#Plywood Market Insights

Text

Construction Segment to Remain the Fastest Expanding Application of Plywood Market During 2022-2027

Construction Segment to Remain the Fastest Expanding Application of Plywood Market During 2022-2027

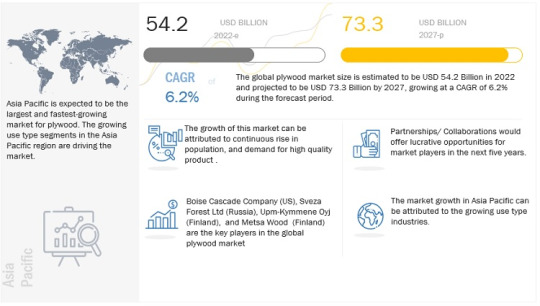

The global plywood market size is projected to grow from USD 54.2 billion in 2022 to USD 73.3 billion by 2027, at a CAGR of 6.2%, According to the MarketsandMarkets™ analysis. Plywood is a well-known manufactured wood-based panel product that has been used in global development projects for many years. Plywood panels for structural applications are made up of many layers or plys of softwood…

View On WordPress

#Demand for Plywood#Plywood Market#Plywood Market Analysis#Plywood Market Forecast#Plywood Market Growth#Plywood Market Insights#Plywood Market Overview#Plywood Market Report#Plywood Market Share#Plywood Market Size#Plywood Market Trends#Plywood Sales

0 notes

Text

The report "Plywood Market by Type (Hardwood and Softwood), Application (Construction and Industrial), Uses Type (New Construction and Rehabilitation), and Region (North America, Europe, APAC, MEA, South America) - Global Forecast to 2027", Plywood market size is projected to reach USD 73.3 billion by 2027 from USD 54.2 billion in 2022 growing at a CAGR of 6.2%. The Asia Pacific region is the largest market for plywood across the globe. The market in the Asia Pacific has been studied for China, India, Japan, South Korea, Taiwan, Thailand, Malaysia and the Rest of Asia Pacific (Australia, Indonesia, and others). Among these countries, China accounted for the largest share of 80.0% of the Asia Pacific plywood market in terms of value.

India and China have experienced close to double-digit GDP growth in recent years, as well as a population boom. The stable economy and growing building and construction industry has augmented the growth of plywood in India and China. Furthermore, furniture sector is one of the main consumers of plywood in India. During the 2018 to 2023, it is predicted that the India furniture market by commercial sector will have a CAGR of 11.97%. India is the fourth-largest consumer of furniture worldwide and the fifth-largest producer of furniture. The Indian furniture industry is estimated to be worth $8 billion, represents 0.5% of the GDP in 2022 according to IBEF (Indian Brand Equity Foundation). The domestic organized industry has roughly 5000 businesses, and there are almost 10,500 furniture imports. The industries that contribute most to the sectors growth include real estate, housing & hospitality, and consumer base growth.

Major players operating in the plywood include Georgia Pacific LLC (US), Boise Cascade Company (US), Weyerhaeuser Company Ltd (US), UPM-Kymmene Oyj (Finland), Svezza Forest Ltd (Russia), PotlatchDeltic Corporation (US), Greenply Industries Ltd (India), Century Plyboards India Ltd. (India), Austral Plywoods (Australia), and others.

#Plywood Market#Plywood Market Report#Plywood Market Insights#Plywood Market Size#Plywood Market Share#Plywood Market Forecast#Plywood Market Overview#Plywood Market Trends#Plywood Market Analysis#Demand for Plywood#Plywood Sales#Plywood Market Growth#Plywood Market Opportunity

0 notes

Text

2023 Saw a 6% Dip in European Wood-Based Panels Production

In 2023, the European wood-based panel industry faced a notable downturn. The year was marked by a 6.3% decrease in production, a figure that has been characterized as "disappointing" by industry experts. This decline, as reported by the European Panel Federation (EPF), reflects a significant shift in the sector's dynamics. The statistics not only underscore the challenges faced by the industry but also signal a need for a deeper analysis of the underlying causes.

In this blog, we will discuss the factors contributing to this downturn and explore its implications for the European timber market and its global standing in wood-based panel production.

Wood-Based Panels Gain Market Share

Despite the overall downturn, wood-based panels emerged as a bright spot, outperforming the two principal consumer sectors—furniture and construction. This trend indicates an increase in market share for wood-based products, a silver lining amidst broader industry challenges.

This encouraging development is detailed in the EPF's Annual Report 2023. The report was unveiled during the EPF's Annual General Meeting, which took place from June 19-21 in Riga, Latvia. The event, hosted by the Latvian plywood manufacturer Latvijas Finieris, brought together 180 professionals from across the industry, creating a forum for dialogue and collaborative efforts in the face of market challenges.

The Varied Fortunes of Wood-Based Panels in 2023

The product-specific analysis for 2023 reveals a fragmented market in the wood-based panels sector:

OSB (Oriented Strand Board) stood out as the only category to witness growth, with a 2% increase in production, reaching 6.6 million cubic meters (up from 6.5 million cubic meters in 2022).

Particleboard, the industry’s largest segment, experienced a 5% decline, with production falling to 30.9 million cubic meters (down from 32.5 million cubic meters in 2022).

MDF (Medium-Density Fiberboard) suffered a sharper decline, with an 11% decrease leading to 11.1 million cubic meters of production (a drop from 12.5 million cubic meters in 2022).

Softboard, primarily comprising wood fibre insulation boards, which had previously been on an incline, saw a 6% reduction to 4.8 million cubic meters (previously at 5.2 million cubic meters).

Plywood production faced a significant 15% downturn, amounting to 2.6 million cubic meters (compared to 3.1 million cubic meters in 2022).

Hardboard recorded a 17% decrease, although it remains the smallest product area within the European wood-based panel industry, with production at 400,000 cubic meters (down from 500,000 cubic meters in 2022).

The detailed breakdown illustrates how different product areas within the global timber industry have had varying degrees of success and challenges.

Conclusion

Staying informed with the latest developments and understanding price dynamics are essential to success in the global timber industry. This is where the Timber Exchange’s Market Data Hub becomes an indispensable tool. As a comprehensive digital tracker of the global timber market, the Market Data Hub offers far more than mere data. It serves as a repository of detailed news, updates, and webinars.

Through a single, streamlined dashboard, the platform grants access to 200+ market indicators, empowering users to monitor a wide array of forestry operations effectively. The Market Data Hub covers it all, whether it's logging activities, production figures, inventory levels, or export/import volumes. It also provides insights into consumption patterns and pricing across more than 25 global key markets.For those eager to delve deeper into the Market Data Hub's capabilities and leverage its full potential, scheduling a demonstration is just a click away. Discover how this platform can transform your approach to navigating the global timber market.

0 notes

Text

Woodworking Circular Saw Blades Market Size, Global Industry Trend Analysis and Forecast 2024-2030

Global Info Research’s report offers key insights into the recent developments in the global Woodworking Circular Saw Blades market that would help strategic decisions. It also provides a complete analysis of the market size, share, and potential growth prospects. Additionally, an overview of recent major trends, technological advancements, and innovations within the market are also included.Our report further provides readers with comprehensive insights and actionable analysis on the market to help them make informed decisions. Furthermore, the research report includes qualitative and quantitative analysis of the market to facilitate a comprehensive market understanding.This Woodworking Circular Saw Blades research report will help market players to gain an edge over their competitors and expand their presence in the market.

According to our (Global Info Research) latest study, the global Woodworking Circular Saw Blades market size was valued at USD million in 2023 and is forecast to a readjusted size of USD million by 2030 with a CAGR of % during review period.

Woodworking Circular Saw Blades are round circular saw blades that are designed to cut various types of wood, including lumber, plywood, softwood, hardwood, panels and laminates. They can be used in various applications, depending on the type of wood you are cutting and the kind of task you are performing. Blades come in a variety of sizes and can be made of various materials to accommodate different uses.

In Japan market, key players of woodworking circular saw blades include Tenryu, Robert Bosch, Stanley Black and Decker, Tenryu Saw Mfg, TTI, etc. The top five players hold a share over 40%.

The Global Info Research report includes an overview of the development of the Woodworking Circular Saw Blades industry chain, the market status of Residential (Tungsten Carbide, Diamond), Industrial Manufacturing (Tungsten Carbide, Diamond), and key enterprises in developed and developing market, and analysed the cutting-edge technology, patent, hot applications and market trends of Woodworking Circular Saw Blades.

Regionally, the report analyzes the Woodworking Circular Saw Blades markets in key regions. North America and Europe are experiencing steady growth, driven by government initiatives and increasing consumer awareness. Asia-Pacific, particularly China, leads the global Woodworking Circular Saw Blades market, with robust domestic demand, supportive policies, and a strong manufacturing base.

We have conducted an analysis of the following leading players/manufacturers in the Woodworking Circular Saw Blades industry:

Tenryu、Robert Bosch、Stanley Black and Decker、Tenryu Saw Mfg、TTI、Dewalt、HiKOKI、Makita、HILTI、Bahco、TRUSCO、RYOBI、KANEFUSA、Leitz、LEUCO

Market segment by Type: Tungsten Carbide、Diamond、Others

Market segment by Application:Residential、Industrial Manufacturing、Others

Report analysis:

The Woodworking Circular Saw Blades report encompasses a diverse array of critical facets, comprising feasibility analysis, financial standing, merger and acquisition insights, detailed company profiles, and much more. It offers a comprehensive repository of data regarding marketing channels, raw material expenses, manufacturing facilities, and an exhaustive industry chain analysis. This treasure trove of information equips stakeholders with profound insights into the feasibility and fiscal sustainability of various facets within the market.

Illuminates the strategic maneuvers executed by companies, elucidates their corporate profiles, and unravels the intricate dynamics of the industry value chain. In sum, the Woodworking Circular Saw Blades report delivers a comprehensive and holistic understanding of the markets multifaceted dynamics, empowering stakeholders with the knowledge they need to make informed decisions and navigate the market landscape effectively.

Conducts a simultaneous analysis of production capacity, market value, product categories, and diverse applications within the Woodworking Circular Saw Blades market. It places a spotlight on prime regions while also performing a thorough examination of potential threats and opportunities, coupled with an all-encompassing SWOT analysis. This approach empowers stakeholders with insights into production capabilities, market worth, product diversity, and the markets application prospects.

Assesses strengths, weaknesses, opportunities, and threats, offering stakeholders a comprehensive understanding of the Woodworking Circular Saw Blades markets landscape and the essential information needed to make well-informed decisions.

Market Size Estimation & Method Of Prediction

Estimation of historical data based on secondary and primary data.

Anticipating market recast by assigning weightage to market forces (drivers, restraints, opportunities)

Freezing historical and forecast market size estimations based on evolution, trends, outlook, and strategies

Consideration of geography, region-specific product/service demand for region segments

Consideration of product utilization rates, product demand outlook for segments by application or end-user.

About Us:

Global Info Research is a company that digs deep into Global industry information to Woodworking Circular Saw Blades enterprises with market strategies and in-depth market development analysis reports. We provide market information consulting services in the Global region to Woodworking Circular Saw Blades enterprise strategic planning and official information reporting, and focuses on customized research, management consulting, IPO consulting, industry chain research, database and top industry services. At the same time, Global Info Research is also a report publisher, a customer and an interest-based suppliers, and is trusted by more than 30,000 companies around the world. We will always carry out all aspects of our business with excellent expertise and experience.

0 notes

Text

0 notes

Text

Top Factors Influencing Wooden Watch Box Prices in Pakistan

Introduction

In the realm of luxury and practicality, wooden watch boxes stand out as a quintessential accessory for watch enthusiasts. These elegant storage solutions not only keep timepieces organized but also enhance their presentation. However, the price of Wooden Watch Boxes In Pakistan can vary significantly based on several factors. This article delves into the key factors influencing these prices and offers insights into finding the perfect wooden watch box that suits both your style and budget.

1. Material Quality

The quality of the wood used in crafting a watch box plays a pivotal role in determining its price. High-quality, solid wood such as mahogany, walnut, or oak typically costs more than plywood or cheaper alternatives. Premium woods are favored for their durability, rich grain, and sophisticated appearance. For instance, a wooden watch box made from solid mahogany will generally be more expensive than one crafted from lesser-grade wood.

Key Considerations:

Type of Wood: Exotic or premium woods drive up the price.

Finish and Treatment: High-quality finishes and treatments enhance the wood's appearance and longevity but can also increase the cost.

2. Craftsmanship and Design

The level of craftsmanship involved in making a wooden watch box is another significant factor affecting its price. Intricate designs, detailed carvings, and complex joinery require skilled artisans and additional time, thus raising the cost. Handcrafted wooden watch boxes, which showcase exceptional craftsmanship and unique designs, often come at a premium compared to machine-made counterparts.

Key Considerations:

Handcrafted vs. Machine-Made: Handcrafted boxes generally cost more due to the artistry and effort involved.

Design Complexity: More elaborate designs and customizations can increase the price.

3. Size and Capacity

The size and capacity of a wooden watch box directly impact its price. Boxes with larger capacities, which can hold multiple watches, are usually more expensive. A wooden watch box with a higher number of partitions or additional features like a glass lid or drawer will cost more than a simpler design.

Key Considerations:

Number of Partitions: More partitions mean higher costs.

Size Dimensions: Larger boxes will generally be more expensive due to the increased material and labor involved.

4. Interior Lining and Features

The interior lining and additional features of a wooden watch box also influence its price. High-quality linings made from materials such as velvet, leather, or suede add to the overall cost. Features like built-in winders, compartments for other accessories, and customization options also contribute to the price.

Key Considerations:

Type of Lining: Premium linings add to the cost.

Additional Features: Extra features like winders or compartments can increase the price.

5. Brand and Origin

The brand and origin of a wooden watch box can affect its price. Renowned brands known for their quality and design often charge more for their products. Additionally, wooden watch boxes imported from countries known for high-quality craftsmanship, such as Pakistan, may come at a higher price point due to shipping and import duties.

Key Considerations:

Brand Reputation: Well-known brands often have higher price tags.

Import Costs: Imported boxes may be more expensive due to additional costs.

6. Customization and Personalization

Customization and personalization options can significantly impact the price of a wooden watch box. Custom engravings, bespoke designs, and personalized compartments add uniqueness to the watch box but can also raise the cost. Many consumers are willing to pay extra for a personalized touch that makes their watch box truly one-of-a-kind.

Key Considerations:

Engravings and Personalization: Custom details can increase the price.

Bespoke Designs: Unique designs tailored to individual preferences are typically more expensive.

7. Market Trends and Demand

Market trends and demand also play a role in determining the price of wooden watch boxes. Trends in interior design, changes in consumer preferences, and fluctuations in material costs can all impact prices. For example, during periods of high demand or shortages of certain materials, prices may increase.

Key Considerations:

Current Trends: Popular styles and materials can affect pricing.

Supply and Demand: High demand or low supply can drive up prices.

Popular Wooden Watch Boxes in Pakistan

To provide a practical understanding, here are some examples of wooden watch boxes available in Pakistan, highlighting their features and prices:

Wooden Watch Boxes with Glass Lid - 10 PartitionsThis elegant watch box features a glass lid and ten partitions, offering both style and functionality. The use of high-quality wood and a sophisticated design make it a popular choice for those seeking a blend of luxury and practicality.

Customized Wooden Watch BoxesMany artisans in Pakistan offer customizable wooden watch boxes that cater to specific preferences and needs. These boxes can be tailored with custom engravings, unique designs, and personalized features, adding a touch of individuality.

Conclusion

When purchasing a wooden watch box in Pakistan, understanding the factors that influence its price is essential for making an informed decision. From material quality and craftsmanship to size, features, and brand, each element contributes to the overall cost of the watch box. By considering these factors, you can select a wooden watch box that not only fits your budget but also enhances your collection with elegance and functionality.

For those interested in exploring premium wooden watch boxes and other exquisite Pakistani Handicrafts, visit Crafts Emporium. Whether you’re looking for a luxurious Wooden Watch Box or a unique piece to complement your collection, Crafts Emporium offers a diverse range of handcrafted items that reflect exceptional quality and artistry.

0 notes

Text

Which Is the Best Plywood for Interiors?

When designing the perfect interior, choosing high-quality, suitable materials is paramount. Plywood is a favored, versatile material for various furniture and structural applications, but with so many options on the market, selecting the right type can be overwhelming. Let Sylvan Ply, a leading plywood manufacturer in 2024 provide you with the insights you need to make confident choices for your interior spaces.

Understanding Plywood Grades

The first step is to understand that plywood comes in different grades, each with unique properties that make them better suited for specific tasks:

MR Grade (Moisture Resistant): A budget-friendly option for most general indoor furniture and paneling purposes in dry areas. It has some moisture resistance but isn't designed for prolonged water exposure.

BWR Grade (Boiling Water Resistant): A step up from MR, BWR grade plywood is ideal for areas with moderate moisture levels, such as kitchens and bathrooms. It uses a stronger adhesive that resists delamination better in damp conditions.

BWP Grade (Boiling Water Proof): This is the most water-resistant plywood grade for interiors. It can withstand prolonged humidity and even direct water contact, making it suitable for marine use as well as heavy-use kitchen and bathroom applications.

Fire Retardant Plywood: Specially treated plywood with fire-resistant chemicals, providing added safety in kitchens and other potentially fire-prone areas. Contact Sylvan Ply for more information.

0 notes

Text

The Current Landscape of Construction Materials in Saudi Arabia: Challenges and Insights

In the booming construction industry of Saudi Arabia, the demand for high-quality building materials has never been higher. As a pivotal player in the market, Starlinks Corporation understands the nuances and challenges facing builders and developers across the kingdom. Let's delve into some of the critical issues shaping the industry today.

Quality Concerns: A Crucial Factor

Quality assurance remains a primary concern for stakeholders in Saudi Arabia's construction sector. From MS angles to marine plywood, every material must meet stringent standards to ensure durability and structural integrity. At Starlinks Corporation, we prioritize sourcing materials that not only meet but exceed these expectations, providing our clients with peace of mind and long-lasting reliability.

Supply Chain Dynamics: Navigating Challenges

Navigating the supply chain complexities is another significant hurdle. Timely delivery and availability of materials such as GI pipes and cement are critical to project timelines. We at Starlinks Corporation have established robust partnerships with trusted suppliers, ensuring seamless procurement and delivery processes. This allows us to meet our clients' deadlines consistently, contributing to the success of their projects.

Environmental Sustainability: A Growing Imperative

In recent years, environmental sustainability has emerged as a key concern in construction practices worldwide, and Saudi Arabia is no exception. The industry is increasingly shifting towards eco-friendly materials and sustainable building practices. At Starlinks Corporation, we embrace this shift by offering a range of environmentally responsible options, from green meshes to sustainable timber, supporting our clients in achieving their green building goals.

Regulatory Compliance: Navigating the Legal Landscape

Navigating the regulatory landscape is crucial for any construction project in Saudi Arabia. Compliance with local regulations governing materials like concrete nails and binding wire ensures project legality and safety. Starlinks Corporation stays ahead of regulatory changes, ensuring that all materials we supply meet or exceed regulatory standards, minimizing risks for our clients and ensuring smooth project execution.

Local vs. Imported Materials: Finding the Balance

Balancing between locally sourced materials and imported options is another consideration. While locally sourced materials support the economy and reduce logistics costs, imported materials often bring unique qualities and specifications that may be necessary for specialized projects. At Starlinks Corporation, our diverse product range includes both locally sourced and imported materials, providing our clients with flexibility and choice tailored to their project requirements.

The Human Touch: Our Commitment to Excellence

At the heart of Starlinks Corporation lies a commitment to excellence and customer satisfaction. Beyond supplying materials, we strive to build lasting relationships with our clients based on trust, reliability, and personalized service. Whether it's providing expert advice on material selection or ensuring prompt delivery, we are dedicated to meeting and exceeding our clients' expectations every step of the way.

Conclusion

In conclusion, the construction materials landscape in Saudi Arabia presents both challenges and opportunities. By addressing quality concerns, navigating supply chain dynamics, embracing sustainability, ensuring regulatory compliance, and offering a diverse range of materials, Starlinks Corporation stands at the forefront of supporting the kingdom's ambitious construction projects.

For more information about our products and services, visit Starlinks Corporation. Partner with us to experience firsthand how we can elevate your next construction project with our quality materials and dedicated service.

0 notes

Text

Transform Your Home with Expert Kitchen Renovation in Westchester NY

Introduction

A kitchen renovation is a significant investment that can transform your home’s functionality, aesthetic appeal, and value. In Westchester NY, where homes often feature a blend of historical charm and modern luxury, a well-executed kitchen renovation can be a game-changer. This comprehensive guide will walk you through the essentials of a kitchen renovation in Westchester NY, offering insights on planning, design, and execution to ensure your project is a success.

Why Invest in a Kitchen Renovation?

A well-planned kitchen renovation can provide numerous benefits. From increasing your home’s market value to improving its functionality and energy efficiency, the advantages are substantial. In Westchester NY, where the real estate market is competitive, a modern and stylish kitchen can make your home stand out to potential buyers. Even if you’re not planning to sell, a kitchen renovation can make your space more enjoyable and suited to your family’s needs.

Key Considerations for Your Kitchen Renovation

Setting a Budget

One of the first steps in any renovation project is establishing a realistic budget. This should include costs for materials, labor, permits, and a contingency for unexpected expenses. In Westchester NY, the cost of a kitchen renovation can vary widely depending on the scope of the project and the materials used. Working with a professional can help you create a budget that aligns with your vision and financial constraints.

Choosing a Design Style

Your kitchen should reflect your personal taste while complementing the overall aesthetic of your home. Popular design styles in Westchester NY include:

Traditional: Classic elements like wood cabinetry, granite countertops, and ornate details.

Modern: Sleek lines, minimalistic design, and innovative materials.

Transitional: A blend of traditional and modern elements for a balanced look.

Farmhouse: Rustic charm combined with contemporary functionality, featuring open shelving and vintage fixtures.

Essential Elements of a Successful Kitchen Renovation

Layout and Space Planning

The layout of your kitchen is crucial to its functionality. Common kitchen layouts include:

L-Shaped: Offers ample counter space and flexibility in appliance placement.

U-Shaped: Maximizes storage and work areas, ideal for larger kitchens.

Galley: Efficient for smaller spaces, focusing on streamlined workflows.

Open Concept: Integrates the kitchen with adjacent living areas, creating a spacious and social atmosphere.

In Westchester NY, open concept kitchens are particularly popular as they enhance the flow of older homes while creating a modern and inviting space.

Quality Materials

Choosing high-quality materials is essential for the longevity and aesthetics of your kitchen. Consider durable options such as:

Countertops: Quartz, granite, and marble for durability and style.

Cabinetry: Solid wood or plywood with quality finishes ensures longevity.

Flooring: Hardwood, tile, or luxury vinyl plank for beauty and resilience.

Investing in quality materials enhances not only the look of your kitchen but also its functionality and ease of maintenance.

The Renovation Process: Step-by-Step

Planning and Design

A successful kitchen renovation begins with thorough planning. This involves:

Consultation: Meet with a professional to discuss your needs, preferences, and budget.

Design: Collaborate on a design that incorporates your style, functional requirements, and optimal layout.

Permits: Secure necessary permits to ensure compliance with local building codes.

Demolition and Construction

Once the design is finalized, the construction phase begins:

Demolition: Carefully remove existing fixtures, cabinetry, and appliances.

Structural Work: Address any necessary plumbing, electrical, or structural changes.

Installation: Install new cabinetry, countertops, appliances, and fixtures according to the design plan.

Finishing Touches

The final stage involves adding the finishing touches that bring your kitchen to life:

Painting and Backsplash: Choose colors and patterns that complement your overall design.

Lighting: Install task lighting, ambient lighting, and decorative fixtures to enhance functionality and atmosphere.

Hardware and Accessories: Select hardware, faucets, and accessories that add style and convenience.

Working with Professionals

Finding the Right Contractor

Selecting the right contractor is crucial for a successful renovation. Look for professionals with:

Experience: Extensive experience in kitchen renovations, particularly in Westchester NY.

References: Positive reviews and references from previous clients.

Licensing and Insurance: Proper licensing and insurance to protect your investment.

Collaboration and Communication

Effective collaboration with your contractor ensures that your vision is realized. Regular communication helps address any issues promptly and keeps the project on track. A good contractor will provide updates, be transparent about timelines and costs, and work with you to make any necessary adjustments.

Conclusion

A kitchen renovation in Westchester NY offers the opportunity to enhance your home's functionality, aesthetics, and value. By understanding the key considerations, essential elements, and step-by-step process, you can embark on your renovation journey with confidence. With the right planning, materials, and professional support, your dream kitchen is within reach. Transform your space and enjoy the benefits of a beautifully renovated kitchen that meets your needs and reflects your style.

1 note

·

View note

Text

Tile Adhesive India

When it comes to renovating or building a new space, choosing the right tile adhesive is crucial. A quality adhesive not only ensures that your tiles stay in place but also provides durability and longevity to your tiling project. In India, the market is flooded with various tile adhesive brands, each claiming to be the best. So, how do you make an informed choice? This guide aims to provide you with comprehensive insights into selecting the best Tile Adhesive India.

Understanding Tile Adhesive

Tile adhesive, also known as tile mortar or tile glue, is a substance used to bond tiles to a substrate. It plays a vital role in ensuring that tiles are securely fixed, preventing them from cracking or coming loose over time. Tile Adhesive India come in different types, including cement-based, epoxy, and organic mastic adhesives, each suitable for specific tile types and applications.

Factors to Consider When Choosing Tile Adhesive

Tile Type

Ceramic Tiles: For ceramic tiles, a standard cement-based adhesive works well.

Porcelain Tiles: Porcelain tiles are denser and require a high-strength adhesive.

Natural Stone: Natural stone tiles like marble or granite need a flexible adhesive to accommodate their movement.

Substrate

The substrate's condition and material (concrete, plaster, plywood) can influence the choice of adhesive.

Ensure that the substrate is clean, dry, and free from any contaminants before applying the adhesive.

Environment

For areas exposed to moisture or high humidity, opt for waterproof or moisture-resistant adhesives.

For exterior applications, UV-resistant and weatherproof adhesives are recommended.

Top Tile Adhesive Brands in India

While there are numerous tile adhesive brands available in India, some stand out for their quality and reliability:

Pidilite - Dr. Fixit

Known for its high-performance adhesives suitable for various tile types and applications.

Offers both cement-based and epoxy adhesives with excellent bonding strength.

MYK LATICRETE

A globally recognized brand offering a wide range of tile adhesives, including epoxy and polymer-modified adhesives.

Provides solutions for both residential and commercial projects.

Fosroc

Offers a comprehensive range of tile adhesives and grouts tailored for different applications.

Known for its innovative and high-quality products.

Application Tips

Preparation: Ensure that the surface is clean, dry, and free from dust or grease before applying the adhesive.

Mixing: Follow the manufacturer's instructions for mixing the adhesive to achieve the right consistency.

Application: Use a notched trowel to spread the adhesive evenly on the substrate, ensuring full coverage.

Curing: Allow the adhesive to cure as per the manufacturer's recommendations before grouting or walking on the tiles.

Conclusion

Choosing the right tile adhesive is essential for the success and longevity of your tiling project. Consider factors like tile type, substrate, and environment when selecting an adhesive. Additionally, opt for trusted brands like Pidilite, MYK LATICRETE, or Fosroc for quality assurance and reliability.

1 note

·

View note

Text

Choosing the Superior Quality Plywood Manufacturer: Key Considerations by Dhanvardhan Ply

In the realm of construction and woodworking, choosing the right plywood manufacturer is crucial to ensure the quality and durability of your projects. With numerous options available, it can be challenging to determine which is the superior quality plywood manufacturers. In this blog, we'll explore key considerations to help you choose the best superior quality plywood manufacturer, with valuable insights, practical tips, and expert advice from Dhanvardhan Ply, a trusted name in the plywood industry.

Reputation and Experience

One of the first considerations when choosing a superior quality plywood manufacturer is their reputation and experience in the industry. Look for manufacturers like Dhanvardhan Ply with a proven track record of delivering high-quality plywood products and a long-standing presence in the market. A manufacturer's reputation speaks volumes about their commitment to quality and customer satisfaction.

Quality Standards and Certifications

Ensure that the plywood manufacturer adheres to stringent quality standards and holds relevant certifications such as IS 303 for BWP (Boiling Water Proof) grade plywood. These certifications guarantee that the plywood products meet specified quality parameters and are suitable for various applications, including interior and exterior use.

Range of Products

Consider the range of plywood products offered by the manufacturer. Dhanvardhan Ply, for instance, provides a wide range of superior quality plywood products, including MR (Moisture Resistant) grade plywood, BWP grade plywood, marine plywood, and more. A diverse product range allows you to choose the right plywood for your specific project requirements.

Raw Material Quality

The quality of raw materials used in plywood manufacturing significantly impacts the final product's durability and performance. A reputable manufacturer like Dhanvardhan Ply sources high-quality wood species, adheres to sustainable forestry practices, and ensures proper seasoning and treatment of raw materials before plywood production.

Manufacturing Process and Technology

Investigate the manufacturing process and technology employed by the plywood manufacturer. Dhanvardhan Ply utilizes advanced manufacturing techniques, modern machinery, and stringent quality control measures to produce superior-quality plywood products. Understanding the manufacturing process helps assess the consistency and reliability of the plywood products.

Customization Options

Consider whether the plywood manufacturer offers customization options to meet specific project requirements. Dhanvardhan Ply provides customization services such as custom sizes, thickness variations, and special treatments like fire retardant and termite-resistant coatings. Customization ensures that you get plywood products tailored to your unique needs.

Pricing and Value for Money

While price is a consideration, it's essential to prioritize value for money over low prices. Superior quality plywood may come at a slightly higher cost initially, but it offers long-term durability, performance, and aesthetic appeal. Compare pricing among reputable manufacturers like Dhanvardhan Ply and assess the overall value and benefits offered.

Customer Reviews and Testimonials

Research customer reviews and testimonials to gauge the experiences of other buyers with the plywood manufacturer. Positive reviews and satisfied customer testimonials are indicators of a manufacturer's reliability, product quality, and customer service. Dhanvardhan Ply takes pride in positive feedback from satisfied customers, reflecting their commitment to excellence.

Warranty and After-Sales Support

Inquire about the warranty period offered by the plywood manufacturer and the after-sales support services available. Dhanvardhan Ply provides warranty coverage on their plywood products and offers excellent after-sales support, including technical assistance, maintenance tips, and product care guidelines.

Environmental Responsibility

Lastly, consider the plywood manufacturer's commitment to environmental responsibility and sustainable practices. Dhanvardhan Ply emphasizes sustainable forestry, responsible sourcing of raw materials, and eco-friendly manufacturing processes to minimize environmental impact.

Conclusion

Choosing the best superior quality plywood manufacturer involves careful consideration of reputation, quality standards, product range, raw material quality, manufacturing processes, customization options, pricing, customer feedback, warranty, and environmental responsibility. By keeping these key considerations in mind and selecting a trusted manufacturer like Dhanvardhan Ply, you can ensure top-notch plywood products for your projects.

#dhanvardhan ply#flush door manufacturer#plywood manufacturers#best quality plywood manufacturers#Superior Quality Plywood Manufacturers#Plywood Suppliers in India

0 notes

Text

The globalplywood market size is projected to grow from USD 54.2 billion in 2022 to USD 73.3 billion by 2027, at a CAGR of 6.2%. The increasing demand for plywood from end uses, such as building & construction, packaging, industrial, and furniture sector, drives the market. Demand for multifarious plywood is encouraged by many companies to formulate different developmental strategies in the plywood market to expand their footprint in the market. The companies have adopted various strategies, such as investment & expansion, merger & acquisition, new product launches, and joint ventures to increase their global presence and maintain sustained growth in the plywood market.

The plywood market in the Asia Pacific is forecasted to register the highest CAGR, in terms of value, between 2022 and 2027. Asia Pacific is a rapidly developing region that offers many opportunities for various industry players. Most of the leading players in North America and Europe are planning to move their production base to this region because of the availability of inexpensive raw materials, low production costs, and the need to serve the local market better. The demand for premium products is increasing in the region with the growth in the middle-class population. Government initiatives are also helping in the growth of the wooden sectors. These factors will play an important role in driving the plywood market.

There are various small, medium, and large players operating in the market. Some of the major market players include Boise Cascade Company (US), Weyerhaeuser Company Ltd (US), Upm-Kymmene Oyj (Finland), Sveza Forest Ltd (Russia), Austral Plywoods Pty Ltd (Australia), Potlatchdeltic Corporation (US), Greenply Industries (India), Metsä Wood (Metsäliitto Cooperative) (Finland), Centuryply (India), Austin Plywood (India). They have adopted various developmental strategies such as investment & expansions, new product launches, mergers & acquisitions, and joint ventures to increase their share in the market.

#Plywood Market#Plywood Market Report#Plywood Market Insights#Plywood Market Size#Plywood Market Share#Plywood Market Forecast#Plywood Market Overview#Plywood Market Trends#Plywood Market Analysis#Demand for Plywood#Plywood Sales#Plywood Market Growth#Plywood Market Opportunity

0 notes

Text

A Deep Dive into the Global Plywood Industry

The Plywood Market report is the most important research for who looks for all information about the market. The global Plywood market size was valued at USD 53,350 million in 2022 and is projected to reach USD 73,860 million by 2033, growing at a CAGR of 6.2% during the forecast period.The report covers all information about the global and regional markets, including historical and future trends for market dominance, size, trades, supply, competitors, and prices, as well as key vendor information across the globe. Forecast market information, SWOT analysis, Plywood market scenario, and feasibility study are important aspects in this report.

Get a sample copy of this report: https://wemarketresearch.com/reports/request-free-sample-pdf/plywood-market/1240

Companies Covered: Plywood Market:

Georgia-Pacific

Boise Cascade

Weyerhaeuser

Columbia Forest Products

UPM-Kymmene Corporation

Jaya Tiasa Holdings Berhad

Greenply Industries Limited

Century Plyboards (India) Limited

Kitply Industries Limited

Sveza Group

Others

These companies have the potential to drive market growth through various strategies. They can focus on offering innovative and high-performance products, taking advantage of advancements in technology. Additionally, expanding their distribution channels to target new customers would be beneficial. Strategic partnerships and collaborations can also be pursued to strengthen market presence and enhance competitiveness.

Global Plywood Market Segmentation:

Type

Softwood

Hardwood

Application

Furniture

Flooring & Construction

Automotive Interior

Others

Key Market Trends and Highlights:

The need for plywood will continue to be driven by emerging markets like China and India, resulting in market expansion.

Customized plywood is becoming more and more popular for special applications like exterior and marine building.

In order to engage customers and increase the reach of plywood products, online channels will be essential.

Tighter environmental regulations are encouraging ethical sourcing and production methods in the sector.

In order to suit the changing needs of various industries and applications, manufacturers are providing a greater selection of plywood choices.

Plywood Market Regional Insights

The report provides a inclusive examination of the factors driving growth, constraints, prospects, and competitive landscape across all regions. The market is segmented by region into North America, Europe, Asia Pacific, Latin America, the Middle East, and Africa. Additionally, the report identifies the top countries in each region and provides market forecasts for each one.

Plywood Market Dynamics:

Driver: Capacity expansion for increasing demand:

One method employed by many manufacturers to boost sales volume is capacity expansion. Raising demand always calls for higher production capacity, but it also needs to be viewed in terms of an investment, which is a vital point in the value chain. Therefore, it is necessary to determine capacity in terms of process equipment and labor. Producers typically employ a "lead capacity strategy," searching for evolving nations with the potential to become future industrial centers. Plywood's affordability and durability make it a popular choice for building, development, and new industrial setups in the majority of emerging nations. Many enterprises are choosing to expand their production capacity despite the hefty initial setup costs because they see the enormous market potential and long-term

Opportunity: Recycling and reuse offer opportunities for growth:

The surge in feedstock costs is currently having an impact on the plastics business. The cost of intermediate and finished goods will rise due to the high cost of feedstock. Recycled plastics can offer better pricing points and a more circular plastic value chain. Policies such as plastics fees and recycled content requirements can provide financial incentives to reduce use and encourage circularity. In an effort to sustain secondary plastics markets, a number of nations have recently tightened rules to push supply and pull demand through recycled content standards. Emerging innovation in recycling technologies and the recent decoupling of primary and secondary polyethylene terephthalate (PET) prices in Europe are encouraging signs that these policies are supporting secondary markets. The application

Directly Purchase a Copy of this Plywood Market research report at: https://wemarketresearch.com/purchase/plywood-market/1240?license=single

The research includes historical data from 2018 to 2023 and forecasts until 2033, making the report valuable to industry executives, marketing, sales and product managers, consultants, analysts, and stakeholders in clearly presented tables Together, we are looking for documents that are easily accessible graph.

Finally, the Plywood Market report is the believable source for gaining the Market research that will exponentially accelerate your business. The report provides locales, economic conditions, item values, benefits, limits, creations, supplies, requests, market development rates, numbers, etc. Plywood industry report additionally presents a new task SWOT exam, speculation attainability investigation, and venture return investigation.

About We Market Research:

WE MARKET RESEARCH is an established market analytics and research firm with a domain experience sprawling across different industries. We have been working on multi-county market studies right from our inception. Over the time, from our existence, we have gained laurels for our deep rooted market studies and insightful analysis of different markets.

Contact Us:

Mr. Robbin Joseph

Corporate Sales, USA

We Market Research

USA: +1-724-618-3925

Websites: https://wemarketresearch.com/

Email: [email protected]

0 notes

Text

7 Factors influencing the cost of Birch Plywood

Birch plywood is a versatile material widely used in various industries, including construction, furniture making, and interior design. Its relevance stems from its exceptional strength, durability, and aesthetic appeal.

Understanding the factors that influence the cost of birch plywood is crucial for businesses and individuals seeking to make informed purchasing decisions for their projects.

1. Quality of Birch Veneer

The quality of birch veneer significantly impacts the overall cost of plywood. Premium, flawless veneers command a higher price due to their superior strength, durability, and overall visual appeal. Simply put, the better the quality of the veneer, the higher the cost of the plywood.

2. Thickness and Size

The thickness and size of birch plywood sheets directly affect their pricing. Thicker and larger sheets are generally more expensive due to the increased material usage and manufacturing costs. Therefore, it's essential to consider the specific thickness and size requirements for a project to accurately estimate the plywood cost.

3. Grading Standards

Birch plywood comes in various grading standards, such as B/BB, BB/CP, and more. These grading standards impact pricing, with higher grades that exhibit fewer defects commanding a premium price compared to lower grades. Understanding these standards is essential for ensuring that the chosen plywood meets the quality requirements of the intended application.

4. Manufacturing Techniques

Specific manufacturing techniques, such as rotary cut vs. plain-sliced veneers, significantly influence the cost of birch plywood. Advanced manufacturing processes also contribute to a higher-quality product, leading to an associated increase in cost. When assessing the impact of manufacturing techniques on pricing, it's crucial to consider the plywood's intended use and the desired finish.

5. Environmental Certifications

Eco-friendly certifications can affect the price of birch plywood. The growing consumer demand for sustainable products has driven up costs for certified materials, reflecting the industry's shift towards environmentally responsible practices.

6. Market Demand and Supply

Fluctuations in market demand and supply dynamics can significantly impact the cost of birch plywood. Increased demand or limited availability can lead to price spikes, making it important for businesses and individuals to stay informed about market trends and potential price fluctuations.

7. Geographic Location

Geographic location plays a critical role in determining the cost of birch plywood. Shipping expenses and regional market variations contribute to price differentials. Understanding the geographic factors that influence pricing can help identify cost-effective sourcing options without compromising on quality.

Conclusion

In conclusion, understanding the seven factors influencing the cost of birch plywood is essential for making informed purchasing decisions. Businesses and individuals can navigate the plywood market more effectively by considering the quality of birch veneer, thickness and size, grading standards, manufacturing techniques, environmental certifications, market dynamics, and geographic influences. This knowledge empowers consumers to select the right birch plywood for their projects while optimising costs and ensuring quality outcomes.

In summary, the blog has provided valuable insights into the factors that influence the cost of birch plywood, catering to the informational needs of individuals and businesses seeking to establish a strong online presence through informed decision-making in plywood procurement.

By offering detailed explanations and a modern language style, the blog ensures the content is informative and easily accessible to the target audience. The factual nature of the content and the active sentence structures used throughout the blog reinforce its credibility and provide a comprehensive understanding of birch plywood costs.

Source By: 7 Factors influencing the cost of Birch Plywood

0 notes

Text

The Complete Guide to BWP Plywood: Essential Insights for Construction Projects

BWP plywood, also known as Boiling Water Proof plywood, is a vital material in construction, renowned for its durability and versatility. Let's delve into the key aspects of BWP plywood, including its significance, types, applications, suppliers, and market dynamics.

Understanding BWP Plywood's Importance

BWP plywood is a preferred choice in construction due to its resistance to moisture, making it suitable for environments prone to humidity and water exposure. Its strength and durability make it indispensable for various structural and interior applications.

Exploring BWP Plywood Varieties

BWP plywood comes in different grades and thicknesses, catering to specific project requirements. Understanding these variations helps in selecting the appropriate type for applications ranging from roofing to furniture making.

Navigating BWP Plywood Costs

The cost of BWP plywood depends on factors such as grade, thickness, and market demand. While it may have a higher upfront cost compared to standard plywood, its longevity and resistance to moisture-related damage offer significant long-term value.

Selecting Reliable BWP Plywood Suppliers

Choosing reputable suppliers is crucial for procuring high-quality BWP plywood. Look for suppliers with a reputation for consistency, adherence to industry standards, and a wide range of product options to meet diverse project needs.

Analyzing Market Trends

Keeping abreast of market trends helps in making informed decisions regarding BWP plywood procurement. Factors such as raw material availability, demand fluctuations, and industry regulations impact pricing and availability.

Future Outlook and Advanced Applications

The future of BWP plywood involves innovations in manufacturing processes and enhancements in performance characteristics. Advanced applications include use in modular construction, furniture manufacturing, and interior design, driven by evolving consumer preferences and technological advancements.

Conclusion

BWP plywood is an essential material in construction, prized for its durability and resistance to moisture. By understanding its significance, exploring varieties, assessing costs, and partnering with reliable suppliers, stakeholders can ensure successful project outcomes. With a focus on quality and strategic decision-making, BWP plywood remains a cornerstone of modern construction practices.

0 notes

Text

Which Is the Best Plywood for Interiors?

When designing the perfect interior, choosing high-quality, suitable materials is paramount. Plywood is a favored, versatile material for various furniture and structural applications, but with so many options on the market, selecting the right type can be overwhelming. Let Sylvan Ply, a leading plywood manufacturer in 2024 provide you with the insights you need to make confident choices for your interior spaces.

0 notes