Founded in 2010, Athena Technology is an ISO 9001:2008 Certified Company specializing in the manufacturing, exporting, and trading of high-quality scientific instruments and laboratory equipment. Our product range, including the Nitrogen Evaporator, Nitrogen Gas Generator, and Hydrogen Gas Generator, proudly carries the trusted Athena brand, known for unmatched efficiency, reliability, durability, and proven performance. These instruments find applications in Research Labs, Colleges, Schools, and various industries such as Life Sciences, Chemical, Petrochemical, Semiconductor, Pharmaceutical, and Environmental. We also extend our reach to international markets in European countries, the Middle East, South East Asia, Africa, and the USA, reflecting our commitment to contributing to a prosperous human society through innovation, top-notch quality, and flawless Installation Services.

Don't wanna be here? Send us removal request.

Text

HPLC Pump Selection Guide: How to Choose the Right Pump for Your Application

Choosing the correct HPLC pump can significantly influence the quality of results in any laboratory analysis. Whether used for pharmaceutical testing, chemical research, or food safety evaluation, an HPLC pump must be matched accurately to your requirements. This guide provides a clear breakdown of how to make that decision effectively.

What Is an HPLC Pump?

An HPLC pump is a core part of a High-Performance Liquid Chromatography system. It controls the flow rate of solvents through the column, which separates chemical compounds based on their interaction with the stationary phase.

An accurate and consistent flow ensures that the test results are reliable and reproducible. Variations in flow can lead to noisy baselines, retention time shifts, or loss of resolution.

Types of HPLC Pumps

Choosing between pump types depends on your analytical goals and the volume or pressure range required. Below are the most common variants:

1. Reciprocating Pumps

Delivers solvent using a motor-driven piston

Excellent flow accuracy and pressure stability

Suitable for routine, high-pressure work

2. Syringe Pumps

Provides very low flow for micro-analytical needs

Ideal for applications requiring minimal pulsation

3. Constant Pressure Pumps

Maintains constant pressure instead of constant flow

Used in specific gradient applications

Factors to Consider Before Choosing an HPLC Pump

When selecting an HPLC pump, users must assess not only the type of analysis being performed but also environmental and mechanical conditions that influence performance.

1. Flow Rate Range

Different applications need different flow capacities:

Analytical labs typically use 0.1–10 mL/min

Preparative systems often go up to 100 mL/min

Choosing a pump outside the necessary flow range can compromise performance and solvent efficiency.

2. Pressure Capacity

The pressure generated depends on column dimensions, flow rate, and solvent viscosity.

Ensure the pump handles at least 20% more than the maximum backpressure expected.

Most analytical HPLC systems need up to 6000 psi.

3. Solvent Compatibility

Check if the pump components (seals, pistons, tubing) are compatible with the solvents used. For instance, buffers or strong acids may degrade internal parts if not selected appropriately.

4. Pulsation Control

Low pulsation ensures steady baseline and better peak shape. Look for pumps with built-in pulse dampeners or dual pistons for more consistent flow.

5. Ease of Maintenance

Pumps that require fewer part replacements and offer easy access to check valves, seals, and pistons reduce downtime and cost over time.

Applications That Influence Pump Choice

Selecting an HPLC pump also depends on the specific field or purpose of the analysis:

Research Labs:

Require flexible systems with both isocratic and gradient capability

Benefit from programmable control over pressure and flow

Quality Control Testing:

Needs stable, repeatable flow across long hours

Suitable pumps should support auto-purge and low maintenance cycles

Preparative HPLC:

Requires larger volume pumps, stainless steel components

Must manage high flow rates and pressure for compound isolation

Academic Labs:

Seek reliable and versatile systems at optimal cost

Prefer pumps with modular design and standard tubing compatibility

Tips for Buying the Right HPLC Pump

If you are evaluating a system, especially from an HPLC pump supplier like Athena Instruments, follow these practical steps:

Confirm calibration certification from the manufacturer

Check customer support for service and part availability

Look for demo models or application-based consultation

Consider upgrade options for future needs like autosamplers or detectors

Why Athena Instruments Is Trusted

As a known laboratory equipment supplier, Athena Instruments provides quality-controlled systems tailored to the user’s environment. Their pumps are compatible with a wide variety of lab solvents and offer maintenance support backed by local service teams.

From HPLC pump models for academic teaching to those supporting pharmaceutical QA testing, Athena Instruments provides calibrated performance with reliability.

FAQs

Q1: What is the ideal flow rate for an HPLC pump in routine analysis?

Answer: For routine analytical HPLC, a flow rate between 0.5 and 1.5 mL/min is common. This maintains optimal resolution and solvent usage.

Q2: Can I use the same HPLC pump for both isocratic and gradient methods?

Answer: Dual-pump systems or quaternary pumps allow both isocratic and gradient applications. Ensure the control software supports gradient programming.

Q3: How often should an HPLC pump be serviced?

Answer: Typically every 6 to 12 months, or after 1000 hours of operation. Regular maintenance includes seal replacement, piston check, and flow calibration.

Q4: What happens if the pump pulsates too much?

Answer: Excessive pulsation affects baseline stability and causes poor peak shapes. Dual-piston designs or pulse dampeners help control this.

Q5: Is it necessary to use a degasser with the HPLC pump?

Answer: Yes, degassers prevent bubble formation that may disrupt flow. They are especially important when using gradient elution.

Conclusion

Choosing the right HPLC pump is a foundational step in setting up a lab capable of delivering precise and reliable results. By assessing your application's pressure and flow needs, solvent use, and support services, you can invest in a system that operates efficiently for years.

Whether you're working in pharmaceuticals, research, or chemical analysis, selecting the correct pump from a trusted lab instruments provider such as Athena Instruments helps you maintain laboratory performance and avoid analytical disruptions.

#lab instruments#laboratory equipment suppliers#laboratory equipment#athena instruments#HPLC Pump#HPLC Pump Supplier

0 notes

Text

KBR Die Set by Athena Technology

Athena Technology offers a robust range of KBR Die Sets built to deliver outstanding performance under high-pressure operations. Engineered with precision and crafted from hardened steel, our die sets are trusted across multiple industries for accurate shaping and extended operational life. Whether you're in automotive, aerospace, or metal fabrication, our KBR Die Set supports critical production demands with minimal maintenance. What sets Athena Technology apart is our commitment to precision engineering and strict quality control. We offer custom sizing options and fast turnaround on bulk orders. If your goal is optimal forming accuracy and consistent outcomes, choose our KBR Die Set solutions. Athena Technology is where innovation meets industrial excellence, helping you stay ahead in competitive manufacturing.

#athena technology#lab instruments#laboratory equipment suppliers#laboratory equipment#KBR Die Set#KBR Die Set Supplier

1 note

·

View note

Text

Why Athena Technology is a Trusted Gas Manifold System Provider in India

In laboratories and industrial settings, reliable gas delivery systems are essential. Whether for analytical instruments, research processes, or manufacturing, a gas manifold system plays a vital role in managing and distributing gases safely and efficiently. Choosing the right provider can significantly impact the performance, safety, and reliability of your operations.

Athena Technology stands out as a top gas manifold supplier in India. With a focus on quality, safety, and long-term support, they have become the go-to choice for many organisations across the country.

What is a Gas Manifold System?

A gas manifold system is a setup used to regulate and distribute gas from one or more cylinders to various equipment or locations. These systems are common in laboratories, hospitals, and industrial facilities.

Key Functions of a Gas Manifold

Controls the pressure of the gas supply

Directs gas flow to specific instruments or workstations

Allows automatic cylinder changeover

Enhances workplace safety by preventing leaks and pressure drops

Why Choosing the Right Gas Manifold Provider Matters

The safety and performance of your operation rely heavily on the quality of the gas delivery system. A poorly designed or installed manifold can cause:

Gas contamination

Pressure fluctuations

Safety hazards due to leaks or system failures

That’s why selecting a trusted provider like Athena Technology is important for uninterrupted, safe operations.

About Athena Technology—Trusted Name in Lab Equipment

Athena Technology is a reputable laboratory equipment supplier in India, known for its expertise in gas handling systems. The company serves research labs, universities, pharma companies, and industrial units across the country.

What Makes Athena Technology a Trusted Partner?

Decades of ExperienceAthena brings years of industry knowledge, ensuring reliability and compliance with safety standards.

Customised SolutionsEvery lab or plant has unique needs. Athena offers bespoke gas manifold systems that meet specific pressure, gas type, and safety requirements.

High-Quality MaterialsTheir systems use stainless steel, brass, and other corrosion-resistant materials to ensure durability.

Certified and Tested ProductsAll gas manifolds are tested thoroughly to guarantee safety and performance before delivery.

After-Sales SupportFrom installation to routine servicing, Athena provides continued support to keep systems running smoothly.

Applications of Athena's Gas Manifold Systems

Athena Technology serves a wide range of industries:

Laboratory Settings

Research laboratories

Analytical chemistry labs

University and academic labs

Medical and Pharmaceutical Industry

Hospitals for oxygen and anaesthesia gas supply

Pharmaceutical manufacturing units

Industrial Use

Chemical plants

Semiconductor fabrication

Food processing industries

Benefits of Using Athena Gas Manifolds

Athena’s gas manifold systems are not just about gas delivery—they offer a combination of safety, efficiency, and reliability.

Key Benefits

Leak-proof connections and fittings

Automatic cylinder switch-over for uninterrupted gas supply

Easy maintenance with modular designs

Pressure regulators for safe and accurate gas distribution

Compatibility with multiple gases like nitrogen, oxygen, hydrogen, and more

How to Choose the Right Gas Manifold for Your Lab

When investing in a gas manifold system, consider the following:

Factors to Keep in Mind

Type of gas and required purity

Number of supply cylinders

Maximum pressure and flow rate

Whether you need manual or automatic switching

Safety certifications and installation support

Athena’s expert team can assist in selecting or designing a system based on your needs.

Frequently Asked Questions

Q1: What is the purpose of a gas manifold in a laboratory?

Answer: A gas manifold distributes gas from one or more cylinders to various lab instruments, maintaining stable pressure and reducing the risk of leaks.

Q2: Is Athena Technology’s manifold system suitable for all gases?

Answer: Yes, Athena designs manifold systems compatible with a wide range of gases including nitrogen, helium, argon, hydrogen, and oxygen.

Q3: Do they provide installation and after-sales support?

Answer: Yes, Athena offers full installation services and ongoing maintenance to ensure smooth operation of your manifold system.

Q4: How long does it take to deliver a gas manifold system?

Answer: Delivery times vary depending on the complexity of the system, but most orders within India are fulfilled within 2–4 weeks.

Q5: Can Athena customise a system for large industrial use?

Answer: Absolutely. Athena provides both standard and fully customised solutions for industrial applications across sectors.

Conclusion

Reliable gas delivery is not optional for laboratories and industrial facilities it is essential for safety, efficiency, and compliance. Athena Technology has earned its reputation as a trusted provider of gas manifold systems in India by combining engineering expertise, safety standards, and dedicated customer support.

If you’re searching for a dependable laboratory equipment supplier with proven experience in gas systems, Athena is a name worth considering. Their team is ready to help you choose or build the right solution for your requirements.

Get in touch with Athena Technology today for a consultation or visit their official page to explore product offerings.

#athena technology#lab instruments#laboratory equipment#laboratory equipment suppliers#gas manifold system#gas manifold systems#gas manifold

1 note

·

View note

Text

Nitrogen Generation Plant Solutions | Athena Technology

Athena Technology builds high-performance nitrogen generation plants engineered for precision, reliability, and energy efficiency. Ideal for manufacturing, food packaging, pharmaceuticals, and electronics, our systems ensure continuous nitrogen supply with low operational costs. Designed to meet diverse industrial demands, each plant is backed by robust technology and stringent quality control. Whether you need compact on-site units or large-scale systems, Athena Technology delivers scalable nitrogen generation plant solutions trusted by industries across India.

#athena technology#lab instruments#laboratory equipment suppliers#laboratory equipment#nitrogen generation#Nitrogen Generation Plant#Nitrogen Generation Plant Supplier

0 notes

Text

Green Hydrogen Plant Solutions | Athena Technology

The Green Hydrogen Plant from Athena Technology is engineered to support India’s transition towards cleaner industrial fuel alternatives. With an emphasis on safety, output consistency, and long-term sustainability, this solution is ideal for power generation, refineries, and process industries committed to green growth. Designed using state-of-the-art controls and modular systems, the plant reduces environmental impact without compromising productivity. Athena Technology integrates domain expertise and high-quality manufacturing to deliver a hydrogen production system that is future-ready, cost-effective, and adaptable for real-world industrial use.

#athena technology#lab instruments#laboratory equipment suppliers#laboratory equipment#Green Hydrogen Plant#Green Hydrogen Plant Supplier

0 notes

Text

High-Performance Gas Manifold System in India | Athena Technology

Choose Athena Technology for expertly designed Gas Manifold System setups built to handle complex gas distribution needs across sectors like healthcare, pharmaceuticals, manufacturing, and research. Our systems are engineered for optimal pressure control, seamless switching between cylinders, and continuous gas flow without disruption. Designed using high-grade stainless steel and brass fittings, we offer configurations suitable for both corrosive and non-corrosive gases. With custom layouts, pressure regulators, and safety features, our gas manifold systems ensure operational excellence, improved efficiency, and long-term reliability. Athena is your trusted industrial gas solution partner.

#athena technology#lab instruments#laboratory equipment suppliers#laboratory equipment#Gas Manifold System#Gas Manifold System supplier#gas manifold systems#Gas Manifold System in india

0 notes

Text

Hydrogen Generator for Labs & Industry | Athena Technology

Looking for a powerful and safe hydrogen generator solution? Athena Technology provides advanced hydrogen generators designed for lab and industrial use. With compact footprints and high-efficiency output, our generators eliminate the need for bulky cylinder storage. You get a consistent, high-purity hydrogen supply with low energy consumption and reduced emissions. Perfect for gas chromatography, fuel cells, and chemical processes. With a solid track record in precision engineering, Athena helps you transition to cleaner, smarter gas generation systems with ease.

#athena technology#lab instruments#laboratory equipment suppliers#laboratory equipment#hydrogen generator#hydrogen generator Supplier In India

0 notes

Text

Trusted Laboratory Equipment Supplier in India – Athena Technology

Find reliable Laboratory Equipment that delivers consistent results across education, R&D, and quality control labs. Athena Technology offers a broad selection of certified instruments built for accuracy, safety, and efficiency. Each product is tested to handle intensive lab conditions and meet evolving industry standards. From basic lab tools to advanced instruments, we support institutions with robust solutions at competitive prices. Our range is ideal for chemical, biotech, and pharmaceutical labs. With timely delivery, service support, and expert consultation, Athena is your partner in precision and performance. Browse now and build a smarter, safer lab setup.

#athena technology#lab instruments#laboratory equipment suppliers#laboratory equipment#Laboratory Equipment Supplier in India

0 notes

Text

Green Hydrogen Plant for Clean Energy Production | Athena Technology

Athena Technology presents a robust Green Hydrogen Plant designed for industries seeking a sustainable and low-emission energy solution. Our system uses renewable energy sources like solar or wind to produce hydrogen through electrolysis, ensuring zero carbon emissions. Engineered for high efficiency and low maintenance, our green hydrogen systems support energy independence and align with future-ready decarbonisation goals. Ideal for industrial applications, this plant is modular, scalable, and compliant with safety and environmental regulations. Join the transition to clean energy and explore how a Green Hydrogen Plant can reshape your operations with long-term savings and environmental compliance. Backed by Athena Technology’s proven engineering expertise, this solution is ready for tomorrow’s energy needs today.

#athena technology#lab instruments#laboratory equipment suppliers#laboratory equipment#green hydrogen plant#Green Hydrogen Plant Supplier In India

0 notes

Text

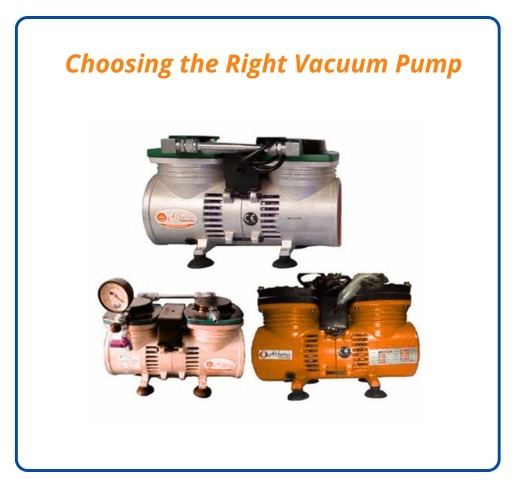

Choosing the Right Vacuum Pump for Your Industry

Selecting the right vacuum pump for your industrial or laboratory operation is a decision that directly affects process efficiency, equipment life, and output quality. Whether you're working with sensitive laboratory equipment or running a high-demand industrial line, understanding what type of vacuum pump fits your needs can prevent downtime and excessive maintenance.

This guide explains how to make an informed choice based on technical functionality, operating environment, and budget.

Understanding Vacuum Pumps

A vacuum pump removes air or gas from a sealed chamber to create a partial or full vacuum. The goal is to reduce pressure for various industrial or scientific processes such as packaging, coating, distillation, filtration, or even freeze-drying.

Vacuum pumps are essential in multiple sectors, including:

Pharmaceuticals

Food and beverage

Manufacturing

Chemical processing

Medical laboratories

Each application requires different pressure ranges, gas-handling capabilities, and levels of contamination control.

Types of Vacuum Pumps

There are several types of vacuum pumps. Each serves a specific function based on how it generates vacuum.

1. Rotary Vane Pumps

These oil-sealed pumps are widely used in both industry and labs. Ideal for: Medium vacuum applications. Benefits: Durable, good for continuous operation, cost-effective.

2. Diaphragm Pumps

Dry-running and oil-free, these are commonly used for sensitive equipment. Ideal for: Laboratories, medical settings, and cleanroom environments. Benefits: No contamination risk, low maintenance.

3. Scroll Pumps

Known for quiet operation and minimal vibration. Ideal for: Environments requiring clean, oil-free vacuum. Benefits: Compact design, minimal servicing.

4. Screw Pumps

Suited for heavy-duty industrial operations. Ideal for: High throughput systems and harsh environments. Benefits: High efficiency, handles vapour loads well.

Factors to Consider Before Buying

1. Nature of Application

The process you need the vacuum for will guide the required pressure range and pump durability. Examples:

Distillation requires deep vacuum levels

Filtration may need medium-range vacuum

2. Type of Gas or Vapour

If your process involves corrosive or moisture-laden gases, a dry pump like a diaphragm or screw pump is better suited. Moisture and chemical compatibility are non-negotiable when choosing your system.

3. Pressure Range

Vacuum levels are broadly classified as:

Rough vacuum (up to 1 mbar)

Medium vacuum (up to 10⁻³ mbar)

High vacuum (up to 10⁻⁷ mbar)

The more precise the requirement, the more specialised the equipment needs to be.

4. Budget and Operational Costs

Beyond the purchase cost, consider power consumption, servicing needs, and part replacements. An energy-efficient pump may be slightly costlier upfront but cheaper to operate long term.

5. Maintenance and Downtime

Regular maintenance schedules should match your production downtime window. Some pumps like scroll or diaphragm pumps require minimal maintenance.

How Vacuum Pumps Relate to Laboratory Equipment

In laboratory setups, vacuum pumps are paired with tools like rotary evaporators, freeze dryers, and filtration assemblies. Selecting a quiet, oil-free, and vibration-free pump such as a diaphragm or scroll pump is often the best choice for sensitive instruments.

Athena Technology, known for its industrial equipment, provides vacuum pumps suited for both research and large-scale usage. Their models cater to laboratories, manufacturing lines, and other specialised applications, offering flexibility across multiple processes.

Frequently Asked Questions

Q1. What is the most suitable vacuum pump for a laboratory?

Answer: A diaphragm or scroll pump is typically preferred due to its oil-free operation, minimal maintenance, and quiet performance. These are ideal for clean, controlled environments.

Q2. How often should vacuum pumps be serviced?

Answer: Service intervals depend on the pump type and application. Oil-sealed pumps may require monthly or quarterly oil changes, while dry pumps need less frequent maintenance.

Q3. Can one vacuum pump type work across all applications?

Answer: Not always. A pump suitable for general manufacturing may not meet the cleanroom or temperature sensitivity standards required in labs or medical settings.

Q4. Are oil-free vacuum pumps better than oil-sealed pumps?

Answer: It depends on the application. Oil-free pumps offer cleaner operation and lower contamination risk, while oil-sealed pumps are robust and suited for processes with demanding loads.

Conclusion

Choosing the right vacuum pump for your industry is a function of both performance needs and practicality. Consider the type of process, nature of gases involved, maintenance capability, and budget before deciding. For best results, match the equipment to your specific workload, whether it's delicate laboratory use or heavy-duty manufacturing.

When evaluating options, look into reputable providers like Athena Technology that offer a range of vacuum solutions to match varied industrial and research needs.

#athena technology#lab instruments#laboratory equipment suppliers#laboratory equipment#Vacuum Pump#Vacuum Pump Supplier

0 notes

Text

Uses of a Stomacher Blender in Food Testing Labs

When it comes to maintaining safety in food testing labs, accuracy and hygiene are essential. One important tool that supports both is the stomacher blender. Despite its simple look, this device plays a crucial role in sample preparation by thoroughly mixing food samples without cross-contamination.

From public health labs to private quality testing centres, stomacher blenders help technicians analyse food items with confidence. This article explains how these blenders are used, why they matter, and how they fit into the wider setup of laboratory instruments and equipment.

What Is a Stomacher Blender?

A stomacher blender is a laboratory instrument used to homogenise samples, particularly in food and microbiological testing. It blends samples by crushing them within a sterile, sealed plastic bag using paddles. This process breaks down the sample for even distribution of any microbes, chemicals, or particles present.

Unlike traditional blenders, the stomacher does not use blades. This reduces the risk of contamination and sample loss, making it ideal for labs dealing with sensitive material.

Top Uses of a Stomacher Blender in Food Testing Labs

1. Microbiological Analysis

A stomacher blender is often the first step in detecting pathogens like Salmonella, E. coli or Listeria. Blending helps release bacteria from the food surface, making it easier to culture and identify harmful microbes.

2. Nutrient Content Testing

To test for vitamins, proteins, or minerals in a food sample, a homogenous mix is needed. The stomacher ensures every part of the sample is represented equally, giving reliable results.

3. Pesticide and Chemical Residue Analysis

When checking for traces of pesticides or chemical residues, an even blend makes extraction and measurement more accurate. The stomacher supports consistent and repeatable testing.

4. Allergen Testing

Blending helps detect allergens like nuts, dairy or gluten that may be present in trace amounts. Even distribution ensures that small allergens are not missed during analysis.

Why Labs Choose Stomacher Blenders Over Other Mixers

No blades involved: Less sample damage and no risk of metal contamination

Sterile procedure: Uses disposable bags, removing the need to clean between tests

Time-efficient: Fast sample preparation with minimal handling

Better repeatability: Standardises sample preparation across batches

Minimal waste: Almost complete recovery of blended material

Compared to other lab equipment used for mixing, stomacher blenders are preferred for their hygiene, consistency, and ease of use.

Industries and Applications Beyond Food Testing

Though stomacher blenders are popular in food labs, they are also used in:

Pharmaceutical testing – for preparing pill and powder samples

Environmental testing – for blending soil or sludge samples

Veterinary and animal health labs – for animal tissue analysis

Their ability to prepare samples without altering their structure makes them a go-to solution across sectors.

Choosing the Right Model for Your Lab

Selecting the correct stomacher depends on:

Sample size

Throughput (how many samples per day)

Lab space

Compatibility with other lab instruments

Brands like Athena Technology offer models with adjustable speed, automatic timers, and digital displays. These features help streamline lab workflows and reduce errors.

Maintenance and Care Tips

To keep your stomacher running efficiently:

Clean the paddles and chamber regularly

Replace worn-out or damaged parts

Use only recommended bags to avoid leakage

Calibrate periodically to maintain accuracy

With basic care, these machines can last for years, making them a reliable part of any laboratory setup.

FAQs

Q1. What is the purpose of a stomacher in food testing labs?

Answer: A stomacher is used to blend and homogenise food samples without contamination. It helps in accurate microbial, chemical, and allergen testing.

Q2. Can I use a normal blender instead of a stomacher in the lab?

Answer: No. Regular blenders can damage samples and introduce contamination. A stomacher uses sealed bags and no blades, making it suitable for sensitive tests.

Q3. How often should a stomacher be cleaned or serviced?

Answer: Daily cleaning is advised, especially when used frequently. Servicing depends on the usage level, but general checks every 6–12 months are ideal.

Q4. Which industries benefit from using stomacher blenders?

Answer: Apart from food testing labs, stomacher blenders are used in pharmaceuticals, animal health, and environmental labs.

Q5. Is Athena Technology a trusted brand for stomacher blenders?

Answer: Yes, Athena Technology is known for quality lab instruments and offers a range of stomacher models with useful features for efficient testing.

Conclusion

The uses of a stomacher blender in food testing labs go far beyond simple mixing. From improving test reliability to ensuring hygiene, it plays a central role in food safety practices. Whether you’re building a new lab or upgrading your existing equipment, investing in the right stomacher can streamline your testing process and improve your outcomes.

Looking for dependable lab equipment? Explore models by Athena Technology to meet your testing needs efficiently.

#athena technology#lab instruments#laboratory equipment suppliers#laboratory equipment#stomacher blender#Stomacher Blender in Food Testing Labs

0 notes

Text

Nitrogen Generation Plant Solutions from Athena Technology

Athena Technology brings more than two decades of process-gas expertise to your site with a purpose built nitrogen generation plant that cuts cylinder expense, lifts workplace safety, and keeps production timelines steady. The skid mounted system delivers high-purity nitrogen on demand through pressure swing adsorption and energy-saving compressors, freeing your team from supply chain delays. Each plant is configured around real flow data to maximise uptime, minimise maintenance, and shorten pay-back. In-house technicians handle design, installation, and lifetime support, so you deal with one trusted partner from first enquiry to yearly service audit. Request your tailored quotation today and see how consistent, cost-friendly nitrogen sharpens your competitive edge. Our monitoring software gives live purity reports, keeping quality managers confident.

#athena technology#lab instruments#laboratory equipment suppliers#laboratory equipment#Nitrogen Generation Plant#Nitrogen Generation#Nitrogen Generation Plant supplier

0 notes

Text

Nitrogen Gas Generator for Precision Labs by Athena Technology

Ensure high-purity nitrogen on demand with the Nitrogen Gas Generator from Athena Technology. Designed to meet the needs of advanced laboratories, our systems offer dependable performance, reduced operational cost, and efficient gas delivery. Built for longevity and accuracy, they support various lab instruments and processes including chromatography, sample preservation, and pharmaceutical analysis. As a trusted name in laboratory equipment, Athena Technology provides robust engineering and support tailored to modern lab demands. Whether you're upgrading existing lab instruments or setting up a new facility, this solution integrates seamlessly with your workflow. Choose reliable innovation in gas generation for your laboratory with Athena Technology.

#athena technology#lab instruments#laboratory equipment suppliers#laboratory equipment#nitrogen gas#nitrogen gas generator#nitrogen gas generator supplier in India

0 notes

Text

What is a PSA Nitrogen Generator? Advantages for Industrial Usage Explained

Industries across sectors rely on nitrogen for a wide range of applications. Traditionally, they depended on cylinders or bulk liquid nitrogen from external suppliers. However, more facilities are turning to on-site generation solutions. One such technology is the PSA nitrogen generator.

What is a PSA Nitrogen Generator? Advantages for Industrial Usage Explained, providing an in-depth, practical explanation of how the system works and why industries increasingly choose it. The goal is to clarify its working principles, applications, and performance-related benefits without relying on technical jargon or service-oriented language.

What is a PSA Nitrogen Generator?

A PSA nitrogen generator produces nitrogen gas by separating it from the air using a method called Pressure Swing Adsorption. Ambient air is made up of around 78 percent nitrogen and 21 percent oxygen. This generator filters out the oxygen and other gases, leaving behind high-purity nitrogen.

The system works by using two towers filled with carbon molecular sieves. When compressed air enters one of the towers, oxygen molecules are adsorbed by the sieve. Nitrogen molecules pass through and are collected as the final output. The other tower regenerates during this time, preparing for the next cycle. The process alternates between the two towers continuously, ensuring uninterrupted nitrogen supply.

Why Industries Choose PSA Nitrogen Plants

Several industries now prefer PSA nitrogen plants over conventional nitrogen delivery. The reasons lie in operational efficiency, consistent purity, and long-term reliability.

When nitrogen is generated on-site, dependency on third-party logistics reduces. This results in less downtime and lower risks of supply chain disruption. For operations requiring constant access to nitrogen, such as electronics manufacturing, laser cutting, or chemical processing, this is critical.

Many also consider PSA systems due to their lower environmental impact. Eliminating the need for nitrogen transport vehicles reduces fuel consumption and emissions. Additionally, industries have tighter control over gas quality and flow, which is essential in precision-driven sectors.

Advantages of PSA Nitrogen Generators in Industrial Use

There are distinct advantages to using PSA nitrogen generators for industrial operations. These are not limited to cost or convenience but include core operational benefits:

Lower operating costs: Over time, the cost of generating nitrogen in-house is significantly less than repeated purchases from external vendors.

Consistent gas purity: Systems can be designed to deliver nitrogen purity levels ranging from 95 percent up to 99.999 percent, based on industrial needs.

Increased workplace safety: PSA generators operate at low pressure and do not require high-pressure cylinder storage, reducing safety hazards.

Minimized downtime: Uninterrupted nitrogen production ensures that machines and processes stay active without delays.

Smaller carbon footprint: Fewer delivery trucks mean less fuel usage and emissions.

Custom configurations: Generators can be built for various sizes and outputs depending on business scale.

As a technology partner, Athena Technology supports industries by integrating PSA nitrogen solutions within existing production environments. These generators are also compatible with a range of laboratory equipment and lab instruments, enhancing control in research or chemical testing setups.

Choosing the Right PSA Nitrogen Generator for Your Business

Selecting the appropriate nitrogen generator depends on several practical factors. The following criteria typically influence the decision:

Nitrogen purity requirements: Applications like food preservation may work with 99 percent purity, while electronics or pharma labs might need higher levels.

Flow rate and capacity: Based on how much nitrogen the process needs per hour or per shift.

Energy availability: PSA generators run on electricity and require compressed air. Ensuring stable utility support is essential.

Maintenance schedule: Understanding filter replacement cycles and routine checks ensures uptime remains optimal.

Footprint and layout: Space availability at the site can influence the generator’s design and configuration.

Athena Technology often helps facilities assess these parameters during the planning stage. Their systems are used across industrial and lab settings where lab instruments and laboratory equipment require stable and controlled nitrogen environments.

Common Applications of PSA Nitrogen Generators

Industries using PSA nitrogen generators span across several categories:

Food and Beverage: For packaging under a nitrogen atmosphere to extend shelf life.

Electronics: Nitrogen protects sensitive components from oxidation during manufacturing.

Pharmaceuticals: Nitrogen ensures sterile packaging and stability in chemical storage.

Metal fabrication and laser cutting: Nitrogen assists in clean and precise cuts.

Chemical industries: Used for blanketing and purging operations.

Research laboratories: For maintaining inert conditions in experiments using precision lab instruments.

PSA nitrogen generators also support consistent performance of analytical and diagnostic tools, making them suitable for modern laboratory equipment setups.

How PSA Compares with Membrane Nitrogen Generators

While membrane generators also produce nitrogen by filtering air, PSA systems offer certain advantages in terms of purity and efficiency. Membrane units are typically used for lower purity applications, such as tire inflation or fire prevention systems. PSA, by contrast, is chosen for higher purity demands and scalable operations.

From a maintenance perspective, PSA systems can be slightly more complex but yield better control and output over time. Facilities prioritizing purity and long-term cost-efficiency often lean toward PSA technology.

Frequently Asked Questions

Q1. What is a PSA Nitrogen Generator and how does it function?

Answer: A PSA nitrogen generator separates nitrogen from the air using carbon molecular sieves under alternating pressure conditions, providing a reliable and continuous nitrogen supply.

Q2. Why Industries Choose PSA Nitrogen Plants instead of conventional nitrogen supply?

Answer: PSA plants reduce operational costs, eliminate delivery delays, and allow for customized purity levels depending on industrial need.

Q3. Are PSA Nitrogen Generators suitable for small-scale operations?

Answer: Yes. PSA systems are available in various capacities and can be configured to match the requirements of small or medium-sized operations.

Q4. What is the difference between PSA and membrane nitrogen generators?

Answer: PSA generators offer higher purity and are suited for critical applications. Membrane generators are typically more compact and used for lower purity needs.

Q5. How do I determine the right capacity PSA system for my plant?

Answer: You will need to evaluate the required nitrogen flow rate, working hours, purity level, and available utilities. Most vendors provide sizing tools or support for these calculations.

Q6. What are the long-term cost benefits of using a PSA Nitrogen Generator?

Answer: Savings come from eliminating recurring gas delivery costs, reducing downtime, and minimizing operational disruptions.

Q7. How can PSA nitrogen benefit laboratory environments and sensitive lab instruments?

Answer: It ensures a stable nitrogen atmosphere that prevents oxidation or contamination, especially critical in sensitive measurements and material testing.

Conclusion

Understanding What is a PSA Nitrogen Generator? Advantages for Industrial Usage Explained provides clarity on how this technology aligns with modern industrial priorities. PSA systems offer control, reliability, and efficiency that external nitrogen supply methods cannot match.

Facilities working with laboratory equipment, precision lab instruments, or complex manufacturing systems benefit from the operational certainty PSA generators provide. With the support of manufacturers like Athena Technology, these systems are now accessible to a wider range of industries aiming to improve their internal processes without compromising quality or safety.

#athena technology#lab instruments#laboratory equipment suppliers#laboratory equipment#PSA Nitrogen Generator#PSA Nitrogen Generator Supplier In India

0 notes

Text

Top 5 Applications of Probe Sonicators in Research Labs

Introduction

Probe sonicators are a mainstay in scientific environments where accuracy, repeatability, and control over microscopic interactions are essential. Researchers rely on this ultrasonic tool to break apart cells, disperse particles, and process materials with high energy efficiency. In this context, it is important to clarify what probe sonicators are, how they work, and where they provide measurable advantages across research disciplines.

The article presents the top 5 applications of probe sonicators in research labs and integrates scientific reasoning into practical examples. The content also examines how probe sonicators support research workflows and highlights common benefits of probe sonicators relevant to laboratory professionals using advanced lab instruments and laboratory equipment such as those provided by Athena Technology.

What Are Probe Sonicators?

Probe sonicators are laboratory tools that deliver ultrasonic energy through a titanium probe immersed in a sample. This energy creates cavitation bubbles that collapse violently, generating localised high pressure and temperature. The physical disruption caused by this process allows scientists to achieve outcomes not possible through conventional mixing or grinding methods.

Probe sonicators are typically used where precise particle size reduction, cell lysis, emulsification, and chemical activation are required. Their design ensures uniform energy distribution, which is critical when processing biological or nanoscale samples.

Why Researchers Use Probe Sonicators

The central benefit of probe sonication lies in its mechanical precision. Researchers working in biochemistry, material science, pharmacology, and environmental chemistry often require consistent outcomes across test cycles. How probe sonicators support research becomes evident in procedures where reproducibility, sample purity, and low thermal disruption are necessary.

Key benefits include:

Accelerated sample breakdown with minimal contamination

Controlled cell disruption without altering target compounds

High-efficiency mixing at microscale

Compatibility with closed systems, reducing risk of external interference

These common benefits of probe sonicators position them as versatile tools within modern laboratory equipment setups.

Nanoparticle Dispersion in Material Science

Achieving homogenous dispersions of nanoparticles is fundamental to the development of advanced composites and engineered fluids. Probe sonicators facilitate uniform particle distribution without the use of stabilising chemicals. This ensures repeatable sample consistency in applications like conductive inks, coatings, and polymer additives.

The ability to avoid agglomeration and reduce particle size to the nanoscale also improves material performance in terms of strength, conductivity, and thermal stability.

DNA Shearing and RNA Isolation in Molecular Biology

Precision fragmentation of nucleic acids is essential for sequencing, library preparation, and analysis of genomic data. Probe sonicators deliver consistent shearing, enabling researchers to fine-tune fragment sizes while avoiding thermal degradation.

Unlike enzymatic methods, sonication does not introduce contaminants or biases. This makes it especially useful in protocols where purity and size distribution affect downstream accuracy. As a result, laboratories often standardise DNA/RNA workflows around probe sonicator systems.

Cell Lysis in Microbiology and Biotechnology

Effective cell lysis is foundational for protein extraction, metabolomics, and microbial analysis. Probe sonicators generate strong mechanical forces capable of rupturing tough cell walls, including bacterial, fungal, and mammalian types.

This method eliminates the need for chemical reagents that may interfere with sensitive biological assays. It also supports cold lysis, preserving protein structure and function. This is particularly beneficial in proteomics, where sample quality directly influences analytical resolution.

Emulsification in Pharmaceutical Research

Pharmaceutical formulations often depend on creating stable emulsions of oil and water-based compounds. Sonicators are used to form fine emulsions where droplet sizes are uniform and thermodynamically stable.

This technique enables testing of bioavailability, drug release profiles, and product shelf life. In early-stage drug development, probe sonication is used to evaluate excipient interactions and nanoparticle delivery systems. It provides more reliable outcomes than mechanical mixing or magnetic stirring.

Sonochemical Reactions in Green Chemistry

In energy-conscious research, sonication offers a route to sustainable reaction acceleration. This includes synthesis of fine chemicals, catalysis of biofuels, and oxidation-reduction processes where thermal energy is typically required.

Cavitation-induced hot spots drive chemical transformations under milder bulk conditions. The resulting efficiency reduces solvent use and lowers reaction time, aligning with green chemistry principles. This positions probe sonicators as vital lab instruments in environmentally responsible research labs.

Common Benefits of Probe Sonicators

Across disciplines, probe sonicators provide measurable improvements to research workflows. Their benefits can be summarised as follows:

Improved reaction control with precise energy delivery

Reduction in chemical waste and reagent use

High throughput with consistent results

Scalable design from microliter to liter-scale volumes

Integration with advanced laboratory equipment like temperature monitors and automated sample holders

Why Probe Sonicators Are Essential Lab Instruments

Modern labs prioritise adaptability and efficiency. Probe sonicators meet these needs through modular designs, programmable settings, and broad material compatibility. They work with a range of sample viscosities, temperatures, and chemical compositions.

Instrument providers such as Athena Technology support laboratories with sonicators that adhere to industry safety standards and research compliance protocols.

Selecting the Right Sonicator

To use a probe sonicator effectively, researchers should consider:

Sample volume and container compatibility

Required amplitude and frequency settings

Duration of exposure and temperature sensitivity

Need for closed or sterile systems

Correct selection not only ensures reliable data but also extends the operational life of the equipment.

Frequently Asked Questions

Q1. What are probe sonicators, and how do they work in research labs?

Answer: Probe sonicators use ultrasonic energy to agitate particles in a sample, enabling processes like cell lysis, dispersion, and emulsification through cavitation effects.

Q2. How do probe sonicators support reproducible research?

Answer: They deliver consistent energy, ensuring uniform treatment of samples, which minimises experimental variability.

Q3. Are probe sonicators better than bath sonicators?

Answer: For applications requiring high energy concentration and rapid processing, probe sonicators are more effective than bath sonicators.

Q4. Can probe sonication damage DNA or proteins?

Answer: Improper settings may lead to overheating. Using pulse mode and cooling can prevent such degradation.

Q5. What are the common benefits of using a probe sonicator?

Answer: Improved sample homogeneity, reduced chemical usage, faster processing, and minimal contamination.

Q6. How is probe sonication used in pharmaceutical development?

Answer: It supports emulsion stability testing, nanoparticle delivery studies, and drug compound dispersion.

Q7. Is a probe sonicator suitable for green chemistry applications?

Answer: Yes, it reduces the need for heating and solvents by enhancing reaction kinetics through ultrasonic activation.

Conclusion

The top 5 applications of probe sonicators in research labs highlight their critical role in nanoparticle science, genomics, microbiology, drug formulation, and green chemistry. Their functionality spans across academic, industrial, and environmental domains. When integrated with compatible lab instruments and supported by trusted providers like Athena Technology, probe sonicators offer a scalable, precise, and clean approach to complex sample processing.

Their contribution to method development, reproducibility, and chemical innovation continues to support researchers in delivering more accurate and efficient results.

#athena technology#lab instruments#laboratory equipment suppliers#laboratory equipment#Probe Sonicators

0 notes

Text

Types of Gas Manifolds and Their Applications

Athena Technology presents a clear overview of the different types of gas manifolds and their applications across industries. Whether for laboratory, medical, or industrial systems, understanding manifold types ensures safety, efficiency, and proper pressure control. Our expert guide highlights the functionality and purpose of each system design, from simple manual to advanced automatic manifolds. Let Athena Technology help you select the right configuration for optimal gas flow and operational success. Stay informed, stay compliant.

0 notes

Text

High Pressure Regulators Supplier In India

Athena Technology stands out as a trusted High Pressure Regulators Supplier In India, offering premium-grade solutions for consistent performance in industrial settings. With a strong track record of reliability and engineering expertise, we support industries where safety, precision, and durability are non-negotiable. Our pressure regulators are designed for seamless integration and consistent output under variable conditions. Athena Technology ensures prompt support, competitive pricing, and unmatched quality for every order. Power your process with systems built to perform in the most demanding environments.

#athena technology#lab instruments#laboratory equipment suppliers#laboratory equipment#High Pressure Regulators Supplier In India#High Pressure Regulators Supplier In Mumbai

0 notes