#steel rolling mill

Text

Essential Features of a Steel Rolling Mill

A steel rolling mill processes metal sheets into desired shapes and thicknesses through hot or cold rolling. It is essential in producing steel products like sheets, rods, and beams with uniform dimensions and surface finish. If you require any other details about the steel rolling mill then visit our website.

0 notes

Text

Why Metal Barns Are the Best Investment for Your Farm

The agriculture industry has seen a rise in the use of metal barns because of their many benefits over conventional timber barns. Because of their dependability, affordability, and adaptability, they are a great option for farmers and other agricultural workers. The top five advantages of employing metal barns for agricultural purposes will be discussed in this article, emphasizing its superiority as a choice for your farming activities.

1. Durability and Longevity

Resistance to Harsh Weather Conditions

Weather-Resistant: Metal barns are designed to withstand severe weather conditions, including heavy snow, strong winds, and torrential rain.

Pest-Resistant: Unlike wooden barns, metal barns are not susceptible to pests such as termites, which can cause significant damage over time.

Low Maintenance

Minimal Upkeep: Metal barns require less maintenance compared to wooden structures. They do not rot, warp, or crack, ensuring long-lasting performance.

Corrosion Resistance: High-quality metal barns are often made from galvanized steel, which is resistant to rust and corrosion, further extending their lifespan.

2. Cost-Effectiveness

Lower Initial Costs

Affordable Construction: The cost of constructing a metal barn is generally lower than that of a wooden barn, making it a cost-effective option for farmers.

Quick Assembly: Metal barns are easier and quicker to assemble, reducing labor costs and construction time.

Energy Efficiency

Insulation Options: Metal barns can be easily insulated to maintain stable temperatures, reducing energy costs for heating and cooling.

Reflective Roofing: Many metal barns come with reflective roofing options that help keep the interior cooler in the summer, further lowering energy expenses.

3. Versatility and Customization

Flexible Design Options

Customizable Layouts: Metal barns offer a high degree of customization, allowing you to design the interior layout to suit your specific agricultural needs, whether it’s for livestock housing, equipment storage, or feed storage.

Expandable: As your farming operations grow, metal barns can be easily expanded to accommodate additional space requirements.

Multi-Purpose Use

Livestock and Storage: Metal barns can be used for a variety of purposes, from housing livestock to storing crops and farm equipment.

Workshops and Offices: They can also be adapted for use as workshops, offices, or processing areas, providing a versatile solution for various agricultural activities.

4. Enhanced Safety and Security

Fire Resistance

Non-Combustible Materials: Metal barns are made from non-combustible materials, reducing the risk of fire and providing a safer environment for your livestock and equipment.

Fireproof Insulation: Additional fireproof insulation options are available to further enhance the safety of the structure.

Secure Storage

Sturdy Construction: The robust construction of metal barns provides a secure storage solution for valuable equipment and livestock, protecting them from theft and vandalism.

Lockable Doors: Metal barns often come with lockable doors and windows, adding an extra layer of security to your agricultural operations.

5. Environmental Benefits

Sustainable Materials

Recyclable Steel: Metal barns are typically made from steel, which is 100% recyclable. This makes them an environmentally friendly choice for sustainable farming.

Reduced Wood Usage: By opting for metal barns, you are reducing the demand for wood, helping to preserve forests and reduce deforestation.

Energy Efficiency

Eco-Friendly Insulation: The use of eco-friendly insulation materials in metal barns helps to reduce energy consumption, lowering your farm’s carbon footprint.

Solar Panel Compatibility: Metal roofs are ideal for installing solar panels, allowing you to harness renewable energy and further reduce your environmental impact.

Conclusion

Metal barns are a great option for agricultural applications because they provide a number of advantages. Differentiating them from typical wooden barns are their greater safety, durability, affordability, and environmental benefits. Farmers can contribute to sustainable farming practices and ensure the smooth and effective functioning of their agricultural activities by using metal barns product.

Metal barns offer a dependable and flexible solution, regardless of the function of the structure—least expensive housing for cattle, equipment storage, or multipurpose application. Purchasing a metal barn will be a wise investment that will meet your farming demands for a very long time.

Visit Bulldog Steel Structures to learn more about customizable options and superior metal barns. Our staff is committed to assisting you in locating the ideal metal barn to satisfy your farming requirements.

0 notes

Text

0 notes

Text

Steel being an Alloy of Iron with carbon generally requires the carbon to be fairly uniform to improve ductility, and thus the fresh cast iron which has carbon distributed unevenly throughout it, in order to fix this you must work the iron to turn into steel, if it is lightly worked by hand like say a hammer an anvil you get wrought iron but to get your good modern steel you need to roll it with big ass rollers which can be done both hot or cold

26 notes

·

View notes

Text

rolling mill

45 notes

·

View notes

Text

sometimes you just feel the inner need to make an image that just goes hard

#digital art#oc: mill#oc art#anthro shark#shark furry#art#They're not smoking#that's a rolled wafer stick#or a steel drill bit#depends on the day

9 notes

·

View notes

Photo

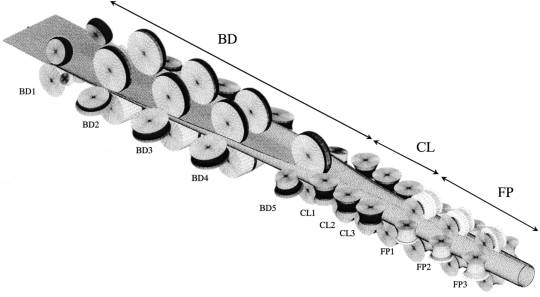

The new forming mill (FF mill) used for the study, Outline of New Forming Equipment for Hikari 24” ERW Mill, NIPPON STEEL TECHNICAL REPORT No. 90 July 2004

12 notes

·

View notes

Text

It was deja vu all over again on The Gilded Age tonight; Robert Sean Leonard can't stop dying from cancer, but Morgan Spector saw factory men with guns and decided not to repeat his Boardwalk exit.

#The Gilded Age#is anyone on this show allowed the SLIGHTEST moral ambiguity?#I can't believe they had Mr. Russell back down#that's not how steel mill strikes went#they were bloody and people died they didn't just shout for a few minutes and then the barons gave in#rolling my eyes so hard

5 notes

·

View notes

Text

Leading Steel Manufacturer and Rebar Supplier in the UAE

Gulf Steel stands as a premier steel manufacturer in the UAE, renowned for delivering high-quality steel products and services that cater to the diverse needs of the construction industry. As a trusted name among rebar suppliers in the UAE, we specialize in the production of top-grade reinforcement steel bars and plain bars, ensuring our clients receive materials that are both durable and reliable for various construction projects.

Our extensive experience in the steel industry has positioned us as one of the leading rebar manufacturers in the UAE. Gulf Steel is equipped with advanced manufacturing facilities, including a state-of-the-art rebar cut and bend factory in the UAE, where precision and quality are at the forefront of our production processes. Our cut and bend steel manufacturers in the UAE provide tailored solutions to meet specific project requirements, making us a preferred partner for both small and large-scale construction projects.

At Gulf Steel, we understand the critical role that reinforcement steel plays in ensuring the structural integrity of buildings and infrastructure. As a result, our reinforcement steel suppliers in the UAE are committed to delivering products that meet stringent industry standards. We take pride in being among the top steel rebar manufacturers in the UAE, with a focus on producing steel bars that offer superior strength and flexibility.

Our commitment to quality is evident in every aspect of our operations, from manufacturing to distribution. Gulf Steel’s strategic location and efficient logistics make us a reliable reinforcement steel bar supplier in Abu Dhabi and throughout the UAE. Whether you are looking for steel bar suppliers in the UAE or a steel factory in Abu Dhabi, Gulf Steel ensures that you receive top-tier products delivered on time.

As one of the best steel manufacturers in the UAE, Gulf Steel continuously invests in modern technology and infrastructure to maintain our position at the forefront of the industry. Our steel rolling mills in the UAE are equipped with the latest technology, allowing us to produce a wide range of steel products that meet the diverse needs of our clients. From steel manufacturers in Abu Dhabi to rebar suppliers in the UAE, Gulf Steel is recognized for our quality, reliability, and commitment to excellence.

Gulf Steel is more than just a steel manufacturing company in Abu Dhabi; we are a partner in your construction success. Our products are designed to meet the highest standards of safety and performance, ensuring that every project we contribute to is built on a foundation of strength and durability. Our reputation as one of the best steel factories in Abu Dhabi is built on our unwavering commitment to quality, innovation, and customer satisfaction.

Whether you are in need of rebar UAE, steel suppliers in Abu Dhabi, or a leading steel manufacturing company in the UAE, Gulf Steel is your go-to partner. We are dedicated to providing superior steel solutions that contribute to the success of your construction projects, helping you build a stronger future with Gulf Steel.

#Rebar Exporters#Plain Bars uae#steel rebar manufacturers in uae#reinforcement steel suppliers in uae#reinforcement steel bar suppliers in abu dhabi#reinforcement steel bar supplier in abu dhabi#rebar manufacturers#rebar suppliers in uae#reinforcement steel bars#rebar manufacturers in uae#steel bar suppliers in uae#rebar cut and bend factory in uae#cut and bend steel manufacturers in uae#steel uae#Rebar Supplier#steel manufacturer in uae#best steel factory in abu dhabi#Best steel manufacturers in uae#Rebar UAE#steel suppliers in abu dhabi#steel manufacturers in abu dhabi#steel companies in uae#Steel Factory in Abu Dhabi#steel manufacturing company in Abu Dhabi#steel factory in uae#steel manufacturing companies in uae#steel rolling mills in uae

1 note

·

View note

Text

Evolving Iron and Steel Landscape_Tata Steel Industrial Consulting

The iron & steel industry is the backbone of modern civilization. But to stay competitive, you need to embrace innovation and harness the power of cutting-edge technology.

That's where we come in. Our iron & steel technology solutions are designed to revolutionize your production process from the ground up. We don't just offer generic solutions - we work closely with you to understand your specific needs and challenges.

Visit our official website at https://consulting.tatasteel.com/ to learn more.

#steel production processes#iron making#iron ore processing#iron production process#steel plant consultants in india#steel industry consultants in india#steel business consulting#rolling mill consultant#rolling mill consultants in india#technology consulting#technology consulting firms#technology consultancy services#material testing#laboratory testing services

0 notes

Text

The Benefits of Rent-to-Own Metal Buildings: Flexibility and Affordability

The popularity of metal buildings has increased dramatically in recent years because of its affordability, adaptability, and durability. Metal structures are a great option if you need more storage, a workshop, or a personalised garage. For many, though, the initial outlay required to acquire these structures can be a major deterrent. The Rent-to-Own option excels in this situation since it is cost-effective and flexible. In this article, we will explore the numerous benefits of Rent-to-Own metal buildings and why this financing option is becoming increasingly popular.

Understanding Rent-to-Own

Rent-to-Own is a financing arrangement that allows individuals to lease a metal building with the option to purchase it over time. Instead of paying the full purchase price upfront, you make manageable monthly payments that contribute towards owning the building. This arrangement provides immediate access to the building while spreading the cost over a period, making it easier to manage financially.

Affordability: Breaking Down Financial Barriers

No Large Upfront Costs

One of the most significant advantages of Rent-to-Own metal buildings is the elimination of large upfront costs. Traditional purchasing methods often require a substantial down payment, which can be a financial burden. With Rent-to-Own, you can acquire the building you need without draining your savings or taking out a large loan.

Manageable Monthly Payments

Rent-to-Own arrangements feature predictable, manageable monthly payments. This allows you to budget more effectively and avoid financial strain. The structured payment plan ensures that you can gradually work towards owning the building without compromising other financial obligations.

No Credit Check Required

Unlike traditional financing options that often require a credit check, Rent-to-Own typically does not. This inclusivity makes it accessible to a broader range of individuals, including those with less-than-perfect credit scores. It provides an opportunity for everyone to improve their property with a metal building, regardless of their credit history.

Flexibility: Adapting to Your Needs

Immediate Access

Rent-to-Own metal buildings provide immediate access to the structure. Whether you need extra storage space, a workshop, or a garage, you can start using the building right away. This is particularly beneficial for those who require a quick solution without the wait associated with saving for a full purchase.

Easy Upgrades and Customizations

As your needs evolve, so can your Rent-to-Own metal building. These structures are highly customizable and expandable. If you require additional space or specific features, you can easily modify the building to suit your requirements. This flexibility ensures that your investment remains valuable and relevant over time.

Opt-Out Options

The Rent-to-Own model offers the flexibility to opt out of the agreement if your circumstances change. If you find that you no longer need the building or if your financial situation shifts, you can typically end the lease without severe penalties. This flexibility provides peace of mind, knowing that you are not locked into a long-term commitment if your needs change.

Building Equity: Investment Over Time

Equity Accumulation

With each monthly payment, you are building equity in the metal building. Unlike renting, where payments do not contribute to ownership, Rent-to-Own ensures that your investment grows over time. Each payment brings you closer to owning the building outright, making it a more satisfying and rewarding investment.

Increased Property Value

Adding a metal building to your property can significantly enhance its value. Potential buyers often look for additional storage, workshops, or garage spaces when considering a property. By opting for Rent-to-Own, you can improve your property's appeal and market value without the burden of large upfront costs.

Versatility and Practical Applications

Storage Solutions

Rent-to-Own metal buildings are perfect for storage solutions. Whether you need space for gardening tools, equipment, or seasonal items, these structures offer secure and weather-resistant storage. Immediate access to additional storage can declutter your home and improve organization.

Workshops and Garages

For those in need of a workshop or garage, Rent-to-Own metal buildings provide an ideal solution. Whether you're a hobbyist, mechanic, or craftsman, having a dedicated space can enhance productivity and enjoyment. The flexibility to customize the space to suit your specific needs adds tremendous value.

Agricultural Uses

Farmers and agricultural businesses can greatly benefit from Rent-to-Own metal buildings. They provide essential storage for equipment, feed, and supplies and can also serve as barns, livestock shelters, or greenhouses. The adaptability of these buildings ensures they meet the diverse needs of agricultural operations.

Environmental and Maintenance Benefits

Durability and Longevity

Metal buildings are known for their durability and longevity. They withstand harsh weather conditions, resist pests, and require minimal maintenance compared to traditional wooden structures. Investing in a Rent-to-Own metal building ensures you have a reliable, long-lasting structure that will serve your needs for many years.

Eco-Friendly Option

Steel is a recyclable material, making metal buildings an eco-friendly choice. By opting for a metal structure, you contribute to sustainability efforts. Additionally, the energy efficiency of metal buildings can reduce heating and cooling costs, providing further financial and environmental benefits.

Conclusion

Metal building rent-to-own metal buildings are a popular choice for many people and businesses because they provide a special blend of affordability and flexibility. Rent-to-Own is a great option because it allows you to have a sturdy, high-quality building without having to pay a lot of money up front, and it gives you the freedom to modify the building to suit your needs. Whether you require an agricultural building, a workshop, or additional storage, Rent-to-Own offers a useful and affordable solution to improve your property.

At Bulldog Steel Structures, we specialize in providing high-quality, customizable metal buildings with Rent-to-Own options tailored to your specific needs. Contact us today to learn more about how Rent-to-Own can benefit you and start transforming your property with a versatile and affordable metal building.

#metal garage buildings#rent-to-own#metal garages#usa news#steel rolling mill#steel structure#metal carport#metal barns#steel products#steel ball run

0 notes

Text

Tata Steel Employee Dies in Crane Accident at Cold Rolling Mill

High-Level Investigation Initiated Following the Fatal Incident

A tragic accident occurred at Tata Steel’s Cold Rolling Mill (CRM) plant, resulting in the death of a crane operator, Naresh Prasad, from Kadma, Jamshedpur.

JAMSHEDPUR – Naresh Prasad, a 32-year-old permanent employee of Tata Steel’s Cold Rolling Mill (CRM) plant, has reportedly died after falling from a crane early Friday…

#बिजनेस#business#cold rolling mill#crane accident#employee support#high-level investigation#Jamshedpur News#Naresh Prasad#Tata Steel#TMH#Workplace Safety

0 notes

Text

How to Choose the Right Shearing Machine for Your Operations

In steel rolling mills, where precision and efficiency reign supreme, the selection of the right shearing machine stands as a pivotal decision. These machines are the linchpin of operations, facilitating the precise cutting of metal sheets to meet stringent quality standards. However, with a multitude of options available in the market, choosing the optimal shearing machine demands a comprehensive understanding of various factors. This article is a guide for businesses in steel rolling mills who need help choosing the right machine. It explains the factors they should consider when making their decision.

Factors to Consider When Choosing a Shearing Machine

1. Cutting Capacity and Blade Length

The cornerstone of any shearing machine lies in its ability to handle the workload effectively. The cutting capacity and blade length of the machine should align seamlessly with the thickness and width of the metal sheets utilised in operations. Undersized machines risk inefficiency and strain, while oversized ones may lead to unnecessary expenditure. It's imperative to strike a delicate balance that ensures optimal performance without compromise.

2. Cutting Precision and Accuracy

The efficacy of a shearing machine hinges on its ability to deliver clean, precise cuts consistently. Advanced cutting mechanisms and precise positioning systems are indispensable allies in this quest for perfection. Every cut should be a testament to the machine's unwavering accuracy, ensuring that the end products meet the most exacting quality standards.

3. Safety Features and Operator Controls

Shearing machines equipped with robust safety features and intuitive operator controls are indispensable allies in mitigating the inherent risks associated with metalworking. Emergency stop buttons, protective guards, and ergonomic controls not only safeguard the operators but also bolster productivity by instilling confidence and peace of mind.

4. Maintenance Requirements

The smooth operation of a shearing machine is contingent upon meticulous maintenance. Machines that demand excessive downtime for servicing can impede productivity and erode profitability. Conversely, those designed with ease of maintenance ensure uninterrupted operation, maximising uptime and prolonging the machine's lifespan. Regular upkeep is the cornerstone of longevity and reliability in the fast-paced realm of steel rolling mills.

5. Integration with Other Manufacturing Processes

The shearing machine must harmonise effortlessly with other equipment and processes, facilitating a smooth flow of operations. Compatibility with upstream and downstream processes ensures a cohesive workflow, minimising bottlenecks and optimising efficiency across the production spectrum.

6. Environmental Impact and Energy Efficiency

In an era defined by sustainability, the environmental footprint of industrial equipment cannot be overlooked. Energy-efficient shearing machines not only reduce operational costs but also mitigate environmental impact, aligning with the ethos of responsible manufacturing. Features such as automatic shut-off functions and energy-saving modes are imperatives in the pursuit of eco-friendly operations.

7. Cost Considerations

When making decisions, the cost is often the main consideration. However, it's important to also think about the long-term implications. Investing in a high-quality shearing machine tailored to specific requirements yields dividends far beyond the initial expenditure. A holistic cost-benefit analysis, encompassing factors such as productivity gains, operational efficiency, and total cost of ownership, is instrumental in making an informed investment decision.

8. Type of Metal Being Sheared

Steel rolling mills often work with a diverse array of metals, each with its own unique properties and challenges. Selecting a shearing machine tailored to the type of metal being processed is paramount. Whether it's stainless steel, aluminium, or carbon steel, the machine must be capable of handling the material's specific characteristics with finesse and precision.

9. Sheared Metal Output

The quality of the sheared metal output is the ultimate test of a shearing machine's efficacy. Steel rolling mills often encounter issues such as distortion, burrs, and other defects that can negatively impact the quality of their products, leading to customer dissatisfaction. Machines that deliver pristine cuts, devoid of imperfections, uphold the integrity of the end products, cementing the mill's reputation for excellence.

10. Shearing System

The choice of a shearing system—guillotine, swing beam, or rotary—profoundly impacts cutting performance and operational efficiency. Each system boasts its own advantages and limitations, necessitating careful consideration of specific requirements and production demands. The optimal shearing system seamlessly integrates with existing processes, enhancing productivity and precision with every cut.

11. Design of the Shearing Machine

Behind every efficient shearing machine lies a meticulously crafted design that balances form with function. The choice of construction materials, ergonomics, and overall design profoundly influences performance and longevity. A well-designed machine not only enhances operational efficiency but also withstands the rigours of industrial use, delivering consistent performance day in and day out.

12. Fixed or Adjustable Rake Angle

The rake angle serves as the linchpin of shearing force and cutting quality. Choosing between fixed or adjustable rake angle hinges on the specific cutting requirements and material properties. While a fixed angle may suffice for standardised operations, adjustable options offer unparalleled versatility, catering to diverse cutting needs and evolving production demands.

13. Operation Size

The size of the shearing machine must align with the scale of operations within the steel rolling mill. Oversized machines squander valuable space and resources, while undersized ones risk impeding productivity and hampering growth. A judicious assessment of operational needs and spatial constraints ensures optimal utilisation of resources, fostering efficiency and scalability.

14. Manufacturer Reputation

In a market teeming with options, the manufacturer's reputation stands as a beacon of trust and reliability. Established manufacturers with a proven track record of quality craftsmanship and exemplary customer service inspire confidence and assurance. Thorough research, testimonials, and industry certifications, are instrumental in selecting a partner committed to excellence.

15. After Sales Support

The journey doesn't end with the purchase; it merely marks the beginning of a partnership. Comprehensive after-sales support, encompassing technical assistance, spare parts availability, and maintenance services, is indispensable in ensuring the seamless operation of shearing machines. A responsive support network serves as a lifeline, minimising downtime and maximising productivity throughout the machine's lifecycle.

Why Choose Us for Your Shearing Machine Requirement:

Elevate your steel rolling mill operations to new heights of precision and efficiency with our cutting-edge shearing machines. Backed by a legacy of excellence and a relentless commitment to innovation, The Steefo Group stands as your trusted partner in the quest for manufacturing excellence. As one of the leading rolling mill manufacturers in India, we offer meticulously engineered products, empowering you to meet the most demanding production challenges with confidence.

Experience the difference of working with a manufacturer that prioritises your success above all else. From customised solutions tailored to your unique requirements to comprehensive after-sales support that ensures uninterrupted operation, we are with you every step of the way. Contact us at +91 98240 76873 or +91 87589 98607 for all your rolling mill needs.

0 notes

Text

hot rolled

20 notes

·

View notes

Text

How Does the Rolling Mill Rolls Angle Steel?

As a common building material, hot-rolled angle steel is widely used in various industries. It has good mechanical properties and toughness and can withstand complex mechanical environments. So, what is the manufacturing process of hot-rolled angle steel? Let’s learn more about it below.

The manufacturing process of hot-rolled angle steel mainly includes raw material processing, hot rolling, cold rolling, cutting, and heat treatment. Below, these processes will be explained one by one.

Raw Material Processing

Raw material processing is the first step in the hot-rolled angle steel manufacturing process. Generally speaking, the raw materials of hot-rolled angle steel are mainly hot-rolled plates and billets. First, the raw materials are sawed into blocks of a certain length and width. Next, the blocks are subjected to a heat treatment to bring them to a certain temperature. Doing so improves the plasticity of the steel, making subsequent rolling operations smoother.

Hot Rolled

Hot rolling is the core link in the manufacturing process of hot-rolled angle steel. The heat-treated steel billet is fed into the hot rolling mill for rolling. The whole process is mainly divided into two stages: rough rolling and finish rolling. Rough rolling is mainly to compress the steel billet to a certain thickness in preparation for entering the next stage of finishing rolling. Finish rolling is to further suppress the steel billet to reach the required standard size. During the hot rolling process, the billet experiences constant pressure and friction, causing the shape and size of the billet to change.

Cold Rolled

Cold rolling is a complementary link in the manufacturing process of hot-rolled angle steel. During the hot rolling process, due to the continuous high temperature and pressure, the internal structure of the steel will change, forming certain grains and defects. Through cold rolling, the internal structure of the steel can be rearranged and adjusted, thereby improving the strength and hardness of the steel. In addition, cold rolling can also improve the surface finish and dimensional accuracy of steel, making the steel more suitable for various process requirements.

Cutting

Cutting is one of the subsequent processing steps in the hot-rolled angle steel manufacturing process. During the hot and cold rolling processes, steel billets are pressed into angles of different shapes and sizes. In practical applications, it is often necessary to cut to a specific length. Therefore, it is very necessary to cut the steel. The cutting method can be selected according to specific requirements. Common methods include flame cutting, plasma cutting, and mechanical cutting.

Heat Treatment

Heat treatment is the final step in the manufacturing process of hot rolled angle steel. During the hot rolling and cold rolling processes, the internal structure and properties of steel will change due to the effects of temperature and pressure. To further adjust and improve the properties of steel, it needs to be heat treated. Heat treatment methods mainly include normalizing treatment, quenching treatment, tempering treatment, etc. Through heat treatment, the hardness, toughness, and strength of steel can be improved, making it more suitable for various application scenarios.

In short, the manufacturing process of hot-rolled angle steel is complex and delicate. Through raw material processing, hot rolling, cold rolling, cutting, and heat treatment, hot-rolled angle steel products that meet various standards and requirements can be produced. Hot-rolled angle steel provides strong and reliable building materials for various industries with its excellent performance and wide range of applications.

0 notes