#Stationary Asphalt Plant Layout

Text

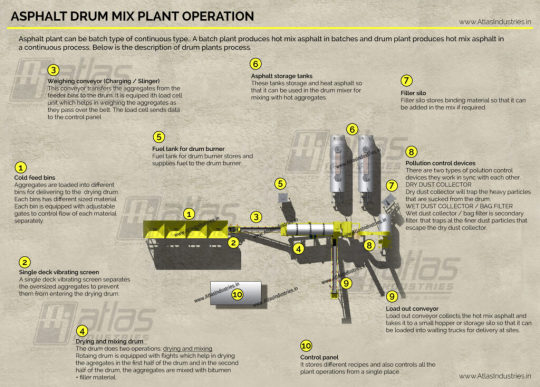

Stationary Asphalt Drum mix Plant Layout - Atlas Industries

A stationary asphalt drum mix plant is the most widely used asphalt mixing plant. It allows operating in less space requirement, the running cost is less and the material produced is of good quality. Visit Us: https://www.atlasindustries.in/blog/asphalt-drum-mix-plant-layout/

0 notes

Text

High Capacity ZAP-S240 Stationary Asphalt Mixing Plant, 240tph Asphalt Road Construction Machine

ZAP-S240 Stationary Asphalt Mixing Plant is the product combined with various advantages of western models, modular design, compact structure, simple assembly and transport.

Components of 240tph Asphalt Mix Plant adopt international famous brand, keep pace with the international advanced technology, which can guarantee high reliability and security of the equipment in long operating terms. There are strict trial assembly and test machine of each asphalt plant and road construction equipment before delivery, so we can guarantee stable quality and high standard of the asphalt plant mixer.

Besides, ZOOMLINE Asphalt Hot Mix Plant adopts human-computer interface and PLC control system, perfect human-machine exchange function, reasonable and multiple layout mode, which can change the layout according to different requirement,and also can adapt the actual construction requirement better.

Asphalt plant machine also have other excellent expansibility for satisfied customers requirement, such as can add RAP, wood fiber adding equipment, big and solid installation foundation, low consumption and high efficiency etc.

#asphalt mixing plant#bitumen#road construction#asphalt drum mix plant#asphalt plant#concrete#heavy equipment#asphaltplant#construction#mobile asphalt drum mix plant#asphalt plant machine#asphalt#asphalt mixing plants#bitumen decanter#bitumen melting machine#bitumen melting#bitumen melter#asphalt plant equipment#road construction equipment#road construction machines#recycled hot mix asphalt production plant#mobile hot mix plant#high capacity

1 note

·

View note

Text

Things You should keep in Mind While Buying Asphalt batch mix plant.

If you've chosen to purchase an asphalt plant, it's going be a hard decision. The motives and the parameters needed to design the ideal machine could be difficult. It is often a difficult task choosing what storage containers, feeder bins and the type of controls needed. There are times when the distinction between the portable and stationary asphalt mixing plant could be complicated. On this page, we'll guide you through the purchase of asphalt plants.

When you've made the decision to build an asphalt plant of your own,, you must now take important choices. The choices will be related to the dimensions of the plant as well as the kind of asphalt plant, and the cost as well as the brand to choose. After these decisions are made, then we will decide on the design of the plant like bin size, tank size, kind of pollution control system storage silo.

There are two main kinds that asphalt plants can be found:

· Drum mix plant (continuous plant)

· Mix plant for batch mix (tower plant)

Batch Mix Plant

Batch mix plant creates hot mix asphalt large batches. Aggregates are fed into cold feed bins where they are transferred to the drum to be dried and heated. Following this, they are transferred to the tower unit by the bucket elevator. Then, on the tower unit, they will be divided and placed in several hot bins. In the meantime, bitumen and filler materials is transferred to separate weighing units that are on the top that of the tower.

Then, based on the needed percentage, the aggregates will be incorporated into a unit of pug milling. The process is followed by the addition of filler and bitumen to the mixer unit. After the mixing process, the material will be discharged to the trucks that are waiting or the storage silo.

All Tech Group

Advantages of batch mix plants

The main advantage of a batch mix plant is that it is able to produce high-quality hot mix asphalt of any mix type. The final product is of high quality hot mix asphalt, with the highest level of precision. Additionally, it is possible to incorporate various mix designs and run the plant with various mix designs. Because the components are modular, it is possible to upgrade or retrofit parts as and as needed. This enhances the functionality that the mixer can offer.

The weaknesses from the batch mixer plant

A batch plant is required to spend much of its time moving and weighing the materials. A significant amount of energy is used during this process which makes the batch plant use more energy in order to produce hot mix asphalt. Because the number of steps used are higher and the amount of energy required is also higher. Additionally, the batch plant will require more space, and a high initial cost to set up.

Drum mix plant

The drum mix plant a basic form of asphalt plant. It employs a straightforward method to produce the hot mix asphalt. It is a straightforward and continuous method to produce HMA continually. The process begins with the material being fed into the Cold feed bins. The aggregates are progressively taken to the drum to be heated as well as for mixing. Within the drum, mixing and heating are done in one unit. When the aggregates are introduced into the drum, they weigh them together and this weight is transmitted through the panel in order to ensure that how much bitumen as well as filler material.

In the beginning, the drum heating process, the drum is heated and mixing takes place in the latter part of the drum. After mixing thoroughly with bitumen and filler material the filler material is taken out of the storage silos or waiting trucks.

Continuous drum mix plants may be a parallelflow as well as counterflow types. Parallelflow means that the material flow and the burner flame are both in the exact same direction. Counterflow is when both the material flow and burner flame are in opposite directions.

The main advantages of mixing drums

The primary benefit of a drum mix plants is that it employs the most basic procedure to make hot mix asphalt. In removing many processes drum mix plants use less energy to create hot mix asphalt. The initial investment cost is less, as well as the power required for operation is also reduced. Maintenance costs are lower when compared to batch. The overall cost for running and maintaining is significantly lower than an asphalt batch plant.

If it is necessary to have a portable unit for your needs, a drum plant would be superior because it uses a lesser quantity of components. A drum plant will make use of fewer components, which means the expense of transport will be lower.

The weaknesses of the batch mixing plant for drums

A lower degree of accuracy in the end product is the primary problem with Drum mix plants. Bag filters are a type of pollution control device can't be utilized with drum mixers. The numerous customization options offered on a batch facility might not be available in the mixing plant for drums.

The style of asphalt plant

There are two main types of asphalt plants: stationary and portable. The choice between the two is easy. If the plant has to move frequently, an asphalt plant that is portable is the an ideal choice, whereas stationary plants are preferred.

If we evaluate specifications against the specifications of various manufacturers, then a mobile asphalt plant is more expensive when compared to stationary asphalt plants. If the plant is required to be moved only a couple of times throughout the year or more frequently, then a mobile form of asphalt plant can be beneficial. If the movement of the plant needs to be performed once in the next few years, the portable or mobile plant is not the best choice because the price for portability is higher.

In these cases plants with a skid-mounted design is far superior. Atlas also produces and sells skid-mounted plants that are wired components that are ready for installation.

Dimensions and components of the asphalt plant

It is essential to study the requirements of the plant, and determine the capacity. It is important to keep in mind that a high capacity plant is not going to be favored. The plant must be moderate and medium-sized, with a focus on the inclusion of crucial elements.

The plant shouldn't be tiny with small components that are too small. This will make it difficult to upgrade later on. When the plant's size is of a medium size, consider whether it is feasible to increase the capacity of the plant by replacing a few parts.

The ideal plant is one that it's operating at around 80percent capacity. This makes certain that the components perform better and last longer. But, you could also select a moderate-sized plant that has an storage silo in order to boost production prior to.

Important to have the correct configuration of components of the asphalt plant

· Correct and proper configuration of components is essential for the selecting the asphalt plants. A proper selection of configuration and the set of components is crucial to the overall success of the project. The main components that are crucial include:

· Cold aggregate bins for feeders. The design of the feeder bins is crucial. It is all dependent on the amount of aggregates required to be used and this can influence the layout that the bins are placed in.

· The size that the tanks for bitumen must to be of a sufficient size. It is not advisable to make larger amounts of asphalt without an adequate supply of bitumen. It is essential to have enough of the storage tank for bitumen in order to allow production to be carried out without issue.

· The burner's configuration is crucial because in some areas, various fuel choices like coal, natural gas, etc . are readily available. If the consumer is informed and chooses the right burner it will save a significant amount of dollars in the long term.

· Storage of hot mix asphalt Storage of hot mix asphalt must have enough capacity. When the number of trucks is smaller in number , the plant must not be waiting for to get the following truck. This ensures uninterrupted output for the factory. The silo is an extremely useful device when continuous production is required to be maintained.

0 notes

Text

Choosing an Appropriate Asphalt Mixing Plant in Road Construction Factory

Choosing an Appropriate Asphalt Mixing Plant in Road Construction Factory

Asphalt concrete is still referred to as gravel, black top or bitumen. This is a composite material used in the road building, car parks, airports and much more. Hotmix asphalt concrete seems to be a type of asphalt widely used for high-traffic building. Concrete curing or asphalt mixing here are the two key aspects for road construction. When concrete curing involves maximizing the strength in concrete; asphalt mixing processes are conducted to generate hot mixtures of asphalt concrete used in the road production. It is also used for landfills, basins and fish broiler lakes.

Asphalt Plant & Its Types

Asphalt Plant mixes aggregates, as well as other ingredients in a certain amount, at high temperature to create a hot mixture of asphalt to be used in road building. There are basically two kinds (in the light of an overview) of Plants (1) Batch Mix Plants (Discontinuous type), and (2) Drum Mix Plant (Constant sort).

Most of the time, contractors leave this to the suppliers to choose another best design and layout of the asphalt mixing factory as required by the project. It is really is prudent to understand the difference as well as the benefits that these two techniques offers.

The motivation behind the Asphalt Plant is to blend totals, asphalt and distinct additional substances to a necessary extent as per the employment mix calculation. However, at higher temperatures, it produces a homogeneous warm blend clearing mixture. The hot blend of asphalt is used for street growth.

Essential Distinguishing Factors:

- In Batch type Plant, the drying and heating of a total occurs once the drum is turned and the warmed totals are weighed and tested in hot cans for proportioning prior to combining with fastener in such an isolated Pug mill mixer to making up one cluster.

- In Drum type Plant, the heating, drying and combining of totals takes place in a separate drum in which the nourishing with quantities and covers and the production of hot mixture of asphalt is continuous. This kind of plant provides a higher level of creation and seems to be easy and simple to operate.

In either case, the type of asphalt plant, its basic design is just like the performance of hot mix asphalt that can be used for road development.

Major Components of Asphalt Plant

The prime or major components of Asphalt Mix Plants includes: Wet Scrubber, Fuel Support Tank, Several Cold, Asphalt Storage, Aggregate Feeder Bins, Single Deck Scalping Panel, Slinger Conveyor, Loadout Conveyor, Mineral Filler System, , and Control Panel of Isolated Control Suite. Such plants are portable and stationary shape to comply with the customer's decision.

In Asphalt Plant, the distinctive amount of virgin amounts is processed in separate feeder tanks. The container is equipped with manually controlled openings and conveyor belts powered by the factor speed engine which customizes the scale of the sums to be extracted from each container.

Totals from all of the receptacles are collected on a social event line, which swaps them on even a single deck scalping panel for overweight substance removal. Screened averages are then traded for spinning the drum by moving the slinger. Heavy-weight stream oil burner, mounted on an in feed side of a rotating drum, dries and heats the total throughout the essential area of the drum.

Advantage of

Asphalt Drum Mix Plant

Reduce the cost for manufacturing of asphalt

Ease of shipping

Energy savings processes

Environmentally friendly development of asphalt

Higher production volume

Quality assurance quality

Ease with demobilization or demobilization

The Final Thought!

There is really is no ideal scenario and circumstance characterized to choose a specific type of Asphalt Plant. Nonetheless, if you are searching for a more versatility to operate for a few customers; batch style plants are the correct choice. On the other side, if low operating costs and continuous output are required, it is easier to choose from a continuous factory.

#Asphalt Mixing Plants#Asphalt Batch Mix plant#Asphalt plant#Wet mix plant#Hot Mix Plants#Asphalt batching plant manufacturers#Concrete batching plant manufacturers#RMC plant manufacturers#Concrete mixing plant manufacturer#Asphalt Drum mix plant manufacturers

0 notes

Text

Stationary Asphalt Mixing Plant

Atlas industries asphalt batching plants are suitable for everlasting installations, specifically when the manufacturing volumes are required. they allow flexibility for future. Stationary asphalt plant can accommodate unconventional plant layouts.

Asphalt plants are outfitted with double drum mixers and garage silos are used to maintain the mix. Like portable and stationary plant, also asphalt batch plants are prepared with many, innovative capabilities no longer to be had. We also pollutants and noise manipulate gadget consist of load out tunnels, structures that capture hydrocarbon vapors, stack silencers, and burner blower silencers. This technology makes these everlasting facilities accurate acquaintances of their communities.

Asphalt Drum Mixing Plant Supplier :

youtube

The batching plant is right for metropolitan areas requiring a big variety of different asphalt mixes. Instead to a continuous mixer, these facilities use a batch tower. Containers inside the pinnacle phase of the tower preserve dried combination in various sizes. Relying upon the mix wanted, the containers robotic ally dispense the appropriate amount of the required aggregate. the dry cloth is routed to a drum mixer positioned at the bottom of the tower. Here the liquid asphalt is added. After thorough blending, the bottom of the mixer opens and the batch is distributed into a truck or conveyed to a garage silo.

0 notes

Link

Stationary Asphalt Mixing Plant has the modular design and rational layout. It is easy to assemble and disassemble the parts of the plant, thus setting up a stationary Asphalt Mixing Plant anywhere near or at a distance from the construction site.

0 notes

Text

Mobile Asphalt Drum Mix Plant Layout - Atlas Industries

The layout of the mobile asphalt drum mix plant is the same as its stationary counterpart. The units are designed to be mobile. This means all components of the Atlas mobile asphalt drum plant can be easily shifted from one place to another. The ease of shifting and containerized design helps in achieving the desired goal.We have installed mobile drum mix plants in the Philippines, Nigeria, Algeria, American Samoa, Cameroon, Somalia, Botswana, Oman, Malawi, Tanzania, and Myanmar.

0 notes

Text

Stationary drum mix asphalt plant

The stationary drum mix asphalt plant is also called as continuous asphalt mixing plant because of the uninterrupted asphalt production process. Different from the batch type asphalt mixing plant, the mixing of aggregate, powder and asphalt in the continuous asphalt mixing plant is carried out in the drying drum. Therefore, the drying drum here is called the drum mixing pot, and the length of drum mix plant is much longer than that of the batch asphalt mixing plant.

The characteristic of this technological innovation is that under the condition of precise inspection of raw materials, a simple and economical drying cylinder can ensure high productivity and high quality of finished materials. There are two different types of continuous drum mix asphalt plant: downstream heating drum mixing pot (the simplest and cheapest mixing plant) and countercurrent heating mixing station (from the perspective of heat exchange, this mixing Stations are more efficient). Like the traditional asphalt mixing plant, the asphalt produced in the drying mixing drum will be sent to the storage warehouse, then unloaded into the transport truck, and then transported to the road construction site.

The performance characteristics of the stationary drum mix asphalt plant are:

1, Integrated design of dust removal and drying, compact structure, small footprint, and high thermal efficiency;

2, Modular design, a variety of layout options, suitable for installation in narrow, complex, and irregular sites, and the footprint is reduced by 33% compared with traditional structures;

3, The self-developed dual frequency conversion burner has higher combustion efficiency and better oil adaptability.

For Price Plz Contact Whatsapp/Wechat: 0086 181 3788 9531

Or Email to [email protected]

0 notes