#Thermoplastic Elastomers Market Forecast

Text

#Thermoplastic Elastomers Market#Thermoplastic Elastomers Market Trends#Thermoplastic Elastomers Market Growth Analysis#Thermoplastic Elastomers Market Forecast#Thermoplastic Elastomers Market Share#Thermoplastic Elastomers Industry#Thermoplastic Elastomers Market Top Key Players#What is the CAGR of the Thermoplastic Elastomers Market?#What will be the Thermoplastic Elastomers market size by 2028?

0 notes

Text

Concerns about the biocompatibility of particular elastomers may stifle the market for medical elastomers!

A comprehensive overview of the global medical elastomers market is recently added by UnivDatos Market Insights to its humongous database. The report has been aggregated by collecting informative data from various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the medical elastomers markets globally. This report offers a detailed analysis of the latest industry developments and trending factors that are influencing market growth. Furthermore, this statistical market research repository examines and estimates the global market at regional and country levels. The Global Medical Elastomers Market is likely to grow at a CAGR of around 7% during the forecast period (2021-2027).

Market Overview

Medical grade elastomers are polymers with elastic qualities that are useful in the production of medical devices. These elastomers meet worldwide regulatory standards and are particularly intended to be bio-compatible, i.e. suitable for use in the medical industry. Medical elastomers are used in a variety of applications, including IV solution bags, tubes, and syringes, cardiovascular and orthodontic implants. According to The Global Burden of Disease Study 2019, oral illnesses impact around 3.5 billion people globally. This huge prevalence of oral diseases can be attributed to the factors such as bad oral hygiene, dental disease, malnutrition, genetics to incorrect eating habits. Owing to these factors, there is an increase in demand for orthodontic implants, which is positively affecting the market for medical elastomers because different elastomers are utilized in different orthodontic implants.

COVID-19 Impact

The COVID-19 pandemic has adversely impacted the global medical elastomer industry. Several countries enforced nationwide lockdowns as part of measures to limit the spread of the coronavirus. As a result, the medical elastomers supply chain has been hindered, notably in terms of raw materials for medical-grade elastomers. The mismatch between demand & supply of several raw materials hampered the growth of the industry.

Ask for Price & Discounts @

The global medical elastomers market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

Market Insight, by type

Thermoplastic

Thermoset

Based on type, the market is classified into thermoset and thermoplastic. Thermosets do not melt upon heating. While thermoplastic has low-melting-point and is best suited for applications that use recycled material. The enormous potential is observed for thermoplastics because of their re-molding ability and a growth in demand for catheters, tubes, and medical bags as recycling and sustainability become more popular.

Market Insight, by application

Medical tubes

Catheters

Gloves

Syringes

Medical bags

Implants

Face Masks

Based on application, the market is categorized into medical tubes, catheters, gloves, syringes, medical bags, implants, and face masks. The medical tubes category held the greatest share of this market in recent times. However medical elastomers are predicted to grow in demand, due to the growing use of medical tubes in sickness detection & treatment. The Indian government's focus on the ‘Make in India Initiative’ would further propel the medical sector in the country, boosting demand for medical elastomers throughout the projected period.

Market Insight, by region

North America

Europe

Asia-Pacific

Rest of World

For a better understanding of the market adoption of the medical elastomer industry, the market is analyzed based on its worldwide presence in the countries such as North America (US, Canada, Rest of North America); Europe (Germany, France, UK, Italy, and Rest of Europe); Asia-Pacific (China, India, Japan, Rest of Asia-Pacific), and Rest of World. Asia-Pacific is expected to show the highest CAGR growth in the medical elastomers market. The major contributors to the growth of this market are China and India. Additionally, growing private and public sector expenditures to strengthen healthcare infrastructure across nations are predicted to raise demand for medical devices, supporting the region's medical elastomers market expansion. However, biocompatibility concerns about some elastomers, along with tight regulatory regulations throughout the world, may hamper the growth of the medical elastomers market during the projection period.

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=24113

The major players targeting the market include:

BASF SE

DowDuPont

Eastman Chemical Company

Royal DSM

Solvay S.A.

Trelleborg AB

Kuraray Co. Ltd.

Teknor Apex

Momentive Performance Materials Inc.

Celanese Corporation

Competitive Landscape

The degree of competition among prominent companies has been elaborated by analyzing several leading key players operating globally. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the global medical elastomers market. The major players have been analyzed by using research methodologies for getting insight views on market competition.

Key questions resolved through this analytical market research report include:

What are the latest trends, new patterns, and technological advancements in the global medical elastomers market?

Which factors are influencing the global medical elastomers market over the forecast period?

What are the global challenges, threats, and risks in the global medical elastomers market?

Which factors are propelling and restraining the global medical elastomers market?

What are the demanding global regions of the global medical elastomers market?

What will be the market size in the upcoming years?

What are the crucial market acquisition strategies and policies applied by the companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature. Please let us know If you have any custom needs.

About UnivDatos Market Insights

UnivDatos Market Insights (UMI) is a passionate market research firm and a subsidiary of Universal Data Solutions. We believe in delivering insights through Market Intelligence Reports, Customized Business Research, and Primary Research. Our research studies are spread across topics across the world, we cover markets in over 100 countries using smart research techniques and agile methodologies. We offer in-depth studies, detailed analysis, and customized reports that help shape winning business strategies for our clients.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

Thermoplastic Elastomer (TPE) Prices | Pricing | Price | News | Database | Chart | Forecast

Thermoplastic Elastomer (TPE) Prices have become increasingly significant in various industries due to their unique properties, which combine the advantages of both rubber and plastic. These materials are highly versatile, offering the flexibility of elastomers with the processability of thermoplastics, making them suitable for a wide range of applications. The pricing of TPEs is influenced by several factors, including raw material costs, global demand, production capacity, and technological advancements. In recent years, the market for TPEs has been dynamic, with fluctuations in prices driven by changes in these underlying factors.

The raw materials used in the production of thermoplastic elastomers play a crucial role in determining their price. TPEs are generally made from a blend of rubber and plastic polymers, and the cost of these inputs can vary depending on market conditions. For example, fluctuations in the price of crude oil, which is a key raw material for many polymers, can directly impact the cost of producing TPEs. Additionally, the availability and price of specific rubber materials, such as natural rubber or synthetic rubber, also contribute to the overall cost structure of TPEs. When raw material prices increase, manufacturers may pass on these costs to consumers, leading to higher TPE prices.

Global demand for thermoplastic elastomers is another critical factor affecting their prices. TPEs are widely used in industries such as automotive, construction, medical, and consumer goods. The demand for TPEs in these sectors can fluctuate based on economic conditions, technological advancements, and consumer preferences. For instance, the automotive industry, which is one of the largest consumers of TPEs, can significantly influence TPE prices. When the automotive industry experiences growth, the demand for TPEs increases, driving up prices. Conversely, a slowdown in the automotive sector can lead to a decrease in demand, resulting in lower prices. Similarly, the construction industry’s demand for TPEs, particularly in applications such as sealing and roofing, can also impact prices based on the level of activity in the construction sector.

Get Real Time Prices for Thermoplastic Elastomer (TPE): https://www.chemanalyst.com/Pricing-data/thermoplastic-elastomer-tpe-1113

Production capacity and technological advancements in TPE manufacturing also play a significant role in pricing. As new production facilities are established or existing ones are expanded, the supply of TPEs in the market increases. This increase in supply can lead to lower prices, particularly if demand does not keep pace with the additional capacity. However, if there are constraints in production capacity, perhaps due to supply chain disruptions or technical issues, prices may rise due to limited availability. Furthermore, advancements in TPE manufacturing technologies can lead to more efficient production processes, reducing the overall cost of TPEs. These technological improvements can help stabilize prices or even lead to a gradual decline over time as manufacturers optimize their production methods.

Another factor that can influence TPE prices is the level of competition in the market. The TPE market is characterized by a large number of suppliers and manufacturers, each vying for market share. In highly competitive markets, suppliers may reduce their prices to attract customers, leading to downward pressure on TPE prices. On the other hand, if the market is dominated by a few major players, these companies may have more control over pricing, potentially leading to higher prices. The level of competition can also affect innovation in the industry, as companies strive to differentiate their products through the development of new TPE formulations or applications. These innovations can command premium prices, particularly if they offer enhanced performance or unique properties compared to standard TPEs.

Environmental regulations and sustainability considerations are becoming increasingly important in the TPE market, and these factors can also impact prices. As governments and industries push for more sustainable materials, there is growing demand for eco-friendly TPEs made from renewable or recycled materials. The production of these sustainable TPEs may involve higher costs, which can translate into higher prices for consumers. However, as the market for sustainable materials grows and production processes become more efficient, the price gap between conventional and sustainable TPEs may narrow. Additionally, companies that invest in sustainable practices may be able to differentiate themselves in the market, potentially commanding higher prices for their products.

The geopolitical landscape and trade policies can also influence TPE prices. Tariffs, trade restrictions, and changes in international trade agreements can affect the cost of importing or exporting TPEs and their raw materials. For example, if tariffs are imposed on key raw materials used in TPE production, the cost of these materials could increase, leading to higher TPE prices. Conversely, trade agreements that reduce tariffs or open up new markets can lead to more competitive pricing and increased market access, potentially lowering prices. Geopolitical tensions and instability can also disrupt supply chains, leading to shortages of raw materials or finished products, which can drive up prices.

In conclusion, the pricing of thermoplastic elastomers is influenced by a complex interplay of factors, including raw material costs, global demand, production capacity, technological advancements, competition, environmental regulations, and geopolitical considerations. As the market for TPEs continues to evolve, prices are likely to remain dynamic, reflecting changes in these underlying factors. Manufacturers, consumers, and industry stakeholders must stay informed about these trends to make strategic decisions in the rapidly changing TPE market.

Get Real Time Prices for Thermoplastic Elastomer (TPE): https://www.chemanalyst.com/Pricing-data/thermoplastic-elastomer-tpe-1113

Contact Us:

ChemAnalyst

GmbH - S-01, 2.floor, Subbelrather Straße,

15a Cologne, 50823, Germany

Call: +49-221-6505-8833

Email: [email protected]

Website: https://www.chemanalyst.com

#Thermo Plastic Elastomer#Thermo Plastic Elastomer Price#Thermo Plastic Elastomer Price Monitor#Thermo Plastic Elastomer Pricing

0 notes

Text

Polyurethane Elastomers Market - Forecast(2024 - 2030)

Polyurethane Elastomers Market Overview

The Polyurethane Elastomers Market size is forecasted to grow at a CAGR of 4.5% during the forecast period 2022-2027 and reach US$10.8 billion by 2027. Polyurethane Elastomers can be blended into various materials which include polymethyl methacrylate, polypropylene, polystyrene, vinyl ester, polyamide and other materials. It is used in a wide range of industries such as automotive, aerospace, construction, footwear and other industries. In 2020, the COVID-19 lockdown had significantly reduced production activities as a result of the country-wise shutdown of manufacturing sites, shortage of labor and the decline of the supply and demand chain all across the world, thus, affecting the polyurethane elastomers industry. However, a steady recovery in automobile production has been witnessed across the world since 2021. Polyurethane elastomers are primarily used in the automotive industry for the production of tires and body panels of an automobile. For instance, according to the International Organization of Motor Vehicle Manufacturers (OICA), the total global automobile production reached 80.2 billion units in 2021, an increase of 3% as compared to 77.7 billion units in 2020. An increase in automotive production along with the surging demand from the construction industry is expected to drive the growth of the polyurethane elastomers market size in the upcoming years. On the other hand, fluctuating prices of raw materials may confine the growth of the market.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐒𝐚𝐦𝐩𝐥𝐞

Polyurethane Elastomers Market Report Coverage

The “Polyurethane Elastomers Market Report – Forecast (2022-2027)” by IndustryARC, covers an in-depth analysis of the following segments in the Polyurethane Elastomers Market.

By Material Type: Thermoplastic (Polyether, Polycaprolactone, Polymethyl Methacrylate, Polypropylene, Polystyrene, Others), Thermoset (Polyamide, Vinyl Ester, Others).

By Processing Method: Injection Molding, Extrusion, Blow and Compression Molding.

By Application: Automotive Body Panels, Tires, Adhesives, Fibers, Industrial Tools, Appliances, Conveyor Belts, Sealing Gaskets, Lubricants, Consumer Products, Others.

By End-Use Industry: Transportation (Automotive (Passenger Cars, Light Commercial Vehicle, Heavy Commercial Vehicles), Aerospace (Commercial, Military, Others), Marine, Locomotive), Construction (Residential, Commercial, Industrial), Footwear, Electrical & Electronics, Adhesives & Sealants, Medical, Textile, Others.

By Geography: North America (USA, Canada and Mexico), Europe (UK, Germany, France, Italy, Netherlands, Spain, Denmark, Belgium and the Rest of Europe), Asia-Pacific (China, Japan, India, South Korea, Australia and New Zealand, Indonesia, Taiwan, Malaysia and the Rest of Asia-Pacific), South America (Brazil, Argentina, Colombia, Chile and the Rest of South America), the Rest of the World (the Middle East and Africa).

Key Takeaways

The injection molding segment held a significant share in The Polyurethane Elastomers Market in 2021. Its wide range of characteristics and higher efficiency made it stand out in comparison to other types of processing methods in the market.

Footwear industry held the largest share in the Polyurethane Elastomers Market in 2021, owing to the increasing demand for polyurethane elastomers for the production of footwear, owing to its properties such as durability, flexibility and lightness.

Asia-Pacific dominated the Polyurethane Elastomers Market in 2021, owing to the increasing demand for polyurethane elastomers from the footwear industry in the region.

A detailed analysis of strengths, weaknesses, opportunities and threats will be provided in the Polyurethane Elastomers Market Report

#Polyurethane Elastomers Market price#Polyurethane Elastomers Market size#Polyurethane Elastomers Market share#Polyurethane Elastomers Market forecast

0 notes

Text

Thermoplastic Vulcanizates Market Outlook, Research, Trends and Forecast to 2030

Thermoplastic Vulcanizates Industry Overview

The global thermoplastic vulcanizates market size was estimated at USD 1.65 billion in 2023 and is projected to grow at a CAGR of 8.7% from 2024 to 2030. The market for thermoplastic vulcanizates (TPV) is expected to grow during the forecast period due to rising demand for lightweight, environmentally friendly solutions that offer exceptional durability as well as increased safety. High-performance elastomers known as thermoplastic vulcanizates (TPV) provide exceptional flexibility, processing ease, durability, and resistance to heat, fluids, and chemicals. Due to these qualities, they may be used to create lightweight automobile parts, including car doors, weather seals, and engine-related elements.

Thermoplastic Vulcanizates (TPV) are now increasingly being used as an alternative to PVC plastic due to several stringent regulations regarding the use of polyvinyl chloride (PVC) in the automotive industry, which in turn is expected to increase market demand in the coming years. In addition, a strong shift towards replacing metals with lightweight materials such as thermoplastic vulcanizates (TPV) to improve fuel efficiency in automobiles is expected to increase demand for thermoplastic vulcanizates (TPV) during the forecast period. TPVs are widely used for making automobiles' interior and exterior components, such as wiper systems, air guides and dams, spoilers and trims, and flappers. The inclination of consumers toward fuel-efficient vehicles across the globe is leading to rising demand for TPV in the automotive application and is expected to drive market growth over the forecast period.

Gather more insights about the market drivers, restrains and growth of the Thermoplastic Vulcanizates Market

Favorable federal regulations set by agencies such as the Environmental Protection Agency (EPA) and the National Highway Traffic Safety Administration (NHTSA) on carbon emissions, along with EU initiatives to develop a TPV app to build light and fuel-efficient vehicles, are likely to boost market growth. The high raw material costs associated with EPDM are expected to hinder profitability.

Favorable government policies for encouraging lightweight and recyclable material applications in various industries including automotive and construction are expected to support the demand for thermoplastic vulcanizates over the forecast period. The investment of USD 2 trillion by the U.S. government as a part of the coronavirus responsible for the development of infrastructure, including hospital building and construction, is expected to further propel the demand for thermoplastic vulcanizates (TPV) in medical and fluid handling applications in the coming years.

Browse through Grand View Research's Plastics, Polymers & Resins Industry Research Reports.

The North America tin cannabis packaging market size was estimated at USD 75.91 million in 2023 and is projected to grow at a CAGR of 12.8% from 2024 to 2030.

The global BOPP dielectric films market size was estimated at USD 1.51 billion in 2023 and is projected to grow at a CAGR of 31.5% from 2024 to 2030.

Key Thermoplastic Vulcanizates Company Insights

Key companies are adopting several organic and inorganic growth strategies, such as new product development, mergers & acquisitions, and joint ventures, to maintain and expand their market share.

In August 2023, Teknor Apex Company, Inc. announced the launch of its new Sarlink RX 3100B Series of TPVs containing up to 40% recycled content. These multi-purpose TPVs are suitable for various automotive applications, such as extruded seals, and offer sustainability benefits by reducing dependency on virgin petroleum-based plastics. The two new grades, with 84 Shore A and 94 Shore A hardness, are based on the existing Sarlink 3100 Series technology but incorporate post-industrial recycled (PIR) content, which provides a more controlled and consistent raw material stream compared to post-consumer recycled (PCR) content.

Key Thermoplastic Vulcanizates Companies:

The following are the leading companies in the thermoplastic vulcanizates market. These companies collectively hold the largest market share and dictate industry trends.

Dawn Polymer

Ravago Manufacturing.

RTP Company

DuPont de Nemours, Inc.

Mitsui Chemicals Inc.

Celanese Corp.

LyondellBasell Industries Holdings B.V.

Mitsubishi Chemical Corp.

KRAIBURG TPE GmbH & Co. KG

Teknor Apex Company, Inc.

Trinseo

Hexpol AB

JSR Corporation

Zeon Corporation.

Order a free sample PDF of the Thermoplastic Vulcanizates Market Study, published by Grand View Research.

0 notes

Text

Disposable Lead Wires Market: Analyzing Size, Share, and Growth Patterns

The global disposable lead wires market size is expected to reach USD 1.7 billion by 2030, registering a CAGR of 6.6% from 2023 to 2030, according to a new study by Grand View Research, Inc. Rising incidence of hospital-acquired infections (HAIs) is the key driving factor for the market growth. The reusable lead wires are the major cause of hospital-acquired bloodstream infections. The use of disposable lead wires eliminates the risk of cross-contamination. In addition, it reduces the cost associated with HAIs. The aforementioned benefits are presumed to boost the usage rates over the forecast period.

As per the data published by the University of Wisconsin Hospital and Clinics, Madison, more than 77% of cases of contamination with Multidrug-Resistant Bacterial Pathogens (MRSA, Vancomycin-Resistant Enterococci (VRE) were connected with the use of reusable ECG lead wires in hospitalized patients.

Disposable Lead Wires Market Report Highlights

Thermoplastic Elastomer (TPE) is expected to witness lucrative growth during the forecast period, owing to the rising adoption to reduce infection rates in healthcare facilities

The advantages of TPE over other materials like PVC and rubber latex such as providing better flexibility, ease of processing enabling high performance in a variety of applications

The demand for the 5-lead machine type is expected to increase in coming years owing to the surge in demand for cost-effective equipment in critical care settings

Ambulatory care centers are presumed to witness exponential growth throughout the forecast period. This can be attributed to the rising significance of disposable LWs inpatient monitoring

North America accounted for the largest share in the market for disposable lead wires, owing to the rising mortality rates pertaining to heart diseases

The Asia Pacific is anticipated to witness lucrative growth as a result of unmet patient needs, rising healthcare expenditure, and the establishment of major global players is expected to drive segment growth during the forecast period

The key players are involved in strategic alliances to sustain the competition, such as mergers & acquisitions, strategic partnerships, and geographic expansion

For More Details or Sample Copy please visit link @: Disposable Lead Wires Market Report

According to World Health Organization (WHO), 7 out of every 100 hospitalized patients will develop hospital-acquired infections in developed countries, whereas, the number will increase to 10 in developing countries due to poor healthcare infrastructure. The rate of ICU-acquired infections is at least 2-3 times higher in developing countries. Hence, significant demand for these products prevails due to such factors.

Moreover, the rising number of government initiatives to promote the incorporation of patient safety procedures in hospital settings is presumed to drive the overall market growth during the forecast period. Furthermore, an introduction of technologically advanced disposable LWs is anticipated to drive the market growth during the forecast period. For instance, advanced disposable ECG-LWs with patented push-button design have superior capabilities in reducing alarms that are created by a failure of leads and the absence of telemetry. These above-mentioned factors are anticipated to fuel the market growth.

List of Major Companies in the Disposable Lead Wires Market

3M

BD

Mindray

Schiller AG

Carlisle Medical Technologies

OSI Systems, Inc.

CONMED

Hill-Rom Services, Inc.

#DisposableLeadWiresMarket#LeadWires#DisposableECGLeadWires#ECGLeadWires#ECGCables#ECGEquipment#PatientMonitoringSystems#Healthcare#Telemetry#Telehealth#Telemedicine

0 notes

Text

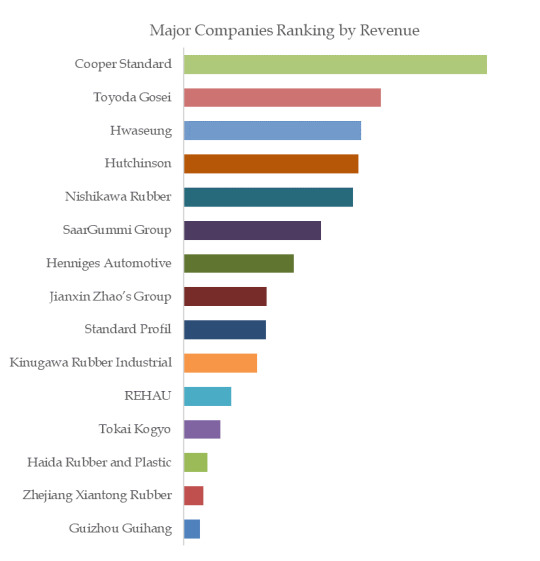

Global Top 15 Companies Accounted for 57% of total Automotive Body Sealing Systems market (QYResearch, 2021)

Body sealing system is commonly made of EPDM rubber and PVC, a thermoplastic elastomer (TPE) mix of plastic and rubber, and a thermoplastic olefin (TPO) polymer/filler blend. The goal of body sealing system is to prevent rain and water from entering entirely or partially and accomplishes this by either returning or rerouting water. A secondary goal of body sealing system is to keep interior air in, thus saving energy on heating and air conditioning.

The automotive body sealing system means the edges of a vehicle's windshield, windows, doors and trunk lid, etc. Automobile Sealing System strip is usually made into a hollow sponge foam tube.

According to the new market research report “Global Automotive Body Sealing Systems Market Report 2023-2029”, published by QYResearch, the global Automotive Body Sealing Systems market size is projected to reach USD 25.95 billion by 2029, at a CAGR of 13.3% during the forecast period.

Figure. Global Automotive Body Sealing Systems Market Size (US$ Million), 2018-2029

Figure. Global Automotive Body Sealing Systems Top 15 Players Ranking and Market Share(Based on data of 2021, Continually updated)

The global key manufacturers of Automotive Body Sealing Systems include Cooper Standard, Toyoda Gosei, Hwaseung, Hutchinson, Nishikawa Rubber, SaarGummi Group, Henniges Automotive, Jianxin Zhao’s Group, Standard Profil, Kinugawa Rubber Industrial, etc. In 2021, the global top five players had a share approximately 57.0% in terms of revenue.

About QYResearch

QYResearch founded in California, USA in 2007.It is a leading global market research and consulting company. With over 16 years’ experience and professional research team in various cities over the world QY Research focuses on management consulting, database and seminar services, IPO consulting, industry chain research and customized research to help our clients in providing non-linear revenue model and make them successful. We are globally recognized for our expansive portfolio of services, good corporate citizenship, and our strong commitment to sustainability. Up to now, we have cooperated with more than 60,000 clients across five continents. Let’s work closely with you and build a bold and better future.

QYResearch is a world-renowned large-scale consulting company. The industry covers various high-tech industry chain market segments, spanning the semiconductor industry chain (semiconductor equipment and parts, semiconductor materials, ICs, Foundry, packaging and testing, discrete devices, sensors, optoelectronic devices), photovoltaic industry chain (equipment, cells, modules, auxiliary material brackets, inverters, power station terminals), new energy automobile industry chain (batteries and materials, auto parts, batteries, motors, electronic control, automotive semiconductors, etc.), communication industry chain (communication system equipment, terminal equipment, electronic components, RF front-end, optical modules, 4G/5G/6G, broadband, IoT, digital economy, AI), advanced materials industry Chain (metal materials, polymer materials, ceramic materials, nano materials, etc.), machinery manufacturing industry chain (CNC machine tools, construction machinery, electrical machinery, 3C automation, industrial robots, lasers, industrial control, drones), food, beverages and pharmaceuticals, medical equipment, agriculture, etc.

0 notes

Text

Unleashing Elastic Potential: Navigating the Shifting Horizons of the Elastomers Market

The global Elastomers Market was valued at USD 96.96 billion in 2023 and is projected to reach USD 144.86 billion by 2031, growing at a CAGR of 5.23% from 2024 to 2031.

Key Takeaways:

The global elastomers market is expected to reach USD 144.86 billion by 2031, growing at a steady 5.23% CAGR.

Rising demand from automotive, construction, and consumer goods industries fuels market growth.

Specialty elastomers for harsh environments and biocompatible medical applications are trending.

Precise forecasts and regional analysis help businesses make informed investment and marketing decisions.

Get a New Look of Sample PDF:

Market Insights:

This comprehensive report provides a deep dive into the elastomers market, offering valuable insights for industry stakeholders. It analyzes:

Market trends and future growth drivers

Profitable market segments and high-growth regions

Competitive landscape and key player strategie

Benefits of the Report:

Make data-driven business decisions with precise market forecasts and in-depth analysis.

Gain a competitive edge by understanding rival strategies and market share.

Identify lucrative opportunities in high-growth regions and profitable segments.

Strategically plan investments with insights on potential growth areas.

Who will benefit:

Elastomer manufacturers and distributors

Automotive, construction, and consumer goods companies

Investors seeking opportunities in the elastomers market

This report empowers you to navigate the dynamic elastomers market with confidence and make future-proof business decisions.

The key players in the Elastomers Market are:

Dow Inc.

BASF SE

Exxon Mobil Corporation

LANXESS AG

DuPont de Nemours, Inc.

Mitsui Chemicals, Inc.

Sinopec Corporation

LG Chem Ltd.

Kuraray Co., Ltd.

Bridgestone Corporation

The global Elastomers Market is segmented as:

By Nature

Natural Rubber

Synthetic Rubber

Thermoplastic

By Type

General Purpose

Specialty Elastomers

By Application

Automotive

Adhesives & Coatings

Consumer Goods

Sports & Leisure

Electrical & Electronics

Industrial

Others

By Region

North America

U.S.

Canada

Mexico

Europe

France

U.K.

Spain

Germany

Italy

Russia

Rest of Europe

Asia-Pacific

China

Japan

India

South Korea

Rest of Asia-Pacific

Middle East & Africa

GCC

North Africa

South Africa

Rest of Middle East & Africa

Latin America

Brazil

Argentina

Rest of Latin America.

0 notes

Text

Thermoplastic Elastomer Market Size, Share and Growth Report, 2031

Global thermoplastic elastomers market is projected to witness a CAGR of 3.9% during the forecast period 2024-2031, growing from 6.25 million tons in 2023 to 8.49 million tons in 2031. The flourishing footwear industry is augmenting the demand for thermoplastic elastomers market growth. This growth is attributed to footwear sales through e-commerce sites and increasing sports events. The increasing deployment of thermoplastic elastomers in transport parts bolstered market growth. For instance, according to the Alliance for Automotive Manufacturers, in 2022, investments in automotive parts manufacturing reached USD 43 billion.

The robust growth of the transportation sector is ascribed to various factors, including the production expansion of aircraft, multiple government initiatives to develop electric vehicle manufacturing hubs, and the ongoing manufacturing activities associated with the new marine vessels. The increasing consumer demand for a new range of footwear, shifting consumer preferences, and advancements in manufacturing technologies are some of the prime attributes influencing the growth of the footwear industry at the global level. Thus, the robust growth of the transportation and footwear sectors at the global level is boosting the demand for thermoplastic elastomers to ensure superior chemical resistance, which, in turn, is supplementing the market growth.

In addition, the recent opening of new facilities for thermoplastic elastomer development will boost the supply of products in the global market, thereby creating a lucrative opportunity for market growth in the long run. For instance, in October 2022, Audia Elastomers launched a new manufacturing plant in Changshu, China. The new manufacturing facility of Audia Elastomers is manufacturing a range of elastomers, including thermoplastic elastomers (TPEs). However, thermoplastic elastomers have several performance limitations, restraining the market’s growth.

The Booming Transportation Industry at the Global Level is Augmenting the Market Traction

In the transportation industry, deploying thermoplastic elastomers is vital as the material ensures superior benefits, such as being lightweight, cost-effective, and highly durable, as opposed to thermoset materials in the total system cost, thereby making it increasingly desirable for transport product manufacturers. Thermoplastic elastomers are employed in transportation products such as commercial aircraft, passenger vehicles, cruise ships, and others. The development of new transport manufacturing facilities, rising commercial flight activities, increasing aircraft production, and surging innovations in the upgraded transport vehicle models are some of the prominent variables fostering the transportation sector’s growth at the global level.

For instance, according to Airbus, a global aircraft manufacturer, the production of A330 aircraft reached 3 per month in 2022. Moreover, Airbus is focusing on increasing the production of A330 aircraft by 4 in 2024. Furthermore, Airbus delivered 611 commercial aircraft units, and in 2022, it was 661 units, an annual growth rate of 8%. Hence, the booming transportation industry is fueling the adoption of thermoplastic elastomers for manufacturing bumpers, air ducts, and high & low-pressure pipes, which forms a major aspect accelerating the market growth.

Download free Sample Report- https://www.marketsandata.com/industry-reports/thermoplastic-elastomers-market/sample-request

The Bolstering Footwear Sector is Supplementing the Growth of the Market

Thermoplastic elastomers are ideal for manufacturing footwear midsoles as TPEs serve significantly higher levels of flexibility than traditional materials such as ethylene-vinyl acetate (EVA) foams. Additionally, thermoplastic elastomers can be molded into complex shapes for enhanced cushioning, shock absorbency, and support. The footwear sector is experiencing significant demand growth due to several key factors, including the growing sales facilitated by e-commerce, extensive spending on advertising by footwear brands, rising demand for athletic, trendy, and comfortable footwear, and rapid urbanization.

According to the recent statistics published by the World Footwear Yearbook 2023, 2022 global footwear production was 23.9 billion pairs, representing a year-on-year growth rate of 7.6%. Likewise, according to the Sports & Fitness Industry Association (SFIA), the sporting goods industry experienced record-breaking sales in 2021, with a 15.8% increase in revenue from 2020 and a 16.4% increase since 2019 pre-pandemic numbers. Henceforth, the bolstering footwear sector is spurring the demand for thermoplastic elastomers to ensure superior damping properties, propelling the market growth.

Superior Technical Properties of Thermoplastic Elastomers are Amplifying the Market Growth

The thermoplastic elastomers are equipped with beneficial technical properties such as specific gravity at 0.89-1.0, shore hardness of 60A-75D, low-temperature limit at -60°C, high-temperature limit at 120°C, compression set resistance at 100 °C, and resistance to hydrocarbon fluids. Thus, due to the above technical properties, thermoplastic elastomers are often deployed in various applications such as transport parts, construction extruded seals, and electrical and electronic components.

For instance, according to the recent data published by Invest India, in 2022, the production of electronic components in India was valued at USD 11 billion and is projected to reach USD 18 billion by 2026. Therefore, the superior technical properties associated with thermoplastic elastomers augment the adoption of TPEs across various applications, thereby proliferating the market growth.

Asia-Pacific Held a Significant Share in the Thermoplastic Elastomers Market

The regional economic growth of the Asia-Pacific is driven by the expansion of the various end-use industries such as medical equipment, transportation, building & construction, and industrial. Prominent variables, such as increasing spending power of people, flexible trade regulations, easy availability of raw materials, and ease of import-export policies, are some of the favorable aspects fostering the growth of the transportation sector in the Asia Pacific region.

According to the recent report published by the Organisation Internationale des Constructeurs d’Automobiles (OICA), in 2022, the Asia Pacific region held the highest manufacturing share in the global automotive share, which was 58.8% of the global automotive share. Moreover, in 2021, the production of automobiles in the Asia-Pacific region was 46,768,800 units, whereas in 2022, it was 50,020,793, representing a year-on-year growth rate of 7%. Thus, the booming transportation sector in the Asia-Pacific region is boosting the adoption of thermoplastic elastomers to ensure superior durability, thereby supplementing the market growth in the region.

Impact of COVID-19

The COVID-19 pandemic in 2020 restrained the supply of raw materials, labor movement, and halt in the production of non-essential industrial products. As a result, the demand for thermoplastic elastomers declined. Furthermore, the demand revenue losses incurred by various end-use industries, such as transportation, industrial, and building and construction, resulted in the decline in the growth of the thermoplastic elastomers industry.

For instance, according to the statistics published by the Organisation Internationale des Constructeurs d’Automobiles (OICA), in 2019, the global production of automotive was 92,175,805 units and in 2020, it was 77,621,582, a decline of 15.8%. However, the sudden surge in the need for medical equipment boosted the demand for thermoplastic elastomers. Additionally, favorable government measures across various countries efficiently promoted the resurgence of various end-use industries, including thermoplastic elastomers, thereby accelerating the market growth in the years 2021 and 2022.

Impact of Russia Ukraine War

The Russia and Ukraine war had a strong impact on respective economies. Since Russia is among the major trade partners of Europe, the supply chain disruption strongly impacted the production activities in the region. As a result, there was a shortage of automotive components in the European countries during 2022, ultimately resulting in a decline in automotive production in the region.

For instance, according to the recent data published by the Organisation Internationale des Constructeurs d’Automobiles (OICA), in 2021, the automotive production in Netherlands was 107,021 units and in 2022, it was 101,670 units, an annual decline of 5% as compared to 2021. However, the procurement of materials from local sources and other prominent markets such as China and India aided the growth of the thermoplastic elastomers market despite the impact of the Russia-Ukraine war in the first half of 2022.

Report Scope

“Thermoplastic Elastomers Market Assessment, Opportunities and Forecast, 2017-2031F”, is a comprehensive report by Markets and Data, providing in-depth analysis and qualitative and quantitative assessment of the current state of the global thermoplastic elastomers market, industry dynamics and challenges. The report includes market size, segmental shares, growth trends, COVID-19 and Russia-Ukraine war impact, opportunities, and forecast between 2024 and 2031. Additionally, the report profiles the leading players in the industry mentioning their respective market share, business model, competitive intelligence, etc.

Click here for full report- https://www.marketsandata.com/industry-reports/thermoplastic-elastomers-market

Contact

Mr. Vivek Gupta

5741 Cleveland street,

Suite 120, VA beach, VA, USA 23462

Tel: +1 (757) 343–3258

Email: [email protected]

Website: https://www.marketsandata.com

#Thermoplastic Elastomer Market#Thermoplastic Elastomer Market Size#Thermoplastic Elastomer Market Share

0 notes

Text

Thermoplastic Polyolefin Market: Current Analysis and Forecast (2022-2028)

According to a new report published by UnivDatos Markets Insights, the Thermoplastic Polyolefin Market was valued at more than USD 4.5 billion in 2020 and is expected to grow at a CAGR of around 6% from 2022-2028. The analysis has been segmented into Type (In-Situ TPO, Compounded TPO, Others); Application (Automotive, Building & Construction, Medical, Industrial, Footwear, Home Appliances); Region/Country.

The thermoplastic polyolefin market report has been aggregated by collecting informative data on various dynamics such as market drivers, restraints, and opportunities. This innovative report makes use of several analyses to get a closer outlook on the thermoplastic polyolefin market. The thermoplastic polyolefin market report offers a detailed analysis of the latest industry developments and trending factors in the market that are influencing the market growth. Furthermore, this statistical market research repository examines and estimates the thermoplastic polyolefin market at the global and regional levels.

Market Overview

Thermoplastic Polyolefin (TPO) is defined as a polymer/filler blend that usually consists of some fraction of a thermoplastic, an elastomer, or rubber, and usually a filler. Also, TPO compounds are resin blends of polypropylene (PP) and uncrosslinked EPDM rubber and polyethylene. They are characterized by high impact resistance, low density, and good chemical resistance. Furthermore, TPOs are used for exterior body parts such as bumpers, rocker panels, body seals, automotive gaskets, doors & windows, and other parts. Moreover, many companies are expanding their product portfolio by focusing on launching new products in the market which in turn is also contributing to the growth of the market. For instance, in Dec 2020, SABIC launched a new polyolefin plastomer-based solution for liquid containers with superior leakage resistance.

Some of the major players operating in the market include The Dow Chemical Company, Lyondellbasell Industries Holdings B.V., ExxonMobil Corporation, Mitsui Chemicals, Borealis AG, Mitsubishi Chemical Holdings Corporation, Chevron Phillips Chemical Company LLC, Avient Corporation, A.Schulman, and INEOS Capital Limited.

COVID-19 Impact

The recent covid-19 pandemic has disrupted the world and has brought a state of shock to the global economy. The global pandemic has impacted many industries and has transformed the way industries work is delivered. The thermoplastic polyolefin market has been significantly affected during these times owing to the delay in construction, manufacturing of vehicles, and others during the pandemic.

The global thermoplastic polyolefin market report is studied thoroughly with several aspects that would help stakeholders in making their decisions more curated.

Based on type, the market is segmented into in-situ TPO, compounded TPO, and others. The compound TPO category is to witness a higher CAGR during the forecast period. This is mainly because these are high-performance elastomers designed to improve performance in a wide range of end products and applications. Additionally, properties such as weather resistance and non-degradable to sunlight exposure are also some of the factors due to which they are widely used in the production of roofing and other exterior materials

On the basis of application, the market is categorized into automotive, building & construction, medical, industrial, footwear, and home appliances. Among these, the automotive to hold a significant share of the market in 2020. The growth of this segment can be attributed to the growing usage of TPO in automobiles mainly because it provides lightweight and highly durable auto parts. In addition, rapid economic growth in various countries leading to improvements in the transportation infrastructure and construction of vehicle production plants are also expected to positively influence the market of this segment in the upcoming years

Thermoplastic Polyolefin Market Geographical Segmentation Includes:

North America (U.S., Canada, and Rest of North America)

Europe (Germany, UK, Spain, Italy, France, and the Rest of Europe)

Asia-Pacific (China, Japan, India, and the Rest of Asia-Pacific)

Rest of the World

Asia-Pacific is anticipated to grow at a substantial CAGR during the forecast period. This is mainly due to the increasing construction and automotive industries. In addition, the growth of the healthcare sector and the development of the renewable energy industry is also driving the growth of the market. Furthermore, increased construction production is contributing to the demand for the thermoplastic polyolefin industry in the Asia-Pacific region as it finds applications in commercial and residential roofing owing to its properties such as weather resistance and cold resistance. Further, the TPO roofing systems offer significant reflectivity and energy efficiency, as well as strong UV resistance. Therefore, the use of the TPO in the roof system reduces the heat gain of the building

Request Free Sample Pages with Graphs and Figures Here https://univdatos.com/get-a-free-sample-form-php/?product_id=26877

The major players targeting the market include

The Dow Chemical Company

Lyondellbasell Industries Holdings B.V.

ExxonMobil Corporation

Mitsui Chemicals

Borealis AG

Mitsubishi Chemical Holdings Corporation

Chevron Phillips Chemical Company LLC

Avient Corporation

A.Schulman

INEOS Capital Limited

Competitive Landscape

The degree of competition among prominent global companies has been elaborated by analyzing several leading key players operating worldwide. The specialist team of research analysts sheds light on various traits such as global market competition, market share, most recent industry advancements, innovative product launches, partnerships, mergers, or acquisitions by leading companies in the Thermoplastic Polyolefin market. The major players have been analyzed by using research methodologies for getting insight views on global competition.

Key questions resolved through this analytical market research report include:

• What are the latest trends, new patterns, and technological advancements in the thermoplastic polyolefin market?

• Which factors are influencing the thermoplastic polyolefin market over the forecast period?

• What are the global challenges, threats, and risks in the thermoplastic polyolefin market?

• Which factors are propelling and restraining the thermoplastic polyolefin market?

• What are the demanding global regions of the thermoplastic polyolefin market?

• What will be the global market size in the upcoming years?

• What are the crucial market acquisition strategies and policies applied by global companies?

We understand the requirement of different businesses, regions, and countries, we offer customized reports as per your requirements of business nature and geography. Please let us know If you have any custom needs.

About UnivDatos Market Insights (UMI)

Browse Other Related Research Reports from UnivDatos Market Insights

Flotation Reagent Market

Graphite Market

Ammonium Sulfate Market

Oilfield Chemicals Market

Gear Oil Market

About UnivDatos Market Insights

UnivDatos Market Insights (UMI) is a passionate market research firm and a subsidiary of Universal Data Solutions. We believe in delivering insights through Market Intelligence Reports, Customized Business Research, and Primary Research. Our research studies are spread across topics across the world, we cover markets in over 100 countries using smart research techniques and agile methodologies. We offer in-depth studies, detailed analysis, and customized reports that help shape winning business strategies for our clients.

Contact us:

UnivDatos Market Insights (UMI)

Email: [email protected]

Web: https://univdatos.com

LinkedIn: www.linkedin.com/company/univ-datos-market-insight/

Ph: +91 7838604911

0 notes

Text

1 note

·

View note

Text

Polycaprolactone Market to Grow at a CAGR of 9.5% during the 2023 to 2031

The global polycaprolactone market stood at US$ 500 million in 2023 and is projected to reach US$ 1.1 billion in 2031. The global polycaprolactone market is anticipated to expand at a CAGR of 9.5% between 2023 and 2031.

Polycaprolactone (PCL) is a partially crystalline biodegradable polyester produced either by polycondensation of carboxylic acid or ring-opening polymerization using catalysts such as stannous octoate. Biodegradable polyesters help address environmental concerns associated with plastic pollution. PCL is used to make thermoplastic polyurethane, which, in turn, is employed as an elastomer, adhesive, and coating in various end-users including automobiles, paints & coatings, and construction. Polycaprolactone resin has a low melting point, making it easy to process and shape.

Polyurethane-based materials are gaining in the construction sector due to their elasticity and flexibility. R&D of novel polyurethane adhesives is projected to offer lucrative opportunities to vendors in the global polycaprolactone industry. Vendors are developing sustainable products for use in the production of transient and biodegradable electronics. They are also specializing in the production of biodegradable polycaprolactone for medical devices.

Download PDF Brochure: https://www.transparencymarketresearch.com/sample/sample.php?flag=S&rep_id=35069

Market Segmentation

The Polycaprolactone market can be segmented by service type, sourcing type, application, industry vertical, and region.

By Service Type:

PCL Pellets

PCL Nanoparticles

PCL Microspheres

By Sourcing Type:

Petroleum-Based

Renewable Sources

By Application:

Biomedical (tissue engineering, drug delivery systems, sutures)

Packaging (films, bags)

Additive Manufacturing (3D printing filaments)

Others (coatings, adhesives)

By Industry Vertical:

Healthcare

Packaging

Manufacturing

Consumer Goods

By Region:

North America

Europe

Asia-Pacific

Latin America

Middle East & Africa

Regional Analysis

North America: Dominates the market due to high investment in research and development, advanced healthcare infrastructure, and increasing demand for biodegradable polymers.

Europe: Significant growth is anticipated due to stringent environmental regulations and a strong focus on sustainability.

Asia-Pacific: Expected to be the fastest-growing region, driven by rapid industrialization, increasing healthcare expenditure, and growing awareness of biodegradable materials.

Latin America and Middle East & Africa: Emerging markets with potential growth opportunities due to rising environmental awareness and regulatory changes.

Market Drivers and Challenges

Drivers:

Increasing demand for biodegradable and sustainable materials.

Technological advancements in biomedical applications.

Government regulations and policies promoting the use of eco-friendly materials.

Challenges:

High production costs compared to conventional plastics.

Limited availability of raw materials from renewable sources.

Technical limitations in specific applications.

Market Trends

Innovation in Biomedical Applications: Continuous research leading to new medical uses of PCL, such as advanced drug delivery systems and tissue engineering.

Growth in Additive Manufacturing: Increased adoption of PCL in 3D printing for various applications.

Sustainability Initiatives: Rising trend of using renewable sources for PCL production to enhance sustainability.

Future Outlook

The future of the Polycaprolactone market looks promising with advancements in technology and growing environmental awareness. Innovations in biomedical applications and additive manufacturing are expected to open new avenues for market growth. Additionally, the shift towards renewable sources for PCL production will further drive the market forward.

Key Market Study Points

Market size and forecast from 2023 to 2031.

Detailed segmentation and regional analysis.

Identification of key drivers, challenges, and trends.

Competitive landscape analysis.

Recent developments and innovations in the market.

Competitive Landscape

The Polycaprolactone market is competitive with several key players striving to enhance their market position through innovation and strategic partnerships. Major players include:

Perstorp Holding AB

BASF SE

Sigma-Aldrich Corporation

Daicel Corporation

Corbion N.V.

These companies are focusing on expanding their product portfolio, investing in research and development, and exploring new applications for PCL to maintain a competitive edge.

Place an Order Copy of Polycaprolactone Market Report at: https://www.transparencymarketresearch.com/checkout.php?rep_id=35069<ype=S

Recent Developments

Innovation in PCL-based medical devices: Companies are developing advanced medical devices using PCL due to its biocompatibility.

Partnerships and Collaborations: Strategic alliances between companies to enhance research capabilities and product offerings.

Sustainability Initiatives: Increased focus on producing PCL from renewable resources to meet regulatory requirements and consumer demand for sustainable products.

About Transparency Market Research

Transparency Market Research, a global market research company registered at Wilmington, Delaware, United States, provides custom research and consulting services. Our exclusive blend of quantitative forecasting and trends analysis provides forward-looking insights for thousands of decision makers. Our experienced team of Analysts, Researchers, and Consultants use proprietary data sources and various tools & techniques to gather and analyses information.

Our data repository is continuously updated and revised by a team of research experts, so that it always reflects the latest trends and information. With a broad research and analysis capability, Transparency Market Research employs rigorous primary and secondary research techniques in developing distinctive data sets and research material for business reports.

Contact:

Transparency Market Research Inc.

CORPORATE HEADQUARTER DOWNTOWN,

1000 N. West Street,

Suite 1200, Wilmington, Delaware 19801 USA

Tel: +1-518-618-1030

USA – Canada Toll Free: 866-552-3453

Website: https://www.transparencymarketresearch.com

0 notes

Text

0 notes

Text

Pressure Sensitive Adhesives Market Overview

Pressure Sensitive Adhesives Market size is forecast to reach US$ 9.5 billion by 2026, after growing at a CAGR of 6.5% during 2021-2026. Globally, the rising demand for pressure-sensitive adhesives (PSA) owing to its thin, flexible material with single or double-sided coating in various end-use industries such as packaging, automotive, and electronics is estimated to drive the market growth. The increasing usage of resins such as silicone polymers, polyisobutene, and elastomers, generally synthetic rubber as the base polymer owing to its functionality and durability, in various end-use sectors will also substantially drive the demand for PSAs. Nitrocellulose adhesive, hydrogenated hydrocarbon resins, and ethylene-vinyl acetate are the thermoplastic resins generally employed in pressure-sensitive adhesives. Moreover, the increasing usage of bio-based pressure-sensitive adhesives and advancements in pressure-sensitive adhesive tapes is expected to offer enormous market expansion opportunities and boost the pressure-sensitive adhesives (PSA) industry in the projected time frame.

𝐃𝐨𝐰𝐧𝐥𝐨𝐚𝐝 𝐑𝐞𝐩𝐨𝐫𝐭 𝐒𝐚𝐦𝐩𝐥𝐞

Impact of Covid-19

The COVID-19 pandemic and its disruption to several manufacturing activities declined the growth of the pressure sensitive adhesives market in the year 2020. Due to the supply chain disruption and insufficient labor, the manufacturing activities of the packaging, automotive, and electrical and electronic industries were set at a pause which affected the market growth. Furthermore, considering the new government norms and reopening of several industries, it is presumed that the market for pressure sensitive adhesives will return to normal conditions.

Report Coverage

The: “Pressure Sensitive Adhesives Market Report – Forecast (2021-2026)”, by IndustryARC, covers an in-depth analysis of the following segments of the pressure sensitive adhesives Market.

By Formulation: Water-based, Solvent-based, Hot Melt, Others

By Resin Type: Elastomer (Natural and Synthetic), Acrylic, Silicone, Ethylene-Vinyl Acetate, Polyvinyl Ether, Polyisobutene, Polybutadiene, and Others

By Application: Tapes, Labels, Graphics, and Others

By End Use Industry: Construction, Automotive, Electronics, Medical and Healthcare, Paper, Furniture, Renewable Energy, Wood Working, and Others

By Geography: North America (USA, Canada, and Mexico), Europe (UK, Germany, Italy, France, Spain, Netherlands, Russia, Belgium, and Rest of Europe), Asia Pacific (China, Japan, India, South Korea, Australia and New Zealand, Taiwan, Indonesia, Malaysia, and Rest of Asia Pacific),South America (Brazil, Argentina, Colombia, Chile, and Rest of South America), and RoW (Middle East and Africa)

Key Takeaways

Asia-pacific region dominated the pressure sensitive adhesives Market due to the rising government investments in the healthcare, electronics, and construction and infrastructure segments in countries such as China, India, South Korea, and Australia.

Current product innovations to improve modulus of elasticity and rigidity are expected to broaden the application range of pressure sensitive adhesives in structural applications and drive the growth of the market in the projected period.

Rising demand for silicone polymers based pressure sensitive adhesive (PSA) in the electronic and medical industry will further drive the growth of the pressure sensitive adhesives market.

Low adhesive strength provided by the pressure-sensitive adhesives (PSA) would further affect the growth of the market over the forecast period.

#Pressure Sensitive Adhesives market price#Pressure Sensitive Adhesives market size#Pressure Sensitive Adhesives market share

0 notes

Text

The Future of Acoustic Insulation Market: Innovations and Emerging Technologies

Introduction:

In an era where noise pollution is increasingly recognized as a significant health and environmental concern, the demand for effective acoustic insulation solutions is on the rise. As technology advances, new innovations and emerging technologies are shaping the future of acoustic insulation, offering improved soundproofing capabilities and enhanced environmental sustainability.

In this article, we will explore the latest trends and developments in the field of acoustic insulation, from novel materials and manufacturing techniques to cutting-edge applications of artificial intelligence and machine learning.

By understanding these innovations, stakeholders in the construction, automotive, and manufacturing industries can stay ahead of the curve and leverage the latest advancements to create quieter, more comfortable environments for work, leisure, and everyday living.

According to Next Move Strategy Consulting, the global Acoustic Insulation Market is predicted to reach USD 19.84 billion by 2030, with a CAGR of 4.1% from 2024 to 2030.

Download FREE Sample: https://www.nextmsc.com/acoustic-insulation-market/request-sample

Nanotechnology in Acoustic Insulation: Nanotechnology is revolutionizing the field of acoustic insulation by offering materials with unprecedented soundproofing properties. Nanostructured materials, such as aerogels and nanocomposites, feature microscopic structures that trap and absorb sound waves more effectively than traditional insulation materials. These nanomaterials can be incorporated into building materials, automotive components, and industrial equipment to reduce noise transmission and improve acoustic comfort.

Additionally, nanocoatings applied to surfaces can enhance their sound-absorbing capabilities, making them ideal for noise control applications in architectural and industrial settings. As nanotechnology continues to advance, the potential for innovative acoustic insulation solutions will only continue to grow, offering greater flexibility, durability, and performance than ever before.

Geographical Analysis:

Asia-Pacific region is expected to hold the lion’s share in the global acoustic insulation market during the forecast period. This is attributed to factors such as fast-paced expansion of the economies such as Indonesia and China due to growing population, rapid industrial expansion, and increased consumer spending, among others.

Furthermore, increasing disposable income and rapid urbanization are the key factors that drive the demand for acoustic insulation in India. In addition, the presence of key players such as H.S. Engineers, Langfang Osking Business Co. Ltd., ACOEM Group, and Guangzhou Hui Acoustics Building Materials Co. Ltd. is expected to propel the growth of the acoustic insulation market in this region in the upcoming years.

Inquire before buying: https://www.nextmsc.com/acoustic-insulation-market/inquire-before-buying

3D Printing for Customized Acoustic Solutions: 3D printing technology is revolutionizing the manufacturing process for acoustic insulation products, allowing for highly customized solutions tailored to specific applications and environments. By using CAD (Computer-Aided Design) software, designers can create intricate geometries and structures optimized for sound absorption and insulation. These designs can then be printed using a variety of materials, including thermoplastics, foams, and elastomers, to achieve desired acoustic properties. 3D printing enables rapid prototyping and iterative design processes, allowing for quick evaluation and optimization of acoustic solutions.

Moreover, the flexibility of 3D printing allows for on-demand production of acoustic insulation components, reducing lead times and waste associated with traditional manufacturing methods. As 3D printing technology continues to evolve, we can expect to see even more innovative and customizable acoustic insulation solutions entering the market, offering unparalleled performance and versatility.

Smart Acoustic Insulation Systems: Advancements in smart technology are transforming acoustic insulation systems into intelligent solutions that can adapt to changing environmental conditions and user preferences. Smart acoustic panels equipped with sensors and actuators can dynamically adjust their properties in response to ambient noise levels, optimizing sound absorption and insulation in real-time. These panels can be integrated with building management systems to create adaptive acoustic environments that prioritize occupant comfort and productivity.

Additionally, machine learning algorithms can analyze environmental data and user feedback to optimize acoustic insulation settings automatically. Smart acoustic insulation systems offer unprecedented flexibility and control over indoor sound environments, allowing users to create personalized acoustic experiences tailored to their needs.

As smart technology continues to advance, we can expect to see even more sophisticated and responsive acoustic insulation solutions entering the market, revolutionizing the way we approach noise control in buildings, vehicles, and industrial settings.

Sustainable Materials for Eco-Friendly Acoustic Insulation: As sustainability becomes a top priority in the construction and manufacturing industries, there is a growing demand for eco-friendly materials in acoustic insulation products.

Manufacturers are increasingly turning to renewable and recycled materials, such as natural fibers, recycled rubber, and cellulose insulation, to reduce the environmental impact of their products. These sustainable materials offer excellent soundproofing properties while minimizing resource consumption and carbon emissions.

Additionally, biodegradable acoustic insulation materials are gaining popularity for their eco-friendly disposal options at the end of their lifecycle. By incorporating sustainable materials into acoustic insulation products, manufacturers can meet the demand for environmentally responsible solutions while maintaining high standards of performance and durability.

As sustainability continues to drive innovation in the acoustic insulation market, we can expect to see more eco-friendly materials and manufacturing techniques entering the mainstream, offering greener alternatives for noise control in buildings, vehicles, and industrial applications.

Competitive Landscape:

Various market players operating in the global acoustic insulation market include Rockwool International, Saint-Gobain, Knauf Insulation, InsulTech, Armacell International, Suprema, Huntsman, Owens Corning, Kingspan Group, and Johns Manville, among others. The key market players are actively indulging in R&D initiatives, product & technology innovations, and industrial collaborations to enhance their product portfolio and increase their geographical reach.

For instance, in January 2021, Armacell partnered with German TITK Group and Melamine to manufacture affective acoustic insulation products with melamine resin-based nonwovens. Moreover, in July 2020, InsulTech announced the expansion of its plant in Yuma, the U.S., effectively doubling the manufacturing space at the site. This new plant will be used to produce foil encapsulated insulation blankets for transportation, industrial, and aerospace applications.

Conclusion:

The future of acoustic insulation is bright, with innovations and emerging technologies poised to revolutionize the way we approach noise control in various industries. From nanotechnology and 3D printing to smart systems and sustainable materials, the latest developments in acoustic insulation offer unprecedented performance, customization, and environmental sustainability. By embracing these innovations, stakeholders can create quieter, more comfortable environments that enhance productivity, well-being, and overall quality of life.

As technology continues to advance, we can expect to see even more exciting developments in the field of acoustic insulation, driving further improvements in soundproofing capabilities and expanding the range of applications for these innovative solutions.

1 note

·

View note