#subminiature

Video

untitled by Michael Bovee

Via Flickr:

expired kodak gold 110 film

0 notes

Text

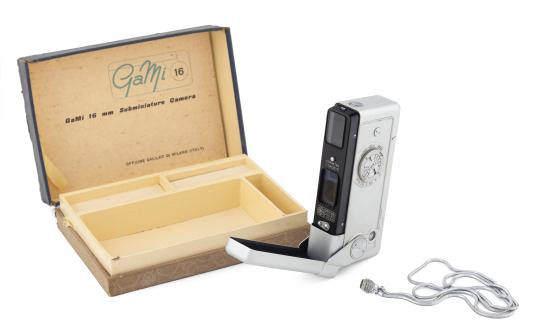

GaMi 16 Subminiature Camera with Box, 1953

Source:

East Dennis, MA

Eldred's

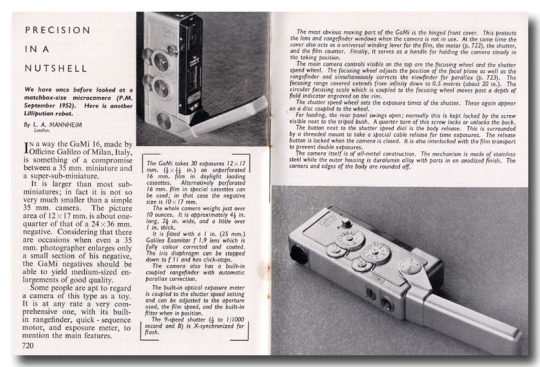

"Precision In a Nutshell" , L.A. Mannheim, Photoguide Magazine, London, August 1954:

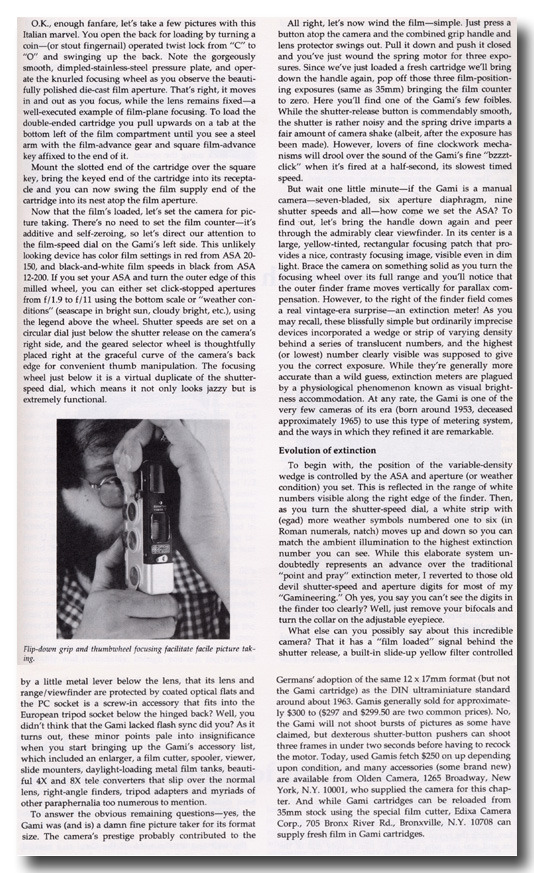

"Jason Schneider On Camera Collecting, Book Two" 1982:

#subminiature#miniature#camera#GaMi#camera collecting#italian#made in italy#1950s#auction#online#auctioned

0 notes

Text

Untitled (YOMOGI)

MINOX B

COMPLAN 15㎜ F3.5

Fuji PRO 400H

0 notes

Text

Autism truly is the most deranged disorder, like to the average person, "I've been getting really into subminiature film cameras" is an insane statement and yet,

231 notes

·

View notes

Note

a fun detail, the model of camera ichimonji uses is mentioned in some of the shin kamen rider promotional material! it's subminiature camera minolta 16 p (manufactured in 1960), if i recall correctly.

THIS IS SO AMAZINGLY COOL, THANK YOU FOR FINDING THIS OUT

I was really really wondering about this!

And according to @neckspike, it's a match for the model used in Kamen Rider (1971)!

I love all the little details in this movie,,, amazing,,,

AND WOW IT'S IMPRESSIVE HOW FAST THIS GOT SLEUTHED OUT

#I love little details and I extra extra love when other people care about them too#Thank you so much for answering the question that was burning a hole in my brain

15 notes

·

View notes

Link

Check out this listing I just added to my Poshmark closet: Vintage Kodak Disc 6100 “Close-Up Lens” Legacy Disc Film Camera.

0 notes

Text

TNC Threaded Connector Market: Enabling Secure Connections

In the realm of electrical and electronic engineering, secure and reliable connections are essential for ensuring optimal performance and safety in a wide range of applications. TNC (Threaded Neill-Concelman) connectors have emerged as a popular choice for establishing secure connections in high-frequency RF (Radio Frequency) and coaxial cable systems, offering a robust and versatile solution for transmitting signals with minimal interference and loss. The TNC threaded connector market is witnessing steady growth, driven by the increasing demand for high-performance connectivity solutions across various industries and applications.

One of the primary drivers behind the growth of the TNC threaded connector market is the widespread adoption of RF and microwave technology in telecommunications, aerospace, defense, and other critical industries. TNC connectors are well-suited for high-frequency applications, offering low impedance and excellent electrical performance up to GHz (Gigahertz) frequencies. Their threaded coupling mechanism provides a secure and stable connection, minimizing signal loss and ensuring reliable transmission of data, voice, and video signals in demanding environments.

Moreover, the versatility and compatibility of TNC connectors make them suitable for a wide range of applications, from wireless communication systems and radar systems to test and measurement equipment and medical devices. TNC connectors are available in various configurations, including straight, right-angle, and bulkhead mount options, allowing for flexible installation and integration into diverse systems and environments. This versatility enables engineers and designers to select the appropriate TNC connector for their specific application requirements, whether it's for indoor or outdoor use, harsh environments, or high-vibration applications.

Request the sample copy of report @ https://www.globalinsightservices.com/request-sample/GIS26899/?utm_source=Govind-Article

Additionally, the rugged construction and durability of TNC connectors make them ideal for use in harsh and demanding environments, such as aerospace, military, and industrial applications. TNC connectors feature a threaded coupling mechanism that provides a secure and vibration-resistant connection, preventing accidental disconnection and ensuring reliable performance in mission-critical applications. Their robust construction and resistance to environmental factors, such as moisture, dust, and temperature extremes, make TNC connectors well-suited for outdoor and harsh environment installations.

Furthermore, the TNC threaded connector market benefits from ongoing advancements in materials, manufacturing techniques, and design innovations, enabling manufacturers to enhance the performance, reliability, and durability of TNC connectors. For example, the use of high-quality materials, such as stainless steel and brass, improves corrosion resistance and mechanical strength, while precision machining and assembly techniques ensure tight tolerances and consistent performance across production batches. Additionally, innovations such as sealed connectors and IP-rated designs provide added protection against environmental factors, further enhancing the reliability and longevity of TNC connectors in challenging applications.

Despite the opportunities for growth, the TNC threaded connector market also faces challenges, including competition from alternative connector technologies, such as SMA (SubMiniature version A) and N-Type connectors, as well as the need to continually innovate and adapt to evolving industry requirements and standards. However, with their proven performance, reliability, and versatility, TNC connectors are expected to remain a preferred choice for high-frequency RF and coaxial cable applications across a wide range of industries and applications.

In conclusion, the TNC threaded connector market plays a vital role in enabling secure and reliable connections in high-frequency RF and coaxial cable systems across various industries and applications. With their robust construction, versatility, and compatibility, TNC connectors provide engineers and designers with a trusted solution for transmitting signals with minimal interference and loss, ensuring optimal performance and safety in demanding environments. As technology continues to advance and connectivity requirements evolve, the demand for high-performance TNC connectors is expected to grow, driving further innovation and investment in this critical segment of the connector market.

0 notes

Text

D-Sub Mixed Contact Connector Market Competitive Analysis and Forecast 2023-2033

Market Definition

A D-Sub Mixed Contact Connector is a type of electrical connector that is commonly used in computer and data communication systems. It is named after its D-shaped metal shell, which provides mechanical support and protection for the connector.

The term “mixed contact” refers to the fact that this type of connector can accommodate different types of contacts, including signal, power, and coaxial contacts. This allows for a variety of different signals to be transmitted through a single connector, making it a versatile and space-saving option.

Market Outlook

D-Sub mixed contact connectors are a type of electrical connector commonly used in a variety of applications, such as computers, telecommunications, and industrial equipment. They are named after their D-shaped connector shell and are characterized by a combination of signal and power contacts within the same connector. In recent years, there have been several key trends in D-Sub mixed contact connector technology that have improved their performance and expanded their capabilities.

1. Miniaturization: One of the key trends in D-Sub mixed contact connector technology is miniaturization. With the increasing demand for smaller and more compact devices, there has been a need for connectors that can accommodate a high number of contacts in a smaller space. This has led to the development of miniaturized D-Sub connectors, which have a smaller footprint compared to traditional D-Sub connectors. These miniaturized connectors are also lighter in weight, making them ideal for portable devices.

2. Higher data transfer rates: Another important trend in D-Sub mixed contact connector technology is the ability to handle higher data transfer rates. With the increasing demand for faster and more reliable data transfer, D-Sub connectors have evolved to support higher data rates. This has been achieved through the use of advanced materials and design techniques, such as improved contact plating and shielding, which help reduce signal loss and interference. As a result, D-Sub connectors can now support data rates of up to 10 Gbps, making them suitable for high-speed data applications.

3. Increased power handling capacity: In addition to higher data transfer rates, there has been a trend towards increased power handling capacity in D-Sub mixed contact connectors. This is particularly important in industrial and automotive applications, where there is a need to transmit both data and power through the same connector. To meet this demand, D-Sub connectors now come with a higher number of power contacts and are designed to handle higher current and voltage levels. This has made them more versatile and suitable for a wider range of applications.

4. Enhanced durability and reliability: D-Sub mixed contact connectors are often used in harsh and demanding environments, where they are exposed to extreme temperatures, vibrations, and moisture. To ensure their durability and reliability in such conditions, there has been a trend towards the use of high-quality materials and improved designs. For instance, some D-Sub connectors now come with a sealed housing and enhanced sealing features to protect the contacts from dust and moisture. Additionally, the contacts themselves are made of more robust materials such as gold or palladium, which can withstand frequent mating cycles without degrading.

D-Sub Mixed Contact Connectors, also known as D-Subminiature connectors, are electronic connectors used in a variety of industrial, commercial, and military applications. They are designed to provide reliable and secure connections for data, power, and signal transmission between electronic devices.

1. Increasing Demand for Electronic Devices: The demand for electronic devices such as computers, laptops, smartphones, and other consumer electronics is continuously increasing. This is due to the growing adoption of advanced technologies, such as Internet of Things (IoT), artificial intelligence, and virtual reality. D-Sub Mixed Contact Connectors are widely used in these devices to provide reliable and secure connectivity, thus driving the growth of the market.

2. Growing Industrial Automation: The increasing adoption of automation in various industries such as manufacturing, automotive, and aerospace is also a major driver of the D-Sub Mixed Contact Connector market. These connectors are used in industrial automation systems to connect different electronic components and devices, enabling efficient data and power transmission. With the rise of Industry 4.0 and smart factories, the demand for D-Sub Mixed Contact Connectors is expected to further increase.

To Know More: https://www.globalinsightservices.com/reports/d-sub-mixed-contact-connector-market//?utm_id=1014

Research Objectives

Estimates and forecast the overall market size for the total market, across product, service type, type, end-user, and region

Detailed information and key takeaways on qualitative and quantitative trends, dynamics, business framework, competitive landscape, and company profiling

Identify factors influencing market growth and challenges, opportunities, drivers and restraints

Identify factors that could limit company participation in identified international markets to help properly calibrate market share expectations and growth rates

Trace and evaluate key development strategies like acquisitions, product launches, mergers, collaborations, business expansions, agreements, partnerships, and R&D activities

Thoroughly analyze smaller market segments strategically, focusing on their potential, individual patterns of growth, and impact on the overall market

To thoroughly outline the competitive landscape within the market, including an assessment of business and corporate strategies, aimed at monitoring and dissecting competitive advancements.

Identify the primary market participants, based on their business objectives, regional footprint, product offerings, and strategic initiatives

Request Sample: https://www.globalinsightservices.com/request-sample/GIS26888/?utm_id=1014

Market Segmentation

The D-Sub Mixed Contact Connector Market has been segmented into Type, Application, End-User, and Region. Based on the Type, the D-Sub Mixed Contact Connector Market is Segmented into Standard D-Sub Mixed Contact Connectors, High-Density D-Sub Mixed Contact Connectors, and Others. On the basis of Application, the market is segmented into Industrial Machinery, Aerospace and Defense, and Others. Based on End-User, the market is bifurcated into Commercial and Industrial. Region-wise, the market is analyzed across North America, Europe, Asia Pacific, and the Rest of the World.

Request Customization@ https://www.globalinsightservices.com/request-customization/GIS26888/?utm_id=1014

Major Players

Some of the key players of D-sub mixed contact connector market are TE Connectivity (Switzerland), Amphenol (United States), NorComp (United States), Cinch Connectivity Solutions (United States), ITT Cannon (United States), HARTING Technology Group (Germany), Phoenix Contact (Germany), Kycon, Inc. (United States), Omnetics Connector Corporation (United States), and ITT Interconnect Solutions (United States).

Request Discounted Pricing@ https://www.globalinsightservices.com/request-special-pricing/GIS26888//?utm_id=1014

Research Scope

Scope – Highlights, Trends, Insights. Attractiveness, Forecast

Market Sizing – Product Type, End User, Offering Type, Technology, Region, Country, Others

Market Dynamics – Market Segmentation, Demand and Supply, Bargaining Power of Buyers and Sellers, Drivers, Restraints, Opportunities, Threat Analysis, Impact Analysis, Porters 5 Forces, Ansoff Analysis, Supply Chain

Business Framework – Case Studies, Regulatory Landscape, Pricing, Policies and Regulations, New Product Launches. M&As, Recent Developments

Competitive Landscape – Market Share Analysis, Market Leaders, Emerging Players, Vendor Benchmarking, Developmental Strategy Benchmarking, PESTLE Analysis, Value Chain Analysis

Company Profiles – Overview, Business Segments, Business Performance, Product Offering, Key Developmental Strategies, SWOT Analysis

Buy your copy here: https://www.globalinsightservices.com/checkout/single_user/GIS26888/?utm_id=1014

With Global Insight Services, you receive:

10-year forecast to help you make strategic decisions

In-depth segmentation which can be customized as per your requirements

Free consultation with lead analyst of the report

Infographic excel data pack, easy to analyze big data

Robust and transparent research methodology

Unmatched data quality and after sales service

Contact Us:

Global Insight Services LLC

16192, Coastal Highway, Lewes DE 19958

E-mail: [email protected]

Phone: +1-833-761-1700

Website: https://www.globalinsightservices.com/

0 notes

Video

untitled by Michael Bovee

Via Flickr:

expired kodak gold 110 film

0 notes

Text

What are Bayonet Connectors?

What are Bayonet Connectors?

Bayonet connectors are a circular connector that delivers a secure and easy to operate connection by turning the locking ring until it latches into the mechanism. This standardized locking type allows for faster and more secure connections, compared to screw and push-fit connectors. It is often referred to as a “quick-disconnect” connector because complete coupling or decoupling is achieved with a quick one-third turn of the coupling nut.Get more news about Bayonet Lock Coupling,you can vist our website!

Rather than threads, bayonet coupling uses bayonet pins and ramps to mate. The most common approach has three equally spaced passivated stainless steel bayonet pins on the receptacle’s perimeter. The pins slide through undercut ramps on the plug’s coupling ring into locking detents. Tactile, audible (clicks), and visual (markings) means confirm the connector is mated securely. For added strength, some plastic connectors may have a metal coupling nut. Bayonet connectors are used to transmit either power or signal.

A reverse-bayonet coupling configuration is often used in connectors that previously involved threaded coupling. The bayonet pins are on the underside of the coupling nut. The reverse bayonet coupling arrangement provides easy mating and un-mating, requiring only 120 ̊ rotation, with audible, tactile, and visual indications of positive coupling.

Bayonet connectors are used to connect two cables or to connect a cable to another connector, such as BNC, C, and ST connectors.

The versatility of the bayonet makes it useful for different product series (e.g., subminiature, miniature, and power categories), as well as for a variety of applications (e.g., medical equipment, outdoor, and heavy machinery). The bayonet’s secure mating makes it ideal for applications that require resistance to moisture, or shock and vibration.

Bayonet connectors are use in a wide range of markets, including Transportation, Medical, and MIL-Aero, and for a variety of applications including aircraft, off-road vehicles, construction machinery, industrial devices, and Test & Measurement.

0 notes

Text

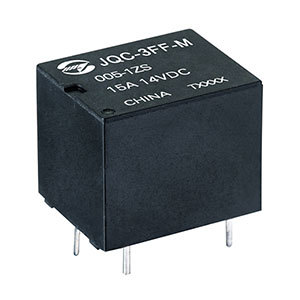

12V Automotive Relay JQC-3FF-M

12v Automotive Relay Jqc-3ff-M is a relay with a compact internal structure, small size, low power consumption, and low contact resistance. It features high voltage and shock resistance. It is widely used in air conditioners, fans, range hoods, refrigerators, lighting equipment, electric kettles, and other kinds of appliances with universal applicability.

Benifits of 12V Automotive Relay JQC-3FF-M

01

Small size with 15A contact switching capability.

02

Ultra-small size and -> Subminiature, standard PCB Layout.

03

Plastic seal version and anti-solder version are available.

04

With a set of normally open, a set of switching contact form.

0 notes

Text

Understand EMI Filters: How They Work and Why You Need Them

From hospitals to industrial manufacturing to the military, electronic devices are used widely throughout a wide range of industries. For some devices to function properly, the electricity must be reliable and uninterrupted.

As more and more electronic products hit the market, electromagnetic interference is produced. It can lead to device failure, malfunction, or crash. The emi filters block harmful implications and provides a constant power flow to safeguard electronic systems and devices from damage. Here you will learn how EMI work and why you need them:

What is an EMI filter?

EMI filters are electronic circuits or devices that are used to reduce the high-frequency electromagnetic noise produced by many electronic and electrical devices.

The performance of electrical or electronic devices as well as signal transmissions could be hampered by this electromagnetic noise. Its frequency usually spans from 9KHz to 10GHz.

Electromagnetic compatibility is an essential factor for determining an electronic product's quality and has taken prominence in its design.

Beginning with EMC design at the time of power system design can increase the system's overall anti-interference capacity and extend its useful life. So, an emc filter is a device used to provide good electromagnetic compatibility.

Working on EMI filter

EMI filters are usually built on circuit boards or included in electrical products. Electronic power supplies and electrical current switching are the principal sources of electromagnetic interference.

Passive components like capacitors and inductors that are paired to create LC circuits make up emi rfi filters and power supplies. Inductors allow low-frequency currents or DC to flow through while blocking unnecessary high-frequency currents. The capacitors offer a low-impedance lane to divert noise away from the i/p of the EMI filter.

To comply with EMI rules, an emi filter supplier India must meet protective standards. You can measure the rise in inductor temperature and regulate the electrical distance between the line, ground, and neutral for mains operation. The risk of electrical shock or fire is hence reduced.

Why do you need EMI filters?

Due to the high radiation levels released by other electronic devices, emi emc filter protects delicate electronics from harm. It allows desired currents to flow unrestricted by removing undesirable currents carried through wiring or cables that might block power and signal lines.

To match any need or design structure, a large range of EMI filters are now offered on the market. For managing EMI at the signal and power I/O, d-subminiature, or circular connectors, EMI filters, and single-phase and three-phase power line filters are included.

EMI filters can be created for weight-saving purposes or to withstand AC and lights in transitory situations. Various standard, high-quality part numbers are created to meet or exceed a wide range of criteria and are intended for use in harsh and RoHS environments.

Elcom International is one of the few reputable Emi filter manufacturer india. High-quality EMI filters can be produced and delivered in our cutting-edge manufacturing facility.

The EMI RFI filters from Elcom International are also capable of overcoming unintentional interference and assisting in lowering unnecessary background noise and operational disturbance.

1 note

·

View note

Text

Hermetic D Subminiature Connectors- Interconn Technical Sales

If you want impenetrable connections in your device, Hermetic D Subminiature Connectors are considered the best option! They offer strong sealing and protection; our connectors create an airtight bond that shields against moisture, dust, and other contaminants. Buy high-quality Hermetic D Subminiature Connectors from Interconn Technical Sales and provide your connections with a new level of durability!

0 notes

Text

High performance D-Sub connectors for harsh environments – TechToday

Sean Fitall, positronic product manager at electrical connector specialist PEI-Genesis, discusses the versatility of D-Sub connectors and explains why they remain the best connector for the job in many challenging applications.

D-Subminiature electrical connectors, commonly known as D-Subs, have been around for decades, and are often used in everything from military, space, commercial aerospace,…

View On WordPress

0 notes