#iiot

Text

#AIart#art#machinelearning#deeplearning#artificialintelligence#datascience#iiot#data#MLsoGood#code#python#bigdata#MLart#algorithm#chatGPT#openAI#programmer#pytorch#DataScientist#Analytics#AI#VR#iot#TechCult#Digitalart#DigitalArtMarket#generativeai#ArtMarket#DataArt#GAN

484 notes

·

View notes

Text

#AIart#art#machinelearning#deeplearning#artificialintelligence#datascience#iiot#data#MLsoGood#code#python#bigdata#MLart#algorithm#programmer#pytorch#DataScientist#Analytics#AI#VR#iot#TechCult#Digitalart#DigitalArtMarket#ArtMarket#DataArt#GAN#GANart#arttech#ai art

11 notes

·

View notes

Text

4 notes

·

View notes

Photo

💥 Meet Honey Drone ▶️ #Analytics #BigData #AI #IoT #MachineLearning #Serverless #TensorFlow #flutter #javascript #Robotics #CyberSecurity #IIoT #Robotic #Fintech #CES2023 #programming #Coding #100DaysOfCode Cc: @jblefevre60 (at Honey & Drone) https://www.instagram.com/p/CmdLGn5MQFC/?igshid=NGJjMDIxMWI=

#analytics#bigdata#ai#iot#machinelearning#serverless#tensorflow#flutter#javascript#robotics#cybersecurity#iiot#robotic#fintech#ces2023#programming#coding#100daysofcode

3 notes

·

View notes

Text

Snowflake’s open-source Arctic LLM to take on Llama 3, Grok, Mistral, and DBRX

https://www.infoworld.com/article/3715390/snowflake-s-open-source-arctic-llm-to-take-on-llama-3-grok-mistral-and-dbrx.html?utm_source=dlvr.it&utm_medium=tumblr#tk.rss_machinelearning

0 notes

Text

Explore the limitless possibilities of IIoT automation! 🤩

#IIoT#Automation#Benefits#Data#Efficiency#Insights#DecisionMaking#Innovative#iot#iotsolutions#websitedevelopment#blogpost#TechNews2024#sdreatech

0 notes

Text

PLC Automation Panels: Enhancing Efficiency in Industrial Automation

Introduction to PLC Automation Panels

PLC Automation Panels play a crucial role in modern industrial automation systems. They serve as the backbone of automated processes in various industries, offering efficiency, reliability, and flexibility.

What are PLC Automation Panels?

PLC Automation Panels, or Programmable Logic Controller Automation Panels, are control systems that use digital computers to automate industrial electromechanical processes. These panels receive input signals from sensors and switches, process the data using a programmed logic, and generate output signals to control machines or processes.

Components of PLC Automation Panels

PLC Automation Panels consist of several key components:

PLC (Programmable Logic Controller)

The PLC acts as the brain of the automation system. It processes input data, executes programmed logic, and controls output devices based on predefined instructions.

Input Modules

Input modules receive signals from sensors and switches, converting them into digital signals that the PLC can process.

Output Modules

Output modules receive signals from the PLC and control actuators such as motors, valves, and relays to perform desired actions.

Power Supply

The power supply unit provides the necessary electrical power to the PLC and other components of the automation panel.

Types of PLC Automation Panels

There are several types of PLC Automation Panels designed to meet different requirements and applications:

Compact PLC Panels

Compact PLC Panels are suitable for small-scale automation applications where space is limited. They offer a compact design with integrated input/output modules and are ideal for standalone machines or processes.

Modular PLC Panels

Modular PLC Panels consist of separate modules for the PLC, input/output, and power supply, allowing for flexibility and scalability. They can be easily expanded by adding additional modules to accommodate growing automation needs.

Rack-mounted PLC Panels

Rack-mounted PLC Panels are designed for larger automation systems that require high performance and extensive I/O capabilities. They feature a rack-mounted design with multiple slots for installing PLC modules and expansion cards.

Advantages of PLC Automation Panels

PLC Automation Panels offer several advantages over traditional relay-based control systems:

Flexibility: PLCs can be easily reprogrammed to adapt to changes in production requirements or process parameters.

Reliability: PLCs are highly reliable and operate in harsh industrial environments without the risk of mechanical failure.

Efficiency: PLCs can execute complex control algorithms with high speed and accuracy, leading to improved efficiency and productivity.

Remote Monitoring: PLC Automation Panels can be remotely monitored and controlled, allowing for real-time optimization and troubleshooting.

Applications of PLC Automation Panels

PLC Automation Panels find applications in various industries and processes, including:

Industrial Automation: PLCs control automated manufacturing processes, material handling systems, and assembly lines in industries such as automotive, pharmaceuticals, and food processing.

Manufacturing Processes: PLCs regulate parameters such as temperature, pressure, and flow rate in manufacturing processes to ensure product quality and consistency.

Energy Management Systems: PLCs monitor and control energy consumption in buildings, factories, and utilities, helping to optimize energy usage and reduce costs.

Considerations for PLC Automation Panel Selection

When selecting a PLC Automation Panel for a specific application, several factors should be considered:

Environmental Conditions: Choose a panel that can withstand the operating environment’s temperature, humidity, and vibration levels.

Scalability: Select a panel that can accommodate future expansion and integration with additional devices or systems.

Integration with Existing Systems: Ensure compatibility with existing automation equipment and communication protocols to facilitate seamless integration.

Installation and Maintenance of PLC Automation Panels

Proper installation and maintenance are essential for ensuring the reliable operation of PLC Automation Panels. Installation should be performed by trained technicians following manufacturer guidelines, and regular maintenance checks should be conducted to identify and address any issues promptly.

Future Trends in PLC Automation Panels

The future of PLC Automation Panels is characterized by advancements in technology such as:

Integration with IIoT: PLCs will increasingly integrate with the Industrial Internet of Things (IIoT) to enable real-time data exchange and predictive maintenance.

Edge Computing: PLCs will leverage edge computing capabilities to perform advanced data analytics and decision-making at the edge of the network, reducing latency and enhancing responsiveness.

Machine Learning: PLCs will incorporate machine learning algorithms to optimize control strategies and adapt to changing operating conditions autonomously.

Conclusion

PLC Automation Panels play a vital role in modern industrial automation, offering efficiency, reliability, and flexibility across various applications. By understanding the components, types, advantages, and considerations for selection, businesses can leverage PLC Automation Panels to enhance their operational efficiency and competitiveness in the global market.

If you want to interested in these things so

visit here👉https://www.pujacontrols.com/

#automation#plc#technology#software development#industrial automation#iiot#system integration#machine learning#labviewsoftware

0 notes

Text

Automation is a necessity for industries to remain competitive.

Automation can be classified into Mechanical, comprising Robots, Cobots, Gantries, Conveyors etc and Digital, including IIoT networks, AI and Big Data.

Mechanical Automation allows us to perform manual, repetitive, time-consuming, hazardous and high-throughput operations in a cost-effective and safe manner. Digital Automation enables interconnectivity and autonomy of decisions on the shop floor.

Automation has not only increased productivity, it has improved quality, availability, timely delivery and safety wherever it has been implemented.

We offer a wide range of high-ROI automation solutions for industrial and manufacturing applications to drive efficiency, quality, productivity and safety.

For more Info: https://zurl.co/aqM6

0 notes

Text

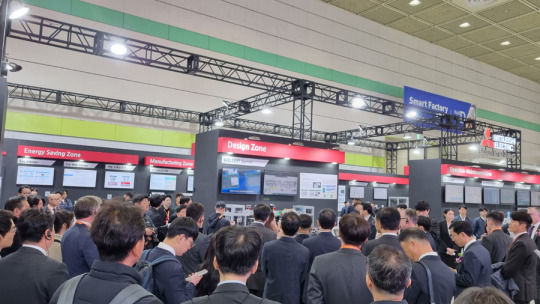

로크웰오토메이션, 산업현장용 클라우드 소프트웨어 선보여

스콧 울드리지 APAC 사장, 스마트공장∙자동화산업전 참석… 최신 솔루션과 파트너사 협업 사례 소개

로크웰 오토메이션의 오토메이션월드 2024 전시 부스 (사진. 아이씨엔미래기술센터)

세계 최대 산업 자동화 및 디지털 트랜스포메이션 전문기업인 로크웰 오토메이션(Rockwell Automation)이 산업 현장의 자동화와 지능화를 위한 클라우드 소프트웨어 솔루션을 제시한다.

로크웰오토메이션은 지난 3월 27일부터 29일까지 코엑스에서 개최된 스마트 공장 자동화 산업 전문 전시회인 ‘2024 스마트공장·자동화산업전’에 참가했다.

이번 전시회에서 로크웰오토메이션은 새롭게 출시한 클라우드 소프트웨어 솔루션을 중심으로 생산 최적화(Optimize Productivity), 역량 강화(Empower…

View On WordPress

0 notes

Text

#AIart#art#machinelearning#deeplearning#artificialintelligence#datascience#iiot#data#MLsoGood#code#python#bigdata#MLart#algorithm#chatGPT#openAI#programmer#pytorch#DataScientist#Analytics#AI#VR#iot#TechCult#Digitalart#DigitalArtMarket#generativeai#ArtMarket#DataArt#GAN

13 notes

·

View notes

Text

#AIart#art#machinelearning#deeplearning#artificialintelligence#datascience#iiot#data#MLsoGood#code#python#bigdata#MLart#algorithm#programmer#pytorch#DataScientist#Analytics#AI#VR#iot#TechCult#Digitalart#DigitalArtMarket#ArtMarket#DataArt#GAN#GANart#arttech#ai art

2 notes

·

View notes

Text

PLC SCADA, your gateway to seamless industrial automation! 🤖💡 Perfect for engineers, tech enthusiasts, and anyone passionate about optimizing processes. Dive into the world of Programmable Logic Controllers (PLC) and Supervisory Control and Data Acquisition (SCADA) systems. Elevate your skills and transform industries with cutting-edge automation technology.

Read more: https://livewirecoimbatore.com/plc-scada/

Reach Us: 8807148869

PLC Scada

#PLC#SCADA#Automation#IndustrialTech#ControlSystems#SmartFactory#PLCProgramming#SCADASystems#AutomationEngineer#Industry40#IoT#SmartManufacturing#ProcessAutomation#DigitalTransformation#ControlEngineering#HMI#Robotics#IIoT#PLCControl#SCADATech

0 notes

Text

Industrial IoT: Transforming Manufacturing through Connected Intelligence

The convergence of industrial processes with cutting-edge technology has given rise to the Industrial Internet of Things (IIoT), revolutionizing the landscape of manufacturing and industrial operations. This comprehensive exploration delves into the intricacies of Industrial IoT, examining its definition, key components, applications, benefits, and the transformative impact it has on optimizing efficiency, enabling predictive maintenance, and ushering in a new era of connected intelligence within the industrial sector.

Defining Industrial IoT

1. Overview of Industrial IoT

The Industrial Internet of Things (IIoT), also known as Industrial IoT, refers to the integration of internet-connected devices, sensors, and smart technologies into industrial and manufacturing processes. It leverages data analytics, machine learning, and real-time connectivity to enhance operational efficiency, monitor equipment health, and enable intelligent decision-making in industrial settings.

2. Key Components of Industrial IoT:

Sensors and Actuators: These devices capture real-time data from industrial equipment and processes, providing valuable insights into performance, conditions, and anomalies.

Connectivity Solutions: IIoT relies on robust communication protocols and networks to ensure seamless connectivity between devices and systems, enabling data transmission and analysis.

Edge Computing: Edge computing processes data locally near the source, reducing latency and enabling quick decision-making without relying solely on centralized cloud servers.

Cloud Platforms: Cloud-based platforms store and analyze vast amounts of data generated by IIoT devices, offering scalable and accessible solutions for data storage, analytics, and management.

Analytics and Machine Learning: Advanced analytics and machine learning algorithms interpret the collected data, providing actionable insights, predictive maintenance predictions, and optimization recommendations.

Applications of Industrial IoT

1. Predictive Maintenance

IIoT enables predictive maintenance by continuously monitoring equipment conditions. By analyzing data from sensors, manufacturers can predict when machinery is likely to fail, allowing for proactive maintenance and minimizing downtime.

2. Asset Tracking and Management

Tracking the location and status of assets within a manufacturing facility becomes efficient with IIoT. RFID tags and sensors provide real-time visibility, optimizing inventory management and reducing the risk of asset misplacement.

3. Supply Chain Optimization

IIoT facilitates end-to-end visibility in the supply chain. From raw material sourcing to product delivery, manufacturers can track and optimize each step, reducing lead times, minimizing disruptions, and improving overall supply chain efficiency.

4. Energy Management

Smart sensors and meters integrated with IIoT systems help monitor energy consumption in real time. Manufacturers can identify energy inefficiencies, implement energy-saving measures, and reduce operational costs.

5. Quality Control and Monitoring

IIoT enhances quality control by continuously monitoring production processes. Real-time data analysis ensures that products meet quality standards, reducing defects, and improving overall product quality.

6. Worker Safety and Health

Wearable devices equipped with IIoT capabilities enhance worker safety by monitoring environmental conditions, detecting potential hazards, and providing real-time alerts. This contributes to a safer working environment.

Benefits of Industrial IoT

1. Improved Operational Efficiency

IIoT optimizes operational processes by providing real-time insights into equipment performance, production efficiency, and resource utilization. This leads to streamlined operations, reduced waste, and increased overall efficiency.

2. Cost Reduction

Predictive maintenance, energy optimization, and efficient resource management enabled by IIoT contribute to significant cost reductions. Manufacturers can minimize downtime, extend equipment lifespan, and make informed decisions to optimize spending.

3. Enhanced Productivity

IIoT empowers manufacturers to make data-driven decisions that positively impact productivity. Automation, real-time monitoring, and predictive analytics contribute to smoother production processes and higher output.

4. Strategic Decision-Making

The data generated by IIoT devices provides valuable insights for strategic decision-making. Manufacturers can make informed choices regarding production schedules, resource allocation, and overall business strategies.

5. Innovation and Agility

The adoption of IIoT fosters innovation within the industrial sector. Companies that embrace connected technologies can quickly adapt to changing market demands, introduce new products, and stay ahead of the competition.

6. Customer Satisfaction

By optimizing production processes, ensuring product quality, and minimizing delays, IIoT contributes to higher customer satisfaction. Timely delivery of high-quality products enhances the reputation of manufacturers in the market.

Challenges and Considerations in Industrial IoT Implementation

1. Security Concerns

The interconnected nature of IIoT devices raises cybersecurity concerns. Safeguarding sensitive data, protecting against cyber threats, and ensuring secure communication between devices are critical considerations.

2. Interoperability Issues

Compatibility between different IIoT devices and systems can be a challenge. Establishing industry standards and protocols is essential to ensure seamless integration and interoperability.

3. Data Privacy and Compliance

With the vast amount of data generated by IIoT, ensuring compliance with data privacy regulations and standards is crucial. Manufacturers must implement robust data governance practices to protect customer and operational data.

4. Initial Investment Costs

The upfront costs associated with implementing IIoT infrastructure, including sensors, connectivity solutions, and analytics platforms, can be a barrier for some organizations. However, the long-term benefits often outweigh the initial investment.

Future Trends in Industrial IoT

1. 5G Integration

The rollout of 5G networks will enhance connectivity and enable faster data transmission for IIoT devices. This will further improve real-time monitoring, decision-making, and overall efficiency in industrial settings.

2. Edge Computing Advancements

Continued advancements in edge computing technologies will enable more processing capabilities at the device level. This reduces reliance on centralized cloud servers and enhances the speed of data analysis for critical applications.

3. AI and Machine Learning Integration

The integration of artificial intelligence (AI) and machine learning (ML) with IIoT will enable more advanced predictive analytics, anomaly detection, and optimization capabilities, further enhancing the intelligence of industrial processes.

4. Digital Twins for Simulation

The use of digital twins – virtual replicas of physical assets or systems – will become more prevalent. Manufacturers can simulate and analyze the behavior of assets in a virtual environment before implementing changes in the physical world.

Conclusion

The Industrial Internet of Things stands at the forefront of a transformative wave, reshaping the manufacturing and industrial landscape. As organizations continue to embrace connected intelligence, the benefits of IIoT in terms of efficiency, productivity, and innovation become increasingly evident. While challenges such as security and interoperability must be addressed, the potential for optimized operations, predictive maintenance, and enhanced decision-making positions IIoT as a cornerstone of the fourth industrial revolution. The ongoing evolution of IIoT promises not only to connect machines but also to empower industries with the intelligence needed to thrive in an ever-evolving, interconnected world.

Read More: Smart Manufacturing: A Revolution in Industry 4.0

#IIoT#industrialiot#connectedintelligence#manufacturing#predictivemaintenance#iotapplications#SmartManufacturing

0 notes

Text

OpenAI ramps up enterprise support with a focus on security, control, and cost

https://www.infoworld.com/article/3715241/openai-ramps-up-enterprise-support-with-a-focus-on-security-control-and-cost.html?utm_source=dlvr.it&utm_medium=tumblr#tk.rss_machinelearning

0 notes

Text

Unlock precision through audits!

Is your data center a well-oiled machine, or harboring hidden inefficiencies? Are your smart buildings truly living up to their name? In today's ever-evolving technological landscape, thorough audits are more crucial than ever.

Unlock precision through audits! Cypress Solutions leads the way in Data Centre and Smart Building audits, ensuring safety, efficiency, and reliability. Discover the power of thorough assessments.

Ready to experience the power of #AuditsForExcellence? Contact Cypress Solutions today and schedule your personalized audit!

#AuditsForExcellence#CypressSolutions#DataCenter#SmartBuilding#DataSecurity#FacilityManagement#Sustainability#EnergyEfficiency#IoT#IIoT#Technology#PerformanceOptimization#BusinessContinuity#RiskManagement#Cybersecurity#CloudComputing#DigitalTransformation#FutureProof

0 notes