1CUTFAB specializes in high-quality precision fabrication services, combining advanced technologies to bring your ideas to life. At 1CUTFAB, we cater to industries from Achieving precise Waterjet Cutting on a variety of materials, including metals, glass, ceramics, and composites, with minimal waste. High-precision laser cutting and engraving for intricate designs and complex shapes. Rapid prototyping and production using cutting-edge 3D printing technology for customized, functional, and aesthetic parts.Website : - https://1cutfab.com/

Don't wanna be here? Send us removal request.

Text

Sheet Metal Welding: 5 Available Methods and 10 Important Tips

When you watch someone weld sheet metal, it looks like a show full of flying sparks and glowing metal. Under that flash, though, lies a mix of science, skill, and a dollop of patience. Whether you're fixing a rusty vent cover or crafting a one-off table, picking the right weld style saves time and keeps the joint strong.

In the pages ahead, we'll explain five go-to weld methods for thin metal and drop ten quick tips. With these tricks, your seams stay neat, your parts fit as planned, and you finish the job proud instead of frustrated.

Why Welding Matters in Sheet Metal Fabrication

Sheet-metal fabrication is all about cutting, bending, and locking thin sheets into items like signs, boxes, or small covers. Welding seals those parts together, giving them strength and a tidy look. Yet that metal is so thin that too much heat can turn it into a taco or burn a hole you cant fix. Knowing how each weld style acts lets you control the heat and avoid costly mistakes.

MIG Welding (Gas Metal Arc Welding)

MIG welding sends solid wire through a gun while a cloud of shielding gas keeps air away. Shops love it because the speed is great and the skill curve is gentle, even for beginners.

MIG welding shines most when youre working with medium or heavy sheet metal. Because the basics arent hard to pick up, many newbies jump in with this method. It lays down solid beads on steel and handles aluminum almost as easily.

So, why go MIG?

Its usually the fastest option on the shop floor.

Getting the machine ready is quick and simple.

When you set the dial right, the welds come out smooth and clean.

Just remember that with very thin metal, you still have to watch for that pesky burn-through.

TIG Welding (Gas Tungsten Arc Welding)

TIG is a little fussier, because it runs off a tungsten rod and feeds in a separate filler wire. The welder has to keep an eye on the heat and push the filler by hand, so it takes time to feel comfortable-honestly, the welds can turn out show-quality.

Its the go-to process for thin stuff, especially where people will see the seams, like door frames or inner panels. Sectors that care about spotless beads-food plants, art shops, and high-end builds-lean on TIG.

So, why pick TIG?

You get rock-solid heat control from start to finish.

Aluminum and stainless steel both love this process.

Its the champ for thin, decorative, or even sculptural parts.

Fair warning: Because it travels slower, TIG wont keep pace with MIG when production speed is the main goal.

Stick Welding (Shielded Metal Arc Welding)

Stick welding is no-nonsense and hard to break. People use it outside, on shaky jobs, and in rain, snow, or dust. It needs neither gas bottles nor spotless metal, so grime or light rust is not a deal breaker.

But that same heat makes it risky on thin sheet metal- you can burn through fast and spray spatter everywhere.

Why use stick welding?

Works in wind, mud, and bad lighting

No gas lines or regulators

Gear costs little and fits in a truck

Keep in mind: its not for delicate metal and you’ll scrub off more slag.

Spot Welding (Resistance Spot Welding)

Spot welding seems fancy, yet its roots run deep. It shines when two thin sheets overlap and need a quick bond. The operator presses electrodes onto the joint and a short electric blast melts a tiny nugget that cools almost at once.

That speed is why manufacturers use it by the thousands when building cars, microwaves, or any part that stacks layers of metal.

Why use spot welding?

Blazing fast on mass runs

No rods, wire, or filler

Perfect for lap joints

Watch out: both sides must stay clear, and some shapes simply wont fit.

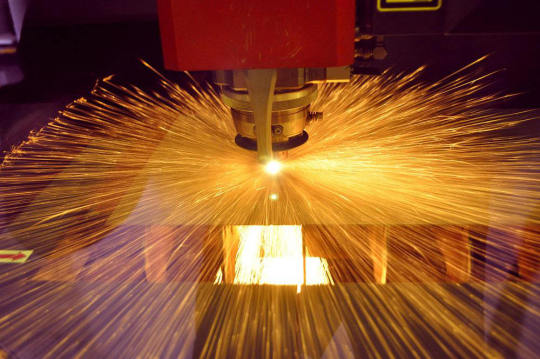

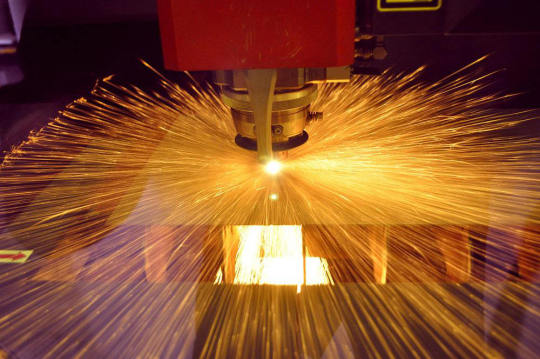

Laser welding uses a narrow, powerful light beam to fuse metal parts. Because the heat zone stays tiny, the welds come out smooth and the surrounding metal barely bends.

People rely on it for electronics, surgical tools, and any job where small, tidy joints count. You wont find it in most garages yet, but sheet-metal fabrication pros are slowly adopting it.

Why bother with laser welding?

Crystals developed by close-tolerance optics

Tiny heat zone means less twist

Safe on fragile parts

On the downside, the gear costs a fortune and usually lives in clean, air-conditioned labs.

10 Tips for Better Welding in Sheet-Metal Work

Whatever process you pick, these quick reminders can lift your game.

Clean Your Metal: Dust, oil, or rust hides defects and ruins the bead. A fast wipe pays off.

Choose the Right Method: Match the process to the metal type and thickness. Thin stuff calls for gentle heat.

Practice on Scrap: Burn a few beads on throw-aways before you touch the final piece.

Wear Safety Gear: Gloves, a good helmet, and long sleeves stop burns and shield your eyes. Sparks and UV light dont play nice.

Control Heat: Too much heat can twist sheet metal. Keep runs short, use fans, or select a pulse option.

Clamp the Pieces: Hold your metal parts steady and lined up so the seams stay even.

Use the Right Rod or Wire: Pick filler that matches the base metal, or you invite porosity.

Ventilate the Area: Work where fresh air blows in, so toxic fumes dont settle in your lungs.

Inspect the Welds: Look over each bead for gaps, cracks, spatter, or anything that shouts weak.

Keep Learning: Skill builds slowly. Watch clips, join a class, then repeat the weld until it shines.

Final Thoughts

Welding sits at the heart of sheet-metal work. Which process you use depends on the job, the stock, and how much practice you have. MIG and TIG deliver neat, user-friendly joints on most common sheets. Stick handles thicker metal or rough sites with reliable speed. Spot and laser welding lock in super-fast, exact seams for bulk orders or tight tolerances.

Best of all, you dont have to learn every technique today. Pick the one that suits your project and drill it until muscle memory kicks in. With steady practice, a curious mind, and a little patience, your metal joints will tighten up with every new piece.

0 notes

Text

Laser Cutting Quote

Looking for a laser cutting quote? At 1CUTFAB, we make it easy to get accurate, competitive quotes for your laser cutting projects. Simply upload your design files, and receive an instant quote based on material, size, and complexity. Our state-of-the-art laser cutting technology ensures precise, clean cuts for all types of materials, including metals, acrylics, and wood. Whether you're working on prototypes, custom parts, or large production runs, our fast and affordable services are tailored to meet your needs. Get your laser cutting quote today and start your project with confidence!

0 notes

Text

Laser Cutting Services

Looking for high-quality laser cutting services? At 1CUTFAB, we offer state-of-the-art laser cutting solutions for a wide range of materials including steel, stainless steel, aluminum, copper, and brass. Our 6kW fiber laser cutter delivers precise, clean cuts with minimal distortion, ensuring your parts meet the highest standards.

0 notes

Text

Laser Cutting Services San Diego

Looking for laser cutting services in San Diego? At 1CUTFAB, we provide high-quality laser cutting solutions for businesses and individuals in the San Diego area. Our state-of-the-art equipment ensures clean, precise cuts on various materials, including metals, acrylics, wood, and more. Whether you need custom parts, prototypes, or large production runs, our team delivers fast turnaround times, accurate results, and exceptional customer service. Get a quick online quote today and experience the best laser cutting services San Diego has to offer!

Link : https://1cutfab.com/pages/laser-cutting-services-san-diego

0 notes

Text

Metal Laser Cutting

For high-quality metal laser cutting, visit 1CUTFAB. Our advanced laser cutting technology provides precise, clean cuts on various metals, including steel, stainless steel, aluminum, and more. Whether you're working on prototypes, custom parts, or large production runs, our state-of-the-art fiber laser cutter ensures minimal distortion and tight tolerances. With instant online quotes and fast turnaround times, we make it easy to get the metal parts you need, exactly to your specifications.

0 notes

Text

Laser Cutting Services

Looking for high-quality laser cutting services? At 1CUTFAB, we offer state-of-the-art laser cutting solutions for a wide range of materials including steel, stainless steel, aluminum, copper, and brass. Our 6kW fiber laser cutter delivers precise, clean cuts with minimal distortion, ensuring your parts meet the highest standards.

0 notes

Text

Laser Cutting Services San Diego

Looking for laser cutting services in San Diego? At 1CUTFAB, we provide high-quality laser cutting solutions for businesses and individuals in the San Diego area. Our state-of-the-art equipment ensures clean, precise cuts on various materials, including metals, acrylics, wood, and more. Whether you need custom parts, prototypes, or large production runs, our team delivers fast turnaround times, accurate results, and exceptional customer service. Get a quick online quote today and experience the best laser cutting services San Diego has to offer!

Link : https://1cutfab.com/pages/laser-cutting-services-san-diego

0 notes

Text

Laser Cutting Quote

Looking for a laser cutting quote? At 1CUTFAB, we make it easy to get accurate, competitive quotes for your laser cutting projects. Simply upload your design files, and receive an instant quote based on material, size, and complexity. Our state-of-the-art laser cutting technology ensures precise, clean cuts for all types of materials, including metals, acrylics, and wood. Whether you're working on prototypes, custom parts, or large production runs, our fast and affordable services are tailored to meet your needs. Get your laser cutting quote today and start your project with confidence!

0 notes

Text

Laser Cut Parts

Need laser cut parts for your project? At 1CUTFAB, we specialize in delivering custom laser cut parts with precise accuracy and fast turnaround times. Our advanced laser cutting technology ensures clean, sharp edges on a variety of materials, including metal, acrylic, wood, and more. Whether you need parts for prototypes, small runs, or large-scale production, our laser cut services provide you with the precision you need to meet your specifications. Get an instant online quote and bring your designs to life with high-quality, cost-effective laser cut parts today!

0 notes

Text

Laser Cutting Services

Laser cutting services at 1CUTFAB offer precise, high-quality cutting solutions for a wide range of materials, including metal, wood, acrylic, and more. Utilizing advanced laser technology, 1CUTFAB provides custom cutting with intricate detail and clean edges, ideal for both small and large-scale projects. Whether you're designing prototypes, creating intricate patterns, or manufacturing components, 1CUTFAB's laser cutting services ensure accuracy and efficiency.

0 notes

Text

Laser Cut Parts

Laser cut parts are precision components produced using advanced laser cutting technology. This process involves a focused laser beam that melts, burns, or vaporizes material to create intricate and accurate shapes from materials like metal, plastic, wood, and acrylic. Laser cut parts are ideal for a variety of applications, including custom mechanical components, decorative elements, prototypes, and production runs. The precision of the laser cutting process ensures smooth, clean edges with minimal waste, while allowing for complex designs that would be difficult or impossible to achieve with traditional cutting methods. Laser cut parts are widely used in industries like automotive, aerospace, construction, and manufacturing, offering high quality, fast turnaround times, and versatility.

0 notes

Text

Laser Cutting Services san diego

0 notes

Text

Online CNC Services

Online CNC services at 1CUTFAB provide convenient, high-precision machining solutions for a variety of industries. Whether you need parts for prototypes, custom components, or large-scale production runs, 1CUTFAB’s online platform offers an easy way to upload designs and receive accurate, professionally machined parts. Their state-of-the-art CNC machines can work with various materials like metal, plastic, and wood, ensuring precise cuts, drilling, and milling with exceptional detail. The online service streamlines the process, providing fast turnaround times, competitive pricing, and expert support throughout your project. For anyone looking for reliable CNC machining services from design to delivery, 1CUTFAB is a trusted, efficient choice.

0 notes

Text

Laser Cutting Quote

Get an instant Laser Cutting Quote from 1CUTFAB, where we offer precise laser cutting services using our advanced Watt Fiber Laser Cutter. Capable of cutting Steel, Stainless Steel, Aluminum, Copper, and Brass with exceptional speed and accuracy, our technology ensures top-quality results every time. Simply upload your files through our easy-to-use quoting software, and you’ll receive a quote and your custom parts quickly. Whether you’re looking for prototypes or high-volume production runs, we provide efficient service at competitive rates.

0 notes

Text

Metal Bending

Metal bending is a manufacturing process that involves the deformation of metal to form a desired shape or angle without breaking or cracking the material. This process is commonly used in the production of parts and components for industries such as automotive, aerospace, construction, and furniture. Metal bending can be performed using various techniques, including press brakes, roll bending, and laser bending, depending on the material's thickness, type, and the specific bend required. Common metals used in bending include steel, aluminum, copper, and stainless steel. The result is typically a high-strength, precise part with smooth bends, often used for structural components, brackets, enclosures, and piping. Metal bending is highly versatile, allowing for complex and intricate shapes with high accuracy and repeatability.

0 notes

Text

Online Cnc Services

Online CNC services at 1CUTFAB provide convenient, high-precision machining solutions for a variety of industries. Whether you need parts for prototypes, custom components, or large-scale production runs, 1CUTFAB’s online platform offers an easy way to upload designs and receive accurate, professionally machined parts. Their state-of-the-art CNC machines can work with various materials like metal, plastic, and wood, ensuring precise cuts, drilling, and milling with exceptional detail. The online service streamlines the process, providing fast turnaround times, competitive pricing, and expert support throughout your project. For anyone looking for reliable CNC machining services from design to delivery, 1CUTFAB is a trusted, efficient choice.

0 notes