#safety compliance

Text

Best Practices for Protecting Road Construction Workers

Road construction workers operate in an environment where danger is a constant companion. The proximity to moving traffic, the use of heavy machinery, and the exposure to various environmental elements make their workplace one of the more hazardous ones. Therefore, implementing best practices for protecting road construction workers is not just a regulatory requirement but a moral imperative.

To…

View On WordPress

#construction site hazards#drone surveillance#employee well-being#high-visibility clothing#industry standards#road construction safety#Safety Compliance#Safety Culture#Safety Training#technology in safety#traffic control strategies#wearable safety devices#worker protection#zero accidents

2 notes

·

View notes

Text

In the world of healthcare, possessing the right skills can make the difference between life and death. Among these essential skills, CPR (Cardiopulmonary Resuscitation) stands out. Every healthcare provider, from seasoned professionals to newcomers, must prioritize mastering this life-saving technique.

0 notes

Text

Integrated NDE Solution in Pune: Pioneering Positive Material Identification for Quality Control and Safety Compliance

In the modern industrial landscape, ensuring the integrity and composition of materials is crucial for maintaining quality control and safety compliance. Positive Material Identification (PMI) is an essential non-destructive method used to verify the chemical composition of materials. Integrated NDE Solution in Pune offers comprehensive PMI services, utilizing advanced technologies such as X-Ray Fluorescence (XRF) analyzers and Optical Emission Spectroscopy (OES). This article delves into the intricacies of PMI, its benefits, and the cutting-edge services provided by Integrated NDE Solution.

Understanding Positive Material Identification

Positive Material Identification (PMI) is a non-destructive testing method used to verify the alloy composition of materials. PMI ensures that the materials used in manufacturing processes meet the specified chemical composition, thereby maintaining product quality and safety standards. This verification process is crucial for industries where material composition directly impacts performance, reliability, and safety, such as aerospace, oil and gas, power generation, and pharmaceuticals.

Importance of Positive Material Identification

Quality Control: Ensures that materials conform to the required specifications, maintaining the integrity and quality of the final product.

Safety Compliance: Verifies that materials meet industry safety standards, reducing the risk of failures and accidents.

Material Verification: Confirms the correct alloy composition of materials, preventing mix-ups and ensuring proper material usage.

Regulatory Compliance: Helps industries adhere to stringent regulatory requirements and standards.

Cost Savings: Prevents costly material failures and recalls by ensuring the correct material is used from the start.

How Positive Material Identification Works

Positive Material Identification is typically conducted using two main technologies: X-Ray Fluorescence (XRF) and Optical Emission Spectroscopy (OES).

X-Ray Fluorescence (XRF) Analyzers

XRF analyzers use X-rays to excite the atoms in a sample, causing them to emit secondary (fluorescent) X-rays. These fluorescent X-rays are characteristic of the elements present in the sample, allowing for a semi-quantitative chemical analysis. The key steps in the XRF process are:

Preparation: The surface of the material is cleaned to ensure accurate readings.

Excitation: The XRF device directs X-rays at the material, exciting the atoms within the sample.

Detection: The device detects the emitted fluorescent X-rays and measures their energy levels.

Analysis: The energy levels correspond to specific elements, allowing for the identification of the material's composition.

Optical Emission Spectroscopy (OES)

OES involves exciting the atoms in a sample using a high-energy spark or arc, causing them to emit light. The emitted light is then analyzed to determine the material's composition. The key steps in the OES process are:

Preparation: The surface of the material is cleaned and sometimes ground to create a flat, uniform surface.

Excitation: The OES device generates a spark or arc that excites the atoms in the material.

Detection: The emitted light is collected and passed through a spectrometer.

Analysis: The spectrometer measures the wavelengths of the emitted light, which correspond to specific elements, allowing for precise material identification.

Benefits of Positive Material Identification

Non-Destructive: PMI does not damage or alter the material being tested.

Accurate: Provides precise and reliable identification of alloy composition.

Quick and Efficient: Delivers immediate results, enabling rapid decision-making.

Versatile: Applicable to a wide range of materials, including metals and alloys.

Portable: PMI equipment is often portable, allowing for on-site testing.

Integrated NDE Solution in Pune: Leaders in Positive Material Identification

Integrated NDE Solution in Pune is a leader in non-destructive testing, offering a broad spectrum of services, including Positive Material Identification. Their expertise, state-of-the-art equipment, and commitment to quality make them a trusted partner for industries requiring reliable material verification.

Comprehensive NDT Services Offered

Positive Material Identification (PMI)

Remote Visual Inspection (RVI)

Magnetic Particle Inspection (MPI)

Ultrasonic Testing (UT)

Radiographic Testing (RT)

Liquid Penetrant Testing (LPT)

Eddy Current Testing (ECT)

Portable Hardness Testing

Ferrite Testing

Industries Served

Integrated NDE Solution in Pune caters to a diverse array of industries, including:

Aerospace: Ensuring the safety and reliability of aircraft components.

Automotive: Inspecting critical parts to prevent failures.

Construction: Verifying the integrity of structural components.

Oil and Gas: Ensuring the reliability of pipelines and equipment.

Power Generation: Maintaining the integrity of infrastructure components.

Pharmaceuticals: Verifying the composition of materials used in drug manufacturing.

Positive Material Identification in Action

Case Study: Oil and Gas Pipeline Inspection

In the oil and gas industry, the reliability of pipelines is crucial. Integrated NDE Solution was approached by a leading oil and gas company to conduct PMI on pipeline materials. Using advanced XRF analyzers, the team verified the alloy composition of the pipeline materials, ensuring they met the specified standards for corrosion resistance and mechanical strength. The inspection helped prevent potential failures and ensured the safety and reliability of the pipeline network.

Case Study: Aerospace Component Verification

A major aerospace manufacturer required PMI for critical components used in aircraft engines. Integrated NDE Solution employed both XRF and OES technologies to verify the alloy composition of the components. The precise identification confirmed that the materials met the stringent specifications required for aerospace applications, ensuring the safety and performance of the aircraft engines.

Advanced Positive Material Identification Equipment

Integrated NDE Solution in Pune utilizes the latest PMI equipment to ensure the highest level of accuracy and reliability in their inspections. Some of the advanced equipment includes:

Handheld XRF Analyzers: Portable devices that provide rapid, on-site analysis of alloy composition.

Stationary XRF Analyzers: High-precision instruments used for detailed laboratory analysis.

Mobile OES Units: Portable units that offer precise material identification in the field.

Stationary OES Systems: Advanced systems used for comprehensive laboratory analysis of materials.

The Role of Certified Technicians

The effectiveness of Positive Material Identification largely depends on the expertise of the technicians conducting the tests. Integrated NDE Solution in Pune employs certified technicians who undergo rigorous training and continuous professional development. Their skills and knowledge ensure that clients receive the highest quality of service.

Commitment to Quality and Safety

Integrated NDE Solution in Pune is dedicated to maintaining the highest standards of quality and safety. They adhere to international standards and best practices, ensuring that all inspections are performed with utmost precision and reliability. This commitment to excellence has earned them a stellar reputation in the industry.

Customer-Centric Approach

At Integrated NDE Solution in Pune, customer satisfaction is a top priority. They work closely with clients to understand their specific needs and tailor their services accordingly. Whether it’s a small-scale inspection or a large industrial project, they provide personalized solutions that meet the highest standards of quality and reliability.

Why Choose Integrated NDE Solution in Pune?

Expertise: Extensive experience and technical know-how in NDT services.

Technology: Utilization of the latest and most advanced testing equipment.

Quality: Commitment to providing accurate and reliable results.

Customer Service: Focus on building long-term relationships through excellent service.

Compliance: Adherence to all relevant industry standards and regulations.

Conclusion

In industries where precision and reliability are non-negotiable, Integrated NDE Solution in Pune stands out as a leader in non-destructive testing, particularly in Positive Material Identification. Their dedication to quality, use of advanced technology, and customer-centric approach make them the go-to choice for businesses across various sectors. By partnering with Integrated NDE Solution, companies can ensure the integrity and safety of their materials and components, safeguarding their operations and reputation.

Integrated NDE Solution in Pune continues to set the standard for excellence in non-destructive inspection. Their expertise in Positive Material Identification and other NDT services is pivotal in industries where safety and reliability are crucial. As technology advances and industries evolve, Integrated NDE Solution remains at the forefront, offering unparalleled service and support to their clients.

In conclusion, for businesses seeking the highest standards in Positive Material Identification, alloy composition verification, and comprehensive NDT services, Integrated NDE Solution in Pune is the trusted partner that delivers results. Their innovative approach, advanced technology, and unwavering commitment to quality ensure that every inspection meets the stringent requirements of today’s demanding industrial environments.

#positive material identification#alloy composition#non destructive method#semi quantitative chemical analysis#material verification#material identification#quality control#safety compliance#x ray fluorescence analyser#optical emission spectroscopy

0 notes

Text

Blood Bank Management 101: Ensuring Safety and Accessibility

Welcome to Blood Bank Management 101, your comprehensive guide to maintaining the safety and accessibility of blood supplies. In this blog, we'll delve into key aspects of blood bank management, including donor screening, inventory control, testing & processing, distribution, and safety compliance.

Donor Screening is the crucial first step in maintaining the integrity of blood supplies. By screening potential donors for eligibility and assessing their health history, blood banks can minimize the risk of transmitting infections or other complications through donated blood.

Once blood is collected, inventory control becomes paramount. Efficient inventory management ensures that the right blood types are available when needed, minimizing waste and maximizing the utility of donated blood.

Testing & processing are vital stages in the journey of donated blood. Thorough testing protocols, including screening for infectious diseases and compatibility testing, help guarantee the safety of blood products. Meanwhile, processing techniques ensure that blood components are separated and stored properly for future use.

Effective distribution is essential for making blood products available to those in need. Blood banks must establish reliable distribution channels to transport blood products to hospitals and medical facilities efficiently, ensuring timely access for patients.

Throughout every stage of blood bank operations, safety compliance is non-negotiable. Adhering to stringent safety protocols and regulatory requirements safeguards both donors and recipients, maintaining the trust and integrity of the blood banking system.

In conclusion, Blood Bank Management 101 underscores the critical importance of donor screening, inventory control, testing & processing, distribution, and safety compliance in ensuring the safety and accessibility of blood supplies. By prioritizing these key elements, blood banks can fulfill their mission of saving lives and supporting public health initiatives.

0 notes

Text

as a stockholder for CSX railroad, the board recommended I vote against forming a safety committee

#csx#csxrailroad#railroad#safety committee#safety compliance#safety#committee#occupationalsafety#occupationalhealth#occupationalhazards#occupational health and safety#railroads#class war#fascism#capitalism#oppression#repression#derailment#ausgov#politas#auspol#tasgov#taspol#australia#fuck neoliberals#neoliberal capitalism#anthony albanese#albanese government#eat the rich#eat the fucking rich

1 note

·

View note

Text

Ensuring Safety in the Industrial Labyrinth: The Critical Role of Warehouse Safety Signage

In the heart of an industrial area stands a colossal warehouse, a labyrinth of aisles, machines, and bustling activity. Amidst the symphony of forklifts and conveyor belts, a network of signs serves as the silent guardians of safety. These signs are not mere decorations but vital tools in preventing accidents and ensuring a seamless workflow. The importance of warehouse safety signage cannot be overstated, especially when we delve into the statistics and data that underline their critical role in maintaining workplace safety.

The Stark Reality: Numbers Don't Lie

According to the Occupational Safety and Health Administration (OSHA), over 5,000 workers were fatally injured in workplace accidents in the United States in a recent year. Of these, a significant portion occurred in warehouse settings, where the combination of heavy machinery, high shelves, and constant movement creates a complex hazard landscape.

Furthermore, the Bureau of Labor Statistics (BLS) reports that the warehousing and storage sector experienced an injury and illness rate of 5.1 per 100 full-time workers. This rate is notably higher than the average across all industries, which stands at 3.1. This data underscores the unique risks present in warehouses and the urgent need for effective safety measures, including clear and comprehensive signage.

The Significance of Signage

Warehouse safety signage plays a pivotal role in hazard communication. These signs provide critical information regarding:

Hazardous Areas: Clearly marked zones where special precautions are needed.

Traffic Flow: Directional signs for forklifts and other vehicles to prevent collisions.

Emergency Exits and Equipment: Essential in ensuring quick evacuation and response during emergencies.

Safe Handling Instructions: Guidelines for safely operating machinery and handling materials.

Compliance and Best Practices

OSHA standards dictate specific requirements for safety signs in the workplace. For instance, OSHA 1910.145 stipulates that safety signs must be used to indicate and define specific hazards that, without identification, may lead to accidental injury or property damage.

But compliance is just the starting point. Best practices go beyond mere adherence to regulations. They involve:

Regular Audits: Periodic reviews to ensure all signage is up-to-date and visible.

Customization: Tailoring signs to address specific hazards and workflows in each warehouse.

Training: Educating employees on the meaning of signs and the actions they necessitate.

The Impact of Technology

In recent years, technology has enhanced the effectiveness of warehouse safety signage. Digital signs, which can be updated in real-time, offer dynamic solutions for changing conditions. For example, Electronic Status Boards (ESBs) can provide live updates on safety conditions, alerting workers to new hazards or changes in the operational environment.

Conclusion: A Crucial Investment in Safety

In conclusion, warehouse safety signage is not just a regulatory requirement but a crucial investment in worker safety and operational efficiency. The statistics are clear: where safety communication is prioritized, accidents decrease, and productivity increases. By committing to robust safety signage practices, warehouses can ensure that their complex environments are navigable, compliant, and, above all, safe for every person who steps inside.

Read More : Ensuring Safety in the Industrial Labyrinth: The Critical Role of Warehouse Safety Signage

0 notes

Text

Fall Protection Market and Its Crucial Role in Shaping the Future of Workplace Safety

The global fall protection market size is expected to reach USD 4.77 billion by 2030, according to a new report by Grand View Research, Inc, expanding at a CAGR of 7.0% during the forecast period. The global industry is primarily driven by the growing demand for workers’ safety, coupled with mandated policies by regulatory agencies for companies to maintain worker safety in various end-user industries. Fast-paced GDP growth and increasing employment in industries across the Asia Pacific and the Middle East have increased the focus on workers’ safety. Companies are emphasizing worker safety and establishing safety norms to avoid fall accidents, which have a negative influence on operating expenses in the form of compensation and arbitrated settlements, hence aiding industry growth.

Fall Protection Market Report Highlights

The soft goods segment led the global industry in 2021 owing to increasing demand for harnesses coupled with rising awareness pertaining to worker safety in various end-use industries

The construction industry is expected to witness considerable growth from 2022 to 2030 on account of mandates by governments of various countries to reduce the number of accidents and causalities during construction activities

Asia Pacific is expected to witness the fastest CAGR during the forecast period owing to a rise in M&A activities and increased infrastructure development by governments, thus driving the industrial construction sector

North America is expected to be the largest region in terms of global revenue during the forecast period, owing to rising worker safety concerns, and early adoption of cutting-edge technology

In January 2022, Diversified Fall Protection (DFP) completed the acquisitions of two similar line companies, namely Rooftop Anchor, Inc. (RTA) and Versatile Systems

In November 2021, Rothoblaas increased its line of fall prevention systems & protective gear. This allowed the firm to broaden its product range while also meeting the technical & regulatory international standards for its goods

For More Details or Sample Copy please visit link @: Fall Protection Market Report

The ongoing innovations in product development for manufacturing products that offer improved comfort, functionality, and movement, while adhering to regulatory standards, through the use of improved fabrics and materials are anticipated to fuel the industry growth. The Asian Development Bank (ADB) allocated USD 250 million as a loan for the National Industrial Corridor Development Program of India (NICDP) in November 2021 for the construction of 11 industrial corridors connecting 17 states of India. Such initiatives are anticipated to increase product demand during the forecast period.

Growing population, rapid industrialization in developing nations, increasing construction activities worldwide, and the rising popularity of recreational activities like rock climbing and ice climbing are some of the major factors anticipated to propel the industry growth during the forecast period. Companies are launching new products to strengthen their product portfolio. In September 2020, McNetiq launched a series of magnetic anchors intended for fall protection for workers when working at heights and this is used in places constructed of steel and not having edge protection. This product launch also helped the company diversify its product portfolio.

FallProtection #WorkplaceSafety #SafetyGear #OccupationalSafety #HeightSafety #SafetyHarness #FallPrevention #SafetyStandards #WorkplaceSecurity #FallArrest #SafetyEquipment #SafetyAtHeight #FallSafety #OccupationalHealth #SafetyInnovation #FallArrestSystems #SafetyCompliance #HeightenedSafety #SafetyFirst #WorkerProtection

#Fall Protection#Work place Safety#Safety Gear#Occupational Safety#Height Safety#Safety Harness#Fall Prevention#Safety Standards#Work-place Security#Fall Arrest#Safety Equipment#Safety At Height#Fall Safety#Occupational Health#Safety Innovation#Fall Arrest Systems#Safety Compliance#Heightened Safety#Safety First#Worker Protection

1 note

·

View note

Text

lol i love how yesterday morning i was like “i love nightmares pls send me one” and i had 3 back to back 💀

*hesitantly* i ... i love nightmares..? send me one... once a week? no, twice a week

#one was living in a kind of big 1 story house w other ppl and trying to survive a bear attack#my middle dream i don't remember#and my third dream is kind of long to explain ૮ – ﻌ–ა#but basically me n a bunch of other ppl were trapped in a big house by ppl who were analogous to the iof and we needed to get out#before they killed us all.. most ppl were too scared to try running but compliance does not guarantee safety.. only 2 others left w me#and there was some thing.. like an ogre ig?? sorta looked like a v tall v buff dude and he kept trying to throw a ball at us w full force#but it hits like a cannon so we had to dodge that or be obliterated (´-﹏-`;) we made it but i def left some stuff behind back at the#house like my wallet n maybe my phone etc so they had more info to go off of but i woke up a lil after the ogre guy#all i remember from the second dream is i remember being atop a large tower and the stones in the walls were part of an#ancient magical seal that had something to do w the creator's connection w birds and it was sort of a sacred site?#bc the stones together formed an invisible barrier over the area and birds were attracted to the area. u could pull the stones out#the wall if u wanted to 🤭 ur not supposed to but You Could. all else i remember is being in my car w three others#w me in the back and we drove past a fucking tornado akfkakak. i don't remember the actual plot of that dream or what#pushed it into nightmare territory but i have had quite an adrenaline filled night 🫡 being locked up in the torture/slavery/prisoner house#was the one that made me get up. where did these come from???¿ i basically just fell asleep watching Steven universe#👉🏾👉🏾 at least they weren't emotional nightmares.. i much prefer situational ones

11 notes

·

View notes

Text

god the way miguel intimately understands both desiring the ideal that promises a better future (his spiderman identity is specifically a means to protect, to be a different man than everything else he considers miguel o'hara to be), as well as the notion of being manipulated by the promise of something better (for him, it was conditional acceptance and validation of his worth by those who held power, and by extension, the systems they operated within). anyways! <- falls over and dies.

#sm2099#i have both of these panels saved to my phone like a dweeb because they give me insane emotions <3#feeling insane ALSO about how miguel is unable to reckon w the fact that Stone takes advantage of him.#He blames himself for having somehow not predicted Stone would poison him. He doesn't acknowledge the ways in which Stone took advantage of#him as a child. leveraged the safety of Conchata and Gabriel over his head in order to ensure compliance - let alone the effects of#spending a majority of ur formative years in the school designed to be a alchemax employee pipeline.#'im not scared of you' he tells Stone as a boy. and yet it is only when hes so angry at the thought of Stone hurting Gabriel and Conchata#that he can acknowledge how powerless and terrified being drugged made him feel#he NEVER acknowledges fear until that point even though its obvious to the reader.#i just💥💥💥💥💥💥💥💥#tunes talks 2099

26 notes

·

View notes

Text

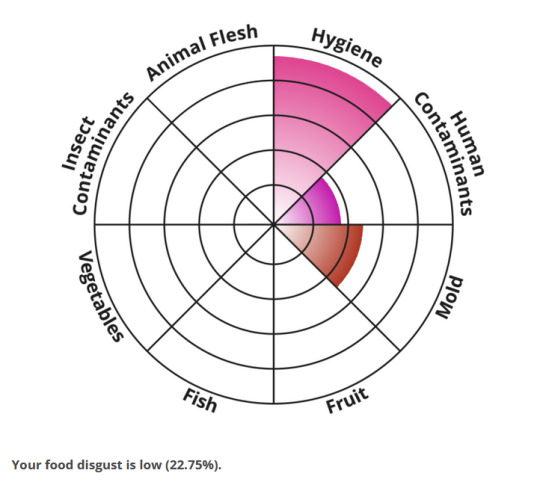

Food service worker diagnosis

#talk#Mold is safe to remove in some instances but not most any building with unhygienic practices in one corner has it in the kitchen too#You get given food by strangers any time you go to a restaurant it is not the concept of a person you don't know that unnerves you it is a#lack of regulation and confirmed compliance to safety standards#Which is why everywhere is legally required to have their safety score framed in a place visible to customers#Which btw speaking as a food service worker anything under an 85 veers into serious risk territory because restaurants are stricter on#Inspection days. So really you want to be subtracting 5-10 points from any given rating and judging based on that.#Like I'm not saying high levels of disgust boil down to a lack of exposure to the reality of food service and distribution but I do think#most people would be more confident and thus less disgusted by certain things if they just understood them better#Hence my previous post.

8 notes

·

View notes

Text

Boosting Employee Engagement in Safety Practices in the Construction Industry

Employee engagement in safety practices is more than just a buzzword in the construction industry. It’s the cornerstone of maintaining a safe, productive, and happy workplace. This article dives into why fostering a culture of safety through employee engagement is essential and how it can significantly reduce accidents and improve project outcomes. By integrating safety into the core values of…

View On WordPress

#Construction Safety#Continuous Improvement#employee empowerment#Employee Engagement#Leadership in Safety#open communication#proactive safety#Safety Compliance#Safety Culture#safety metrics#safety practices#safety recognition#Safety Rewards#Safety Training#Workplace Safety

0 notes

Text

He helmet too big for he gotdam head !!!!

#rottmnt#rise of the tmnt#rottmnt casey jones#casey jones#casey jr#rottmnt donnie#rottmnt movie#rottmnt movie spoilers#i guess?#one thing abt donnie they care abt safety compliance when it comes to the little guy#given the right circumstances the Hamatos would have spoiled that kid rotten

76 notes

·

View notes

Text

Happy Halloween!

Stay safe out there!

#trobl#troblsomart#happy halloween!#this is my halloween costume#no joke#I AM SAFETY COMPLIANCE#that hi-vis vest came out SO good tho#i'm so unreasonably proud of this

15 notes

·

View notes

Text

Got additional info in DM about the Outlander Season 7 Wrap Party. Remember this guy on the left in pics with Sam and separately with Cait and Rik? 👇

A friend DMed me who he is. 👇

Mystery solved 👇

#samheughan#caitrionabalfe#harrymackinnon#outlander#outlander wrap party#outlander season 7 wrap party#health and safety#health and safety compliance#rikrankin#richard rankin

21 notes

·

View notes

Text

#At Refrigerant Center INC#we specialize in providing comprehensive refrigerant solutions tailored to meet the diverse needs of our clients. With a deep understanding#Ventilation#and Air Conditioning) industry and its evolving regulatory landscape#we are committed to offering environmentally responsible refrigerant products and services.#Our company prides itself on being a trusted partner for businesses operating in various sectors#including commercial#industrial#and residential. Whether you're a facility manager#HVAC contractor#or equipment manufacturer#we have the expertise and resources to fulfill your refrigerant requirements efficiently and affordably.#Key Services and Products:#Refrigerant Sales: We offer a wide range of refrigerant products#including traditional HFCs (Hydrofluorocarbons)#low-GWP (Global Warming Potential) alternatives like HFOs (Hydrofluoroolefins)#and natural refrigerants such as CO2 and ammonia. Our extensive inventory ensures that clients can find the right refrigerant for their spe#Refrigerant Reclamation: Recognizing the importance of sustainability#we provide refrigerant reclamation services aimed at recovering#purifying#and reprocessing used refrigerants. Through our state-of-the-art reclamation facilities#we help clients minimize environmental impact while maximizing cost savings.#Regulatory Compliance Assistance: Navigating the complex regulatory landscape surrounding refrigerants can be challenging. Our team stays u#national#and international regulations#including EPA (Environmental Protection Agency) regulations in the United States.#Technical Support: We understand that proper handling and usage of refrigerants are critical for the safety and efficiency of HVAC systems.#training#and educational resources to assist clients in handling refrigerants safely and effectively.#Customized Solutions: Every client has unique requirements

3 notes

·

View notes

Text

Coming to the realisation that I may now be our de facto HR guy. How tf do I get out of this one.

#we have a health and safety/compliance manager who comes in. occasionally.#and we have an HR consultant#but guess who just had to do all the new employee intake paperwork#had to figure it out by going into the employee files and seeing what forms everyone else had#this sucks#nobody is actually in to do their job so it just ends up being mine

16 notes

·

View notes