#metal sheet manufacturer

Text

Stainless Steel Uses and Applications in Aviation and Aerospace Industry - SPP Metals & Alloys

Stainless steel is a highly versatile metal that is widely used in various industries due to its exceptional properties. Among these industries, aviation and aerospace are among the most prominent users of stainless steel. This metal is used extensively in the manufacturing of aircraft components and parts due to its high strength, durability, and resistance to corrosion.

In this article, we will discuss stainless steel and the applications stainless steel uses in the aviation & aerospace Industries

Definition of Stainless Steel:

Stainless steel is a type of steel alloy that contains a minimum of 10.5% chromium by mass. The addition of chromium to the steel creates a passive layer of chromium oxide on the surface of the metal, which gives it excellent corrosion resistance properties. This layer also helps to prevent staining, rusting, and other types of surface degradation.

Properties of Stainless Steel:

Stainless steel has a unique set of properties that make it an ideal material for use in the aviation and aerospace industry.

Here are some of the most notable properties:

High strength and durability

Excellent corrosion resistance

Resistance to high and low temperatures

Non-magnetic

Easy to fabricate and weld

Hygienic and easy to clean

Types of Stainless Steel grades that are available:

At SPP Metal & Alloys we provide stainless steel in various types such as

Flanges

Fittings

Fasteners

Plates

Coils

Sheets,

Pipes,

Tubes & Round Bars.

Welded Tubes

Seamless Pipes

Sheets, Plates and Coils

Advantages of Stainless Steel in the Aviation and Aerospace Industry

Stainless steel offers many benefits in the aviation and aerospace industry, including:

Reduced maintenance costs

Longer service life

Improved safety and reliability

Enhanced resistance to corrosion, erosion, and fatigue

Lower weight compared to other metals

Easy to sterilize and maintain hygiene

Types of Stainless Steel

There are several types of stainless steel that are used in the aviation and aerospace industry. The most commonly used types are:

Austenitic stainless steel

Martensitic stainless steel

Ferritic stainless steel

Duplex stainless steel

Precipitation hardening stainless steel

Applications of Stainless Steel in the Aviation and Aerospace Industry:

Stainless steel is used in various applications in the aviation and aerospace industry, including:

Stainless Steel Uses in Aerospace:

Stainless steel is used in the aerospace industry in a variety of applications, including spacecraft components, satellites, and missiles.

Spacecraft components, such as fuel tanks and rocket engines, require high strength, durability, and resistance to corrosion, which stainless steel provides.

Stainless steel is also used in the manufacture of satellite components, including antennas, reflectors, and structural supports. These components must be able to withstand extreme temperatures and harsh space environments, and stainless steel provides excellent resistance to both.

In addition, stainless steel is used in the manufacture of missile components, including guidance systems and rocket motor casings. These components require high strength and durability, which stainless steel provides.

· Aircraft Structures

Stainless steel is used in the manufacture of aircraft structures, including wings, fuselage, landing gear, and engine components. It is highly resistant to corrosion and fatigue, which makes it an ideal material for use in these critical parts.

· Aircraft Interiors

Stainless steel is also used extensively in the manufacture of aircraft interiors, including cabin fittings, lavatories, and galleys. Its easy-to-clean and hygienic properties make it a popular choice for these applications.

· Aerospace Fasteners

Stainless steel is used in the manufacture of aerospace fasteners, including bolts, screws, and rivets. These fasteners require high strength and resistance to corrosion, and stainless steel provides both.

· Aerospace Exhaust Systems

Stainless steel is used in the manufacture of aerospace exhaust systems, which must withstand high temperatures and corrosive gases. Its high-temperature resistance and corrosion resistance make it an ideal material for these applications.

· Aircraft Engine Components

Stainless steel is used in the manufacture of aircraft engine components, such as combustion chambers, exhaust nozzles, and turbine blades. These components require high strength, heat resistance, and resistance to corrosion, which stainless steel provides.

· Aircraft Hydraulic Systems

Stainless steel is used in the manufacture of aircraft hydraulic systems, including pipes, fittings, and valves. These components must be able to withstand high pressures and corrosive fluids, and stainless steel provides excellent resistance to both.

· Aircraft Fuel Systems

Stainless steel is also used in the manufacture of aircraft fuel systems, including tanks, pipes, and fittings. These components must be able to withstand the corrosive effects of fuel, and stainless steel provides excellent resistance to fuel corrosion.

Stainless Steel Uses in Aviation:

Stainless steel is used in the aviation industry in a variety of applications, including aircraft engine components, hydraulic systems, and fuel systems.

Aircraft engine components, such as combustion chambers, exhaust nozzles, and turbine blades, require high strength, heat resistance, and resistance to corrosion, which stainless steel provides.

Stainless steel is also used in the manufacture of aircraft hydraulic systems, including pipes, fittings, and valves. These components must be able to withstand high pressures and corrosive fluids, and stainless steel provides excellent resistance to both.

Conclusion

Stainless steel is an essential material in the aviation and aerospace industry due to its exceptional properties, including high strength, durability, and resistance to corrosion. SPP Metals & Alloys is a leading stainless steel products manufacturer and supplier in India, providing high-quality stainless steel products for use in the aviation and aerospace industry.

With its wide range of applications, stainless steel will continue to play a crucial role in the growth and advancement of the aviation and aerospace industry for many years to come.

If you are looking for high-quality stainless steel products for use in the aviation and aerospace industry, look no further than SPP Metals & Alloys. Contact us today to learn more about our products and services.

#flange types#steel pipe manufacturing company#metal sheet manufacturer#aerostructures market#aerospace#airplain

0 notes

Text

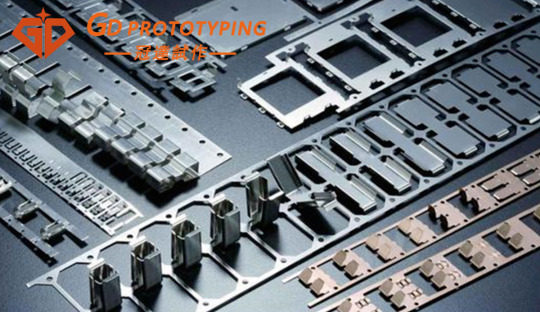

Sheet metal fabrication

#design#autos#business#prototype#prototyping#rapid prototyping#prototype machining#sheet metal services tauranga#sheet metal manufacturing#sheet metal fabrication#sheet metal work contractor financing#sheet metal design#metal machining#sheet metal bending#sheet metal stamping#sheet metal welding#sheet metal

2 notes

·

View notes

Text

Mastering Precision Sheet Metal Fabrication: Where Art Meets Science

Precision sheet metal fabrication is the artful synergy of craftsmanship and scientific knowledge. Whether it's in the automotive industry, electronics manufacturing, or medical equipment production, precision sheet metal plays a pivotal role. In this blog post, we delve deep into the world of precision sheet metal and explore how this art and science intertwine.

Defining Precision Sheet Metal

Precision sheet metal fabrication is a highly specialized manufacturing process that encompasses various methods of cutting, bending, stamping, and welding metal sheets. The goal of these processes is to produce parts and components to exact specifications and dimensions without compromising the quality of the metal material. These parts are typically used in applications that demand high levels of precision, requiring meticulous control and inspection at every step.

Applications of Precision Sheet Metal

Precision sheet metal finds wide-ranging applications across various industries, including but not limited to:

Electronics Manufacturing: Precise enclosures, panels, and connectors are essential to ensuring the safety and stability of internal components in electronic products.

Medical Equipment: Medical devices often require highly precise components to ensure accurate measurements and operations.

Aerospace Industry: Aerospace demands lightweight, high-strength components, and precision sheet metal is key to achieving this goal.

Automotive Manufacturing: Various components in automobiles, including bodywork, chassis, and engine parts, rely on precision sheet metal fabrication.

The Craftsmanship of Precision Sheet Metal

The manufacturing process of precision sheet metal is an art that marries precision with expertise. It involves critical steps such as:

Design and Planning: Careful design and planning are necessary before commencing fabrication, ensuring accuracy and consistency.

Material Selection: Choosing the right metal material is crucial for the performance of the final product.

Cutting and Stamping: Employing cutting and stamping machinery to shape the metal sheets into the desired form.

Bending and Shaping: Utilizing bending and shaping operations to curve metal sheets into the required shapes.

Welding and Assembly: Welding individual components together to assemble the final product.

Quality Control

The essence of precision sheet metal lies in quality control. Rigorous quality control procedures and inspection methods ensure that every component meets specifications. This includes the use of high-precision measuring tools, visual inspections, and material testing.

Conclusion

Precision sheet metal fabrication is a domain where craftsmanship and scientific knowledge beautifully converge. Its wide-ranging applications, from electronics to aerospace, make it indispensable in our modern world. Through continual refinement of processes and quality control methods, precision sheet metal fabrication will continue to play a pivotal role in supporting our modern way of life and technological advancements. It's a testament to how art and science work hand in hand to create excellence in manufacturing.

#aviation#sheet metal fabrication#sheet metal manufacturing#sheet metal stamping#sheet metal design#sheet metal market#robots#robotics

8 notes

·

View notes

Text

2023 Future trends in the use of ASTM A240 S32205 Perforated Coil

ASTM A240 S32205 Perforated Coil is a highly durable and corrosion-resistant material used extensively in various industrial applications.

As we move into the future, the demand for this material is expected to increase due to its exceptional properties and versatility.

One of the major trends we can expect to see in the use of ASTM A240 S32205 Perforated Coil is its use in the automotive industry. With the growing emphasis on lightweight and fuel-efficient vehicles, there is a greater need for strong, durable, yet lightweight materials. It fit the bill perfectly, and we can expect to see increased adoption of this material in the automotive industry.

Another trend we can expect is the use of ASTM A240 S32205 Perforated Coil in the construction industry. With the growing demand for sustainable and eco-friendly buildings, there is a greater emphasis on using environmentally friendly materials with a low carbon footprint. ASTM A240 S32205 Perforated Coil is a highly recyclable material that can be reused without losing its properties, making it an ideal choice for sustainable construction.

The Use of ASTM A240 S32205 Perforated Coil is also expected to increase in the marine industry. This is because of its exceptional corrosion resistance properties, making it ideal for use in harsh marine environments. With the growing demand for offshore energy and the increasing use of ships and boats for transportation, there is a greater need for materials that can withstand the harsh marine environment. This Perforated Coil is a perfect fit for this purpose.

Apart from these industries, S32205 Perforated Coil is also expected to increase in the chemical and petrochemical industries. This is because of its exceptional resistance to corrosion and high-temperature environments, making it ideal for use in chemical processing plants and refineries.

In conclusion, the future looks bright for Perforated Coil, which is expected to increase its use in various industrial applications. Its exceptional properties and versatility make it an ideal choice for many industries, and we can expect to see continued adoption of this material in the years to come.

#metal industrial#architecture#stainless steel#construction#buildings#alloy#sheets#stainless steel coil suppliers#perforatedmetal#preforated coils#perforated sheets manufacturer#s32205 perforated coil

7 notes

·

View notes

Text

Sheet metal panels with copper coated mild steel weld studs fired in place. For more information on stud welding take a look at our blog post.

https://www.vandf.co.uk/blog/stud-welding-custom-sheet-metal-work-components/

2 notes

·

View notes

Text

Sheet Metal Fabrication

Avalon the top-rated EMS companies in India renowned for their quality services, technical expertise, and customer satisfaction.

#Sheet Metal Fabrication#Powder Coating & Welding#Complete Turnkey Solutions#electronics manufacturing services#electronic manufacturing services#electronic manufacturing services companies#electronics manufacturing services India#electronics manufacturing services chennai#top Ems companies in India#bestEmscompanies in India#EMS

2 notes

·

View notes

Video

youtube

Auto CNC Groove Lathe Machine for PEM Hex Blind Standoff Self Clinching Rivet Nut Cabinet Metal Sheet Fasteners.

Whatsapp: +86 13431255254

#youtube#CNC Lathe machine#groove cutting machine#self clinching rivet nut#standoff rivet nut machine#cold forging#standoff rivet nut groove cutting machine#hex blind rivet nut#fasteners#auto cnc lathe machine#metal sheet rivet nut#rivet nut manufacturer#rivet nut supplier#self clinching rivet nut price#standoff self clinching nut#cnc machine#groove cutting machine supplier

2 notes

·

View notes

Text

Why 6061 Aluminium Sheet is a Great Choice for Your Business

If you're in the market for aluminium sheets, you've come across a variety of different types, but one alloy that stands out is the 6061 Aluminium Sheet. It's versatile, strong, and a top choice for many industries. But what makes 6061 aluminium so special? In this blog, I'll explain what makes the 6061 aluminium sheet a fantastic option and why it might be precisely what your business needs.

What is 6061 Aluminium?

6061 aluminium is an alloy with magnesium and silicon as its major elements. Due to its excellent mechanical properties, it is one of the most common and widely used aluminium alloys today. The 6061 aluminium sheet is known for its good strength, workability, weldability, and corrosion resistance.

This alloy is often chosen because it can be easily formed, machined, and welded while maintaining good performance in a wide range of applications. If you're a business owner looking for reliable material for your next project, 6061 might be the answer.

What Makes 6061 Aluminium Special?

You might wonder why so many industries choose 6061 aluminium over other materials. Here are some key reasons why it's so popular:

Great Strength-to-Weight Ratio

6061 aluminium offers an excellent balance between strength and weight. It's strong enough for heavy-duty applications but lightweight enough to make transportation and handling easier. If you're looking for a material that doesn't compromise on strength but still helps in reducing overall weight, 6061 is a great choice.

Corrosion Resistance

One of the standout features of 6061 aluminium is its corrosion resistance. Whether you're working in an environment exposed to harsh weather conditions or near the ocean, 6061 will resist corrosion, reducing long-term maintenance costs. This makes it a favourite in marine and outdoor construction applications.

Weldability and Machinability

6061 aluminium is easy to weld and machine. It makes it suitable for industries where parts need to be shaped, fabricated, or connected via welding. It's a go-to material for projects that require a lot of customisation and assembly.

Heat Treatability

6061 aluminium can be heat-treated to improve its strength and durability. By adjusting its temper (which I'll explain a little later), you can enhance its properties to suit the specific requirements of your project.

Affordable

While some aluminium alloys can get pricey, 6061 aluminium is cost-effective without sacrificing quality. It makes it an excellent option for businesses looking for high performance at a reasonable cost.

Typical Applications of 6061 Aluminium

Due to its versatility, the 6061 aluminium sheet is used in a wide range of industries and applications. Here are just a few examples:

Construction

6061 is frequently used in the construction industry, particularly for structural framing, roofing, and other exterior applications. Its corrosion resistance and durability make it perfect for projects where the material will be exposed to the elements.

Automotive and Aerospace

In the automotive and aerospace sectors, 6061 aluminium is prized for its light weight and strength. It's used for everything from car frames to aircraft components, reducing weight and improving fuel efficiency.

Marine

Because of its excellent resistance to corrosion, 6061 is commonly used in marine applications, including boat hulls, docks, and other structures that come into direct contact with water.

Industrial Machinery

6061 is often used to create parts for machinery and equipment due to its workability and strength. From brackets to frames, this alloy can be easily shaped to fit various applications.

Sizes and Tempers Available

When selecting aluminium, it's crucial to choose the right size and temper for your specific needs. The good news is that 6061 aluminium comes in a variety of options, making it easy to find the right fit for your project.

Common Sizes

6061 aluminium sheets are available in a wide range of standard sizes, such as:

1000 mm x 2000 mm

1250 mm x 2500 mm

1500 mm x 3000 mm

If you need a specific size, many suppliers offer custom-cutting services to match your exact specifications.

Tempers

The temper of aluminium refers to how it's been treated to improve specific properties, like strength or flexibility. 6061 aluminium comes in various tempers, with each one offering different benefits. Some common tempers include:

T6: This is one of the most common tempers for 6061 aluminium. T6 temper means the aluminium has been heat-treated and then artificially aged to reach maximum strength. It makes it ideal for structural applications that require a high level of durability.

T651: Similar to T6, but this temper has been stress-relieved by stretching. It's often used in applications that require additional resistance to warping.

O Temper: This is a fully annealed version of the alloy, which makes it softer and more pliable. It's easier to work with if you need to do a lot of bending or forming.

Choosing the proper temper will depend on your project requirements. For example, if you need a sheet that's easy to bend and form, O temper might be the best choice. If you need maximum strength, go with T6 or T651.

Should You Choose 6061 Aluminium for Your Business?

The answer to this question depends on what you're looking for in a material. However, the 6061 aluminium sheet ticks many boxes for business owners:

Strength: It's strong enough for structural and industrial applications.

Corrosion Resistance: It will stand up to harsh environments, making it perfect for outdoor or marine use.

Cost: It's affordable, making it an excellent option for businesses looking to balance price and quality.

Versatility: Whether you're in construction, automotive, or aerospace, 6061 aluminium can meet your needs.

6061 aluminium sheet is a versatile, reliable, and cost-effective material that offers a wide range of benefits. Whether you need a strong, corrosion-resistant material for outdoor construction or a lightweight, high-strength option for automotive or aerospace applications, 6061 aluminium is an excellent choice.

#aluminium sheets stockist#aluminium sheets#aluminium industries#aluminium sheets supplier#aluminium sheets manufacturer#aluminium supplier#aluminium alloy sheets#aluminium metal#supplier#business

0 notes

Text

"UNI-TECH: Leading Automation Solution Providers in Pune"

UNI-TECH: Your top choice for automation solutions in Pune. Specializing in Capacitive Fuel level sensors, Genset Electronic Controller & Sensors. Innovate with us!

#UL & CSA approved Cables India#Control Panel Suppliers Pune#Wiring harness manufacturer Pune#Sheet metal fabrication & Powder coating#Genset Electronic Controller & Sensors#Capacitive Fuel level sensors

0 notes

Text

List of Automotive Parts Manufacturing Companies in India

If you are looking for a list of automotive parts manufacturing companies in India, Metalman Auto Ltd. is a name that stands out. As one of the leading manufacturers of metal components for the automotive industry, we offer a diverse range of products that cater to various vehicle categories. Our expertise in sheet metal fabrication, tubular parts, and precision assemblies, combined with our state-of-the-art facilities, enables us to produce components that meet the highest standards of quality and performance. We serve a wide range of clients, including OEMs and Tier-1 suppliers, providing them with reliable and efficient solutions that enhance vehicle safety and efficiency. With a strong focus on innovation and sustainability, Metalman Auto is committed to setting new benchmarks in automotive component manufacturing in India.

#metal fabrication#oem manufacturing#fabricationservices#automotive#automotive industry#metalman auto#automotive parts#electric vehicles#manufacturer#Metalman Auto#tubular parts#sheet metal fabrication#oems

1 note

·

View note

Text

With our powder coating services, which provide high-quality finishes for any application, you can elevate your projects. Our knowledgeable staff applies gorgeous, long-lasting coatings that improve both appearance and protection. Our solutions offer a durable, smooth finish and are perfect for use in commercial, industrial, and residential settings. Count on us for excellent powder coating outcomes! Visit us now to know more about Powder Coating Services.

#powder coating services#metal skills in new zealand#sheet metal fabrication#outsourced manufacturing#metal design#metal programming#laser cutting service#best laser cutting services in new zealand#metal skills#steel fabrication#metal fabrication#welding engineering#turret punches#welding services near me#perforated metal sheet#assembly line#hardware insertion

0 notes

Text

Blog Manufacturer & Supplier of Flanges, Pipe Fittings, Fasteners SPP Alloys and Metals

We are passionate about serving Premium Quality material to our customers along with being their Reliable Partners. Here, we'll be sharing the latest news and insights on alloys and the manufacturing process. As a leading manufacturer of high-quality alloys, we understand the importance of staying up-to-date with the latest developments in our industry. We're committed to sharing our knowledge and expertise with our customers, partners, and anyone else who shares our passion for alloys. If you're interested in learning more about our alloys, please visit our website or contact us directly.

#Steel Pipe Manufacturing Company#Metal Sheet Manufacturer#Buttweld Fittings Manufacturer#Flange manufacturing company in India#Buttweld Pipe Fitting#Fittings Supplier In Mumbai#Stainless Steel Manufacturers

0 notes

Text

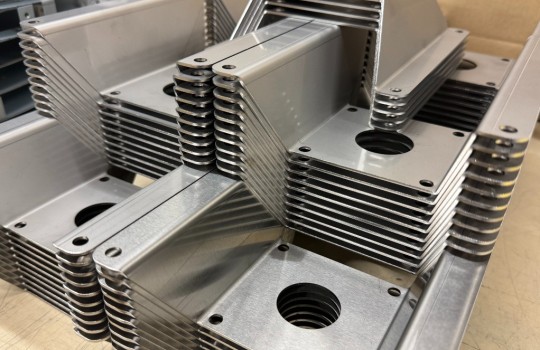

What is Sheet Metal Fabrication? Processing Principle and Method

Sheet metal fabrication refers to the processing of sheet metal (usually under 6mm) by shearing, bending, forming, stamping, welding, stretching and other processes.

A broad definition is that the thickness is unchanged in the processing of parts.

1.Processing Principle of Sheet Metal Working

The processing principle of sheet metal working is mainly based on the plastic deformation properties of metal materials. Through the action of external forces, such as stretching, compressing, bending, etc., the shape and size of the sheet metal is changed to achieve the desired shape and structural requirements. This process requires precise calculation and control of the magnitude, direction and point of action of the force to ensure that the sheet metal does not suffer from rupture, folds and other defects during deformation.

2.Processing Method of Sheet Metal Working

Do you know what are the common processing methods for sheet metal fabrication? The following several commonly used processing methods are introduced:

① Single stamping

Metal parts of musical instrument with curved distribution or in the state of pinholes, grids, etc. can be sheet-metal processed by a single stamping, which makes it possible to separate the metal structure and shape the metal product in a short period of time.

② Continuous feeding

This sheet metal processing method can be divided into two types: unidirectional and multidirectional. Of these, the multi-directional blanking method is usually suitable for processing large metal layers or forming large metal holes, while the unidirectional blanking method is suitable for processing multiple metal parts in a stacked state. Different processing results can be achieved by setting different machine angles and functions in the continuous blanking processing mode.

③ Punching material processing

This drop-feed processing method, also known as punch processing, is mainly used to polish and finish the post-processing of sheet metal working parts, which plays a role in precise positioning and fine grinding during sheet metal processing. Usually the processing mill used in this process has small round type, small arc type, etc.

④ Array formation

With the help of CNC machines, this method is often used to meet the needs of mass production sheet metal working. Large sheet metal products can be processed quickly by combining several existing moulds. In this process, the styles and types of sheet metal working products are basically the same, which facilitates the design of templates in the form of arrays.

⑤ Single or multiple continuous processing

On the basis of CNC machine tools, the metal parts to be processed are stretch-formed in a single operation according to the requirements for the selection of the moulds, thus obtaining metal parts that match the existing moulds. However, if the metal part after the above treatment does not meet the desired requirements, it should be machined several times in succession to form the final shape.

Sheet metal fabrication is used in a wide range of applications including but not limited to aerospace, automotive manufacturing, construction, petrochemical, aviation, electronics, electrical appliances and other fields. In addition, sheet metal processes play an important role in vehicle maintenance and repair which are widely used for body damage analysis, measurement, shaping, tensile straightening, stress relief welding, accessory assembly and adjustment.

#sheet metal bending#design#sheet metal design#sheet metal manufacturing#sheet metal fabrication#sheet metal#prototype machining#prototyping#prototype#rapid prototyping

1 note

·

View note

Text

Your Investment Our Protection - Kamdhenu Colour max

Upgrade your space with the best with our colour-coated sheets that are crafted with the highest quality materials and advanced technology to ensure long-lasting performance and unmatched durability. With its weather-resistant coatings and a wide range of colors and finishes, you get endless possibilities to express your personal style.

#kamdhenucolourmax#colorcoatedsheets#Colour coated sheets Manufacturers#Color coated sheets#color coated metals sheets#roofing profile sheets

0 notes

Text

Top S S Sheet Manufacturer in Ahmedabad | Premium Quality Stainless Steel Sheets

At Diamond Metal, we pride ourselves on being the top S S sheet manufacturer in Ahmedabad. With a commitment to quality and excellence, we offer premium stainless steel sheets that are perfect for all your industrial needs. Our reputation as a leading S S sheet manufacturer in Ahmedabad is built on our dedication to providing products that are durable, reliable, and competitively priced.

We…

0 notes

Text

Crafting Precision with CNC Folding: Stainless Steel Brackets

CNC folding, a cutting-edge technology, is revolutionizing the way we create stainless steel brackets. This process utilizes computer numerical control (CNC) systems to manipulate stainless steel sheets into precise, customized shapes.

One of the standout benefits of CNC folding with stainless steel is the exceptional precision it offers. Whether you need brackets for industrial machinery, architectural structures, or custom applications, CNC folding ensures each bracket is exact to your specifications. This precision minimizes material waste and guarantees a perfect fit for your project.

Stainless steel is a popular choice for brackets due to its corrosion resistance and durability. With CNC folding, intricate designs and complex geometries can be achieved with ease, making it ideal for both functional and decorative brackets.

Additionally, CNC folding enhances efficiency, reducing production time and labor costs, which is especially beneficial for high-volume orders. The result is high-quality stainless steel brackets that meet the strictest industry standards.

https://www.vandf.co.uk/tooling/what-is-cnc-bending/

In conclusion, CNC folding is a game-changer in the production of stainless steel brackets, providing unmatched precision, versatility, and efficiency. This technology paves the way for the creation of brackets that not only serve their intended purpose but also exhibit exceptional craftsmanship.

#sheet metal work#manufacturing#cnc folding#cnc brake press#sheet metal manufacturing#cnc bend#angle brackets

3 notes

·

View notes