on a personal project, ordering PCBs online provides a seamless and efficient solution.

For those ready to place a printed circuit board order online, consider the factors outlined above to select the right PCB manufacturer for your needs. With the right partner, you can bring your electronic designs to life with precision and quality.

#printed circuit board#pcb manufacturer#pcb supplier#printed circuit board order online#pcb design & manufacturing services#pcb circuit manufacturer in ahmedabad#electronic circuit design company

2 notes

·

View notes

Text

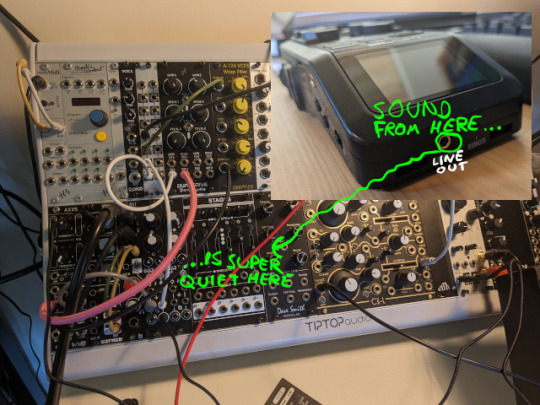

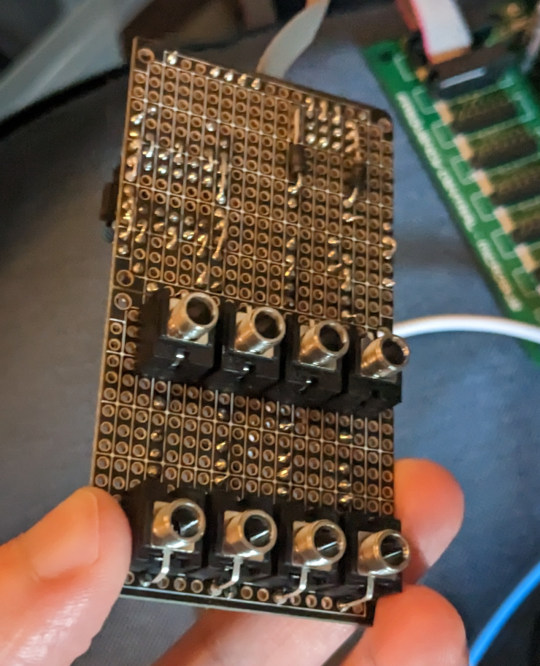

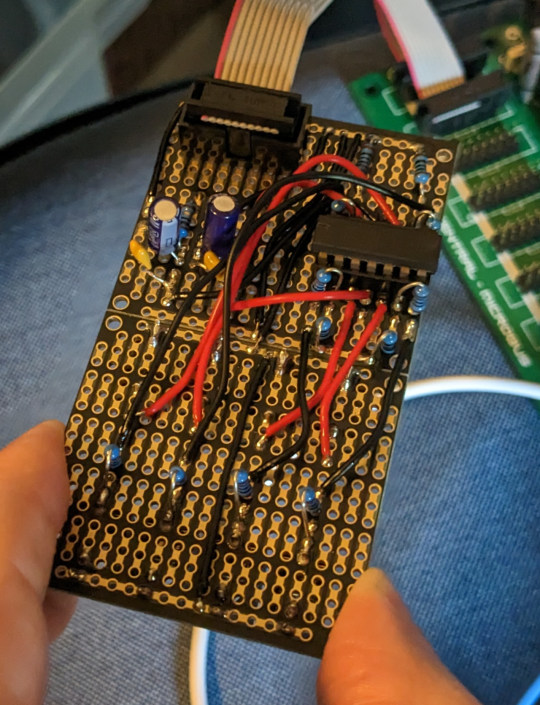

DIY line-out to Eurorack-in amp explainer now up on depthbuffer.uk!

always wanted to add an electronics hobby to your mid-life crisis, but never bothered to learn?

spent so much on eurorack gear that you now can't afford an audio input module for your line out jacks?

like reading long-winded explanations, written in overly flowery prose, by passionate nerds who don't actually know what they're talking about, but want to tell you all about it anyway?

then boy, do I have a poorly-illustrated, badly researched five-article series for you!

#memento potato#electronics#diy#synth#modular synth#modular synth diy#circuit design#tutorial#explained#magic#artisanal jank

25 notes

·

View notes

Text

Multilayer PCBs (Printed Circuit Boards) offer numerous advantages over their single-layer or double-layer counterparts. These benefits arise from their enhanced design capabilities, improved performance, and greater flexibility. Here are some key advantages of multilayer PCBs:

#PCB#printed circuit board manufacturers#electronic cable assembly#pcb manufacturing#pcb assembly manufacturer#pcb assembly services#pcb board manufacturer#printed circuit board manufacturer in india#circuit board manufacturing#pcb exporters#pcba#pcb manufacturer#pcb design#pcbassembly#multilayer pcb

2 notes

·

View notes

Text

PCB Design: The Key to Engineering Innovation

3 notes

·

View notes

Text

Gentle reminder that

Smart ≠ Wise ≠ Literate ≠ Jerk ≠ Know-it-all

A character can be really good with, say, numbers but know absolutely nothing of history. Or be really clever and tactical but never once in their life has opened a book. Or be a genius when it comes to music, but being a complete idiot when trying to efficiently arrange objects in certain space. Or instinctively coming up with clever solutions, but lacking the words to express them. Or having a very vast vocabulary, but but it's not someone actually clever.

The say way someone can posses a lot of knowledge in a variety of areas but being unable to put that knowledge to practice, to use, or intertwine that knowledge to find a new and creative way to come up with an answer to a problem.

There are a lot of way to be smart. A character can be smart and ignorant. A character can be smart but know oh-so-little about a lot of things.

Yes, the character can be your stereotypical know-it-all that has all the solutions in less than a minute, doesn't miss a thing, gets impatient and cocky because no one can keep up with them and so one, but it doesn't need to.

#Like look at me- I'm what everyone calls smart and do you think I'm a clever jerk that effortlessly solves all their problems??? lmao no#I'm just someone with like two braincells available- ask me anything about- idk- design#I can have a lengthy conversation about physics or history and so on#but try to get me to talk about cars#or fashion#or modern politics#i don't know a THING about those#You can also take as an example my friend- she's really REALLY smart#she's good with numbers- whatever thise numbers may be#she can do math like a calculator#all physics problems- no matter how elaborate and difficult - are a piece of cake for her#she can see a room a calculate how much paint or cement or wall tiles or rafters or whatever you'll need to make a renovation#she know how to code and knows how to make electronic circuits#try and ask her what ethereal means#she's so bad with words and explaining herself to the point that I am her intermediary when we're in a group#and she doesn't know English either#she knows only one language#I could go on and on#about people who are really smart in something and really dumb in another thing#myself included#it's more common to be smart in a few things and dumb in others than be a complete genius#and ofc you CAN write a complete genius if you want to#there's nothing wrong with it#just saying that it's not the only way to be smart or clever#writing#writers#writers on tumblr#writing humor#long post

21K notes

·

View notes

Text

What’s impressive is that Voler offers complete Circuit Design Services—from early concept discussions to building the final prototype. They’re not just consultants; they’re hands-on partners who work closely with clients through every stage of product development. This collaborative approach ensures the end product meets both performance standards and regulatory requirements, especially important in the medical field.

0 notes

Text

Electronic Circuit Board Design & Services: Reasons to Work with Experts!

Electronic circuit board design is one of the most crucial aspects of creating and constructing any electrical device in this modern period. Ascertain the product's dependability in addition to its functionality and affordability when it is designed by

Skilled and certified electronic engineering specialists from recognised companies provide faultless circuit design and electrical repair services in the present day's high competition.

A few recognised companies employ trained and skilled have decades of experience and state-of-the-art software, making them manufacturing and comprehensive support experts.

In the Australian market, consumer electronics are becoming more disposable, with these companies. Their vital contributions support sustainability and resource conservation.

The Value of Services for Electronics Design, Development, and Repair:

Typically, knowledgeable electronic specialists offer precise and thoroughly recorded schematic capture and PCB design procedures that lower downstream errors and expensive recalls to boost production efficiency.

Experienced circuit designers offer vital assistance from basic design to prototype and final product, as well as new solutions to keep ahead of the competition. They are specialists in component selection and planning to prevent product shortages and ensure long-term viability.

Their background not only helps with competitive advantages in the quick-paced electronics industry, but they also enhance product quality and streamline manufacturing procedures.

With a deep understanding of circuits and components, these experts not only design and create electrical devices but also ensure their longevity and functionality.

In addition, their experts can quickly identify defective PCBs or other electronic problems, fix them with little downtime, and prolong product life to cut down on waste or resources. Their comprehension of schematic electronics design enables them to investigate intricate systems, identify underlying problems, and implement effective fixes.

Overall, find a trusted circuit board design company by analysing their market's total offerings and pick a reliable design and repair service that meets your needs to enjoy better performance, less downtime, and more affordable maintenance.

Source: https://extrondesignservice.blogspot.com/2025/05/electronic-circuit-board-design.html

0 notes

Photo

Microchip Assembly in a Circuit Board 🖥️

Hey tech enthusiasts! 🌟 Today, we're super excited to share one of our latest creations: a stunning close-up wallpaper that captures the intricate beauty of microchip assembly on a circuit board. This isn’t just any wallpaper; it’s a glimpse into the fascinating world of semiconductor components that power our modern gadgets!

Every detail in this design showcases the meticulous manufacturing process that goes into creating the technology we often take for granted. From the tiny circuits to the shiny solder points, it’s a reminder of the innovation that drives our digital age.

Perfect for tech lovers, engineers, or anyone who appreciates the art behind technology, this wallpaper will definitely add a sleek, modern touch to your devices. Whether you're working from home or just want to spruce up your desktop, this design is sure to impress! 🎨✨

Ready to give your screens a techy makeover? Click here to explore the intricate world of microchips and grab your own copy of this eye-catching wallpaper!

Stay tuned for more amazing designs coming your way!

Happy downloading! 😄

#technology#circuit board#microchip#semiconductor#wallpaper#digital art#electronics#innovation#design#engineering#tech lovers#modern technology#close-up#high-tech#gadget#soldering#manufacturing#art#creative#desktop wallpaper

0 notes

Text

Why does digital elecronics is important for engineering?

Digital electronics is super important in engineering for a bunch of reasons—it's pretty much the backbone of modern technology. Digital electronics powers everything from smartphones and computers to cars and medical devices. Engineers across disciplines need to understand it to design, troubleshoot, or innovate with modern systems.

GET CIRCUIT DESIGNING VIDEO TUTORIAL 👈.

Digital tech allows for very large-scale integration (VLSI), meaning engineers can cram millions of logic gates into a single chip (like microprocessors or memory). It enables powerful, compact, and cost-effective designs.

#digital circuit design#digital electronics#electronics circuit#and gate#or gate#not gate#complex gate design#vlsi designing

1 note

·

View note

Text

Driving Innovation: 8 Ways How PCBs Are Powering the Future of Automotive Tech

Have you ever wondered what links every modern car feature together? Whether it's a smart display, lane detection, or battery monitoring—PCBs are at the core of it all. They’re the silent operators, working behind the scenes to connect sensors, manage data, and support smarter driving.

Today’s cars rely on layers of tech, and PCBs are the base that holds it all together. Their design affects performance, safety, and even energy use. As the auto world moves faster toward electric and autonomous options, understanding how these boards work matters more than ever.

Get ready to learn the 8 biggest ways PCBs are reshaping the way we drive. Stick around—you’ll never look at your dashboard the same way again.

Let’s get started!

The Impact of PCBs On Automobile Industry - A Basic Overview

Printed Circuit Boards (PCBs) have become a major part of modern car design. As vehicles shift from mechanical systems to more advanced electronics, PCBs are helping make everything work together smoothly. They connect and support various components that control key features like lighting, entertainment, safety, and engine systems.

From electric cars to traditional vehicles, PCBs are used to manage how systems communicate and function. Whether it’s a simple dashboard display or a complex navigation system, PCBs are the foundation that brings it all to life. Their ability to handle more tasks in smaller spaces has made it easier for manufacturers to add new features without increasing vehicle size or weight.

As the auto industry continues to focus on smart features, electric mobility, and automation, PCB assembly services are expected to play an even bigger role.

Here are some of the most significant ways PCBs are shaping today’s automotive technology behind the scenes:

Used in over 90% of modern automotive systems: From engine control units to digital displays, PCBs are essential for managing operations across the vehicle.

Vital for electric vehicle battery systems: They regulate energy use, monitor battery health, and maintain safe temperature levels.

Help reduce size and wiring complexity: PCBs allow compact designs by combining functions on a single board, which also lowers manufacturing costs.

Built to handle harsh conditions: Automotive PCBs are designed to resist vibration, heat, and moisture—making them reliable on the road.

Support smart and self-driving features: PCBs enable communication between sensors, cameras, and processors that are critical for advanced driving technologies.

The Role of PCBs in Shaping the Future of Automotive Engineering

As the automotive industry moves toward smarter, safer, and more efficient vehicles, Printed Circuit Boards (PCBs) are at the heart of these innovations. From electric vehicles to autonomous driving, PCBs enable critical systems to work together seamlessly.

With automotive electronics projected to account for 40% of a vehicle's value by 2030, the demand for high-performance PCBs is set to soar. As the global automotive PCB market reaches over $6 billion by 2025, these boards are becoming essential in shaping the future of automotive engineering and driving the next generation of vehicles.

Here’s a quick overview of the strong impacts of PCBs and how they are significantly transforming the automobiles’ efficiencies and functionalities.

1. Enhanced Safety Features

PCBs play a critical role in vehicle safety systems, such as airbags, anti-lock braking systems (ABS), and collision avoidance systems. They help these systems communicate and respond in real-time to ensure maximum protection for passengers.

2. Improved Electric Vehicle (EV) Efficiency

PCBs are essential in managing the battery systems in electric vehicles, handling power distribution, temperature regulation, and charging cycles to improve efficiency and lifespan.

3. Autonomous Driving Support

The intricate network of sensors, cameras, and processors in autonomous vehicles relies heavily on PCBs. They ensure seamless communication between various systems for safe navigation.

4. Advanced Infotainment Systems

PCBs are the backbone of modern infotainment systems, providing the platform for touchscreens, navigation, audio controls, and connectivity features like Bluetooth and smartphone integration.

5. Lightweight and Compact Designs

With the growing demand for more compact designs, PCBs allow manufacturers to reduce the size of electrical components, freeing up space for more features and reducing vehicle weight.

6. Real-Time Monitoring and Diagnostics

PCBs are integral to real-time monitoring systems in vehicles, including engine performance tracking and diagnostic features, helping to detect faults early and improve maintenance.

7. Battery Management Systems (BMS)

PCBs in battery management systems are crucial for monitoring the health and performance of a vehicle’s battery, balancing charge cycles, and optimizing energy usage in electric and hybrid vehicles.

8. Smart Climate Control Systems

With the help of PCBs, modern vehicles can implement intelligent climate control systems that adjust cabin temperature based on user preferences, external weather, and real-time vehicle conditions.

Final thoughts

In conclusion, Printed Circuit Boards (PCBs) are more than just essential components—they are the driving force behind the future of automotive technology. As vehicles become smarter, safer, and more efficient, PCBs are enabling innovations that were once thought impossible. From electric and autonomous vehicles to advanced safety features, these boards are shaping the way we drive. As the automotive industry continues to evolve, the importance of PCBs will only grow, paving the way for a new era of automotive engineering. The road ahead is paved with innovation, and PCBs will continue to lead the charge.

1 note

·

View note

Text

Printed Circuit Board Basics

Most of us are using Printed Circuit Board in our daily life. Printed Circuit Boards are used in almost all the Electronic products, from consumer gadgets such as PCs, tablets, smartphones, and gaming consoles to industrial and even high tech products in strategic and medical electronics domains.

Here, we have some statistics for you that shows how many electronic devices connect worldwide from 2015 to 2025. This statistic shows an increase in the use of a number of PCB in people daily life. Hence, CircuitWala took this opportunity to provide a basic knowledge about PCB via this article.

There are so many books available online which teach about Printed Circuit Board design and hardware part. There are few links available online which shows only a few basic fundamentals of PCB and few are there for Basics of Printed Circuit Board (PCB) Design. Few which gives good know knowledge on Printed Circuit Board terminology. But in the end for the hobbyist, there is no such material available which make their work easy.

Now days there few online designing websites available which allow hobbyist and students to create their design and Printed Circuit Board fabrication part. These websites provide limited features and charge high for the full edition. We, @CircuitWala are in try to provide one platform which provides plenty of Printed Circuit Board knowledge digitally to make your work simple and easy.

Alternatives of PCB include wire wrap and point-to-point construction. Creating a layout of PCB is a little bit time-consuming method as compared to its alternative solution but manufacturing of PCB is cheaper and faster then other wiring methods as electronic components are mounted and wired with one single part.

Let’s start with some basics of Printed Circuit Board with this article. Here in this article we will discuss about history of PCB to understand the emerge of PCB, Types of PCB to make your complex PCB a very simple using different types, Usage of PCB to provide you an idea to create more Printed Circuit Board projects, Advantages and Disadvantages, Possible Future to know about new technological change in Printed Circuit Board manufacturing and also about how to destroy and manage your PCB’s e-waste? We know you are eager to know all the stuff in details but before that let’s make a simple definition of Printed Circuit Board.

What is Printed Circuit Board?Printed Circuit Board is an electronic device made of conductive material(FR-4) like copper which connects components mounted on it to to get desired output by providing an input on another end.

When the board has not mounted with any of the components is called as Printed Circuit Board or Printed Wired Board. Mounting of an electronic component on Printed Circuit Board is called as PCB assembly.

History of Printed Circuit BoardThe invention of Printed Circuit Board was by Austrian engineer Paul Eisler as part of a radio set while working in England around 1936.

In early days before Printed Circuit Board became common in use, Point-to-Point construction was used. This meant some bulky and unreliable design that required plenty of sockets and regular replacement of it. Most of this issue directly address when PCB went into regular production.

Originally, every electronic component had wire leads, and the PCB had holes drilled for each wire of each component. The components’ leads were then passed through the holes and soldered to the PCB trace. This method of assembly is called Through-Hole construction. There is one other method to mount component is called as Surface Mount.

Type of Printed Circuit BoardPCBs are produced from the different types of material and on the basis of that material PCBs are divided mainly into two parts: Rigid PCB and Flexible PCB. Nowadays, a combination of Rigid and flexible PCB is also possible and that is called as Flexi-Rigid PCBs.

Most of the PCBs are built in layers. The inner layer is the base material called as a substrate. Rigid PCBs are mainly made of material like epoxy materials and Flexible PCBs are made of plastic material that can withstand high temperatures.

Rigid PCBs are generally, hard materials that hold the component in a better way. The motherboard in the tower of a computer is the best example of Rigid PCBs. Flexible PCBs fundamental material allows PCB to fit into forms that Rigid PCBs can not. Flexible PCBs can turn round without harmful the circuit on PCB.

All Rigid and Flexible PCBs can come in three formats by layers: Single Layer, Double Layer, and Multi-Layer.

1. Single Layer PCBSingle Layer PCBs have been around since the late 1950s and still dominate the world market in sheer piece volume. Single Sided PCBs contain only one layer of conductive material and are best suited for low-density designs. Single-sided PCBs are easy to design and quick to manufacture. They serve as the most lucrative platform in the industry.

2. Double Layer PCBDouble Layered printed circuit board technology is conceivably the most popular type of PCB in the industry. Double Sided PCB (also known as Double-Sided Plated Thru or DSPT) circuits are the gateway to advanced technology applications. They allow for a closer (and perhaps more) routing traces by alternating between top and bottom layers using vias.

3. Multi Layer PCB

Multilayer PCB is a circuit board that has more than two layers. Unlike a Double-Sided PCB which only has two conductive layers of material, all multilayer PCBs must have at least three layers of conductive material which are buried in the center of the material.

Usage of Printed Circuit BoardBy reading this article till this point, we hope that you are now able to get about printed circuit boards. Now, we will make you understand about different applications of printed Circuit Board.

In this digital world, Printed Circuit Board is in almost all our daily life electronic devices and in our industrial electronics as well. Below are the industries where PCBs are used:

Possible FutureNowadays, most of the circuits are replaced to produce Printed Circuit Board from the old methods. Revolution in technology made many of the processes automated and hence it is easy to manufacture PCB. But still, these processes are a bit expensive to hire, involve toxic waste and use high temperatures and acids. With technological advances we have seen in the past years, it is not hard to imagine PCB will soon be revolutionized. Not only that but research institutes predict a more ‘green’ future for PCBs; PCBs being made of paper.

Electronic Waste (e-waste)Electronic Waste or e-waste is described as discarded electrical or electronic devices. Informal processing of e-waste in developing countries can lead to adverse human health effects and environmental pollution.

Electronic scrap components contain a hazardous substance such as lead, cadmium, beryllium, or brominated flame retardants. Recycling and disposal of e-waste may involve significant risk to health of workers and communities in developed countries and great care must be taken to avoid unsafe exposure in recycling operations

Nowadays, developing countries are encouraging electronic users to take care while recycling the e-waste or submit them to the organization who are involved in such activities.

SummaryIn this blog, we have learned the basics of Printed Circuit Board. CircuitWala is planning to write as many blogs to provide more and more knowledge of Printed Circuit Board. Either it is basics or manufacturing or usages or advantages and disadvantages of PCBs. We will also try to make our users/customers up to date for the new technology innovations, including past histories and revolution of the PCB industries.

In the next blog, we will look at more briefly about the different types of Printed Circuit Board. We also understand the process to make it and different usage and application for the same.

#electronic circuit design company#pcb circuit manufacturer in ahmedabad#pcb design & manufacturing services#printed circuit board companies#printed circuit board order online#PCB manufacturer#Printed Circuited Board#double layer PCB#PCB Quality Control

2 notes

·

View notes

Text

Important Ohm’s Law Problems for Competitive Exams

Series Circuit Resistance

Three resistors of 5 Ω, 10 Ω, and 15 Ω are connected in series. What is the total resistance?

In a series circuit, total resistance is the sum of all resistances:

Rtotal = R1+R2+R3 = 5Ω+10Ω+15Ω = 30Ω

Parallel Circuit Resistance

Two resistors, 6 Ω and 12 Ω, are connected in parallel. What is the total resistance?

youtube

GET MORE FREE SOLUTION 👈.

#digital learning#online education#online courses#online tutoring#online learning#electronics components#electronics manufacturing#electronics design#electronics industry#electronics#learn about circuits#basic circuits#electronics circuit#Youtube

0 notes

Text

Boost Your Professional Skills with Free Electric Engineering PDF Books!

Are you studying or working in the field of electrical engineering?

To help you learn and grow, I’ve curated a fantastic collection of essential electric engineering PDF books.

Download PDF

Joine for more PDF

These resources include:

.Key theories and concepts

.Detailed diagrams and case studies

.Practical guidelines

Take this opportunity to enhance your knowledge and skills.

Don’t wait—connect with me now!

---

#pcb design#flexible pcb board#flex circuit pcb#circuit breaker#circuit of the americas#electronic#electro house#download ebooks pdf#free ebooks#pdf file

0 notes