#manufacturing IT

Text

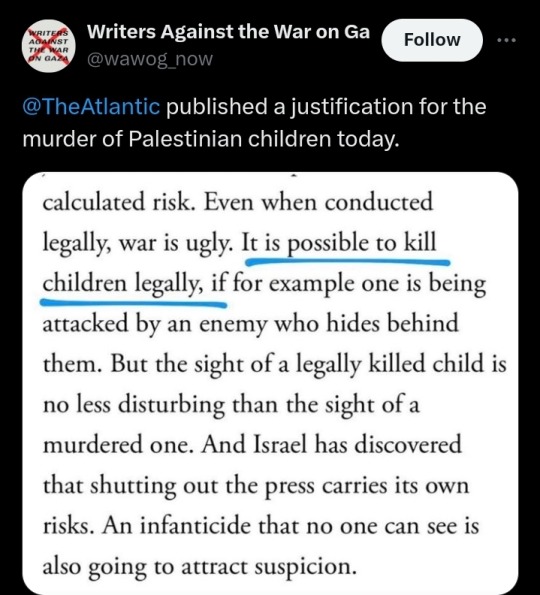

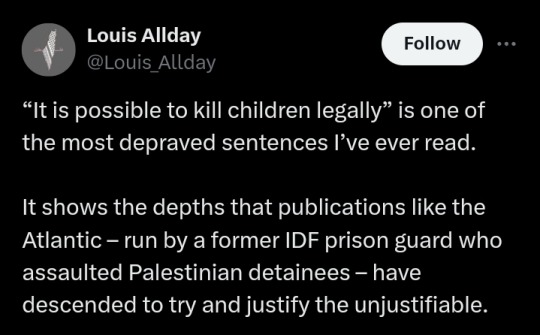

If you, for some reason, still have a subscription to the Atlantic, cancel it

#yemen#jerusalem#tel aviv#current events#palestine#free palestine#gaza#free gaza#news on gaza#palestine news#news update#war news#war on gaza#children of gaza#gaza genocide#genocide#media bias#manufactured consent

65K notes

·

View notes

Text

this is what everyone has been saying!! no one is looking at celebrities for political statements, but they should and must use their platform to amplify the voices of those who need and most importantly be against this genocide!!

#if you’re not being openly against a genocide then you are being silently complicit in it#i don’t know how else to put it anymore and there is no excuse to not be using your platform#so to say the least I’m extremely dissapointed in my own favorite artists for being absolutely in silence about this#they keep proving themselves to be soulless people and to call themselves artists when they have no humanity in them is quite ironic#you’re not an artist you’re an entertainer that happens to be good at songwriting and your entire existence is manufactured#you’re a modern capitalism's little toy not an artist#free palestine#b talks

20K notes

·

View notes

Text

i love graffiti. "comics and jazz are the only american art forms" you forgot graffiti. did you remember graffiti? That art form birthed in Philly and NYC in the early 70s by poor Black kids. that art form that spread all over the world and influenced so many. that's used without irony in commercials when they're trying to appeal to a "young urban" customer.

did you forget graffiti? that racism broken windows theory victim? that reach the establishment takes claiming that it's exclusively violent gang members throwing up those full-color pieces and wildstyle tags in the middle of the night outsmarting fifty security cameras because the billboard was ugly anyway. as if, even if it was, it wouldn't be impressive as all hell. risking brutality and fall damage so your art can occupy the space a gentrified condo named something like "Coluumna" took away from you. proving that despite only assholes affording to live here anymore there's still a soul beneath it. an animal with dripping stripes and teeth that go clack-clack tsssss

#graffiti#it's like how they claim touching a paper that had drugs on it can kill a police officer#manufactured fear of art itself because of who made it#you won't invest in addiction recovery or keeping libraries open or extracurricular programs but you'll sure as hell give cops overtime#so they can beat a kid writing on a shutter#writers have such big dick energy

33K notes

·

View notes

Text

Unlocking Efficiency: The Role of Robot Preventive Maintenance Market in Industrial Operations

In today's fast-paced industrial landscape, efficiency is a key driver of success. This article explores the significance of the robot preventive maintenance market in enhancing efficiency within industrial operations. Drawing on insights from industry experts and research studies, it delves into the various aspects of preventive maintenance, its impact on productivity, safety, and cost-effectiveness, and its role in shaping the future of industrial automation.

With a focus on practical strategies and case studies, this comprehensive guide provides valuable insights for businesses seeking to optimize their operations through proactive maintenance of robotic equipment.

According to a study by Next Move Strategy Consulting, the global Robot Preventive Maintenance Market size is predicted to reach USD 10.04 billion with a CAGR of 10.1% by 2030.

Introduction

In an era defined by rapid technological advancements and fierce global competition, efficiency has become a cornerstone of success for businesses across industries. In no sector is this more evident than in manufacturing and industrial operations, where every minute of downtime can translate into significant losses in terms of production output, revenue, and customer satisfaction.

Request a FREE sample, here: https://www.nextmsc.com/robot-preventive-maintenance-market/request-sample

Robots have emerged as indispensable assets in modern industrial settings, performing a wide range of tasks with speed, precision, and reliability. From automotive assembly lines to warehouse logistics, robots play a critical role in streamlining operations and maximizing productivity. However, such any other machinery, robots require regular maintenance to ensure optimal performance and longevity.

This is where the concept of preventive maintenance comes into play. Rather than waiting for equipment failures to occur, preventive maintenance involves proactively monitoring, inspecting, and servicing robots at regular intervals to identify and address potential issues before they escalate into costly problems. In recent years, the robot preventive maintenance market has witnessed significant growth as businesses recognize the value of proactive maintenance in optimizing efficiency, minimizing downtime, and reducing operational costs.

The Growing Importance of Robot Preventive Maintenance Market

The global robot preventive maintenance market has experienced steady growth in recent years, driven by several factors including the increasing adoption of industrial automation, advancements in sensor technology, and the growing emphasis on predictive analytics and condition monitoring.

One of the primary drivers of this growth is the rising demand for increased uptime and reliability in industrial operations. With businesses facing mounting pressure to meet customer demands and stay ahead of competitors, minimizing unplanned downtime has become a top priority. Proactive maintenance of robotic equipment helps businesses achieve this goal by identifying and addressing potential issues before they disrupt production schedules.

Another key factor driving the adoption of robot preventive maintenance is the shift towards predictive maintenance strategies. Traditional reactive maintenance approaches, which rely on fixing equipment after it has already failed, are no longer sufficient in today's fast-paced industrial environment. Predictive maintenance leverages advanced analytics and sensor technology to anticipate equipment failures before they occur, allowing businesses to schedule maintenance activities proactively and avoid costly disruptions.

Moreover, the growing complexity of robotic systems and the increasing reliance on automation in industrial settings have heightened the importance of preventive maintenance. Unlike traditional machinery, robots often consist of intricate mechanical, electrical, and software components that require specialized expertise to maintain and repair. Implementing a structured preventive maintenance program ensures that these complex systems are properly maintained, calibrated, and optimized for performance.

Key Components of Robot Preventive Maintenance

Effective preventive maintenance of robotic equipment involves a combination of proactive inspections, routine servicing, and data-driven analytics. Here are some key components of a comprehensive preventive maintenance program:

3.1 Regular Inspections: Regular inspections are essential for identifying potential issues with robotic equipment before they escalate into major problems. This includes visually inspecting robots for signs of wear and tear, checking for loose connections or damaged components, and ensuring that safety features are functioning properly.

3.2 Lubrication and Cleaning: Proper lubrication and cleaning are essential for maintaining the efficiency and longevity of robotic equipment. Over time, dust, debris, and friction can cause components to wear out prematurely, leading to performance issues and breakdowns. Implementing a regular lubrication and cleaning schedule helps to prevent these issues and keep robots operating smoothly.

3.3 Calibration and Alignment: Accurate calibration and alignment are critical for ensuring the precision and accuracy of robotic systems. Misaligned or improperly calibrated robots can result in defective products, production delays, and increased maintenance costs. Regularly calibrating and aligning robots to manufacturer specifications helps to optimize performance and minimize errors.

3.4 Component Replacement: As robotic equipment ages, certain components may wear out and require replacement. This includes motors, sensors, actuators, and other mechanical and electrical components. Implementing a proactive component replacement schedule based on manufacturer recommendations and equipment usage patterns helps to prevent unexpected failures and extend the lifespan of robotic systems.

3.5 Data Analysis and Predictive Maintenance: Leveraging data analytics and predictive maintenance algorithms can further enhance the effectiveness of preventive maintenance programs. By collecting and analyzing data from sensors, controllers, and other monitoring devices, businesses can identify patterns and trends that may indicate potential issues with robotic equipment. This enables them to predict and prevent failures before they occur, maximizing uptime and productivity.

The Impact of Robot Preventive Maintenance on Industrial Operations

The adoption of robot preventive maintenance has far-reaching implications for industrial operations, impacting efficiency, productivity, safety, and cost-effectiveness.

4.1 Efficiency: Perhaps the most significant impact of preventive maintenance is its ability to unlock efficiency within industrial operations. By proactively addressing potential issues and optimizing the performance of robotic equipment, businesses can minimize downtime, reduce production delays, and maximize overall equipment effectiveness (OEE). This allows them to meet production targets more consistently and respond quickly to changing market demands.

4.2 Productivity: Improved equipment reliability and uptime translate directly into increased productivity for businesses. With robots operating at peak efficiency and experiencing fewer breakdowns, production output can be maintained at optimal levels, leading to higher throughput, faster cycle times, and greater overall output. This not only enhances competitiveness but also enables businesses to capitalize on growth opportunities and expand their market share.

4.3 Safety: Preventive maintenance also plays a crucial role in enhancing workplace safety within industrial settings. Well-maintained robots are less likely to malfunction or experience unexpected failures, reducing the risk of accidents, injuries, and near misses on the factory floor. This helps to create a safer working environment for employees and minimizes the potential for costly workplace incidents and liability claims.

4.4 Cost-effectiveness: While investing in preventive maintenance may require upfront resources and investment, the long-term cost savings and ROI are substantial. By avoiding costly repairs, emergency service calls, and unplanned downtime, businesses can significantly reduce maintenance expenses and operational costs over time. Moreover, preventive maintenance helps to extend the lifespan of robotic equipment, delaying the need for costly replacements and upgrades.

Practical Strategies for Implementing Robot Preventive Maintenance Programs

Implementing an effective preventive maintenance program for robotic equipment requires careful planning, coordination, and execution. Here are some practical strategies for businesses looking to optimize their maintenance practices:

5.1 Establish Clear Goals and Objectives: Before implementing a preventive maintenance program, businesses should define clear goals and objectives based on their specific operational needs and priorities. This may include reducing downtime, improving equipment reliability, enhancing safety, or minimizing maintenance costs. By aligning maintenance activities with overarching business objectives, businesses can ensure that their preventive maintenance efforts are focused and impactful.

5.2 Invest in Training and Education: Properly maintaining and servicing robotic equipment requires specialized knowledge and expertise. Investing in training and education for maintenance personnel ensures that they have the skills and competencies needed to perform maintenance tasks effectively and safely. This may include technical training on specific robot models, certification programs for maintenance technicians, and ongoing professional development opportunities to stay abreast of emerging technologies and best practices.

5.3 Leverage Technology and Automation: Technology plays a key role in streamlining preventive maintenance processes and enhancing efficiency. Businesses can leverage software systems and automation tools to schedule maintenance activities, track equipment performance, and generate real-time alerts and notifications for maintenance tasks. Integrating sensors and monitoring devices into robotic systems enables businesses to collect valuable data on equipment health and performance, facilitating predictive maintenance and proactive decision-making.

5.4 Implement a Data-driven Approach: Data analytics is a powerful tool for optimizing preventive maintenance programs and maximizing equipment uptime. By collecting and analyzing data from sensors, controllers, and other monitoring devices, businesses can gain valuable insights into equipment health, performance trends, and failure modes. This enables them to identify potential issues early, prioritize maintenance activities, and optimize maintenance schedules for maximum efficiency and effectiveness.

5.5 Foster a Culture of Continuous Improvement: Continuous improvement is essential for maintaining the effectiveness of preventive maintenance programs over time. Businesses should regularly review and evaluate their maintenance practices, performance metrics, and key performance indicators (KPIs) to identify areas for improvement and optimization. This may involve soliciting feedback from maintenance personnel, conducting root cause analyses of equipment failures, and implementing corrective actions to address underlying issues and prevent recurrence.

Example

To illustrate the real-world impact of robot preventive maintenance on industrial operations, let's explore some examples from businesses that have successfully implemented preventive maintenance programs:

6.1 Automotive Manufacturing Facility

A leading automotive manufacturer implemented a proactive preventive maintenance program for its robotic welding systems to minimize downtime and improve production efficiency. By conducting regular inspections, lubrication, and component replacements, the company was able to reduce equipment failures by 30% and increase overall equipment effectiveness (OEE) by 15%. This resulted in significant cost savings and productivity gains, enabling the company to meet growing customer demand and maintain its competitive edge in the market.

6.2 Food Processing Plant

A food processing plant implemented a predictive maintenance solution for its robotic packaging equipment to optimize uptime and ensure product quality and safety. By leveraging advanced analytics and condition monitoring technologies, the company was able to detect early signs of equipment degradation and schedule maintenance activities proactively. This helped to reduce unplanned downtime by 20% and improve equipment reliability, leading to higher throughput and lower maintenance costs over time.

6.3 E-commerce Warehouse

An e-commerce warehouse implemented a data-driven preventive maintenance program for its robotic picking and sorting systems to enhance operational efficiency and meet increasing order volumes. By collecting and analyzing data on equipment performance and failure modes, the company was able to identify and address potential issues before they impacted production. This enabled the warehouse to process orders more quickly and accurately, resulting in higher customer satisfaction and repeat business.

Future Trends and Outlook

Looking ahead, the future of the robot preventive maintenance market appears promising, with continued growth and innovation on the horizon. Several key trends are shaping the future of preventive maintenance in industrial operations:

7.1 Adoption of Predictive Analytics and AI: The adoption of predictive analytics and artificial intelligence (AI) technologies is expected to accelerate, enabling businesses to further optimize their preventive maintenance programs and maximize equipment uptime. Advanced analytics algorithms can analyze vast amounts of data in real-time, predicting equipment failures with greater accuracy and enabling proactive decision-making.

7.2 Integration with Industry 4.0 Technologies: The integration of preventive maintenance with Industry 4.0 technologies such as the Internet of Things (IoT), cloud computing, and digital twin simulations is expected to revolutionize maintenance practices. IoT sensors embedded in robotic equipment can collect real-time data on equipment health and performance, while cloud-based platforms enable remote monitoring and management of maintenance activities.

Inquire before buying, here: https://www.nextmsc.com/robot-preventive-maintenance-market/inquire-before-buying

7.3 Emphasis on Sustainability and Green Technologies: With growing concerns about environmental sustainability, businesses are increasingly seeking green technologies and practices for their operations. Preventive maintenance plays a crucial role in extending the lifespan of equipment, reducing resource consumption, and minimizing waste. As a result, there is a growing emphasis on sustainability-driven maintenance strategies in the robot preventive maintenance market.

7.4 Rise of Service-based Models: The shift towards service-based models and predictive maintenance-as-a-service (PdMaaS) offerings is expected to gain traction in the coming years. Rather than purchasing robotic equipment outright, businesses may opt for subscription-based models where they pay for access to equipment and maintenance services on a recurring basis. This enables businesses to minimize upfront capital expenditures and align maintenance costs with usage.

Conclusion

In conclusion, the role of the robot preventive maintenance market in enhancing efficiency within industrial operations cannot be overstated. By proactively monitoring, inspecting, and servicing robotic equipment, businesses can minimize downtime, improve productivity, enhance safety, and reduce operational costs.

With the global market for robot preventive maintenance poised for continued growth, businesses that embrace proactive maintenance strategies will be well-positioned to succeed in an increasingly competitive and dynamic marketplace. As technology continues to evolve and new innovations emerge, the future of preventive maintenance holds exciting possibilities for businesses seeking to unlock efficiency and drive operational excellence.

0 notes

Text

people sometimes ask if I'd ever consider becoming a university professor and I'm like yeah sure I'd love to do a shit-tonne of unpaid busywork in the sexual harassment factory just so some cis guy can plagiarise my work while my debt-crushed students get arrested for daring to question why their fees are being invested in weapons companies

#sometimes universities sneer at Philosophy Tube for not being 'proper education'#but at least I've never invested my Patrons' money in a weapons manufacturer#and then called the cops on them

6K notes

·

View notes

Text

i dont care what kind of lore they're coming up with for that zepotha film or whatever the fuck over on tiktok, nothing will ever come close to the fact goncharov was spawned entirely from a label on a boot

#like its so artificially manufactured its intolerable#you're missing the whole point of the bit#it wasn't just that a movie got made up it was the fact we all spontaneously entered into a collective fever dream#based entirely on the label for a fake film on the tongue of knock off boots !!!!!!!!#goncharov#zepotha

11K notes

·

View notes

Text

The Shawn & Gus dynamic in Psych is so subtly yet beautifully shaped by the fact that they cast a naturally deadpan introvert to play the world's most hyperactive attention-seeking detective, then cast a chronic theater kid to play his supposedly boring, reasonable best friend

#Shawn's friendly and reasonable tone as he manufactures 8 deranged lies for attention in a row#vs Gus' increasingly hysterical assertions that he is being VERY normal and rational given the circumstances. SHAWN.#make a legendary pair#psych

1K notes

·

View notes

Text

#western media complicity#the process of manufacturing consent#jason hickel#current events#politics#media#media analysis#israeli occupation#israel#free palestine#palestine#gaza#gaza strip#free gaza#end the occupation#russia#ukraine

1K notes

·

View notes

Text

usamerican zionist propagandist: Every night our hearts ache for our dead children. We are vulnerable and hurting. Jews in Israel are trying to defend themselves, and they're facing the hatred of the world for it. What people don't understand is the profound fear and horror that Israelis are feeling right now, and [click to show rest of tweet]

israeli government official on live tv: its ethnic cleansing o clock babey !!

4K notes

·

View notes

Text

I was really glad but like... 3 months, same size???

I never got a real reason it took so long to get this uniform... But at least i did get it eventually.

Ughh... (old comic)

1K notes

·

View notes

Text

This is the important part

We're going to see A LOT of pro Israel propaganda in the media in late June. More than usual I mean.

We need to be prepared to combat it all especially with the current invasion of Rafah killing and displacing thousands

#yemen#jerusalem#tel aviv#current events#palestine#free palestine#gaza#free gaza#news on gaza#palestine news#news update#war news#war on gaza#hasbara#media bias#manufactured consent

26K notes

·

View notes

Text

Leo: *frantically rubbing himself down with balloons*

Nico: What on earth are you doing?

Leo: I’m about to try asking Jason out.

Nico, sarcastically: Sure, that explains everything.

Leo, impatiently: I need it to go well. Look at that face. He must have people hitting on him all the time, so I need a way to stand out.

Leo, grinning: So I’m going to use static electricity to create an electric shock when I casually touch him, so sparks will literally fly when I ask him out.

Nico, amused: Okay, well have fun tricking Jason into falling in love with you.

#Leo: If it hasn’t happened naturally by now I will MANUFACTURE some magic for us#pjo fandom#pjo verse#pjo hoo#nico di angelo#leo valdez#jason grace#heroes of olympus#incorrect heroes of olympus#incorrect valgrace quotes#incorrect valdangelo#incorrect leo valdez#incorrect nico di angelo quotes#incorrect pjo quotes#incorrect percy jackson#incorrect hoo quotes#percy jackson#percy jackson and the olympians#pjo stuff#pjo text post#pjo boys#Argo II boys#valdangelo bromance#valgrace#valgrace bromance#demidorks#demidorks in love#demidorks being cute#happy demidorks#chaotic dumbasses

1K notes

·

View notes

Text

maia arson crimew does it again, leaking 2600 PAGES of hateful emails revealing a (not-surprising) concerted effort to strip trans people -- not just children -- of their rights, all for a few extra votes. cohorts, of course, include every religious freakshow org you can think of

#anti-trans#transphobia#warning: these people are monstrous hateful little freaks#manufactured outrage

10K notes

·

View notes

Text

Shoes or No Shoes?

#oc art#sanction#quiver#this is how I manufacture civil unrest among my followers so they can't unite and topple my regime

2K notes

·

View notes

Text

old blood noise endeavors sunlight dynamic reverb (art by jon carling)

#havent even watched demos just think it looks cool. sorry#pedals#added art credit - sorry i didn’t earlier!#also first link is to the manufacturer’s blog post with cool behind the scenes info/photos but the product link is in the photos at the top#of the blog post

7K notes

·

View notes

Text

Furniture merchant, 1880s New York: okay R.J., so I think this desk needs-

R.J. Horner: GRIFFINS

R.J. Horner GREEN MEN

R.J. Horner: SEMI-NUDE MAIDENS BUT LIKE COLUMNS ALSO

merchant:

merchant: R.J. stop headbanging to Vox Vulgaris I was going to say "drawers"

#history#he was a furniture manufacturer who did the equivalent of chugging the Renaissance Revival movement from the bottle#and I just bought a desk In His StyleTM (unmarked so I can't really say if it's one of his but)#(quality and aesthetic check out)

748 notes

·

View notes