Don't wanna be here? Send us removal request.

Text

Printing Machine Maintenance: Tips for Keeping Your Equipment in Top Condition

Introduction

Proper maintenance is essential for keeping your printing machines running smoothly and efficiently. This blog provides tips for maintaining your printing equipment and preventing costly downtime.

Regular Cleaning

Regular cleaning is essential for preventing ink buildup and other maintenance issues. Be sure to clean your printing machine according to the manufacturer's recommendations.

Lubrication

Proper lubrication is essential for preventing wear and tear on your printing machine. Use the recommended lubricants and follow the manufacturer's instructions.

Inspection

Regular inspections can help identify potential problems before they become serious. Check for signs of wear and tear, leaks, and other issues.

Preventive Maintenance

Preventive maintenance involves performing routine tasks to keep your printing machine in good condition. This may include replacing parts, calibrating the machine, and performing other maintenance tasks.

Conclusion

By following these tips, you can help ensure that your printing machines are running at their optimal performance. Proper maintenance can help prevent costly downtime and extend the life of your equipment.

0 notes

Text

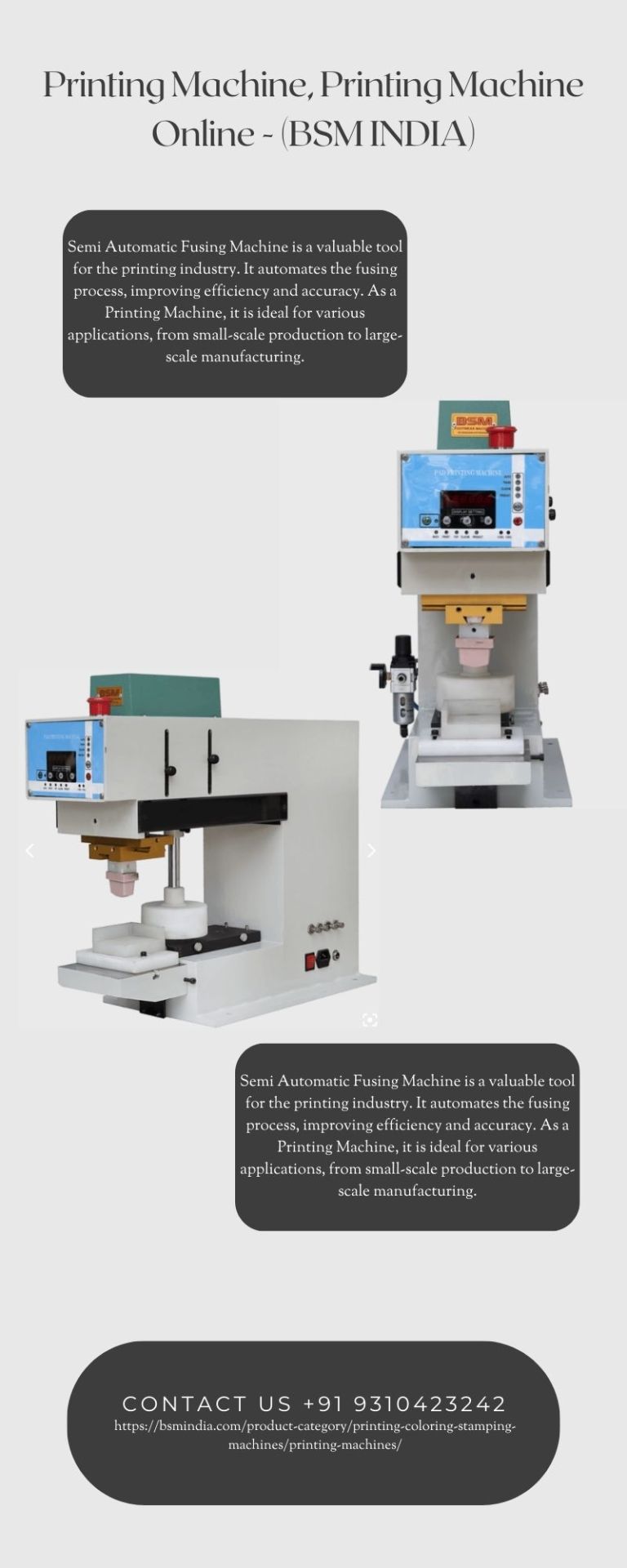

Semi Automatic Fusing Machine is a versatile heat transfer tool. As a Heat Transfer Machine (BSM), it automates fusing for various materials. It's user-friendly and reliable, making it ideal for printing and manufacturing.

0 notes

Text

Grinding Machines are essential tools for various industries. At BSM, we offer a wide range of high-quality Grinding Machines to meet your specific needs. Whether you're looking for a bench grinder for small tasks or an industrial surface grinder for large-scale projects, we have the perfect machine for you. Our online store makes it easy to browse and purchase Grinding Machines that fit your budget and requirements.

0 notes

Text

Packaging Machines from BSM offer high-quality solutions for various industries. Our online store provides a wide range of machines for efficient and reliable packaging. Discover innovative features like automatic sealing, labeling, and filling. Streamline your packaging process and improve your overall operations with BSM.

0 notes

Text

Semi Automatic Fusing Machine is a valuable tool for printing. It automates fusing, improving efficiency and accuracy. As a Printing Machine, it's ideal for various applications. It's user-friendly and reliable, making it a must-have for any printing operation.

0 notes

Text

Maintaining Your Packaging Equipment: Tips for Longevity and Performance

Are you looking to extend the life of your packaging machine and boost its performance? Regular maintenance is key to ensuring your equipment operates efficiently and lasts for years to come. In this blog, we'll explore essential tips to keep your packaging equipment in top shape.

Develop a Maintenance Schedule

Create a comprehensive maintenance plan for your packaging machine. Regular check-ups prevent small issues from becoming major problems.

Clean Regularly

Cleanliness is crucial for packaging equipment. Remove debris, dust, and product residue daily. Pay special attention to moving parts and sensors. A clean machine runs smoother and lasts longer.

Lubricate Moving Parts

Proper lubrication reduces wear and tear on your packaging machine. Follow the manufacturer's guidelines for lubrication frequency and recommended products.

Check and Replace Worn Parts

Inspect your equipment regularly for signs of wear. Replace parts before they fail to avoid unexpected downtime.

Train Your Staff

Ensure all operators are properly trained on how to use and maintain the packaging machine. This reduces the risk of misuse and improves overall equipment performance.

Monitor Performance

Keep track of your packaging machine's output and efficiency. Any sudden changes could indicate a need for maintenance or repairs.

Update Software

If your packaging equipment uses software, keep it up to date.Software updates regularly introduce speed optimizations and eliminate errors.

Conduct Regular Inspections

Schedule professional inspections of your packaging machine. Experts can spot potential issues that might be missed during routine maintenance.

Address Issues Promptly

Don't ignore small problems. Address any issues with your packaging equipment as soon as they arise to prevent more significant damage.

Keep Detailed Records

Maintain a log of all maintenance activities, repairs, and part replacements. This information can help identify patterns and predict future maintenance needs.

By following these tips, you'll extend the life of your packaging machine, improve its performance, and reduce costly downtime. Remember, a well-maintained packaging equipment is an investment in your business's efficiency and success.

0 notes

Text

BSM India offers top-quality Printing Machines online. Discover the best Printing Machine solutions for your business needs at BSM India's digital storefront.

0 notes

Text

Using Trimming Machines for Efficiency: Reducing Waste and Embracing Sustainability

New designs, attractive styles and uncompromised comfort are the factors on which the footwear industry relies and prospers. But there is a dark side to it– the trimming process can produce significant material waste. Discarded leather scraps and leftover fabric pieces can add up quickly, badly affecting the environment in more ways than one. However, sustainable practices are gaining traction, and focusing on minimizing waste using trimming machines isn't just good for the environment; it can also improve efficiency and profitability.

Understanding Trimming Waste:

Trimming involves chopping away excess material from pre-shaped leather, fabric, or synthetic pieces to create the final upper components of a shoe. While inevitable, the amount of waste generated can be significantly reduced through careful planning and innovative techniques.

Strategies for a More Sustainable Trim:

Here are some key strategies to minimize waste and promote sustainability in your footwear-trimming processes:

Optimizing Cutting Patterns: Using computer-aided design (CAD) software allows for precise digital patterns that minimize material usage. These optimized patterns ensure each piece is cut efficiently, reducing the amount of scrap generated.

Nested Layering: Nesting software arranges the cutting patterns like puzzle pieces on the material spread. This maximizes material utilization and reduces the amount of wasted space between cuts.

Automated Scrap Collection: Modern trimming machines can be equipped with automated scrap collection systems. These systems capture leftover pieces during the cutting process, allowing them to be recycled or repurposed for smaller components.

Utilizing Leftover Pieces: Not all scraps are useless! Think creatively! Smaller leftover pieces can be incorporated into smaller shoe components like embellishments. This reduces overall waste and adds a touch of unique detail to your footwear.

Material Selection: Consider using materials with lower inherent waste. For example, synthetic fabrics with pre-determined widths can minimize trimming compared to wider rolls that require significant trimming.

The Benefits of Minimizing Trimming Waste

By implementing these strategies, you'll not only be contributing to a more sustainable future for the footwear industry, but you'll also experience several practical benefits:

Reduced Material Costs: Less waste translates to using less raw material, leading to significant cost savings in the long run.

Improved Efficiency: Optimizing cutting patterns and utilizing scraps can streamline production processes, potentially increasing output.

Enhanced Brand Image: Consumers are increasingly conscious of sustainability. Demonstrating a commitment to minimizing waste can boost your brand image and attract eco-conscious customers.

A Sustainable Future for Footwear Trimming

Reducing waste in trimming processes is no longer just a trend; it's a necessary step towards a sustainable future for the footwear industry. By embracing innovative technologies, utilizing resources efficiently, and fostering a culture of responsible production, we can create stylish footwear while reducing our environmental impact. Let's pave the way for a future where trimming leaves a smaller footprint and a bigger positive impact.

0 notes

Text

The Invisible Prep Work: Why Surface Matters in Fusing Machines

Let’s suppose you are building a house. You wouldn't just slap the bricks together and hope for the best. You'd meticulously lay the foundation, ensuring a strong, lasting, and enduring structure. The same logic applies to fusing machines in footwear manufacturing. While the fusing machine itself is the new-age miracle that creates permanent bonds, the invisible prep work done on the surfaces before fusing is equally important.

Why Surface Prep Matters in Fusing Machines?

Fusing machines use heat, pressure, and sometimes adhesives to create a permanent bond between two materials in footwear components. For these bonds to be strong and durable in the final shoe, the surfaces entering the fusing machine need to be clean, compatible, and ready to form a secure connection. Let’s look at it with an analogy. Think of it like creating a handshake - just how clean hands with a strong grip will hold tightly whereas dirty or greasy ones might slip. Proper surface preparation ensures the fusing machine can do its job effectively.

Pre-Treatment Techniques for Optimal Bonding in Fusing Machines

Now that we understand the importance of surface prep, let's explore some common pre-treatment techniques used before materials enter the fusing machine:

Cleaning: This might seem obvious, but removing dirt, dust, oil, and any contaminants is essential. Depending on the materials, cleaning methods can involve solvents, detergents, or even light abrasion. A clean surface allows the adhesive (if used) to spread evenly and form a strong connection with the material in the fusing machine.

Roughening: For some materials, creating a slightly rough surface can significantly improve the bond strength achieved by the fusing machine. This can be achieved through sanding, brushing, or chemical etching. The increased surface area created by roughening provides more "grip" for the adhesive and the fused materials, leading to a stronger bond when they enter the fusing machine.

Priming: Primers are specialized coatings applied to surfaces before fusing. They can serve multiple purposes, such as improving adhesion, promoting even adhesive flow, or creating a moisture barrier. Primers are particularly helpful for materials with low surface energy, which can make bonding challenging in the fusing machine.

Choosing the Right Pre-Treatment for Fusing Machines

The best pre-treatment method depends on the specific materials being fused. Here are some general guidelines:

Leather: Cleaning with a solvent or mild detergent is usually sufficient. Roughening with a light abrasive might be needed for heavily finished leather before it enters the fusing machine.

Synthetics: These often require a combination of cleaning and roughening. Some synthetics might benefit from a specific primer designed for their material makeup to optimize the performance of the fusing machine.

Fabrics: Cleaning and potentially a light abrasive treatment are common. For some fabrics, a heat treatment might be used to activate hidden adhesive properties within the fibres before they reach the fusing machine.

The Takeaway: A Strong Foundation for Optimal Fusing

By understanding the importance of surface preparation and implementing the appropriate pre-treatment techniques, footwear manufacturers can ensure optimal bonding strength and long-lasting results when using fusing machines. Just like a well-prepared foundation ensures a sturdy house, proper surface prep lays the groundwork for high-quality, durable fused footwear components coming out of the fusing machines.

0 notes

Text

Choosing the Right Machine for Your Needs: A Footwear Manufacturer's Guide

The footwear manufacturing industry thrives on innovation and a constant stream of fresh designs. But behind the eye-catching styles lies a complex dance of machinery, each playing a vital role in transforming ideas into reality. As a footwear manufacturer, navigating the vast world of footwear machines can be daunting. This guide aims to empower you by providing key factors to consider when selecting machines that perfectly align with your production goals.

Know Your Niche: Define Your Production Needs

Before diving into specific footwear manufacturing machines, take a step back and clearly define your footwear niche. Are you specialising in athletic shoes, high-end dress footwear, or comfortable sandals? Each footwear type has unique production requirements.

Production Volume

Are you a high-volume manufacturer catering to mass markets, or a boutique producer focused on handcrafted excellence? High-volume operations may prioritise faster cycle times and automation, while smaller-scale producers might value versatility and manual control.

Material Focus

The type of footwear you produce heavily influences the machines needed. Working with sturdy leather requires robust cutting and stitching machines compared to those used for lightweight textiles.

Shoe Style

Are you creating complex athletic footwear with intricate details or minimalist sandals with clean lines? The level of detail and customization needed will influence your choice of lasting and finishing machines.

Understanding footwear machine categories

Now that you understand your production needs, let's explore some key footwear machine categories:

Cutting Machines

These machines, like computerized die cutters or laser cutters, precisely cut the various components that make up the shoe upper.

Sewing Machines

From heavy-duty machines tackling thick leather to specialized machines handling intricate seams, the right sewing machine ensures a secure and aesthetically pleasing assembly.

Lasting Machines

These cornerstones of shoemaking shape the upper around a mould, creating the shoe's base structure. The level of automation and customization capabilities will vary depending on your needs.

Sole Attaching Machines

As the name suggests, these machines securely fasten the sole to the constructed upper. The chosen method, such as cementing or direct injection, depends on the type of sole and desired shoe properties.

Finishing Machines

The final touch! These machines handle tasks like trimming excess material, polishing surfaces, and adding decorative elements, bringing your shoe to its final polished state.

Beyond the Machine: Additional Considerations

While the machines themselves are crucial, remember, they're just one piece of the puzzle. Here are some additional factors to keep in mind:

Budget

Footwear machines come in a wide range of price points. Identify your budget constraints and prioritize machines that deliver the most value for your investment.

Supplier Support

Reliable after-sales service and readily available spare parts are essential for maintaining smooth operations. Choose a supplier with a strong reputation for support.

Scalability

Consider your future growth plans. Will your chosen machines be able to adapt as your production volume increases or your product line expands?

The Final Step: Research and Due Diligence

Once you have a clearer picture of your needs and the types of machines required, thorough research is key. Talk to established footwear manufacturers, consult industry publications, and connect with reputable machinery suppliers.

Request demonstrations

Seeing machines in action and discussing their capabilities with knowledgeable representatives are invaluable.

Consider used equipment

For budget-conscious manufacturers, high-quality used machines can be a viable option, but ensure they are well-maintained and come with reliable support.

The Takeaway: Investing in Success

Choosing the right footwear-making machines is an investment in the future of your business. By carefully considering your production needs, researching available options, and prioritizing factors like budget and support, you can select machines that empower you to create high-quality footwear efficiently and profitably. Remember, the perfect machine is the one that seamlessly integrates with your vision and propels your footwear brand towards continued success.

0 notes

Text

Demystifying the Lasting Machine: The Heart of Shoemaking

The amount of love and craze we have for our amazing-looking footwear is not hidden from anyone. And so is not our appreciation for the process of shoe-making. The efforts that go into making a comfortable and well-fitting piece can never be over-emphasized. But did you know there is an underdog that doesn’t get much of the limelight when it comes to applauding the shoe manufacturing process? It’s the lasting machines.

Imagine the upper part of your shoe, everything above the sole. Now picture this upper being meticulously shaped and secured around a three-dimensional mold. That's precisely what a lasting machine does. Often referred to as the "heart of shoemaking," it's a technological marvel that takes flat, pre-cut pieces of leather, fabric, or synthetic materials and transforms them into the base structure of your shoe.

So, how exactly does this happen? Let's dig deep into the fascinating world of lasting machines:

The Lasting Process: A Step-by-Step Look

Meet the Last

The last is a meticulously crafted form replicating a human foot. It comes in various shapes and sizes to accommodate different shoe styles and functionalities.

Preparing the Upper

The pre-cut pieces of leather, fabric, or synthetic materials that will form the upper are meticulously prepared. This might involve punching holes or adding reinforcements.

Taking Shape

The lasting machine takes centre stage. The upper pieces are carefully fed into the machine, which strategically positions them around the last.

The Grip of Precision

Multiple arms or grippers come into play. These are akin to mechanical hands that stretch and manipulate the upper sections with remarkable precision.

Holding it All Together

Once the upper is securely positioned, the machine uses its secret weapon: either tiny nails, staples, or specialised adhesives. These fasten the upper firmly onto the last, ensuring a smooth and secure fit.

The Lasting Impact: Why It Matters

The lasting machine's role goes beyond just shaping the shoe upper. Here's why it's so crucial in shoe manufacturing:

Efficiency Boost

Before the invention of lasting machines in the 1800s, shaping uppers was a manual task requiring skilled craftspeople. Lasting machines revolutionized the process, significantly increasing production speed and efficiency. This paved the way for mass-produced footwear, making shoes more affordable and accessible to everyone

Consistent Quality

Manual lasting, while an impressive feat of craftsmanship, can introduce slight variations in shape and tightness. Lasting machines, on the other hand, ensure a consistent and uniform fit across a production run, guaranteeing quality for every shoe.

Accommodating Variety

Modern lasting machines are incredibly versatile. They can be programmed to handle different upper materials and even adjust to various last shapes within a single production run. This allows for greater flexibility in shoe design and caters to a wider range of footwear styles.

A Look Ahead: The Future of Lasting

The world of lasting machines is constantly evolving. Automation and computer-controlled systems are playing an increasingly important role, allowing for even more precise control and customization. Additionally, sustainable practices are being incorporated. Some machines are being adapted to work with eco-friendly materials and minimize waste.

So, the next time you lace up your shoes, take a moment to appreciate the lasting machine's silent contribution to shoe manufacturing. It transforms raw materials into comfortable companions that take us wherever we need to go.

0 notes

Text

Discover creativity with specialized sewing machines that cater to every unique stitching need. The perfect sewing companion for your projects.

0 notes