#pneumatic conveyor system

Text

Understanding the Benefits of a Pneumatic Conveyor System

A pneumatic conveyor system is an advanced material handling solution that uses air pressure or vacuum to transport bulk materials through a series of pipelines. This system is ideal for industries that require the efficient and safe movement of fine powders, granules, or pellets over long distances or through complex layouts.

One of the key advantages of a pneumatic conveyor system is its ability to minimize product contamination. Since the materials are enclosed within the pipeline, they are protected from external contaminants, ensuring a higher level of purity and quality. Additionally, this system reduces the risk of spillage and dust emissions, making it a cleaner and more environmentally friendly option compared to traditional mechanical conveyors.

Another benefit is the flexibility in routing. Pneumatic conveyor systems can be easily adapted to fit existing plant layouts, allowing for seamless integration into production processes. This adaptability is particularly useful in industries such as food processing, pharmaceuticals, and chemical manufacturing, where space and cleanliness are critical.

Noggrann Australia specializes in designing and implementing customized pneumatic conveyor systems that meet the unique needs of your operation. Whether you’re looking to improve efficiency, reduce maintenance costs, or enhance safety, our solutions are engineered to deliver exceptional performance. Trust Noggrann Australia to provide you with the right pneumatic conveyor system to optimize your material handling processes.

0 notes

Text

Pneumatic conveyor | Pneumatic conveyor manufacturer | Pneumatic conveying system | pneumatic material handling | bulk material handling

youtube

Enquiry : [email protected]

Contact : 95851 31112

Website: https://altomech.com/pneumatic-conveying-system.php

#pneumatic conveyor#pneumatic conveyor manufacturer#bulk material handling#pneumatic conveying system#pneumatic conveyor system#pneumatic conveying system manufacturers#pneumatic conveying companies#pneumatic powder transfer system#vacuum pneumatic conveying system#pneumatic conveyor systems#pneumatic conveyors#pneumatic grain conveying systems#manufacturer#altomech#Youtube

0 notes

Text

Navigating the Essentials: Equipment Used in this pneumatic conveying system.

Pneumatic conveying equipment governs the material transport area in industry and serves as the technology of picking up materials from a point over varied distances and then transferring them up to certain locations. A number of special equipment types are indispensable to the efficiency of the system which performs the main functions of providing the safety of both the materials and the workers via the smooth, clean and secured flow of materials. Pneumatic conveying is a prevalent industrial process employed to transport materials over long distances. This blog specifically focuses on the types of equipment which are vital in these pneumatic conveying system and how these equipment function, the benefits these equipment bring to the table and their areas of application.

Bag Dump / Unloading Station

Functionality

A manual dumping station is the name given to the unloading stations for bulk materials, and they can be considered as the gateway to the pneumatic conveying system. They have been engineered in a bid to help in emptying bags, sacks or other containers containing products of respiratory hazards or dust forms for the operator and for generation of dust.

Applications and Benefits

Suitable to use when entities move bulk items in the bagged form, these stations often come with a dust collection system as an additional feature to boost environmental compliance and ensure safe work. Their design can be altered to conquer different materials that can give them opportunity for the use in industries such as pharmaceuticals, food and chemicals.

Roots Blower / Centrifugal Fan

Functionality

Not only are the roots blowers and centrifugal fans, but also they are constructive in bringing the certain needed air volume for pneumatic conveying. A roots blower is an option in the industrial fields due to its ability to supply a consistent volume of air with variable pressures, while a centrifugal fan is mainly intended for those applications which require a lot of air at low pressures.

Applications and Benefits

Such air movers are then selected among those that are suitable to the particular requirements of the specific system of pneumatic transportation—high-velocity air-flow is the main thing to be taken into account for dilute phase systems (the centrifugal fans are preferable), and the ability to maintain consistent pressure over longer distances is the key for the dense phase systems (roots blowers are more preferable in this case).

RAL(Rotary AirLock Valve), / Venturi Feeder

Functionality

Conveyor systems employ RALs and Venturi feeders to introduce materials to the above lines. Different types of RALs have their own characteristics, enabling them to maintain air pressure and allowing bulk materials to get into the system. Meanwhile, Venturi feeders are distinct from RALs in that materials are pumped into the air stream via the Venturi effect without any mechanical parts.

Applications and Benefits

Flexibility of RALs is in their function than to handle an array of materials together with their working environments. First, Venturi feeders, being more keeping, have fewer failures and necessity of repairs than the others and that proves that they are quite suitable for abrasive materials and those principally composed of fine particulates. These systems, though different, are of equal importance since they guarantee a flow which is not jerky and always accurate.

Pressure Vessel & Control Instruments

Functionality

As temporary storage receptacles, pressure vessels in a pneumatic conveying system inject materials to which the pressure is applied and then fine convection occurs towards the removing point. Certain security instruments, such as pressure gauges, flow meters, and sensors ensure system parameters control and optimal performance by providing real-time monitoring and regulation.

Applications and Benefits

These are the most important matters for forming the "dense phase", which has a close relationship with a proper monitoring of material flow and system pressure. The complex controllers supported by this kind of workflows is a tool for automation which, in turn, optimizes the efficiency and lowers the demand for human supervision.

Product Separator / Vent Filter / Dust Collector

Functionality

Post transportation, the product separators, which are the vent filters, and dust collectors, are included in the systems. These accessories purify the conveyed air flow steam and reduce dust emissions to the minimum. The cyclone separators, the bag filters, and the cartridge filters are examples of the predominantly used types of the filters.

Applications and Benefits

These systems are broadly required for ensuring the best air condition and the recycling of the invaluable items around us. They are formulated to comply with the strict environmental regulations, this not only makes delivery to be smooth but are environmentally friendly and provide safe working conditions for people.

Expansion Sections

For each of the following components, you would expand similarly, covering their functions, applications, benefits, and any relevant technical considerations:For each of the following components, you would expand similarly, covering their functions, applications, benefits, and any relevant technical considerations:

Storage Silos/Hoppers: Talk on their tasks such as storing of materials in bulk prior to or after conveying them, various factors to be discovered and incorporated to suit distinct types of materials and methods of integrating them with the conveyor system.

Special Valves for Diverting the Flow/Metering: Investigate the variety of valves implemented in pneumatic setups consisting of diverters to steer flow and metering valves to adjust the rate of the material movement including analysis of their flexibility and efficiency.

Control Panel: Expound on the central nervous system of the system, revealing the control panels and the systems monitoring, controlling and safeguarding capability within the process.

Piping with Special Cross-Section Bends: Home in on the key to pipe design, that is, the durable material and the bends which reduce the wear and impact on the system while maintaining the optimal flow of materials.

Gas Cooling Heat Exchanger for Closed Loop Systems: Explore the function of heat exchangers as the primary temperature regulators in pneumatic systems, noting their relevance to materials that get easily affected when subjected to high temperatures or applications where the temperature of the materials determines the material properties.

Conclusion

Restating, now shows why knowing about each part within a pneumatic conveying system and what it does is essential. The rightness of the system's selecting and incorporation of the elements will affect its both efficiency and reliability and also environment. These concerns will be dealt with in the standards.

#pneumatic conveying#pneumatic conveyor system#pneumatic conveying system#pneumatic conveying systems#conveying system

0 notes

Text

Discover essential powder handling solutions tailored for the food industry. This guide provides insights into the best practices, equipment, and technologies designed to optimise powder processing, improve efficiency, and ensure product quality. Explore the latest innovations and find out how to enhance your food manufacturing operations.

0 notes

Text

Bulk Material Handling Equipment

Unlock the potential of seamless bulk material handling with Sodimate's cutting-edge equipment. Our comprehensive systems streamline the storage, release, and transportation processes, ensuring efficiency and reliability for projects of any scale. Reach out to us today at 773.665.8800 to discover how our innovative solutions can elevate your operations.

#bulk material handling#bulk handling#sodimate#screw conveyor#feeder hopper#screw feeder#pneumatic conveying systems

0 notes

Text

Grain and Malt Handling for Brewers and Distillers

Brewing and distilling is a realm that boast of all of these- Art, Science, and a little bit of fascination. Therefore, the voyage from barley to bottle is wonderfully captivating. At the heart of this process lies a critical step that can significantly influence the flavor, quality, and efficiency of production: exactly the kind of thing their new grain and malt handling team can handle. Grain and malt handling might seem like a trivial component of brewing and distilling processes, but it is of utmost importance to both master brewers and the budding distiller. The next workshop will center on this essential aspect of making good craft beer and distilling spirits.

The Importance of Proper Grain and Malt Handling

Grain and its feedstocks (malt) are the foundation of brewing and distilling, giving the beer and spirit the needed sugars which fermentation utilizes. On the other hand, the way pieces are being dealt with from storage to milling is what matters as much as the end result in mind. Deliberate management of products in line with their quality and flavor guarantees minimized wastes and optimal level of efficiency in addition to consistency. The consequences of ineffective handling practices go beyond the sole contamination, as inconsistent grind sizes arise, leading to unanticipated end-products.

Storage Solutions

First of all we deal with storage when the right way grain and malt are handled is considered. Grains and malts cannot be generally stored in a place without temperature and moisture control otherwise they will spoil and get infested with pests. For the larger-scale industries, silos and grain bins would be a choice means of storing, while the smaller breweries and distilleries may avail their bottling and sealed containers or even separate storage rooms. Regardless of the size of the operation, the goal remains the same: the integrity of the grains and malts is maintained so that they stay fresh and are ready to use when needed.

The Milling Process

This process is called milling and it is performed in order to force grains down into particular particle sizes, for the purpose of mashing. In this process, the grains are broken open to let the trapped starch out while the grains don't turn into flour. Grind-size consistency is of paramount importance; too coarse, you won’t extract the required sugar particles while too fine, a blockage of your equipment is a possible effect and unneeded sugars are extracted.

Conveyance Systems

After that, we need to carry the sawed grains to mashing tun. It is at this point we see why conveyance systems are useful. The choices vary from augers or elevators to pneumatic systems, where selection is made on the basis of benefits and disadvantages each of them have. This type is economical and is also easily operated for this reason, but it should be properly arranged if it is to successfully be used to treat grain crops. In the case of pneumatic systems, on the contrary, beans are not hurt and arrange shafts more flexibly; but they are also very costly.

As a matter of fact, current system selection should take into account the damage to grains' integrity and efficiency of the production process.

Automation and Control

Through technologically advanced equipment, like automation and control systems for grain and malt handling, technology has developed really sophisticated mechanisms used to handle these grains.

This set-up of systems, which covers everything from storage conditions to milling settings and conveyance speeds, are designed to increase uniformity and through-put across the entire process. Automation can lower the labor costs and lessen the chance of human mistake drastically that can be an important factor for a brewery or a distillery to make a decision to invest in such systems regardless their size.

The Impact on Quality and Flavor

Precise actions taken in regards to grains and malts determine the quality and taste of the last barley batch. Sprued milled grain leads to the mash fermentation process, which then results in the more accurate mash efficiency. Thus, this mils the fermentation process. In addition, the byproduct of this grain distillation process is lightened to prevent extracting those undesirable tastes, such as tannins, which are then after treated in a more favorable manner.

Conclusion

Grain and malting process would make the brewing and distilling steps a bit unattractive, but the process itself anyway is the most significant component of them. Investing into those sectors which include smart storage, manufacturing, conveyance, and automation, which are very beneficial to brewers and distillers, can help enhance the quality, consistency, and efficiency in the production of their products.

#pneumatic conveyor process#pneumatic conveying#pneumatic conveying system#pneumatic conveying systems

0 notes

Text

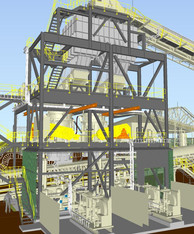

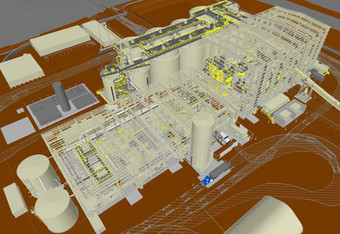

Transforming the Landscape of Bulk Material Management through Structural and Mechanical Design

Across the vast expanse of industrial operations, where bulk material management is paramount, Little P.Eng. Engineering has etched a significant mark. The firm's reputation in structural and mechanical design extends beyond just equipment, touching several critical aspects of material management. This article will delve into how Little P.Eng. Engineering is transforming four pivotal sectors: Material Handling Facilities & Building, Bulk Material Transport, Bulk Material Treatment, and Bulk Material Transfer.

Little P.Eng. Engineering is an American / Canadian company that provides economical bulk material handling engineering services that are designed to meet the specific needs of our customers. We have a long history of partnering with supervisors, engineers, planners, and vendors, across a wide variety of industries to provide bulk material handling engineering solutions and systems that improve safety and productivity. Whether you need help designing, installing or maintaining any aspect of your bulk material system, we have the skills and experience to meet your needs.

Our bulk material handling engineering specialists can re-engineer and upgrade existing systems while providing customer solutions and processes. We work with customers through every part of the engineering process to create a one-stop destination for all their needs.

We also work to provide superior customer service that extends well beyond the initial installation or execution of a solution. Our customers can contact us and receive immediate assistance whenever needed for continued support that keeps businesses up and running without having to worry about delays or downtime.

1. Material Handling Facilities & Building

Material handling facilities are the heartbeats of many industries. From mining to agriculture and manufacturing, they facilitate the smooth and efficient movement of bulk materials.

Understanding Infrastructure Needs: Little P.Eng. Engineering begins its design process with a comprehensive study of the client's requirements. The aim is to understand the volume of material to be handled, the rate of throughput, and the kind of materials involved.

Structural Integrity: Buildings designed for material handling need robust foundations. Little P.Eng. ensures that every facility they design can withstand the tremendous loads and stresses associated with bulk material handling.

Optimized Workflow Design: Beyond just structural integrity, Little P.Eng. focuses on creating a streamlined workflow within these buildings. Through the strategic placement of equipment, chutes, conveyors, and storage areas, they ensure that materials move seamlessly, minimizing disruptions and maximizing efficiency.

Innovation at the Forefront: Little P.Eng. is known for incorporating innovative solutions like automated sorting systems, advanced ventilation systems, and sustainable energy solutions, making these facilities both state-of-the-art and environmentally responsible.

2. Bulk Material Transport

Once materials are sourced and sorted, they need to be transported. Little P.Eng. Engineering has a vast portfolio of solutions tailored to this very requirement.

Vehicle Design: Depending on the type of material, the firm designs transport vehicles, whether trucks, railcars, or even conveyor systems. Their designs emphasize both capacity and safety, ensuring that large volumes can be transported without risks.

Infrastructure Design: Little P.Eng. also specializes in designing transport-related infrastructure. This includes everything from loading and unloading docks to advanced conveyor belt systems and even pneumatic transport solutions.

Addressing Challenges: Transporting bulk material is fraught with challenges like spillage, degradation, and contamination. Little P.Eng.'s designs account for these challenges, providing solutions such as sealed transport containers and dust suppression systems.

3. Bulk Material Treatment

Treatment of bulk materials, whether it's refining, purification, or simply grading, is a complex process. Little P.Eng.'s role in this domain is critical.

Treatment Facility Design: Little P.Eng. engineers facilities where bulk materials undergo various treatment processes. Their designs accommodate equipment like crushers, separators, graders, and more, ensuring they operate at optimal capacities.

Safety and Compliance: Treatment processes can sometimes involve chemicals or generate waste. Little P.Eng. prioritizes safety and regulatory compliance, designing facilities that minimize environmental impact and risks to workers.

Energy Efficiency: Many treatment processes are energy-intensive. Recognizing this, Little P.Eng. incorporates energy-saving solutions, from efficient machinery layouts to the use of alternative energy sources, thus driving down operational costs.

4. Bulk Material Transfer

Transferring bulk materials from one point to another, or even from one mode of transport to another, is a task that requires precision and speed.

Transfer Point Design: Little P.Eng. is adept at creating transfer points that minimize material loss. Whether it's transferring grain from a truck to a silo or coal from a railcar to a ship, their designs ensure smooth transitions.

Material Integrity: When transferring materials, there's a risk of contamination or degradation. Little P.Eng. addresses this by designing enclosed transfer systems or integrating rapid sealing mechanisms.

Automation and Technology: In an age of technology, Little P.Eng. leverages advanced automation systems in their transfer point designs. This not only speeds up the transfer process but also reduces human errors.

Little P.Eng.'s Journey to Excellence

At its core, Little P.Eng. Engineering’s success can be attributed to its comprehensive approach. Instead of viewing these four sectors in isolation, they consider them parts of a holistic system. Their designs, thus, seamlessly integrate across the spectrum, from handling facilities to transfer points.

Client-Centric Approach

Little P.Eng. has always prioritized the unique requirements of its clients. They understand that every industry and even individual businesses within those industries can have varying needs. This client-centric approach has resulted in solutions that aren't just efficient but are also tailored to the specific challenges and objectives of their clientele.

Embracing Future Challenges

As the world continues to evolve, so do the challenges associated with bulk material management. Little P.Eng. Engineering, with its commitment to research, innovation, and adaptability, is well-equipped to tackle these challenges head-on.

With a growing demand for efficiency, safety, and sustainability, industries will find in Little P.Eng. a partner that's not just equipped to meet these demands but one that's committed to exceeding expectations.

In the world of bulk material management, Little P.Eng. Engineering stands tall, not just as a solution provider but as an innovator and trailblazer. Through their expertise in structural and mechanical design across the four critical sectors detailed in this article, they're not just shaping industries but also the very future of bulk material management.

Little P.Eng. Engineering’s Bulk Material Handling Team is a dynamic and diverse group with experience in conveying systems – mechanical and pneumatic; chutes transfers, dust control & collection, etc. Our experience in material handling for the power and manufacturing industries will provide rapid development of realistic concepts, and reliable designs which optimize operating and maintenance cost for your project. Our goal will be to not only deliver successful design to the field but to provide you with the information you need to make informed decisions to meet your objectives.

Industries served through our Bulk Material Handling Engineering Services

Grains

Mining

Mills

Metals

Manufacturing

Maintenance

Fabrication

Agriculture

Packaging

Safety

Fire & Explosion

Ship/Barge Loading & Unloading

Steel and Metals Industry

Energy and Power Generation Industry

Water and Wastewater Industry

Oil & Gas Industry

Chemicals and Plastics Industry

Pulp & Paper Industry

Facility Services

Residential Buildings Sector

Hospitality and Hotel Sector

Commercial Buildings Sectors

Sports and Stadia Buildings Sector

Education Buildings Sector

Government Buildings Sector

Hospitals Engineering Services

Biotech / Pharmaceutical – Engineering Services

Food & Beverage – Engineering Services

We offer the following Engineering Services within our Bulk Material Handling Engineering Services :

Discrete Element Modeling (DEM)

Calculation based modeling

Allows for visualizing results

Particle velocity

Forces (shear and normal) and moments (bending and torsional)

Acceleration and material scatter

More than just flow simulation of bulk materials

wear Patterns

Mixing

Center loading

DEM Benefits

Reduced Dust Levels

Reduced Noise

Reduced Chute Plugging

Better Conveyor Tracking (Center Loading)

Reduced Belt Cover Wear

Reduced Chute Wear

Reduced Equipment Wear

Structural Engineering Services

Foundation Design

Concrete Structure Design

Steel Structure Design

Piping Engineering Services

Bulk material handling engineering specifically focuses on the design, processing, and transportation of bulk materials, which can include items such as ores, coal, minerals, and grains, among others. These materials often present unique challenges due to their bulk nature, including issues related to flowability, abrasiveness, corrosiveness, weight, and other specific characteristics. Here are the various aspects of bulk material handling engineering services:

Storage Solutions:

Design and layout of silos, bins, and stockpiles

Assessment of material flow properties to reduce issues like bridging or rat-holing

Conveyor Systems:

Design and optimization of belt, screw, chain, and pneumatic conveyors

Selection of appropriate conveyor belts, idlers, and drives

Loading and Unloading Systems:

Railcar and truck loading/unloading facilities

Ship and barge loading/unloading equipment

Reclaiming Systems:

Design of stacker-reclaimers, bucket wheel reclaimers, and scraper reclaimers

Size Reduction Equipment:

Crushers, grinders, and milling equipment

Sizers and chutes to manage particle sizes

Screening and Sorting:

Vibrating screens, trommels, and sorters

Density separation using jigs or cyclones

Feeding and Metering Equipment:

Feeders for accurate and controlled material flow

Rotary valves, weigh feeders, and volumetric feeders

Material Transfer:

Chutes, hoppers, and gates

Transfer tower and junction house design

Dust Control and Suppression:

Dust collection and filtration systems

Wet suppression and foam suppression systems

Safety and Environmental Considerations:

Explosion and fire protection in dusty environments

Erosion control and spill prevention

Flow Aids and Devices:

Vibrators and air cannons to aid material flow

Flow liners and internal coatings

Bulk Material Testing:

Evaluating flowability, abrasiveness, and other material properties

Moisture content and material density testing

Rail and Marine Infrastructure:

Rail siding design and layout

Port and harbor infrastructure for bulk material export/import

Automation and Controls:

Automated monitoring of material levels in bins and silos

Control systems for conveyor speed, material flow, and routing

Maintenance and Wear Protection:

Wear liners and abrasion-resistant materials

Maintenance strategies and schedules

Bulk Material Transport:

Pipeline transport for slurry and other bulk fluids

Pneumatic transport systems for powders and granules

Economic Analysis:

Cost estimation for bulk material handling projects

Return on investment (ROI) calculations

Regulatory Compliance and Standards:

Ensuring designs meet relevant industry standards

Adherence to safety and environmental regulations

Continuous Improvement and Upgrades:

Evaluation of existing systems for performance enhancement

Retrofitting and upgrading older infrastructure

Consultation and Advisory Services:

Providing expertise on specific bulk material challenges

Assisting with vendor and equipment selection

Given the unique nature and challenges of handling bulk materials, these services are essential to ensure efficient, safe, and economical processing, transportation, and storage. Properly designed and managed systems reduce product loss, minimize environmental impacts, and ensure safety while optimizing costs.

Tags:

Little P.Eng. Engineering

Structural design

Compliance

Mechanical design

Energy efficiency

Single-boom spreaders

Bulk material transfer

Bulk material transport

Client-centric approach

Environmental impact

Material handling

Treatment facilities

Conveyor systems

Infrastructure design

Pneumatic transport

Refining

Material grading

Transfer points

Dust suppression

Material contamination

Bulk material degradation

Silo design

Loading docks

Workflow optimization

Advanced ventilation systems

Risk assessment

Sustainable engineering

Material integrity

Client testimonials

Automation in material handling

Bulk Material Handling & Processing

Engineering Services

Structural Engineering Consultancy

Located in Calgary, Alberta; Vancouver, BC; Toronto, Ontario; Edmonton, Alberta; Houston Texas; Torrance, California; El Segundo, CA; Manhattan Beach, CA; Concord, CA; We offer our engineering consultancy services across Canada and United States. Meena Rezkallah.

#•#Little P.Eng. Engineering#Structural design#Compliance#Mechanical design#Energy efficiency#Single-boom spreaders#Bulk material transfer#Bulk material transport#Client-centric approach#Environmental impact#Material handling#Treatment facilities#Conveyor systems#Infrastructure design#Pneumatic transport#Refining#Material grading#Transfer points#Dust suppression#Material contamination#Bulk material degradation#Silo design#Loading docks#Workflow optimization#Advanced ventilation systems#Risk assessment#Sustainable engineering#Material integrity#Client testimonials

0 notes

Text

Pneumatic conveyor system Manufacturers

Pneumatic conveyor system Manufacturers

A pneumatic conveyor is a system used to transport materials or objects within a facility or production environment using compressed air or gas as the conveying medium. Instead of using belts, chains, or other mechanical means, pneumatic conveyors rely on air pressure differentials to move materials through a pipeline or ductwork.

There are several types of pneumatic conveyors, including:

Pressure or Dense Phase Pneumatic Conveyors: In this type, materials are conveyed at higher pressures and lower velocities, typically in a batch-wise manner. The material is tightly packed and moves in a slug-like motion through the pipeline.

Vacuum or Dilute Phase Pneumatic Conveyors: These operate at lower pressures and higher velocities compared to dense phase conveyors. They use a vacuum created by a blower or fan to pull materials through the pipeline. Materials are usually conveyed in a dilute phase, meaning they are more spread out within the conveying airstream.

Combination Systems: Some systems combine elements of both pressure and vacuum conveyance, depending on the specific requirements of the application.

Pneumatic conveyors are commonly used in industries such as food processing, pharmaceuticals, chemicals, plastics, and manufacturing, where there is a need to transport materials efficiently and hygienically. They offer advantages such as gentle handling of materials, flexibility in routing, and the ability to convey materials over long distances and around obstacles.

However, pneumatic conveyors also have limitations, including higher energy consumption compared to mechanical conveyors and limitations on the types of materials that can be effectively conveyed. Additionally, proper system design and maintenance are crucial to ensure efficient operation and prevent issues such as material degradation or blockages within the pipeline.

Visit :

As one of the most sought-after pneumatic conveyor system manufacturers, we take great pride in our achievement and also remain humbled by the confidence our customers have bestowed upon us over the years

0 notes

Text

Air conveyor system | EXAIR.com

Discover EXAIR, the leading provider of air conveyor systems that redefine material handling. With minimal compressed air, they transform ordinary pipes, hoses, or tubes into long-distance conveyors. Perfect for hopper loading, trim removal, and more. Choose from aluminium or stainless steel for hygienic applications.

0 notes

Text

Ghee Filling Machine Servo Based

Company Overview:

Shiv Shakti Machtech is based in Ahmedabad and specializes in the Ghee Filling Machine Servo Based in Ahmedabad, Gujarat, India.

A ghee filling machine with servo-based technology is a specialized equipment designed to accurately fill containers with ghee (clarified butter) using servo motors for precise control over the filling process.

Specifications:

Brand: Shiv Shakti Machtech

Conveyor Height: 850mm

Conveyor Length: 6 Feet

Model Number: SSM-SF-100

Number of Filling Stations: 4 Nos

Overhead Tank Capacity: Approx. 60 liters

Warranty: 1 year

Country of Origin: Made in India

Nozzle Type: Pneumatic Shut-off Nozzle

Driven Type: Electric

Capacity: 40 BPM

Operation:

Containers loaded onto conveyor system, which moves them to filling station.

Servo motor controls dispensing of ghee into containers for uniform filling.

PLC system allows parameter setting and adjustment via HMI.

Safety features ensure safe operation, including emergency stop buttons and overload protection.

Maintenance simplified with accessible components and easy cleaning, minimizing downtime.

Application:

The servo-based ghee filling machine caters to precise filling needs in dairy and food processing industries.

Ideal for filling ghee into bottles, jars, and cans.

Suitable for small-scale operations and large industrial setups.

Can fill other viscous products, enhancing production line flexibility.

Shiv Shakti Machtech is Ghee Filling Machine Servo Based in Ahmedabad, Gujarat, India Including

Kathwada, Vadodara, Changodar, Gota, Naroda, Nikol, Mehsana, Palanpur, Deesa, Patan, Vapi,

Surendranagar, Bhavnagar, Jamnagar, Junagadh, Rajkot, Amreli, Mahuva, Surat, Navsari, Valsad,

Silvassa, Porbandar, Mumbai, Vasai, Andheri, Dadar, Maharashtra, Aurangabad, Kolhapur, Pune,

Rajasthan, Jaipur, Udaipur, Kota, Bharatpur, Ankleshwar, Bharuch, Ajmer, Delhi, Noida, Baddi, Solan,

Himachal Pradesh, Una, Jammu Kashmir, Haryana, Hisar, Gurgaon, Gurugram, Madhya Pradesh,

Indore, Bhopal, Ratlam, Jabalpur, Satna, New Delhi, Kolkata, West Bengal, Assam, Asansol, Siliguri,

Durgapur, Bhubaneswar, Odisha, Brahmapur, Puri, Goa, Amaravati, Andhra Pradesh, Visakhapatna,

Hyderabad, Guntur, Chittoor, Kurnool, Vizianagaram, Srikakulam, Karimnagar, Ramagundam, Suryapet,

Telangana, Medak, Bengaluru, Bangalore, Mangaluru, Hubballi, Vijayapura, Davanagere, Kalaburagi,

Chitradurga, Ballari, Kolar, Chennai, Coimbatore, Madurai, Tiruchirapalli, Tiruppur, Salem, Erode,

Tirunelveli, Tamilnadu, Kerala, Kochi, Thiruvananthapuram, Kozhikode, Thrissur, Kollam, Alappuzha,

Kottayam, Kannur, Malappuram, Bharatpur, Jodhpur, Bikaner, Alwar, Bhilwara, Nagpur, Amravati, Solapur,

Malegaon, Navi Mumbai, Thane, Wardha, Vasai-Virar, Gondia, Hinganghat, Barshi, Ulhasnagar, Nandurbar,

Bhusawal, Pimpri-Chinchwad, Kalyan, Satara, Yamuna Nagar, Chhachhrauli.

Read the full article

#Achalpur#Ahmedabad#Ahmednagar#Ajmer#Akola#Alappuzha#Alwar#Amaravati#Amravati#Amreli#Anantapur#Andheri#AndhraPradesh#Ankleshwar#Asansol#Assam#Aurangabad#Baddi#Ballari#Bangalore#Barshi#Bengaluru#Bharatpur#Bharuch#Bhavnagar#Bhilwara#Bhiwandi#Bhopal#Bhubaneswar#Bhusawal

2 notes

·

View notes

Text

0 notes

Text

Reliable Pneumatic Conveyor System by Noggrann Australia

Optimize your material handling with Noggrann Australia pneumatic conveyor system. Our reliable systems ensure efficient transport of bulk materials with minimal maintenance. Ideal for various industries, our solutions provide the flexibility and performance needed to streamline your operations. Trust Noggrann for top-tier conveyor systems.

0 notes

Text

youtube

Altomech Private Limited is a leading manufacturer of Pneumatic conveyors and vacuum conveyors, powder conveying systems, and grain conveying systems.

Email : [email protected]

Contact : 95851 31112

WEBSITE : https://altomech.com/vacuum-conveying-system.php

#powder transfer system#vacuum conveyor manufacturer#vacuum conveyor#pneumatic conveyor manufacturer#pneumatic conveyor#powder conveying system#vacuum conveying system#vacuum conveyor for powder#vacuum conveyor system#vacuum transfer system#portable powder transfer system#Youtube

0 notes

Text

Navigating the Airwaves: An Overview of Different Pneumatic Conveying Systems

In industrialization the movement material of full must be attended to, it usually sums up the manufacture process. The plethora of carrying methods that are in use is impressive but within this group of the methods which is pneumatic transportation systems stands out due to its efficiency, versatility, and ability to many and small materials. In this article, we shall be unveiling the types of pneumatic conveying systems, as their working mechanisms, applications, benefits, and different considerations that ought to be made by different industries as they select suitable systems based on the needs of their operations.

Introduction to Pneumatic Conveying

Pneumatic conveying means the delivery way of flowing powdery substances through a steel pipe by means of gas (e.g. air). The designed material to be carried with it the retained air at a particular ratio is forced through the conveying pipes and transported to its destination. This technic, in contrast to others, ensures the non-polluted, safe, and time-efficient transportation of material from one to another point, in fact, to be liked and used mostly in industries as food, medicine, chemical, and construction.

The Heart of Pneumatic Conveying: The company's mission was to minimize freshwater withdrawal, reduce chemical consumption, and marginalize the emission of wastewater and pollutants to promote a more sustainable and environmentally conscious beers.

Pneumatic conveying systems can be broadly classified into two categories based on their operating principle: dimation and condensation. Every component has the place composing of different systems with their own significance and characteristics. We shall have to explore these systems thoroughly in analyzing their processes and uses.

Dilute Phase Conveying

In that system, the high-speed air used for conveying acts as a carrier of particles in which the particles are fully suspended. This technique goes best with materials which do not happen to get damaged through the high-speed impact and rubbing force which often result. Dilute phase conveying is further divided into two systems based on the air pressure used:

a.Positive Pressure System

In positive pressure system, material impinges into a conveyor belt through a rotary valve or any other similar feeding mechanism. A blower or compressor provides a through flow of air pressure which ends with the materials moving towards the pipe's exit. This method is well equipped and can handle the transporting over long distances from horizontal to vertical.

b.Negative Pressure (Vacuum) System

Then, unlike a negative pressure conveyer which uses a vacuum to move materials via a conveyer line, the positive pressure system uses seals with pressure differences. The material is fed into the processing machinery through a feeding point. There, it is moved towards further processing or collecting at its destination, depending on the type of waste. Vacuum systems are especially good choice for those situations when it is needed to combine multiple pick-up points or when escaping dust is critical.

Dense Phase Conveying

More compact conveying saves time as compared to dilute phase conveying as it transports the materials at lower velocity that allows the soft handling of abrasive, harmful or the already blended materials. Similarly, autoclave is also a good method when it comes to energy consumption since it consumes less. Also, autoclave is suitable for materials that are sensitive to degradation. Dense phase conveying is categorized into:Dense phase conveying is categorized into:

a.Pressure Systems

Materials are transported in the dense phase pressure system achieving the establishment of high pressure but low velocity within the conduit channel by which the materials are moved. This compressor driven system pushes the material through the pipeline by the force obtained in the compressor or pressure vessel. It works well in the application of transportation of materials over the multiple kilometers with slighter amortization.

b.Vacuum Systems

In dense phase vacuum systems a pump creates a vacuum at the convey line's end and the materials move to the inlet of the pump. This approach is just one of the several transport techniques that can be used to cope with this type of traffic. It gives a great deal of freedom in using resources to increase efficiency for specific tasks.

Specialized Pneumatic Conveying Systems: Also, another factor that needs to be considered is the waste collection frequency which plays a vital role in reducing air pollution.

Another development scope is the creation of different industries classifying systems, which are designed to provide more detailed industrial operations needs.These include:

a.Plug Flow Systems

Plug flow regime is a means of material movement consisting of solid plugs progressing at a lower pace. Through this approach, materials ranging from abrasive to short separating stream are very well controlled.

b.Long Distance Conveying

This type of conveyers are designed for distances up to several kilometers, therefore they use principles of dilute and dense phase conveying thus, system can process larger amounts of material with less wear on the conveyer line.

c.Batch Conveying

Batch tailoring systems typically deal with exact meter and handling for specific quantities of substance in batches transforming them into uniform performance volumes.

Selecting the Right System: Factors such as budget, availability of staff, prioritization of target audience, and legal and ethical issues should be taken into account.

Choosing the most suitable pneumatic conveying system requires careful consideration of several factors, including:

Material Characteristics: For these physical parameters, the material properties, such as grain size, shape and conveyability, can affect the decision of which type of carrying system should be used.

Conveying Distance and Layout: A significant environmental impact of bulky waste management is the transport of distance and complexity of route ( which may involve vertical and horizontal sections).

Capacity Requirements: The amount of time necessary to present an extensive amount of information is heavily depending on the system design and its size.

System Reliability and Maintenance: Routine operations and low- effort maintenance should be considered as relevant tools for high protection against unexpected off-mains and non-productive downtimes.

Cost: Initial losses as well as operational costs are important when arriving at a decision.

Conclusion

Consequently, pneumatic systems provide an industrious, tuned and clean process that supports the transfer of uncountable bulk materials within different sectors. The grasp of the different types of pneumatic conveying systems, along with their ideal uses and drawbacks, is a major aspect to carefully consider for making a decision on the appropriate system for your operations. Whatever your requirements are through handling of sensitive materials from the gentleman gesture to over long distance conveyance and flexibility in handling dissimilar types of materials is a pneumatic conveyor advantage that has got a system designed to perform the task. While industries continues to evolve and develop, other pneumatic conveyor types that will be more advanced and specialized are expected in the future, thus adding more possibilities in material handling and logistics.

#pneumatic conveying system#pneumatic conveyor system#conveying system#pneumatic conveying#pneumatic conveying systems

0 notes

Text

Key Benefits Of Powder Transfer System Everyone Must Know

A powder transfer system is a mechanism for the safe and efficient transfer of powdered or granular materials. The system ensures precise handling, preventing contamination and minimising waste. A powder transfer system can transfer materials vertically or horizontally to and from machines. This can handle the direct loading of powder into mixers, vessels, reactors and closed hoppers in a safe way. Moreover, it prevents dust formation during the material transfer.

The powder transfer systems are of different types, such as pneumatic transfer systems, screw conveyors and vacuum transfer systems. Consult a leading powder transfer system manufacturer to learn more about the types.

0 notes

Text

Powder Conveying Systems

Sweep away inefficiencies! Optimize your powder flow with Sodimate's exceptional powder conveying systems. Our advanced tech ensures seamless powder transfer, boosting output and reducing downtime. Contact us now to elevate your productivity and streamline your powder handling processes.

0 notes