#sltl

Text

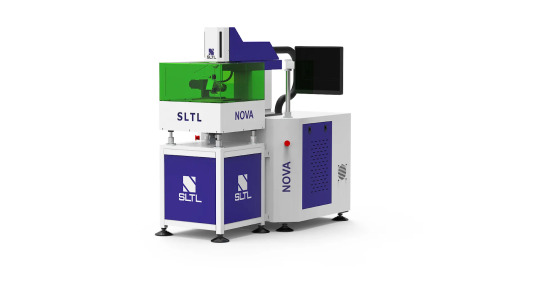

"Revolutionize Marking with SLTL's Ultra Laser Systems! 🚀 Unleash Endless Possibilities in Marking/Engraving, Coding, and More. 🌐✨"

0 notes

Text

#SLTL Group#Laser Experts#Laser cutting Machine#sheet cutting machine#fiber laser cutting machine#cnc laser cutting machine#Imtex 24

0 notes

Text

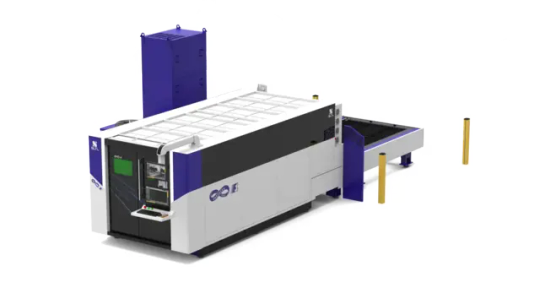

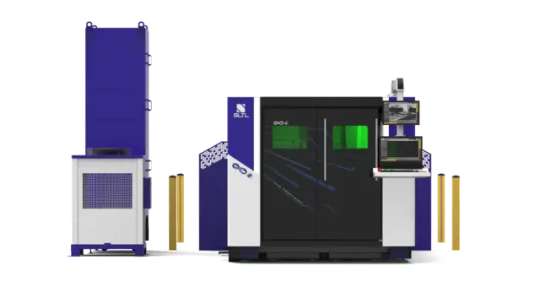

Beyond Limits: Unveiling the Might of High-Power Lasers on 40mm Metal Sheets

Exploring the Capabilities of up to 30KW Laser Cutting Machines and the Advantages of SLTL Infinity Metal Cutting Laser Machine

The world of metal fabrication is undergoing a transformative phase, powered by cutting-edge technology that pushes the boundaries of what was once considered impossible. We delve into the awe-inspiring domain of high-power lasers, where up to 30KW laser cutting machines take center stage. The spotlight is on the remarkable SLTL Infinity Metal Cutting Laser Machine, a marvel that defies limits and sets new standards in precision and efficiency.

1. Laser Precision: A Glimpse into the Future

The introduction of high-power lasers in metal cutting has been a game-changer, revolutionizing an industry that has long grappled with the challenges of cutting thick metal sheets. With the capability to slice through 40mm metal sheets like a hot knife through butter, the technology raises questions that intrigue and inspire.

2. The Power of 30KW Laser Cutting Machines

"30KW Laser Cutting: Redefining Metal Fabrication"

The 30KW laser cutting machines represent a monumental leap in the world of engineering. Imagine harnessing energy equivalent to the powerhouses that fuel entire cities, all focused onto a precise beam that can carve through metal with surgical precision. This level of power is not just about might; it's about rewriting the rules of metal fabrication.

3. The Star of the Show: SLTL Infinity Metal Cutting Laser Machine

"Infinite Potential: Unraveling the Features of SLTL Infinity"

Amidst the universe of high-power lasers, the SLTL Infinity Metal Cutting Laser Machine stands out as a testament to human ingenuity. Designed to handle the toughest challenges, its adaptive controls and state-of-the-art technology redefine what's achievable in metal cutting. The machine's versatility shines as it seamlessly transitions from intricate designs to slicing through 40mm metal sheets.

4. Advantages That Illuminate Possibilities

"Cutting through Advantages: Illuminating the Benefits of SLTL Infinity"

The advantages offered by the SLTL Infinity are a beacon for industries seeking innovation and efficiency. The machine's ability to maintain precision across varying metal types, reduced heat-affected zones, and minimal post-processing are advantages that not only streamline production but also raise the quality bar.

5. Beyond Metal Cutting: Expanding Horizons

"Expanding Boundaries: Beyond Metal Cutting with SLTL Infinity"

While the primary focus is metal cutting, the impact of the SLTL Infinity transcends this singular domain. It has the potential to shape industries that rely on intricate metalwork, from automotive to aerospace. The machine's capabilities become a catalyst for imagination and innovation, propelling industries into uncharted territory.

Conclusion: Carving a New Era in Metal Fabrication

As we conclude this journey through the realms of high-power lasers and the remarkable SLTL Infinity Metal Cutting Laser Machine, the answers to the questions posed at the beginning become evident. The boundaries of what can be achieved with metal cutting have expanded beyond our wildest dreams. The synergy of human ingenuity and technological prowess has birthed a new era where 40mm metal sheets are no longer obstacles but opportunities.

In the world of metal fabrication, limits are no longer barriers; they are merely indicators of what can be surpassed. As we embrace the capabilities of the SLTL Infinity, we are ushered into a future where innovation is boundless, and metal is shaped not just by machines, but by the audacity of human imagination.

In this journey of innovation, the SLTL Infinity Metal Cutting Laser Machine is not just a tool; it's an emblem of progress and a tribute to human determination to reach beyond the confines of what was once considered feasible.

#SLTL Infinity#cnc laser cutting machine#sheet cutting machine#metal cutting machine#fiber laser cutter

0 notes

Text

Laser Marking Machines in the Medical Field: Surgical Instrument Identification and Traceability

In the rapidly evolving medical field, precision and accuracy are paramount. One critical aspect is the identification and traceability of surgical instruments. Laser marking machines have emerged as a revolutionary technology, offering a reliable and efficient solution for marking surgical instruments. This blog explores the role of laser marking machines in the medical field, focusing on their application in surgical Instrument Identification:

The Importance of Surgical Instrument Identification:

In a surgical setting, it is crucial to accurately identify and track surgical instruments throughout their lifecycle. Proper instrument identification ensures patient safety, minimizes the risk of surgical errors, and enhances operational efficiency. Traditional methods like etching or engraving on surgical Instruments often resulted in inadequate markings, compromising readability and durability. This is where laser marking machines offer a superior solution.

Laser Marking Machines for Surgical Instrument Identification:

Laser marking machines utilize high-powered lasers to create precise, permanent markings on surgical instruments. They offer numerous advantages, including:

High Precision: Laser technology allows for precise and intricate markings, even on small or complex surgical instruments. This ensures clear identification and readability.

Durability: Laser markings are resistant to wear, sterilization processes, and harsh environmental conditions. They maintain legibility throughout the instrument's lifecycle, reducing the need for frequent re-marking.

Non-Contact Process: Laser marking is a non-contact method, eliminating the risk of physical damage to delicate instruments during the marking process.

Versatility: Laser marking machines can mark various materials commonly used in surgical instruments, such as stainless steel, titanium, and plastics. They can create barcodes, serial numbers, logos, and other customizable markings.

SLTL Pvt. Ltd. is a reputable company known for its innovative laser solutions in various industries, including the medical field. They offer advanced laser marking machines specifically designed for surgical instrument identification.

SLTL's laser marking machines utilize cutting-edge fiber laser technology, ensuring high-speed and precise markings. These machines are equipped with user-friendly software that enables easy design customization, including barcodes, data matrix codes, and alphanumeric characters. The markings produced by SLTL's laser machines meet stringent quality standards, ensuring long-lasting legibility and reliability.

SLTL's laser marking solutions for the medical industry also prioritize safety and compliance. They incorporate features like real-time monitoring, automated serialization, and validation tools to ensure accurate instrument tracking and traceability.

Laser marking machines have revolutionized surgical instrument identification in the medical field. Their precision, durability, and versatility make them an ideal choice for marking surgical instruments with crucial information. Companies like SLTL Pvt. Ltd. have played a significant role in providing state-of-the-art laser marking solutions, enhancing patient safety and operational efficiency in healthcare facilities. With the continuous advancements in laser technology, the future holds even more promising possibilities for laser marking in the medical field.

#Laser marking machines#SLTL Pvt. Ltd.#LASER CUTTING MACHINE#LASER ENGRAVING MACHINE#SURGICAL INSTRUMENTS

1 note

·

View note

Text

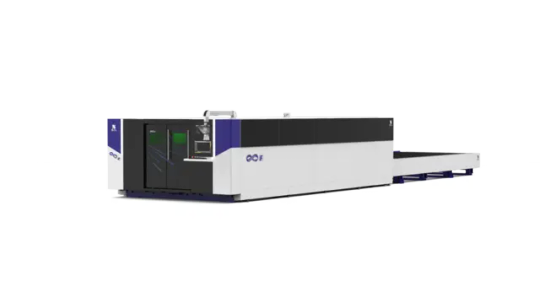

Sltl vector 2d laser cutting machine

Laser Marking compared to Laser Engraving With Laser Engraving the material keeps its original shape. When a material (in most cases, metal) is etched, it expands and creates a raised cavity. However, it functions as a tool that melts the material rather than vaporizes it. Laser Etching may be used as a synonym for Laser Engraving. Is Laser Etching the same as Laser Engraving? There are laser machines that can laser cut and engrave but would still need a 2D file to function. Many different fields such as aerospace, automotive, medicine, or electronics rely on this technology as it cuts other materials and delivers a smooth finish. Laser cutting, as the name implies, creates clean cuts into the material. The model contained in the file will be converted into dots and the distance between them determines how deep the engraving will be. So you have to use formats like jpg, pdf, png, or ai that are 2D files. What type of file do you need for Laser Engraving? Laser Engraving systems can not read any 3D files like. While the first one uses vector images to follow paths or lines, the second vaporizes the material to create an image into the material or give the design a 3D-like impression. Two different forms should be distinguished: line engraving and surface engraving. When the Laser Engraving process starts, the beam creates a high heat that burns or evaporates the surface according to the image from the file. However, before the actual engraving process can begin, the machine needs a file sent from a computer to the machine’s controller, which then positions the laser. It is a subtractive manufacturing method. Saws for metal - others (hacksaws, slitting saws, circular.The aim of Laser Engraving is to engrave a specific picture or logo onto a selected material.Exapro recommends to check the details with the seller before a purchase The information of this classified ad are only indicative. Please note that this description may have been translated automatically. The machine also comes with innovative auto nozzle cleaning and changing feature. Thus this machine provides a valuable function for sign makers and those working with digital graphics because it allows designs to be cut out of a wide range of substrates with the high accuracy and quality that is provided by vector cutting. The laser starts at a predetermined point and continues along the course of the line until the shape has been cut out. Therefore the designing and cutting process relies on lines to create the desired output. The word vector itself essentially means “line”. SLTL – The World First manufacturer of Fiber Laser Cutting system has introduced ‘Vector’ fiber laser cutting machine, considering specific needs of metal cutting industry. Spring machines - multislide / formers / coilers 26.Shaping - vertical / horizontal shaping / slotting machines 34.Saws for metal - others (hacksaws, slitting saws, circular.) 94.Milling - portal / gantry milling machines 125.Milling - cnc universal milling machines 249.Milling - cnc bed type milling machines 319.Milling - universal milling machines 253.Milling - travelling column milling machines 67.Machining centers - high-speed (18000+ rpm) 28.Lathes - vertical turret lathes with cnc 162.Lathes - Multispindle automatic lathes 579.Lathes - > 3001 mm - heavy duty lathes 224.Grinding machines - surface grinders 303.Grinding machines - miscellaneous (crankshaft, sharpening, tool grinders.Grinding machines - cylindrical external / internal grinders 267.Grinding machines - cylindrical centerless grinders 134.Gear machines - others (milling, testing, inspection.) 33.Finishing - others (washing / tumbling / vibratory.) 28.Finishing - lapping / honing / deburring machines 74.Drilling - others (multispindle, column, pillar.) 29.Drilling - floor type drilling machines (column, pillar) 15.Drilling - automatic/ CNC turret drilling machines 29.Borers - table type boring machines CNC 150.Borers - table type boring machines 140.Borers - floor type boring machines CNC 78.Borers - deep hole boring / drilling machines 41.

0 notes

Text

Maximizing the Capabilities of SLTL Laser Cutting Machines

SLTL laser cutting machines are cutting-edge tools that utilize laser beams to precisely cut through various materials. These machines offer several features that make them highly efficient and versatile. They are equipped with advanced control systems, high-power lasers, and intelligent software for optimal performance. Additionally, they often come with automated features like material handling systems and real-time monitoring capabilities.

The advantages of using SLTL laser cutting machines are numerous.

high precision and accuracy, allowing for intricate and complex designs

clean cuts with minimal material wastage

fast cutting speeds,.

can work with a wide range of metals, including Aluminum,Copper,Iron, Steel, Brass, Bronze, Silver, Gold, etc

Overall, SLTL laser cutting machines provide efficiency, flexibility, and quality in cutting.

youtube

To unleash the full potential of SLTL laser cutting machines, businesses can take several steps:

Upgrade the software and hardware

Keeping the machines up to date with the latest software and hardware upgrades ensures optimal performance. This includes installing the latest control systems, software updates, and laser sources. Upgrades can enhance cutting precision, speed, and overall efficiency.

Optimize the cutting parameters

Fine-tuning the cutting parameters, such as laser power, cutting speed, and focus, can improve the quality and efficiency of the cutting process. Conducting tests and experiments to find the optimal settings for different materials and thicknesses is crucial.

Train operators to maximize efficiency

Providing comprehensive training to operators is essential for utilizing the full potential of SLTL laser cutting machines. Operators should be well-versed in machine operation, maintenance, and troubleshooting. Continuous training and skill development can ensure efficient operation and minimize downtime.

SLTL laser cutting machines find extensive applications in various industries, including:

Automotive industry

These machines are used for cutting components like body panels, frames, and exhaust systems. The high precision and speed of SLTL laser cutting machines enable the automotive industry to achieve superior quality and efficiency in manufacturing processes.

Aerospace industry

SLTL laser cutting machines play a crucial role in aerospace manufacturing. They are utilized for cutting complex shapes in materials like aluminum, titanium, and composite materials. These machines enable the production of lightweight components with high structural integrity, meeting the stringent requirements of the aerospace industry.

Medical industry

SLTL laser cutting machines are employed in the medical field for cutting surgical instruments, implants, and medical devices. The precise cutting capabilities of these machines ensure accurate and reliable production of medical equipment, contributing to improved patient outcomes.

In conclusion, unleashing the potential of SLTL laser cutting machines can bring significant advantages to businesses across various industries. These machines offer high precision, clean cuts, and fast cutting speeds. By upgrading software and hardware, optimizing cutting parameters, and training operators, businesses can maximize the efficiency and productivity of these machines. Furthermore, SLTL laser cutting machines find applications in the automotive, aerospace, and medical industries, enabling superior quality and advanced manufacturing capabilities.

#cnc laser cutting machines#laser cutting machines#fiber laser cutting machines#laser machine#Youtube

2 notes

·

View notes

Text

How Fiber Laser Cutting Machines Benefit Marine Equipment Manufacturing

The marine industry demands precision, durability, and efficiency in manufacturing components for ships, boats, and other marine equipment. Fiber laser cutting machines have emerged as a key technology in meeting these demands. SLTL Group, a leader in laser cutting solutions, offers state-of-the-art fiber laser cutting machines that provide numerous advantages for marine equipment manufacturing.

The Importance of Precision in Marine Manufacturing

Marine equipment, such as ship hulls, propellers, and engine components, requires precise cutting and shaping to ensure proper function and longevity. Any errors in manufacturing can lead to serious consequences, such as equipment failure or reduced performance. Traditional cutting methods, like mechanical sawing or plasma cutting, often struggle to achieve the required precision and can introduce imperfections or stress into the materials.

Advantages of SLTL Group's Fiber Laser Cutting Machines

SLTL Group’s fiber laser cutting machines are designed to meet the high standards of the marine industry. Here are the key benefits:

1. Unmatched Precision

High Accuracy: Laser cutting machine can cut with incredible precision, allowing for tight tolerances and intricate designs that are essential in marine equipment manufacturing.

Smooth Edges: The clean cuts reduce the need for additional finishing processes, saving time and resources.

2. Efficiency and Speed

Faster Production: SLTL Group’s fiber laser machines cut faster than traditional methods, speeding up production timelines.

Automation Capabilities: These machines can be integrated into automated production lines, reducing labor costs and increasing throughput.

3. Material Versatility

Wide Range of Materials: Fiber lasers can cut various materials used in marine manufacturing, such as steel, aluminum, and composite materials.

Thickness Handling: The machines can handle different material thicknesses, providing flexibility in design and manufacturing.

4. Cost-Effective Operation

Low Maintenance: Fiber lasers require less maintenance compared to other cutting technologies, resulting in lower downtime and reduced operating costs.

Energy Efficiency: SLTL’s fiber lasers are energy-efficient, reducing overall energy consumption and contributing to a more sustainable manufacturing process.

5. Durability and Reliability

Robust Design: SLTL Group’s fiber laser machines are built to withstand the demanding environments of marine manufacturing facilities.

Consistent Performance: These machines deliver consistent cutting quality, ensuring every component meets the highest standards.

Best Features of SLTL Group's Laser Cutting Machines

SLTL Group's laser cutting machines are renowned for their advanced features, which make them a preferred choice in various industries. Here are the standout features:

High Precision Cutting

Ensures accurate cuts with tight tolerances.

Produces clean, burr-free edges, minimizing the need for secondary finishing.

Versatile Material Handling

Capable of cutting a wide range of materials, including metals, plastics, and composites.

Can process varying thicknesses, offering flexibility in manufacturing.

Advanced Automation

Supports integration with automated production lines for seamless operation.

Reduces manual intervention, lowering labor costs and increasing productivity.

Energy Efficiency

Utilizes fiber laser technology, which is more energy-efficient compared to traditional laser systems.

Contributes to lower operational costs and a reduced carbon footprint.

Durability and Reliability

Built with robust components designed to withstand industrial environments.

Provides consistent performance over long periods, ensuring reliability in production.

Benefits for Marine Equipment Manufacturing

Integrating SLTL Group’s fiber laser cutting machines into marine equipment manufacturing offers several key benefits:

Enhanced Quality Control: The precision and consistency of fiber lasers help maintain strict quality standards.

Reduced Waste: Accurate cutting minimizes material waste, leading to cost savings and a more sustainable operation.

Increased Production Capacity: Faster cutting speeds and automation allow for higher production volumes, meeting the growing demand in the marine industry.

Flexibility in Design: With the ability to cut complex shapes and various materials, manufacturers can innovate and create advanced designs for marine equipment.

Conclusion

SLTL Group fiber laser cutting machines provide the marine industry with a powerful tool for improving manufacturing processes. With their unmatched precision, efficiency, and versatility, these machines help marine equipment manufacturers achieve higher quality, reduce costs, and increase production capacity. As the marine industry continues to evolve, adopting advanced technologies like fiber laser cutting will be essential for staying competitive and meeting the demands of modern marine equipment.

For more information visit SLTL official website or contact at [email protected] or WhatsApp at +919925036495

0 notes

Text

The Future of Laser Welding: Why SLTL Leads the Way in India and Beyond

Introduction

Laser welding technology has revolutionized modern manufacturing by providing unmatched precision, speed, and efficiency. As industries evolve, the demand for advanced welding solutions grows, and SLTL (Sahajanand Laser Technology Limited) stands at the forefront of this transformation in India and beyond. This article explores the world of laser welding, highlights SLTL's pioneering contributions, and examines the future of this innovative technology.

Overview of Laser Welding Technology

Definition and Brief History of Laser Welding

Laser welding involves using a high-intensity laser beam to join materials, offering precision and control that traditional welding methods cannot match. Developed in the 1960s, laser welding has advanced significantly, becoming an essential tool in various industries.

Evolution of Laser Welding Techniques

Over the decades, laser welding has evolved with improvements in laser sources, automation, and integration capabilities. These advancements have expanded its applications, making it a critical technology in modern manufacturing.

Importance of Laser Welding in Modern Manufacturing

Laser welding’s precision, speed, and ability to join dissimilar materials make it invaluable in today’s manufacturing landscape. It reduces production times, improves quality, and opens new possibilities for innovative product designs.

Advantages Over Traditional Welding Methods

Laser welding offers several advantages over traditional methods, including greater precision, faster processing times, and the ability to weld a wider range of materials. These benefits have made it a preferred choice for many industries.

SLTL: Pioneering Laser Welding Technology in India

Introduction to SLTL (Sahajanand Laser Technology Limited)

Company Background and History

SLTL was established with the goal of innovating and has developed into a world leader in laser technology.Their commitment to excellence and continuous improvement has made them a trusted name in laser welding.

Vision and Mission

SLTL aims to revolutionize manufacturing through cutting-edge laser solutions, enhancing efficiency, precision, and sustainability across industries.

Innovations by SLTL in Laser Welding

Breakthrough Technologies and Patents

SLTL has introduced numerous breakthrough technologies in laser welding, holding several patents that underscore their innovative prowess.

Unique Selling Points of SLTL’s Laser Welding Machines

SLTL's machines are renowned for their high precision, speed, and integration capabilities, setting them apart from competitors.

Manufacturing Excellence

State-of-the-Art Production Facilities

SLTL's production facilities are equipped with the latest technology, ensuring that every machine meets the highest standards of quality and precision.

Commitment to Quality and Precision

SLTL's dedication to quality is evident in their rigorous testing and quality control measures, ensuring that each machine performs flawlessly.

Advanced Features of SLTL’s Laser Welding Machines

High Precision and Accuracy

SLTL's machines utilize advanced laser sources and control systems to achieve unmatched precision in welding.

Examples of High-Precision Applications

From intricate medical devices to complex aerospace components, SLTL's machines excel in applications requiring the highest precision.

Speed and Efficiency

SLTL's laser welding machines are designed for speed, significantly reducing processing times and increasing productivity.

Case Studies Demonstrating Efficiency

Numerous case studies highlight SLTL's machines' ability to enhance efficiency in various manufacturing processes.

Automation and Integration

SLTL's machines are compatible with automated systems and robotics, allowing seamless integration into existing production lines.

Applications of SLTL Laser Welding Machines

Automotive Industry

SLTL's machines play a crucial role in automotive manufacturing, providing precise and reliable welding solutions. Numerous automotive manufacturers have benefited from SLTL's advanced welding technology, improving quality and efficiency.

Aerospace and Defense

The strict requirements needed in aircraft manufacturing are met by SLTL's machinery, guaranteeing the best quality and dependability. Their technology is also vital in producing defense equipment, where precision and durability are paramount.

Electronics and Electrical Industries

SLTL's laser welding machines offer the precision needed for electronics manufacturing, ensuring high-quality products. From circuit boards to battery components, SLTL’s machines provide reliable welding solutions for various electrical applications.

Medical Devices and Equipment

In the medical field, precision and safety are critical. The precision required for the production of medical devices is provided by SLTL's machinery. Notable projects include advancements in medical technology driven by SLTL’s innovations.

SLTL’s Global Impact and Market Reach

Expanding Beyond India

SLTL has established a strong presence in international markets, exporting their cutting-edge laser welding machines worldwide. Their strategies for global expansion include forming partnerships, participating in international exhibitions, and continuous innovation.

Partnerships and Collaborations

SLTL collaborates with leading global companies to develop advanced welding solutions tailored to various industries' needs. These collaborations often result in joint ventures and research partnerships, driving further advancements in laser welding technology.

The Future of Laser Welding Technology

Emerging Trends in Laser Welding

The future of laser welding looks promising, with emerging trends like increased automation, AI integration, and enhanced precision. Upcoming technological advancements will further elevate the capabilities of laser welding, making it even more integral to modern manufacturing.

SLTL’s Role in Shaping the Future

SLTL continues to innovate, with several upcoming projects that promise to push the boundaries of laser welding technology. Their long-term vision includes leading the way in sustainable and efficient manufacturing practices, setting new standards for the industry.

Sustainability and Environmental Impact

Conclusion

SLTL has firmly established itself as a leader in laser welding technology, driving industry advancements and setting new standards with their pioneering innovations and global reach. As we look to the future, the potential for laser welding continues to grow, with SLTL leading the charge in enhancing manufacturing efficiency, precision, and sustainability. Businesses eager to stay competitive in the evolving manufacturing landscape should consider exploring SLTL's advanced laser welding solutions. For more information or to get started, visit SLTL's website or contact their sales team today.

0 notes

Text

Meeting Aerospace Standards: The Role of Fiber Laser Cutting Machines

The aerospace industry demands precision, reliability, and compliance with stringent standards to ensure the safety and performance of aircraft. One technology that has become indispensable in meeting these rigorous requirements is fiber laser cutting. Companies like SLTL are at the forefront of this technological revolution, offering advanced solutions that cater to the exacting needs of aerospace manufacturing.

The Importance of Precision in Aerospace Manufacturing

Aerospace components must adhere to tight tolerances and precise specifications. Even the smallest deviation can lead to significant performance issues or, worse, catastrophic failures. Therefore, precision is non-negotiable. Fiber laser cutting machines excel in delivering the high accuracy required, producing clean, exact cuts without the need for secondary finishing processes.

What Are Fiber Laser Cutting Machines?

Fiber laser cutting machines use a high-powered laser beam generated by fiber optics to cut materials. This beam is incredibly focused, allowing for fine, precise cuts with minimal heat-affected zones. The technology's versatility enables it to cut various materials, including metals, composites, and polymers, which are commonly used in aerospace applications.

Advantages of Fiber Laser Cutting in Aerospace

High Precision and Accuracy: Fiber lasers can achieve extremely tight tolerances, essential for aerospace parts. The precision reduces material wastage and ensures components fit perfectly in assemblies.

Speed and Efficiency: These machines offer high cutting speeds, increasing productivity while maintaining quality. Faster production cycles mean quicker turnaround times for aerospace manufacturers.

Material Versatility: Fiber lasers can cut a wide range of materials used in aerospace, from lightweight aluminum to tough titanium alloys. This flexibility is crucial as it allows manufacturers to use the best material for each application without changing their cutting technology.

Enhanced Cut Quality: The clean cuts produced by fiber lasers reduce the need for secondary finishing, saving time and reducing labor costs. The high-quality edges also improve the performance and lifespan of the components.

Reduced Heat Affected Zone (HAZ): Minimal heat input during cutting reduces thermal distortion and preserves the integrity of the materials, which is vital for maintaining the mechanical properties of aerospace components.

Automation and Integration: Modern fiber laser cutting systems can be integrated with automation solutions, such as robotic arms and automated loading/unloading systems. This integration further enhances efficiency and consistency in production.

Compliance with Aerospace Standards

Meeting aerospace standards such as AS9100 and ISO 9001 is essential for manufacturers. Fiber laser cutting machines help in achieving these standards through their precision, repeatability, and reliability. The technology ensures that every cut part meets the stringent quality requirements, facilitating certification and compliance processes.

Case Study: SLTL’s Contribution to Aerospace Manufacturing

SLTL Group, a leader in laser cutting solutions, provides advanced fiber laser cutting machines designed specifically for the aerospace industry. Their machines are equipped with state-of-the-art features that ensure high precision, efficiency, and versatility. By incorporating SLTL’s fiber laser technology, aerospace manufacturers can enhance their production capabilities, reduce costs, and ensure compliance with industry standards.

Future Trends and Innovations

As aerospace technology evolves, so do the demands on manufacturing processes. Future trends in fiber laser cutting include:

Increased Automation: Greater integration of AI and machine learning to optimize cutting processes.

Enhanced Material Capabilities: Development of lasers that can cut newer, more advanced materials.

Sustainability: Focus on reducing energy consumption and improving the environmental impact of manufacturing processes.

Conclusion

Fiber laser cutting machines are revolutionizing aerospace manufacturing by providing the precision, efficiency, and versatility needed to meet stringent aerospace standards. Companies like SLTL are leading the way with innovative solutions that empower manufacturers to produce high-quality components while maintaining compliance and enhancing productivity. As technology advances, the role of fiber laser cutting in aerospace will only continue to grow, driving the industry towards new heights of excellence and innovation.

0 notes

Text

✨ NEO Laser: Swift Setup, Precision Performance! 🌐🚀 Versatile, seamless integration for diverse applications. 🔍🏭

0 notes

Text

Experience the Future of Sheet Metal Working at EUROBLECH with SLTL Group

Are you ready to explore the latest advancements in sheet metal working? EUROBLECH 2024 is set to be a groundbreaking event, bringing together industry professionals from around the globe. SLTL Group is excited to be part of this prestigious event, where we will showcase our innovative laser cutting technologies that are transforming the industry.

Discover SLTL Group’s Innovations

At EUROBLECH, we will present our cutting-edge fiber laser cutting machines, including:

INFINITY F1: Our Ultra High Power Laser Cutting Machine, designed for unparalleled precision and efficiency.

INTEGREX: Innovative Fiber Laser Cutting Technology offering exceptional versatility.

X5: A 5 Axis 3D Fiber Laser Cutting Machine that effortlessly handles complex geometries.

Visit our booth to see live demonstrations, interact with our experts, and learn how SLTL Group is redefining sheet metal working.

Why Attend EUROBLECH 2024?

Advanced Technology: Get hands-on with the latest tools and technologies in sheet metal working.

Expert Knowledge: Attend educational sessions and workshops led by industry leaders.

Networking Opportunities: Meet professionals from around the world.

Inspiration: Discover new ideas and strategies to elevate your business.

Event Details

EUROBLECH 2024: October 22-25, 2024, at the Hanover Exhibition Centre in Germany.

Hall No: 12

Booth No: D86

Visit Us at Booth D86, Hall 12

Join SLTL Group at EUROBLECH 2024. Our team will be available to answer your questions, provide personalized consultations, and demonstrate how our solutions can help you achieve your manufacturing goals. Don’t miss the chance to see the future of sheet metal working up close.

Register Now

EUROBLECH 2024 is an event you won’t want to miss. Register today to secure your spot and be part of the most exciting gathering in the sheet metal industry. We look forward to seeing you there and sharing the innovations shaping the future of sheet metal working.

About SLTL Group

SLTL Group is a global leader in laser cutting technology, committed to delivering high-quality, innovative solutions to the metal fabrication industry. With a focus on precision, efficiency, and reliability, we help our clients stay ahead of the competition.

Conclusion

Join us at EUROBLECH 2024 to experience SLTL Group’s cutting-edge technology and discover how we can help you elevate your manufacturing capabilities. This is your chance to be part of an event that is driving the industry forward. See you at EUROBLECH!

For more information about EUROBLECH 2024 and to register, visit Registration . Follow us on Linkedin for updates and sneak peeks of what’s to come at the event.

0 notes

Text

Wie Schweizer Branchenführer Laserschneidtechnologie Einsetzen

Einleitung

EuroBLECH 2024, die führende Ausstellung für die Metallverarbeitungsindustrie, wird ein transformatives Ereignis für Schweizer Branchenführer sein. Der Fokus auf Laserschneidtechnologie bei der diesjährigen Veranstaltung wird den Schweizer Herstellern die Einblicke und Werkzeuge bieten, die sie benötigen, um der Kurve voraus zu sein. Einer der herausragenden Aussteller, die SLTL Group, wird ihre ultra-hochleistungsfähigen Laserschneidmaschinen präsentieren, die für die Schweizer Industrie ein Wendepunkt sein könnten.

Die Bedeutung von EuroBLECH 2024

EuroBLECH ist bekannt für seine Rolle bei der Förderung von Innovationen im Metallverarbeitungssektor. Diese zweijährliche Ausstellung zieht die weltweit führenden Hersteller, Lieferanten und Innovatoren an, die alle darauf erpicht sind, ihre neuesten Fortschritte zu präsentieren. Für Schweizer Branchenführer bietet EuroBLECH 2024 eine unschätzbare Gelegenheit, modernste Technologien zu erkunden und sich mit globalen Fachleuten zu vernetzen.

youtube

Der Aufstieg der Laserschneidtechnologie in der Schweiz

Der Bedarf an Präzision und Effizienz

Die Schweizer Fertigung ist gleichbedeutend mit Präzision und Qualität. Branchen wie die Uhrenherstellung, Medizintechnik und Luft- und Raumfahrt erfordern extrem hohe Standards, die die Laserschneidtechnologie erfüllen kann. Die Präzision des Laserschneidens stellt sicher, dass komplexe Designs und enge Toleranzen eingehalten werden, was für diese hochsensiblen Industrien entscheidend ist.

Der Übergang zur Automatisierung

Automatisierung ist ein weiterer treibender Faktor hinter der Einführung der Laserschneidtechnologie in der Schweiz. Automatisierte Laserschneidsysteme reduzieren den Bedarf an manuellen Eingriffen, was zu einer erhöhten Produktivität und niedrigeren Betriebskosten führt. Schweizer Hersteller sind bestrebt, diese Systeme zu integrieren, um ihre Effizienz zu steigern und ihre Wettbewerbsfähigkeit zu erhalten.

SLTL Group auf der EuroBLECH 2024

Die SLTL Group, ein Pionier in der Laserschneidtechnologie, wird ein wichtiger Aussteller auf der EuroBLECH 2024 sein. Ihre ultra-hochleistungsfähigen Laserschneidmaschinen versprechen, die Blechbearbeitungsprozesse für Schweizer Hersteller zu revolutionieren.

Treffen Sie die Laserexperten und entfalten Sie Ihr Blechpotenzial

Das Team von SLTL mit Laserspezialisten wird während der gesamten Veranstaltung zur Verfügung stehen, um Fragen zu beantworten, spezifische Anwendungen zu besprechen und personalisierte Beratung anzubieten. Dieser praxisorientierte Ansatz stellt sicher, dass die Besucher die perfekte Laserlösung finden, um ihre Abläufe zu transformieren.

Verpassen Sie nicht diese Gelegenheit!

EuroBLECH 2024 ist ein unverzichtbares Ereignis für diejenigen, die die Leistungsfähigkeit und Präzision der Lasertechnologie von SLTL aus erster Hand erleben möchten. Die Teilnehmer werden erfahren, wie diese innovativen Lösungen die Produktivität steigern und die Abläufe optimieren können. Die Ausstellung bietet auch eine Plattform, um sich mit Branchenführern und Fachleuten aus der ganzen Welt zu vernetzen.

Besuchen Sie uns am Stand 12-D86, Halle 12

Die SLTL Group lädt alle Teilnehmer ein, ihren Stand auf der EuroBLECH 2024 zu besuchen. Der Stand befindet sich in Halle 12, Stand 12-D86, wo die Besucher aus erster Hand sehen können, wie die Lasertechnologie von SLTL ihre Blechbearbeitungsprozesse revolutionieren kann.

Warum die ultra-hochleistungsfähige Laserschneidmaschine von SLTL ein Wendepunkt ist

Unübertroffene Präzision und Geschwindigkeit

Die ultra-hochleistungsfähigen Laserschneidmaschinen von SLTL bieten unübertroffene Präzision und Geschwindigkeit. Diese Maschinen können komplexe Designs mühelos verarbeiten und gewährleisten, dass jeder Schnitt mit höchster Genauigkeit erfolgt. Für Schweizer Industrien, in denen Präzision von entscheidender Bedeutung ist, ist diese Technologie von unschätzbarem Wert.

Erhöhte Effizienz

Die Effizienz der Laserschneidmaschinen von SLTL führt zu höherer Produktivität und niedrigeren Betriebskosten. Die Fähigkeit, Materialien schnell und präzise zu schneiden, bedeutet, dass Produktionslinien schneller arbeiten können, um den Anforderungen eines wettbewerbsintensiven Marktes gerecht zu werden.

Vielseitigkeit in den Anwendungen

Die Laserschneidtechnologie von SLTL ist vielseitig und kann eine breite Palette von Materialien und Anwendungen verarbeiten. Ob dünne Metalle für Uhrenkomponenten oder dickere Materialien für Luft- und Raumfahrtteile, diese Maschinen können sich an verschiedene Bedürfnisse anpassen und sind daher perfekt für Schweizer Hersteller geeignet.

Engagement für Nachhaltigkeit

Neben ihren Leistungsmerkmalen sind die Laserschneidmaschinen von SLTL auf Nachhaltigkeit ausgelegt. Sie verbrauchen weniger Energie im Vergleich zu herkömmlichen Schneidmethoden und reduzieren den ökologischen Fußabdruck von Fertigungsprozessen. Dies entspricht dem Engagement der Schweiz für ökologische Verantwortung.

Wie Schweizer Branchenführer diese Technologie einsetzen

Fallstudien zur Einführung

Mehrere Schweizer Unternehmen haben bereits begonnen, die Laserschneidtechnologie von SLTL in ihre Abläufe zu integrieren. Ein führender Uhrenhersteller beispielsweise hat bedeutende Verbesserungen bei Produktionsgeschwindigkeit und Präzision gemeldet, die es ihm ermöglichen, höhere Nachfrage zu erfüllen, ohne die Qualität zu beeinträchtigen.

Schulung und Unterstützung

Die Einführung neuer Technologien kann herausfordernd sein, aber SLTL bietet umfassende Schulungen und Unterstützung, um einen reibungslosen Übergang zu gewährleisten. Schweizer Hersteller profitieren von praxisorientierten Schulungssitzungen und kontinuierlicher Unterstützung, die es ihnen ermöglichen, die Fähigkeiten ihrer neuen Laserschneidmaschinen voll auszuschöpfen.

Zukünftige Aussichten

Die Einführung der Laserschneidmaschinen von SLTL ist erst der Anfang. Da immer mehr Schweizer Unternehmen die Vorteile erkennen, wird erwartet, dass diese Technologie zum Standard in der Industrie wird. Dies wird zu weiteren Fortschritten in den Fertigungsprozessen und einer stärkeren Wettbewerbsposition der Schweizer Industrie auf globaler Ebene führen.

Fazit

EuroBLECH 2024 wird ein entscheidendes Ereignis für Schweizer Branchenführer sein, das das transformative Potenzial der Laserschneidtechnologie aufzeigt. Die ultra-hochleistungsfähigen Laserschneidmaschinen der SLTL Group stehen an der Spitze dieser Revolution und bieten unübertroffene Präzision, Effizienz und Vielseitigkeit. Durch die Einführung dieser modernen Lösungen können Schweizer Hersteller ihre Produktivität steigern, Kosten senken und ihren Ruf für Qualität und Innovation aufrechterhalten.

Besuchen Sie SLTL am Stand 12-D86, Halle 12, um zu entdecken, wie ihre Lasertechnologie Ihre Blechbearbeitungsprozesse revolutionieren kann. Verpassen Sie nicht diese Gelegenheit, die Laserexperten zu treffen und Ihr Blechpotenzial zu entfalten.

#Laserschneidmaschine#Rohrschneidmaschine#Blechlaserschneidmaschine#Metallschneidmaschine#Laserschneidhersteller#Youtube

0 notes

Text

Cutting-Edge Technology: Ultra High Power Lasers Changing the Game in USA Sheet Metal Fabrication

In the realm of sheet metal fabrication, technological advancements continually redefine what’s possible. One such innovation making waves across the industry is the advent of Ultra High Power laser cutting machines. These cutting-edge tools are not just pushing boundaries but reshaping the very landscape of sheet metal fabrication in the USA.

What are Ultra High Power Lasers?

Ultra High Power lasers represent a significant leap forward in laser cutting technology. Traditionally, CO2 and fiber lasers have been prevalent, but UHP lasers take performance to a whole new level. These lasers operate at power levels beyond 10 kW, sometimes even reaching up to 30 kW or more. This immense power output translates to faster cutting speeds, increased thickness capabilities, and superior cutting quality across a wide range of metals.

youtube

The Impact on Sheet Metal Fabrication

Increased Efficiency and Speed

UHP lasers can cut through thick metal sheets at unprecedented speeds. This efficiency not only accelerates production but also reduces lead times significantly. Manufacturers can now handle larger volumes with greater ease, meeting tight deadlines without compromising on quality.

Expanded Design Possibilities

With UHP lasers, intricate designs and complex geometries are more achievable than ever before. The precision of these lasers allows for finer detailing and tighter tolerances, opening doors to innovative product designs that were previously challenging or impossible to realize.

Enhanced Material Flexibility

From stainless steel to aluminum and beyond, UHP lasers demonstrate remarkable versatility. They can effortlessly cut through a variety of metals and alloys, offering manufacturers greater flexibility in material selection without sacrificing cutting performance.

Cost Efficiency and Sustainability

Despite their high power output, UHP lasers are designed to be energy-efficient. Their optimized cutting processes minimize waste material, leading to reduced operational costs and environmental impact. This combination of productivity and sustainability is increasingly attractive to modern fabrication facilities.

Adoption and Future Trends

The adoption of UHP lasers in USA sheet metal fabrication is rapidly gaining momentum. Leading manufacturers are investing in this technology to stay competitive in a global market that demands both speed and precision. As these lasers continue to evolve, advancements in automation and artificial intelligence promise even greater efficiency and consistency in production processes.

SLTL is Excited to Connect with Florida's Growing Manufacturing Base

This year, we can't wait to bring SLTL’s Ultra High-Powered Laser Innovations to Orlando and provide the expanding Florida manufacturing sector with another opportunity to witness SLTL's cutting-edge laser technology up close. Manufacturers from all over the world will gather in Orlando for FABTECH 2024 to witness innovative solutions and remain ahead of the curve in manufacturing technology. SLTL is going to offer attendees the opportunity to witness live equipment demonstrations, build strategic partnerships, identify solutions, and stay ahead of the curve in the ever-evolving manufacturing landscape.

Knowledge Hub at SLTL’s Booth

The 2024 SLTL booth will be a knowledge hub for attendees, featuring demonstrations and insights into laser cutting, laser marking, laser welding, automation, smart manufacturing, and much more. In addition, attendees will gain knowledge about IoT-integrated machinery and witness live demonstrations of them.

Prepare for the Groundbreaking Experience

Get ready because SLTL is prepared to have an amazing time with the attendees at this event, which promises to be an incredible experience in its own way. Come see us in Hall No – S31150 at Orange County Convention Center in Orlando, Florida, from October 15-17, 2024.

Conclusion

Ultra High Power lasers are not just a technological evolution but a revolution in USA sheet metal fabrication. They empower manufacturers to achieve levels of productivity and quality that were previously unimaginable, reshaping industry standards and driving innovation forward. As this technology matures, its impact will likely extend beyond fabrication, influencing various sectors reliant on metal components. For those at the forefront of this transformation, embracing UHP lasers isn’t just about keeping pace; it’s about leading the charge towards a future where possibilities in sheet metal fabrication are limitless.

0 notes

Text

SLTL Group präsentiert auf der EuroBLECH 2024 in Deutschland eine Lösung zum Ultrahochleistungs-Laserschneiden mit IoT-Technologie

Auf der mit Spannung erwarteten EuroBLECH 2024 in Deutschland wird die SLTL Group ihre neueste Innovation im Bereich der Blechbearbeitung vorstellen: eine Ultrahochleistungs-Laserschneidmaschine, die mit modernster IoT-Technologie ausgestattet ist. Diese bahnbrechende Entwicklung verspricht, die Branche zu revolutionieren, indem sie Präzision, Effizienz und Konnektivität in Herstellungsprozessen verbessert.

Hauptmerkmale der Ultra High Power Laser Cutting Solution

Erweiterte IoT-Integration: Die Integration der IoT-Technologie ermöglicht Echtzeitüberwachung und Datenanalyse und ermöglicht so vorausschauende Wartung, reduzierte Ausfallzeiten und optimierte Leistung. Bediener können per Fernzugriff auf Maschinendaten zugreifen, was die Verwaltung und Fehlerbehebung von Vorgängen von überall aus erleichtert.

Hochleistungslasertechnologie: Mit deutlich erhöhten Leistungsstufen können diese Laser dickere und härtere Materialien mit höherer Geschwindigkeit und Genauigkeit schneiden. Dieser Fortschritt verbessert nicht nur die Produktivität, sondern erweitert auch die Palette der verarbeitbaren Materialien, einschließlich hochfester Legierungen und Verbundwerkstoffe.

Verbesserte Präzision und Qualität: Die Hochleistungslaserschneidlösung bietet beispiellose Präzision, was zu saubereren Schnitten und minimalem Materialabfall führt. Diese Präzision ist entscheidend für Branchen, die komplizierte Designs und enge Toleranzen erfordern, wie z. B. die Luft- und Raumfahrt, die Automobilindustrie und die Elektronik.

Energieeffizienz: Trotz der höheren Leistungsabgabe sind diese neuen Lasersysteme energieeffizienter konzipiert, was die Betriebskosten und die Umweltbelastung reduziert. Der Einsatz moderner Kühlsysteme und Energiemanagementtechniken trägt zur allgemeinen Nachhaltigkeit bei.

Benutzerfreundliche Schnittstelle: Die Maschinen verfügen über eine intuitive Benutzeroberfläche, die es den Bedienern erleichtert, den Schneidevorgang einzurichten und zu steuern. Die Schnittstelle ist darauf ausgelegt, komplexe Vorgänge zu vereinfachen, die Lernkurve zu verkürzen und die Produktivität zu verbessern.

Revolutionierung der Blechbearbeitungsbranche

Die Einführung der Laserschneidmaschine mit IoT-Technologie durch die SLTL Group wird die Blechbearbeitungsbranche in mehrfacher Hinsicht verändern:

Höhere Produktivität: Die Fähigkeit, dickere Materialien mit höherer Geschwindigkeit zu schneiden, steigert die Produktionsraten erheblich. Dies bedeutet, dass Hersteller höhere Nachfrageniveaus erfüllen können, ohne Kompromisse bei der Qualität einzugehen.

Kosteneffizienz: Verbesserte Präzision reduziert Materialverschwendung und IoT-gesteuerte vorausschauende Wartung minimiert ungeplante Ausfallzeiten, was beides zu niedrigeren Betriebskosten beiträgt. Das energieeffiziente Design reduziert die mit dem Stromverbrauch verbundenen Kosten weiter.

Verbesserte Flexibilität: Die Fähigkeit, eine größere Bandbreite an Materialien zu verarbeiten, ermöglicht es Herstellern, ihr Produktangebot zu diversifizieren. Diese Flexibilität ist besonders wertvoll in Branchen, in denen Anpassung und Materialvielfalt von entscheidender Bedeutung sind.

Echtzeitüberwachung und -wartung: Die IoT-Integration ermöglicht eine kontinuierliche Überwachung der Maschinenleistung, erleichtert eine proaktive Wartung und verringert die Wahrscheinlichkeit unerwarteter Ausfälle. Dies gewährleistet einen zuverlässigeren und konsistenteren Produktionsprozess.

Nachhaltigkeit: Energieeffiziente Designs und reduzierte Materialverschwendung entsprechen der zunehmenden Betonung der Nachhaltigkeit in der Fertigung. Diese Innovationen helfen Unternehmen, ihren CO2-Fußabdruck zu reduzieren und Umweltvorschriften einzuhalten.

Der Auftritt der SLTL Group auf der EuroBLECH 2024 ist ein Beweis für ihr Engagement, die Grenzen der Laserschneidtechnologie zu erweitern und neue Maßstäbe in der Blechbearbeitungsbranche zu setzen. Mit diesen Fortschritten können sich Hersteller auf eine Zukunft mit verbesserter Effizienz, Präzision und Konnektivität freuen.

Treffen Sie die Laserexperten und entfesseln Sie Ihr Blechpotenzial

Unser Team aus Laserspezialisten ist während der gesamten Veranstaltung am Stand und steht bereit, Ihre Fragen zu beantworten, spezifische Anwendungen zu besprechen, die Sie im Sinn haben, und Ihnen eine persönliche Beratung zu bieten. Ganz gleich, welche Anforderungen Sie an Blech stellen, wir sind hier, um Ihnen zu helfen, die perfekte Laserlösung zu finden, um Ihren Betrieb umzugestalten.

Verpassen Sie diese Gelegenheit nicht!

Dies ist Ihre Chance:

Erleben Sie die Leistung und Präzision der Lasertechnologie von SLTL aus erster Hand.

Erfahren Sie, wie unsere innovativen Lösungen Ihre Produktivität steigern und Ihren Betrieb rationalisieren können.

Vernetzen Sie sich mit Branchenführern und Kollegen aus der ganzen Welt.

Besuchen Sie uns am Stand 12-D86, Halle 12

Wir laden Sie ein, an unserem Stand auf der EuroBLECH 2024 vorbeizuschauen. Lassen Sie sich zeigen, wie die Lasertechnologie von SLTL Ihre Blechbearbeitungsprozesse revolutionieren kann.

0 notes

Text

From Design to Reality: Transforming Ideas with SLTL's Laser Cutting Machines

Introduction

In the realm of advanced manufacturing and creative industries, laser cutting technology has revolutionized the process of transforming intricate designs into tangible products. Sahajanand Laser Technology Ltd (SLTL), a pioneer in laser technology, plays a crucial role in this transformation. This blog explores how SLTL's cutting-edge laser cutting machines bridge the gap between design concepts and physical reality with unparalleled precision and innovation.

Understanding SLTL's Laser Cutting Machines

SLTL's laser cutting machines harness cutting-edge technology to deliver precise cutting, engraving, and marking capabilities across a wide range of materials. These machines are trusted by industries worldwide for their reliability, efficiency, and ability to handle complex designs with ease.

The Journey from Design to Reality with SLTL

1. Designing with Precision

SLTL's laser cutting machines begin with a digital design file that outlines every detail of the intended product. Designers can create intricate patterns, geometric shapes, and custom artworks knowing that SLTL's machines will faithfully replicate their vision.

2. Material Selection and Preparation

SLTL machines accommodate various materials, including metals like stainless steel and aluminium, as well as non-metals such as wood, acrylic, and textiles. Each material undergoes meticulous preparation to ensure optimal cutting results, maintaining high standards of quality and durability.

3. Precision Cutting and Engraving

Once the design and material are set, SLTL's laser cutting machines execute the cutting process with unmatched precision. High-energy laser beams precisely follow the design specifications, producing clean edges, intricate details, and smooth finishes that meet the exacting demands of modern manufacturing.

4. Versatility in Applications

From industrial parts and automotive components to architectural models and personalized gifts, SLTL's laser cutting machines offer versatility in both industrial and artistic applications. They empower businesses to prototype new ideas swiftly and efficiently, facilitating innovation and rapid product development.

Advantages of SLTL's Laser Cutting Machines

- Precision and Accuracy: SLTL's machines deliver precise cuts and engraving with minimal material waste, ensuring consistent quality across production runs.

- Versatility: They can handle a wide range of materials and thicknesses, adapting to various manufacturing and artistic requirements.

- Efficiency: SLTL's laser cutting technology is faster than traditional methods, reducing production times and enabling quick turnaround for customized projects.

- Customization: Designers benefit from the ability to create unique, personalized products with intricate details and complex geometries that showcase their creativity.

Case Studies and Success Stories

Numerous industries have embraced SLTL's laser cutting technology to streamline operations and elevate their product offerings. By integrating SLTL's machines into their workflows, businesses have achieved significant improvements in efficiency, cost-effectiveness, and customer satisfaction.

Conclusion

SLTL's laser cutting machines epitomize innovation and excellence in the realm of manufacturing and design. Their ability to transform ideas into reality with precision and efficiency makes them indispensable tools for forward-thinking businesses and creative professionals alike. As technology continues to evolve, SLTL remains at the forefront, driving advancements in laser cutting technology and unlocking new possibilities for industries worldwide.

Embrace the transformative power of SLTL's laser cutting machines and embark on a journey to bring your most ambitious ideas to life with unmatched precision and creativity.

1 note

·

View note

Text

Choosing the Best Laser Cutting Machine for Your Sheet Metal Fabrication Business in the USA

Selecting the right laser cutting machine is crucial for the success of any sheet metal fabrication business in the USA. SLTL Group, a leader in laser technology, offers a range of cutting-edge solutions, including advanced 3D laser cutting machines. This blog explores the features, advantages, and reasons to invest in SLTL Group's 3D laser cutting machines, helping you make an informed decision for your fabrication business.

Understanding SLTL Group's 3D Laser Cutting Machines:

SLTL Group's 3D laser cutting machines represent the pinnacle of precision and versatility in sheet metal fabrication. These machines are designed to handle complex geometries and provide unmatched accuracy, making them ideal for industries that demand high-quality output and innovative design capabilities.

Key Features of SLTL Group's 3D Laser Cutting Machines:

Multi-Axis Cutting Capability:

SLTL Group's 3D laser cutting machines operate on multiple axes, allowing for intricate cuts on three-dimensional surfaces. This capability enables the fabrication of complex parts with precise detailing and minimal material waste.

High-Power Laser Technology:

Equipped with high-power laser sources, these machines deliver superior cutting speeds and exceptional cutting quality. The powerful laser beam ensures clean, precise cuts even on thick materials, enhancing productivity and reducing production times.

Advanced Control Systems:

The machines feature advanced control systems that enable precise control over the cutting process. This includes real-time monitoring, automatic adjustments, and programmable cutting paths, ensuring consistent and accurate results for every project.

Robust Construction:

Built with durability in mind, SLTL Group's 3D laser cutting machines are constructed from high-quality materials and components. Their robust design ensures reliable performance and longevity, even in demanding industrial environments.

Advantages of SLTL Group's 3D Laser Cutting Machines:

Precision and Accuracy:

The multi-axis capability of SLTL Group's 3D laser cutting machines allows for intricate cuts with high precision. This ensures that each component meets exact specifications, reducing errors and improving overall product quality.

Versatility in Applications:

From simple flat sheets to complex three-dimensional parts, SLTL Group's machines can handle a wide range of materials and thicknesses. This versatility makes them suitable for diverse applications across various industries, including automotive, aerospace, and electronics.

Increased Efficiency and Productivity:

The advanced features of SLTL Group's 3D laser cutting machines, such as high-speed cutting and automated processes, enhance efficiency and productivity. By reducing setup times and optimizing production workflows, businesses can meet tight deadlines and increase throughput.

Why Invest in SLTL Group's 3D Laser Cutting Machines:

Advanced Technology and Innovation:

SLTL Group is known for its commitment to innovation and technological advancement. Investing in their 3D laser cutting machines allows businesses to stay ahead of competitors by offering cutting-edge capabilities and superior product quality.

Cost-Effectiveness:

While the initial investment in a 3D laser cutting machine may be higher, the long-term benefits include significant cost savings. These machines reduce material waste, labor costs, and energy consumption, leading to a more efficient and cost-effective production process.

Support and Service:

SLTL Group provides comprehensive support and training for their 3D laser cutting machines. From installation to ongoing maintenance and technical support, businesses can rely on SLTL Group to ensure optimal performance and maximum uptime.

Sustainability:

SLTL Group's 3D laser cutting machines are designed to be energy-efficient, contributing to sustainable manufacturing practices. By minimizing environmental impact and reducing carbon footprint, businesses can align with global sustainability goals.

Conclusion:

Choosing the best laser cutting machine for your sheet metal fabrication business in the USA requires careful consideration of features, capabilities, and long-term benefits. SLTL Group's3D laser cutting machines offer unmatched precision, versatility, and efficiency, making them an excellent investment for businesses looking to enhance their capabilities and achieve superior results.

By investing in SLTL Group's advanced technology, fabrication businesses can streamline operations, improve productivity, and meet the demands of a competitive market. This strategic investment not only positions companies for growth but also ensures they remain at the forefront of innovation in sheet metal fabrication.

1 note

·

View note