#Mobile Asphalt Drum Mix Plant

Text

What is Asphalt Recycling Plant?

The use of reclaimed asphalt, or recycling, has become a necessity. Governments increasingly want the reclaimed asphalt from old roads re-used in an effort to be more environmentally friendly. Recycled asphalt also can provide you with cost savings on several fronts.

To use this valuable secondary resource, ZOOMLINE offers the Asphalt Recycling Plants to help your recycling and cost-saving efforts. Regardless of the system you choose, modern ZOOMLINE plant technology will provide a quality recycling process and product.

Asphalt Recycling Plant | Hot & Cold RAP Recycling, RAPpro 100% Recycled Asphalt Hot Mix Plant, Recycled asphalt hot mix plant, RAPpro 100% Recycled Hot Mix Asphalt Production Plant.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#heavy equipment#asphaltplant#construction#mobile asphalt drum mix plant#recycling asphalt plant#asphalt recycling plant#recycled asphalt plant#RAP Recycling#recycled asphalt hot mix plant#recycled hot mix asphalt production plant#asphalt production plant

3 notes

·

View notes

Text

youtube

Mobile asphalt drum mix plant -

Atlas MDM 25 is an ideal small asphalt drum mix plant designed for customers looking for a asphalt plant which can be started in short time and can be shifted frequently. This plant is placed on two chassis (without wet dust collector) or three chassis (with wet dust collector).

0 notes

Text

Mobile Asphalt Drum Mix Plant - Atlas Industries

Atlas is manufacturers of mobile drum mix plant. We are supplier and exporters of mini asphalt plant with low price. Buy high quality of portable mixing plants.

0 notes

Text

Advantages of Mobile Asphalt Drum Mix Plant - Atlas Technologies

Mobile asphalt plants come with some inherent advantages over their stationary counterpart and size and features like additional portability are not the only ones.With mobile drum mix plants, the components are preassembled on a maximum of three or four chassis.

0 notes

Text

Asphalt Plant | Bitumen Sprayer Manufacturer in India - S.P. Enterprise

S.P. Enterprise is a manufacturer of road construction machinery like asphalt plant, hot mix plant, asphalt drum mix plant, bitumen sprayer in India. We are exporter and supplier of road construction equipments. Call us on +91-9712583240.

#asphalt plant#bitumen sprayer#mobile asphalt plant#asphalt drum mix plant#asphalt mixing plant#asphalt hot mix plant#bitumen pressure distributor

2 notes

·

View notes

Text

Revolutionizing Road Construction with Mobile Asphalt Drum Mix Plants

In the ever-evolving landscape of road construction, Mobile Asphalt Drum Mix Plants have emerged as a game-changer. These compact and efficient plants offer unparalleled flexibility, enabling seamless on-site production of high-quality asphalt mixes. Mobile Drum Mix Plants have revolutionized project timelines, eliminating the need for transportation delays and ensuring a continuous and reliable supply of asphalt. Their portability and quick setup make them ideal for remote locations, reducing overall project costs. Embracing innovation, these plants embody efficiency, environmental consciousness, and durability. As the construction industry adapts to changing demands, Mobile Asphalt Drum Mix Plants stand as a beacon of progress, redefining the future of road infrastructure.

For More details, Kindly contact us at 90999 41311 this Number and visit our site:https://www.coninfra.in/

0 notes

Text

Mobile Asphalt Plant - For sale - Asphalt Batch Mix Plants

Explore top-quality portable asphalt plants and mobile drum mix plants crafted by a trusted manufacturer in India. Choose from a variety of mobile asphalt plant and asphalt batch mix plants solutions engineered for durability.

0 notes

Text

Asphalt Plant PDF

This asphalt plant pdf is the brief introduction of asphalt batching plant including components, working process, types, capacity, models and characteristics. Asphalt mixing plant is a kind of equipment specialized in producing asphalt concrete mixture. It mainly consists of asphalt mixer, aggregate bin, powder bin, control system and so on. Asphalt batch mix plant is usually used in the construction of roads, bridges, tunnels and other projects for the production of asphalt concrete of various specifications to meet the needs of engineering construction.

The working principle of asphalt mixing plant is to add aggregate, asphalt, powder and other raw materials into the mixer according to a certain proportion for mixing, after a certain time of mixing, the mixture reaches a certain degree of homogeneity, and then the mixture will be transported to trucks for transportation. Asphalt mixing plant has the advantages of high production efficiency, stable production quality and easy operation, so it is widely used in engineering construction.

Equipment classification of asphalt mixing plant:

Classified according to production capacity:

Small: the production rate is below 40t/h.

Medium-sized: production rate of 40-400t/h.

Large-scale: production rate above 400t/h.

Classified by handling method:

Mobile type: silo and mixing pot with its own tires, can be transferred with the construction site, suitable for county and township roads and low-grade highway projects.

Semi-fixed: the equipment is installed on several trailers and assembled at the construction site, mostly used in highway construction.

Fixed type: the equipment operating location is fixed, also known as stationary asphalt mixing plant, applicable to the project is concentrated, urban road construction.

Classified according to the mixing method:

Continuous drum type: the continuous uninterrupted mixing mode of production, heating and drying of aggregate and mixing the mixture in the same drum continuously.

Forced intermittent: the heating and drying of the aggregate and mixing of the mixture is forced cyclical, the equipment is mixed separately in one pot, each pot is mixed for 45 to 60 seconds, the output depends on the model of the equipment.

In summary, as an important road construction equipment, asphalt mixing plant play an important role in guaranteeing the quality of the road, improve construction efficiency.

This resource is from http://www.asphalt-mixing-plants.net/industry-news/asphalt-plant-pdf.html

Should you be interested in buying our product, please contact us at:

Haomei Machinery Equipment Co.,ltd

Whatsapp/Wechat: 0086 181 3788 9531

Email: [email protected]

0 notes

Text

https://aaspaequipment.com/asphalt-drum-mix-plant/

Asphalt Drum Mix Plant

Salient Features Stationary Plant:

Easy Operation and Less maintenance.

Designed for the International Market.

Modern Drum Mix Technology.

Proper Asphalt Coating and saving.

Proper Drying and Homogeneous Mixing of Aggregate.

Less Fuel Consumption.

Continuous Electronic Belt weighing system with Load cell.

SCADA / PLC based control panel with online print out facility.

Schneider make HMI with touch screen.

Salient Features of Mobile Plants

Easy to Operate

Modular Design For Transport

Completely Pre Wired Get set and Go

No Civil Works Massive saving

SCADA / PLC Based control Panel with online print out facility.

Complete chassis with wheel Hub axle assembly in chassis with Drum Front rear break kaman patta Air tank landing gear king pin wheel rims, tyres.

+91 98983 41024 (For Domestic Inquiries)

+91 94283 25161 (For Export Inquiries)

0 notes

Text

Understanding Asphalt Mixing Plant Prices: Factors Influencing Costs

Asphalt mixing plants play a crucial role in the construction industry, providing the necessary asphalt mix for roads, highways, and various infrastructure projects. When considering the purchase of an asphalt mixing plant, understanding the factors influencing prices is essential. From project requirements to equipment specifications, several factors contribute to the variability in asphalt mixing plant prices. In this article, we delve into the key considerations that impact the cost of asphalt mixing plants.

Capacity and Output

The capacity of an asphalt mixing plant, measured in tons per hour (TPH), significantly affects the asphalt mixing plant price. Plants with higher capacities are generally more expensive due to their ability to produce larger volumes of asphalt mix in a shorter time frame. The size of your project and anticipated asphalt demand will dictate the required capacity of the plant. It's crucial to assess your project requirements accurately to invest in a plant with an appropriate capacity to meet your needs efficiently.

Plant Type and Configuration

Asphalt mixing plants come in various types and configurations, each catering to specific project requirements and operational preferences. Drum mix plants and batch mix plants are the two primary types available, with each offering distinct advantages in terms of production efficiency and flexibility. Additionally, the configuration of the plant, including the number of bins, storage silos, and auxiliary equipment such as dust collectors and asphalt tanks, influences the overall price. Customizable features and optional add-ons may also impact the cost of the plant.

Technology and Innovation

Advancements in technology and innovative features incorporated into asphalt mixing plants can contribute to higher prices. Modern plants equipped with state-of-the-art control systems, advanced automation, and energy-efficient components may command a premium due to their enhanced performance, reliability, and sustainability. While the initial investment may be higher for technologically advanced plants, they often offer long-term cost savings through improved efficiency and reduced operational expenses.

Quality and Durability

The quality of materials and components used in the construction of asphalt mixing plants directly impacts their price. High-quality materials, such as robust steel structures, corrosion-resistant coatings, and durable mechanical components, contribute to the longevity and reliability of the plant. While plants constructed with premium materials may entail higher upfront costs, they offer greater durability and require fewer repairs and replacements over their operational lifespan, resulting in lower overall ownership of mobile asphalt mixing plant price.

Manufacturer Reputation and Support

The reputation of the manufacturer and the level of after-sales support provided can influence the price of asphalt mixing plants. Established manufacturers with a track record of delivering quality products and comprehensive customer service may command higher prices due to the perceived value and reliability they offer. Investing in a plant from a reputable manufacturer ensures access to technical expertise, spare parts availability, and ongoing support, enhancing the overall value proposition of the plant.

Geographic Location and Regulations

Local market conditions, geographic location, and regulatory requirements can also impact asphalt mixing plant prices. Factors such as transportation costs, import/export tariffs, taxes, and environmental regulations may vary from region to region, affecting the final cost of the plant. Additionally, compliance with local emissions standards and environmental regulations may necessitate the incorporation of specific features or technologies, which can influence the price accordingly.

Conclusion

Asphalt mixing plant prices vary based on a multitude of factors, including capacity, plant type, technology, quality, manufacturer reputation, and regulatory considerations. By understanding these factors and assessing your project requirements carefully, you can make informed decisions when selecting an asphalt mixing plant that offers the best balance of performance, reliability, and value for your investment. Prioritize quality, efficiency, and long-term sustainability to ensure the success of your asphalt production operations. Contact aimix machinery for more details.

0 notes

Text

What's the Functions of Asphalt Plant Dryer Drum?

The asphalt plant dryer drum is to preheat the cold aggregate, dry and heat it up to ensure that discharge temperature meets the requirements.

Drying drum is one of the core components of asphalt mixing plant. The performance of drying drum directly determine the production of a complete set of asphalt mixing plant.

The Advantages of Drying Drum:

Long service life

Energy saving

Low emission

Low fuel cost

ZOOMLINE provide stationary and mobile type drying drums for choice.

#dryer drum#drying drum#asphalt plant dryer#asphalt dryer drum#asphalt drum mix plant#asphalt mixing plant#road construction#asphalt plant#construction#asphaltplant#mobile asphalt drum mix plant#heavy equipment#concrete#bitumen#dryer#dryer drum mix

2 notes

·

View notes

Text

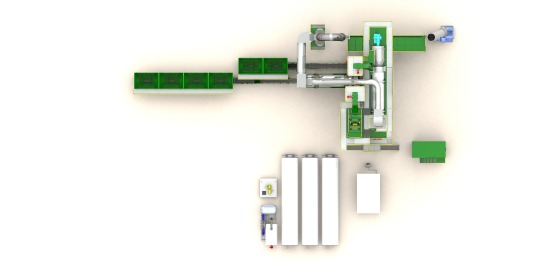

Mobile Asphalt Drum Mix Plant Layout - Atlas Industries

The layout of the mobile asphalt drum mix plant is the same as its stationary counterpart. The units are designed to be mobile. This means all components of the Atlas mobile asphalt drum plant can be easily shifted from one place to another. The ease of shifting and containerized design helps in achieving the desired goal.We have installed mobile drum mix plants in the Philippines, Nigeria, Algeria, American Samoa, Cameroon, Somalia, Botswana, Oman, Malawi, Tanzania, and Myanmar.

0 notes

Text

https://proplusexim.com/concrete-batching-mixing-plant/

Concrete Batching / Mixing Plant in Arusha, Tanzania

Proplus Exim is a Merchant Exporter based in Ahmedabad, Gujarat. We export products such as concrete equipment, road construction equipment, personal care, dairy & bakery, sanitary, food, and so on. Our construction equipment includes compact concrete batching plants, asphalt drum mix plants, cement and fly ash silo systems, concrete batching / mixing plants, GDB / DLC plant, hydraulic broomer, mobile batching plant with pan mixer, skid type concrete batching plant and wet mix macadam plant. The company's primary focus is customer service.

1 note

·

View note

Text

1 note

·

View note

Text

Asphalt Drum Mix Plant - Exporter - Mobile Hot Mixing Plants

Atlas is a leading manufacturer and exporter of asphalt drum mix plants worldwide. We offer high-quality small and mini mobile hot mixing plants at low prices.

#asphaltdrummixplant#drummixasphaltplant#asphaltplant#asphaltdrummixplantindia#drummixasphaltplantindia

0 notes

Text

Mobile Asphalt Stations Models and Features

The mobile asphalt stations meet the requirements of high efficiency, flexibility, durability and environmental protection. The structural design of mobile asphalt mixing station is generally simple and compact, easy to disassemble and move, and at the same time to ensure the stability and efficiency of the production process.

The models of the mobile asphalt stations usually starts with YLB, followed by a set of numbers indicating different models and specifications of the asphalt mixing plant. The specific output depends on the different models and configurations of the mobile asphalt mixing plant, which can generally be categorized into small, medium and large asphalt mixing plants. The following are some common YLB mobile asphalt mixing plant models and their corresponding output ranges:

1. YLB500: the output is about 20-40 tons/hour

2. YLB800: output is about 40-60 tons/hour

3.YLB1000: output of about 60-80 tons / hour

4. YLB1500: output about 90-120 tons/hour

3. YLB2000: output about 120-160 tons/hour

These models and output are for reference only, the actual output will be affected by the type of raw materials, mixing time, ambient temperature and other factors. When choosing a mobile asphalt mixing plant, you need to choose the appropriate model and output according to the specific project requirements and production scale.

The structural design of mobile asphalt mixing station usually includes the following main parts:

1.Mixture collection system:

Including asphalt silo, aggregate silo, powder silo, etc., used to store raw materials, to ensure the continuity and stability of the material supply in the production process.

2.Mixing system:

Including mixer, mixing drum, mixing blade, etc., used to mix asphalt, aggregate and powder fully to produce asphalt concrete in line with the requirements.

3.Control system:

Including PLC control system, touch screen operation interface, etc., which is used to monitor and regulate the whole production process to ensure that the quality of asphalt concrete produced is stable.

4.Conveying system:

Including conveyor belt, unloading hopper, etc., which is used to convey the mixed asphalt concrete to the truck or storage equipment.

5.Electrical system:

Including motors, cables, lighting equipment, etc., used to provide power and lighting to ensure the normal operation of the equipment.

6.Support structure:

Including support legs, support frames, etc., which are used to support and stabilize the whole equipment to ensure that the equipment does not tilt or shake during the production process.

Mobile asphalt mixing plant has the following unique features:

1.Flexibility:

Mobile asphalt mixing plant can be quickly disassembled and moved, which is suitable for projects that require frequent transfer, saving time and cost.

2.Environmental protection:

Mobile asphalt mixing plant adopts closed design, which reduces environmental pollution and noise pollution and meets the modern environmental protection requirements.

3.High efficiency:

Mobile asphalt mixing plant is equipped with high efficient mixing equipment and control system, which can produce various specifications of asphalt concrete quickly and accurately.

4. Energy-saving:

Mobile asphalt mixing plant adopts advanced energy-saving technology, which can effectively save energy consumption and reduce production costs.

5.Convenient maintenance:

Mobile asphalt mixing plant has a simple structure and is easy to maintain, reducing downtime and maintenance costs.

Overall, mobile asphalt stations have the unique features of flexibility, environmental protection, high efficiency, energy saving and convenient maintenance, which is an indispensable and important equipment in modern road construction.

This resource is from http://www.asphalt-mixing-plants.net/industry-news/mobile-asphalt-stations.html

Should you be interested in buying our product, please contact us at:

Haomei Machinery Equipment Co.,ltd

Whatsapp/Wechat: 0086 181 3788 9531

Email: [email protected]

0 notes