#Used Plastic Injection Molding Machines

Text

How Used Plastic Injection Molding Machines Work

You are probably considering investing in used plastic injection molding machines if you want to venture into the business of producing plastic products and you do not have the finances to purchase a new machine. If you get a good used machine, it can serve you just as good as a brand new one.

Used plastic injection molding machine is a specialized machine that is used in the injection molding technology line. This machine adapts well to various products and has a high production capacity. So, it is widely used in the production of plastic products.

Before you go ahead to buy a used plastic injection molding machine to use in your business, it would be good to understand the structure of a plastic injection machine. This machine comprises of two components that are responsible for different jobs. The mold clamping part and the plastic injection part are very crucial.

Additionally, the mold clamp section divides into a fixed mold clamp part and a movable mold clamp part. Particularly, the fixed mold clamp holds the fixed mold part and the mold positions accurately thanks to the positioning ring on the mold and the positioning hole on the machine.

The movable mold clamp is used to clamp the movable mold half. This part is crucial and has the effect of parallel translation in the opening and closing direction of the mold. It performs the closing and opening of the mold in the plastic injection molding machine.

The movable mold of the machine also arranges to help impact the battery ejection plate to push the product out. Additionally, the plastic injection part is the part that is used to convert the material from solid to liquid by temperature. It pushes the molten plastic into the mold by pushing pressure through the screw and nozzle system.

For more information on how used plastic injection molding machines work, visit our website at premierplasticsnj.com

0 notes

Text

Advanced Imported Used Plastic Injection Molding Machine for Sale

Discover a cutting-edge imported used plastic injection molding machine for sale at IndiaBizzness portal. This advanced equipment boasts state-of-the-art technology, ensuring precision and efficiency in manufacturing processes. With its reliable performance and cost-effective operation, it's the ideal solution for businesses seeking to enhance their production capabilities. Don't miss this opportunity to streamline your operations and achieve superior results with this high-quality injection molding machine.

0 notes

Photo

The Mold-A-Rama is pretty specific to the midwest -- it’s not something I ever encountered until I moved to Chicago. The machines, which date from the 1960s, really look it. When you put $5 in (or swipe your credit card), it starts to rumble, and two huge metal plates slide together under the dome. For about thirty seconds, plastic is injected into the mold, the surface is cooled, and then compressed air blows the excess out, leaving a plastic shell in the shape of whatever the mold was, all of it hidden within the mold’s depths.

Then the mold separates, revealing your toy, and a scraper shoves it into a receptacle where you can pick it up, still hot from the mold, and hold it up to your nose to inhale the particular nostalgic smell of molten plastic. (There’s a great article about the history of the machines here.)

There aren’t many left, but the cool thing about the Mold-a-Rama is that you can pop the mold plates out and replace them. There’s a store on the north side that owns one and has modern independent artists create sculptures for the molds every so often. You can get ones from the Henry Ford Museum in Detroit that are shaped like the Wienermobile or the car JFK was assassinated in.

The MSI has nine machines, and they used to be scattered around the museum, but they’ve moved four of them into one of the exhibit spaces along with various Mold-a-Rama related displays displays. It’s not as in-depth as I would like; it’s in the “let the younger kids run around and wear themselves out” section of the museum, so it’s designed for littler kids who can sweet-talk their parents into dropping $5 on a plastic toy. Still, it was cool to see the machines I hadn’t seen, and the displays were very neat. Not worth making a trek to Chicago for, but if you’re already going to the MSI, it’s definitely not something to skip.

[ID: Four images; top, a Mold-A-Rama machine, which looks like a computer from an old scifi film. It has a sixties-style sign reading Mold-A-Rama, a large glass dome covering most of the machinery parts, and a squat, square body hiding the interior machinery. Below that, three photos of exhibit cases; one shows a sculpture of a carousel horse and two examples of the plastic figurine that is eventually produced from it, sandwiched between the open plates of the horse’s mold. The other shows a square plastic building mimicking the appearance of a large dollhouse, the Fairy Castle stashed elsewhere in the MSI. The last image shows a large glass display case full of dozens of plastic figurines, including animals, fantastical creatures, historical figures, various vehicles, and landmarks, among other things.]

280 notes

·

View notes

Text

But I wanted her (knockoff playline dolls)

I don't use Temu! Temu bad! Temu steals your info! Temu -

Ooh. She's pretty. Yeah. I caved.

So technically, Defa Lucy is a Mexican Walmart knockoff of Barbie, but plastic playline knockoffs aren't viewed generally with the same level of distaste as recast BJDs. Others have their reasons, but mine goes a little something like this:

These toys are made with plastic injection molding machines. Here's a sales pitch video by Fit Precision Molding, a company that makes and sells these machines:

youtube

These machines are NOT cheap. This is the CNC (Computer Numerical Control) machine of toys. $20K (USD) for ONE machine is a starter price - and that's if you can get it cheap from China. So a company that has decided to create their own knockoff line also tends to have the funds to pick a legal fight with, say, Mattel (MGAE and Bratz). This is not a backyard art theft sort of operation. This is easily a $200K operation just for the machines.

Granted, YMY still got smacked good and hard by the company that makes Nendoroids, and they deserved to get smacked, cuz stealing is bad.

HOWEVER...

Playline companies steal from each other all the time (cough cough Barbie Extra trying to lift the LOL OMG line like that hot mess of clashing color outfits and ridiculous plastic jewelry can compare to the cohesiveness of MGAE looks cough). Generally, if one company is mad enough, they'll sue the "stealing" company pretty quickly, and the marketplace will figure it out.

The other reason it doesn't bother me is cuz I figure these companies kinda have it coming.

So when China opened up for business, companies all over the world ran there like their houses were on fire, cuz China so cheap! Such affordable labor force. Much lack of regulation - environmental or occupational safety. Companies initially balked at employees being required to join a union, but they were immediately comforted by the fact that Chinese labor unions do exactly squat for people. The unions exist solely to steal from the employees and transfer that money to members of government.

When you open a business in China, you're required to bring on a local company as a joint venture (same in Saudi Arabia, by the way), and the Chinese company will steal with delight and abandon - as actively encouraged by the Chinese government and CCP. Companies have whined extensively about this to their respective governments. "I want cheap labor force! I want to destroy water supply! I want to pollute their air! But they're stealing from me! Waaaaah!"

Well - you get what you pay for, now don't you. You want access to exploited labor forces (forced labor for Uyghurs in the Xinjiang province, imported North Korean slaves). You want rights to dump your toxic crap into the Chinese water supply and the Chinese air without repercussions - which travels over to California and gets trapped in LA, by the way (air moves, idiots).

You'll have to forgive me if my sympathies are not particularly high for you.

This sucks for anyone trying to be an ethical consumer. Walk into your local store and flip over any box. They all say "Made in China." All of them.

This is why even though dolls like Momoko and Obitsu are more expensive, I am willing to pay to import them. Japanese wages suck, but at least they're making some money. The dolls are made in Japan. That's why they cost as much as they do. If you want to be an ethical doll collector, your options are basically BJDs and Japanese dolls (maybe Korean). Anything on US shelves is made in China and therefore unethical AF.

#defa lucy#temu#playline doll companies#yeah I'm banned from visiting China#probably why I can't sign up for Taobao lol#Youtube

20 notes

·

View notes

Text

Just got back from a family trip to Chicago, and had an awesome time! One of our stops was the Griffin Museum of Science and Industry, inside which were these cool machines called Mold-A-Rama that fabricated plastic models using injection molds right in front of you.

My brother opted to get the Willis Tower model, but it unfortunately didn't survive the trip home. So, given his recently-upgraded 3D-printing setup, I figured I'd help him replace what was lost! 🦝

6 notes

·

View notes

Text

Maximize Efficiency in Pressure Die Casting with Our High-Quality Steel!

At Virat Special Steels, we specialize in supplying high-quality tool and die steels to the pressure die casting industry.

Our comprehensive range includes: DIN 1.2344 (#H13), DIN 1.2343 (#H11), DIN 1.2581 (#H21)

Pressure die casting is a metal casting process that is characterized by forcing molten metal under high pressure into a mold cavity. The mold cavity is created using two hardened tool steel dies which have been machined into shape and work similarly to an injection mold during the process.

DIN 1.2344 (H13) is a hot work tool steel that has excellent machinability and polishability, good high toughness and plasticity, high wear resistance at high and low temperatures and overall hardening performance. It is widely used for aluminum, magnesium and zinc die casting, as well as metal extrusion tools, shear knives, and hot forging dies.

DIN 1.2343 (H11) is also a hot work tool steel that has similar properties to DIN 1.2344 (H13), but with less vanadium content, which gives it higher toughness and lower wear resistance. It is suitable for die casting molds for light metal processing, cylinders and pistons on cold chamber machines, and hot forming tools.

DIN 1.2581 (H21) is a tungsten-chrome-vanadium steel for hardening in oil and possibly in air with very good hardenability, very high firmness during the heat and resistance to the tempering, high resistance to the hot tempering and good toughness. It is mainly used for hot-working dies and tooling, such as extrusion, die casting and hot-forming of parts.

Virat Special Steels is one of the largest importer, exporter and stockist of die blocks, tool steels, die steels, special steels and alloy steels in various grades in India. The company maintains a high level of inventory of special steels from the world’s leading manufacturers and provides technical advice and support to its customers.

Choose VIRAT SPECIAL STEELS for a seamless blend of quality, variety, and reliability in every steel grade.

Learn more :

https://www.viratsteels.com/hot-work-steel.html

https://www.viratsteel.in/materials/hot-work-steel-supplier-in-india/

Any queries feel free to contact us : [email protected] or

Call on mobile number +91-9814021775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#DieCasting#PressureDieCasting#DieCastingProcess#CastingIndustry#AluminumCasting#MoldMaking#hot work steel#h11steel#h13steel#h21steel#din 2344#din2343

2 notes

·

View notes

Text

Random thing ive been learning about, ive been looking into vintage sewing machines (just got an elna supermatic im gonna try and get working!) and learned a cool thing about how they used to make different stitches before things were computerized: these discs called "cams"!

simply put, theyre like lil gears that move the needle around to make diff designs, similar to how computerized machines do just like, mechanically. there are both built in cams (usually in cam stacks) and drop in cams that you can switch out.

now, the problem is: cams can be hard to find apparently! theres only so many of course, and while they arent that expensive individually (a few bucks apiece from what im seeing), it seems like its a pain in the ass to track down specific ones (ive seen so many people bemoaning the ducky elna cam. everyone wants that duck!)

because theyre usually just bits of plastic, it wouldnt be THAT hard to just. 3d print em. maybe it wouldnt give the best results, but hey, a ducky thats gonna wear out a lil too fast might be better than not having a ducky at all, and if people had the files at least someone could theoretically produce them thru better means, like injection molding or whatever.

but of course making a 3d printing database of cams is easier said than done. not for lack of trying apparently! ive found stuff like this thread of someone trying to put together a project to make a database of elna cams (which was later abandoned going by the comments), i found at least one for the elna zigzag cam (nice, might need it if i get my machine working!) , and there are at least a few files available for more popular cams like on singers. heres a thread with someone sharing a buncha files, which i cant verify bc i dont have a printer but they have the duck! and also apparently the dick, which is nice.

if you reverse engineer this shit you could design your own cams, like heres someone who made a 3-step zig zag cam, and a couple of projects for "design your own cams" which. sound cool but idk how modeling works so idk how to do this lmao. but thats so neat!

and theoretically it would be SO easy for someone to just make a database of every cam they could find and upload em for anyone to use but well. again, easier said than done. im finding a lotta scattered files, but unless im missing it i dont think anyones made a single nice lil page filled with the files for cams across diff machines.

...anyway, if anyone knows how this shit works I think it would b really cool if someone made a heartbeat cam and a lil bat cam. those would be fun!

9 notes

·

View notes

Text

Rapid Prototyping Services Revolutionizes Innovation

Rapid prototyping is a process that uses three-dimensional computer-aided design (CAD) data to quickly produce a scale replica of a physical item or assembly. The intention is to provide engineers and designers the opportunity to assess a design's shape, fit, and functionality before mass production. The procedure allows for rapid prototype, which cuts down on the development cycle's duration and expense.

Important Elements of Services for Rapid Prototyping

3D Manufacturing

3D printing is one of the most popular methods for fast prototyping. It entails the layer-by-layer deposition of material from a computer design to produce a tangible item. The versatility of materials, such as metals, ceramics, and plastics, allows for the flexible prototyping of a wide range of items.

CNC Machining: CNC machining is a type of subtractive manufacturing in which a machine tool controlled by a computer removes material from a solid block to mold it into the desired shape. Prototypes may be made with this technique using a variety of materials, including metals and polymers.

Molding by Injection

High-volume prototypes are produced by the rapid prototyping manufacturer using injection molding. The prototype is created by pouring molten material into a mold cavity, where it hardens. Larger production runs result in lower per-unit costs, notwithstanding the greater initial tooling cost.

Advantages of Services for Rapid Prototyping

Accelerated Product Development: From concept to final design, the time it takes to produce a product is greatly decreased by rapid prototyping. Businesses can gain a competitive edge by bringing items to market faster because of this speed.

Savings: When adjustments are needed, traditional prototyping techniques may be costly. Quick modifications are made possible by rapid prototyping, which lowers tooling costs and development costs overall.

Iterative Design Process: An iterative design process is supported by the capacity to swiftly create and test prototypes. Designers can quickly retest, make changes, and get feedback, which results in a better and more optimized final product.

Customization & Complexity: Using Chinese rapid prototyping services makes it feasible to produce extremely intricate and personalized designs that would be difficult or impossible to produce using conventional manufacturing techniques. In sectors including consumer electronics, healthcare, and aerospace, this capacity is very useful.

#Chinese Rapid Prototyping Services#Rapid Prototyping China#Rapid prototyping Supplier#Rapid prototyping manufacturer#Rapid Prototype

4 notes

·

View notes

Text

UHMWPE lining sheet,road mats,soccer rebounder board.plastic cut to size....

Dezhou New Origin Rubber&Plastic CO.,Ltd. is located at the China polyethylene engineering plastic products intensive center, Dezhou City, close to Beijing and Tianjin City. We are engaging in the engineering plastics from 1996.

Kelly Wei

Sales Manager

Email:[email protected]

Cell:+86 17705445030

Whatsapp: +86 17705445030

Website:www.dz-neworigin.com

Our plastic products cover a full range from semi-finished sheets to various machined parts, including CNC machining parts, injection molding parts, marine fender pads, lining sheet, temporary road mats, outrigger pads, synthetic ice rink, curling lanes, cutting board,soccer rebounder boards, as well as plastic irregular machinery parts, which are widely used in marine system, mining, construction, events and projects, sports, food and machinery industries. Which have been exported to United States, United Arab Emirates, India, Russia, Australia, Ukraine, Lithuania, Peru, Germany, Spain Saudi Arabia, South Africa etc. All the customers give good appreciation to our products.

2 notes

·

View notes

Text

Expert mechanical design engineering company offering services such as 3D moulding products design, plastic mould design, 2D drafting DFM for mould manufacturing CNC programming for machines

Thiram is capable of providing product development and design. Our three decades of experience in the engineering field have helped us develop unmatched expertise in the market. Our strong material technology has helped us serve time and distance for the customers.

2 notes

·

View notes

Text

Unlock Savings and Efficiency with Pre-Owned Plastic Processing Machinery

Discover the key to cost-effective production with pre-owned plastic processing machinery. Unlock significant savings and enhance operational efficiency by investing in high-quality, reliable equipment at a fraction of the cost of new machines. From extruders to injection molding machines, IndiaBizzness pre-owned selection offers a range of solutions tailored to meet your manufacturing needs. Maximize your output and minimize expenses with trusted pre-owned machinery.

#Pre-Owned Plastic Processing Machinery#IndiaBizzness#Used injection molding machines#Second Hand extruders Machines

0 notes

Text

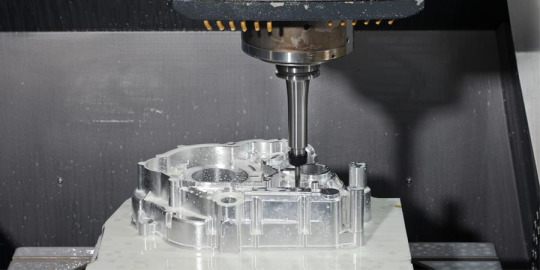

Application of 3+2 CNC Machining in Mold Making Factory

Plastic injection mold manufacturers have long embraced simultaneous multiple-axis machining on machine tools with five or more axes, but more and more China injection mold makers have begun machining mold components on multiaxis platforms in the past few years, said Charlie Chan, engineering manager HS Mold & Die Co.,LTD

He mentioned, however, that the common approach for machining mold parts in houses is 3+2, or 5-axis positional machining. According to his estimate, about 80% to875% of the multi-axis work is performed via 3+2 rather than simultaneous when cutting up to five sides of a prismatic metal workpiece in one fixturing.

What is 3+2 CNC Machining

3+2 (5 axis) CNC machining, also called “positional five-axis machining”, is a technique whereby a three-axis milling program is executed with the cutting tool locked in a tilted position using the 5-axis machine’s two rotational axes, hence the name, 3+2 machining. During the machining process, the fourth and fifth axes are used to rotate the cutting tool in a fixed position rather than to manipulate the tool continuously. On a standard three-axis machine, the only part face that the CNC machine could cut with a cutting tool in its normal position is the horizontal face that faces directly at the spindle.

3+2 CNC Machining Advantages

Compared to conventional three-axis machining, the main advantage of 3+2 CNC machining is the reduction of setup time. According to data from our mold making shop, we could save easily 20% to 25% in setup time because we don’t have to handle that part multiple times.”

Another big benefit of 3+2 CNC Machining is that it allows for the use of a shorter, more rigid cutting tool. With 3+2 machining, the spindle head can be lowered closer to the work piece with the tool angled toward the part surface. This means that a good surface finish and more accurate dimensional results can be achieved .This helps to improve part accuracy by being able to position a work piece so that short, rigid cutting tools are applied, such as when producing undercuts in mold cavities and steep wall inserts in addition, with 3+2 machining, we can use standard, off-the-shelf tools

Rather than using some custom, extra-long tool or holder and risk vibration, this helps to save money easily by 10% to 15% in injection mold costs because there is no need to use special tools for mold manufacturers in china, 3+2 Machining is an ideal option because they can use more off-the-shelf, standard catalog tooling. They have the freedom to reach into my part at different angles without using an especially long tool or special to make that feature on that part.

Application of 3+2 CNC Machining

Where applicable, 3+2 machining will save time and improve operations.This technique is more and more popular with mold making company because it offers great convenience while deep cavities or inserts in complex plastic molds that would otherwise have to be machined with long, slender tools or with tool extensions. Long, slender tools increase the risk of deflection or chatter and tool extensions can create clearance problems. Using 3+2 machining also allows undercuts in cavities and steep walls on standing mold cores to be machined directly. This technique might reduce or eliminate operations for electrical discharge machining (EDM).Relatively few parts are not suitable for 3+2 machining, including complex components. 3+2 CNC Machining is usually used to machine below parts:

deep cavities or inserts in complex plastic molds

certain types of parts from the solid rather than from a complex casting

Drilling holes of metal parts at compound angles such as aluminum brake cylinders in a single setup

We are a China injection mold maker and our CNC machining center has both 3+2 and full 5 axis machining capability, capable of making prototypes and production parts as fast as one day. Reach out HS Mold and see how we could benefit your next CNC rapid prototyping or low-volume manufacturing project.

4 notes

·

View notes

Text

What are the specialties of H13 and P20 Laser Welding Wires

H13 and P20 are two of the most commonly used materials in the manufacturing of molds and dies, and their laser welding wires have gained prominence due to their unique characteristics that make them ideal for specific applications. These wires are used in various industries, such as automotive, aerospace, and plastic molding, to repair or enhance molds and other tooling components. Understanding the specialties of H13 and P20 laser welding wires can help in selecting the right material for specific industrial applications.

H13 Laser Welding Wire Specialties

H13 is a chromium hot-work tool steel known for its excellent strength, toughness, and resistance to thermal fatigue. This makes H13 welding wire particularly well-suited for applications where the tool or mold is exposed to high temperatures and extreme wear conditions. The specialties of H13 laser welding wire available from the Shop Castron Electrode include:

High-Temperature Resistance: H13 has exceptional resistance to thermal fatigue, making it an ideal choice for molds and dies that experience frequent temperature fluctuations during operations, such as hot forging, extrusion, and die-casting. When used in laser welding, the H13 wire ensures that the weld zone can withstand repeated heating and cooling cycles without cracking or losing its mechanical properties.

Toughness and Durability: H13 laser welding wire provides excellent toughness, ensuring that welded components can handle significant mechanical stress. This toughness is crucial for tooling and dies used in high-pressure applications, such as metal forming and injection molding.

Corrosion and Wear Resistance: H13 offers good resistance to wear and corrosion, which prolongs the life of molds and dies. Laser welding wires with H13 wire helps repair damaged surfaces without compromising the overall integrity of the mold or tool, restoring it to its original specifications.

Precision Welding: Laser welding with H13 wire allows for highly precise repairs and additions, minimizing heat-affected zones and reducing the need for post-weld machining. This precision is critical when working with complex mold geometries and tight tolerances.

P20 Laser Welding Wire Specialties

P20 is a versatile pre-hardened tool steel widely used in the plastic injection molding industry. Its welding wire is particularly suited for repairing and modifying molds due to its balanced combination of strength, hardness, and machinability. The specialties of P20 laser welding wire include:

Good Machinability: One of the most significant advantages of P20 by the Shop Castron Electrode is its excellent machinability, making it easy to shape and repair after welding. P20 laser welding wire ensures that repairs or modifications can be performed efficiently, reducing downtime and improving productivity in mold manufacturing and repair processes.

Uniform Hardness: P20 is supplied in a pre-hardened state, usually at a hardness level between 28 and 32 HRC. This uniform hardness ensures that laser welding repairs with P20 wire can be done without introducing significant hardness variations in the weld zone, which could lead to stress concentrations and premature failure. The even hardness distribution is especially beneficial for large, complex molds where dimensional accuracy is crucial.

Polishability: P20 tool steel is known for its excellent polishability, which is essential for plastic molds requiring smooth surface finishes. When using P20 laser welding wire, the repaired area can be polished to match the original mold surface, ensuring that the plastic parts produced have a consistent finish.

Toughness and Strength: P20 offers good toughness and strength, making it suitable for molds that must withstand repeated injection molding cycles under high pressure. Laser welding with P20 wire restores the mold's structural integrity, allowing it to continue functioning in demanding production environments.

Cost-Effectiveness: P20 is generally more cost-effective than other tool steels, making it a popular choice for mold repair and modification. The use of P20 laser welding wire provides a cost-efficient solution for extending the life of molds without the need for expensive replacements.

Conclusion

Both H13 and P20 laser welding wires offer unique advantages tailored to specific industrial needs. H13 is well-suited for high-temperature applications where thermal fatigue and mechanical stress are concerns, while P20 excels in plastic injection molding with its machinability, uniform hardness, and polishability. By selecting the appropriate welding wire, manufacturers can extend the life of their molds and dies, reduce downtime, and improve overall production efficiency. To get more information, visit https://shop.castonelectrode.in/product-category/laser-welding-wires/

0 notes

Text

The tabletop injection molding machine is a compact and efficient solution tailored for small-scale production, prototyping, and educational applications. These machines are especially popular among startups, educational institutions, and hobbyists looking to explore the world of plastic manufacturing without the need for large industrial equipment.

Design and Features

One of the standout features of tabletop injection molding machines is their compact design. They occupy significantly less space compared to traditional injection molding machines, making them ideal for workshops, labs, or even home use. Despite their small footprint, these machines are engineered to deliver high performance and precision, capable of producing intricate parts with fine details.

Typically, a tabletop injection molding machine includes a user-friendly interface that allows operators to easily set and adjust parameters such as injection speed, temperature, and pressure. Many models come equipped with digital displays that provide real-time feedback, enhancing the user experience and ensuring accurate monitoring of the molding process.

Versatility in Material Use

Tabletop machines are designed to work with a variety of thermoplastic materials, including ABS, PLA, and polycarbonate. This versatility allows users to experiment with different materials and applications, from creating prototypes for product designs to manufacturing small batches of functional parts. The ability to quickly switch between materials and molds also enhances their utility in a range of projects.

Safety Features

Safety is a key consideration in the design of tabletop injection molding machines. Most models include essential safety features, such as emergency stop buttons, safety guards, and temperature controls, to protect operators during the molding process. These features not only ensure a safer working environment but also help prevent damage to the machine itself.

Applications

The applications of tabletop injection molding machines are vast. In educational settings, they serve as valuable teaching tools, allowing students to learn about the principles of injection molding and materials science hands-on. For small manufacturers and startups, these machines provide a cost-effective way to produce small runs of products or test new designs without the substantial investment required for larger machines.

Cost-Effectiveness

One of the primary advantages of tabletop injection molding machines is their cost-effectiveness. They offer a more affordable entry point into plastic manufacturing, making it accessible for individuals and small businesses. Lower operational costs, combined with the ability to produce high-quality parts, make these machines a smart investment for those looking to explore or expand their manufacturing capabilities.

Conclusion

In summary, tabletop injection molding machines are an essential tool for anyone interested in plastic manufacturing. Their compact size, versatility, and safety features make them suitable for a wide range of applications, from education to small-scale production. As technology continues to advance, these machines are becoming increasingly efficient, enabling users to achieve professional-quality results without the need for large, expensive industrial equipment. Whether you are a hobbyist, educator, or entrepreneur, a tabletop injection molding machine can significantly enhance your ability to create and innovate in the field of plastic manufacturing.

0 notes

Text

Custom Plastic Injection Molds: High-Quality Molding Solutions by Topwell Moulding

In today’s fast-paced industrial world, precision, efficiency, and customization are key drivers in product development. One of the most crucial manufacturing processes for creating durable and versatile plastic components is plastic injection molding. Whether for automotive parts, electronics, medical devices, or consumer goods, custom plastic injection molds are the foundation of high-quality plastic production. At Topwell Moulding, we specialize in offering advanced, reliable, and tailored molding solutions that meet the unique needs of our clients.

What is Custom Plastic Injection Molding?

Plastic injection molding is a manufacturing process where molten plastic is injected into a custom-designed mold cavity, cooled, and solidified to form a desired shape. This process is ideal for producing high volumes of parts with precision and consistency. However, for industries that require specific designs or components, custom plastic injection molding allows manufacturers to create parts tailored to precise specifications.

Key Benefits of Custom Plastic Injection Molding:

Precision and Consistency: Custom molds ensure each part is identical, maintaining quality standards even with high production volumes.

Versatility: Whether for simple or complex designs, custom molds allow for intricate details and specialized shapes to meet a wide variety of industrial needs.

Cost-Effectiveness: While the initial investment in custom mold creation can be significant, the long-term benefits, such as reduced material waste, shorter production cycles, and lower labor costs, make it highly cost-effective over time.

Why Choose Topwell Moulding for Custom Plastic Injection Molds?

1. State-of-the-Art Technology

At Topwell Moulding, we use the latest technology and advanced machinery to design and produce custom molds with unparalleled precision. Our cutting-edge injection molding machines ensure consistent results, regardless of the complexity of the project.

2. Expert Design and Engineering Team

Our skilled design and engineering team works closely with clients from the initial concept phase to the final production stage. We utilize advanced CAD software to create detailed mold designs that meet the client’s specifications and industry standards.

3. Material Expertise

Different applications require different types of plastic materials. Whether it’s thermoplastics, thermosetting polymers, or composite materials, our team has the expertise to guide you in selecting the right material for your project. This ensures that the final product is durable, functional, and cost-effective.

4. Customization for Various Industries

Our custom plastic injection molds are designed to serve a variety of industries, including:

Automotive: Producing intricate parts for engines, interiors, and exteriors.

Medical: High-precision molds for medical devices and surgical equipment.

Consumer Electronics: Custom molds for housings, buttons, and components.

Packaging: Specialized molds for creating plastic containers, caps, and closures.

5. High-Volume Production Capability

Topwell Moulding is equipped to handle high-volume production runs while maintaining quality and efficiency. Our advanced mold design and efficient production processes allow us to meet tight deadlines and large orders without compromising on quality.

The Custom Plastic Injection Molding Process

At Topwell Moulding, our custom plastic injection molding process is thorough and detail-oriented. Here’s a quick overview of how we bring your ideas to life:

1. Concept and Design

We begin with a detailed discussion of your requirements, including product dimensions, material preferences, and functionality. Our design team then creates 3D models of the mold using advanced CAD software, ensuring every specification is met.

2. Prototyping

Before mass production, we offer prototyping services to create a working model of your product. This step helps identify potential design flaws and allows for any necessary adjustments before full-scale production.

3. Mold Manufacturing

Once the design is approved, our team begins the process of manufacturing the custom mold. We use high-quality steel or aluminum, depending on the application, to create durable molds capable of withstanding extensive production cycles.

4. Production and Testing

After the mold is complete, it’s installed into our injection molding machines, and the production process begins. Each batch undergoes rigorous testing and quality control checks to ensure that every component meets your exact specifications.

5. Final Delivery

Once the products have passed our strict quality assurance tests, they are prepared for packaging and shipment. We ensure timely delivery to meet your project deadlines.

The Topwell Moulding Advantage

Choosing Topwell Moulding for your custom plastic injection molding needs offers numerous advantages. Our commitment to quality, precision, and customer satisfaction is reflected in every product we manufacture. From small-scale projects to large industrial orders, our team is dedicated to delivering excellence at every step of the process.

Key Features of Topwell Moulding Services:

Short Lead Times: We understand the importance of deadlines, and our efficient production processes ensure timely delivery without compromising on quality.

Competitive Pricing: We offer competitive pricing for custom molds and mass production, making high-quality injection molding accessible to businesses of all sizes.

Comprehensive Support: Our team provides ongoing support throughout the project, ensuring a seamless experience from design to delivery.

Conclusion

Custom plastic injection molds are the foundation of high-quality, durable, and efficient plastic components. At Topwell Moulding, we pride ourselves on delivering advanced molding solutions tailored to meet the specific needs of our clients. Our expertise, cutting-edge technology, and commitment to customer satisfaction make us a leading choice for businesses seeking reliable, high-quality plastic injection molds.

For more information on how Topwell Moulding can help you with your custom plastic injection molding needs, visit our website at www.topwellmoulding.com and explore our range of solutions designed to elevate your production process.

0 notes

Text

Looking for the Best Tool & Die Steel Supplier in Hyderabad?

Look no further! Virat Special Steels Pvt. Limited is your go-to supplier for all kinds of tool steel, die steel, plastic mold steel, high speed steel, and alloy steel.

Virat Special Steels Pvt. Limited stands out as one of the premier Tool & Die Steels Suppliers in Hyderabad. Let’s explore why they’re a top choice:

Wide Range of Materials:

Virat Special Steels deals in various steel types, including:

Tool Steel: DB6 / DIN-1.2714 / AISI L6, essential for cutting, shaping, and forming tools.

Die Steel: DIN 2343, 2344 / AISI H11, H13, crucial for molds, dies, and precision components.

Plastic Mold Steel: DIN 2738, 2311 , AISI P 20, tailored for plastic injection molding.

High-Speed Steel: DIN 3243 , 3343 / AISI M2 , M35, ideal for high-speed machining.

Alloy Steel: Versatile and robust for diverse applications.

Value-Added Services:

They go beyond supplying raw materials. Their services include:

- Material Machining: Precision shaping and customization.

- Cut Pieces: Ready-to-use segments for efficiency.

- Tailor-Made Material: Customized to specific requirements.

Metallurgical Expertise:

Virat Special Steels provides metallurgical advice to ensure optimal material selection and performance.

Their team understands the nuances of steel properties and applications.

Quality Assurance:

Quality is non-negotiable. They adhere to stringent standards.

Ultrasonic inspection ensures material integrity.

State-of-the-Art Facilities:

Their Gurugram and Ludhiana plants boast cutting-edge technology.

Consistent quality and timely delivery are their hallmarks.

Strong Distribution Network:

Virat Special Steels reaches across India, ensuring accessibility.

Whether in Hyderabad or beyond, their steel is within reach.

For more information, visit Virat Special Steels. Trust in their expertise for all your steel needs! 🛠️🔥

Consultation:

For further assistance, consult their #Gurugram office. Learn more

https://www.viratsteel.in/locations/tool-and-die-steel-supplier-in-hyderabad/

Choose Virat Special Steels for your steel needs and experience the difference quality makes. Contact us today to learn more about our products and services!

Any further queries feel free to contact us :

🌐https://www.viratsteels.com/ 📨 [email protected] 📞 +91 98140-21775

#ludhiana#india#viratsteels#gurgaon#viratspecialsteels#toolsteelsupplier#gurugram#pune#iso9001#steel#Hyderabad#SteelSupplier#MetalTraders#db6 steel#h13toolsteels#h11steel#din 2714#din2344#din3343

2 notes

·

View notes