#cnc bend

Text

Crafting Precision with CNC Folding: Stainless Steel Brackets

CNC folding, a cutting-edge technology, is revolutionizing the way we create stainless steel brackets. This process utilizes computer numerical control (CNC) systems to manipulate stainless steel sheets into precise, customized shapes.

One of the standout benefits of CNC folding with stainless steel is the exceptional precision it offers. Whether you need brackets for industrial machinery, architectural structures, or custom applications, CNC folding ensures each bracket is exact to your specifications. This precision minimizes material waste and guarantees a perfect fit for your project.

Stainless steel is a popular choice for brackets due to its corrosion resistance and durability. With CNC folding, intricate designs and complex geometries can be achieved with ease, making it ideal for both functional and decorative brackets.

Additionally, CNC folding enhances efficiency, reducing production time and labor costs, which is especially beneficial for high-volume orders. The result is high-quality stainless steel brackets that meet the strictest industry standards.

https://www.vandf.co.uk/tooling/what-is-cnc-bending/

In conclusion, CNC folding is a game-changer in the production of stainless steel brackets, providing unmatched precision, versatility, and efficiency. This technology paves the way for the creation of brackets that not only serve their intended purpose but also exhibit exceptional craftsmanship.

#sheet metal work#manufacturing#cnc folding#cnc brake press#sheet metal manufacturing#cnc bend#angle brackets

3 notes

·

View notes

Text

I want you to tell me all of your most fucked up fantasies and then do them to me. Flirting

#send anons#send r3pe threats#i need to be groped#attention wh0r3#fr33use slvt#dumb slvt#cnc slvt#stupid slvt#free use slvt#good slvt#bewbies#feeling slutty#desperate for attention#fill my pussy#fill my holes#fill me up#bend me over#desperate wh0re#stuff my holes#bruises#pinch me#free use toy#needy toy#cumslvt#send 1cky asks

1K notes

·

View notes

Text

THEY ARE FREAKY?? WHEN IN DOUBT EAT IT OUT AND BEND ME OVER???

#sturniolo triplets#chris sturniolo#fanfic#christopher sturniolo#sturniolo smut#sturniolo x reader#sturniolo fanfic#chris sturniolo x reader#chris x reader#chris smut#chris girl#chris sturniolo smut#chris sturniolo imagine#chris sturniolo x you#sturniolo imagine#tiktok#tiktok edits#chris sturniolo edit#sturniolos#sturniolotriplets#the sturniolo triplets#the sturniolos#twitch#bend me over#need dick#dick bulge#food#rough cnc#roughfuck#rough k1nk

707 notes

·

View notes

Text

------------------------------------------------------------

Come bend me over the counter and fuck me until I can't breathe, please? 🥺

#choked while fucked#chubby#cnc k!nk#daddy's good girl#attention wh0r3#cnc free use#dumb slvt#praise and degredation#breeding k1nk#cnc somno#bend me over#olivpix

438 notes

·

View notes

Text

✨🌙🤍👼🏻angel baby👼🏻🤍🌙✨

#girlblogging#latin girls#me#spilled thoughts#thicc girls#thick babe#tumblr girls#dark academia#lizzy grant#bd/sm kink#natural body#thick gorl#thick goth#thick and juicy#full figured#alt aesthetic#fairy aesthetic#soft aesthetic#goth aesthetic#alt girl#soft goth#perfect butt#bend me over#cute girls#cute goth#thickwomen#cnc k!nk#cnc brat#bd/sm babygirl#420stoner

154 notes

·

View notes

Text

#tattoed girls#girl butts#lace underwear#cheeks 🍑#cheeksout#bend me over#bd/sm kink#daddy's good girl#skintight#pink#wet and needy#soft cnc#daddy’s brat#hornyaf#beautiful#choke her#tie me up#spank my pussy#pretty#scenery#dirtygirl#cnc brat

1K notes

·

View notes

Text

V and F Sheet Metal have been producing folded sheet metal components since the 1980s.

Contact us for a quote today on your next sheet metal project.

http://www.vandf.co.uk/tooling/what-is-cnc-bending/

2 notes

·

View notes

Text

how do you like the view?

#want me to bend over? orrrrr#sub thoughts#bi girls#sub texts#always a tease#me#bd/sm brat#it’s me#when will it be my turn#sexy redhead girls#it’s me i want to be the sub#pls gr0pe me#cnc k!nk#cnc free use#cnc thoughts#brain go brrrrrrr#omg when#daddy#pls grope me#me and who

128 notes

·

View notes

Text

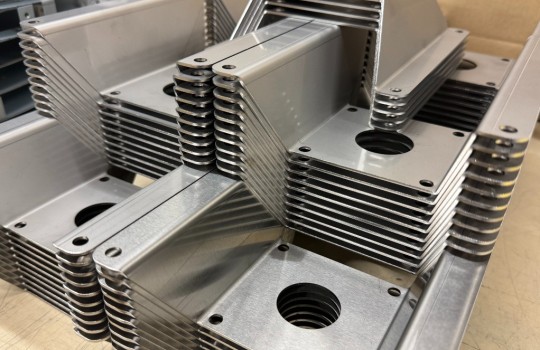

Aluminium sheet metal brackets. CNC punched and CNC folded. Barrel deburred to remove sharp edges, ready for shipping to our customer.

http://www.vandf.co.uk/gallery/bracket-angle-gallery/

#sheetmetal#sheet metal bending#sheet metal fabrication#cnc punching#cnc brake press#cnc bend#aluminium

2 notes

·

View notes

Text

im such a secret slut for secret public sex. like please finger me to overstimulation in a crowded theater while you politely ask me to be quiet, you cant hear the movie. drag me to the bathroom for a quickie. manhandle me in the backseat of an uber while we stifle our sighs.

#wet and needy#bd/sm brat#bd/sm daddy#mommys little girl#overstim nsft#cnc overstim#bend me over#overstim kink#use my pussy#submisive and breedable#grope public#voyerurism#exhibtionist#exhibition kink#public exhibition

794 notes

·

View notes

Text

Oops.. they slipped out 🫢

#oopsie#i swear i didn't bend down that much!#bd/sm community#nsft concept#use me use me use me#soft cnc#bd/sm kink#bd/sm pet#my stuff#it's still my fav sweater 😁

106 notes

·

View notes

Text

Sheet metal forming is a crucial process in the manufacturing of custom metal components, offering numerous cost advantages to customers, especially when using CNC press brakes. This technique involves bending and shaping sheet metal to achieve desired geometries and specifications, which is essential for producing high-quality, precision components.

One of the primary cost advantages of sheet metal forming using CNC press brakes is the high level of precision and repeatability. CNC press brakes, such as those utilised by V&F Sheet Metal, are equipped with advanced computer controls that ensure consistent accuracy in every bend and fold. This precision reduces material waste and minimises the need for rework, thereby lowering production costs. Moreover, the ability to program and store multiple bending sequences allows for quick setup and changeover between different projects, enhancing production efficiency and reducing lead times.

Additionally, the flexibility of CNC press brakes in handling various materials and thicknesses translates to significant cost savings. These machines can process a wide range of metals, including steel, stainless steel, aluminium, copper and brass, accommodating diverse project requirements without the need for specialised tooling. This versatility means that customers can confidently consolidate their sheet metal manufacturing needs with a single supplier, reducing logistical complexities and associated costs.

Furthermore, modern CNC press brakes enable the production of complex geometries and intricate designs that would be challenging or impossible to achieve with manual processes. This capability not only broadens the range of possible applications but also allows for innovative design solutions that can enhance the functionality and aesthetics of the final product. By leveraging the advanced capabilities of CNC press brakes, customers can achieve superior product quality and performance, which can lead to increased market competitiveness and finally customer satisfaction.

Another significant cost advantage is the reduction in labour time / costs. CNC press brakes automate much of the bending process, requiring less manual intervention and oversight. This automation not only speeds up production but also reduces the likelihood of human error, further enhancing product quality and consistency. Additionally, the streamlined workflow enabled by CNC technology allows manufacturers to operate with smaller, more skilled workforces, ultimately lowering labour expenses. Also, with the ability to move from prototype testing to production with the same machines, tooling and programs.

In conclusion, sheet metal forming using CNC press brakes offers substantial cost advantages for custom metal manufacturing. The precision, versatility, and efficiency of these machines lead to reduced material waste, lower production costs, and enhanced product quality. By investing in CNC technology, manufacturers can deliver high-quality, cost-effective solutions that meet the diverse needs of their customers, ultimately driving business success and growth.

https://www.vandf.co.uk/blog/sheet-metal-forming-folding-and-bending-your-custom-components/

0 notes

Text

I feel like I look so much better bent over 😉

What do you think???

#daddy's good girl#dumb slvt#send asks#asks open#send me asks#cvm in me#daddy’s wh0re#mine#big tiddy committee#bend ova#cnc fr33use#cnc k!nk#cnc free use#rough cnc

49 notes

·

View notes