Text

The importance of the composting fermentation process in the organic fertilizer production line

The composting fermentation process holds an extremely important position in the organic fertilizer production line. The following is a detailed analysis:

The role of composting fermentation: Composting fermentation can effectively kill harmful bacteria, eggs and seeds of weeds in organic waste, making organic fertilizer meet harmless standards and reducing the harm to the environment and crops.

2. The impact of composting fermentation on the quality of organic fertilizer: The organic fertilizer after fermentation is rich in humus, organic matter and various microorganisms, which can improve soil structure, enhance soil fertility and reduce the use of chemical fertilizers. The fermentation process reduces the emission of odors and harmful gases from organic waste, lowering environmental pollution. The organic fertilizer after fermentation is more stable during storage and transportation, and is less likely to deteriorate or cause secondary pollution.

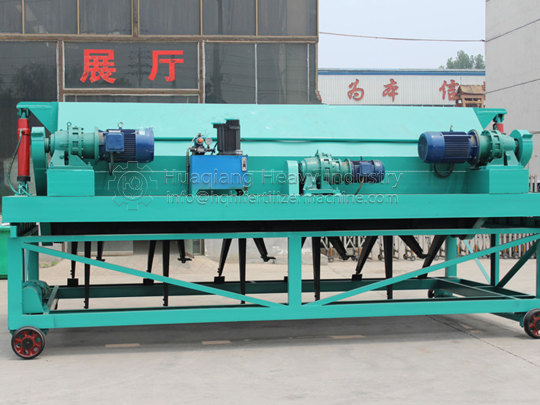

3. Application of composting fermentation in organic fertilizer production lines: Before composting fermentation, organic waste is pre-treated, such as crushing, screening, and moisture regulation, to ensure the smooth progress of the fermentation process. According to the production scale and raw material characteristics, select the appropriate organic fertilizer fermentation equipment to improve the fermentation efficiency.

In conclusion, the composting fermentation process plays an irreplaceable and significant role in the organic fertilizer production line. It can not only effectively handle organic waste, improve the quality and efficiency of organic fertilizer, but also has significant economic and environmental benefits. In the future, with the continuous advancement of technology and the expansion of application fields, composting fermentation will play a greater role in the production of organic fertilizers.

0 notes

Text

What advantages does organic fertilizer equipment have in reducing pollution

Organic fertilizer equipment has significant advantages in reducing pollution, mainly reflected in the following aspects:

1. Harmless treatment: Organic fertilizer equipment can carry out high-temperature fermentation treatment on organic waste such as livestock and poultry manure and crop straw to meet harmless standards.

2. Reduce odor and harmful gas emissions: Organic fertilizer fermentation equipment can effectively reduce the emission of odors and harmful gases produced by organic waste during the fermentation process by precisely controlling the fermentation environment.

3. Resource recycling: Organic fertilizer equipment can convert agricultural waste into high-quality organic fertilizers, achieving the recycling of resources.

4. Energy conservation and consumption reduction: Organic fertilizer equipment mainly relies on solar energy, bioenergy and a small amount of electricity during the production process, with relatively low energy consumption.

5. Reduce the cost of agricultural waste treatment: Traditional methods of agricultural waste treatment usually require a large amount of human and material resources and have relatively high costs. The use of organic fertilizer equipment can convert waste into organic fertilizer, which not only reduces processing costs but also brings economic benefits.

6. Promoting sustainable agricultural development: The application of organic fertilizers helps reduce the use of chemical fertilizers and pesticides, lowers the negative impact of agricultural production on the environment, and promotes the green transformation of agriculture. This conforms to the requirements of green and sustainable development of modern agriculture.

In conclusion, organic fertilizer equipment has multiple significant advantages in reducing pollution. It can not only effectively handle agricultural waste and reduce environmental pollution, but also promote sustainable agricultural development through resource recycling and energy conservation and consumption reduction.

0 notes

Text

How can customized organic fertilizer equipment meet diverse demands

Customized organic fertilizer equipment can meet diverse demands, mainly reflected in the following aspects:

Personalized production plans: Customized organic fertilizer equipment can provide personalized organic fertilizer production line design plans based on the actual needs of customers.

2. Flexible formula adjustment: The customized organic fertilizer equipment has the ability to flexibly adjust the formula, and can produce customized organic fertilizers according to the soil conditions and crop requirements of different regions. This flexibility and customized service can meet the diverse demands of agricultural production.

3. High-efficiency and energy-saving equipment: Customized organic fertilizer equipment adopts low-energy consumption and high-efficiency devices, such as solar drying equipment and waste heat recovery technology, to reduce energy consumption and carbon emissions. This highly efficient and energy-saving design not only reduces production costs but also meets environmental protection requirements.

4. Environmental Protection and Sustainable Development: Customized organic fertilizer equipment is designed with full consideration of environmental protection and energy conservation requirements. For instance, it reduces dust and noise emissions by improving the mechanical structure and lowers production costs by optimizing the energy consumption structure. This environmentally friendly and energy-saving design conforms to the sustainable development concept of modern agriculture.

5. Continuous technological innovation: Customized organic fertilizer equipment is constantly undergoing technological innovation, such as installing a PLC system to achieve precise control and integrating with the Internet of Things to realize remote monitoring, etc. These innovations have enabled it to continuously improve in terms of intelligence and automation, further enhancing its market competitiveness.

Through the above measures, customized organic fertilizer equipment can effectively meet the diverse demands of the market, enhance market competitiveness, and promote the sustainable development of the industry.

0 notes

Text

The value of the blended fertilizer production line

The value of the blended fertilizer production line is mainly reflected in the following aspects:

1. Simple production process: The production process of blended fertilizer is relatively simple and does not require complex chemical reactions. It is mainly produced by blending through fertilizer equipment. This not only reduces production costs, but also decreases energy consumption and environmental pollution during the production process.

2. Flexible product proportioning: Blended fertilizers can be flexibly configured with different proportioning products based on the nutrient requirements of various crops, different growth stages, and soil nutrient conditions. This flexibility enables blended fertilizers to better meet the diverse demands in agricultural production.

3. Environmentally friendly: The production process of blended fertilizers causes almost no pollution, making it an environmentally friendly type of fertilizer. The waste emissions during its production process are low, which meets the development requirements of modern green agriculture.

4. High degree of automation: Modern compound fertilizer production lines feature a high degree of automation, capable of achieving full-process automated operations from batching, mixing to packaging, thereby enhancing production efficiency.

5. Small land occupation: The equipment of the compound fertilizer production line is relatively compact, occupies a small area, and has low requirements for the factory building, reducing infrastructure investment.

6. Promoting sustainable agricultural development: The use of blended fertilizers helps enhance soil fertility, reduce excessive application of chemical fertilizers, and promote sustainable agricultural development.

7. Enhance agricultural production efficiency: Blended fertilizers can provide precise nutrient supply based on the needs of crops, increase crop yield and quality, and thereby enhance agricultural production efficiency.

The market potential is huge: With the enhancement of environmental awareness and the emphasis on green agriculture, the market demand for blended fertilizers continues to grow, providing a broad market space for blended fertilizer production line enterprises.

0 notes

Text

The reasons why organic fertilizer equipment needs to be customized

The reasons why organic fertilizer equipment needs to be customized mainly lie in the following aspects:

1. Enhance equipment coordination: Customized equipment can fully consider the suitability of coordination between the process and raw materials, conveying and feeding, and main equipment. Each piece of equipment can be produced moderately in accordance with the established production capacity, avoiding production congestion and improving the overall production efficiency.

2. Optimize space utilization: Based on factors such as site area, shape, raw material quantity, and planned output, customized equipment can rationally design the size of the equipment and the conveying distance, and optimize the equipment layout diagram of the process flow. This not only enhances the efficiency of the equipment in occupying the working area, but also avoids space waste.

3. Meeting specific production demands: Different organic fertilizer producers may have different raw material sources, product requirements and production capacity targets. Customized equipment can be adjusted according to these specific requirements to ensure that all links of the organic fertilizer production line are closely coordinated and meet the personalized production needs of enterprises.

4. Enhance equipment stability: Customized equipment can be optimized based on the actual usage environment and conditions of the enterprise, improving the stability and reliability of the equipment and reducing the failure rate. This is of great significance for ensuring the continuity of production and reducing maintenance costs.

In conclusion, the customization of organic fertilizer equipment can better meet the production needs of enterprises, enhance production efficiency, optimize space utilization, improve product quality, reduce investment costs, and increase the stability and environmental performance of the equipment. These advantages make customization a reasonable choice for the procurement of organic fertilizer equipment.

0 notes

Text

How to operate and maintain an organic fertilizer ball shaping machine

The operation and maintenance of organic fertilizer ball shaping machine mainly include the following aspects:

1. Preparatory work: Before starting up, make sure all screws are tightened and check that the power cord is connected correctly to prevent malfunctions caused by loose components or circuit issues. Add lubricating oil to ensure the normal operation of all moving parts, reduce wear and tear, and extend the service life of organic fertilizer equipment. Before starting the equipment, make sure there are no foreign objects inside to avoid damaging the machine and affecting the quality of rounding.

2. Operation process monitoring: During operation, it is strictly prohibited to insert hands or other objects into the equipment to prevent safety accidents. After the equipment is started, observe its operation and confirm that there are no abnormal sounds or vibrations.

3. Daily cleaning: After each use, clean the residual organic fertilizer raw materials inside the machine to prevent the formation of hard lumps, which may affect the next use and equipment performance. Clear the residues and leftover materials around the equipment to keep the working environment clean and tidy.

4. Regular maintenance: Regularly lubricate the equipment, inspect the oil seals and bearings to prevent component damage caused by long-term hard grinding. Pay attention to the wear of the vulnerable parts of the equipment. Replace them in time when the wear is severe to ensure the circular polishing effect and the normal operation of the equipment.

5. Operator safety: Before operation, personal protective equipment such as protective clothing and safety helmets must be worn properly to avoid accidental injuries.

6. Equipment Safety: It is strictly prohibited to put hard objects or substances that are too large into the equipment to prevent overloading and ensure the safety of the equipment and personnel.

Through the above operation and maintenance measures, the service life of the organic fertilizer polishing machine can be effectively prolonged, production stability can be ensured, and product quality can be improved.

0 notes

Text

Technical features of the organic fertilizer chain crusher

The technical features of the organic fertilizer chain crusher mainly include the following aspects:

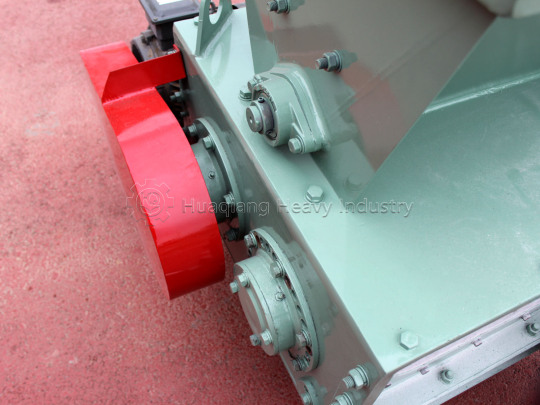

1. High-efficiency crushing capacity: The chain crusher uses high-speed rotating chains to impact and shear materials, which can efficiently crush materials into fine particles and quickly process materials with high moisture content and high fiber content.

2. Precise particle size control: The chain crusher controls the particle size of the crushed materials by adjusting the rotational speed of the chain, which can meet the particle size requirements of organic fertilizer production. The crushed materials have uniform particle size, which is conducive to the subsequent fermentation and granulation processes.

3. Environmental protection and energy conservation: Although the power of the chain crusher is relatively high, due to its highly efficient crushing capacity, the unit energy consumption is relatively low. The inlet and outlet ports of the equipment are reasonably designed, ensuring uniform crushing of materials, preventing them from sticking to the walls, facilitating cleaning, and reducing the overflow of dust.

4. Easy operation and maintenance: The organic fertilizer equipment has a reasonable structure, is easy to operate and maintain. During the flow process, the materials will carry away the residues, reducing the accumulation of materials inside the equipment and the difficulty of cleaning.

5. Optimize the fermentation process: The crushed materials have uniform particle size and increased specific surface area, which is conducive to the contact and decomposition of microorganisms and improves the fermentation efficiency.

6. Reduce production costs: The high efficiency of the chain crusher shortens the production cycle, enhances production efficiency, and lowers the production cost per unit product.

In conclusion, the organic fertilizer chain crusher has significant advantages in organic fertilizer production due to its high-efficiency crushing capacity, precise particle size control, strong wear resistance, environmental protection and energy conservation, as well as simple operation and maintenance.

0 notes

Text

How to optimize the equipment parameters of the organic fertilizer granulator to improve the pelletizing rate

To optimize the equipment parameters of the organic fertilizer granulator to increase the pelletizing rate, the following aspects can be considered:

1. Strictly control the quality of powder materials: Carefully control the quality of various raw materials in accordance with the formula of organic fertilizer, ensuring that there are no iron blocks, overly large wood blocks or stones in the feed and discharge, and control the particle size distribution of raw materials.

2. Optimize the nozzle and spray parameters: Select the appropriate nozzle. According to the principles of fluid mechanics, the greater the nozzle pressure and the smaller the spray holes, the larger the droplet diffusion surface and the smaller the droplet density, which is conducive to improving the balling rate.

3. Adjust the speed and inclination Angle of the disc granulator: Adjust the speed and inclination Angle of the disc granulator according to the characteristics of the material. For materials with good fluidity and weak adhesiveness, the rotational speed can be appropriately increased. For materials with strong adhesiveness, the rotational speed should be reduced. The movement of materials is monitored in real time through the automatic control system to ensure that the disc Angle of the disc granulator adopts an integral arc structure, reducing the phenomenon of material sticking to the wall.

4. Control the amount of return material: During the granulation process of organic fertilizer, the size of the return material directly affects the output and quality. Controlling the return material volume between 30% and 35% can effectively control the generation of large particles.

5. Operator training: Provide pre-job training for operators to enhance their operational skills and technical proficiency, ensuring the efficient operation of the equipment.

Through the above measures, the parameters of organic fertilizer equipment can be effectively optimized, the pelletizing rate can be increased, and thereby the production efficiency and product quality can be enhanced.

0 notes

Text

The differences between high-configuration organic fertilizer production lines and ordinary production lines

The main differences between high-configuration organic fertilizer production lines and ordinary production lines are reflected in the following aspects:1. Equipment configuration and degree of automation: High-end production lines are usually equipped with more advanced organic fertilizer equipment. These devices are seamlessly connected through an automated control system, reducing manual intervention and enhancing production efficiency. The equipment configuration of ordinary production lines is relatively simple and may lack some high-end equipment. The degree of automation is relatively low, and some production links require manual operation, resulting in relatively low production efficiency.2. Production process and product quality: The high-end production line adopts more refined production processes to ensure uniform and stable fertilizer particles. The production process of ordinary organic fertilizer production lines is relatively simple, and the product quality may be affected by human factors, with slightly poorer stability.3. Production Efficiency and Cost: High-configuration production lines significantly enhance production efficiency and reduce energy consumption and costs by optimizing process flows and equipment configurations. The production efficiency of ordinary production lines is relatively low, and their energy consumption and costs are relatively high.4. Product diversity and market competitiveness: The high-configuration production line can produce various forms (such as powder and granular) and formulations of organic fertilizers, meeting the needs of different customers. This diversity and high-quality products help enhance market competitiveness. The product types of ordinary production lines are relatively single and their market competitiveness is weak.To sum up, high-configuration organic fertilizer production lines are superior to ordinary production lines in terms of equipment configuration, production processes, environmental protection performance, production efficiency, product diversity and market competitiveness. Although the initial investment is relatively high, they have more advantages in the long run.

0 notes

Text

The new trends brought about by the innovation of organic fertilizer equipment

The innovation of organic fertilizer equipment has brought about many new trends, promoting the efficient, green and sustainable development of the organic fertilizer industry. The following are the specific directions:

1. Intelligence and Automation: Organic fertilizer equipment is evolving towards intelligence and automation. The equipment is capable of achieving fully automated production from raw material pretreatment, fermentation, granulation to packaging. Intelligent devices can also monitor the operational status of the equipment in real time. Key data can be remotely monitored via mobile phones or computers. Once a fault occurs, the system can promptly issue an alarm and initially determine the cause of the fault, facilitating rapid maintenance.

2. Environmental protection and energy conservation: The new organic fertilizer equipment pays more attention to environmental protection and energy conservation. Equipment designers are still constantly exploring more environmentally friendly materials and processes to reduce pollution emissions during operation.

3. High-efficiency fermentation and new processes: Modern organic fertilizer production lines adopt advanced biological fermentation technology. By precisely controlling temperature, humidity and ventilation conditions, they accelerate the reproduction of microorganisms and efficiently convert organic waste into high-quality organic fertilizer.

4. Customization and modularization: To meet the diverse needs of different users, customized services for organic fertilizer equipment are gradually emerging. Enterprises can choose appropriate modules for combination based on their own scale and demands, which not only saves costs but also ensures the performance and efficiency of the equipment.

5. Diversified organic fertilizer products: In the future, the application fields of organic fertilizer equipment will be further expanded. Besides traditional solid organic fertilizers, new types of fertilizers such as liquid organic fertilizers and gaseous organic fertilizers will also emerge to meet the needs of different crops.

0 notes

Text

The improvement of agricultural product quality by organic fertilizer production lines

The organic fertilizer production line plays a significant role in improving the quality of agricultural products, mainly reflected in the following aspects:

Improving soil structure and fertility: The fertilizers produced by organic fertilizer equipment are rich in organic matter and various microorganisms, which can significantly improve the physical, chemical and biological properties of the soil. Organic fertilizers can also enhance the availability of nutrients in the soil, reduce nutrient loss and increase the utilization rate of chemical fertilizers.

2. Enhance the nutritional quality of agricultural products: Organic fertilizers can provide comprehensive and balanced nutrients, promoting the healthy growth of crops and thereby increasing the nutritional content of agricultural products. Organic fertilizers can also improve the taste and flavor of agricultural products.

3. Reduce the residue of harmful substances: Compared with chemical fertilizers, the use of organic fertilizers reduces the input of chemically synthesized substances. The microorganisms in organic fertilizers can decompose harmful substances in the soil, enhance the self-detoxification ability of crops, and further reduce the accumulation of harmful substances in agricultural products.

4. Promoting crop growth and disease resistance: The microorganisms and organic substances in organic fertilizers can promote the growth and development of crop roots, enhancing the crops' disease resistance, drought resistance and waterlogging tolerance.

5. Enhance the market competitiveness of agricultural products: Agricultural products produced with organic fertilizers not only have higher quality but also better meet consumers' demands for green and organic food, thus having greater market competitiveness and added value.

In conclusion, organic fertilizer equipment has significantly enhanced the overall quality of agricultural products through multiple functions such as improving soil structure, enhancing the nutritional quality of agricultural products, reducing the residue of harmful substances, and promoting crop growth, providing strong support for the sustainable development of agriculture.

0 notes

Text

How does an organic fertilizer granulator ensure the quality of granulation

To ensure the quality of granules produced by organic fertilizer granulators, efforts should be made from multiple aspects such as equipment maintenance, process optimization, raw material processing, parameter adjustment and quality monitoring. The following are specific measures:

1. Equipment maintenance and inspection: After the end of each production day, conduct a thorough cleaning of the granulator to remove any residual materials on the surface and inside the organic fertilizer equipment. Regularly inspect the key components of the granulator, such as the pressure roller, ring die, cutter, screen, etc. Regularly add lubricating oil to the components that need lubrication, such as the pressure roller, to ensure their normal operation.

2. Raw material pretreatment: According to the requirements of the granulator, high-moisture materials are dried to control the moisture content within an appropriate range. For larger particle materials such as crop straw and branches, they need to be crushed to meet the feeding requirements of the granulator in terms of particle size.

3. Process optimization: Based on the production requirements of the organic fertilizer production line and the characteristics of raw materials, select an appropriate granulation process. For materials that require quenching and tempering, such as processes involving the addition of binders or steam, the quenching and tempering parameters must be strictly controlled.

4. Parameter Adjustment: During the production process, operators should closely monitor the operating status of the equipment and the quality of the products. According to the characteristics of the materials and production requirements, they should adjust the various parameters of the granulator in real time.

5. Quality Control: During the production process, the finished particles are regularly inspected, including indicators such as particle size, shape, strength, and moisture content. Ensure that the particle size deviation of the particles is extremely small, the compressive strength is high, and they are not easy to break during storage and transportation. Based on the test results, promptly feed back to the operators and adjust the equipment parameters or processes to ensure the stability and consistency of product quality.

0 notes

Text

How can small-scale organic fertilizer production lines reduce costs

To reduce the cost of small-scale organic fertilizer production lines, the following aspects can be considered:

1. Optimize equipment selection: Choose efficient organic fertilizer equipment to reduce heating energy consumption. Energy-saving organic fertilizer crushers, such as variable frequency speed regulation crushers, can be selected. The rotational speed can be flexibly adjusted according to the characteristics of the material and production requirements, avoiding energy waste caused by excessive rotational speed.

2. Process optimization: Through scientific testing and analysis of raw materials, the raw material formula is optimized to promote efficient microbial fermentation and reduce energy consumption during the fermentation process.

3. Adopt renewable energy: Where conditions permit, enterprises may consider using renewable energy sources such as solar and wind power to provide part of the energy for organic fertilizer production lines.

4. Reduce the cost of waste treatment: Treat the waste gas and wastewater generated during the fermentation process to achieve the recycling of resources. Secondary processing is carried out on by-products such as fine powder and substandard particles after screening to improve the utilization rate of resources.

5. Reduce raw material costs: Prioritize the use of raw materials with lower costs, such as livestock and poultry manure and crop straw. These raw materials not only have low costs but also can achieve the resource utilization of waste.

6. Enhance production efficiency: By adopting an automated control system, manual intervention is reduced and production efficiency is improved. Reduce production links and lower resource waste during the production process.

Through the above methods, small-scale organic fertilizer production lines can effectively reduce production costs and enhance market competitiveness while ensuring product quality.

0 notes

Text

What aspects of production is the automatic batching system for organic fertilizer mainly used in

The automatic batching system for organic fertilizer is mainly used in the following production fields:

Organic fertilizer production: The automatic organic fertilizer batching system can precisely control the proportion of various raw materials, such as livestock and poultry manure, crop straw, sludge, etc., ensuring the balanced nutritional components of the fertilizer. In the production of organic fertilizer production lines, this system can also be used to add various trace elements and biological functional bacteria agents to improve the quality of fertilizers.

2. Compound fertilizer production: The production of compound fertilizers requires precise control of the proportion of nutrients such as nitrogen, phosphorus and potassium. The automatic batching system can automatically complete the weighing and mixing of raw materials according to the preset formula. This system adopts automatic control, reducing manual operation and improving production efficiency and batching accuracy.

3. Compound fertilizer production: In the production of compound fertilizers, the automatic batching system can handle granular raw materials and achieve the mixing of fertilizers of different particle sizes. According to market demand, users can adjust the formula at any time, and the system can respond quickly and complete new ingredient tasks.

4. Chemical industry: Automatic batching systems can be used for the mixing and batching of chemical raw materials to ensure the stability of product quality.

5. Food processing: In food processing, this system can be used for the batching operation of raw materials such as seasonings and flour.

6. Pharmaceutical industry: In the pharmaceutical process, it can be used for the batching operation of raw materials such as powder and liquid.

Through the above applications, the automatic batching system for organic fertilizers can significantly enhance production efficiency, reduce labor intensity, and ensure product quality. It is an indispensable and important equipment in modern fertilizer production

0 notes

Text

Precautions for maintaining the pig manure organic fertilizer production line

To ensure the efficient operation and long-term stability of the pig manure organic fertilizer production line, the following are some key maintenance measures:

1. Keep the workplace clean: After each use, thoroughly remove any residual materials both inside and outside the equipment, and sweep up any scattered or splashed debris on the equipment. Wipe the exposed processing surfaces of the equipment and apply anti-rust paint to prevent dust from re-entering.

2. Regular maintenance of equipment: Regularly apply grease to the bearings, check the oil level in the reducer, and ensure that the organic fertilizer equipment is well lubricated. Regularly inspect the insulation condition of the electrical system to ensure that the electrical connections are firm.

3. Check the operating status of the equipment: Pay attention to whether there are any abnormal sounds or metal friction sounds during the operation of the equipment. If any abnormalities are found, stop the machine immediately for inspection. Regularly check the gaps between the components of the equipment to ensure compliance with the standards.

4. Preventive maintenance: Regularly inspect key components of the equipment, such as gears, bearings, motors, etc., and promptly identify and address potential issues. Regularly replace vulnerable parts such as belts and chains to ensure the normal operation of the equipment.

5. Operating Procedures: Ensure that operators are familiar with the operating procedures of the equipment to prevent equipment failure caused by misoperation. Operators should strictly abide by the operating procedures to avoid overloading the equipment.

6. Equipment upgrading and optimization: Timely update equipment and technology to enhance production efficiency and product quality. According to production demands, optimize the production process and reduce resource waste.

Through the above measures, the failure rate of the pig manure organic fertilizer production line can be effectively reduced, production efficiency and product quality can be improved, and the service life of the equipment can be prolonged at the same time.

0 notes

Text

How to prevent the organic fertilizer equipment from being damaged due to rapid discharge

To prevent the organic fertilizer equipment from being damaged due to rapid discharge, the following aspects can be considered:

1. Control the feeding speed: When feeding materials, discharge them slowly to avoid excessive speed or force. The feeding amount can be controlled by adding a feeder. There are two types of feeders: manual and automatic. Users should choose the appropriate feeder according to the actual situation.

2. Optimize the discharge system: Install pressure sensors and flow sensors at the discharge port to monitor the discharge pressure and flow in real time. When the discharge pressure is too high or the flow rate is abnormal, the sensor transmits a signal to the control system, which automatically adjusts the stirring speed or starts the auxiliary discharge device to ensure stable discharge. The automated discharge control system is adopted. According to the production requirements of the organic fertilizer production line, the discharge volume and discharge time are set. The system can precisely control the opening degree and time of the discharge valve to achieve quantitative and timed discharge.

3. Regular maintenance of equipment: Regularly clean the interior of the equipment to prevent material accumulation and blockage. Regularly inspect the key components of the equipment, such as bearings and gears, to ensure their normal operation.

4. Adjust equipment parameters: Add a frequency converter as needed to adjust the discharge speed and control the flow rate. Wear-resistant stainless steel screen mesh is selected, which extends the service life by three times. Adjust the aperture of the screen mesh for different materials.

5. Prevent material blockage: When the forklift is feeding materials, prevent hard foreign objects or large pieces of materials from entering. If the material is viscous, a vibrating motor or air flow device can be equipped to help the material fall smoothly and avoid blockage.

Through the above measures, it can effectively prevent the organic fertilizer equipment from discharging too quickly and damaging the equipment, and improve the production efficiency and service life of the equipment.

0 notes

Text

The prominent features of the organic fertilizer loader feeding hopper

1. Efficient storage and transportation: The organic fertilizer loader feeding hopper is designed to store a large amount of organic fertilizer, effectively storing various organic wastes and providing a stable raw material source for the operation of organic fertilizer equipment. The forklift silo can evenly and continuously transport materials to the next processing stage, ensuring the process stability of the subsequent processes in the organic fertilizer production line.

2. Simple structure and convenient maintenance: The structure is simple with a small number of components, making it easy to disassemble and maintain. It is usually made of high-strength steel and features corrosion resistance and durability, with a long service life.

3. Environmental protection and energy conservation: Advanced sealing technology is adopted, reducing the emission of dust and waste gas during the production process of organic fertilizer. The closed structure reduces the escape of odors. Some equipment is equipped with dust removal interfaces, which is conducive to environmental protection.

4. Strong adaptability: The size of the silo can be customized according to the user's requirements to meet the needs of various organic fertilizer equipment. It has functions such as stirring, mixing and fermentation, enabling organic waste to fully ferment in a short time and improving the quality of organic fertilizer.

5. Stability and Reliability: It features high traction, low power consumption, minimal wear, less material leakage, smooth operation and reliable performance. The tail tensioning device is equipped with a disc spring, which can reduce the impact load on the chain and increase the service life of the chain.

Through the above features, the organic fertilizer forklift silo can not only significantly improve the efficiency and quality of organic fertilizer production, but also reduce production costs. It is an indispensable important equipment in the organic fertilizer production process.

0 notes