#parylene coating process

Text

Advanced Parylene Coating Process from DawnTechsb

Get the innovative Parylene Coating Process from DawnTechsb. Their cutting-edge coating technology ensures durability, chemical resistance, and moisture protection, offering unmatched protection for sensitive components ideal for electronics and more. Learn how the precise and environmentally friendly application of parylene enhances product performance while meeting industry standards. Visit Dawntechsb for more on their expert Parylene coating solutions.

0 notes

Text

PTFE Coated O-Rings: Benefits, Applications, and Maintenance

O-rings are essential sealing components used in various applications to prevent leakage between two surfaces, however, they do have their limitations. Depending on the material, an O-ring could have higher than preferred friction, low chemical resistance, or confusing coloration. In situations like this, a specialty coating like Parylene or PTFE might be the right answer. In this blog, we will focus on PTFE-coated O-rings, their advantages, and their applications.

What are PTFE-Coated O-rings?

PTFE-coated O-rings are O-rings that are coated with a layer of PTFE material. PTFE, or polytetrafluoroethylene, is a type of fluoropolymer that is known for its non-stick properties, chemical resistance, and high-temperature resistance. When applied as a coating to O-rings, PTFE can provide an additional layer of protection, improving certain properties of the O-ring.

Most of our coating systems are applied using conventional compressed air driven spraying techniques. The coatings are supplied as liquids and are decanted into either gravity fed or pressure fed spraying equipment.

Powder systems such as PFA and FEP are applied electrostatically, where the coating material (powder) and the part receive opposing electrical charges so that the powder will be attracted to the part. This is particularly useful where complex shapes are involved. If you would like to learn more, see our PTFE Coatings page.

Advantages of PTFE-Coated O-rings

PTFE-coated O-rings offer several advantages over other types of O-rings. These include:

Color Identification: PTFE coatings can be produced in any color. This makes PTFE coated O-rings easy to identify.

Chemical Resistance: PTFE is highly resistant to chemicals, making the PTFE coating fully functional in applications involving harsh chemicals. However, PTFE coatings are porous, and wear off easily. They will not protect the O-ring from chemical contact.

High Temperature Resistance: PTFE can withstand high temperatures, making PTFE coatings suitable for applications where high temperatures are expected.

Low Friction: PTFE has a low coefficient of friction, making PTFE coatings an ideal, clean, dry lubrication for installation purposes.

Non-stick Properties: PTFE is known for its non-stick properties, which make PTFE-coated O-rings easy to remove and clean.

Thin Coat: PTFE coatings are extremely thin and typically have virtually no effect on the tolerances of the end part.

Limitations of PTFE-Coated O-rings

While PTFE coatings have their uses, their limitations can sometimes exclude their use from certain applications.

Poor Dynamic Wear Resistance: PTFE coatings can easily be rubbed off, meaning that they really only function as a one-time-use surface lubricant.

Flaking: Because PTFE coatings can easily flake off due to dynamic wear, pieces of the coating can sometimes contaminate clean systems.

Porous: PTFE coatings do not provide additional chemical resistance for the O-ring. Because of this, it is important to use an O-ring material that is resistant to the chemicals and temperatures used in the application.

Applications of PTFE-Coated O-rings

PTFE-coated O-rings are used in various industries, including:

Chemical Processing: PTFE-coated O-rings are used in chemical processing equipment, where they provide improved installation lubrication, reliable sealing properties, and chemical resistance.

Aerospace: PTFE-coated O-rings are used in aerospace applications, where they provide high-temperature resistance and easy colored identification.

Conclusion

PTFE-coated O-rings offer useful niche benefits and can be ideal for use in various industries depending on the use case. PTFE-coated O-rings provide an inexpensive dry surface lubricant and color identification system; however, the limitations of PTFE coatings can sometimes make them prohibitive for certain applications. If you are interested in the benefits of other coating types, see our blog about Parylene Coatings. Parylene coatings frequently fill the roles that PTFE coatings fail to. For more information, please visit our website: https://www.canyoncomponents.com/

0 notes

Text

Efficient PCB Conformal Coating Spray for Superior Protection

In the fast-paced world of electronics manufacturing, Printed Circuit Boards (PCBs) serve as the backbone of countless electronic devices, from smartphones to industrial machinery. Ensuring the longevity and reliability of these PCBs is paramount, especially in harsh or demanding environments. This is where conformal coatings come into play, offering a protective shield that guards against moisture, dust, chemicals, and other environmental factors. To achieve superior protection efficiently, PCB conformal coating spray has become an invaluable tool. In this comprehensive guide, we will delve into the world of PCB conformal coating, explore the importance of efficiency, and highlight key considerations when choosing the right spray method.

Understanding PCB Conformal Coating

PCB conformal coating is a protective layer applied to the surface of a printed circuit board to safeguard it against a variety of external threats. These threats include moisture, dust, dirt, chemicals, temperature fluctuations, and even physical damage. The primary purpose of conformal coating is to ensure the reliability and longevity of electronic devices.

There are several common types of conformal coatings, each with its unique properties and advantages:

1. **Acrylic Coatings**: These coatings are easy to apply, dry quickly, and offer excellent moisture resistance. However, they may not provide the best protection against chemicals or extreme temperatures.

2. **Silicone Coatings**: Silicone coatings are known for their flexibility and resistance to high temperatures. They are often used in applications where thermal stability is crucial.

3. **Urethane Coatings**: Urethane coatings provide good protection against chemicals and abrasion. They are suitable for applications requiring durability and resistance to harsh environments.

4. **Parylene Coatings**: Parylene is a vapor-deposited conformal coating that offers exceptional protection against moisture, chemicals, and temperature extremes. It also has excellent dielectric properties, making it suitable for sensitive electronic components.

5. **Epoxy Coatings**: Epoxy coatings are known for their high dielectric strength and excellent adhesion properties. They provide robust protection against moisture and chemicals.

Selecting the right PCB conformal coating spray depends on the specific requirements of the PCB and the environment in which it will operate. Regardless of the type of coating chosen, the method of application plays a crucial role in determining the efficiency and effectiveness of the protective layer.

The Importance of Efficiency in Conformal Coating

Efficiency is a critical factor in the conformal coating process for several reasons:

1. Cost-Effectiveness:

Efficient conformal coating methods reduce material waste, saving costs in both material usage and labor. A precise application ensures that only the necessary amount of coating is used, preventing over-application.

2. Consistency:

Efficient coating methods provide a consistent and uniform coverage, reducing the risk of uneven protection. Inconsistent coating can leave vulnerable spots on the PCB, potentially leading to failure in critical applications.

3. Time Savings:

Efficiency in the coating process translates to faster production times. Reduced drying or curing times can significantly improve overall manufacturing throughput.

4. Environmental Impact:

Efficient coating methods contribute to a lower environmental impact by minimizing the use of chemicals and reducing waste. This aligns with sustainability goals and regulatory requirements.

5. Quality Assurance:

Efficient coating methods are more likely to produce high-quality results that meet or exceed industry standards. This is particularly crucial in applications where reliability is paramount, such as aerospace, automotive, and medical devices.

Choosing the Right Conformal Coating Spray Method

Selecting the appropriate PCB conformal coating spray method is essential to achieve efficiency and superior protection. There are several spray methods available, each with its advantages and limitations:

1. **Manual Spray**:

Advantages: Manual spraying allows for precise control over the coating application, making it suitable for small-scale production or prototyping.

Limitations: It can be time-consuming and labor-intensive, making it less efficient for high-volume manufacturing.

2. **Automated Spray**:

Advantages: Automated spray systems offer consistent and uniform coating application, making them ideal for high-volume production. They are efficient and can be customized for specific PCB designs.

Limitations: Initial setup costs can be high, and maintenance is required to ensure continuous performance.

3. **Selective Coating**:

Advantages: Selective coating systems target specific areas of the PCB, providing precise protection where it is needed most. This minimizes material usage and maximizes efficiency.

Limitations: These systems may not be suitable for fully coating complex PCBs with intricate designs.

4. **Aerosol Spray Cans**:

Advantages: Aerosol spray cans are convenient for small-scale projects or touch-up applications. They are readily available and require minimal equipment.

Limitations: They may not provide the same level of precision and consistency as automated systems. They are also less efficient for large-scale production.

5. **Parylene Vapor Deposition**:

Advantages: Parylene coating offers exceptional protection and dielectric properties. It is highly uniform and conformal, making it suitable for intricate PCB designs.

Limitations: The equipment required for parylene vapor deposition is specialized and costly. It is typically used for critical applications where the highest level of protection is necessary.

Factors to Consider When Selecting a Conformal Coating Spray Method

Choosing the right PCB conformal coating spray method involves considering various factors to ensure both efficiency and superior protection:

1. **PCB Design Complexity**:

Evaluate the complexity of your PCB design. For intricate designs, selective coating or parylene vapor deposition may be necessary to ensure uniform coverage.

2. **Production Volume**:

Determine your production volume. For high-volume manufacturing, automated spray systems are the most efficient choice. Manual methods or aerosol cans are suitable for smaller volumes.

3. **Coating Material**:

Consider the type of conformal coating material you intend to use. Some coating materials are better suited for specific spray methods.

4. **Budget**:

Assess your budget for both equipment and materials. Automated systems and parylene vapor deposition require a more significant initial investment compared to manual or aerosol methods.

5. **Environmental Regulations**:

Ensure that your chosen method complies with environmental regulations regarding emissions and waste disposal.

6. **Quality Requirements**:

Determine the level of quality and reliability required for your application. Critical applications may demand the use of parylene or automated systems for the highest level of protection.

7. **Maintenance and Training**:

Consider the maintenance requirements of your chosen spray method and whether your team has the necessary training and expertise to operate it effectively.

Conclusion

Efficient PCB conformal coating spray is the key to achieving superior protection for electronic devices. By understanding the various conformal coating types and choosing the right spray method, manufacturers can ensure that their PCBs are safeguarded against environmental threats, while also optimizing cost, time, and quality aspects of the production process. Whether it's high-volume manufacturing with automated systems or precision protection with parylene vapor deposition, the choice of method should align with the specific needs of the application and the desired level of protection. In a world where electronics play an increasingly essential role in our daily lives, efficient conformal coating is a vital component of ensuring reliability and longevity in electronic devices.

#PCB Conformal coating spray#industrial parts#parts washing machines#contact cleaner spray#industrial component cleaning machine

0 notes

Text

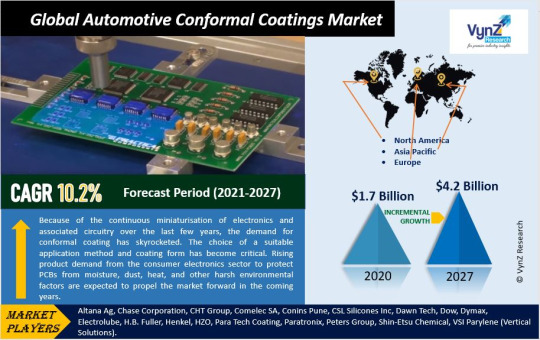

Global Automotive Conformal Coatings Market - Growth, Trends, COVID-19 Impact, and Forecasts (2021-2027)

The global automotive conformal coatings market is expected to reach USD 4.2 billion by 2027, from USD 1.7 billion in 2020. The market is growing at a CAGR of 10.2%, driven by the increasing adoption of electronics in vehicles and the development of new technology.

Market Overview

The global automotive conformal coatings market is segmented by material, component, vehicle type, application, and region.

By material: The market is segmented into acrylic, silicone, epoxy, polyurethane, and parylene. Acrylic is the most widely used material, followed by silicone.

By component: The market is segmented into ECU, PCB, sensor, battery casing, LED, and infotainment system. ECUs are the largest application segment, followed by PCBs and sensors.

By vehicle type: The market is segmented into passenger vehicles, light commercial vehicles, and heavy commercial vehicles. Passenger vehicles are the largest application segment, followed by light commercial vehicles and heavy commercial vehicles.

By application: The market is segmented into brush coating, dipping, spray coating, selective coating, and vapor deposition. Brush coating is the most widely used application method, followed by dipping and spray coating.

By region: The market is segmented into North America, Europe, Asia Pacific, Middle East & Africa, and South America. Asia Pacific is the largest market for automotive conformal coatings, followed by Europe and North America.

Get a free sample copy of the research report: https://www.vynzresearch.com/automotive-transportation/automotive-conformal-coatings-market/request-sample

Key Players

The key players in the global automotive conformal coatings market are:

• Altana Ag

• Chase Corporation

• CHT Group

• Comelec SA

• Conins Pune

• CSL Silicones Inc

• Dawn Tech

• Dow

• Dymax

• Electrolube

• H.B. Fuller

• Henkel

• HZO

• Para Tech Coating

• Paratronix

• Peters Group

• Shin-Etsu Chemical

• VSI Parylene (Vertical Solutions)

Trends and Opportunities

The global automotive conformal coatings market is expected to witness significant growth in the coming years. This growth will be driven by a number of factors, including:

The increasing adoption of electronics in vehicles

The development of new technology, such as self-driving cars and electric vehicles

The growing demand for conformal coatings in harsh environments

Challenges

The automotive conformal coatings market faces a number of challenges, including:

The high cost of conformal coatings

The complexity of the application process

The need for regular maintenance

Conclusion

The global automotive conformal coatings market is expected to grow significantly in the coming years. This growth will be driven by a number of factors, including the increasing adoption of electronics in vehicles, the development of new technology, and the growing demand for conformal coatings in harsh environments. The key players in the market are major suppliers of conformal coatings to OEMs and aftermarket distributors. The market faces a number of challenges, including the high cost of conformal coatings, the complexity of the application process, and the need for regular maintenance.

About Us:

VynZ Research is a global market research firm offering research, analytics, and consulting services on business strategies. We have a recognized trajectory record and our research database is used by many renowned companies and institutions in the world to strategize and revolutionize business opportunities.

Source: VynZ Research

0 notes

Text

How Medical Device Coatings can be Picked and Tested?

The coatings on medical devices can benefit to guarantee protection against corrosion, prurience, bone infiltration, and improved toughness. When choosing a precise coating, it’s imperative to select a solution offering the correct properties for the job, as this will make the most of the advantage to your device and guarantee ideal performance of the medical devices.

Though, selecting which kind of coating will be the best suited for an application is a pretty difficult task at hand. In these cases, having a reliable corporation conducting a laboratory coating assessment can be enormously treasured for defining the perfect solution for a definite job.

When looking for a coating assessment lab, one should take care to select a company offering a number of testing services, like corrosion testing, composition testing, morphology, metallurgical evaluation, and mechanical testing. Having several options up your sleeve will assist you to ensure that you find the coating complementing your parts and devices. It’s also indispensable to ply a squad of coating specialists using these up-to-the-minute tools and knowhows, providing clients with the most advanced, dependable solutions that are available in the medical device coating market.

Coating Assessments for the Medical Device Sector

The medical device sector, especially, can significantly take advantage from the usage of coatings. As innovative, pioneering technologies are available, the medical sector has begun to take part in many of them into trailblazing medical devices. But these coatings need cutting-edge features that guarantee optimal sturdiness, safety, sterility, and permanency. These precise necessities often require assessments to find coatings that will not just increase the lifespan of the medical device, but correspondingly make it biocompatible and corrosion resistant.

For medical devices, specifically, there are tests obtainable for a number of coatings like Parylene, beta-tri-calcium phosphate, hydroxyapatite, titanium and others to guarantee greater production control. These services support the R&D efforts, along with overflow testing.

Browse detailed report Medical Device Coating Industry Growth and Future Scope

What to Hunt for When Directing a Coating Assessment Process

Working with the appropriate coating solution aids guarantee the delivery of top-notch medical products, the ones that not just improves the eminence of life for patients, but also meet stringent standards of the industry, minimalize the probabilities of disappointment, and comply with applicable regulations. Proper evaluations will aid regulate the apt adhesion properties coating thickness, and chemical cleanliness required.

Concluding the Scene

Choosing the fitting medical device coating can really be a hard nut to crack in general, but if you can select the right company to do so, this can become a tad easier. With an increased demand for device coatings because of mass-scale development of healthcare infra and rise in the number of chronic diseases and healthcare-related infection, the device coating market will rise to a value of about $15,166 million in the years to come.

0 notes

Text

Features and application of parylene film in rubber products

Parylene is prepared by vapor deposition polymerization of reactive monomers. The vapor deposition of the monomers occurs almost simultaneously with the film formation, and there is no liquid phase transition state.

Because the film is formed at room temperature, the coated part is protected from deformation caused by surface tension, and the polymer film can be uniformly formed on solid surfaces (including acute angles, crevices, and inner pores), and is extremely thin and needle-free. It has transparency, good air tightness, mechanical properties, electrical properties, and chemical inertness.

Compared with common coating materials (such as epoxy resin and polyurethane, etc.), parylene is superior to other common coating materials in terms of mechanical properties, electrical properties, and chemical inertness.

The properties of parylene films can be summarized as follows:

(1) It can realize the coating of the substrate with completely the same shape;

(2) Good optical transparency;

(3) Low moisture absorption and good moisture-proof effect;

(4) Good electrical insulation;

(5) Small residual stress;

(6) Good dry lubricity;

(7) Good air tightness;

(8) Fix surface debris to prevent particle contamination;

(9) No outgassing, suitable for aerospace applications;

(10) Good biocompatibility, in line with FDA (Class VI) and other requirements.

Application of Parylene Film in Rubber Products

Parylene has a wide range of applications and has been successfully used in various fields, such as aerospace, optics, electronics, biomedicine, and cultural relics protection.

1 Silicone rubber button

Using the parylene coating process, a uniform, extremely thin (2-3 μm) polymer protective layer can be formed on the surface of the silicone key product, which is consistent with the surface contour of the original product. This protective layer can make silicone rubber products such as silicone rubber keys more wear-resistant, thereby improving the service life of silicone rubber products.

Due to the protection of the tightness of the parylene film, the characters printed on the silicone rubber keys are not attacked by oil, chemicals, solvents, and moisture, which can improve the silicone rubber keys and keys used in various environments on the durability of the characters. The parylene film also improves the voltage breakdown resistance of the silicone rubber keys.

In addition, the parylene film can remove the viscosity of the silicone rubber, make the surface of the silicone rubber more lubricated, and change the feel of the silicone rubber keys. Due to its thin thickness, the parylene film is transparent or nearly transparent and does not affect the appearance and size of the keys.

2 Tire inner liner or inner tube

Butyl rubber is used to make inner tubes or tire inner linings due to its good air-tightness. Using rubber as an inner tube or inner liner will increase the weight of the tire and increase the rolling resistance of the tire.

Parylene film can be used as a barrier layer for inflatable products due to its good fluid barrier properties. The parylene film with a thickness of 0.5 μm to 100 μm can be applied on the inner surface of the inflatable article, on the interface layer of two layers, on the inner surface of the inner tube, on the outer surface, or the inner surface of the inner tube at the same time and outer surface to provide air tightness.

Using parylene film, the inner tube can be prepared with less or no butyl rubber with high rolling resistance, and other low-hysteresis rubber materials can be used to prevent the migration of inflation gas.

Maggie Nano Technology (Suzhou) Co., Ltd. provides customers with high-quality Parylene conformal coating services for supporting automated intelligent equipment. We are committed to manufacturing professional parylene conformal coating equipment. Parylene conformal coating equipment Model MQP-8001 is one of our products, you can click to view more details.

Related news of parylene

Examples of protective applications of parylene coatings

The application value of parylene ink and wash element clothing

Color fixation of parylene coating in ink element clothing

0 notes

Link

Parylene coatings offer outstanding uniform while ensuring your surface is free from defects and pinholes, unlike the thin coatings of one micron. Besides, these coatings come with a uniformly thick film, regardless of the surface's complexity. The parylene coatings processes are applied by vapor disposition into a vacuum chamber.

0 notes

Video

undefined

tumblr

We all know many unforgiving environments that can compromise your electronics products. Safeguarding and waterproofing against those environments is what we do. We will always support you, the manufacturer, every step of the way by implementing HZO's conformal PCB coatings into your manufacturing process to protect and help the best waterproof products you’ve ever created. HZO is at its core an engineering company, with parylene technology and custom solutions that keep these harmful environmental factors at bay.

1 note

·

View note

Photo

Parylene Market Research for 2017 Examined in New Report Summary Parylene is a common generic name for a unique series of polymers based on paraxylene. It is a polymer created from a chemical compound known as dimer, which is actually a powder.

#Parylene#parylene coating process#parylene coating services in india#parylene deposition system#Parylene forecast#Parylene growth#Parylene Market#Parylene price#Parylene share#Parylene size#Parylene trends#Parylene uses

0 notes

Text

Inkjet-printed Ultrathin Solar Cells

The rainbow-colored soap bubbles under the sun always paint a dreamy, unrealistic, and airy-fairy picture. Yet, the scientists from King Abdullah University of Science and Technology (KAUST), Saudi Arabia, have used these fragile surfaces to demonstrate their groundbreaking innovation. They have invented an ultrathin solar cell that is so light that it can sit on the soap bubble surface. Yes, for real.

Indium is a toxic and expensive metal, which is a necessary element to produce thin-film solar cells. Thin-film solar cells, or what we call the CIGS (copper indium gallium selenide) solar cells, are the third generation of photovoltaic cells. They have been proven to have high power generation efficiency of up to 20.3% with just a tiny cell. When the cells are put together as a module, the efficiency can still reach 14%. Yet, because of the high costs of the rare materials and complex production processes, scientists have been working hard to find alternatives to make highly-efficient-low-budget thin-film solar cells.

The researchers from KAUST made a breakthrough. They have developed a transparent conductive polymer called PEDOT: PSS. A layer of organic photovoltaic material is in the middle of the polymer. The solar cells can work indium-free and be inkjet-printed, while the structure is thin and light enough to be carried on soap bubble surfaces.

Inkjet printing is a science on its own. The scientists need to formulate functional inks for each layer of the solar cell architectures. They also need to overcome the intermolecular force within the cartridge and the ink to let the tiny nozzle eject the very fine ink droplets one by one before they go for the drying stage and other processes to finish the entire production.

These inkjet-printed ultrathin solar cells are coated with waterproof parylene, which can prevent damage from the weather. In the glass plate tests, the researchers found that the inkjet-printed solar cells’ light-electric power conversion efficiency is 4.73%, which is not high. However, the researchers believe that this new technology has its competitive advantages: with the support from computers, inkjet printing can diversify the design of solar cells because the inks can be printed on specific places. So, the ultrathin solar cells can flexibly be made or applied to various devices, skipping the molding process, which saves materials and costs.

The size of batteries is very important to some devices, such as miniaturized sensors, wearable electronics, electronic skins, sensors for flying devices, and biosensors. The toxic-free inkjet-printed solar cell, with its ultrathin and superlight structure, is the perfect power solution for the mentioned devices. Let’s hope scientists can further advance this technology, especially its power generation efficiency, to broaden its application.

(To read the article at SolarCare Programme’s website HERE)

可貼在肥皂泡上的超薄太陽能電池

在陽光底下泛出七彩炫光的肥皂泡,總會給人一種夢幻、虛浮、不切實際的感覺。但一班來自沙地阿拉伯阿卜杜拉國王科技大學(KAUST)的科學家,卻利用這些浮幻的肥皂泡,向我們確實地展示了他們的研究成果。他們研發了一種超薄的太陽能電池,材質又薄又輕,使其能黏附在肥皂泡的表面上,可謂給太陽能科技帶來了革新。

銦(Indium)是貴金屬,而且有毒,但在現有的薄膜太陽能技術中,卻是不能缺少的元素。銅銦鎵硒型(CIGS)是第三代太陽能電池的代名詞,效能極高,一塊細小面積的電池,光轉電效率已經達到20.3%,而模組的效率也達14%。可是,因原料稀有,再加上複雜的製作過程,這種電池的生產成本非常高。因此科學家們都在積極研發效率高、成本低的薄膜太陽能電池。

KAUST的研究團隊在這一範疇中得到了革命性的突破。他們研發出一種極為透明的導電聚合物PEDOT:PSS,這種聚合物中間夾了一層有機太陽能材料,不含任何銦元素,只需利用噴塗印刷(inkjet printing),就能製造出薄得能黏在肥皂泡表面上的超薄太陽能電池。

噴塗印刷並不是一門簡單的學問。要運用這技術製造超薄膜太陽能電池,科學家須特意為太陽能電池調配出具特殊功能的油墨(functional inks),更要克服墨盒和墨水之間的分子間作用力(intermolecular force),方能從極小的噴嘴中噴射出一滴滴油墨,然後才處理乾燥墨膜、成品等工序。

這種「噴塗式超薄膜太陽能電池」(inkjet-printed ultrathin solar cell)的外層塗有防水的聚對二甲苯(parylene),可避免太陽能電池因風雨而導致的耗損。在玻璃基板實際測試後,研究團隊發現其光轉電效率為 4.73%。雖然效率不高,但研究團隊認為,這種技術另有優勢:噴墨印刷透過電腦輔助,不但使太陽能板的設計更多樣化,更能將墨水準確地噴印於特定位置上,不用模具,就能製作出各式各樣的特殊元件,既節省原料、又能降低成本。

再者,噴塗式超薄膜太陽能電池不含有毒貴金屬銦,加上它極輕極薄,適合應用在發展受限於電池大小的設備上,例如小型感測器、穿戴式電子設備、電子皮膚、飛行器感測器、生物感測器等。希望在不久的將來,科學家能進一步提高噴塗式超薄膜太陽能電池的發電效率,進而擴大它的應用範圍。

#bilingual article#CCIL#SolarCare Programme#carboncare innolab#ultra thin solar cells#solar energy#soap bubbles#inkjet-printed ultrathin solar cells#hmremi

0 notes

Text

What is Parylene Coating and Do You Need It?

Parylene Coating is a highly effective protective coating used in various industries to ensure the longevity and durability of products. At Dawntechsb, we specialize in providing top-quality Parylene coating services to meet the unique needs of our clients. Whether you are looking to enhance the performance of electronic components or protect medical devices from harsh environments, polyethylene coating may be the solution you need. Contact us today to learn more about how Parylene Coating can benefit your products.

#parylene coating#parylene coating process#parylene coating manufacturer#parylene coating in malaysia

0 notes

Text

Black Neodymium Magnets

https://www.magnetic-holders.com/products/black-neodymium-magnets.html

Rare earth Nd-Fe-B permanent magnet material is a kind of high performance and strong magnetic material, which is one of the key materials for miniaturization and super miniaturization of micro motor. However, this kind of material is very unstable in the air, and the larger size rare earth neodymium magnet is usually protected by electroplating or epoxy electrophoretic paint.

Neodymium strong rare earth magnet with the coating is generally nickel, zinc, epoxy resin, etc. The color of NdFeB magnet surface will be different with different electroplating. The name of black neodymium(NdFeB) magnets comes from the coating of magnets. The surface of black rare earth neodymium(NdFeB) magnets are usually coated with epoxy. The epoxy coated rare earth neodymium magnets you get from Beilun Meank are with at least 3 layers(Nickel-Copper-Epoxy).

Two processes of rare earth neodymium magnets with epoxy coated

One of the production principles for neodymium rare earth magnet with the epoxy coating is electrophoresis, which usually adopts the method of hanging plating, so there will be two small spots on the surface of the magnet to see the color of the bottom layer.

Another way for epoxy coated neodymium(NdFeB) rare earth magnets is spraying, by using spraying to make black epoxy coated rare earth neodymium NdFeB magnets, the surface of rare earth NdFeB magnets can be fully coated, but the coating is easy to fall off.

All Available Surface Treatments for the Small Black Round Neodymium Magnets

Surface

Coating

Thickness (Microns)

Color

Resistance

Passivation

1

Silver Grey

Temporary Protection

Nickel

Ni+Ni

10-20

Bright Silver

Excellent Against Humidity

Ni+Cu+Ni

Good Against Salt Spray

Zinc

Zn

8-20

Bright Blue

Excellent Against Salt Spray

C-Zn

Shinny Color

Superior Against Humidity

Tin

Ni+Cu+Sn

15-20

Silver

Superior Against Humidity

Silver

Ni+Cu+Ag

10-20

Silver

Superior Against Humidity

Gold

Ni+Cu+Au

10-20

Gold

Temporary Protection

Copper

Ni+Cu

10-20

Gold

Excellent Against Humidity&Salt Spray

Epoxy

Epoxy

15-25

Black, Red, Grey

Excellent Against Humidity, Salt Spray, Superior Against Solvents, Gases, Fungi and Bacteria, FDA Approved

Ni+Cu+Epoxy

Excellent Against Humidity

Zn+Epoxy

Resistance

Parylene

Parylene

5-20

Grey

Excellent Against Humidity

Chemical

Ni

10-20

Silver Grey

Excellent Against Humidity

0 notes

Text

Examples of protective applications of parylene coatings

Compared with ordinary life clothing, the nature and characteristics of professional clothing are not universal in a certain industry. Every enterprise must have its professional clothing, and professional clothing is also required to be relatively durable. In large companies, the service life of general work clothes is very long, which can establish a corporate image for the enterprise for a long time, achieve repeated understanding, and deepen the degree of recognition. Economically, it is not practical to change clothes frequently, which requires work clothes' durability.

One of the parylene properties is protection. Parylene coating has a certain wear resistance on the surface of the fabric, so it is suitable for coating the part of work clothes, increasing the service life of the clothing, and reducing some economic costs for the company. burden. Parylene-coated clothing has a certain waterproof function. The service staff of the hotel must not only maintain the image of the company but also keep it clean at work. When serving guests, the clothes are often stained, so the clothing parts such as aprons are required to be waterproof. Features, improve its anti-fouling properties.

1 restaurant waiter's clothing

The starting point of the design is the farmer's characteristic restaurant clothing, which adopts the design of printed cloth and buckles to highlight the friendly and natural image of the farmer girl, which is in line with the professional image of the waiter's enthusiasm and generosity. The overall style of the clothing adopts a split collocation, which alternately combines blueprinting and white printing so that the professional wear remains elegant and solemn without losing dullness and rigidity.

The work status of the waiter is matched with the design of the apron. The apron is combined with the parylene coating, and the parylene coating process is used to make it waterproof, dirt-resistant, and wear-resistant so that the service personnel can serve enthusiastically. At the same time, it can maintain a clean and tidy professional image. Don't worry about getting your clothes dirty when you clean the dishes, so you can provide the best service for your guests.

Parylene coating can be applied to the fabric partially or completely, depending on the needs of the specific occupation. Here is an example to illustrate the specific application of parylene coating on tooling, especially the one-piece suit as an example.

2 Professional tooling

The design style is a one-piece suit, the fabric is made of pure cotton fabric, which is composed of red and gray. The neckline and cuffs of the overalls should be designed to be tight to prevent exposure to various parts of the body during activities. At the same time, the overalls are also required to have better air permeability, which is convenient for the operator to move freely. The overalls are specially designed for specific work needs. Clothing, this kind of clothing generally requires a lot of bending and squatting movements, such as lathe repairers, due to the need for waist movement, the design of the back waist should be folded, which is convenient for bending during work.

The specific application of Parylene coating can be determined according to occupational needs. Take mechanic clothing as an example. Generally, the working time under the car is longer, and there are many movements of squatting and digging. Therefore, Parylene is coated on the knees and elbows. To increase the service life of the clothing, the thickness of the coating can be adjusted according to the needs without affecting the texture of the coated clothing.

Clothing fabric is an indispensable part of clothing design. Only through the material carrier of clothing fabric can clothing design convey design ideas and be accepted and appreciated by people. The continuous innovation and breakthrough of clothing fabrics create conditions for the diversification and individualization of clothing design.

Maggie Nano Technology (Suzhou) Co., Ltd. provides customers with high-quality Parylene coating services for supporting automated intelligent equipment. We are committed to manufacturing professional parylene conformal coating equipment. Parylene conformal coating equipment Model MQP-8001 is one of our products, you can click to view more details.

Equipment Model

Main Parameter

8001

Voltage

3 phases 380V 50Hz

Power

10KW

Overall Dimensions

3000*1800*1500mm

Cavity Size

Ø750*900mm

If you are interested in our products, please get in touch with us as soon as possible.

Related news of parylene coating

Operating Procedures for Parylene Coating Equipment for sale

Applicability of properties of parylene coated apparel fabrics

0 notes

Link

The chemicals coatings suppliers are specialized in eco-friendly nano-coatings and parylene coatings. The parylene coating process can address the limitations of the conventional coating process as it demonstrates extremely superior features. You can contact the parylene coating suppliers to select a parylene coating of your choice.

0 notes

Text

What is the current status of Electronic Protection Device Coating Market?

Gadgets – they have managed to install themselves in our lives and seem to have stuck on us like magnets. This dominant species emerging in today’s century has drastically changed our lives. Humans invented gadgets for ease of living and it’s up to mankind to care for these devices. A profound sector that has taken up the responsibility for protecting gadgets is the electronic protection device coating industry. This sector safeguards the crucial components of the devices by using various materials.

The electronic protection device coating sector helps in shielding the devices from contaminants that can shorten the device’s life. This sector uses materials like organic and inorganic compounds, polymers and metals for coating the devices. The usage of material depends on the function and application of the devices. Coatings are used for better functioning of electrical, magnetic, optic, mechanical and thermal factors. On the other hand, coatings also provide aid in circuit board manufacturing, protection and decoration of the devices.

Impact of Covid-19 on the Electronic Protection Device Coating Sector:

The Covid-19 pandemic has led to the shutdown of factories that manufactured electronic devices, thus, resulting in the downfall of the electronic protection device coating sector in the year 2020. However, this sector still holds a grip over healthcare and remote sensing industries during the pandemic. The electronic protection device coating sector continues to serve the healthcare and remote sensing industries as ample of gadgets are used there.

The post pandemic session will be a boon for the electronic protection device coating sector as the demand will enhance in the automotive industry. According to a report published by Research Dive, the electronic protection device coating sector will witness a rise in CAGR by 4.3 % by 2026.

Access Full brochure ( Imapct of COVID-19) Here @ https://www.researchdive.com/download-sample/205

Preferred Solutions by the Electronic Protection Coating Sector:

The electronic protection device coating sector provides a vast array of options for safeguarding the devices from contaminants. A few noteworthy solutions are mentioned below:

Acrylic:

This material is fungus proof and dries in 30 minutes at room temperature. Acrylic is feasible for rapid production of devices; however, it cannot survive temperatures above 125?C. This eliminates the possibility of using acrylic for excessive heat emitting devices.

Epoxy:

The coating strength of epoxy is the highest and has the potential to resist abrasions, vibrations, chemical incursions, and humidity. This material shrinks during polymerization process and possesses low stress resistance during extreme temperatures. Furthermore, it is difficult to repair and rework epoxy compound.

Silicone:

This material has the ability to tolerate temperature till 200?C, thus, it is used in automobile industry. Silicone can resist corrosion and humidity; however, it is powerless against abrasions and solvents.

Urethane:

This material supports Nano miniaturization by providing insulation to the electronic signals situated close to the printed circuit board (PCB). Urethane has longer dielectric functioning and resists solvents, humidity and moisture. However, urethane is difficult to remove and cannot be used in high temperature and vibration conditions.

Chemical Vapor Deposition (CVD) Derived Parylene:

This material provides continuous, consistent and pin-hole free conformal films. The gaseous Parylene can easily permeate through ceramic, resins, plastics, paper, metal, glass and ferrite. The CVD Parylene coating can blend in any geometrical shapes like crevices, corners, edges, and internal spaces. This durable micro-thin film has high dielectric strength and chemical inertness. The CVD Parylene is compatible with various devices; however, it is an expensive material.

Ultra Violet Coating:

This type of coating protects the devices from the harmful UV rays. The coating guarantees higher curing time when exposed to UV light. One of the UV lights called the UV Florescence light glows in the dark, thus, simplifying the verification and inspection of the material used.

Brush Coating:

This is a manual process which is used for small scale products. The accuracy, precision and consistency of the protective coating depend on the person’s skill and practice.

Dip Coating:

The printed circuit board (PCB) is dipped via machine, thus, coating the entire surface. This technique is unsuitable for components that lie in close proximity on the PCB because of low viscous flow of the coating.

Conformal Coating

These are thin polymeric films that protect the solder joints, leads of electronic components, and metallized areas on PCB from corrosion. The conformal coatings protect the devices from pollution, water, moisture, UV light, chemicals, and high temperature. The hydrophobic properties of the conformal coatings add on to its versatile nature. This type of coating is used in aerospace, automotive, consumer products, LED industries, marine, military, and energy sectors.

The Road Ahead:

The electronic protection device coating sector ensures the longevity of the devices, thus, making the devices durable, reliable and consumer friendly. The various methods, materials, and techniques used to safeguard the gadgets have enhanced the significance of electronic protection device coating sector.

0 notes

Text

What Is Parylene Used For?

What Is Parylene Used For?

The poly para xylylene, commonly known as parylene, refers to specific polymers belonging to a unique chemical family used to provide protective coatings. The subject undergoes a robust coating process to deposit the parylene through vacuum deposition.

This coating type provides excellent protection as it is chemically inert and physically stable when used at the appropriate temperature. Here,…

View On WordPress

0 notes