#multi-cavity mold

Text

Precision-crafted small cup with lid mould – perfect fit, perfect seal, every time.Email: [email protected]

#Injection mold#Plastic injection molding#Custom mold design#Multi-cavity mold#Plastic mold manufacturing#Hot runner system#manufacturer#china#factory#pp

0 notes

Text

Injection molding materials and mold design professional knowledge sharing (Part 1)

Plastic mold design process requirements

To design an advanced plastic mold, we first need to have a high-level design idea, and we must also study product processability, characteristics and uses of plastic materials, selection of mold steel, processing methods, mold structure design, molding schemes and injection machine models.

Among them, it is very necessary to study processability of mold…

View On WordPress

#Composition of plastics#Demolding mechanism#Demolding slope of plastic parts#Design of gate#design of pouring system#design of runners#Direct gate#ejection mechanism#ejection mechanism of plastic part#ejector mechanism#injection mold#injection mold design#injection molding#mechanical processing#mold design#mold designers#mold manufacturing#mold structure#mold structure design#Molecular structure of plastics#multi-cavity mold#one-cavity mold#Pin-point gate#plastic mold#plastic mold design#plastic parts#plastic products#side gate#Submerged gate#thermosetting plastics

0 notes

Text

multi cavities thin wall stack mold

China precision mold maker, offer multi cavities thin wall mold, thin wall stacking mold, stack thin wall box mold, hamburger mold, fresh container stack mold

#China mold#multi cavities mold#thin wall mold#stack mold#stacking mold#hamburger mold#double stack mold#fresh container stack mold

0 notes

Text

#single cavity mould design#mold cavity and core#core and cavity of a mold#collapsible core mould design#multi cavity mold design

0 notes

Text

The reason why we manufacture multi cavity plastic molds is very simple. It is to control the unit cost of plastic molding parts production. For example, the production cost of a 160 ton injection molding machine is USD8 per mold. If you use an 8-cavity mold to produce parts, the production cost of each part is USD1. If you only use a 2-cavity mold to produce parts of this machine, the unit production cost is USD4. If you need one million or more parts, You can imagine how much cost can be saved from the 8-cavity mold, which is why the multi cavity mold is so popular with customers.

0 notes

Text

JWZ-BM05D/12D/20D Double Station Blow Molding Machine

Performance and advantages

1. Suitable for producing 1-5L different size of gear oil bottle, lubrication oil bottle, cooling water tank etc.

2. Optional multi-layer co-extrusion.

3. Optional view strip line system.

4. According to the product size,select different cavity of die head.

5. According to the different material,optional JW-DB single station hydraulic screen-exchanger system.

6. According to customer's requirement,optional auto-deflashing on line,scrap conveying on line,finished product conveying on line.

Technical Parameters

Model

Unit

BM05D

BM12D

BM20D

Max product volume

L

5

12

20

Dry cycle

Pc/h

700*2

600*2

600*2

Die head structure

Continuous type

Main screw diameter

mm

75

90

90

Max plasticizing capacity (PE)

kg/h

90

160

160

Driving motor

Kw

30

45

45

Oil pump motor power

Kw

11

15

15

Clamping force

KN

70

120

160

Space between platen

mm

150-510

240-640

280-680

Platen size W*H

mm

350*400

450*500

500*520

Max.mould size

mm

360*400

500*520

560*520

Platen moving stroke

mm

450/520

600/650

650

Heating power of die head

Kw

7.5

10

12.5

Machine dimension L*W*H

m

3.7*3.1*2.7

4.2*3.2*3.0

4.3*3.2*3.1

Machine weight

T

8.5

12

14

Total power

Kw

60

90

93

Note: Informations listed above are for reference only, the production line can be designed by customer’s requirements.

Product image display

JWELL Co., Ltd. was founded in 1978, the Chinese biggest plastic extrusion machinery manufacturers with over 24 years in extrusion industry .Now we have 6 production base , more than 3000 employees, having a strong technical & after sales service team for serving more than 150 countries.

Core components: screw and barrel, mold, roller, all processed by us. jwell group has 16 professional branches, each of which produces different products, You can get all the plastic extrusion equipments you need in jwell company and provide you with one-stop service.

Our processing equipment is all CNC imported from Japan and Europe.

The steel used in our machine is superior to our peers. For the same equipment, the lifetime of jwell company's equipment is generally two or three times longer than our peers.

The electrical components used in our equipment are imported brands or Chinese famous brands, and they are specially optimized and designed according to the requirements of jwell company, which can well match our equipment. Other companies do not have such strength and influence.

There is an old saying in China:You get what you pay for!

Read the full article

2 notes

·

View notes

Text

Application of 3+2 CNC Machining in Mold Making Factory

Plastic injection mold manufacturers have long embraced simultaneous multiple-axis machining on machine tools with five or more axes, but more and more China injection mold makers have begun machining mold components on multiaxis platforms in the past few years, said Charlie Chan, engineering manager HS Mold & Die Co.,LTD

He mentioned, however, that the common approach for machining mold parts in houses is 3+2, or 5-axis positional machining. According to his estimate, about 80% to875% of the multi-axis work is performed via 3+2 rather than simultaneous when cutting up to five sides of a prismatic metal workpiece in one fixturing.

What is 3+2 CNC Machining

3+2 (5 axis) CNC machining, also called “positional five-axis machining”, is a technique whereby a three-axis milling program is executed with the cutting tool locked in a tilted position using the 5-axis machine’s two rotational axes, hence the name, 3+2 machining. During the machining process, the fourth and fifth axes are used to rotate the cutting tool in a fixed position rather than to manipulate the tool continuously. On a standard three-axis machine, the only part face that the CNC machine could cut with a cutting tool in its normal position is the horizontal face that faces directly at the spindle.

3+2 CNC Machining Advantages

Compared to conventional three-axis machining, the main advantage of 3+2 CNC machining is the reduction of setup time. According to data from our mold making shop, we could save easily 20% to 25% in setup time because we don’t have to handle that part multiple times.”

Another big benefit of 3+2 CNC Machining is that it allows for the use of a shorter, more rigid cutting tool. With 3+2 machining, the spindle head can be lowered closer to the work piece with the tool angled toward the part surface. This means that a good surface finish and more accurate dimensional results can be achieved .This helps to improve part accuracy by being able to position a work piece so that short, rigid cutting tools are applied, such as when producing undercuts in mold cavities and steep wall inserts in addition, with 3+2 machining, we can use standard, off-the-shelf tools

Rather than using some custom, extra-long tool or holder and risk vibration, this helps to save money easily by 10% to 15% in injection mold costs because there is no need to use special tools for mold manufacturers in china, 3+2 Machining is an ideal option because they can use more off-the-shelf, standard catalog tooling. They have the freedom to reach into my part at different angles without using an especially long tool or special to make that feature on that part.

Application of 3+2 CNC Machining

Where applicable, 3+2 machining will save time and improve operations.This technique is more and more popular with mold making company because it offers great convenience while deep cavities or inserts in complex plastic molds that would otherwise have to be machined with long, slender tools or with tool extensions. Long, slender tools increase the risk of deflection or chatter and tool extensions can create clearance problems. Using 3+2 machining also allows undercuts in cavities and steep walls on standing mold cores to be machined directly. This technique might reduce or eliminate operations for electrical discharge machining (EDM).Relatively few parts are not suitable for 3+2 machining, including complex components. 3+2 CNC Machining is usually used to machine below parts:

deep cavities or inserts in complex plastic molds

certain types of parts from the solid rather than from a complex casting

Drilling holes of metal parts at compound angles such as aluminum brake cylinders in a single setup

We are a China injection mold maker and our CNC machining center has both 3+2 and full 5 axis machining capability, capable of making prototypes and production parts as fast as one day. Reach out HS Mold and see how we could benefit your next CNC rapid prototyping or low-volume manufacturing project.

4 notes

·

View notes

Text

Unveiling the Cost Structure of Injection Molding Services Procurement Intelligence

The injection molding services category is anticipated to grow at a CAGR of 4.8% from 2023 to 2030. The trends such as on-demand injection molding, adoption of automation, and focus on sustainability are driving the demand for the category. Rising awareness about pollution created by waste has increased the focus on sustainability within the industry. According to the Journal of Clean Production 2023 report, the category accounts for 90% of the Global Warming Potential (GWP) created by the complete molding lifecycle, majorly because of energy consumption. As a result, companies are focusing on incorporating plastics such as PLA, or bio-PET materials that are biodegradable or can be recycled. Additionally, to provide energy savings, there is an increase in the adoption of all-electric injection molding machines over the traditional hydraulic-based machines.

The industry has been already automated. However, injection molding facilities can still adopt some new technologies such as robots, and artificial intelligence (AI). Collaborative robots, or cobots are increasingly used in processes along with human operators to improve productivity. AI-driven productivity is impacting across industries by collecting real-time production data to enhance production and reduce costs within injection molders. AI systems can indicate pain points and opportunities to enhance efficiencies. For instance, adoption of in-mold sensors can improve injection molding performance and gage the cavity pressure. The usage of multi-material molding machines is also rising as they can create complex components in one shot by injecting various materials into the mold during a single cycle.

China is a major player in the injection molding machines industry. China exported machines worth USD 4.8 billion in 2022. The rising need for machinery in industries such as packaging, automotive, electronics, and healthcare are expected to drive the demand for machines in these industries. On the other hand, injection molding majorly finds its application in the packaging industry and the U.S. being the top country in the packaging industry is expected to drive the demand for the category.

Order your copy of the Injection Molding Services Procurement Intelligence Report, 2023 – 2030, published by Grand View Research, to get more details regarding day one, quick wins, portfolio analysis, key negotiation strategies of key suppliers, and low-cost/best-cost sourcing analysis

The category is fragmented with the presence of numerous players seeking low-cost production. Molders involved in electronics, consumer products, automotive, and medical applications are continuously looking for low labor costs abroad. Competition from emerging regions such as Asia-Pacific and Latin America has been so profound that molders are developing new strategies to meet current and possible challenges.

Suppliers in the category provide raw materials such as plastic materials, molds, and machinery. The bargaining power of suppliers can be moderate to high, depending on the availability of alternative suppliers and the uniqueness of their products. However, injection molding companies can often negotiate contracts based on bulk purchases, which may reduce the suppliers' power.

Raw materials (plastic materials, molds), labor, rent and utilities, mold (tooling) costs, machinery & equipment, and others are some of the cost components of the category. Other costs include packing, and transportation costs. The cost of injection molding depends on the size, design, and volume of parts. The more the volume of production, the less the cost of production per part. Raw materials, rent and utilities, and machinery & equipment form a major part of the cost component. As the molding process is automated, for example, 3D printers and CNC machines are Computer Numerical Controlled Software run on their own. As a result, labor costs cannot be a crucial part of the cost structure. However, some steps such as setting up machinery, operating, and repairing machinery can require labor costs. Professional industrial injection molding equipment costs can range from USD 50,000 to USD 200,000.

In terms of sourcing injection molding services, companies usually adopt a complete outsourcing model. Companies outsource the services as it gives advantages such as industry expertise, quality assurance, cost-benefit, and economies of scale. Producing plastic products needs equipment and employees which can require heavy investment. The cost of production by outsourcing can be considerably lower. On the other hand, due to the sudden surge in on-demand injection molding can hit production limits. A trusted service provider can meet the production demand along with adding additional value to manufacturing and product needs.

Browse through Grand View Research’s collection of procurement intelligence studies:

• Flooring Services Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

• Home Healthcare Services Procurement Intelligence Report, 2023 - 2030 (Revenue Forecast, Supplier Ranking & Matrix, Emerging Technologies, Pricing Models, Cost Structure, Engagement & Operating Model, Competitive Landscape)

Injection Molding Services Procurement Intelligence Report Scope

• Injection Molding Services Category Growth Rate: CAGR of 4.8% from 2023 to 2030

• Pricing growth Outlook: 6% - 7% (annual)

• Pricing Models: Product type pricing, Volume based Pricing; Competition based pricing

• Supplier Selection Scope: Cost and pricing, past engagements, productivity, geographical presence

• Supplier selection criteria: Quality of the product, type of material used, end-use, post-casting services, contract terms, delivery option, technology used, safety and environmental compliance, location and presence of supplier, and others

• Report Coverage: Revenue forecast, supplier ranking, supplier matrix, emerging technology, pricing models, cost structure, competitive landscape, growth factors, trends, engagement, and operating model

Key companies profiled

• Protolabs, C&J Industries

• HTI Plastics

• The Rodon Group

• EVCO Plastics

• Tessy Plastics

• Currier Plastics

• Formplast

• Major Plastics

• D&M Plastics

Brief about Pipeline by Grand View Research:

A smart and effective supply chain is essential for growth in any organization. Pipeline division at Grand View Research provides detailed insights on every aspect of supply chain, which helps in efficient procurement decisions.

Our services include (not limited to):

• Market Intelligence involving – market size and forecast, growth factors, and driving trends

• Price and Cost Intelligence – pricing models adopted for the category, total cost of ownerships

• Supplier Intelligence – rich insight on supplier landscape, and identifies suppliers who are dominating, emerging, lounging, and specializing

• Sourcing / Procurement Intelligence – best practices followed in the industry, identifying standard KPIs and SLAs, peer analysis, negotiation strategies to be utilized with the suppliers, and best suited countries for sourcing to minimize supply chain disruptions

#Injection Molding Services Procurement#Procurement Intelligence#Injection Molding Services Market#Injection Molding Services Industry

0 notes

Text

Comprehensive Overview of Pet Blowing Machine Manufacturer: Seppa Solutions

Seppa Solutions is a leading manufacturer of high-quality PET blowing machine, a crucial component of PET bottle manufacturing in industries like beverages, pharmaceuticals, and personal care. Their machines are energy-efficient, consuming less energy than traditional PET-blowing machines, making them environmentally friendly and cost-effective. Seppa Solutions offers customizable solutions for specific production requirements, including mold designs, bottle shapes, and production speeds. Their PET-blowing machines feature advanced heating systems, high-speed production capabilities, precision control, multi-cavity blow molding, and a user-friendly interface. Investing in Seppa Solutions PET-blowing machines offers numerous benefits, including reduced production costs, consistent product quality, environmental sustainability, and long-term durability.

#pet blowing machine#pet bottle blowing machine#automatic pet bottle blowing machine#bottle blowing machine#pet bottle making machine#pet making machine#pet bottle blow machine#pet blowing machine manufacturer in india#automatic pet blowing machine

0 notes

Text

Optimizing Production with Low Volume Injection Molding at TEAM Rapid

In the fast-paced world of manufacturing, the need for high-quality, cost-effective production methods is ever-present. Low Volume Injection Molding has emerged as a pivotal solution for businesses seeking to streamline their manufacturing processes while maintaining precision and flexibility. At TEAM Rapid, we excel in this specialized field, offering comprehensive services designed to meet the demands of low volume production with efficiency and expertise.

Understanding Low Volume Injection Molding

Injection molding is a manufacturing technique that involves injecting molten thermoplastic materials into a pre-designed mold cavity. Once cooled and solidified, the material takes the shape of the mold, resulting in a finished part. This process is renowned for its ability to produce high-quality components with intricate designs and tight tolerances.

Low Volume Injection Molding, as the name suggests, is tailored for smaller production runs. Unlike traditional injection molding, which is often geared towards large-scale production, low volume molding focuses on delivering high-quality parts in quantities that are manageable for smaller projects or initial product launches.

TEAM Rapid's Expertise in Low Volume Injection Molding

At TEAM Rapid, we understand that every project is unique, and we offer a range of services to cater to your specific needs. Our expertise in low volume injection molding includes:

Precision Engineering: We pride ourselves on our ability to achieve tight tolerances, ensuring that each part meets exact specifications. This precision is critical for applications where component accuracy is paramount.

Rapid Tooling: Speed is a crucial factor in the competitive landscape of manufacturing. Our rapid tooling services ensure that molds are created quickly, allowing for faster production cycles and quicker time-to-market for your products.

Multi-Cavity Tooling: To maximize efficiency and reduce production costs, we utilize multi-cavity tooling. This approach allows us to produce multiple parts in a single molding cycle, enhancing productivity and reducing overall costs.

Over-Molding and Secondary Post-Molding Operations: Our capabilities extend beyond basic molding. We offer over-molding, where multiple materials are used in a single part, and secondary post-molding operations to add additional features or enhance functionality.

Versatile Material Options: TEAM Rapid provides access to a wide range of commercially available thermoplastics, allowing you to choose the material that best suits your project's requirements. Our production-grade tooling supports various materials without limitations on quantities or geometries.

Benefits of Low Volume Injection Molding with TEAM Rapid

Cost-Effective: Low volume molding is an economical choice for smaller production runs, eliminating the need for large-scale manufacturing investments while still delivering high-quality parts.

Quick Turnaround: With rapid tooling and efficient processes, we ensure that your products are manufactured and delivered promptly, helping you meet market demands and deadlines.

High-Quality Output: Our commitment to precision and quality guarantees that each part produced meets high standards, ensuring that your products function as intended and perform reliably.

Flexibility: Whether you need prototyping, short-run production, or a solution for niche markets, our low volume molding services offer the flexibility to adapt to various project needs.

Conclusion

Low Volume Injection Molding at TEAM Rapid is more than just a manufacturing process; it’s a strategic advantage that combines precision, speed, and flexibility. Our dedication to delivering high-quality components and efficient production solutions ensures that your project can move forward smoothly, whether you are launching a new product or fulfilling niche market requirements.

Explore the benefits of low volume injection molding with TEAM Rapid and discover how our expertise can drive your success. Contact us today to discuss your project needs and find out how we can support your manufacturing goals.

0 notes

Text

Micro Injection Molding Machine Market Research Insights Shared in Detailed Report

The Micro Injection Molding Machine Market was valued at USD 0.4 billion in 2023-e and will surpass USD 0.8 billion by 2030; growing at a CAGR of 9.4% during 2024 - 2030. The report focuses on estimating the current market potential in terms of the total addressable market for all the segments, sub-segments, and regions. In the process, all the high-growth and upcoming technologies were identified and analyzed to measure their impact on the current and future market.

Micro injection molding is a specialized form of injection molding that focuses on producing very small, highly detailed plastic parts. These parts typically weigh less than 1 gram and have dimensions measured in micrometers. The process involves injecting molten plastic into a mold cavity with extreme precision to achieve the desired shape and features. This technology is essential for manufacturing components that require tight tolerances and intricate geometries.

Read More about Sample Report:

Market Trends and Growth Drivers

Miniaturization in Electronics: The relentless pursuit of smaller, more powerful electronic devices has significantly driven the demand for micro injection molding machines. Components such as connectors, sensors, and micro gears used in smartphones, wearables, and other compact devices require high precision and reliability, which micro injection molding can deliver.

Advancements in Medical Devices: The medical industry is a major contributor to the growth of this market. The production of micro-sized components for minimally invasive surgical instruments, drug delivery systems, and diagnostic equipment necessitates the use of micro injection molding. The ability to produce biocompatible and high-precision parts is critical for medical applications.

Automotive Industry Innovations: As the automotive industry moves towards more sophisticated electronic systems and lightweight materials, the demand for micro-molded parts is increasing. Micro injection molding machines are used to produce connectors, sensors, and other small components that are integral to modern automotive technology.

Sustainability and Material Efficiency: The micro injection molding process is highly efficient in terms of material usage, which aligns with the growing emphasis on sustainability. The ability to produce tiny parts with minimal waste is an attractive feature for industries looking to reduce their environmental footprint.

Challenges in the Micro Injection Molding Machine Market

Despite the promising growth prospects, the micro injection molding machine market faces several challenges:

High Initial Investment: The cost of acquiring micro injection molding machines and the associated tooling can be substantial. This high initial investment may deter small and medium-sized enterprises from entering the market.

Technical Complexity: The process requires a high level of expertise and precision. Maintaining consistent quality and tolerances in micro-molded parts can be challenging, necessitating advanced technology and skilled operators.

Material Selection: Not all materials are suitable for micro injection molding. The selection of appropriate materials that meet the stringent requirements of various applications can be a complex task.

Ask for Customization Report: https://intentmarketresearch.com/ask-for-customization/micro-injection-molding-machine-market-3232.html

Future Prospects

The future of the micro injection molding machine market looks promising, with several factors likely to drive further growth:

Technological Advancements: Ongoing innovations in machine design, process control, and materials will enhance the capabilities of micro injection molding. Developments such as multi-material micro molding and the integration of automation and AI will open new avenues for this technology.

Expansion into New Applications: As industries continue to innovate, new applications for micro-molded parts will emerge. Fields such as aerospace, defense, and biotechnology are expected to adopt micro injection molding for their specialized requirements.

Global Market Expansion: The market is set to expand geographically, with growing demand in regions like Asia-Pacific, driven by the electronics and automotive industries. Increasing industrialization and technological adoption in emerging economies will contribute to market growth.

Customization and Personalization: The trend towards customization in various industries, particularly in medical devices and consumer electronics, will fuel the demand for micro injection molding machines capable of producing tailored parts.

Conclusion

The micro injection molding machine market is poised for significant growth, driven by advancements in technology, increasing demand for miniaturized components, and the pursuit of material efficiency and sustainability. While challenges remain, the industry's future prospects are bright, with ongoing innovations and expanding applications set to propel the market forward

#Micro Injection Molding Machine#Micro Injection Molding Machine Size#Micro Injection Molding Machine Trends#Micro Injection Molding Machine Outlook

0 notes

Text

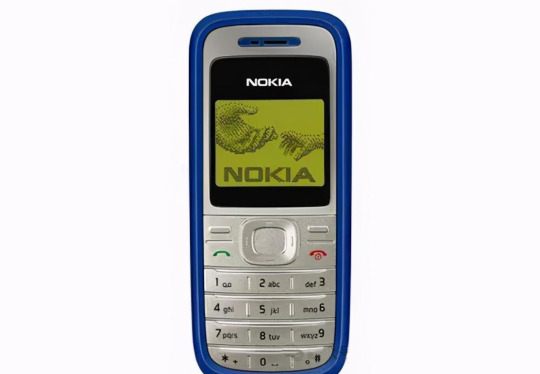

Mobile phone shell injection mold design and moldflow

1 Preliminary preparation

1.1 Overview

Mobile phone products have huge market development space. At the same time, market is also in a stage of rapid development. This is an extremely important development stage for manufacturers, distributors and retailers, and is a stage where market structure is gradually taking shape. Therefore, in next few decades, design and processing of mobile phone…

View On WordPress

#barrel temperature#Cold material well design#cooling system design#Design of demoulding mechanism#design of mold base#design of molded part#Design of molding parts#design of plastic molded parts#Exhaust system design#Flow analysis#Gate design#Gate location selection#gating system design#Grid connectivity diagnosis#Grid related analysis#Guide mechanism design#injection mold design#injection molding machine#large and medium-sized molds#Mesh thickness diagnosis#mobile phone case injection mold#Mobile phone shell injection mold design#mold design#mold manufacturing#mold manufacturing and assembly#Mold temperature#molded parts of injection mold#Moldflow#molding process#multi-cavity mold

0 notes

Text

vinegar bottle caps mold

China multi cavities caps mold maker, offer olive oil cap mold, edible oil plastic closures, vinegar bottle cap mold, cooking oil lid mold, soy sauce bottle caps

#china mold#multi cavities cap mold#olive oil cap mold#edible oil plastic closure mold#vinegar bottle cap mold#cooking oil lid mold#soy sauce bottle caps mold#oil bottle cover mold

0 notes

Text

Design points of gating system-sub runner

Sub runner is material flow channel between main runner and gate. It is transition section where plastic melt flows from main runner into cavity and is responsible for smoothly changing flow direction of melt. In multi-cavity mold, it plays role of distributing melt to each cavity. Generally, no sub runners are set in single cavity molds

1 Design criteria

1) With the shortest distance and the…

View On WordPress

0 notes

Text

The Wonders and Innovations of Injection Molds

Injection molds, as an important cornerstone of modern manufacturing, the development and innovation of their technologies are of crucial importance.

The design process of injection molds is extremely complex and precise. From the initial analysis of the product, including the shape, size, accuracy requirements, etc., to determining the parting surface, the number and arrangement of cavities, every link requires rigorous consideration. For example, when designing the injection mold for a mobile phone case, the position selection of the parting surface should fully consider the structural characteristics of the case to ensure that the mold can smoothly eject the product from the cavity when the mold is opened without affecting the appearance of the product.

The determination of the number of cavities needs to comprehensively consider factors such as the production batch of the product, the specifications of the injection molding machine, and the cost of the mold. If the production batch is large, in order to improve production efficiency, a multi-cavity mold structure may be selected, but this will also increase the manufacturing difficulty and cost of the mold.

The selection of the injection molding machine is also a key link. Different injection molding machines have different parameters such as injection pressure, clamping force, and injection volume. It is necessary to select the appropriate injection molding machine model according to the specific requirements of the mold and the product.

The design of the gating system is related to whether the plastic melt can fill the cavity smoothly and affects the quality of the product. The main runner, the runner, the gate, and the cold slug well all need to be carefully designed. For example, the selection of the location and form of the gate directly affects the appearance and internal quality of the product. For some products with high appearance requirements, a submarine gate may be used to avoid leaving obvious gate marks on the product surface.

The design of the demolding mechanism must ensure that the product can be smoothly ejected from the mold after molding without causing damage to the product. Common demolding mechanisms include ejector pin demolding and ejector plate demolding. The design of its structure and quantity needs to be determined according to the shape and size of the product.

The cooling system plays an important role in controlling the molding cycle and quality of the product. By reasonably arranging the cooling water channels, the mold temperature can be effectively reduced, so that the plastic melt can be quickly cooled and solidified in the cavity, improving production efficiency and product quality.

In short, the design and manufacturing of injection molds is a comprehensive project that requires knowledge and technologies in multiple fields. Continuous innovation and optimization are the keys to promoting the development of the injection mold industry.

0 notes

Text

Advances in Cap Mold Technology: Key Developments and Trends

The evolution of bottle cap mold technology has significantly influenced the packaging industry, bringing about substantial improvements in efficiency, precision, and sustainability. As the demand for more advanced and reliable packaging solutions continues to rise, the development of bottle cap mold technology has been at the forefront of these changes.

One of the key advancements in bottle cap mold technology is the integration of more sophisticated materials. Traditional bottle cap molds were predominantly made from metal alloys that could endure high pressure and temperature. However, recent developments have introduced new composite materials that offer enhanced durability and reduced weight. These modern materials contribute to the longevity of bottle cap molds and the efficiency of the production process.

Another notable trend in bottle cap mold technology is the advancement in computer-aided design (CAD) and manufacturing (CAM) techniques. The use of CAD allows for the creation of highly detailed and precise bottle cap mold designs, which can be tested and modified virtually before actual production begins. CAM technology further streamlines the manufacturing process by automating the production of bottle cap molds with high accuracy. This integration of CAD and CAM not only improves the precision of bottle cap molds but also reduces production times and costs.

The focus on sustainability has also driven significant changes in bottle cap mold technology. Manufacturers are increasingly adopting eco-friendly practices, such as using recyclable materials and reducing waste. Modern bottle cap molds are designed with features that lessen the amount of scrap material generated during production. Additionally, advancements in injection molding technology have led to more efficient use of resources, thereby supporting environmental sustainability.

Furthermore, advancements in bottle cap mold technology have led to the development of multi-cavity molds. These molds are designed to produce multiple bottle caps in a single cycle, greatly enhancing production efficiency. Multi-cavity bottle cap molds are particularly advantageous for high-volume manufacturing, as they help to meet the growing demands of the market while maintaining consistent quality.

Automation and robotics have also made a significant impact on bottle cap mold technology. The incorporation of robotic systems in the production process has improved the precision and speed of mold operations. Robots can handle complex tasks such as mold changes and quality inspections with greater accuracy than manual methods. This automation not only increases production capacity but also reduces the likelihood of human error, resulting in higher-quality bottle caps.

The trend towards smart manufacturing is another development shaping bottle cap mold technology. Smart molds equipped with sensors and data analytics capabilities provide real-time monitoring and feedback on the production process. These smart bottle cap molds can detect anomalies, adjust parameters automatically, and provide valuable insights into the performance of the molds. This technology enhances the overall efficiency and reliability of bottle cap production.

Moreover, the introduction of advanced cooling systems in bottle cap molds has further improved production processes. Effective cooling is crucial for maintaining the quality and consistency of bottle caps. Modern cooling systems are designed to optimize the temperature control during molding, ensuring that the bottle caps are produced with small defects.

In conclusion, advancements in bottle cap mold technology are transforming the packaging industry by enhancing efficiency, precision, and sustainability. The integration of sophisticated materials, CAD and CAM techniques, eco-friendly practices, multi-cavity molds, automation, smart manufacturing, and advanced cooling systems all contribute to the ongoing improvements in bottle cap mold technology. As the industry continues to evolve, these developments will play a crucial role in meeting the demands for higher-quality and more sustainable packaging solutions. The future of bottle cap mold technology promises even greater innovations, further advancing the capabilities and performance of these essential tools in the manufacturing process.

0 notes