#Industrial Refrigeration Systems Market Size

Text

Industrial Refrigeration Systems Market Size, Share & Trends Report, 2030

Industrial Refrigeration Systems Market Growth & Trends

The global industrial refrigeration systems market size is anticipated to reach USD 27.66 billion by 2030, registering a CAGR of 4.4% from 2023 to 2030, according to a new report published by Grand View Research, Inc. The demand for industrial refrigeration is increasing due to the fast-moving consumer goods and retail food which needs efficient storage for perishable edible items. Governments are taking initiatives to support and strengthen the cold chain infrastructure and shifting towards eco-friendly refrigeration systems.

Global warming and climate change have alarmed nations to take the necessary step to curb the crisis. As a result, industrial refrigeration system manufacturing companies have expressed concerns regarding the potential of global warming and ozone depletion of their refrigerants. As a result, companies are focusing on technologies to offer improved cost-effectiveness, lesser toxic refrigerants, lower energy consumption, and less toxic materials.

For instance, DanFoss, a prominent manufacturer of industrial refrigeration systems, introduced Cool selector 2 to help them design and optimize their air conditioning and refrigeration systems. System designers, engineers, and consultants can use the software to make optimum use of energy and HVACR systems. The benefits of using CO2 refrigeration systems are recognized worldwide as CO2 has a GWP (Global Warming Potential) of 1. The new update allows you to calculate components from the standpoint of an application for transcritical high-pressure side systems.

With the advancements in technology, industrial refrigeration systems have shown enhancement in their processes. Innovations have led to the manufacturing of smart and intelligent devices that monitor, set temperature, and notify the person as and when needed. The incorporation of Artificial Intelligence (AI) in the systems became a breakthrough in the market by enhancing productivity and lowering the operational cost for the organizations.

The industry growth in Asia Pacific is anticipated to observe the fastest growth during the forecast period. This expansion is attributed to the rapid growth prospects of cold-chain storage infrastructure in the countries such as Japan, India, and China. For instance, India is the second-largest fruit and vegetable producer, worldwide. The cold storage and handling the refrigeration of this huge vegetable and fruit produce is a challenging job thus fueling the market growth.

Request a free sample copy or view the report summary: https://www.grandviewresearch.com/industry-analysis/industrial-refrigeration-systems-market

Industrial Refrigeration Systems Market Report Highlights

The compressor segment is the largest growing component in the refrigeration system as they are used in commercial as well as industrial refrigeration, heat pumps, and air conditioning applications

Food and beverage applications accounted for the largest market share due to the growing disposable income and the rising population. It has augmented the demand for frozen and processed food products

The 500-1000kW capacity segment led the industrial refrigeration systems market as they helped extend the shelf life and reduce product wastage

Asia Pacific is the highest-growing region in the market due to the maximum number of fruits and vegetable producers and also a requirement for cold-chain storage

Industrial Refrigeration Systems Market Segmentation

Grand View Research has segmented the global industrial refrigeration systems market market based on component, capacity, refrigerant, application, and region

Industrial Refrigeration Systems Component Outlook (Revenue, USD Million, 2018 - 2030)

Compressors

Rotary Screw Compressor

Centrifugal Compressor

Reciprocating Compressors

Diaphragm Compressors

Others

Condensers

Evaporators

Controls

Others

Industrial Refrigeration Systems Capacity Outlook (Revenue, USD Million, 2018 - 2030)

Less than 100kW

100-500kW

500-1000kW

1000-5000kW

More than 5000kW

Industrial Refrigeration Systems Refrigerant Outlook (Revenue, USD Million, 2018 - 2030)

Ammonia

Carbon Dioxide

Hydrofluorocarbon

Hydrochlorofluorocarbons

Others

Industrial Refrigeration Systems Application Outlook (Revenue, USD Million, 2018 - 2030)

Refrigerated Warehouse

Food & Beverage

Chemical Petrochemical & Pharmaceuticals

Refrigerated Transportation

Industrial Refrigeration Systems Regional Outlook (Revenue, USD Million, 2018 - 2030)

North America

S.

Canada

Europe

Germany

K.

France

Italy

Spain

Asia Pacific

Japan

China

India

South Korea

Australia

Latin America

Brazil

Mexico

Middle East and Africa

Saudi Arabia

South Africa

List of the Key Players in the Industrial Refrigeration Systems Market

Johnson Controls

Emerson Electric Co

Dan Foss

DAIKIN Industries Ltd.

GEA Group Aktiengesellschaft

MAYEKAWA MFG Co. Ltd.

BITZER

EVAPCO Inc.

Guntner GmbH & Co. KG

LU-VE S.P.A

Browse Full Report: https://www.grandviewresearch.com/industry-analysis/industrial-refrigeration-systems-market

#Industrial Refrigeration Systems#Industrial Refrigeration Systems Market#Industrial Refrigeration Systems Market Size#Industrial Refrigeration Systems Market Share

0 notes

Text

What Are Most-Significant Applications of Industrial Refrigeration Systems?

The ongoing COVID-19 pandemic has put the spotlight on the global healthcare ecosystem, as many of the myths about how advanced the medical infrastructure around the world is were busted. With the case and death counts rising, the industry was caught gasping for breath (metaphorically), while the patients were literally gasping for breath (COVID is a lung infection). During this time, the number of research studies being conducted in the pharmaceutical and healthcare sectors on virology skyrocketed, as a vaccine was to be the leader of the charge against the pandemic.

Therefore, the number of clinical trials being conducted for viral vaccines rose massively, as did the worldwide trade of vaccines, aided by several such products getting regulatory approvals. With the healthcare and pharmaceutical sectors expected to not drop their guard for many years to come, the industrial refrigeration systems market size, as calculated by P&S Intelligence, is predicted to increase to $41.1 billion in 2030 from $26.8 billion in 2019, at a 5.0% CAGR between 2020 and 2030.

This is because an efficient, unbroken cold chain is essential for drug development and trade. Refrigerators are not only used to store and transport the final pharmaceutical products but also for the storage and transportation of the raw materials. Pharmaceuticals, biosimilars, excipients, active ingredients, tissues, and blood products are extremely sensitive to heat; therefore, effective cooling is necessary to protect them from damage and make them viable for use over a long time.

Another sector where refrigeration is important for the same reason is food and beverage. Most agricultural products spoil in the heat, which is why keeping them in cool conditions is paramount. Several of the processed food packages carry the directions “store in a cool and dry place”. In food processing factories, the ingredients, intermediate goods, and final products must be refrigerated to increase their shelf life. Thus, with the rising disposable income allowing people in developing countries to purchase processed food, the demand for industrial-grade refrigerators among food and beverage companies is surging.

Other industries where refrigeration is vital are oil and gas, construction, and manufacturing. Since, the food and beverage sector has been the largest user of such systems, their sales have been the highest in Asia-Pacific (APAC). Home to the largest number of people in the world, APAC has the most-productive food and beverage industry. India is already home to the fifth-largest processed food industry, which continues to garner extensive government support. “…the food processing sector in India has received around US$ 7.54 billion worth of Foreign Direct Investment (FDI) during the period April 2000-March 2017.”, says the India Brand Equity Foundation (IBEF).

Moreover, recently, the Indian government announced plans to establish 40 mega food parks, which are essentially integrated manufacturing districts for the food and beverage sector. With this, the industrial refrigeration systems market is poised for strong growth, with such equipment being important in this industry. Moreover, Invest India expects the country’s food processing sector to value more than $500 billion by 2025, which reflects a consistently growing demand for processing equipment.

Hence, with the pharmaceutical and food and beverage production growing, the procurement of industrial-grade refrigerators will escalate too.

#Industrial Refrigeration Systems Market Share#Industrial Refrigeration Systems Market Size#Industrial Refrigeration Systems Market Growth#Industrial Refrigeration Systems Market Applications#Industrial Refrigeration Systems Market Trends

1 note

·

View note

Text

Industrial Refrigeration Systems Market Segmented On The Basis Of Component, Capacity, Application, Region And Forecast 2030: Grand View Research Inc.

San Francisco, 29 Sep 2023: The Report Industrial Refrigeration Systems Market Size, Share & Trends Analysis Report By Component (Compressors, Condensers, Evaporators, Controls, Others), By Capacity, By Application, By Region, And Segment Forecasts, 2023 – 2030

The global industrial refrigeration systems market size is anticipated to reach USD 27.66 billion by 2030, registering a CAGR of 4.4%…

View On WordPress

#Industrial Refrigeration Systems Industry#Industrial Refrigeration Systems Market#Industrial Refrigeration Systems Market 2023#Industrial Refrigeration Systems Market 2030#Industrial Refrigeration Systems Market Revenue#Industrial Refrigeration Systems Market Share#Industrial Refrigeration Systems Market Size

0 notes

Text

Industrial Refrigeration System Market: Global Industry Trends, Share, Size, Growth, Opportunity and Forecast 2022-2028

Global Industrial Refrigeration System Market was valued at USD 20.21 Billion in 2021 and is expected to reach USD 26.96 Billion by the year 2028, at a CAGR of 4.2%.

Refrigeration is utilized to remove excess heat from a substance. The modern industrial processes in the various end-use sectors such as food and chemicals are managed by accurate process conditions and temperature is an important parameter in any process. The industrial refrigeration system has a prominent role in maintaining the stability of the overall industrial process and directly influence the quality of the end product. Additionally, refrigeration act as a major role in industry and society. As freezing inhibits microbiological growth, decreasing chemical reactions and delaying physical transformations, it is possible to preserve food, maintaining its quality without wasting, during long storage periods. This capacity is essential for the increasingly demanding modern society. Furthermore, energy can neither be created nor be destroyed and it is transformable from one form to another. Heat is a form of energy that travels owing to the difference in temperature. It transfers from the warmer to the cooler object. There are different refrigerants which are chemicals that are precipitated into the liquid form. They extend into vapor and extract the heat from the surrounding area.

The global Industrial Refrigeration System market research investigates the market in-depth and offers a comprehensive analysis of the major growth determinants, Industrial Refrigeration System market share, current trends, key players, and their future predictions. In addition, market demand and supply, each geographical region's growth rate, and market potential are all included in the Industrial Refrigeration System Market study. Raw materials, marketing channels, client surveys, industry trends and proposals, CAGR status, product scope, Industrial Refrigeration System market trends, major leading countries/regions, market risk, and market driving force are all included in the market research. The market prediction was based on a thorough market investigation completed by several industry experts.

To learn more about this report, request a free sample copy:

https://introspectivemarketresearch.com/request/15902

Key Industry Players in the Industrial Refrigeration System Market:

· Star Refrigeration (Scotland)

· Daikin Industries Ltd. (Japan)

· Emerson Electric Co. (US)

· Danfoss A/S (Denmark)

· GEA Group Aktiengesellschaft (Germany)

· Danfoss (Denmark)

· Mayekawa (Japan)

· Daikin (Japan)

· Ingersoll Rand (Ireland)

· EVAPCO

· Inc. (the US)

· Johnson Controls (Ireland)

· LU-VE Group (Italy)

· MTA S.p.A. (Italy)

· Frascold (Italy)

· HITEMA INTERNATIONAL (Italy)

· Güntner GmbH & Co. KG (Germany)

· KOBELCO (Japan)

· Innovative Refrigeration Systems (US)

· Parker Hannifin (US)

· Lennox International (US)

· Clauger (France)

· Rivacold (Italy)

· Dorin S.p.A. (Italy)

· Industrial Frigo (Lombardy)

· BITZER Kuhlmaschinenbau GmbH (Germany)

· Carnot Refrigeration (Canada)

· SRM Italy (Italy)

· Mayekawa Mfg. Co. Ltd. (Japan)

· Baltimore Aircoil Company (US) and others major key players.

This report forecasts revenue growth at the global, regional, and country levels and provides an analysis of the industry trends in each of the sub-segments from 2012 - 2028. For this study, Grand View Research has segmented the global industrial refrigeration systems market based on component, Refrigerant type, application, and region:

Segmentation Analysis Includes,

By Component:

· Compressor

· Condenser

· Evaporator

· Expansion Valves

· Others

By Application:

· Food & Beverage

· Petrochemicals & Pharmaceuticals

· Electricity Production

· Refrigerated Warehouse

· Refrigerated Transportation

· Others

By Refrigerant Type:

· Ammonia

· Hydrofluorocarbon (HFC)

· Carbon Dioxide

· Others

By Region:

· North America (U.S., Canada, Mexico)

· Europe (Germany, U.K., France, Italy, Russia, Spain, Rest of Europe)

· Asia-Pacific (China, India, Japan, Singapore, Australia, New Zealand, Rest of APAC)

· Middle East & Africa (Turkey, Saudi Arabia, Iran, UAE, Africa, Rest of MEA)

· South America (Brazil, Argentina, Rest of SA)

Will you have any doubt about this report? Please contact us on:

https://introspectivemarketresearch.com/inquiry/15902

Key questions answered by the report: -

· What is the expected revenue CAGR for the global industrial refrigeration market over the forecast period (2022-2028)?

· What was the industrial refrigeration market size in 2021?

· Which factors are expected to drive the adoption of industrial refrigeration?

· What are some restraints for growth of the industrial refrigeration market?

· What are Opportunities in Industrial Refrigeration Market?

Industrial refrigeration systems widely use Chlorofluorocarbon (CFC) R-12 or Hydrochlorofluorocarbon (HCFC) R-22 because of these refrigerants\' thermal stability, safety, nonflammability, minimal toxicity, and high performance. However, due to contribution in increasing ozone layer depletion and surging global warming, Original Equipment Manufacturers (OEMs) of industrial refrigeration systems are moving towards refrigerant alternatives with the same benefits of CFCs and HCFCs. These OEMs are trying to phase out refrigerants with ozone depletion potential.

Purchase This Report: -

https://introspectivemarketresearch.com/checkout/?user=1&_sid=15902

Knowing market share in the base year provides you an idea of the competition and size of the suppliers. It reflects the market's fragmentation, accumulation, dominance, and amalgamation features. The Competitive Scenario provides an outlook study of the suppliers' various industry growth plans. This section's news provides vital insights at various stages while keeping up with the industry and engaging players in the economic discussion. Merger & Acquisition, Collaboration, Partnership, Agreement, Investment & Funding, New Product Launch & Enhancement, Recognition, Rewards & Expansion are the categories that the competitive scenario represents.

Related Report: -

https://introspectivemarketresearch.com/reports/commercial-refrigeration-equipment-market/

https://introspectivemarketresearch.com/reports/industrial-ammonia-refrigeration-systems-market/

https://introspectivemarketresearch.com/reports/industrial-refrigeration-equipments-market/

About us:

Introspective Market Research (introspectivemarketresearch.com) is a visionary research consulting firm dedicated to assisting our clients to grow and have a successful impact on the market. Our team at IMR is ready to assist our clients to flourish their business by offering strategies to gain success and monopoly in their respective fields. We are a global market research company, that specializes in using big data and advanced analytics to show the bigger picture of the market trends. We help our clients to think differently and build better tomorrow for all of us. We are a technology-driven research company, we analyze extremely large sets of data to discover deeper insights and provide conclusive consulting. We not only provide intelligence solutions, but we help our clients in how they can achieve their goals.

Contact us:

Introspective Market Research

3001 S King Drive,

Chicago, Illinois

60616 USA

Ph no: +1-773-382-1047

Linkedin| Twitter| Facebook

Email: [email protected]

0 notes

Text

Milton Orr looked across the rolling hills in northeast Tennessee. “I remember when we had over 1,000 dairy farms in this county. Now we have less than 40,” Orr, an agriculture adviser for Greene County, Tennessee, told me with a tinge of sadness.

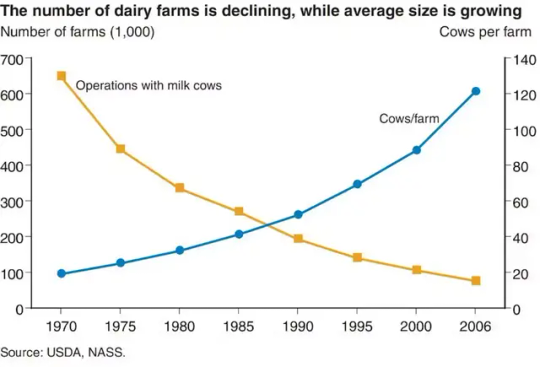

That was six years ago. Today, only 14 dairy farms remain in Greene County, and there are only 125 dairy farms in all of Tennessee. Across the country, the dairy industry is seeing the same trend: In 1970, more than 648,000 US dairy farms milked cattle. By 2022, only 24,470 dairy farms were in operation.

While the number of dairy farms has fallen, the average herd size—the number of cows per farm—has been rising. Today, more than 60 percent of all milk production occurs on farms with more than 2,500 cows.

This massive consolidation in dairy farming has an impact on rural communities. It also makes it more difficult for consumers to know where their food comes from and how it’s produced.

As a dairy specialist at the University of Tennessee, I’m constantly asked: Why are dairies going out of business? Well, like our friends’ Facebook relationship status, it’s complicated.

The Problem with Pricing

The biggest complication is how dairy farmers are paid for the products they produce.

In 1937, the Federal Milk Marketing Orders, or FMMO, were established under the Agricultural Marketing Agreement Act. The purpose of these orders was to set a monthly, uniform minimum price for milk based on its end use and to ensure that farmers were paid accurately and in a timely manner.

Farmers were paid based on how the milk they harvested was used, and that’s still how it works today.

Does it become bottled milk? That’s Class 1 price. Yogurt? Class 2 price. Cheddar cheese? Class 3 price. Butter or powdered dry milk? Class 4. Traditionally, Class 1 receives the highest price.

There are 11 FMMOs that divide up the country. The Florida, Southeast, and Appalachian FMMOs focus heavily on Class 1, or bottled, milk. The other FMMOs, such as Upper Midwest and Pacific Northwest, have more manufactured products such as cheese and butter.

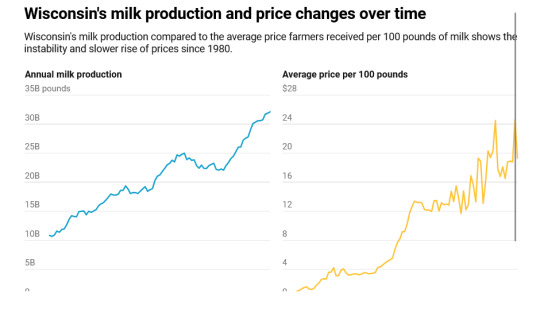

For the past several decades, farmers have generally received the minimum price. Improvements in milk quality, milk production, transportation, refrigeration, and processing all led to greater quantities of milk, greater shelf life, and greater access to products across the US. Growing supply reduced competition among processing plants and reduced overall prices.

Along with these improvements in production came increased costs of production, such as cattle feed, farm labor, veterinary care, fuel, and equipment costs.

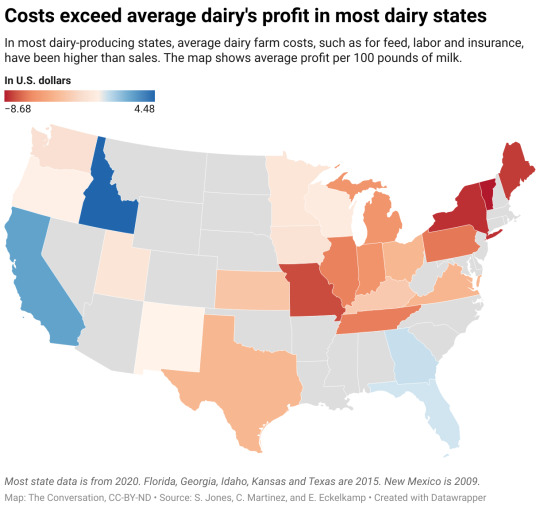

Researchers at the University of Tennessee in 2022 compared the price received for milk across regions against the primary costs of production: feed and labor. The results show why farms are struggling.

From 2005 to 2020, milk sales income per 100 pounds of milk produced ranged from $11.54 to $29.80, with an average price of $18.57. For that same period, the total costs to produce 100 pounds of milk ranged from $11.27 to $43.88, with an average cost of $25.80.

On average, that meant a single cow that produced 24,000 pounds of milk brought in about $4,457. Yet, it cost $6,192 to produce that milk, meaning a loss for the dairy farmer.

More efficient farms are able to reduce their costs of production by improving cow health, reproductive performance, and feed-to-milk conversion ratios. Larger farms or groups of farmers—cooperatives such as Dairy Farmers of America—may also be able to take advantage of forward contracting on grain and future milk prices. Investments in precision technologies such as robotic milking systems, rotary parlors, and wearable health and reproductive technologies can help reduce labor costs across farms.

Regardless of size, surviving in the dairy industry takes passion, dedication, and careful business management.

Some regions have had greater losses than others, which largely ties back to how farmers are paid, meaning the classes of milk, and the rising costs of production in their area. There are some insurance and hedging programs that can help farmers offset high costs of production or unexpected drops in price. If farmers take advantage of them, data shows they can functions as a safety net, but they don’t fix the underlying problem of costs exceeding income.

Passing the Torch to Future Farmers

Why do some dairy farmers still persist, despite low milk prices and high costs of production?

For many farmers, the answer is because it is a family business and a part of their heritage. Ninety-seven percent of US dairy farms are family owned and operated.

Some have grown large to survive. For many others, transitioning to the next generation is a major hurdle.

The average age of all farmers in the 2022 Census of Agriculture was 58.1. Only 9 percent were considered “young farmers,” age 34 or younger. These trends are also reflected in the dairy world. Yet, only 53 percent of all producers said they were actively engaged in estate or succession planning, meaning they had at least identified a successor.

How to Help Family Dairy Farms Thrive

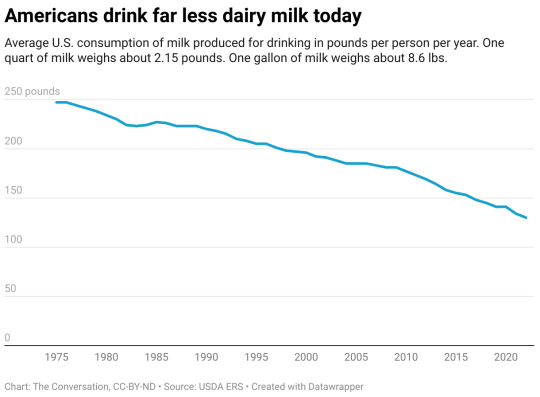

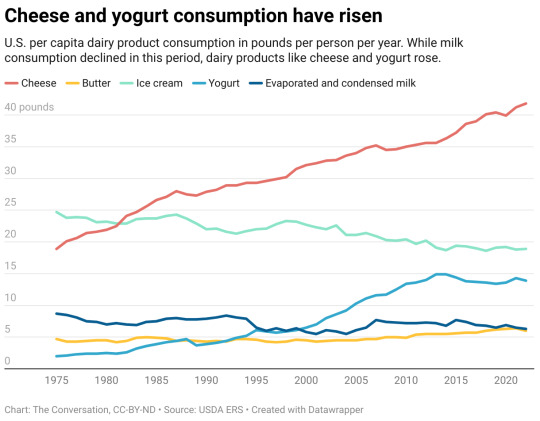

In theory, buying more dairy would drive up the market value of those products and influence the price producers receive for their milk. Society has actually done that. Dairy consumption has never been higher. But the way people consume dairy has changed.

Americans eat a lot, and I mean a lot, of cheese. We also consume a good amount of ice cream, yogurt, and butter, but not as much milk as we used to.

Does this mean the US should change the way milk is priced? Maybe.

The FMMO is currently undergoing reform, which may help stem the tide of dairy farmers exiting. The reform focuses on being more reflective of modern cows’ ability to produce greater fat and protein amounts; updating the cost support processors receive for cheese, butter, nonfat dry milk, and dried whey; and updating the way Class 1 is valued, among other changes. In theory, these changes would put milk pricing in line with the cost of production across the country.

The US Department of Agriculture is also providing support for four Dairy Business Innovation Initiatives to help dairy farmers find ways to keep their operations going for future generations through grants, research support, and technical assistance.

Another way to boost local dairies is to buy directly from a farmer. Value-added or farmstead dairy operations that make and sell milk and products such as cheese straight to customers have been growing. These operations come with financial risks for the farmer, however. Being responsible for milking, processing, and marketing your milk takes the already big job of milk production and adds two more jobs on top of it. And customers have to be financially able to pay a higher price for the product and be willing to travel to get it.

30 notes

·

View notes

Text

Unraveling the Growth Potential of the Geofoams Market: Global Outlook

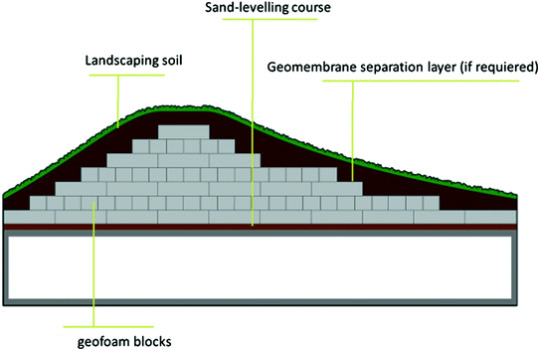

The global geofoams market size is expected to reach USD 972.6 million by 2027, expanding at a CAGR of 2.7%, according to a new report by Grand View Research, Inc. Factors such as availability of geofoams at low cost coupled with its superior strength and durability are projected to fuel the market growth. Expansion of the construction industry across the globe coupled with the infrastructural developments in economies such as India, China, Brazil, Mexico, Saudi Arabia, and others is expected to propel the demand for geofoams over the forecast period. In addition, maintenance of the existing infrastructure in developed nations is likely to drive the growth of the market.

Geofoams Market Report Highlights

The expanded polystyrene geofoams segment accounted for USD 508.2 million in 2019 and is projected to expand at a CAGR of 3.1% from 2020 to 2027. The compatibility of the product has resulted in its increasing adoption for applications including roads and highway construction, building and infrastructure, and others

The road and highway construction application segment accounted for 38.07% of the total market and is projected to expand at a CAGR of 3.4% from 2020 to 2027 on account of the rising infrastructural growth across the developing economies including China, India, Brazil, UAE, Saudi Arabia, and others

Asia-Pacific accounted for USD 278.5 million in 2019 and is estimated to expand at a CAGR of 3.2% from 2020 to 2027 owing to the rising demand for road pavement, which is anticipated to further benefit the growth

China accounted for the highest market share in Asia Pacific on account of the rapidly expanding construction industry in the country

Europe market is estimated to expand at a CAGR of 2.8% owing to the rising number of construction and infrastructural activities in economies including Spain, Italy, and others

For More Details or Sample Copy please visit link @: Geofoams Market Report

Geofoams are increasingly used in the construction industry as it helps in suppressing the noise and vibrations. In addition, it is easy to handle and does not require any special equipment for installation. The product is increasingly used in the railway track systems, below the refrigerated storage buildings, storage tanks, and others to avoid ground freezing.

The geofoams undergo chemical changes when it comes in contact with petroleum solvents. It turns into a glue-type substance, thereby losing its strength. This factor is projected to limit the use of geofoams in the construction industry which is projected to restrict the industry growth over the forecast period.

#Geofoam#Expanded polystyrene (EPS)#Geofoam blocks#Construction materials#Road and highway construction#Retaining walls#Geotechnical engineering#Soil stabilization#Environmental protection#Earthquake resistance#Noise and vibration control#Water management#Hydrostatic pressure#Thermal insulation#Structural stability

8 notes

·

View notes

Text

Frozen Food Market - Forecast (2022 - 2027)

Frozen Food market Overview:

According to the Food and Agriculture Organization of United Nations, nearly one third of the food produced every year amounting to roughly $680 billion (approximately 1.3 billion tons) gets either wasted, or lost[1]

. The issue of food wastage has given birth to the frozen food market which is experiencing a colossal growth with an increase in disposable income, and accentuated refrigeration technology. According to the analyst at Industry ARC, the global frozen food market size in 2018 stood between $225 billion to $228 billion. The market is estimated to grow steadily with a normal CAGR of 3.5%-5% during the forecast period of 2019-2025. Geographically, Europe led the frozen food market with a regional share of 30%-32% in 2018 owing to an increase in mergers and acquisitions between vendors and hypermarkets. On-the-go consumption of food is also driving the European frozen food market.

Frozen Food Market Outlook:

The prospect for frozen food market has never seemed brighter. With a growing awareness in food trends, consumers are resorting to cooking fresh meals at home which are free from any preservatives. For this, they require frozen foods which come in extensive categories these days, some of which are dairy-free, vegan, gluten-free, sugar-free, low fat, etc. Availability of high quality frozen foods makes market growth easier, and less prone to negative fluctuation. Recent trends in technology have introduced cryogenic freezing which prevents addition of any artificial preservatives, while maintaining negligible growth of microorganisms at the same time. Ready meals, a key segment of the frozen food market, is expected to grow at a standard CAGR of 2.5%-4%. It is a convenient, and accessible option for the working class society which is perpetually busy, and consistently short on time.

Request Sample

Frozen Food Market Growth Drivers:

An Increasing Demand for Preservative Free Food

With an increase in organic produce demand, consumers are incessantly on the lookout for fresh vegetables, seafood, and fruits that do not have a short shelf life. Since most of the organic produce expires quickly, hypermarkets are resorting to freezing of frozen foods which customers are interested in buying. Cryogenic freezing of food items extends their shelf lives, and makes them free from any added preservatives. Consumers flock towards these products, and help frozen food market in attaining noticeable growth.

The Shopping Trends of Millennials

Contrary to popular beliefs on millennials being irresponsible buyers, frozen food market heavily relies on their purchasing trends. Millennials are ready to experiment, and invest on novel things unlike the generation before them. They also tend to buy products that preserve their time, and are easy to handle. These traits fuel the market growth of frozen foods as they are convenient, and ready to use, exactly how millennials might prefer. This generation, which drowns in student debts, and underpaying jobs relies majorly on the frozen food market for their nutritional needs.

Frozen Food Market Challenges:

One of the basic challenges faced by the frozen food market is the lack of a proper supply chain system, and the consistent fear of cold chain systems failing. Since frozen foods require a set optimum temperature around -18°C, even the slightest failure in cold chain system can result in massive wastage. A thoroughly functioning power backup, and consistent vigilance is required for assuring negligible frozen food loss.

Inquiry Before Buying

Frozen Food Market Key Players Perspective:

According to the analyst at IndustryArc, some of the key players in the frozen food market are Nestle SA, Unilever, Kellogg Company , General Mills Inc, Conagra Brands, Inc., Grupo Bimbo S.A.B. de C.V., McCain Foods Limited , Kraft Heinz Company, and Associated British.

In 2018, after recognizing the frozen food preference patterns of millennials, and losing out to rivals like LeanMeals, Nestle increased production in its US factories, and introduced a plethora of items in its lineup like frozen coconut chickpea curry, and sweet earth lover’s veggie pizza[2]

Frozen Food Market Trends:

Improved Supply Chain Management

In order to make sure that the frozen food market continues to grow, and is not obstructed by food wastage, companies are employing an ameliorated supply chain management system. Reefer trucks are being used to consistently maintain an optimum environment for frozen foods to stay fresh. These trucks are now being fitted with third party GPS technologies for timely deliveries. This being a primary market disruption, is driving the growth of frozen food market in a positive direction.

The Rise Of IQF Food

IQF stands for ‘individually quick frozen’ which implies that all the items in a frozen food packet are frozen individually, and not as a block. The method involves passing of every individual piece of food through a blast chiller on a conveyor belt. This assures freshness in the food items even after thawing. An amount of peas for example, if frozen using IQF technique and packed in a carton, lidded tray, or crystallized PET tray will sell faster owing to its freshness as compared to the one frozen using ordinary refrigerant technique.

Schedule a Call

Frozen Food Market Research Scope:

The base year of the study is 2018, with forecast done up to 2025. The study presents a thorough analysis of the competitive landscape, taking into account the market shares of the leading companies. It also provides information on unit shipments. These provide the key market participants with the necessary business intelligence and help them understand the future of the frozen food market. The assessment includes the forecast, an overview of the competitive structure, the market shares of the competitors, as well as the market trends, market demands, market drivers, market challenges, and product analysis. The market drivers and restraints have been assessed to fathom their impact over the forecast period. This report further identifies the key opportunities for growth while also detailing the key challenges and possible threats. The key areas of focus include the types of cheese in the frozen food market, and their specific applications in different areas.

Buy Now

Frozen Food market Report: Industry Coverage

Frozen food market can be segmented on the basis of type, and distribution channels. Based on distribution channels, the market can be divided into supermarkets, hypermarkets, online stores, and convenience stores. On the basis of type, the market can be bifurcated into ready to eat meals, seafood, vegetables, fruits, etc.

The frozen food market report also analyzes the major geographic regions for the market as well as the major countries for the market in these regions. The regions and countries covered in the study include:

North America: The U.S., Canada, Mexico

South America: Brazil, Venezuela, Argentina, Ecuador, Peru, Colombia, Costa Rica

Europe: The U.K., Germany, Italy, France, The Netherlands, Belgium, Spain, Denmark

APAC: China, Japan, Australia, South Korea, India, Taiwan, Malaysia, Hong Kong

Middle East and Africa: Israel, South Africa, Saudi Arabia

For more Food and Beverage Market related reports, please click here

#frozen food market price#frozen food market size#frozen food market share#frozen food market forecast#frozen food market report

2 notes

·

View notes

Text

0 notes

Text

The global Pharmaceutical Logistics Market is projected to grow from USD 99,675 million in 2024 to USD 189,329 million by 2032, registering a compound annual growth rate (CAGR) of 8.35%. The pharmaceutical logistics market plays a critical role in the global healthcare sector, ensuring that medicines, vaccines, and other healthcare products are delivered safely and efficiently from manufacturers to end-users. This market has seen rapid growth due to the increasing demand for pharmaceuticals, the expansion of healthcare services, and the need for specialized logistics services to handle sensitive medical products. However, the sector faces several challenges, including stringent regulatory requirements, temperature control management, and supply chain disruptions. This article will delve into the key trends, drivers, and challenges of the pharmaceutical logistics market.

Browse the full report at https://www.credenceresearch.com/report/pharmaceutical-logistics-market

Key Trends in Pharmaceutical Logistics

1. Growing Demand for Biologics and Vaccines

The rise in biologics, vaccines, and complex therapies has spurred the need for specialized logistics services. These products are highly sensitive and require strict temperature control, often within cold chains, to maintain their efficacy. As more biologic-based drugs enter the market, pharmaceutical companies are investing in advanced logistics solutions that can meet the needs of these delicate products.

2. Advancement in Cold Chain Logistics

Cold chain logistics, which refers to the transportation of temperature-sensitive products, has become a significant segment in pharmaceutical logistics. With the rising demand for vaccines, particularly in the wake of the COVID-19 pandemic, the focus on maintaining appropriate temperature conditions during transportation has intensified. Innovations like real-time monitoring systems, temperature-controlled packaging, and advanced refrigeration technologies are helping to ensure that products reach their destinations without compromise.

3. Automation and Digitalization

Technology is transforming the logistics landscape, and the pharmaceutical sector is no exception. Automation, artificial intelligence (AI), and the Internet of Things (IoT) are being increasingly used to enhance operational efficiency, optimize routes, and provide real-time tracking of shipments. Digital platforms are streamlining the supply chain, reducing human error, and ensuring compliance with strict regulations.

4. Increased Regulatory Scrutiny

The pharmaceutical industry is highly regulated due to the critical nature of its products. Regulatory bodies like the U.S. Food and Drug Administration (FDA) and the European Medicines Agency (EMA) impose stringent guidelines on how drugs should be stored, transported, and delivered. Compliance with these regulations is essential for pharmaceutical companies and their logistics partners. As a result, logistics providers must stay updated with changing regulations to avoid penalties and ensure the safety of pharmaceutical products.

Key Drivers of Market Growth

1. Global Demand for Pharmaceuticals

The growing global population, rising life expectancy, and increasing prevalence of chronic diseases are driving the demand for pharmaceuticals. This growth, in turn, creates a higher demand for reliable logistics services that can ensure the timely and safe delivery of healthcare products to various regions worldwide. Emerging markets, particularly in Asia-Pacific, Latin America, and Africa, are seeing an increase in healthcare expenditure, further fueling market expansion.

2. COVID-19 Pandemic Impact

The COVID-19 pandemic highlighted the importance of efficient pharmaceutical logistics. The global rollout of COVID-19 vaccines required complex logistics arrangements, including cold chain management, transportation to remote areas, and real-time tracking of vaccine deliveries. The pandemic underscored the need for resilient supply chains and innovative logistics solutions to meet the challenges of distributing medical products on a massive scale.

3. Outsourcing Trends

Many pharmaceutical companies are increasingly outsourcing their logistics functions to third-party logistics (3PL) providers. By outsourcing, companies can focus on their core competencies while leveraging the expertise and infrastructure of specialized logistics firms. This trend is driving growth in the pharmaceutical logistics market, as more companies seek cost-effective and efficient logistics solutions.

Challenges in the Pharmaceutical Logistics Market

1. Temperature Sensitivity and Cold Chain Failures

One of the most significant challenges in pharmaceutical logistics is maintaining the correct temperature during transportation. Temperature excursions can lead to product spoilage, resulting in financial losses and potentially putting patients at risk. Cold chain failures are particularly costly, and ensuring that logistics systems are reliable and robust is essential.

2. Supply Chain Disruptions

Global supply chain disruptions, such as those caused by natural disasters, geopolitical tensions, or pandemics, can significantly impact the pharmaceutical logistics market. These disruptions can delay the delivery of life-saving medications, leading to shortages and potentially harming patients. Logistics providers must have contingency plans in place to mitigate the effects of such disruptions.

3. High Operational Costs

Managing the logistics of pharmaceutical products, especially cold chain products, comes with high operational costs. Specialized packaging, real-time monitoring systems, and the need for constant temperature control contribute to these expenses. Logistics providers are under pressure to balance cost efficiency with quality and compliance.

Key Player Analysis:

Top Key Players

DHL Supply Chain & Global Forwarding

Kuehne + Nagel International AG

FedEx Corporation

United Parcel Service (UPS), Inc.

DB Schenker

AmerisourceBergen Corporation

SF Express

Ceva Logistics

Panalpina Group

XPO Logistics

Segmentations:

By Type

Cold Chain Logistics

Non-cold Chain Logistics

By Component

Storage

Warehouse

Refrigerated container

Transportation

Sea freight Logistics

Airfreight Logistics

Overland Logistics

Monitoring components

Hardware

Sensors

RFID Devices

Telematics

Networking Devices

Software

By Application

Bio Pharma

Chemical Pharma

Speciality Pharma

By Procedure

Picking

Storage

Retrieval Systems

Handling Systems

By Region

North America

US

Canada

Mexico

Europe

Germany

France

UK

Italy

Spain

Rest of Europe

Asia Pacific

China

Japan

India

South Korea

South-east Asia

Rest of Asia Pacific

Latin America

Brazil

Argentina

Rest of Latin America

Middle East & Africa

GCC Countries

South Africa

Rest of Middle East and Africa

Browse the full report at https://www.credenceresearch.com/report/pharmaceutical-logistics-market

About Us:

Credence Research is committed to employee well-being and productivity. Following the COVID-19 pandemic, we have implemented a permanent work-from-home policy for all employees.

Contact:

Credence Research

Please contact us at +91 6232 49 3207

Email: [email protected]

Website: www.credenceresearch.com

0 notes

Text

Industry Outlook of Fuel Cell Market 2023 Trends to 2030

Fuel Cell Industry Overview

The global fuel cell market size was estimated at USD 7.35 billion in 2023 and is expected to grow at a compound annual growth rate (CAGR) of 27.1% from 2024 to 2030. Increasing demand for unconventional energy sources is one of the key factors driving the growth. Growing private-public partnerships and reduced environmental impact are expected to propel the demand. Governments across the globe are anticipated to supplement the developments by offering support in different forms, including funding R&D activities and funding suitable financing programs. Building a robust regulatory framework is vital as government enterprises need to provide an environment that is favorable for investment.

Gather more insights about the market drivers, restrains and growth of the Fuel Cell Market

Most of the U.S. states, such as California and New York, have set mandates to limit the carbon emissions from commercial and industrial end users in the country. This has resulted in end users opting for clean energy technologies to comply with the mandate and limit their carbon footprint. Bloom Energy, one of the major fuel cell vendors in the U.S., provides its bloom energy servers for power generation application to aid commercial and industrial end users limit their carbon footprint.

For instance, in September 2023, FuelCell Energy, Inc. and Toyota Motor North America announced the completion of Tri-gen system at Toyota's Port of Long Beach operations. Tri-gen is an example of FuelCell Energy's ability to scale hydrogen-powered fuel cell technology. Such innovative ideas is expected to foster the demand of fuel cell market over forecast period.

Fuel cell market is a rapidly growing sector with a wide range of potential opportunities. The technology is constantly improving, with new materials and designs leading to increased efficiency and performance. This is making fuel cells more attractive for a wider range of applications. Transportation sector is one of the largest markets for fuel cells. Fuel cell electric vehicle (FCEVs) offer several advantages over battery-electric vehicles (BEVs), such as longer range and faster refueling times. As the cost of FCEVs comes down and the hydrogen infrastructure grows, the market for fuel cell vehicles is expected to boom. Companies operating in the market continuously launch new products in order to pace up with the growing fuel cell technology. For instance, in January 2024, Nikola Corporation launched 42 and wholesaled 35 Class 8 Nikola hydrogen-powered fuel cell electric vehicles (FCEVs) under HYLA brand for U.S. and Canada customers. The trucks are featured to run with a range of 500 miles with an estimated fueling time as low as 20 minutes.

Browse through Grand View Research's Power Generation & Storage Industry Research Reports.

• The global battery market size was estimated at USD 118.20 billion in 2023 and is projected to grow at a CAGR of 16.1% from 2024 to 2030. The market is experiencing rapid growth, driven primarily by the increasing adoption of electric vehicles (EVs) and the expansion of renewable energy infrastructure.

• The global refrigerant market size was estimated at USD 14.26 billion in 2023 and is projected to grow at a CAGR of 4.7% from 2024 to 2030.The industry is experiencing growth due to increased demand from various end-use sectors, particularly the commercial & industrial refrigeration industry.

Fuel Cell Market Segmentation

Grand View Research has segmented the global fuel cell market report based on product, components, fuel, size, application, and end-use, and region:

Fuel Cell Product Outlook (Volume, Units; Capacity, MW, Revenue, USD Million, 2018 - 2030)

• PEMFC

• PAFC

• SOFC

• MCFC

• AFC

• Others

Fuel Cell Components Outlook (Volume, Units; Capacity, MW, Revenue, USD Million, 2018 - 2030)

• Stack

• Balance of Plant

Fuel Cell Fuel Outlook (Volume, Units; Capacity, MW, Revenue, USD Million, 2018 - 2030)

• Hydrogen

• Ammonia

• Methanol

• Ethanol

• Hydrocarbon

Fuel Cell Size Outlook (Volume, Units; Capacity, MW, Revenue, USD Million, 2018 - 2030)

• Small-scale

• Large-scale

Fuel Cell Application Outlook (Volume, Units; Capacity, MW, Revenue, USD Million, 2018 - 2030)

• Stationary

• Transportation

• Portable

Fuel Cell End-use Outlook (Volume, Units; Capacity, MW, Revenue, USD Million, 2018 - 2030)

• Residential

• Commercial & Industrial

• Transportation

• Data Centers

• Military & Defense

• Utilities & Government

Fuel Cell Regional Outlook (Volume, Units; Capacity, MW, Revenue, USD Million, 2018 - 2030)

• North America

o US

o Canada

o Mexico

• Europe

o Germany

o France

o UK

o Italy

o Spain

• Asia Pacific

o China

o Japan

o South Korea

o India

o Taiwan

o Australia

• Central & South America

o Brazil

o Argentina

• Middle East & Africa

o Saudi Arabia

o UAE

o South Africa

Order a free sample PDF of the Fuel Cell Market Intelligence Study, published by Grand View Research.

Key Companies profiled:

• Ballard Power Systems

• Bloom Energy

• Ceres Power Holdings PLC

• Doosan Fuel Cell America, Inc.

• FuelCell Energy, Inc.

• Hydrogenics Corporation

• Nedstack Fuel Cell Technology B.V.

• Nuvera Fuel Cells LLC

• Plug Power, Inc.

• SFC Energy AG

Key Fuel Cell Company Insights

• In November 2023, Honda in association with General Motors displayed a prototype of its next-generation hydrogen fuel cell system at European Hydrogen Week in Brussels. The company is planning to expand its portfolio in fuel cell technology.

• In December 2023, General Motors and Komatsu announced to develop a hydrogen fuel cell power module for the Japanese construction machinery maker's 930E electric drive mining truck.

• In January 2023, Cochin Shipyard Limited initiated research activities for the development of a hydrogen-fueled electric vessel based on low-temperature proton exchange membrane technology.

• In January 2023, Advent Technologies collaborated with Alfa laval to explore the application of high-temperature proton exchange membrane fuel cells in marine applications.

0 notes

Text

2024-2030: Air Conditioning Compressor for New Energy Vehicle Market Trend And Analysis

On 2024-9-24 Global Info Research released【Global Air Conditioning Compressor for New Energy Vehicle Market 2024 by Manufacturers, Regions, Type and Application, Forecast to 2030】. This report includes an overview of the development of the Air Conditioning Compressor for New Energy Vehicle industry chain, the market status of Consumer Electronics (Nickel-Zinc Ferrite Core, Mn-Zn Ferrite Core), Household Appliances (Nickel-Zinc Ferrite Core, Mn-Zn Ferrite Core), and key enterprises in developed and developing market, and analysed the cutting-edge technology, patent, hot applications and market trends of Air Conditioning Compressor for New Energy Vehicle.

The air-conditioning compressor for new energy vehicles is a key component designed specifically for electric vehicles and other new energy vehicles. It is the power source of the vehicle's air-conditioning refrigeration system and promotes the circulation of refrigerant in the system.

The global Air Conditioning Compressor for New Energy Vehicle market size is expected to reach $ million by 2030, rising at a market growth of %CAGR during the forecast period (2024-2030).

This report studies the global Air Conditioning Compressor for New Energy Vehicle production, demand, key manufacturers, and key regions.

This report is a detailed and comprehensive analysis of the world market for Air Conditioning Compressor for New Energy Vehicle and provides market size (US$ million) and Year-over-Year (YoY) Growth, considering 2023 as the base year. This report explores demand trends and competition, as well as details the characteristics of Air Conditioning Compressor for New Energy Vehicle that contribute to its increasing demand across many markets.

Market segment by Type: <34cc、34-45cc、>45cc

Market segment by Application:Passenger Car、Commercial Vehicle

Major players covered: Toyota Industries、Hanon Systems、Valeo、MAHLE、Sanden、Brose、Denso、Highly Marelli、Aotecar、Suzhou Zhongcheng New Energy、Shanghai Highly、Zhengzhou Yuebo New Energy、Welling Auto Parts、Shanghai Velle Automobile Air Conditioner、Songz Automobile Air Conditioning、Panasonic Corporation、Mitsubishi、Huaqiang Electric

Market segment by region, regional analysis covers: North America (United States, Canada and Mexico), Europe (Germany, France, United Kingdom, Russia, Italy, and Rest of Europe), Asia-Pacific (China, Japan, Korea, India, Southeast Asia, and Australia),South America (Brazil, Argentina, Colombia, and Rest of South America),Middle East & Africa (Saudi Arabia, UAE, Egypt, South Africa, and Rest of Middle East & Africa).

The content of the study subjects, includes a total of 15 chapters:

Chapter 1, to describe Air Conditioning Compressor for New Energy Vehicle product scope, market overview, market estimation caveats and base year.

Chapter 2, to profile the top manufacturers of Air Conditioning Compressor for New Energy Vehicle, with price, sales, revenue and global market share of Air Conditioning Compressor for New Energy Vehicle from 2019 to 2024.

Chapter 3, the Air Conditioning Compressor for New Energy Vehicle competitive situation, sales quantity, revenue and global market share of top manufacturers are analyzed emphatically by landscape contrast.

Chapter 4, the Air Conditioning Compressor for New Energy Vehicle breakdown data are shown at the regional level, to show the sales quantity, consumption value and growth by regions, from 2019 to 2030.

Chapter 5 and 6, to segment the sales by Type and application, with sales market share and growth rate by type, application, from 2019 to 2030.

Chapter 7, 8, 9, 10 and 11, to break the sales data at the country level, with sales quantity, consumption value and market share for key countries in the world, from 2017 to 2023.and Air Conditioning Compressor for New Energy Vehicle market forecast, by regions, type and application, with sales and revenue, from 2025 to 2030.

Chapter 12, market dynamics, drivers, restraints, trends and Porters Five Forces analysis.

Chapter 13, the key raw materials and key suppliers, and industry chain of Air Conditioning Compressor for New Energy Vehicle.

Chapter 14 and 15, to describe Air Conditioning Compressor for New Energy Vehicle sales channel, distributors, customers, research findings and conclusion.

Data Sources:

Via authorized organizations:customs statistics, industrial associations, relevant international societies, and academic publications etc.

Via trusted Internet sources.Such as industry news, publications on this industry, annual reports of public companies, Bloomberg Business, Wind Info, Hoovers, Factiva (Dow Jones & Company), Trading Economics, News Network, Statista, Federal Reserve Economic Data, BIS Statistics, ICIS, Companies House Documentsm, investor presentations, SEC filings of companies, etc.

Via interviews. Our interviewees includes manufacturers, related companies, industry experts, distributors, business (sales) staff, directors, CEO, marketing executives, executives from related industries/organizations, customers and raw material suppliers to obtain the latest information on the primary market;

Via data exchange. We have been consulting in this industry for 16 years and have collaborations with the players in this field. Thus, we get access to (part of) their unpublished data, by exchanging with them the data we have.

From our partners.We have information agencies as partners and they are located worldwide, thus we get (or purchase) the latest data from them.

Via our long-term tracking and gathering of data from this industry.We have a database that contains history data regarding the market.

Global Info Research is a company that digs deep into global industry information to support enterprises with market strategies and in-depth market development analysis reports. We provides market information consulting services in the global region to support enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

Phase Change Material Market Size, Share, Trends & Forecast

According to a new report by Univdatos Market Insights, the Global Phase Change Material Market is expected to reach USD 6,934.49 million in 2032, growing at a CAGR of 20.45%. The market is driven by the rising application in building and construction, increasing demand for HVAC systems, and the growing need for energy-efficient solutions in various industries.

Demand:

The PCM market is growing globally, which can be attributed to several factors increasing the demand for PCM. Firstly, the market has been highly affected by the demand to embrace energy efficiency and sustainability in the construction of buildings. Enhancing the use of PCM in building materials has the following benefits: It enables the control of indoor temperatures, thus espousing heating and cooling, leading to energy conservation. This corresponds to the worldwide practice of promoting sustainable building to maintain green certifications.

Also, with the increasing reliability of the electronics and transport sector, the need for enhanced thermal management has increased. PCMs can be utilized in electronics where miniaturization may lead to the generation of heat and thus aid in reducing heat and possibly improving the efficiency and durability of the devices. In the case of automobiles, the PCMs can be employed in batteries and the climate control of cabins and car interiors to make them more energy-friendly.

Applications:

The market for PCMs is active due to their versatility and ability to be used across many industries. In the building and construction field, they are incorporated into the wallboards, floor, and ceiling to act as thermal mass control of internal environment temperatures. Some benefits of this application include the ability to minimize energy expenses while improving occupant comfort.

In the heating refrigeration and ventilation industry, PCMs are utilized in refrigeration systems by depositing and liberating thermal energy in air conditioning. PCMs render cold chain logistics a convenient way of transferring temperature-sensitive commodities like pharmaceuticals and foods to their intended destinations while maintaining the set temperatures.

In the construction sector, they are used for HVAC systems, building insulation, and energy storage, as well as thermal management solutions applied in electronics like laptops, smartphones, and data centers. Furthermore, in the automobile segment, PCMs are also employed in battery thermal management and cabin thermal regulation, which leads to fuel productivity and a cozy climate for the passengers.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=63882

Technological Advancements:

There is increased research on the PCM market and the development of technologies by many industry players for new, innovative, and green products. The following are some of the new directions that are worth mentioning: bio-based and non-toxic PCMs. Industry players are using funds to work on PCMs that are bio-based. This is in a bid to meet sustainable development goals.

For instance, Rubitherm Technologies recently launched an enhanced PCM range made from natural oils, a better option than petroleum-based PCMs. These bio-based PCMs have thermal characteristics comparable to those of more conventional materials but with much regard for the environment.

Conclusion:

PCM industry remains highly promising for considerable growth in the future because of the growing requirements for energy-saving and efficient solutions in various sectors. The increasing demand for better thermal management in building and construction, electronics, and automotive industries will drive the growth of the PCM market. Manufacturers are still focusing on new opportunities and increasing their product offerings to better serve the needs of these sectors. The growth of new technologies and the invention of environmentally friendly PCMs also continue to fuel product demand in line with global progress.

Contact Us:

UnivDatos Market Insights

Email - [email protected]

Contact Number - +1 9782263411

Website -www.univdatos.com

0 notes

Text

The Stainless Steel Sheet Manufacturing Industry: A Comprehensive Overview

United Stainless LLP is a leading Stainless Steel Sheet Manufacturer in India. Stainless steel sheet manufacturing is a cornerstone of modern industry, providing a material that is highly versatile, durable, and corrosion-resistant. From construction to automotive, household appliances to aerospace, stainless steel sheets are used in countless applications due to their unique properties. In India, the demand for stainless steel continues to rise, as manufacturers focus on delivering high-quality materials that meet international standards. This blog will explore the Stainless Steel Sheet Manufacturer industry, its process, key players in the market, and the growing demand for stainless steel in India.

Overview of Stainless Steel

Stainless steel is an alloy composed primarily of iron, with at least 10.5% chromium. This chromium content forms a thin, protective oxide layer on the surface of the steel, preventing corrosion and rust. Other elements such as nickel, molybdenum, and nitrogen are often added to enhance specific properties like formability, strength, or corrosion resistance.

The unique characteristics of stainless steel make it an ideal material for various industrial applications. It is durable, recyclable, resistant to heat and chemicals, and has an attractive appearance. These qualities make stainless steel sheets an indispensable material in industries that require strength, hygiene, and long-term durability.

The Manufacturing Process of Stainless Steel Sheets

The SS Sheet Manufacturer in India begins with the melting of raw materials such as iron ore, nickel, and chromium in an electric furnace. The furnace heats the raw materials to extremely high temperatures (up to 1500°C) to melt them together. Once the materials are thoroughly melted and mixed, they are cast into slabs or ingots.

The next stage involves hot rolling the slabs, which reduces the thickness of the steel and shapes it into a sheet. During this process, the slabs are passed through a series of rollers at high temperatures. Once the desired thickness is achieved, the hot-rolled sheet is cooled and annealed (a heat treatment process that increases the material's ductility and reduces its hardness). After annealing, the stainless steel sheet undergoes cold rolling, which refines the surface finish and increases the strength of the material.

Finally, the sheets are cut to size, polished, and undergo surface treatments such as pickling or passivation to remove any impurities or scale from the surface. The result is a high-quality stainless steel sheet that is ready for use in various applications.

Applications of Stainless Steel Sheets

The versatility of stainless steel sheets makes them suitable for a wide range of industries. Some of the major sectors that rely heavily on stainless steel sheets include:

Construction and Architecture: Stainless steel is used in building facades, roofing, cladding, and interior applications. Its corrosion resistance and aesthetic appeal make it a popular choice in modern architectural designs.

Automotive Industry: Stainless steel sheets are used in exhaust systems, catalytic converters, and structural components of vehicles due to their strength, heat resistance, and lightweight properties.

Aerospace Industry: Aircraft components, engine parts, and structural components are made from stainless steel sheets because of their durability and ability to withstand extreme temperatures.

Food and Beverage Industry: Stainless steel sheets are used in the manufacture of equipment such as tanks, sinks, and tables, thanks to their hygienic properties and resistance to corrosion.

Medical Industry: Surgical instruments, hospital equipment, and pharmaceutical equipment are often made from stainless steel due to its ability to be easily sterilized.

Household Appliances: Stainless steel sheets are widely used in the production of refrigerators, ovens, dishwashers, and other household appliances because of their sleek appearance, durability, and resistance to staining and rust.

Countries We Supply Stainless Steel Sheet

Stainless Steel Sheet Manufacturer in Vietnam

Stainless Steel Sheet Manufacturer in Taiwan

Stainless Steel Sheets Manufacturers USA

Stainless Steel Sheet Suppliers in UAE

Stainless Steel Sheet Suppliers in Srilanka

Stainless Steel Sheet Suppliers in Qatar

Growing Demand for Stainless Steel Sheets in India

India’s growing industrialization and urbanization have led to an increased demand for stainless steel sheets. Industries such as construction, automotive, and infrastructure are driving this demand, especially as the government invests heavily in infrastructure projects like roads, bridges, and airports. Additionally, the automotive industry’s shift towards electric vehicles is creating new opportunities for SS Sheet Manufacturer.

The rising awareness of sustainability and recycling is also contributing to the demand for stainless steel, as it is 100% recyclable. Furthermore, stainless steel’s long lifecycle and minimal maintenance requirements make it a cost-effective solution for various industries.

Conclusion

Stainless Steel Sheet Supplier in India is a dynamic and growing industry in India, supported by a strong industrial base and increasing demand across multiple sectors. With advancements in technology and a focus on sustainability, manufacturers are continuously improving the quality of stainless steel sheets to meet global standards. As industries expand, the Stainless Steel Sheet Supplier industry will continue to play a pivotal role in supporting India's economic growth and infrastructure development.

#Stainless Steel Sheet Manufacturer in India#ss sheet manufacturer in india#Stainless Steel Sheet Manufacturer#Stainless Steel Sheet

0 notes

Text

Refrigerated Warehousing And Storage Market 2024-2033 : Demand, Trend, Segmentation, Forecast, Overview And Top Companies

The refrigerated warehousing and storage global market report 2024 from The Business Research Company provides comprehensive market statistics, including global market size, regional shares, competitor market share, detailed segments, trends, and opportunities. This report offers an in-depth analysis of current and future industry scenarios, delivering a complete perspective for thriving in the industrial automation software market.

Refrigerated Warehousing And Storage Market, 2024 report by The Business Research Company offers comprehensive insights into the current state of the market and highlights future growth opportunities.

Market Size -

The refrigerated warehousing and storage market size has grown strongly in recent years. It will grow from $172.31 billion in 2023 to $187.87 billion in 2024 at a compound annual growth rate (CAGR) of 9.0%. The growth in the historic period can be attributed to globalization of the food supply chain, consumer demand for fresh products, e-commerce and online grocery shopping, pharmaceutical supply chain requirements.

The refrigerated warehousing and storage market size is expected to see strong growth in the next few years. It will grow to $262.9 billion in 2028 at a compound annual growth rate (CAGR) of 8.8%. The growth in the forecast period can be attributed to population growth and urbanization, sustainability and energy efficiency, economic growth in emerging markets, climate change and extreme weather events. Major trends in the forecast period include technology integration, energy efficiency and sustainability, e-commerce and last-mile delivery, cold storage for e-pharmacies.

Order your report now for swift delivery @

https://www.thebusinessresearchcompany.com/report/refrigerated-warehousing-and-storage-global-market-report

The Business Research Company's reports encompass a wide range of information, including:

1. Market Size (Historic and Forecast): Analysis of the market's historical performance and projections for future growth.

2. Drivers: Examination of the key factors propelling market growth.

3. Trends: Identification of emerging trends and patterns shaping the market landscape.

4. Key Segments: Breakdown of the market into its primary segments and their respective performance.

5. Focus Regions and Geographies: Insight into the most critical regions and geographical areas influencing the market.

6. Macro Economic Factors: Assessment of broader economic elements impacting the market.

Market Drivers -

Warehouses are increasingly using mobile technologies to efficiently monitor warehouse operations. Mobile technology includes the use of tablets, smartphones, mobile printers, and other handheld devices for communication and information. These devices make use of GPS, RFID, VoIP, digital imaging, and voice technology. Technicians operating forklifts and automated material handling equipment in a warehouse are using mobile technologies to obtain information on troubleshooting, repairs, and work orders. This gives warehouse managers access to equipment status and performance reports and enables them to track warehouse operations around the clock. Wearable technology such as smart glasses is being integrated with warehouse management systems to improve hands-free mobility for workers. According to a report by MHI, a material handling, logistics, and supply chain association, 22% of the respondents use mobile technologies in warehouses, and the adoption rate is expected to reach 45% in the next two years.

The refrigerated warehousing and storage market covered in this report is segmented –

1) By Type: Cold Storage, Frozen Storage

2) By Ownership: Private Warehouses, Public Warehouses, Bonded Warehouses

3) By Application: Fruits and Vegetables, Bakery and Confectionery, Milk and Dairy Products, Meat, Seafood, Beverages, Other Applications

Get an inside scoop of the refrigerated warehousing and storage market, Request now for Sample Report @

https://www.thebusinessresearchcompany.com/sample.aspx?id=2256&type=smp

Regional Insights -

Asia-Pacific was the largest region in the refrigerated warehousing and storage market in 2023. North America was the second largest region in the refrigerated warehousing and storage market. The regions covered in the refrigerated warehousing and storage market report are Asia-Pacific, Western Europe, Eastern Europe, North America, South America, Middle East, and Africa.

Key Companies -

Major companies operating in the refrigerated warehousing and storage market include AmeriCold Logistics, Nichirei Corporation, Lineage Logistics Holdings LLC, Henningsen Cold Storage Co., Burris Logistics, Toyo Suisan Kaisha Ltd., Agro Merchants North America Holdings LLC, Nippon Suisan Kaisha Ltd., Snowman Logistics Ltd., Lineage Logistics, Americold Reality Trust Inc., United States Cold Storage Inc., NewCold Cooperatief U.A., Nichirei Logistics Group Inc., Emergent Cold LatAm Management LLC, Interstate Warehousing Inc., Frialsa Frigorificos S.A. De C.V., Constellation Cold Logistics, Superfrio Logistica Frigorificada, FreezPak Logistics, Conestoga Cold Storage Limited, Congebec Logistics Inc., METCOLD Supply Network Management Limited, RLS Logistics, Friozem Armazens Frigorificos Ltda., Magnavale Ltd., Confederation Freezers, Trenton Cold Storage Inc., Nor-Am Cold Storage, Burris Logistics, Agri-Norcold A/S, Vertical Cold Storage, ColdPoint Logistics, Hanson Logistics Ltd., Cloverleaf Cold Storage Co., Henningsen Cold Storage Co., Gruppo Marconi Logistica Integrata, Zero Mountain Inc.

Table of Contents

1. Executive Summary

2. Refrigerated Warehousing And Storage Market Report Structure

3. Refrigerated Warehousing And Storage Market Trends And Strategies

4. Refrigerated Warehousing And Storage Market – Macro Economic Scenario

5. Refrigerated Warehousing And Storage Market Size And Growth

…..

27. Refrigerated Warehousing And Storage Market Competitor Landscape And Company Profiles

28. Key Mergers And Acquisitions

29. Future Outlook and Potential Analysis

30. Appendix

Contact Us:

The Business Research Company

Europe: +44 207 1930 708

Asia: +91 88972 63534

Americas: +1 315 623 0293

Email: [email protected]

Follow Us On:

LinkedIn: https://in.linkedin.com/company/the-business-research-company

Twitter: https://twitter.com/tbrc_info

Facebook: https://www.facebook.com/TheBusinessResearchCompany

YouTube: https://www.youtube.com/channel/UC24_fI0rV8cR5DxlCpgmyFQ

Blog: https://blog.tbrc.info/

Healthcare Blog: https://healthcareresearchreports.com/

Global Market Model: https://www

0 notes

Text

Global Green Hydrogen Market: Growth Opportunities and Technological Barriers

According to a new report published by Allied Market Research, the green hydrogen market size was valued at $2.5 billion in 2022, and is estimated to reach $143.8 billion by 2032, growing at a CAGR of 50.3% from 2023 to 2032.

Green hydrogen, also known as renewable hydrogen, is a form of hydrogen produced using renewable energy sources, such as solar, wind, or geothermal power. Furthermore, the demand for proton exchange membrane electrolyzer is anticipated to witness growth during the forecast period, owing to economic growth in emerging markets continues to surge.

In 2023, Asia-Pacific accounts for the largest green hydrogen market share, followed by Europe and North America.

Major Companies

Green Hydrogen Systems, Air Liquide, Shell plc, Enapter S.r.l., Plug Power Inc., Ballard Power Systems, Linde plc, Reliance Industries, GAIL (India) Limited and Adani Green Energy Ltd.

The green hydrogen market is expected to be driven by factors such as the promising growth of the food and beverages, medical, chemical, and petrochemical industries.

Demand for power generation has escalated due to global population growth, coupled with urbanization and industrialization, leading to increase electricity consumption.

The food and beverage segment are projected to manifest a CAGR of 51.6% from 2023 to 2032, and has significant proportion in green hydrogen market size. Rise in the food and beverage industry significantly influences the green hydrogen market, primarily due to intensive energy demand of the industry.

Food and beverage production requires substantial energy for processing, packaging, refrigeration, and transportation. Green hydrogen presents a sustainable solution to meet these escalating energy demands, especially in processes were direct electrification not efficient.

Rise in living standards and technological advancements also contribute to higher energy needs, especially in emerging economies where electricity access has expanded rapidly.

Ongoing R&D efforts focus on enhancing electrolyzer efficiency, durability, and scaling up production, leading to cost reductions and improved performance. This trend aligns with ambitious governmental targets and corporate commitments aimed at fostering the green hydrogen industry, spurring innovation and market growth.

Increasingly stringent regulations and carbon pricing mechanisms incentivize to transition of industries into low-carbon alternatives, propelling its market penetration. These converging green hydrogen market trends collectively position green hydrogen as a pivotal player in the sustainable energy landscape, driving a fundamental shift toward cleaner, more resilient energy systems across the globe.

the electrification of transportation and heating sectors, driven by the push for cleaner energy sources, further amplifies the demand for power generation. This growth in demand provides a significant opportunity for the green hydrogen market.

Green hydrogen emerges as a versatile solution as traditional energy sources struggle to meet these escalating demands while maintaining environmental sustainability.

This symbiotic relationship between the rise in demand for power generation and the need for clean energy solutions positions green hydrogen as a key player in meeting the escalating energy needs sustainably.

The push toward decarbonization and the reduction of greenhouse gas emissions in the transportation sector amplifies the appeal of green hydrogen market opportunities.

Carbon Solutions, a greenhouse gas reduction consultancy, in May 2023, stated that less than 1% of the 10 million metric tons of hydrogen produced in the U.S. at present counts as green hydrogen. Instead, 76% is derived from natural gas or coal, and 23% is a by-product of petroleum refining or other chemical processes.

Globally, the hydrogen market is about 96 million metric tons per year. The report from Carbon Solutions puts number of electrolyzers operating in the U.S. at just 42, with a combined hydrogen production capacity of about 3,000 tons per year.

The U.S. Department of Energy (DOE) aims to have 10 million tons of clean hydrogen flowing per year by 2030, 20 million tons by 2040, and 50 million tons by 2050. About half that production is expected to come from renewably powered electrolysis. The U.S. government is projected to invest $8 billion in several hydrogen hubs across the country by 2026 and produce about 250 times as much hydrogen per day.

Trending Reports in Energy and Power Industry:

Electrolyzer Market Trend Analysis Report, by Application, by Capacity, by Product : Global Opportunity Analysis and Industry Forecast, 2023-2032