We “ADK Engineering & Solutions” are a Partnership firm engaged in Manufacturing, Wholesale Trading, Importing an optimum quality range of CNC Fiber Laser Cutting Machine, Plasma Cutting Machine, Welding Machine, Press Brake machines. Established in the year 2015 at Ahmedabad (Gujarat, India), these products are highly applauded for their features like sturdy construction, anti-corrosive body and long working life. If you want to get laser cutting machine price please contact us.

Don't wanna be here? Send us removal request.

Text

Unlock the secrets of speed in CNC fiber laser cutting! Our guide demystifies cutting speed calculations for cleaner, faster cuts in any material.

#cnc machines#manufacturer#automation#bendingmetal#cncmachining#technology#machinery#components#equipments

0 notes

Text

Unleash efficiency with our aerospace-standard laser machine. Rapid, durable, and German-engineered for precision cuts. Your key to a versatile and durable future. Explore the ADK advantage now

0 notes

Text

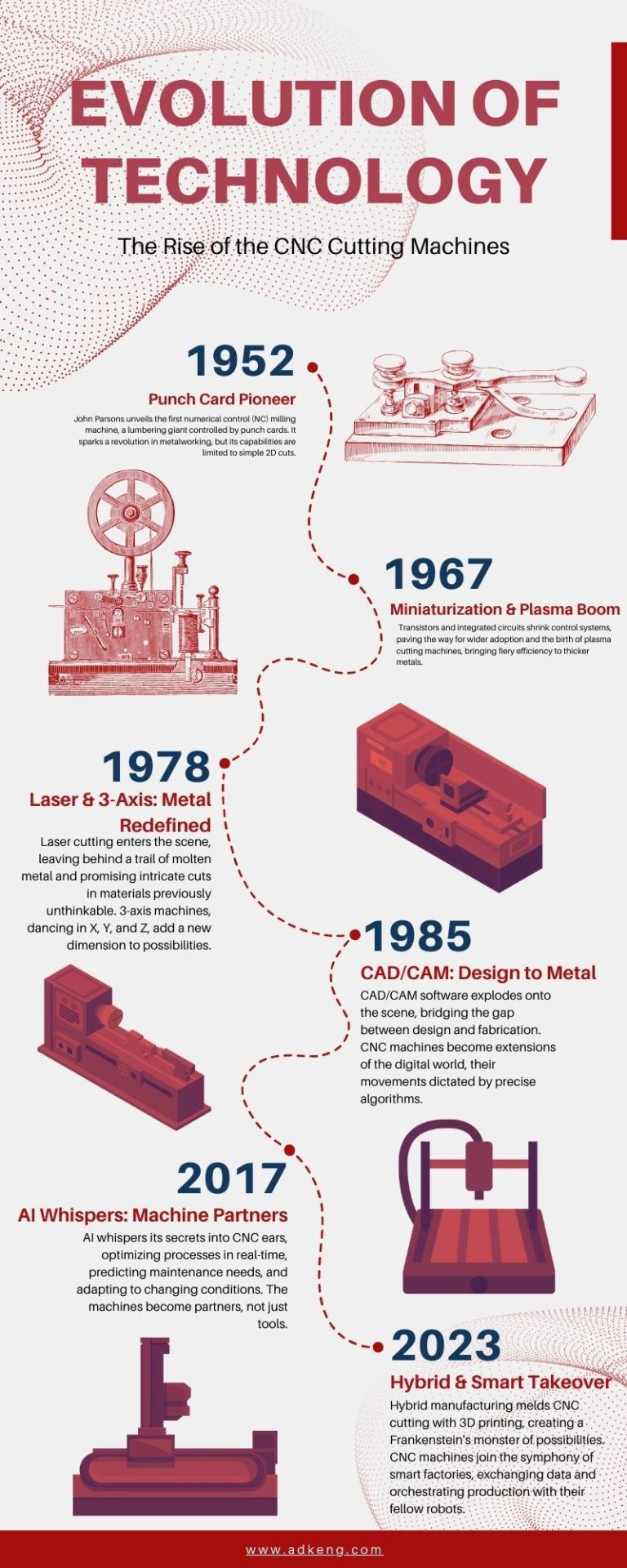

The Rise of the CNC Cutting Machines

From miniaturized circuits to AI-powered "Frankenstein's Factories," explore the remarkable evolution of metal cutting technology and its impact on our world.

Visit Now - www.adkeng.com

0 notes

Text

Why is laser cutting so expensive?

Pricey Magic or Smart Investment? Unmask the truth behind the cost! This blog cuts through the confusion, revealing the 7 factors shaping laser cutting's price tag. From precision paradoxes to power plays, understand the "why" before you decide. Ready to unlock the magic (and value) behind this tech? Dive in

0 notes

Text

ADK Engineering & Solutions: Cutting Industry Leaders with Lasting Relationships

ADK Engineering & Solutions, founded on a commitment to long-term relationships and quality, delivers top-notch cutting machines (fiber laser, plasma, oxyfuel) and exceptional after-sales service. Their expert team provides cost-effective, customer-focused solutions across diverse industries.

Visit Now - https://www.adkeng.com/

#cnc machines#manufacturer#bendingmetal#fiberlaser#automation#tech#technology#india#ahmedabad#electric

0 notes

Text

Choosing the Right Fiber Laser Machine in India: Your Comprehensive Guide

Fiber laser machines are revolutionizing the Indian manufacturing landscape, offering unparalleled precision, speed, and efficiency. This comprehensive guide equips you with the knowledge to navigate the market and select the perfect machine for your needs

0 notes

Text

Precision Laser Cutter: LF3015GC

LF3015GC Fiber Laser Cutter: Swift platform exchange, aerospace-grade aluminum gantry, auto-focus, and precision German tech for efficient, durable cutting

Visit Now - ADK Engineering & Solutions

#fiberlaser#lasermachine#cncmachining#cnc machines#manufacturer#india#ahmedabad#bendingmetal#industrial#automation#equipments#industrial machinery#engineering#technology#electric#innovation

0 notes

Text

Explore the world of precision by reading our infographic titled "Precision Unveiled: Navigating the Factors Influencing Fiber Laser Cutting Accuracy." Find out the secrets behind the precision of fiber laser cutting by investigating its capabilities inherently as well as the technical nuances that are the key factors that determine the precision of its cutting. Discover the reasons the reasons why fiber laser cutting is famous for its precision cuts and find out the components that are responsible for its remarkable precision.

For More Details Click here

#cnc machines#manufacturer#ahmedabad#automation#industrial#cncmachining#lasermachine#bendingmetal#electric

0 notes

Text

CNC Cutting Machines: Aeronautical Precision Unleashed

Journey into the heart of aerospace innovation with CNC cutting machines. Discover how these marvels redefine precision, automate manufacturing, and shape the future of high-performance aircraft components. Explore challenges, innovations, and upcoming trends driving the evolution of CNC technology in aerospace engineering.

#lasermachine#cncmachining#cnc machines#manufacturer#ahmedabad#india#adkeng#cnc cutting machine#technology#automation#industrial

0 notes

Text

Looking to level up your manufacturing game? ADK Engineering & Solutions has got you covered! Discover the ultimate guide on ordering the ideal machinery, including CNC Cutting Machines, for maximum productivity.

Visit Now - ADK Engineering & Solutions

#adkeng#cncmachining#manufacturer#india#lasermachine#tech#manufacturingtech#mechanical#machinery#tools#equipment

0 notes

Text

CNC Plasma Cutting Machines vs. Traditional Gas Cutting

In the realm of metal fabrication, the choice between CNC (Computer Numerical Control) plasma cutting machines and traditional gas cutting methods is a critical decision. Let's explore the advantages and drawbacks of both, helping you make an informed choice for your specific needs.

CNC Plasma Cutting Machines:

Precision: Offers intricate cuts, ideal for complex designs.

Versatility: Handles a wide range of materials and thicknesses.

Speed: Faster than traditional gas cutting, enhancing productivity.

Automation: Ensures consistent and accurate cuts across multiple pieces.

Minimal HAZ: Produces less heat, minimizing distortion and preserving material integrity.

Traditional Gas Cutting:

Cost-Effectiveness: More affordable for smaller operations with budget constraints.

Portability: Ideal for on-site projects, as it doesn't require a power source.

Thickness Capability: Handles thicker materials, suitable for heavy-duty applications.

Low Maintenance: Robust and low maintenance, ensuring reliability.

Choosing the Right Method:

Consider the following factors:

Project Requirements: Assess project complexity, material types, and thicknesses.

Budget: Evaluate initial investment, operating costs, and long-term maintenance expenses.

Precision: For intricate designs, opt for CNC plasma cutting.

Portability: Gas cutting is practical for on-site projects and remote locations.

In the dynamic metal fabrication field, the decision between CNC plasma cutting and traditional gas cutting depends on specific project needs. While CNC plasma cutting offers precision and efficiency, traditional gas cutting remains cost-effective and portable. Consider your budget, project complexity, and evolving cutting technologies to make the right choice for your fabrication endeavors.

1 note

·

View note

Text

Tips for Creating Effective CNC Plasma Cutting Patterns

CNC plasma cutting has revolutionized metal fabrication, providing precision and efficiency in creating intricate designs. Whether you're a seasoned professional or a novice, crafting effective CNC plasma cutting patterns requires a combination of creativity, technical knowledge, and attention to detail. In this blog, we'll explore some essential tips to help you create stunning and precise patterns for your CNC plasma cutting projects.

Understand Your Material: Before diving into the design process, it's crucial to have a solid understanding of the material you're working with. Different metals have varying cutting requirements, such as speed, power, and gas type. Knowing the properties of your chosen material will ensure clean cuts and prevent unnecessary errors.

Select the Right Software: Choosing the right software is paramount to the success of your CNC plasma cutting patterns. Opt for user-friendly design software that allows you to create and edit your designs easily. CAD (Computer-Aided Design) software is commonly used in the industry and offers a range of tools for precise pattern creation.

Precision Planning: Start with a detailed plan for your design. Consider factors such as cut paths, entry points, and the sequence of cuts. This planning phase will help minimize wasted material, reduce cutting time, and enhance the overall efficiency of the CNC plasma cutting process.

Optimize for CNC Cutting: Ensure your designs are optimized for CNC cutting by using vector-based files. Vector files are scalable without losing quality and provide CNC machines with the necessary information for precise cuts. Common file formats for CNC plasma cutting include DXF and SVG.

Experiment with Textures and Gradients: Don't limit yourself to simple outlines. Experiment with textures and gradients in your designs to add depth and visual interest. However, keep in mind that intricate details may require slower cutting speeds and more precise control.

Consider Kerf Width: Kerf refers to the material removed by the cutting process. It's crucial to factor in the kerf width in your design, as it can affect the final dimensions of your cut pieces. Adjust your patterns accordingly to achieve the desired end result.

Test on Scrap Material: Before executing your final design, conduct tests on scrap material. This allows you to identify potential issues, such as warping, and make adjustments as needed. Testing on scrap material also ensures that your CNC machine is properly calibrated.

Maintain Your CNC Machine: Regular maintenance of your CNC plasma cutting machine is essential for achieving consistent and high-quality results. Keep the machine clean, check for worn-out parts, and calibrate it regularly to maintain optimal performance.

Document Your Settings: Keep detailed records of your cutting settings, including speed, power, and gas pressure. This documentation will serve as a valuable reference for future projects and help you replicate successful cutting conditions.

Stay Informed and Inspired: Stay updated on the latest trends and techniques in CNC plasma cutting. Join online forums, attend workshops, and follow industry experts to stay informed and inspired. Continuous learning will enhance your skills and open up new possibilities for creative designs.

Creating effective CNC plasma cutting patterns is a blend of artistry and technical proficiency. By understanding your materials, utilizing the right software, planning meticulously, and staying informed, you can elevate your CNC plasma cutting projects to new heights. Whether you're working on custom metal art, industrial components, or intricate decorations, these tips will help you achieve precise and visually stunning results. Happy cutting!

0 notes

Text

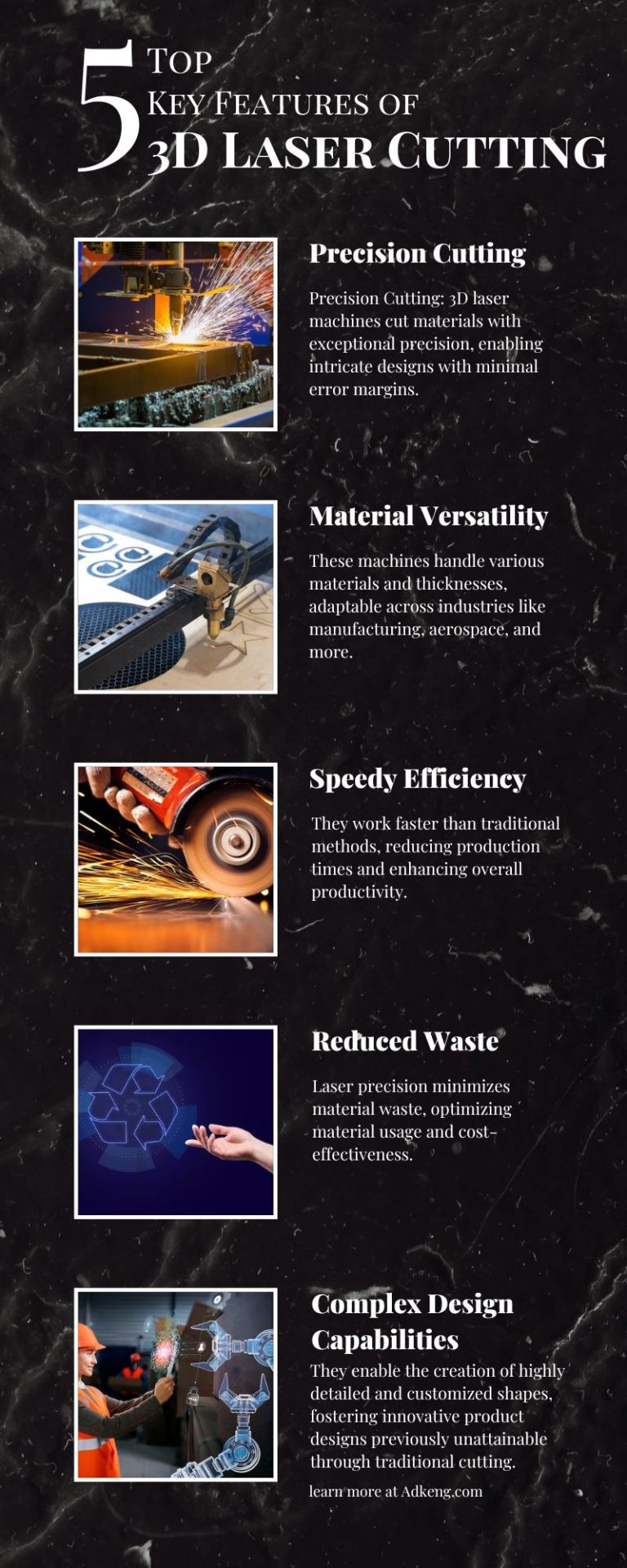

Top 5 points about 3d laser cutting machine

Dive into the transformative world of 3D laser cutting machines and unravel their standout features. These cutting-edge machines redefine precision cutting, offering unparalleled accuracy in shaping diverse materials. From metals to plastics, their versatility spans across industries like manufacturing, aerospace, and beyond, accommodating various material thicknesses with ease. Speed and efficiency are their hallmark, significantly reducing production times while maximizing productivity. Learn More At - ADK Engineering & Solutions

0 notes

Text

3D Laser Cutting & Ergonomics: Elevating Product Functionality

In the fast-paced world of product design and manufacturing, the quest for enhancing functionality while prioritizing user experience remains an ongoing pursuit. Amidst various innovative methodologies, the convergence of 3D laser cutting and ergonomics has emerged as a game-changer, revolutionizing the way products are conceptualized, designed, and produced.

The Marriage of 3D Laser Cutting and Ergonomics

Unveiling the Power of 3D Laser Cutting

At the heart of this revolution lies 3D laser cutting, a sophisticated technology that enables precision and intricacy in shaping raw materials. Its ability to carve out complex designs with utmost accuracy has transformed traditional manufacturing processes, offering unparalleled possibilities in crafting products with enhanced functionality.

The precision and versatility of 3D laser cutting have transcended industry boundaries, from automotive and aerospace to consumer electronics and healthcare. Intricate components, once deemed impossible to create, now take form effortlessly, thanks to the precision and speed offered by this cutting-edge technology.

Ergonomics: Redefining User-Centric Design

Simultaneously, the integration of ergonomics into product design has redefined the approach towards user interaction. Ergonomics, the science of optimizing design to enhance human well-being and performance, considers user comfort, efficiency, and safety as primary principles.

By employing ergonomic principles during the design phase, products are tailored to fit the human body's mechanics, minimizing user fatigue and maximizing usability. From furniture to gadgets, ergonomics has been pivotal in creating products that seamlessly integrate with the user's needs and movements.

Elevating Product Functionality

Precision Meets Comfort: The Synergy

The amalgamation of 3D laser cutting and ergonomics has unlocked new dimensions in product functionality. Designers and engineers now wield the power to fashion products that not only boast intricate designs but also prioritize user comfort and usability.

Innovations in furniture design showcase this synergy impeccably. Chairs, desks, and even automotive interiors are meticulously crafted using 3D laser cutting techniques, ensuring both structural integrity and ergonomic superiority. The result? Products that not only look aesthetically pleasing but also align with the natural contours of the human body, providing unparalleled comfort and support.

Shaping the Future: Possibilities and Beyond

Looking ahead, the possibilities are boundless. The marriage of 3D laser cutting and ergonomics continues to push the boundaries of product design. From personalized medical devices tailored to individual anatomies to futuristic automotive interiors that prioritize both safety and comfort, the impact of this convergence is reshaping industries and consumer experiences. The fusion of 3D laser cutting and ergonomics stands as a testament to human ingenuity and technological advancement. It heralds a new era where functionality, precision, and user-centric design harmoniously coexist. As this synergy continues to evolve, it promises not just enhanced products but an elevated user experience that transcends conventional boundaries, setting new benchmarks for innovation and excellence.

0 notes

Text

The Power of CNC Fiber Laser Cutting

Explore the cutting-edge world of Fiber Laser Technology with our infographic. From the fundamental mechanics of precision cutting to its versatile applications in manufacturing, discover the cost-effective advantages, stringent safety measures, and future trends shaping the industry. Uncover the smart integration of AI and Industry 4.0, ushering in a new era of efficiency and customization in cutting technology

Know More - https://www.adkeng.com/fiber-laser-cutting-machines/

0 notes

Text

Unveiling the Power of Swing Beam Shearing Machines

In the world of industrial metalworking, precision and efficiency are paramount. Among the many tools and machines that aid in this process, swing beam shearing machines stand out as an essential and versatile tool. These machines are the unsung heroes of metal fabrication, providing precise cuts and streamlined operations that are crucial in various industries.

Understanding Swing Beam Shearing Machines

Swing beam shearing machines are mechanical devices designed for cutting metal sheets with high precision. They utilize a swinging beam motion that applies force to a metal workpiece, delivering clean and accurate cuts along a predefined line. This technology is ideal for cutting various materials such as stainless steel, aluminum, and mild steel.

How Do They Work?

The functionality of swing beam shearing machines is relatively straightforward yet highly effective. The machine's blade descends at an angle, creating a precise cut by pressing against the material placed on the worktable. This process produces minimal distortion and leaves a clean edge, making it ideal for applications where accuracy is paramount.

Advantages of Swing Beam Shearing Machines

Precision Cutting

One of the primary advantages of these machines is their ability to make precise cuts consistently. This accuracy is crucial in industries where even the slightest deviation can lead to significant ramifications in the final product.

Versatility

Swing beam shearing machines can handle a wide range of materials and thicknesses, making them incredibly versatile. From thin sheets to thicker metal plates, these machines adapt to various cutting needs with ease.

Efficiency and Speed

Their efficiency in cutting materials ensures quicker turnaround times, enhancing overall productivity. With their ability to make clean cuts swiftly, they contribute to streamlining manufacturing processes.

Minimal Material Waste

The precision cuts produced by swing beam shearing machines minimize material waste, optimizing resource utilization and reducing costs in the long run.

Applications Across Industries

The versatility and precision of swing beam shearing machines make them indispensable in several industries:

Automotive: Used for fabricating components such as chassis and body panels.

Construction: Ideal for manufacturing metal components used in building structures.

Aerospace: Critical in producing precise parts for aircraft and spacecraft.

Shipbuilding: Essential for creating various metal parts used in ship construction.

Embracing Technology for Efficiency

Advancements in technology have further enhanced the capabilities of swing beam shearing machines. Modern iterations come equipped with features like computerized controls, automated blade adjustments, and programmable settings, allowing for even greater precision and efficiency.

Swing beam shearing machines play an indispensable role in the metalworking industry, offering precision, versatility, and efficiency. As technology continues to evolve, these machines will likely become even more integral to various manufacturing processes, contributing to the production of high-quality products across multiple sectors.

From automotive to aerospace, these machines remain a cornerstone of metal fabrication, empowering industries to achieve greater accuracy and efficiency in their operations. As we continue to innovate, the power of swing beam shearing machines will undoubtedly remain at the forefront of modern manufacturing.

#manufacturer#shearingprocess#shearingtools#shearing machine#cnc machines#tools#industrial machinery#equipment#lasermachine#automation

0 notes

Text

Explore the Inner Workings of Fiber Laser Welding with ADK Engineering & Solutions

Step into the realm of innovation with ADK Engineering & Solutions! Our latest blog unveils the mysteries behind Fiber Laser Welding Machines and how they redefine precision in welding. Curious to understand the technology driving industries forward? Click now to empower your knowledge and stay ahead in the world of engineering. Discover the transformative capabilities of Fiber Laser Welding – knowledge is power, and your expertise starts here!

#fiberlaser#lasermachine#adkeng#demonstration#india#ahmedabad#manufacturer#industrialcutting#automation

0 notes