#Yttrium alumina garnet

Text

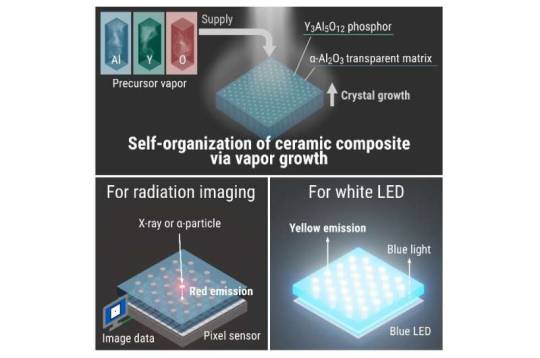

3D pattern generation via chemical vapor deposition of ceramic eutectic system for novel solid-state phosphors

The eutectic structure of metals and ceramics occurs when multiple solid phases solidify from a liquid phase, forming a three-dimensional (3D) pattern through a self-organizing phenomenon. Traditionally, it was believed that eutectic structures could only be obtained through a melt-solidification process.

Researchers at Yokohama National University (YNU) have developed a chemical vapor deposition (CVD) process that allows precursor gases to react and generate solid-state composites with ordered structures in a YAG (yttrium alumina garnet)-alumina ceramic eutectic system.

In their study, they observed the growth of spatially ordered rod- and lamellar-shaped YAG crystals within an alumina matrix on a sapphire wafer under Al-rich conditions. Conversely, under Y-rich conditions, they observed the growth of ordered alumina crystals with a YAG matrix. The choice of sapphire seed crystal and the composition of the precursor determined the 3D patterns. Compared with the melt-solidification process, the CVD process expanded the range of chemical compositions that could generate such patterns.

Read more.

#Materials Science#Science#Chemical vapor deposition#Ceramics#Phosphors#Eutectic#Phases#Yttrium alumina garnet#Yttrium#Alumina#Yokohama National University

14 notes

·

View notes

Text

Optical Ceramics Market is Projected to Grow at a CAGR of 15% by 2024 | TechSci Research

Increasing expenditure on advanced materials & technologies and surging adoption of substitute to glass, metals & plastics to drive growth of optical ceramics market through 2024

According to TechSci Research report, “Optical Ceramics Market By Material Type, By Application, By End-User Industry, By Region, Competition Forecast & Opportunities, 2024”, the optical ceramics market is expected to grow at a CAGR of around 15% during the forecast period. The growth in the market can be attributed to rising adoption of optical ceramics across various industries on account of its durability, increasing defense expenditure on advanced technologies and materials and their adoption as a substitute to glass, metals and plastics. However, cost of optical ceramics is likely to hamper the growth of the market during forecast period.

Browse market data Tables and Figures spread through 110 Pages and an in-depth TOC on " Optical Ceramics Market"

https://www.techsciresearch.com/report/optical-ceramics-market/4092.html

optical ceramics market is segmented based on material type, application, end user industry, region and company. Based on type, the market can be segmented into Sapphire, Phosphor, Alumina, Selenide, Oxynitride, Spinel, Yttrium Aluminium Garnet [YAG] and Others. Sapphire is estimated to dominate the market during the forecast period as a large number of manufacturers are present in the market. Moreover, various properties of Sapphire such as easy availability, ease of manufacturing, and suitability for a wide range of optical applications, makes it a preferable choice across different applications.

Key Players:

Konoshima Chemicals Co., Ltd.

Coorstek Advanced Materials Crewe Limited

CeramTec-ETEC GmbH

Brightcrystals Technology Inc.

Schott AG

Surmet Corporation

Murata Manufacturing Co. Ltd.

II-VI Optical Systems Inc.

Compagnie Industrielle des Lasers CILAS SA, and Ceranova Corporation

These are some of the leading players operating in optical ceramics market. Companies operating in the market are using organic strategies such as product launches, mergers and collaborations to boost their share.

Download Sample Report @ https://www.techsciresearch.com/sample-report.aspx?cid=4092

Customers can also request for 10% free customization on this report.

“Asia-Pacific is expected to be the largest and fastest growing market for optical ceramics during the forecast period, owing to the easy availability of raw materials, low-cost labor and higher demand in the region. These factors have made Asia-Pacific the most preferred destination for the manufacturers of optical ceramics. Moreover, rising manufacturing of optoelectronic devices using materials such as sapphire and Yttrium aluminium garnet in countries like Japan, China, and India is further fuelling growth in the market.” said Mr. Karan Chechi, Research Director with TechSci Research, a research based global management consulting firm.

“Optical Ceramics Market By Material Type, By Application, By End-User Industry, By Region, Competition Forecast & Opportunities, 2024” has evaluated the future growth potential of global optical ceramics market and provides statistics & information on market size, structure and future market growth. The report intends to provide cutting-edge market intelligence and help decision makers take sound investment decisions. Besides, the report also identifies and analyzes the emerging trends along with essential drivers, challenges and opportunities in optical ceramics market.

About TechSci Research

TechSci Research is a leading global market research firm publishing premium market research reports. Serving 700 global clients with more than 600 premium market research studies, TechSci Research is serving clients across 11 different industrial verticals. TechSci Research specializes in research-based consulting assignments in high growth and emerging markets, leading technologies and niche applications. Our workforce of more than 100 fulltime Analysts and Consultants employing innovative research solutions and tracking global and country specific high growth markets helps TechSci clients to lead rather than follow market trends.

Contact

Mr. Ken Mathews

708 Third Avenue,

Manhattan, NY,

New York – 10017

Tel: +1-646-360-1656

Email: [email protected]

#opticalceramics#opticalceramicsmarket#opticalceramicsreport#opticalceramicsindustry#opticalceramicsmarketsize#opticalceramicsmarketshare#opticalceramicsmarketanalysis#opticalceramicsmarkettrends#opticalceramicsmarketgrowth#opticalceramicsdemand#opticalceramicsmarketscope

1 note

·

View note

Text

Aluminum Oxide Powder | Aluminum Oxide Grit Manufacturer in India

Aluminum oxide is employed during a blasting machine for surface preparation thanks to its high durability and reusability. Aluminum oxides are utilized in granulating haggles wheels, covered abrasives (paper and fabric), sand blasting abrasives thanks to high durability. Aluminum oxides are quick to get rid of rust, mill scale, paint, carbon stores.

Aluminum Oxide Grit Manufacturer

Aluminum oxide grit manufacturer is often used easily in portable sand blasting machine and wheel shot blasting machine. to gather and reuse aluminum oxide grit manufacturer mostly blasting cabinets and blast room systems are used. In portable blasting machines cleaning or blasting wiped out an open area so it's hard to gather blasting media for reuse. Sand Blasting Nozzle size is additionally considered while choosing aluminum oxide grit manufacturer size for blasting. the dimensions of blasting media use depend upon the dimensions of the nozzle. If aluminum oxide size is large it makes chock the nozzle and blasting not done.

Aluminum oxide use in both dry blasting machines and wet blasting machines because aluminum oxide grit manufacturer impact media is understood for its high thickness and high sharpness which makes it among the foremost adaptable of the impacting media types. Aluminum oxide blasting abrasively available in much standard size to satisfy any surface preparation and finishing requirements in both virgin and commercial types.

Aluminum oxide is lighter in weight than other metallic blasting media. thanks to light in weight aluminum oxide rough grain have twice an equivalent number of particles per pound. alumina has angularity and has high hardness. aluminum oxide is an aggressive abrasive blasting media that's suitable for both ferrous and non-ferrous substrates.

The grit size is consistent and cuts much faster than sand, leaving a smoother surface. Generally, the larger the grit size, the faster the aluminum oxide will cut, alumina (or aluminum oxide) are often recycled repeatedly. It's the foremost widely used abrasive grain in sandblast finishing and surface preparation due to its cost, longevity, and hardness. Harder than other generally used blasting materials, aluminum oxide manufacturer grit powder penetrates and cuts even the toughest elements and sintered carbide.

Features of Aluminum Oxide Grit Manufacturer

Fast cutting action.

Highly durable.

Reusable.

Long-lasting and lighter.

Harder.

Aluminum Oxide Grit Manufacturing Process

Aluminum oxide nanoparticles can be orchestrated by numerous methods including ball processing, sol-gel, pyrolysis, faltering, aqueous, and laser removal. Laser removal is an ordinarily utilized procedure to create nanoparticles since they can be blended in a gas, vacuum, or fluid. The procedure offers a few points of interest, for example, fast and high immaculateness measures contrasted and different strategies. Furthermore, nanoparticles arranged by the laser removal of materials in the fluid are gathered simpler, than those in gas air.

Applications of Aluminum Oxide Grit Manufacturer

In coordinated circuit baseboards.

Transparent pottery, high-pressure sodium lights, and EP-ROM window.

In YAG laser precious stones.

As restorative fillers.

A single precious stone, ruby, sapphire, sapphire, and yttrium aluminum garnets.

High-strength aluminum oxide ceramic and C substrates.

Packaging materials, cutting devices, high virtue cauldron, winding pivot, and heater tubes.

Polishing materials, glass items, metal items, semiconductor materials.

Plastic, tape, and grinding belts.

Paint, elastic, plastic wear-safe support, and progressed waterproof materials.

Catalyst, impetus transporter, scientific reagents.

Aerospace airplane wing driving edges.

Vapor affidavit materials, uncommon glass, fluorescent materials, composite materials, and tars.

Aluminum Oxide Grit Manufacturer in India

We provide steel shot, SS shot, copper slag, steel grit, garnet sand, quartz shot, aluminum oxide, glass beads, etc for the Sand Blasting Machine. We provide a large range of products and are checked on various parameters, such as density, physical and chemical properties, microstructure, hardness, durability. We are focused on our quality products and customer satisfaction.

To enable us to quote for your requirement, kindly give us the following info –

1. Particle size required (You may choose from above or give your own range).

2. Packing required.

3. Quantity required with the delivery schedule.

4. Destination port.

5. Payment terms.

6. Discharge rate at the destination, if in break-bulk.

7. Any other point which may impact the quote.

We can also offer ungraded material for shipments in bulk in any quantities as desired by our buyers on FOB or CNF FO basis terms.

0 notes