#injectionmachines

Text

Are you interested in molds? We can design a variety of injection molds for plastic thin wall products.We offer you thin wall container mould,high speed mould, IML thin wall mould.The minimum wall thickness we can make to 0.35mm. Contact us.

our wbsite:www.aeromoulds.com

#injectionmouldingmachine#injectionmoldingmachine

#injectionmoldingmachines#moldingmachine

#plasticmouldingmachine#plasticmoldingmachine#plasticinjectionmoldingmachine#plasticinjectionmoldingmanufacturer#injectionmoldingmachineparts#plasticindustries#injectionplastic#plasticinjection#injectionmachine#automotive#houseware#thinwallmould#wallthickness#disposableparts#thinwallbox#thinwallbucket#foodpackaging

#injectionmouldingmachine#injectionmoldingmachine#injectionmoldingmachines#moldingmachine#plasticmouldingmachine#plasticmoldingmachine#plasticinjectionmoldingmachine#plasticinjectionmoldingmanufacturer#injectionmoldingmachineparts#plasticindustries#injectionplastic#plasticinjection#injectionmachine#automotive#houseware#thinwallmould#wallthickness#disposableparts#thinwallbox#thinwallbucket#foodpackaging

0 notes

Text

Used injection molding machine in China,ماكينة قولبة بالحقن مستعملة في الصين

Haida 290T, it’s original servo machine,

tie bar distance; 630*630mm

injection glue weight: 1200g

Model: 2023year

payment term : T/T , BTC and USDT;

WhatsApp: wa.me/+8618576477029

#usedinjectionmoldingmachine

#usedplasticmachine

#injectionmoldingmachine

#plasticmachine

#plasticinjectionmachine

0 notes

Photo

Delivery day! #injectionmachine #plasticmachine #plastmachine#injectmachine #chinamachine #householdproducts #dailyusepack #brazilmachine #kenyamachine #chinamachinery https://www.instagram.com/p/Crxi-LTJd8k/?igshid=NGJjMDIxMWI=

#injectionmachine#plasticmachine#plastmachine#injectmachine#chinamachine#householdproducts#dailyusepack#brazilmachine#kenyamachine#chinamachinery

0 notes

Photo

Injection Molding: How Does It Work?

The injection molding process may seem easy on the surface; however, it can be more complicated than it looks. Although the mold has been designed and the plastic injection machine is functioning well, if the process is not closely monitored and controlled, it may affect the outcome of the finished product.

1 note

·

View note

Text

India Delhi Plastfocus Exhibition

Haituo High Quality Injection Molding Machine

HALL-2 Booth G33

Welcome to Visit!!!❤🥰💯🎉

#injectionmoldingmachine

#moldingmachine

#plasticmouldingmachine

#plasticinjectionmoldingmachine

#injectionmachine

#injectionmouldingmachineprice

#desktopinjectionmoldingmachine

#plasticinjectionmachine

#haitianinjectionmoldingmachine

#moldingmachineprice

#verticalinjectionmouldingmachine

#smallinjectionmoldingmachine

#handinjectionmouldingmachine

#arburginjectionmoldingmachine

#haitianinjectionmachine

#injectionmoldingmachinemanufacturers

#engelinjectionmolding

#handmoldingmachine

#injectionmolder

#jswinjectionmoldingmachine

#plasticmoldingmachineprice

#injectionmoldingmachineforsale

#engelinjectionmoldingmachine

#miniinjectionmoldingmachine

#milacroninjectionmoldingmachine

#sumitomoinjectionmoldingmachine

#rubbermoldingmachine

#secondhandinjectionmouldingmachineprice

#nisseiinjectionmoldingmachine

#injectionstretchblowmolding

#usedinjectionmouldingmachine

#plasticmoldingelectrical

#diyinjectionmoldingmachine

#stretchblowmolding

#electricalmolding

#toshibainjectionmoldingmachine

#plasticinjectionmoldingmachineprice

#benchtopinjectionmoldingmachine

#battenfeldinjectionmoldingmachine

#puinjectionmachine

#300gramplasticmouldingmachineprice

#plasticmolder

#microinjectionmoldingmachine

#waxinjectionmachine

#toyoinjectionmoldingmachine

#electronicainjectionmouldingmachine

#rubberinjectionmouldingmachine

#blowmoldmachine

#usedinjectionmoldingmachineforsale

#windsorinjectionmouldingmachine

#moldmaker#injectionmolding#plasticinjectionmold#haituo#injectionmoldingmachine#haitian#mould#plasticmachine#injectionmold#haitai

0 notes

Text

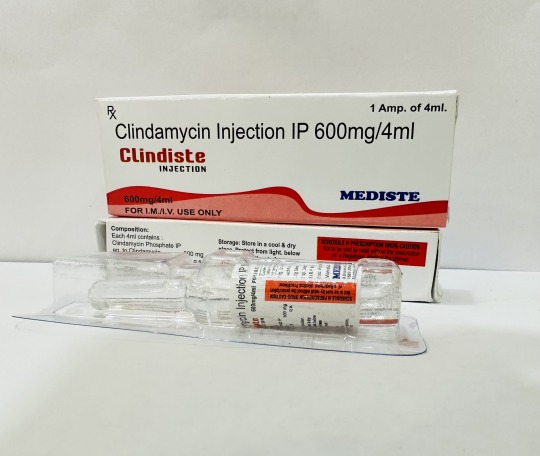

INJ. CLINDAMYCIN 600MG 4ML

.

.

injectionputihmalaysia #injectionevent #injectionbooster #injectionmoulding #injectionph #injectiontooling #injectionmachine #injectionstoronto #injectionstemcell #Injectionday #injectionmold #injectioncars #injectionmoldingparts

1 note

·

View note

Video

youtube

RAYING MOULD THANK YOU & WISH YOUR BUSINESS IS BOOMING

Mold was shipped out.🥳🥳🥳

Thank you for all the supports and trust❤️❤️❤️

wish all of your business is booming🌹🌹🌹

#casting #injectionmold #molding #toolings #mouldmaker #plasticinjectionmould #diecastings #pressuremachine #injectionmachine #toolingsolutions #mouldmaker #moulds

0 notes

Photo

Our company Ningbo Leadway Machinery Technology Co.,ltd is professional injection molding machines manufacturer. We were involved in ITALY OEM machines project since 2006. So we are professional in design and make European style injection machines. And we are the first supplier (maybe the only one) involved in making Eurostyle injection machines. Our quality is the most close to European machines quality. Our quality is leading in China. We can compete with Haitian in quality. Our machines are strong clamping, fast injection, energy saving, high precision, user-friendly which is mainly for mid-high end use. Now we have deleoped Italy, Spain, Czech, Poland, Tunis, Iran, India, Philipine, Malaysia, Russia, Mexico, Brazil, Argentina, Peru, etc. @fuhrungplasticinjectionmachine www.fuhrung.com [email protected] whatsapp:008618969867076 injection,injection molding,machine,plastic injection machine,injection molding machine,injection machine,plastic injection molding machine,plastic,eva injection moulding machine,injection moulding,pet preform injection molding machine,machines,injection machines,pu injection machine,pvc injection machine,lsr injection machine,mold injection machine,sound injection machine,top 50 injection machine,badge injection machine #injectionmoldingmachine #plasticinjectionmachine #injectionmachines #injectionmoldingmachines #injectionmouldingmachine #plasticinjectionmoldingmachine #injectionmouldingmachines #injectionmachinesize #specialistusedinjectionmachine #injectionmachinescrewdesign #injectionmachineforsale #injectionmachinesecondhand #injectionmachinetechnician #injectionmachinesetting #injectionmachineryturkey #verticalinjectionmouldingmachine #injectionmachinetraining #injectionmachinesumitomo #injectionmachinenozzle #injectionmachinebrands #injectionmachinetiebar #injectionmachinetoggle #injectionmachinecost #injectionmachinecalculation #injectionmachineinpoland #injectionmachineendcapangle (at China) https://www.instagram.com/p/BzPKMx0gPPK/?igshid=8to0gxba1p45

#injectionmoldingmachine#plasticinjectionmachine#injectionmachines#injectionmoldingmachines#injectionmouldingmachine#plasticinjectionmoldingmachine#injectionmouldingmachines#injectionmachinesize#specialistusedinjectionmachine#injectionmachinescrewdesign#injectionmachineforsale#injectionmachinesecondhand#injectionmachinetechnician#injectionmachinesetting#injectionmachineryturkey#verticalinjectionmouldingmachine#injectionmachinetraining#injectionmachinesumitomo#injectionmachinenozzle#injectionmachinebrands#injectionmachinetiebar#injectionmachinetoggle#injectionmachinecost#injectionmachinecalculation#injectionmachineinpoland#injectionmachineendcapangle

0 notes

Text

What is a plastic mold injection molding machine?

1. The injection part of the injection molding machine mainly has two forms:

Piston type and reciprocating screw type. Piston-type injection molding machines are rare now, so I won’t introduce them here. The reciprocating screw injection molding machine melts and mixes solid plastic particles (or powder) through the rotation of the screw in the heating barrel, and squeezes it into the cavity at the front end of the barrel. Then the screw moves forward in the axial direction to remove the plastic in the cavity. The melt is injected into the mold cavity. During plasticization, the plastic is compacted in the screw groove under the push of the screw ridge, and receives the heat transferred from the barrel wall. In addition, the friction between the plastic and the plastic, the plastic and the barrel and the screw surface generates heat, and the temperature gradually rises. High to melting temperature. The melted plastic is stirred and further mixed by the screw, and enters the front of the barrel along the screw groove and pushes the screw back. The injection parts and plasticization-related components mainly include: screw, barrel, shunt shuttle, check ring, nozzle, flange, hopper, etc.

The following is an explanation of its role and influence in the plasticization process:

(1) Screw Screw is an important part of injection molding machine. Its function is to transport, compact, melt, stir and press plastic. All of this is accomplished by the rotation of the screw in the barrel. When the screw rotates, the plastic will generate friction and mutual movement on the inner wall of the barrel, the bottom surface of the screw groove, the screw edge advancement surface, and the plastic and the plastic. The advancement of plastic is the result of this combination of movements, and the heat generated by friction is also absorbed to increase the temperature of the plastic and melt the plastic. The structure of the screw will directly affect the extent of these effects. Ordinary injection screw structure is also designed as a separate screw, barrier screw or split screw in order to improve the quality of plasticization.

(2) The structure of the barrel is actually a round tube with a discharge opening in the middle. In the plasticization process of plastics, the driving force for advancement and mixing comes from the relative rotation of the screw and barrel. According to the different forms of plastic in the screw groove, the screw is generally divided into three sections: solid conveying section (also called feeding section), melting section (also called compression section), and homogenizing section (also called metering section).

(3) Diversion shuttle (passing rubber head) Diversion shuttle is a torpedo-shaped part mounted on the front end of the screw. The function of the shunt shuttle in the plasticization of plastics is mainly to shunt and mix the plastic melt, so that the melt is further mixed evenly. At the same time, the shunt shuttle has the function of limiting the position of the anti-reverse ring during plasticization. In order to further strengthen the mixing effect, it is recommended to use barrier-type mixing structure shunt shuttles on injection molding machines with a clamping force of over 250 tons. Not only can the uniformity of the color of the product be improved, but also the mechanical strength of the product can be higher.

(4) The anti-reverse ring (over the rubber ring), as the name implies, the role of the anti-reverse ring is to prevent inversion. It is a part that prevents the plastic melt from leaking back during injection. When working, the non-return ring and the non-return washer (over-rubber washer) contact to form a closed structure to prevent the plastic melt from leaking. The precision of the weight of an injection molding machine's injection product has a great relationship with the speed of the anti-return ring's anti-reverse movement. The speed of a non-return ring action response is determined by its non-reverse movement stroke, seal pressing time, time to leave the shunt shuttle and other factors. We have tried a variety of non-return ring structures and part parameters, and finally determined the optimal non-reverse surface parameters, the non-reverse ring and the shunt shuttle fitting parameters, the non-reverse ring and the barrel gap parameters through experiments. High-precision injection volume control can be achieved.

2. Mold clamping control:

Mold clamping is to close the mold tightly with a huge mechanical thrust to resist the huge opening force of the mold caused by the high pressure injection of molten plastic during the injection molding process and the filling of the mold. Close the safety door, each travel switch will give a signal, and the mold clamping action will start immediately. The first is that the movable template starts at a slow speed. After a short distance, the control rod pressing block that originally held the slow switch is released, and the movable plate rotates to advance quickly. When advancing to close to the end of mold clamping, the other end of the control rod presses the slow switch again, and the movable plate rotates at a slow speed and advances at a low pressure at this time. During the low-pressure mold clamping process, if there are no obstacles between the molds, they can be smoothly closed until the high-pressure switch is pressed. The high-pressure switch is to straighten the hinge of the machine to complete the mold clamping action. The distance is very short, generally only 0.3~1.0mm. The mold clamping termination limit switch is touched as soon as the high voltage is turned on. At this time, the action stops and the mold clamping process ends.

LISONG machine rofessional provide the plastic injection molding machine.Factory direct sales, quality assurance, and price concessions.~~~ Would you like it? Wellcome to contact us.The manufacturers email:[email protected]. http://lisongmachine.com/

1 note

·

View note

Photo

Ningbo Harun Yi Ye Plastic Machinery Co., Ltd. condition #injectionmachine#injectionblowmouldingmachines#injectionmolded #injectionmolds#plasticmachinery #plasticinjection Contact information: Tel: +86 13567847373 WeChat:+86 13567847373 WhatsApp:+86 15155959552(在 Ningbo) https://www.instagram.com/p/Bunv7eogdvj/?utm_source=ig_tumblr_share&igshid=1q62ytl0i7thm

#injectionmachine#injectionblowmouldingmachines#injectionmolded#injectionmolds#plasticmachinery#plasticinjection

2 notes

·

View notes

Link

Acmedisys India is one of the leading manufacturer company in Delhi with varieties of items like pet preform plastic injection moulding, injection molding molds

0 notes

Photo

Professional injection machine manufacturer from ningbo China 🇨🇳 #chinamachine #injectionmachine #chinamold#chinamoulding chinaplasticmachine #chinainjectionmold https://www.instagram.com/p/CoKWUrvJsZw/?igshid=NGJjMDIxMWI=

0 notes

Photo

Plastic injection.panel. are u interest ? Ai02 computer controller chen hsong injection need pls call 13760277212 or wechat same id email [email protected] web www.autochd.com #plasticinjection #injectioncontroller #injection #chenhsong #chenhsonginjection #computercontroller #injectionpanel #industry #injectionmachine # https://www.instagram.com/p/B1uzNCUg8P6/?igshid=z8qleqt0fm54

#plasticinjection#injectioncontroller#injection#chenhsong#chenhsonginjection#computercontroller#injectionpanel#industry#injectionmachine

0 notes

Text

youtube

Haituo injection molding machines in Bangladesh exhibition.

#injectionmoldingmachine

#moldingmachine

#plasticmouldingmachine

#plasticinjectionmoldingmachine

#injectionmachine

#injectionmouldingmachineprice

#desktopinjectionmoldingmachine

#plasticinjectionmachine

#haitianinjectionmoldingmachine

#moldingmachineprice

#verticalinjectionmouldingmachine

#smallinjectionmoldingmachine

#handinjectionmouldingmachine

#arburginjectionmoldingmachine

#haitianinjectionmachine

#injectionmoldingmachinemanufacturers

#engelinjectionmolding

#handmoldingmachine

#injectionmolder

#jswinjectionmoldingmachine

#plasticmoldingmachineprice

#injectionmoldingmachineforsale

#engelinjectionmoldingmachine

#miniinjectionmoldingmachine

#milacroninjectionmoldingmachine

#sumitomoinjectionmoldingmachine

#rubbermoldingmachine

#secondhandinjectionmouldingmachineprice

#nisseiinjectionmoldingmachine

#injectionstretchblowmolding

#usedinjectionmouldingmachine

#plasticmoldingelectrical

#diyinjectionmoldingmachine

#stretchblowmolding

#electricalmolding

#toshibainjectionmoldingmachine

#plasticinjectionmoldingmachineprice

#benchtopinjectionmoldingmachine

#battenfeldinjectionmoldingmachine

#puinjectionmachine

#300gramplasticmouldingmachineprice

#plasticmolder

#microinjectionmoldingmachine

#waxinjectionmachine

#toyoinjectionmoldingmachine

#electronicainjectionmouldingmachine

#rubberinjectionmouldingmachine

#blowmoldmachine

#usedinjectionmoldingmachineforsale

#windsorinjectionmouldingmachine

#boleinjectionmoldingmachine

#moldmaker#haituo#injectionmolding#plasticinjectionmold#haitian#injectionmoldingmachine#injectionmold#haitai#mould#plasticmachine#Youtube

0 notes

Photo

Thanks for your attention and trust & supports !#RAYINGMOULD always keep "Craftman Spirit" to build High Quality #Moulds and #parts . Looking forward to talking with you more details! Joyce at raying -mould dot com.#plasticinjectionmolding #plasticmouldings #tooling #plasticinjection #diecasting #injectionmachine #toolingmaker#plasticinjectionmold, #plasticinjectionmoldedparts, #plasticinjectionmolding, #PlasticInjectionMoldingCompanies, #PlasticInjectionMoldingService, #PlasticInjectionMoulding, PlasticInjectionMouldingChina, #PlasticMoldCompanies, #plasticmoldcompany, #plasticmoldingcompany, #PlasticMoldingPartsManufacturing, #plasticmoldingservice #plasticinjectionmachine

https://www.facebook.com/100009606018690/videos/286007683324113/

0 notes

Photo

Ningbo Leadway Machinery Technology Co.,Ltd is a professional manufacturer of plastic injection molding machines ranging from 60ton to 1300ton all equipped with servo drive and servo pump.This video is showing you our current plastic exhibition in Isfahan Iran . Our brand name is Fuhrung which is Germany 🇩🇪 language. We make European style injection molding machines. Our quality is one of the best in China 🇨🇳. Our target customers are those who want higher quality and hate low quality and prefer to pay more for good quality machines. #injectionmachine #injectionmachines #injectionmachinery #injectionmachinetechnology #injectionmachinewithoutneedle #injectionmachinequality #injectionmachineforsale #ims #fuhrung #fuhrungimm #imm #injectionmoldingmachines #injectionmoldingmachine #injectionmoulds #petpreform #hobikamimahal #pelesitrayaumalaysia #modenas #yuken #techmation #imsmoulds #insoexcamoulds #rexroth (at Ningbo) https://www.instagram.com/p/BuY0xa2DTRO/?utm_source=ig_tumblr_share&igshid=pmi4g0n3gys1

#injectionmachine#injectionmachines#injectionmachinery#injectionmachinetechnology#injectionmachinewithoutneedle#injectionmachinequality#injectionmachineforsale#ims#fuhrung#fuhrungimm#imm#injectionmoldingmachines#injectionmoldingmachine#injectionmoulds#petpreform#hobikamimahal#pelesitrayaumalaysia#modenas#yuken#techmation#imsmoulds#insoexcamoulds#rexroth

0 notes