#Fiber Stages Manufacturer

Text

#fiber wedding stage#wedding fiber gate#fiber wedding pillar#wedding fiber panel#frp wedding stage#wedding fiber stage manufacturer

1 note

·

View note

Text

Glyptic Arts present- FRP Lion Sculpture

🦁 We are proud to present our newest masterpiece - the FRP Lion Sculpture 🤩 This beautiful sculpture is crafted with the finest materials and is perfect for adding a touch of luxury to any space. 🔥 Get it now and experience the beauty of our FRP Lion Sculpture for yourself.

Contact us :- 072518 82227

Gmail:- [email protected]

Insta:- glyptic_arts

FB:- artsglyptic

website:- https://www.glypticarts.com

#fiber wedding stage#fiber statue manufacturer#gazebo manufacturers in india#frp planters manufacturers#grc jali manufacturer

0 notes

Text

adventures in aerospace

So I recently started working at Large Aircraft Manufacturer. (LAM) The plant I work at employs 30,000 people. The company as a whole employs 170,000. Usually you only hear about LAM when something goes wrong. But no matter how bumbling it seems from the outside, it's way worse on the inside.

Three months after my first day, I have been "graduated" from "training." In reality, I'm still completely worthless on the floor: the training center has given me a paltry subset of the production certificates I need to actually to do my assigned job. A commonly cited statistic at LAM is that a hundred men a day are retiring, each one representing decades of experience, walking out the door, forever. The training center is in the unenviable position of managing a generational replacement, and have resorted to shoveling heaps of zoomers through as fast as possible. (As one of the few people with a visible hairline and who is not wearing a Roblox graphic tee; I am frequently mistaken for an instructor, and asked where the bathroom is, what time the next class starts, etc)

In theory, the training center knows what shop I'm assigned to, and can simply assign me all the required classes. In practice, they do the absolute minimum amount of training in a desperate attempt to relive the crowding in their handful of computer labs and tell graduates to pick up their certs later.

Of course, the irresistible force of the schedule meets the immovable object of the FAA. If you don't have the required production certificate to perform a particular job, you don't touch the airplane. Full stop, end of story.

And so the curtain opens on the stage. It reveals a single senior mechanic, supervising a mechanic who finally received all the certs and is being qualified on this particular job, surrounded by another three trainees. Trainees are less than nothing, absolute scum. At best we can fetch and carry. Mostly we are expected to stay out of the way. And the senior mechanic is only senior in title. He is one of six assembler-installers who is certified to actually work on the plane, out of twenty people on the crew, and spends every day with a permanent audience. He is 23 years old.

("Mechanic"? If you think the jargon at your job is bad, try joining a company that's a century old. Assembler-installers are universally referred to as "mechanics", despite doing work that's nothing like what a car mechanic does, and who are generally paid far worse than FAA certified A&P mechanics. Mechanics are the 11 bravos of LAM, grunts, the single largest category of worker. The tip of the spear. Hooah!)

Large Aircraft Manufacturer is in a dilly of a pickle. All of its existing airframe designs are hilariously antiquated. It tried designing a brand new plane from a clean sheet, and lost billions of dollars to a decade-long integration hell. After that, to save money, it tried just tacking bigger engines on an older design without changing anything else, and the stupid things plowed into the ground in an excruciatingly public manner.

LAM is now trying a middle road. It is upgrading one of its designs that is merely middle aged, rather than ancient, and with proven, de-risked components built in-house, rather than scattering them to subcontractors across the world. And it's still blowing past deadlines and burning billions of dollars LAM really doesn't have to spare.

This is the program I've been assigned to.

Advanced Midbody - Carbon Wing has taken the bold step of just tacking on carbon fiber wings to a conventional aluminum fuselage. Shockingly, AMCW is now stuck in lightning strike testing, due to that troublesome join between conductive aluminum and conductive...ish carbon fiber. But LAM, confident as ever, or perhaps driven by complaints of its customers, has announced that full rate production will begin just next year. Thus the tide of newhires. According to the schedule, we're supposed to jerk from one wingset a month to one wingset a week. That's not going to happen, but, oh well, orders from above move down at the speed of thought, while reality only slowly trickles upwards.

"120 inch pounds? Really?"

I startle upright. I have observed one hundred pi bracket installs, and I will observe a hundred more before I can touch aircraft structure. This is the first disagreement I've witnessed. A more advanced trainee is questioning the torque spec on a fastener. It is not an entirely foolish question-- most sleeve bolts we use are in the 40 in-pounds range. Doubling it that is unusual. I cough the dust off my unused vocal cords and venture an opinion.

"Well hey I could look it up? I guess"

The lead mechanic glances at me, surprised that I'm still awake, then looks away. Excuse enough for me!

I unfold myself from the stool I've been sitting on for the last four hours then hobble over to the nearest Shared Production Workstation.

We do not get Ikea-style step by step instructions on how to put together the airplane. Like any company that's been around for long enough, LAM is a tangled wad of scar tissue, ancient responses to forgotten trauma. If you state a dimension twice, in two different places, then it is possible for an update to only change one of those dimensions, thereby making the engineering drawing ambiguous. Something real bad must have happened in the past as a result of that, so now an ironclad rule is that critical information is only stated once, in one place, a single source of truth.

As a result, the installation plan can be a little... vague. Step 040 might be something like "DRILL HOLE TO SIZE AND TORQUE FASTENERS TO SPEC". What hole size? What torque spec?

Well, they tell you. Eventually.

(Image from public Google search)

You are given an engineering drawing, and are expected to figure out how things go together yourself. (Or, more realistically, are told how it's done by coworkers) Step by step instructions aren't done because then dozens of illustrations would have to be updated with every change instead of just one, and drawings are updated surprisingly frequently.

Fasteners are denoted by a big plus sign, with a three letter fastener code on the left and the diameter on the right, like so: "XNJ + 8"

To get the actual part number, we go to the fastener callout table:

(Note the use of a trade name in the table above. There is nothing a mechanic loves more than a good trademark. Permanent straight shank fasteners are always called HI-LOKs™. It's not a cable tie, it's a Panduit™. It's not a wedgelock, it's a Cleco™. Hey man, pass me that offset drill. What, you mean a Zephyr™? Where'd the LAMlube™ go? This also means you have to learn the names of everything twice, one name on the installation plan, and one name it's referred to in conversation.)

We find XNJ on that table, and fill in the diameter: BACB30FM8A. Now we look up the spec table for that fastener:

The eagle eyed among you might note that there is no "diameter: 8" on that table. As a LAM mechanic, you are expected to simply know that "diameter" is measured in 32nds of an inch, which simplifies down to 1/4.

(LAM preserves many old-school skills like fraction reduction and memorizing decimal equivalents like this, like flies caught in amber. Not least is the universal use of Imperial units. Many American manufacturers have been browbeaten into adding parenthetical conversions. Not LAM! Any risk at all of a mechanic seeing a second number and using it by accident is too great, and anyway, it violates SSOT. Lengths are in inches and feet, weights are in pounds, volume is in gallons and if you don't like it then you can go eat shit!)

After 10 minutes of following references, I arrive at that table, print it off, highlight the correct row, and hand it off to my senior mechanic.

"Great, thanks."

Gratified that I have enhanced shareholder value, I sit back down, and immediately fall asleep. Another day living the dream.

(next post in this series)

410 notes

·

View notes

Photo

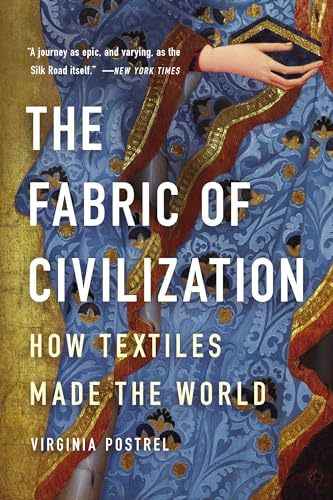

The Fabric of Civilization: How Textiles Made the World

In "The Fabric of Civilization," Virginia Postrel explores how the history of textiles is akin to the story of civilization as we know it. As evidenced throughout her book, Postrel treats each chapter as a standalone story of its production and journey, all the while masterfully weaving it together to show the story of human ingenuity. While academic in nature due to its incredibly well-researched methodology, the general reader will enjoy the book's unique style and approach to world history.

In The Fabric of Civilization: How Textiles Made the World, Virginia Postrel expertly demonstrates how the history of textiles is the story of human progress. Although textiles have shaped society in many ways, their central role in the development of technology and impact on socio-economics have been exceedingly overlooked. Attempting to remedy this issue, Postrel organizes her book into two distinct sections: one focusing on the different stages of textile production (fiber, thread, cloth, and dye) and the other on the consumers, traders, and future innovators of said textiles. To strengthen her argument, Postrel pulls from different primary sources across many regions and cultures, such as the works of people like entomologist Agostino Bassi and the accounts of disgruntled Assyrian merchants. However, Postrel goes beyond relying solely on books and peer-reviewed articles; she personally interviewed textile historians, scientists, businesspeople, and artisans who offered their own insight regarding the importance of textiles in the world. To help the reader envision the intricacies of textile manufacturing, the book is riddled with images that range from ancient spindle whorls and Andean textile patterns to nineteenth-century pamphlets raging over improved cotton seeds. It is quite a laborious task to explain the history of textiles, but Postrel’s way of organizing her chapters and style of writing does an excellent job of conveying her argument.

In Chapter One, Postrel illustrates the many uses of fibers and how their multipurpose functionality served its role in world economies. From the domestication of cotton in the Americas to sericulture in ancient China, such fibers left an indelible mark on trade and technology. Chapter Two looks at the use of thread's connection with social and gender roles as Postrel argues that dismissing fabric as feminine domesticity ignores its integral role in the social innovations that products like clothing and sails provided. Chapter Three connects mathematics with weaving through handwoven textiles by Andean artisans and in the notations written down in Marx Ziegler’s manual, The Weaver’s Art and Tie-Up Book (1677). Chapter Four explains how dyes not only contributed to the distinction between social classes, such as the use of Tyrian purple by Roman emperors but also the ingenuity of humans to ascribe meaning and beauty to a variety of colors. Furthermore, the increasing and competitive trading of dyes in the 16th and 17th centuries would eventually contribute to the discovery of synthetic dyes.

Textile traders and consumers also helped to foster cultural exchanges. Postrel then highlights how traders often also served as innovators. The implementation of the Fibonacci sequence in European trading not only helped traders with bookkeeping but also gave a new perspective to the practicality of learning math by helping traders understand profits and calculate prices. Readers explore in Chapter Six how the Mongol Empire expanded across many different lands for their desire for valuable woven textiles. Under the Pax Mongolica, the textile trade flourished as the Mongols protected the Silk Road, resulting in cross-cultural and technological exchange between Europe and Asia. Lastly, in Chapter Seven, Postrel introduces synthetic polymers like nylon and polyester, where the efforts made by scientists like Wallace Carothers, Rex Whinfield, and James Dickson have revolutionized the use of textiles. Companies like Under Armour use polyester to create water-repellent clothing. Despite synthetic polymers currently being used innovatively, many still seek to look into the future of textiles. As Postrel explains, imagine your pockets can charge your phone or your hat could give you directions. The future of textiles is incredibly exciting.

As an avid writer of socio-economics, Postrel expertly showcases her knowledge of the subject. Postrel’s previous books, such as The Future and its Enemies (1998) and The Power of Glamour: Longing and the Art of Visual Persuasion (2013), cover the interconnectedness between culture, technology, and the economy. Postrel has also worked as a columnist for several news sites, is the contributing editor for the magazine Works in Progress, and was a visiting fellow at the Smith Institute for Political Economy and Philosophy at Chapman University. This book is a wonderful intellectual contribution that feels like a documentary series, perfectly threading the reader through cultures and regions like a needle through fabric.

Continue reading...

89 notes

·

View notes

Text

Bea's Cyberware: FlexxSys

More publicity stills from the Arasaka press conference, at which Bea was displayed on the stage and ordered to contort into various positions and display its use in combat.

(database template by @cybervesna, thank you to @braindancer for giving me the motivation to finally do this dang writeup)

I based her cyberware off of my own experiences with hypermobile ehlers danlos. But, I didn't want it to be magic, I wanted there to be consequences. It was implanted in her two years before the recall. By that point, she had graduated from the Academy and was in Night City as a Solo doing Arasaka's bidding.

If she hasn't protein-loaded before a gig, she will have chronic pain the next day. She also risks being unable to relocate via the cybermod and require manual manipulation. And, you can only protein-load for so long. After a week without an infusion, she will start to sublux and dislocate more frequently and have to relocate manually. The benevolent ripperdoc VIktor Vektor has given her free infusions on more than one occasion when she's been strapped for cash.

Transcript/more details below

In 2050, to compete with Rocklin's Extra-Jointed Cyberlimb and Dynalar's Extra Twist Joint Add-On, Arasaka R&D held an internal competition among junior researchers to develop a unique and innovative cyberware design. The winner would have their design tested and, if successful, added to Arasaka's cyberware portfolio. FlexxSys was the product of this competition.

The Flexible Extension System was designed to work with the user's natural musculoskeletal system. Twelve microcontrollers with spools of myoelectric nanowires were implanted into the user's major joints—the shoulder, elbow, wrist, hip, knee, and ankle—on each side of the body. A coprocessor was then implanted into the brain with another spool of myoelectric nanowiring. Once the body was sewn up, the operating system for FlexxSys, BendOS, would engage and release the nanowires. Over the next twelve hours, all spools of nanowiring would connect to every single joint in the body. Not just the major joints, every area where bone met bone and was connected via some form of collagen was now connected to BendOS allowing the user to dislocate/relocate or sublux/relocate any joint on command.

While inferior systems required artificial replacements for all joints, the FlexxSys coprocessor would monitor and manage the body's production and use of collagen. Signals along the myoelectric wires would allow each microcontroller to bypass the body's natural, genetic coding for handling collage fibers to produce more or less than needed. This prevented deterioration and chronic pain as joints would, in a sense, be self-repairing.

With less than a year of research and human testing, FlexxSys was manufactured and sold between 2051-2068. In 2068, FlexxSys was recalled after a longitudinal study found that the body would eventually rely on FlexxSys for its entire collagen production and use. After two years of usage, the body could no longer produce and use collagen on its own, leaving the user relying on FlexxSys for their joint and musculoskeletal function for the rest of their life.

As FlexxSys no longer had a backup of the body's natural process to rely on, a protein-rich diet or regular enzyme infusions were required to fuel the cyberware, without which, the user's joints would begin to dislocate or sublux more frequently without their input and relocating would be more difficult—if not impossible—using the cybermod. Without the natural source of collagen, FlexxSys's joint self-repair was less effective leading to users experiencing chronic pain and eventually needing full joint replacements.

25 notes

·

View notes

Text

Greetings yet again folks! Before today's news i should ask this: what would you think when wearable tech is mentioned? AR/VR glasses? A smart watch? a pair of fancy glasses? nfc based products or was it something else for you?

what if i tell you there is a battery that is so stretchable and bendable that can be tailored between linings of your clothes now what would you think?

Meet the age of stretchable batteries people!

in that case i should mention when people of today was so busy with nonsense politics and rightist or leftist ideas there were quite a race between the biggest tech schools and companies for manufacturing this tech such as apple, samsung, stanford, Yokohama National University, zotach (japan based wearable tech company), sydney's UNCW, Australian research comity and more.. you get the idea..

so what is this tech in its core?

basically building more softer and more long term reliable materials to replace our common daily use batteries

in term of materials it nearly uses our common li-on batteries but these are mainly works like electrodes and often use polymers, hydrogels, and other flexible materials for electrodes and electrolytes. we can see in recent inovations include the use of stretchable conductors like gold nanowires or carbon nanotubes.

BUT what these mambo, jambo, wombo, combo means for public eye?

much longer active use time, higher adaptability, flexible form factor yet lower energy and power density.

for now this tech has been used in certain medical implant cases, wearable techs, tv's, and watches for now but there is some attempts to imply this in to textile industry recently..

and japan is seems like ahead of the race for now with Zotac’s VR GO 4.0 backpack

this is a backpack pc and its power source is tailored between in entire foam/ fiber pad. this "pc" is specifically made for VR/AR and streaming which includes

11th Gen Intel Core Mobile i7-11800H processor, an NVIDIA RTX A4500 graphics card with 20GB of GDDR6 memory and 7,168 CUDA cores, 16GB (32GB maximum) of DDR4 RAM, an M.2 slot for storage, a 2.5′ SATA 3 hard drive/SSD bay for storage, three USB 3.1 Type-A ports, a single USB 3.1 type-C port, DisplayPort, and a 12V DC outlet, all powered by dual 86.4 watt-hour hot-swappable batteries.

like i said this tech is still under developement stage and people still trying to make this tech better than other compettitives...

time will show us what will it gonna be turn out at the end..

lastly.. see you guys tomorrow...

sources:

https://onlinelibrary.wiley.com/doi/10.1002/adma.202204457

#tech#tech news#daily news#cyberpunk#future tech#scifi tech#research#rnd#r&d#battery#stretchable battery#apple#stanford#samsung#labs

11 notes

·

View notes

Text

Project Blue Beam

Nasa has been working on aircraft that are real, but will become a part of the Global Holographic Alien Invasion/Light show. This may also include a staged 2nd coming of historical fugures; such as Jesus or Mohammed or Krishna.

BLUE BEAM Has 4 Steps:

Step 1

The first step concerns the breakdown of all archaeological knowledge. It deals with staging earthquakes at certain precise locations around the planet where supposed new "discoveries" will finally explain that the meanings of the basic doctrines of all the world`s major religions are wrong. This falsification will be used to make the population believe that all religious doctrine has been misunderstood and misinterpreted. For example, in the entertainment/movie industry, a falsification started with the film(s) 2001: A Space Odyssey, the TV-series Star Trek, the Star Wars films, and E.T., all of which deal with space invasion and protection. Another movie example is Jurassic Park which was released to push the Theory of Evolution.

Step 2

The second step deals with the gigantic space show: 3D optical holograms and sounds, laser projections of multiple holographic images in different parts of the world, each receiving a different image, according to its predetermined original national religious faith. This new "god" image will talk in all languages. As an example, the Soviets have manufactured the advanced computers and have programmed them with the Minute Psychological Particles based upon their studies of the anatomy and biology of the human body, as well as their studies on the anatomy, chemistry and electricity of the human brain. These computers have also been fed with the different languages of the world.

Step 3

The third step deals with telepathic electronic two-way communication, where ELF(Extra Low Frequency), VLF (Very Low Frequency), and LF (Low Frequency) waves will reach the people of the Earth through the insides of their brains, making each person believe that his own God is speaking to him from within his own soul. Such rays, from satellites, are fed from the memory of computers that store much data about the human being and his languages. These rays will then interlace and interweave with the natural thinking processes to form what is called Artificial Talk.

Step 4

The fourth step involves universal supernatural manifestations using electronic means. This step contains three different orientations:

The first one is to make mankind believe that an Alien Invasion is about to occur upon every major city on the earth. This is to push each major nation into using its nuclear capability to strike back. In this manner, it would put each of these nations in a state of full disarmament before the United Nations after the false attack.

The second is to make the vast Christian population believe that a major rapture is occurring, with a simple, orchestrated, divine intervention of an alleged "good" alien force coming to save the good people from a brutal satanic attack. Its goal is to get rid of all significant opposition to the New World Order.

The third orientation is a mixture of electronic and supernatural forces. The waves or frequencies used at that time will allow supernatural forces to travel through fiber optics cable, coaxial cable, electric and telephone lines in order to penetrate all electronic equipment and appliances that will by then all have a special microchip installed. The goal of this step deals with the materialization of satanic ghosts, spectres, and poltergeists all across the globe in order to push all populations to the edge of a wave of suicide, killing and permanent psychological disorder. After that night, humanity is believed to be ready for them to enter in a "New" Messiah to re-establish peace everywhere at any cost, even at the cost of their freedom.

32 notes

·

View notes

Text

Prints and Patterns

A light on Prints & Patterns.

The patterns on a fabric just put colors on are definitely not woven into fabric. called Prints. These are found in several types like, customized shapes, colors, lines, etc. and in the form of objectives as well. The work of art made in multiple iterations, created through a transfer process. The word “Print” is derived from the Old French word for “Impression,” it makes a product look different from its own origin. It has the power to grasp the attention of someone towards it. When prints and patterns work together it gives a hard on its final project. Nowadays, people are using most commonly made from an acrylic polymer.

Why are Prints important?

Printing is used not merely for books and newspapers but as the time flies it is also used for textiles, plates, wallpaper, packaging, and billboards. Several studies have concluded that people simply absorb content better when it's presented on a page, rather than a screen. This is why some college students are reluctant to use PDF versions of their textbooks; reading printed material somehow allows for higher brain function and better information retention. These designs can be simple or super detailed, but they all have the same goal: to make the fabric look even more amazing! Due to some eye-catching prints and patterns, clothes become more appealing to customers, grabbing their attention and making them want to take a closer look. Printing on fabric plays a crucial role in the fashion industry, being a method for applying designs, patterns, or images to fabrics. Textile printing offers a wide range of design options, allowing clothing manufacturers to create a variety of unique Styles, Prints and Patterns, and Colors of Fashion.

Why are Patterns important?

In the garment industry, patterns are used in order to cut the fabric pieces and to make the garment. Patterns are essentially made so that the same style can be easily duplicated when it is needed and multiple pieces can be efficiently made. Improved quality: Patterns can help to ensure that garments are made to the desired specifications, which can lead to improved quality and customer satisfaction. Prints and Patterns making is the process of creating a blueprint of your garment. A pattern is used as a template to cut out fabric that matches the required specifications to sew a garment. Its factors in the type of fabric, the intended fit on the wearer, and any trims that will be used. Prints and Patterns on a fabric makes a plain to be creative.

Final product as printed fabric?

Generally, the finishing process includes three basic stages: washing and drying, stabilizing, and pressing. In addition, some fabrics are then treated to make them anti-static, water repellent, or flame retardant. Many methods applied to fabrics in these stages are very specialized and we can't discuss them all. Definitely, after applying Prints and Patterns on chic indicates customization of fabric then that fabric is processed further for next processes like cutting and stitching.

Addition of Tie & Dye in fabric:-

Tie & Dye is a term used to describe a number of resist dyeing techniques and the resulting dyed products of these processes. The process of tie-dye typically consists of folding, twisting, pleating, or crumpling fabric or a garment, before binding with string or rubber bands, followed by the application of dye or dyes. Textile printing is the process of applying color to fabric in definite prints and patterns or designs. In properly printed fabrics the color is bonded with the fiber, so as to resist washing and friction. In golden era, people were using natural objects to paint the garments i.e. Leaves, Vegetables, Stones, etc. Nevertheless, Tie and Dye fabrics are included in Rajasthani cultural traditions. Moreover, due to Social media, people are connecting globally and sharing their ideas of painting, prints and patterns to give an elegant look to their final outfits.

Prints and its historical background:-

Printing blocks have been discovered that date back to around 3000 B.C." Fabric painting remained popular on the continent, and by the time Alexander the Great invaded India (327 B.C.), fabrics full of colorful printed and painted images were a normal possession among the people. There are several thighs to disclose about the past of prints but our main topic is just for the usage of prints and patterns.

Motifs and Prints:-

A motif is a repeated idea, pattern, image, or theme. In the textile arts, a motif is also called a block or square which is a smaller element in a much larger work. Motifs can be any size, but usually all the motifs in any given work are the same size. There are types of motifs which are defined as:

Symbolic Motifs: These motifs take the form of symbols that represent a larger idea or theme.

Conceptual Motifs: These motifs are built around a particular concept or idea that recurs in the story.

Structural Motifs: These motifs are repeated patterns or structures in the story.

Types of Prints in fabric:-

There are several types of the prints and patterns in the fabric but the majorly are in used are mentioned ahead:-

Boho Prints:- Boho style is a free-spirited aesthetic that mixes different cultures and artistic expressions into an eclectic style with an emphasis on organic elements and nature. When putting together your boho style space, mixing patterns, metals, woods, materials, animal hides and trinkets from your travels is highly encouraged.

Screen Prints:- Screen Printing is a process where ink is forced through a mesh screen onto a surface. Making certain areas of the screen impervious to printing ink creates a stencil, which blocks the printing ink from passing through the screen. The ink that passes through forms the printed image.

Block Printing:- A printing block is sometimes called a printmaking block, a wood block or a block. You can also refer to one simply as a printing block.

Animal Printing:- Animal print is a clothing and fashion style in which the garment is made to resemble the pattern of the skin and fur, feathers or scales of animals such as a leopard, zebra, giraffe, tiger or cow.

Batik Prints:- Batik is an Indonesian technique of wax-resist dyeing applied to the whole cloth. This technique originated from the island of Java, Indonesia. Batik is made either by drawing dots and lines of wax with a spouted tool called a canting, or by printing the wax with a copper stamp called a cap.

Rest there are several prints and patterns which can be used by us, on a daily basis but we are not aware about it. But we should know which prints are suitable for your eyes and your comfort. Rest we are always here to help you out and provide you best opinion as always.

#fashion#fashion designer#fabric#denim#accessories#fashion trends#haute couture#fashion blog#fashion inspiration#prints#art print#printmaking#artwork#art#artists on tumblr#my art#illustration#drawings#tie dye#dyeing#cotton#upcycling#bohochic#bohemian#batik#floral#flowers#roses#plants#garden

6 notes

·

View notes

Text

Things I learned in Forensic Science (off the top of my head)

Rigor Mortis isn't constant. It takes time for the body to stiffen up, the after a few hours it loosens up again.

The temperature of the body slowly lowers. The temp, combined with the stage of Rigor Mortis can give you an estimated time of death.

Some insects can smell dead bodies from about 10 miles (yes I know, wtf) away.

The insects that feed on the dead often have symbiotic relationships. (The bug friends help each other) (They are VERY gross)

Dead bodies decompose faster if 1. The humidity is high and/or 2. The temperature is high. This makes a jungle (or the ocean, I guess) the best place to hide a body.

If you want a foolproof process, the least amount of (the killer's) hairs you want is 30. You can find out who it is from fewer, though. 10 hairs is a realistic number to find and correctly assess.

When my FS teacher invited our local forensic pathologist to the school she gave us a presentation and in it she told us the two highest causes of death related to asphyxiation were 1. Erotic Asphyxiation (The scientific way to say choking kink) and 2. Hanging

You can find a killer though fiber. Fiber includes things like carpet, clothing, towels, cloth gloves, etc. As an example we were told about a person who had been found through the fibers of orange carpet on the deceased's body. The carpet was in the back of the killer's van and the manufacturer was able to give the police a list of all the people in the area who had used the orange carpet in their cars.

People (witnesses) have bad memories. Don't use a witness testimony as a bible. Things witnesses can get wrong include (but is not limited to): hair color, car color, face structure, clothes, street names, license plate numbers, skin tone & skin color, description of stolen items, etc.

Blood Spatter Patterns (yes spatter is the scientific term) can tell you A LOT. The weapon, the killer's height, the dominate hand used, the amount of struggle, and of course if some of the blood is the killer's than you know have DNA evidence. If you decide to become a Blood Spatter Analyst (yes, that is your job title) you will do A LOT of math. Especially geometry.

Usually when an innocent person's response to getting accused of murder is immediate anger. "How DARE you accuse ME of murder? I would NEVER!" A bit cartoonish of an example, but that is usually how it goes.

When someone has a different response you have to ask if it is because they are guilty, they have something to hide (related or unrelated to the current case), or if they are protecting someone. There is also the possibility the person's unusual response is due to their personality, a disability, or neurodivergence. It is up to a (key word) competent detective (or specialty interrogator) to find out why their response is different and if they need to push or if it's just how that person is.

Interrogation rooms are usually well lit, with the seat the person being interrogated sitting in, being close to the door, or at least closer than the interrogator. This is to give the person being interrogated a sense of ease, calm, safety, etc. Depending on the case and the people involved, the interrogation may be more interview style in the detective's office instead. This isn't the best practice, though, since in an office there are lots of distractions for both parties.

A well constructed interrogation room would be well lit, with light cream (not sterile white, that's uncomfortable) walls, and two chairs. The chairs should be fairly comfortable with a desk between them. The person getting interrogated's seat should be close to the door, but not facing away from it. They should have the constant reminder they can leave at any time. There should be some sort of desk or table between the seats, to give more distance (safety) and a place to write or rest your hands.

Both guilty and innocent individuals move their hands and lick their lips quite a lot. There are NO hard and fast rules to body language. It is also (technically) a pseudoscience so it can't really be used in most courts, however, it can be used in questioning or in determining how a individual feels about a topic or person. Someone being uncomfortable talking about a person doesn't mean that doesn't mean they killed them, it could mean they used to be in a relationship or they knew each other for a while. (Again, no hard and fast rules)

Handwriting is not my expertise, but I can add some things. The best handwriting to analyze is private writing someone wasn't expecting someone else to see like a journal or a grocery list. Handwriting, like body language has NO hard and fast rules.

Handwriting analysis is extremely complicated in English alone, but I can tell you that handwriting can give small insights into someone's personality, what they think of their family, their goals, their mental health, and their probability of being a violent criminal (no I'm not kidding)

Criminal Probability Example (Felon's Claw/Felon's Hook):

This is NOT A GUARRENTEE, it's just a weird similarity that SOME killers have. Also some random cashiers and actors???

#tw death#cw death#cw gore#handwriting#body language#tw sui mention#tw mention of sui#cw sui mention#cw mention of death#science#forensic science#true crime#cw blood mention#tw blood mention#animals#animals and wildlife#wildlife#wild animals#bugs#insects#entomology#math#geometry#math and science#science and math#fiber evidence#dna#dna evidence#writing#writers of tumblr

12 notes

·

View notes

Text

Textile Manufacturing Companies | Oswal Group

In the bustling industrial landscape of Ludhiana, where the clang of machinery and the hum of ambition merge, one name stands out as a beacon of excellence: The Oswal Group of Companies. Founded on a vision to redefine the textile industry in Ludhiana, Oswal Group’s journey from inception to industry leader is nothing short of inspiring.

The Genesis: The Oswal Group’s foray into the textile industry dates back to the 1960s when the visionary entrepreneur, Late Shri Rattan Chand Oswal, laid the foundation stone of what would become a textile empire. With a keen eye for opportunities and a steadfast commitment to quality, Oswal ventured into yarn production, setting the stage for the group’s meteoric rise.

Excelling in Ludhiana’s Textile Hub: Ludhiana boasts a rich heritage in textiles. In such a competitive landscape, Oswal Group didn’t just survive; it thrived. Through strategic investments in state-of-the-art technology, a relentless focus on innovation, and nurturing a skilled workforce, the Oswal Group carved a niche for itself.

The group’s vertical integration, from spinning mills to garment manufacturing, enabled streamlined operations and superior quality control. This holistic approach not only ensured consistency in product standards but also bolstered Oswal’s reputation as a reliable textile partner globally.

Moreover, Oswal Group’s commitment to sustainability has been commendable. Embracing eco-friendly practices, optimizing resource utilization, and adhering to stringent environmental regulations have not only reduced the ecological footprint but also enhanced brand credibility.

Evolution in the Textile Industry: As the textile industry in Ludhiana evolves in the digital age, Oswal Group is poised to embrace the winds of change. Embracing automation, leveraging data analytics for predictive maintenance, and integrating IoT (Internet of Things) for smart manufacturing are avenues the group can explore to enhance efficiency and productivity further.

Furthermore, investing in research and development to explore alternative fibers and sustainable manufacturing processes can bolster Oswal Group’s competitive edge. With growing consumer consciousness towards ethical sourcing and eco-friendly products, tapping into this market segment can unlock new growth avenues.

Moreover, expanding the group’s global footprint through strategic alliances and partnerships can diversify market exposure and mitigate risks associated with geographical dependencies. Collaborating with international brands for co-branded collections or joint ventures can not only enhance brand visibility but also facilitate knowledge exchange and technological advancements.

Additionally, nurturing talent through skill development programs and fostering a culture of innovation can fuel Oswal Group’s evolution. Encouraging intrapreneurship and empowering employees to think beyond conventional boundaries can lead to breakthroughs in product design, manufacturing processes, and business models.

In the tapestry of Ludhiana’s textile industry, Oswal Group’s story shines as a testament to perseverance, innovation, and resilience. From humble beginnings to scaling new heights of success, the group has not only excelled but also redefined the textile industry’s standards.

As Oswal Group embarks on the next phase of its journey, the roadmap is clear: embrace technology, foster sustainability, and nurture talent. By staying true to its core values while adapting to emerging trends, Oswal Group is poised to not just survive but thrive in the dynamic landscape of the textile industry. With each thread woven with precision and passion, the Oswal legacy continues to inspire generations, shaping the future of Ludhiana’s textile industry and beyond.

2 notes

·

View notes

Text

Chapter 217 Trivia

Can you believe it's been 25 chapters already?

The meeting Suika and Chrome call is held in the computer room, since that's the only hut with bricks. Exactly where they set up their little podiums I'm not sure, (SAL 9000 takes up most of the room) but it's convenient that the "voting machines"/the computer was right there!

"Senku Birds" is written on the presentation, which is likely a reference to the 1965 TV series Thunderbirds. It follows a group of 5 sons who pilot 5 rescue vehicles, with the goal of saving human life. The 5 vehicles are (very approximately) shaped like Chrome's rocket stages.

NASA's plans are a little more broad than just a rocket. OSAM (On-orbit Servicing, Assembly and Manufacturing) intends to build structures for future space constructs, such as larger telescopes and sunshades.

The ones who definitely know, or are implied to know, about the medusa's secrets are Senku, Tsukasa (who isn't here), Chrome, Xeno, Gen, Ryusui, and Ukyo.

Chrome says only the ones present should vote, which going by those shown in the room, are: Chrome, Suika, Xeno, Senku, Gen, Yo, Chelsea, Kohaku, Kaseki, Ryusui, and Sai, along with several random characters.

Neither group adds up to the 10 votes Sai sees, unless background characters were ignored and Sai himself didn't vote.

Or it's binary and there's only 2 votes haha!

It's no surprise that Sai managed to make a vote counter so fast, all it needs to do is add 1 to a value per vote. You'd also only need to store two values: one for total votes counted, and one for either option A or option B (subtract from the total to get the other amount).

That method doesn't even account for the fact that one CPU register holds 16 bits, which is less than the 10 votes they had, and could have been used to "count" the votes. It'd be harder to produce the final result, however.

Interesting fact, Thomas Edison's first patented invention was a voting machine meant for congress.

They didn't want it.

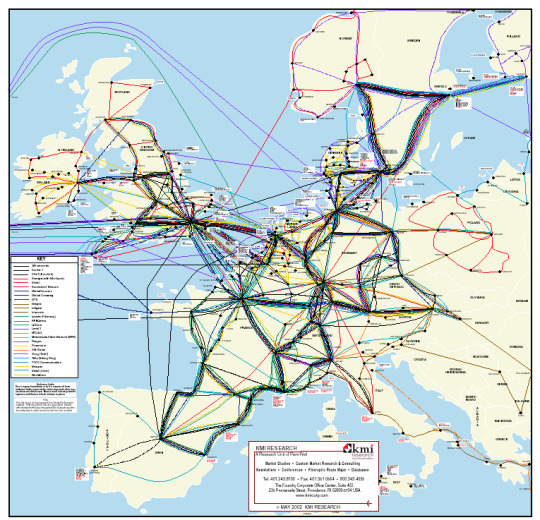

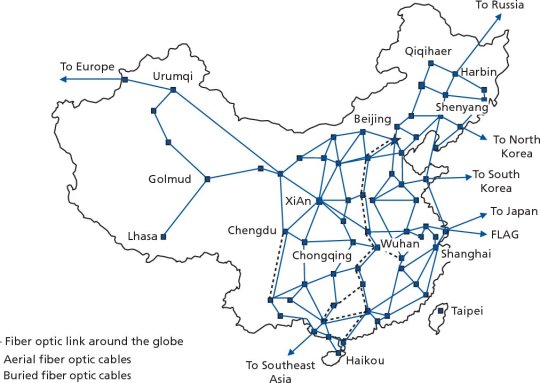

This seems to be an extreme simplification of existing fiber-optic cable networks, however the map itself is somewhat inaccurate making it hard to compare.

Very short trivia this week since there wasn't a lot of content, but soon we may have the return of (Google) Chrome!

12 notes

·

View notes

Text

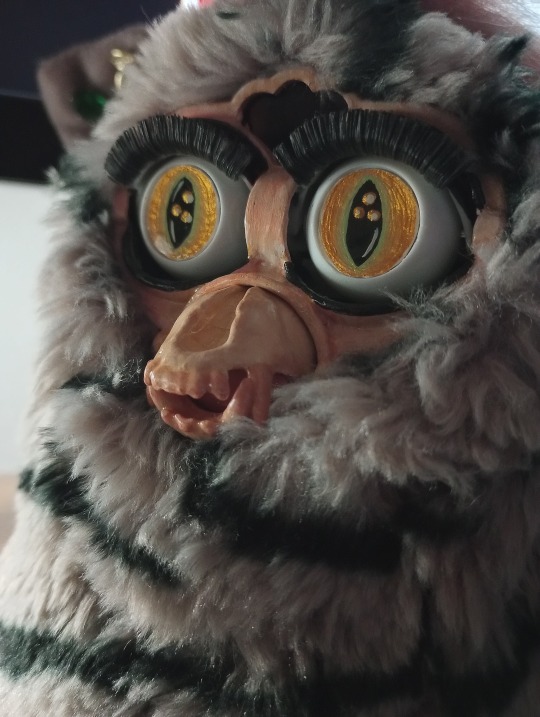

Meet Sweetums (Pt. 2)

As promised, this is my process post for the craft adventure I went on with my very first customized Furby ever!

Of course it started with skinning. As a first timer I was nervous about this first step but I quickly came to see how sturdy these things are. The screws toward the top were hard to get to but once I got it, I was able to remove the pelt!

Not pictured: I washed the pelt in lukewarm water and unscented Eucalan (a great soap for delicate things like vintage or natural fibers).

I knew I wanted to experiment with dye, and my research showed me that it would be a massive challenge. Synthetic fur is usually a polyester and acrylic blend, which is plastic. When faux fur gets colored, it’s done when the plastic is still in its liquid stage. Once it becomes the dry soft fur, it can no longer accept much color. Rit makes a great line of dyes for synthetics that are specially formulated for this, but I knew going in that I would still get limited results. This dye needs to be used on the stovetop with hot water. Faux fur can’t be exposed to that kind of heat because it will damage or even melt the fibers. Furby pelts also still have the plastic mask attached which could melt. Because of this, I would be using the dye in warm water, not hot - hence the limited results

Here’s the Rit I used. I mixed these three colors to attempt to get a reddish orange autumn-like color.

I actually had to dye the pelt twice because 24 hours in the mixture did almost nothing. The second time I only soaked it for 4 hours but I diluted the dye way less. In the photo below you can see how the fur is rejecting the dye.

While the pelt was soaking in the dye, I got to work on removing the beak. You’re supposed to just be able to slide that metal bar in their face out, but mine wouldn’t budge no matter what I did. I even removed the outer shell to try to get at pieces around it, but no such luck (this is why everything is open in the next few pictures). I had a custom beak I wanted to use, so the original had to come off one way or another. It took forever, but I sawed away at it with an X-Acto knife until I was able to get the beak off in pieces.

Next came the eyes. I used the well known hot glue trick where you melt the ends of glue gun sticks with a lighter, attach them to the eyes, freeze it for a little while, and then yank the eye chips out. This process worked beautifully first try and got me some of my favorite Furby pictures I’ve ever taken:

I had lots of time while the pelt was being dyed so I finished up my custom eyes. There were some really cool options on Etsy but ultimately I decided that I wanted to make my own. I traced the old eye chips onto thick mixed media paper and painted my own design with acrylic paint. Then I coated it with resin and cured it with UV light. I had a UV resin pen that I used for this. It actually didn’t work super well, the pre-mixed resin in the pen wasn’t blended well at manufacturing (is the conclusion I came to after some research) so it didn’t cure properly. It had this tacky feel to it. I had this problem all over this project, which I solved by giving everything I had painted (eye chips, eye lids, mask, beak, and tongue) a top coat of clear nail polish lol.

I also used my own waterproof mascara on her lashes. Slay.

I cut the eyes out with scissors and you can see it’s not quite perfect. Not horrible for being done by hand though! It doesn’t bother me on the finished Furby.

I painted the custom beak too. I linked it in my previous post, but I’m going to again because I can’t praise this beak from DuctTapeStuck on Etsy enough. Besides the really cool skull design, the best thing about this beak is how it has open hooks in the back. The original Furby beak has plastic that surrounds that metal bar as a closed ring, meaning that the bar has to be able to come out in order for it go on at all. Like I mentioned before, the bar on my Furby was not moving. But because DuctTapeStuck’s beak has open hooks in the back, I was able to get it onto that bar with it still on the Furby. It was a very tight fit, especially because I still had the tongue on the bar, but it was possible and that’s what matters!

By this time, the pelt was as dyed as it was ever going to get. I definitely lost control of the color but considering I was dying a synthetic under the wrong conditions, I decided that any change at all would be a good change. After I rinsed it, the body was a brownish purple and the mane was a light pink.

I pressed all the water out of the pelt with a towel and air dried it outdoors. After that, the shell and the pelt went back on and Sweetums was complete!

The earrings were some old things I found my jewelry box that I never really open. I’m glad someone is getting use out of my old stuff haha!

And that’s Sweetums! I had some challenges along the way but it was really fun solving the problems I came across. I’d really love to do more of these in the future!

27 notes

·

View notes

Text

We installed a very beautiful and grand 51 feet tall Shiva statue made with high quality FRP material at Pokhara Nepal

#fiber wedding stage#fiber statue manufacturer#gazebo manufacturers in india#frp planters manufacturers#grc jali manufacturer

1 note

·

View note

Text

Lululemon

Worker Wage - ★★☆☆☆

Based on the available information, we have found that Lululemon salaries in the US range from $8-$24.15, which is 9% below the national average. While Lululemon does not publish information on the wages of garment workers, outside sources state that the factory workers, who produce Lululemon’s garments, claim to be paid $110 a month in Bangladesh.

Working Conditions - ★☆☆☆☆

Their clothing is produced in Canada, the US, Peru, China, Bangladesh, Indonesia, India, Israel, Taiwan, South Korea, Malaysia, Cambodia, Sri Lanka, Vietnam, and Switzerland. Lululemon’s outsourced labor has raised questions in the past as to the treatment of the garment workers. In an investigation conducted by The Guardian, the workers claim to have been physically assaulted, verbally abused, and forced to work overtime, while making significantly less than the living wage.

Sustainable Materials - ★★☆☆☆

Lululemon says they aim to source more sustainable raw materials and fibers including recycled and renewable and recycled polyester and nylon. They aim to achieve at least 75% sustainable materials by 2025. Currently, they use low quantities of cotton and recycled materials. According to changingmarkets.org, Lululemon uses 23,390 tonnes of synthetics and 62% synthetic fibers in the production of their garments.

Environmental Impact - ★★★☆☆

On Lululemon’s website, they stress the company's aim towards reducing their carbon footprint by “eliminating waste and closed-loop innovation, making progress toward clean water and better chemistry”. Their website also stresses their goals such as reducing 60% of emissions in all owned and operated facilities and across their global supply chain. They intend to progress toward their goal by sourcing renewable energy, partnering with their manufacturers, and sourcing more raw sustainable materials. They have also joined THE CLIMATE GROUP’S RE100, signed the UN Fashion Industry Charter for Climate Action. There is no evidence of Lululemon reducing their carbon emissions during the logistics stage of exportation.

Social Impact - ★★★☆☆

In 2022, Lululemon announced they would be donating $75.3 million to the BC Parks Foundation to support environmental preservation and habitat conservation efforts in British Columbia.

Inclusivity - ★★☆☆☆

Sizes at Lululemon range from XS-XXL, and model diversity does not reflect diverse sizing. Prices tend to be on the higher end.

Sources:

https://shop.lululemon.com/

#lululemon#sustainability#fashion#2 star worker wage#1 star working conditions#2 star sustainable materials#3 star environmental impact#3 star social impact#2 star inclusivity

8 notes

·

View notes

Text

What is Melange Yarn? How Many Types of Melange Yarn are there?

How Do We Manufacture Melange Yarn?

Melange yarn is either made out of mixing 2 or more different kinds of fibers or by mixing 2 or more colors of the same fibers. The mixing of the fibers commonly takes place before the spinning process. The fibers such as cotton, polyester, viscose and modal are mixed in different ratios according to the desired result. Same fiber of different colors are mixed to get the desired dual tone color.

All About Melange Fabric

Melange fabric is made in the knitting process by knitting the melange yarn. The second method to make the melange fabric is by knitting 2 different types or colors of yarn together. Melange Fabric is also called heather fabric. Wholesalers and Retailers buy t-shirts in bulk made out of melange fabric. Below learn about types of melange yarn.

Learn About Different Types of Melange Yarn

Blended Melange Yarn: This type of melange yarn is made out of 2 different types of fibers. Fibers like cotton, polyester, viscose or modal are blended together before the spinning stage. Different ratios are taken according to the desired result.

Non-Blended Melange Yarn: This yarn is made by mixing different colors of the same fiber together. The fibers are mixed before the spinning stage in different ratios according to the desired dual tone.

Tri-Blend Melange Yarn: This yarn is made out of 3 fibers. The fibers are mixed in a particular ratio such as Polyester:Cotton:Viscose 33:33:34. The mixing takes place in the same way as blended before the spinning process. The dyeing takes place once the fabric is made out of it.

Modal Melange Yarn: Modal Melange Yarn is made out of modal fibers of different colors mixed together before the spinning stage. The modal fibers are made out of modal trees. Modal trees are found near the seashore.

Viscose Melange Yarn: This yarn is manufactured using different colors of viscose fiber. These fibers are mixed before the spinning stage. These different colors of fiber are combined in a particular ratio according to the desired color and dual tone desired.

#textile#manufacturing#textiles#yarn#clothing#pattern#business#dyeing#knitting#fiber art#clothes#apparel#sewing#weaving#fiber#world cup#iraq war

2 notes

·

View notes

Text

Creating a Formula 1 car is a complex and meticulous process that involves a series of steps to transform initial sketches into a fully functional racing machine. Here's a breakdown of how new F1 cars come to life, from conceptualization to reality:

1. Conceptual Design: The journey starts with the conceptual design phase. Engineers, aerodynamicists, and designers collaborate to develop the initial sketches and digital models of the car. These designs take into account aerodynamics, performance requirements, and regulations set by the FIA (Fédération Internationale de l'Automobile).

2. Computational Fluid Dynamics (CFD): Once the initial design is established, it undergoes extensive analysis using computational fluid dynamics. This process involves running complex simulations to evaluate how air flows over the car's surfaces, including the wings, bodywork, and other aerodynamic elements. CFD helps optimize the car's aerodynamic efficiency and stability.

3. Wind Tunnel Testing: After the CFD stage, the car design moves to wind tunnel testing. Scale models of the car are created and subjected to various wind speeds to validate the aerodynamic performance. Data collected during wind tunnel testing aids in refining the design to achieve optimal downforce, drag reduction, and overall balance.

4. Chassis Construction: Simultaneously, the car's chassis is constructed. Formula 1 chassis are typically made using carbon fiber composites, offering high strength and low weight. These monocoque structures are engineered with utmost precision, ensuring driver safety and vehicle rigidity.

5. Power Unit Development: Alongside chassis construction, the power unit undergoes development. Formula 1 engines are hybrid power units, consisting of a highly efficient internal combustion engine coupled with energy recovery systems (ERS). Engine manufacturers work on enhancing power output, fuel efficiency, and reliability while adhering to strict regulations.

6. Mechanical Components and Systems Integration: Mechanical components such as the suspension, gearbox, brakes, and steering system are integrated into the chassis. The team works tirelessly to ensure seamless compatibility between these elements and the car's overall design.

7. Electrical and Electronics Integration: Formula 1 cars are equipped with advanced electrical and electronic systems, including control units, sensors, telemetry systems, and data acquisition tools. These components are integrated to enable real-time data monitoring, performance analysis, and system control.

8. Testing and Development: Once the car is assembled, it undergoes extensive testing and development. On-track testing sessions, such as pre-season testing and private tests, allow teams to collect crucial performance data, optimize settings, and refine the car's overall setup.

9. Production and Manufacturing: With the design and development phase complete, the production and manufacturing phase begins. The final version of the car is meticulously manufactured, with various components being mass-produced or custom-made to the team's specifications.

10. On-Track Debut: Finally, the new Formula 1 car is ready for its on-track debut. Teams unveil their cars at launch events, showcasing the culmination of months of hard work, engineering expertise, and cutting-edge technology. The car's performance and reliability are evaluated during testing and fine-tuned further as the season progresses.

In summary, the process of bringing a new Formula 1 car to life involves conceptual designing, computational analysis, wind tunnel testing, chassis construction, power unit development, mechanical and electrical integration, testing and development, production, and finally, its on-track debut. Each step is crucial in creating a competitive and technologically advanced racing machine that can thrive in the highly demanding world of Formula 1.

11. Ongoing Development: The development of a Formula 1 car is not a one-time affair. Throughout the season, teams continuously work on improving their cars. They analyze performance data, gather feedback from drivers, and identify areas for enhancement. This ongoing development process involves iterative design changes, adjustments to aerodynamic components, and upgrades to the power unit to optimize performance and reliability.

12. Fine-tuning and Optimization: Formula 1 teams employ an army of engineers, mechanics, and specialists who work tirelessly to fine-tune every aspect of the car. They focus on areas like suspension geometry, tire management, brake balance, and aerodynamic configurations to maximize performance on different circuits and under varying weather conditions. Constant optimization ensures that the car remains competitive and adaptable to different racing scenarios.

13. Compliance and Safety Testing: Formula 1 cars must adhere to strict technical regulations set by the FIA. To ensure compliance, the cars undergo thorough inspections to verify that they meet all safety and performance requirements. These inspections encompass elements like crash tests, weight measurements, fuel flow restrictions, and technical inspections to certify that the car is fit for racing.

14. Feedback from Drivers: Formula 1 teams work closely with their drivers, who provide crucial feedback on the car's performance, handling, and feel. This collaboration helps engineers understand the dynamics and characteristics of the car, enabling them to make targeted improvements to suit the preferences and driving style of each driver.

15. Continuous Innovation: Formula 1 is a highly competitive sport, and teams strive for constant innovation to gain an edge over their rivals. Engineers explore new materials, technologies, and manufacturing techniques to enhance the car's performance. From aerodynamic advancements to novel energy recovery systems, Formula 1 serves as a platform for groundbreaking innovation that often trickles down to road car technology.

16. Evolving Technologies: As new technologies emerge, Formula 1 teams explore their incorporation into the cars. Hybrid power units, advanced data analytics, and cutting-edge simulation tools are a testament to the sport's commitment to pushing technological boundaries. Formula 1 stands as a proponent for sustainable engineering, where the pursuit of performance goes hand in hand with environmental responsibility.

In conclusion, the journey of bringing a new Formula 1 car to life doesn't end with its initial creation. It involves ongoing development, optimization, compliance testing, driver feedback, and relentless pursuit of innovation. This process ensures that Formula 1 cars are not only at the forefront of motorsport engineering but also serve as catalysts for technological advancements throughout the automotive industry.

Designing and building a new Formula 1 car for a new season is a complex and time-consuming process that involves a combination of engineering, design, and aerodynamics. While the exact timeline can vary depending on the team and the resources available, it generally takes several months to design and manufacture a new F1 car.

The process typically begins well in advance, often around 12 to 18 months before the start of the new season. This allows teams to conduct research and development, make design decisions, and develop strategies based on the previous season's performance and regulations changes.

Here is a general overview of the steps involved:

1. Concept Design: F1 teams start with conceptualizing the new car's design. This involves considering various factors such as aerodynamics, engine performance, chassis design, and weight distribution. Teams utilize computer-aided design (CAD) software, wind tunnel testing, and simulations to refine their designs and calculate the optimal performance characteristics.

2. Manufacturing: Once the design is finalized, teams move onto the manufacturing phase. Chassis construction, suspension systems, engine and gearbox assembly, electronics, and other components are manufactured or sourced from specialized suppliers. Advanced composite materials, such as carbon fiber, are extensively used to ensure lightweight and high-strength construction.

3. Testing and Iteration: As components are manufactured and assembled, teams conduct testing to evaluate their performance. This involves aerodynamic testing in wind tunnels, computer simulations, and on-track testing using prototypes or previous season's cars. These tests provide invaluable data to refine and optimize the car's performance.

4. Development and Production: Teams continue to develop and improve the car even after the start of the season. They strive to identify weaknesses, enhance performance, and adapt to any rule changes or developments discovered during early races. Teams can introduce upgrades and modifications throughout the season to enhance their car's competitiveness, within regulatory limitations.

Regarding how "new" a new F1 car is, each season brings a set of technical and regulatory changes. Formula 1's governing body, the FIA, introduces new regulations to ensure fair competition and improve safety. These regulations outline broad guidelines for car dimensions, weight, engine specifications, aerodynamics, and more. While teams do carry over some elements from the previous season's car, like the power unit (engine), the majority of the car is redesigned to comply with the new regulations and to improve performance. As a result, even though the term "new" is used, it implies a significant overhaul of various components to adapt to the evolving rules and maintain competitive advantage.

Additionally, the design and development of a new Formula 1 car involve a high level of secrecy and confidentiality. Teams strive to keep their innovations under wraps and conduct extensive research and simulations to gain a competitive edge.

A major aspect of the design process revolves around aerodynamics. The intricate bodywork, wings, and other aerodynamic features are meticulously designed to generate downforce and minimize drag, allowing the car to maintain high speeds and maneuverability through corners. The teams' aerodynamicists employ advanced computational fluid dynamics (CFD) simulations and wind tunnel testing to optimize the car's aerodynamic performance.

The engine, an essential component of an F1 car, plays a critical role in its performance. The power units are developed by the engine manufacturers, often in close collaboration with the teams. The engine teams focus on enhancing power output, efficiency, reliability, and fuel consumption within the limits set by the regulations.

Teams also invest significant resources in the development of electronic systems, such as the on-board telemetry and control systems, to collect and analyze data during races. This data aids in making real-time decisions and improving performance through fine-tuning the car's setup.

The final production of a new F1 car involves meticulous assembly, integrating all the components and systems. As the season approaches, teams conduct comprehensive testing to verify the car's performance, reliability, and safety.

It's worth noting that the development of an F1 car is an ongoing process throughout the season. Teams continuously work on improvements and upgrades to enhance performance and overcome any deficiencies. These upgrades can range from small adjustments to major changes in components or aerodynamic features.

In conclusion, designing and building a new F1 car for a new season is a complex and time-intensive endeavor. It involves an amalgamation of engineering expertise, aerodynamic design, manufacturing precision, and relentless testing. The term "new" refers to significant redesigns and modifications to adapt to evolving regulations and improve performance, positioning teams for a competitive edge in the dynamic world of Formula 1 racing.

1 note

·

View note